Process for preparing methylation catechin by tea

A technology of methylated catechins and process methods, which is applied in the field of extracting methylated catechins, can solve the problems of high process operation requirements, large waste residue treatment capacity, catechin oxidation, etc., and achieves overcoming sample adsorption and safety Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation steps of the present invention are as follows:

[0037] (1) Sample preparation: pick fresh tea leaves with one bud and two or three leaves, and wither in a withering room with a withering sieve for 5 to 12 hours under ventilated conditions. , dry with a dryer, and pulverize the tea leaves into 60-80 mesh powder with a pulverizer;

[0038] (2) Ethanol extraction: put tea powder and 60-80% ethanol solution in the extraction tank for solid-liquid extraction at the same time, the extraction temperature is 70-90°C, the time is 30-120 minutes, and the ratio of solid to liquid is 1:3- 1:10, use a vacuum filter to carry out suction filtration, and the filter residue is repeatedly extracted 2 to 5 times;

[0039] (3) Purification of the crude extract: after merging all the extracts, carry out vacuum concentration in the concentration tank, the concentrate and petroleum ether solution are mixed in a volume ratio of 1: 1 to 1: 2, and the liquid-liquid extraction i...

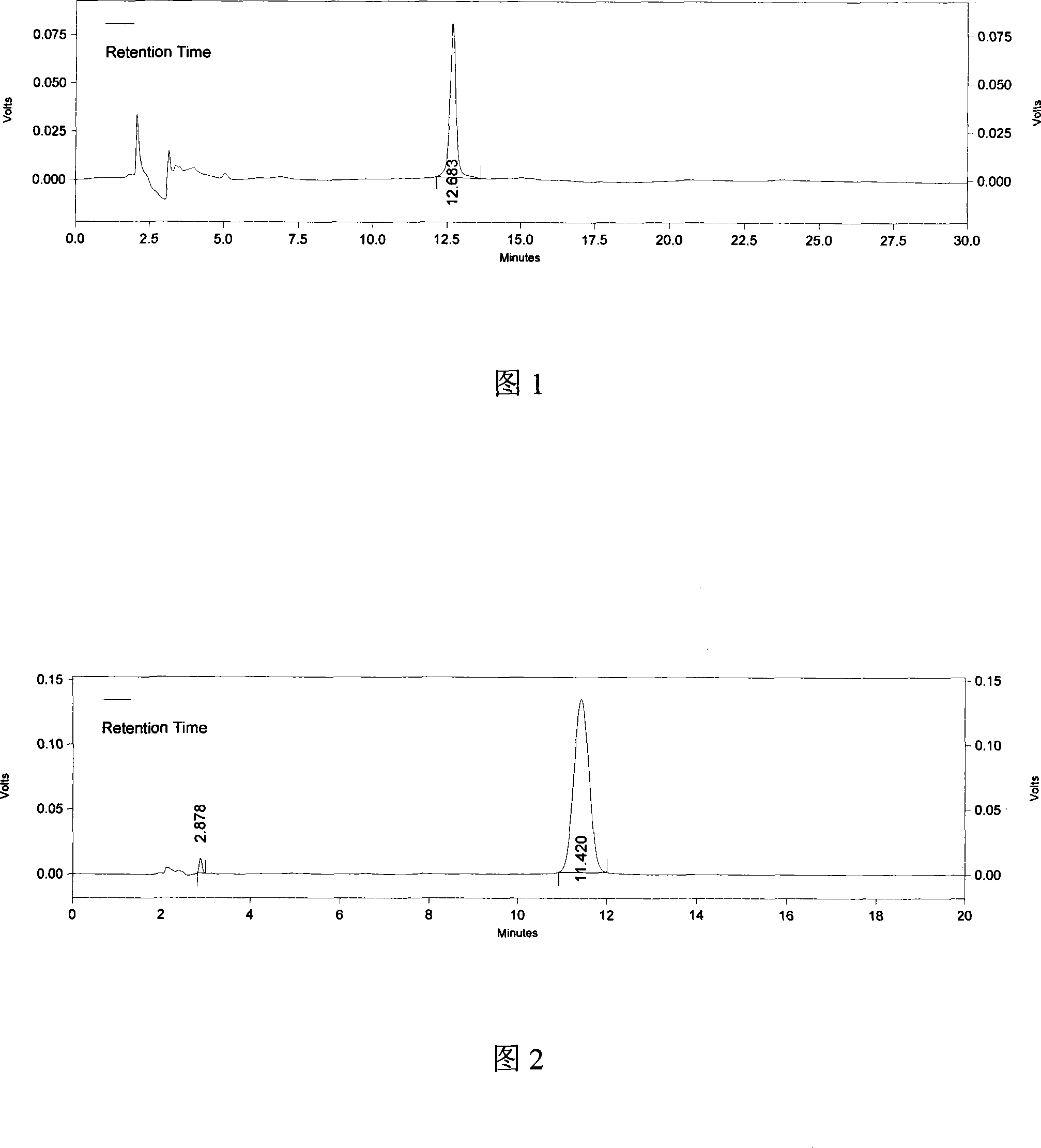

Embodiment 1

[0057] Pick fresh tea leaves with one bud and two or three leaves, and wither in a withering room with a withering sieve for 5 hours under ventilated conditions. Pulverize into 60-mesh powder with a pulverizer; add 60% ethanol to the tea powder according to the ratio of material to liquid 1:3, and extract at 70°C for 30 minutes. After the extraction is completed, filter and extract the filter residue twice. Concentrate, mix the concentrated solution and petroleum ether solution at a volume ratio of 1:1, carry out liquid-liquid extraction for 5 minutes, and repeat the operation twice; then mix the obtained raffinate with ethyl acetate at a volume ratio of 1:1, Carry out liquid-liquid extraction for 5 minutes, repeat the operation 2 times, filter and concentrate the obtained extract to obtain a concentrate, and dry the concentrate to obtain dry powder A of methylated catechin crude extract; use the pretreated Put the 20 mesh crude polyamide resin into the chromatographic column,...

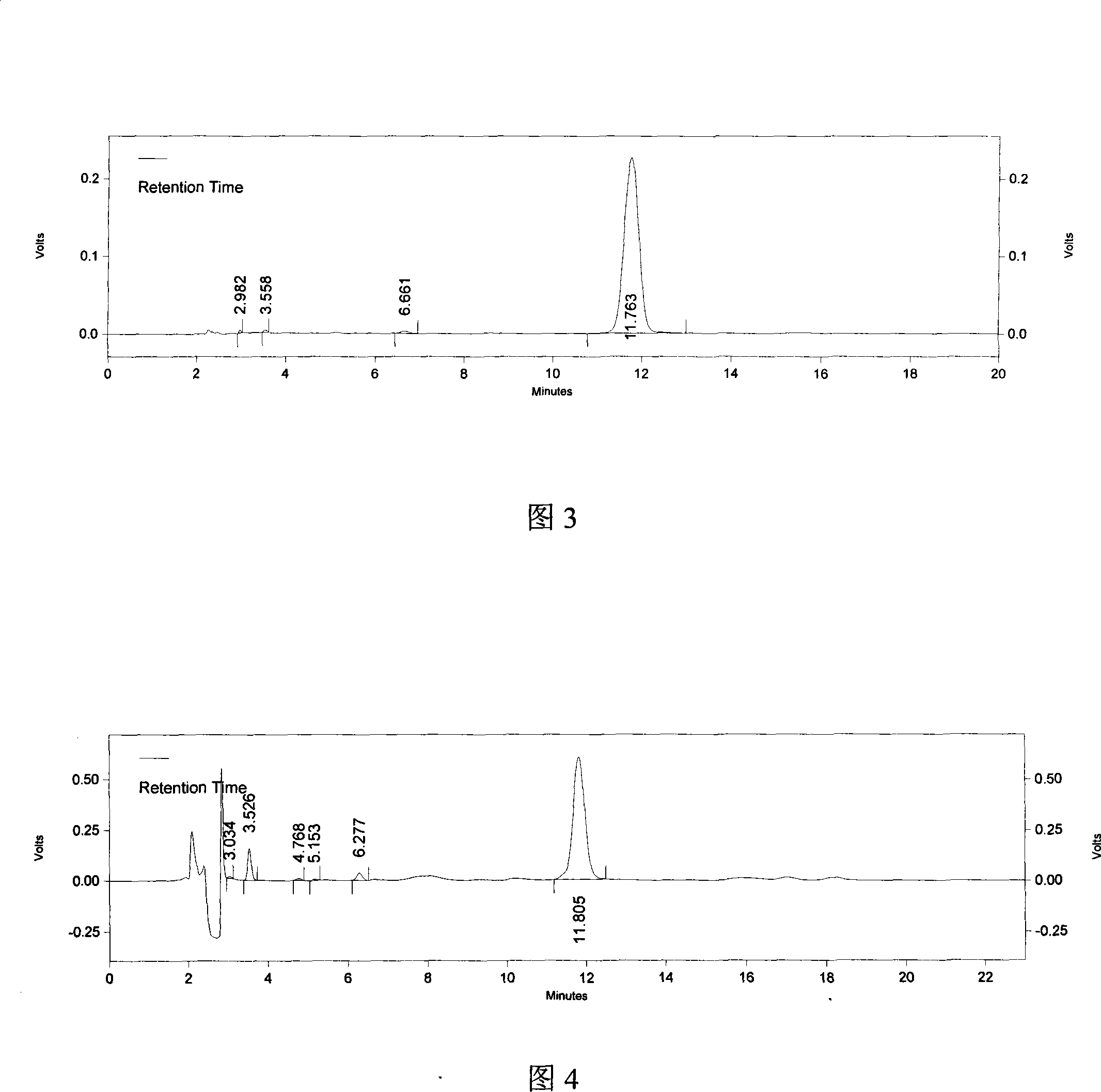

Embodiment 2

[0060] Pick fresh tea leaves with one bud and two or three leaves, and wither in a withering room for 8 hours with a withering sieve under ventilated conditions. Pulverize into a 70-mesh powder; add 70% ethanol to the tea powder according to the ratio of material to liquid 1:6, and extract at 80°C for 60 minutes. After the extraction is completed, filter and extract the filter residue repeatedly for 3 times. Concentrate, mix the concentrated solution and petroleum ether solution at a volume ratio of 1:1, carry out liquid-liquid extraction for 15 minutes, and repeat the operation 3 times; then mix the obtained raffinate with ethyl acetate at a volume ratio of 1:1, Carry out liquid-liquid extraction for 15 minutes, repeat the operation 3 times, filter and concentrate the obtained extract to obtain a concentrate, and dry the concentrate to obtain dry powder A of the crude extract of methylated catechin; 30-mesh crude polyamide resin is loaded into a chromatographic column, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com