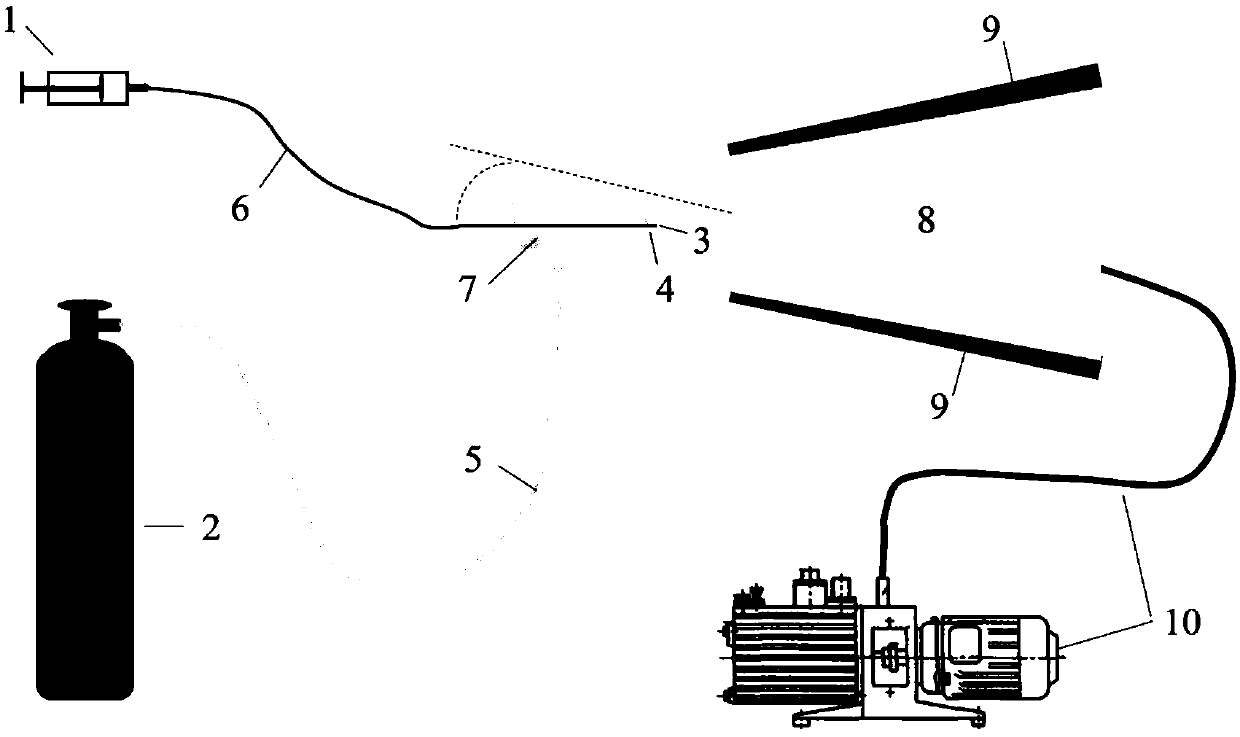

Device and method for preparing directionally arranged fiber by solution blow-spinning technology

A directional arrangement, solution technology, applied in dry spinning, textiles and papermaking, bundling of freshly ejected filaments, etc. Simple, safe and uniform fiber distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

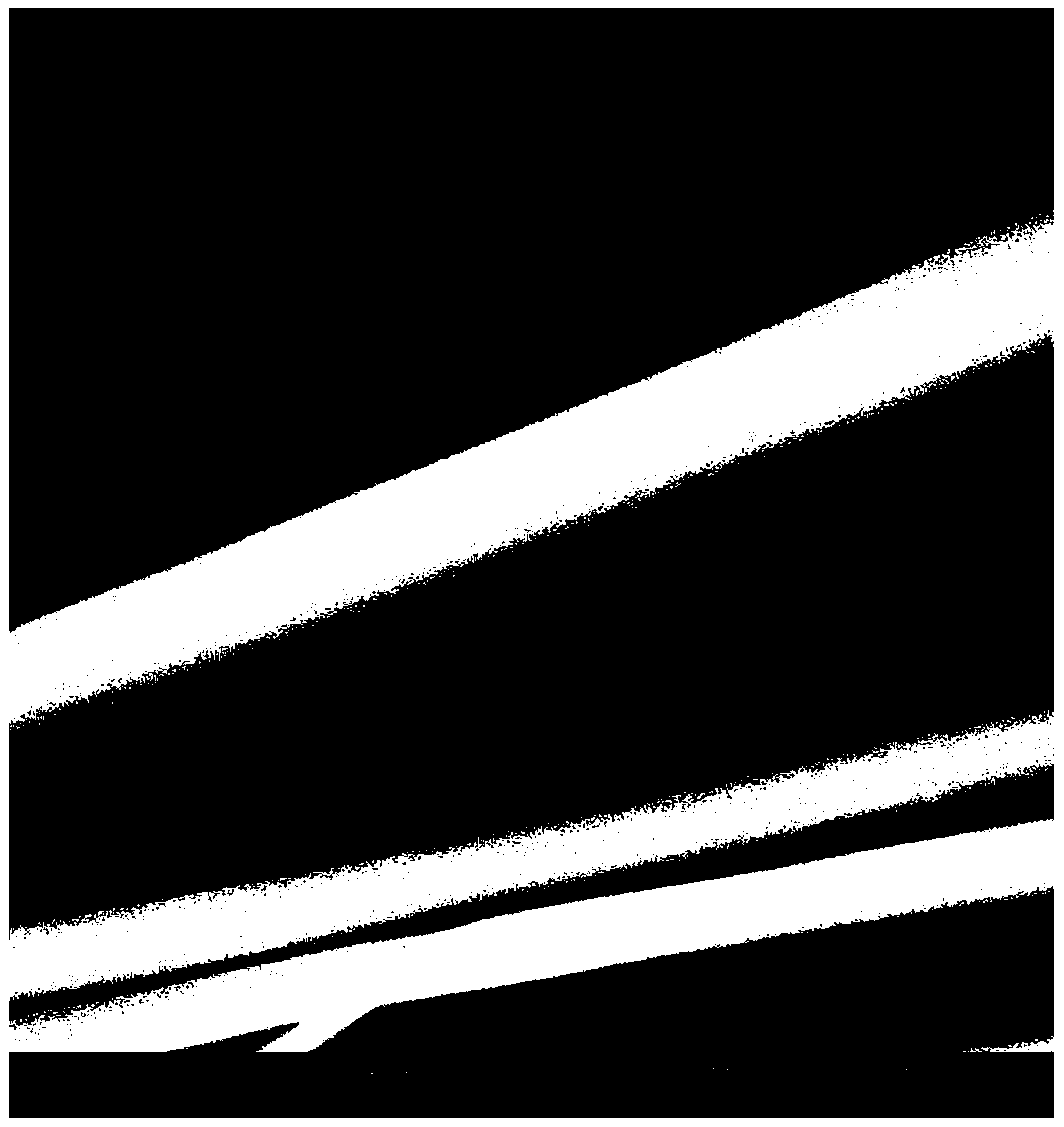

[0053] Mix water, acetic acid, and ethanol with a mass ratio of 1:2:6, add tetrabutyl titanate and barium acetate with a molar mass ratio of 1:1, and then add half of the total mass of tetrabutyl titanate and barium acetate The PVP (1300000g / mol) is prepared into the spinning solution that the mass fraction of solute is 10%. The spinning solution is injected into the syringe, the needle is a 30G needle, the advancing speed is 3ml / h, the spinning environment temperature is room temperature, the humidity is 30%, the airflow pressure is 0.5MPa, and the angle between the nozzle and the horizontal centerline of the flat collection net is 15 °, the distance between the nozzle and the left edge of the flat collection net is 30cm, and the negative pressure is 1MPa. Spinning is carried out under this condition. After spinning for 1 hour, oriented solution-blown fibers of corresponding thickness are collected on the covering surface on the right side of the flat collection net. in the ...

Embodiment 2

[0055] In ethanol, add PVP (1300000g / mol) to prepare a spinning solution with a solute mass fraction of 10%. Inject the spinning solution into the syringe, the needle is a 25G needle, the advancing speed is 0.5ml / h, the spinning environment temperature is room temperature, the humidity is 35%, the airflow pressure is 1MPa, and the angle between the nozzle and the horizontal center line of the flat collection net is 0 °, the distance between the nozzle and the left edge of the flat collection net is 15cm, and the negative pressure is 1MPa. Spinning is carried out under this condition. After spinning for 1 hour, oriented solution-blown fibers of corresponding thickness are collected on the covering surface on the right side of the flat collection net. in the same direction.

Embodiment 3

[0057] Mix acetic acid and ethanol with a mass ratio of 1:3, add tetrabutyl titanate and PVP (1,300,000 g / mol) with a mass ratio of 2:1, and prepare a spinning solution with a mass fraction of solute of 15%. Inject the spinning solution into the syringe, the needle is a 30G needle, the advancing speed is 3ml / h, the spinning environment temperature is room temperature, the humidity is 35%, the airflow pressure is 0.5MPa, and the angle between the nozzle and the horizontal center line of the flat collection net is 45° °, the distance between the nozzle and the left edge of the flat collection net is 35cm, and the negative pressure is 1MPa. Spinning is carried out under this condition. After spinning for 1 hour, oriented solution-blown fibers of corresponding thickness are collected on the covering surface on the right side of the flat collection net. in the same direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com