Patents

Literature

34results about How to "Uniform shear force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

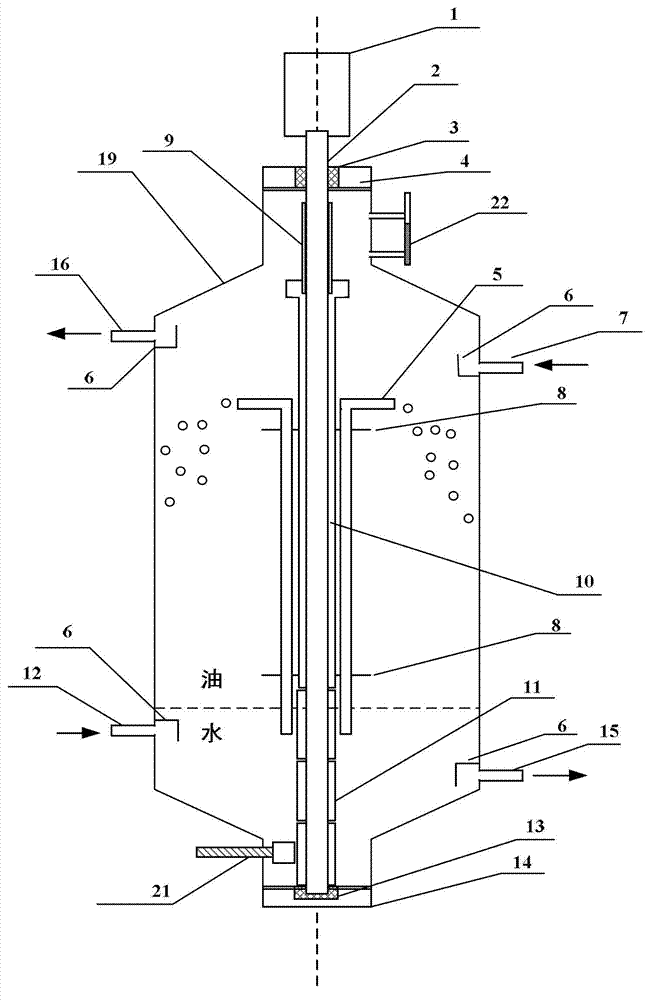

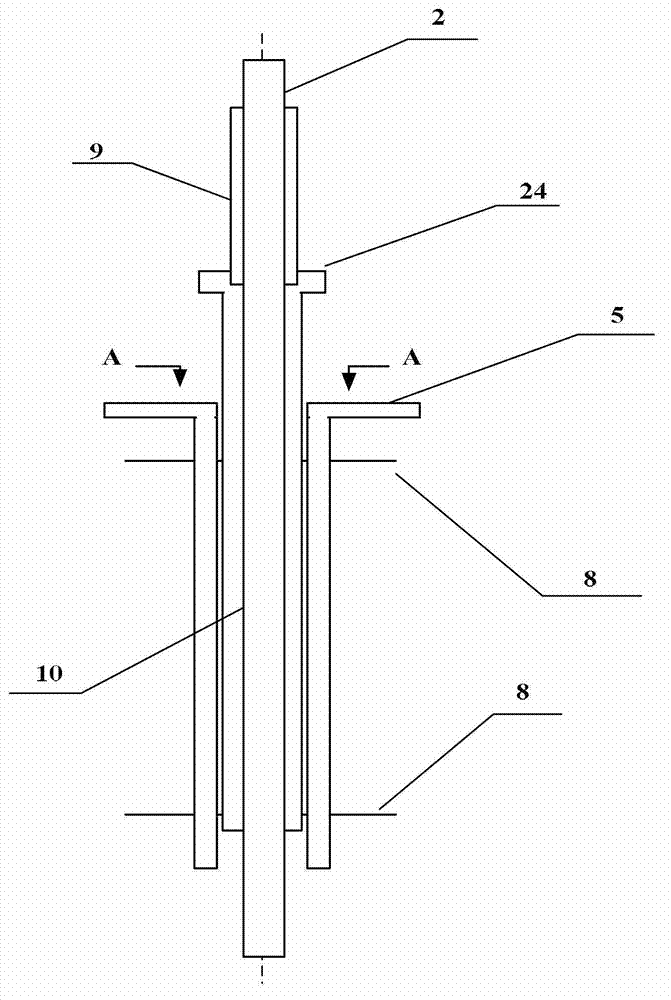

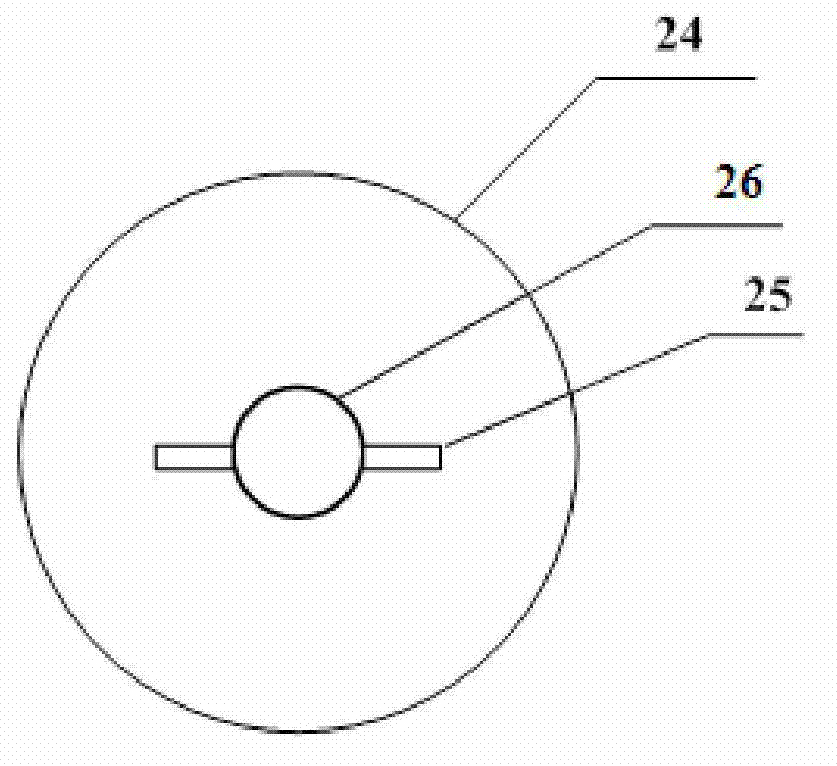

Column type extraction device for pipe bundle multi-channel phase-dispersing and extraction method thereof

InactiveCN102772913ALess prone to turbulenceSuitable for extraction operationLiquid solutions solvent extractionStraight tubeOil phase

The invention relates to a column type extraction device for pipe bundle multi-channel phase-dispersing; a main shaft is arranged inside the column type extraction device; two or at least three hollow thin tubes in parallel to the main shaft are distributed on the outer circumference of the main shaft; one end of each hollow thin tube is provided with a straight tube, and the other end of the hollow thin tube is bent to form a flanged bend; the bending direction of the flanged bend is the remote direction of a mounting shaft; the main shaft is connected with an electric motor, and drives the hollow thin tubes to carry out motion at a same speed with the main shaft when the main shaft rotates. The column type extraction device disclosed by the invention solves the difficult problems that a water phase or an oil phase with relatively small volume is difficult to disperse completely in the conventional mechanical stirring manner when the volume ratio of the water phase to the oil phase in an extraction process is large; and the difficult problems that the water phase and the oil phase are difficult to clarify and separate in an extraction system and the like caused by easy emulsification are also solved when the flow-rate ratio of the water phase to the oil phase is large.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

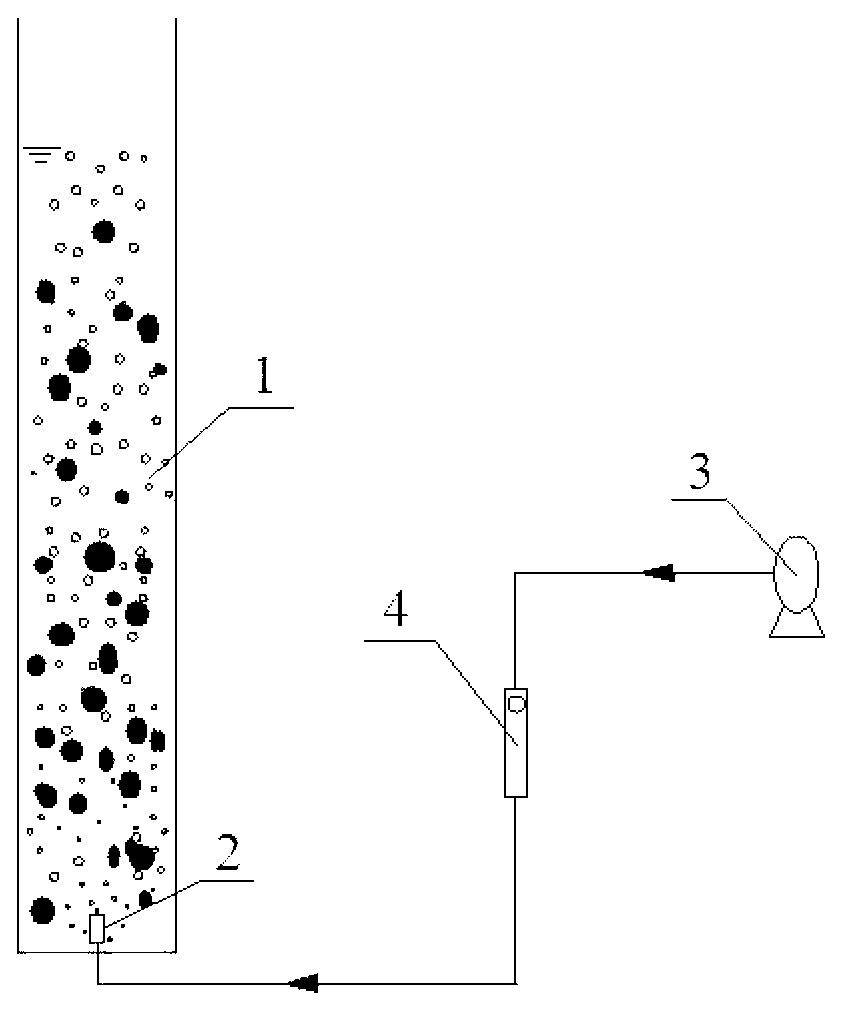

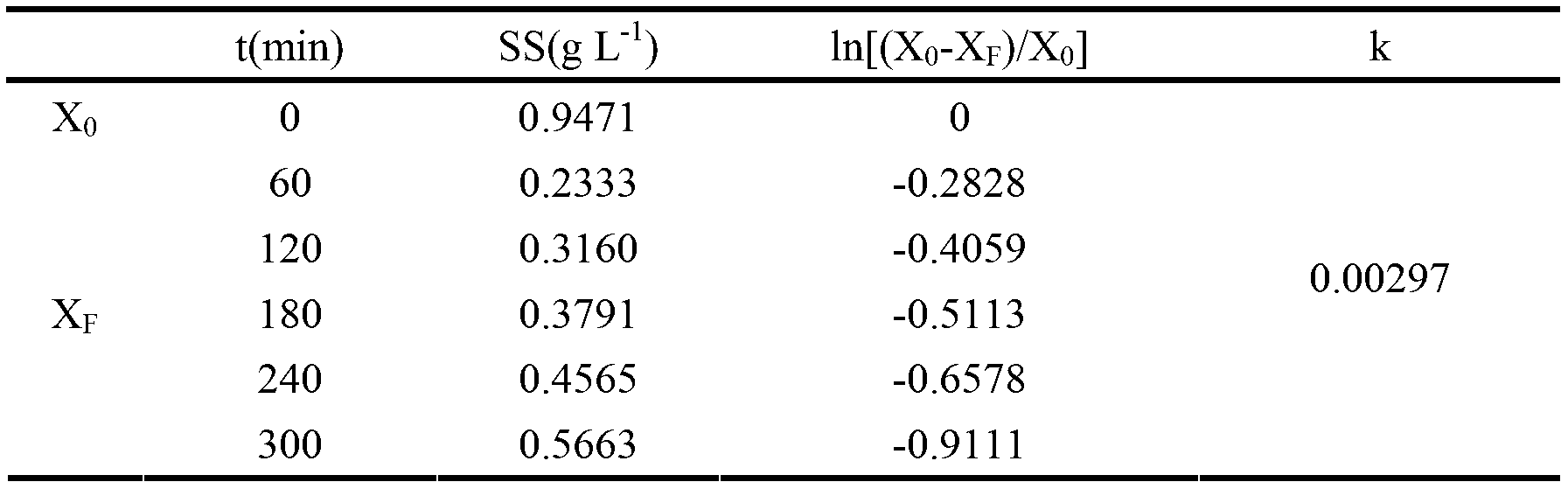

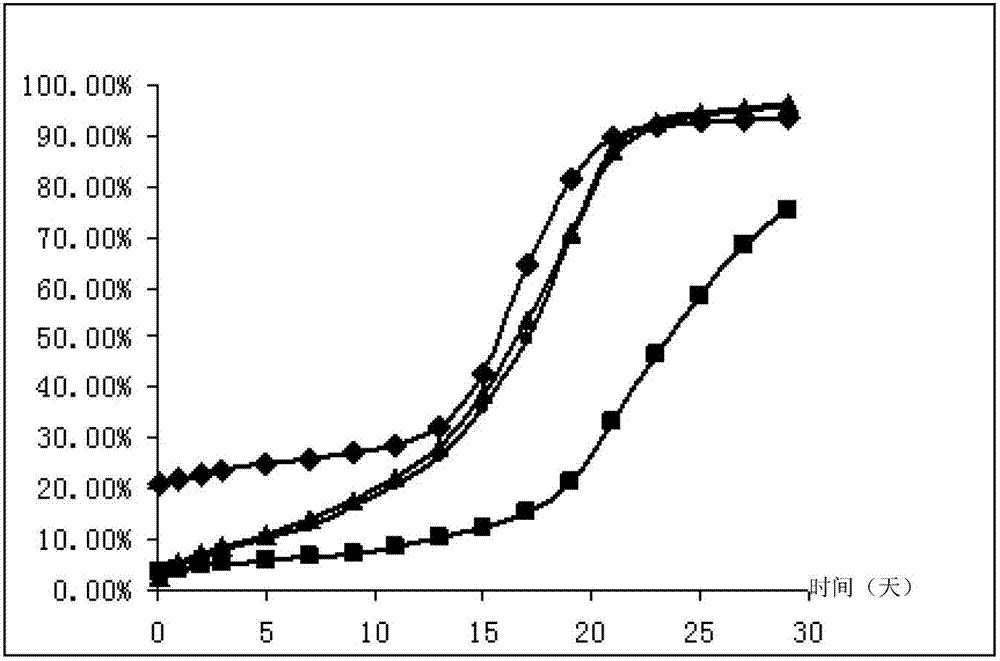

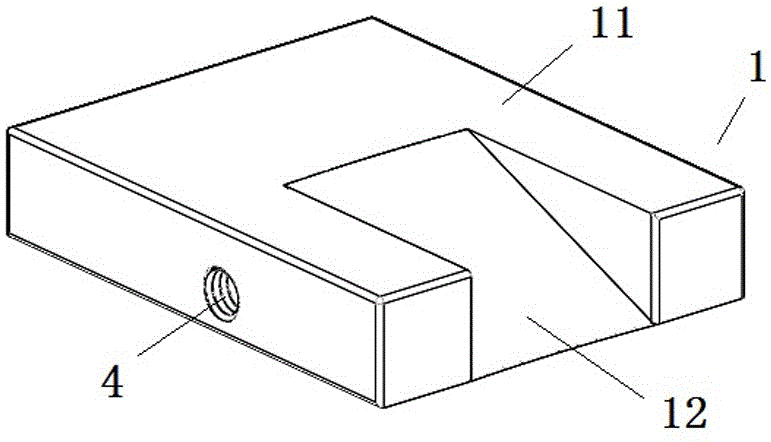

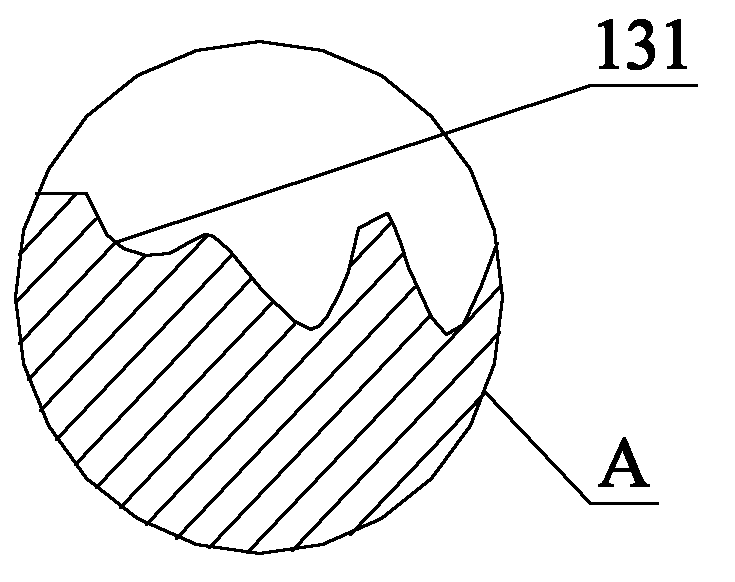

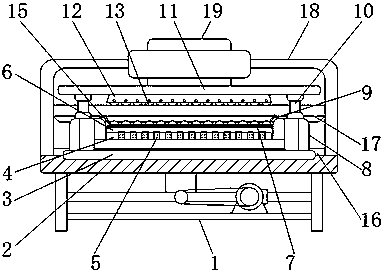

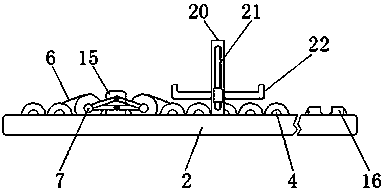

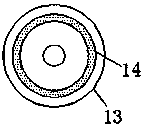

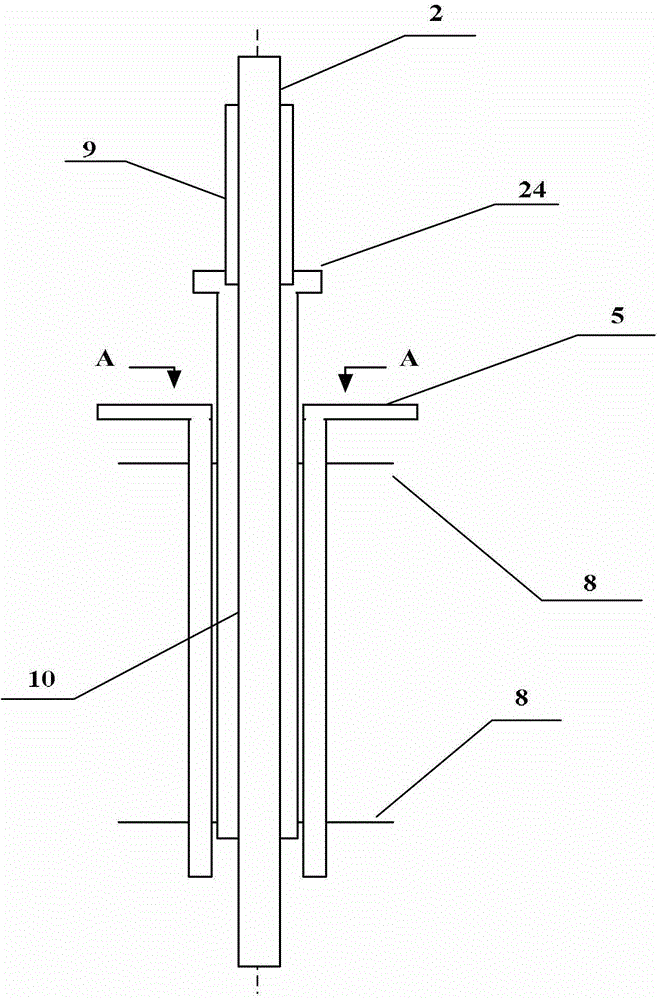

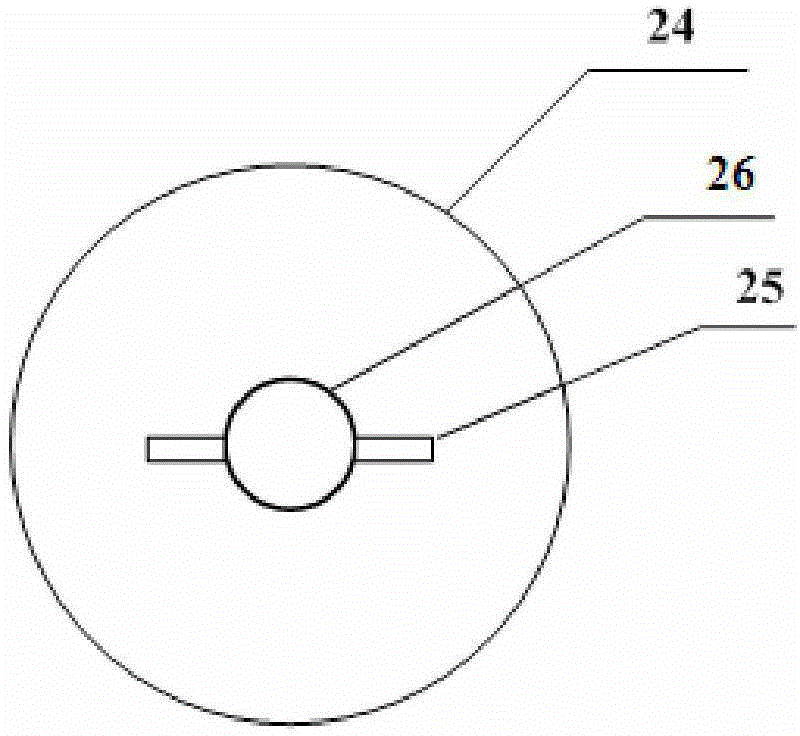

Measuring method and device for mechanical strength of granular sludge

ActiveCN103196781AEasy to controlUniform shear forceWeighing by removing componentSludgeDistilled water

The invention discloses a measuring method and device for mechanical strength of granular sludge. The measuring method comprises the following steps of: sieving the fine granular sludge to be measured through a sieving device, mixing 1L distilled water in the sieved granular sludge, ventilating for 1h, sieving and filtering the ventilated sludge-water mixture, and meanwhile, repeatedly performing the steps above on the residual granular sludge for 4-5 times; and sieving and filtering the granular sludge for the last time, and drying and weighing the residual granular sludge and other filtered sludge to obtain a wear rate coefficient. The measuring device comprises a cylinder, a micropore air distributing device, an air flow meter and an air compressor, wherein the micropore air distributing device is installed on the bottom of the cylinder; and the micropore air distributing device is communicated with the air compressor through the air flow meter. The measuring method and device disclosed by the invention have the beneficial effects that the measuring method is strong in maneuverability and measuring parameters are liable to regulate and control; the method and the device can be used for measuring various kinds of granular sludge, and the testing cost is low; the shear force applied to the granular sludge in the measuring device is uniform, and the mechanical strength of the granular sludge can be accurately measured.

Owner:HANGZHOU NORMAL UNIVERSITY

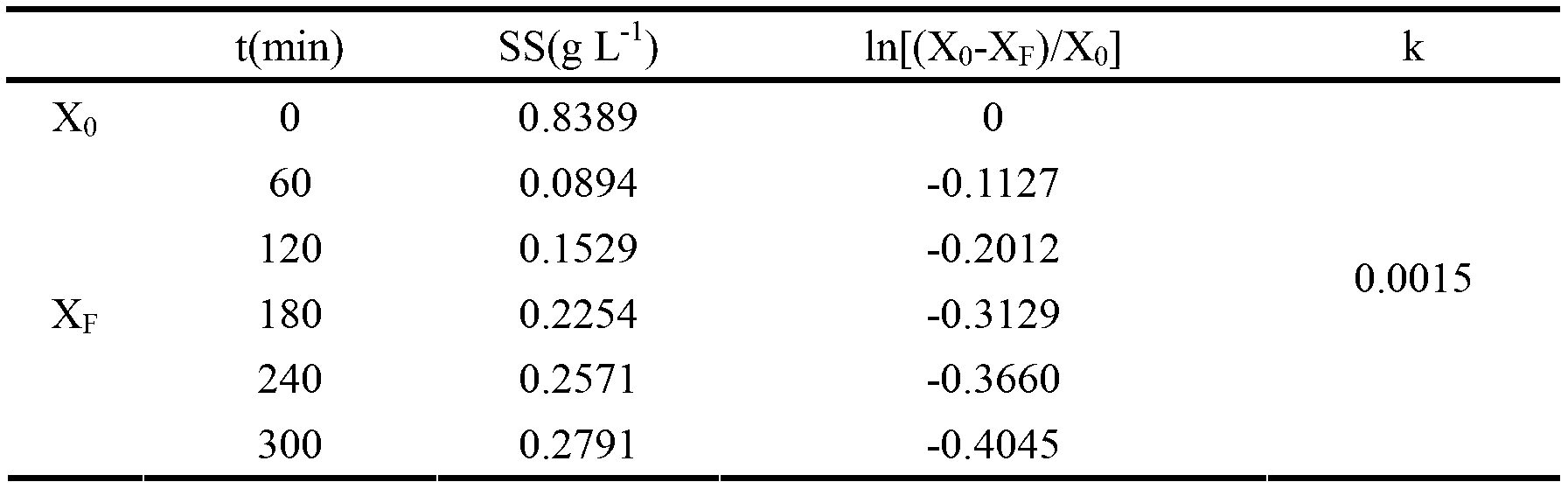

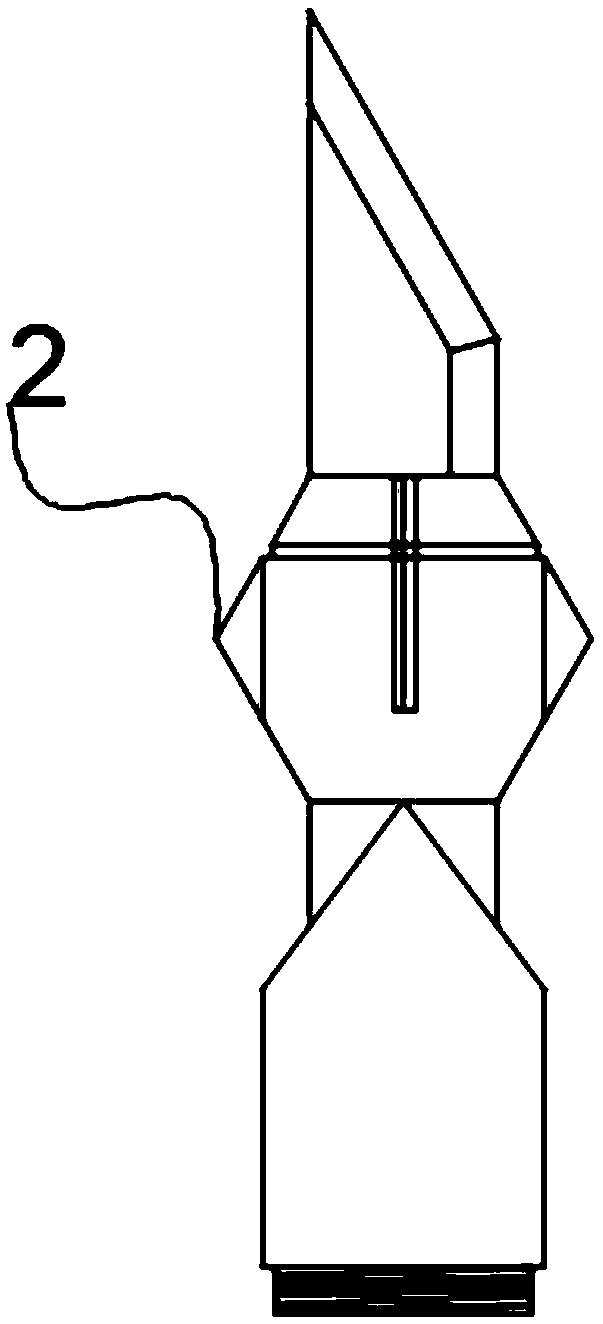

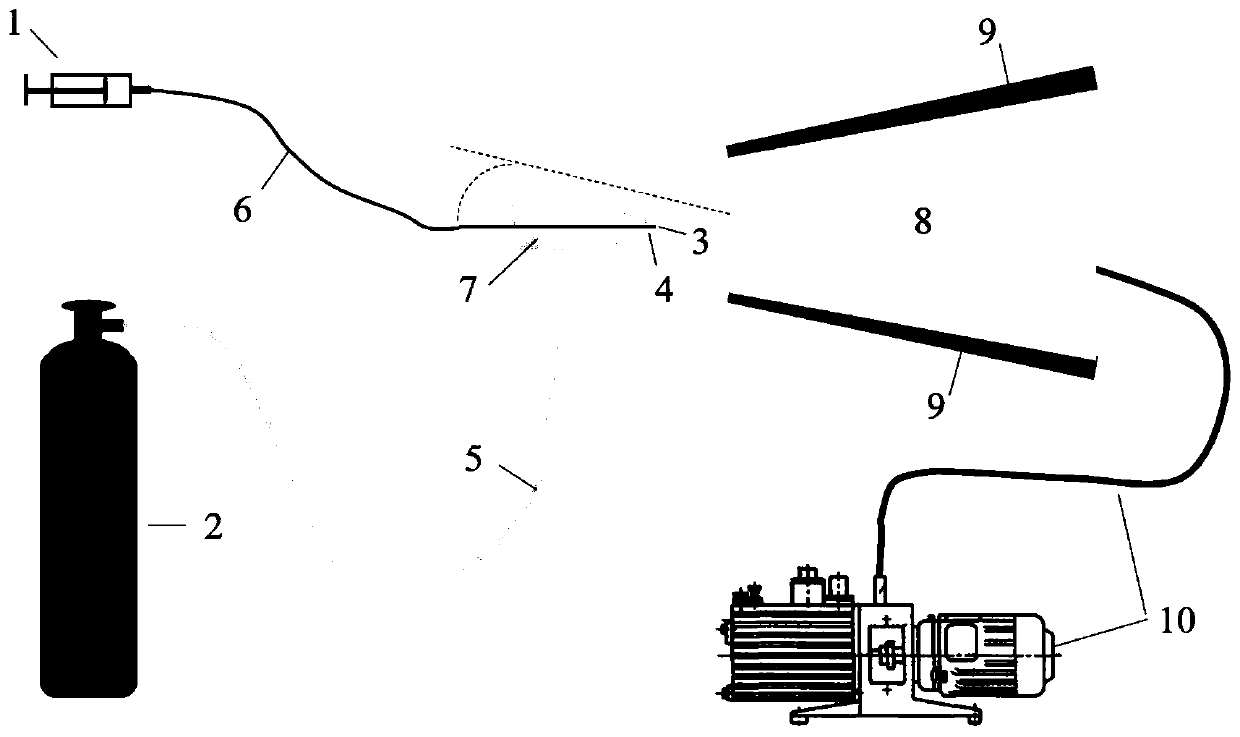

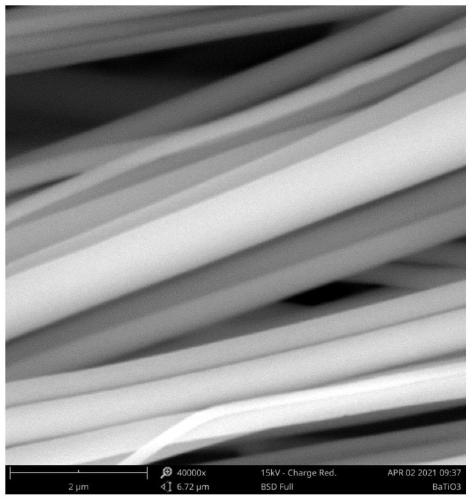

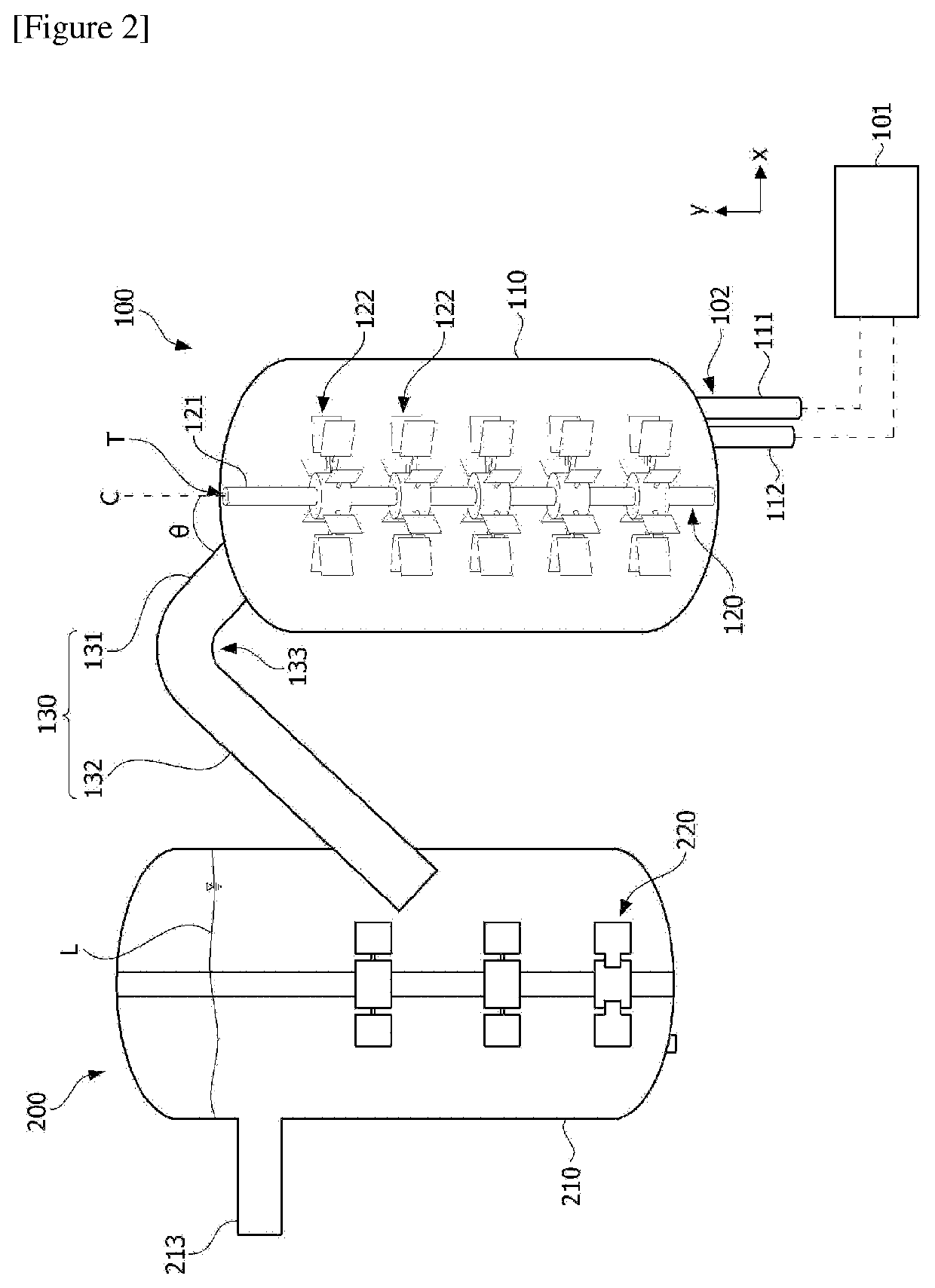

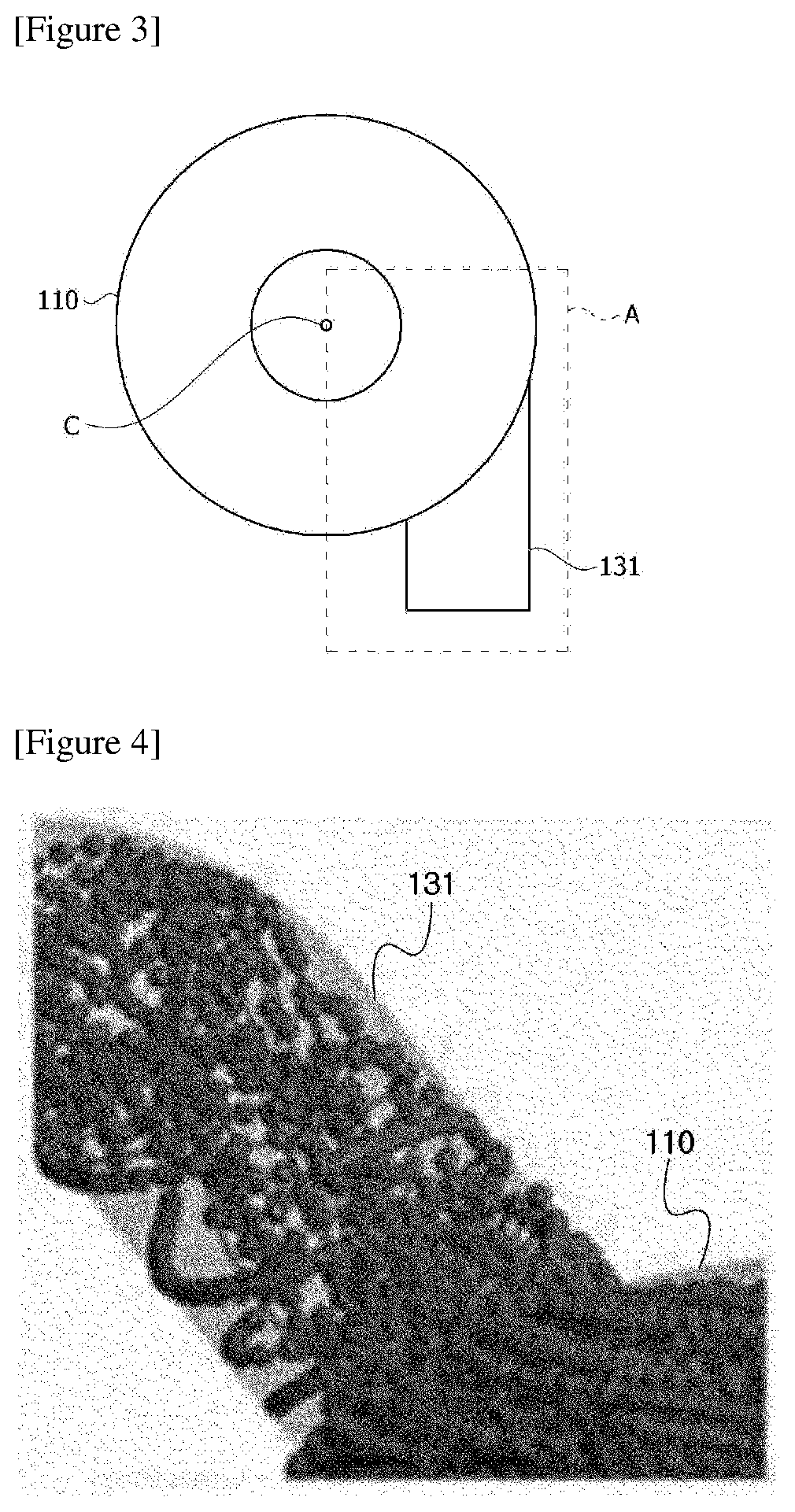

Device and method for preparing directionally arranged fiber by solution blow-spinning technology

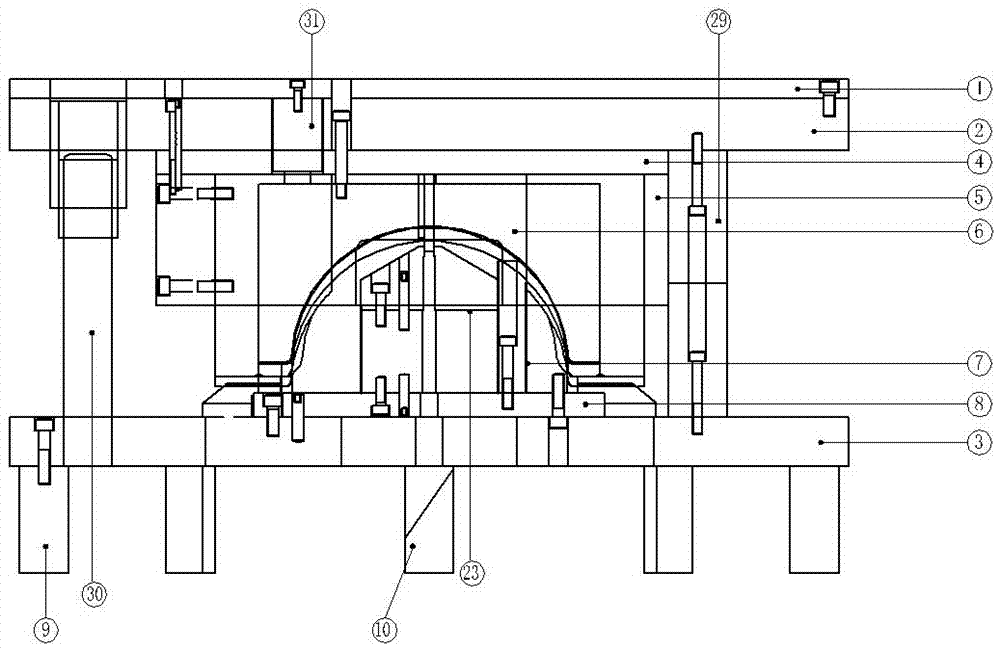

ActiveCN109537073AEase of mass productionFacilitate single batch preparationNew-spun product collectionNon-woven fabricsFiberSpin system

The invention discloses a device and a method for preparing directionally arranged fiber by a solution blow-spinning technology. The device comprises a solution blow-spinning system and a system for collecting fiber directionally arranged by airflow; the solution blow-spinning system comprises a spinning solution, an airflow control system and a blow-spinning device; the blow-spinning device, a spinning solution and the airflow control system are connected; a spinning collection system comprises a paving collection net; the paving collection net is connected with a negative pressure device; and the solution blow-spinning system collects directionally arranged nanometer fiber on the paving collection net by adjusting the angle of the spinning air flow and the paving collection net and by taking high-speed airflow as a directional driving force. The device and the method are relatively simple to operate, have many adjustable parameters and are high in precision; and the fiber obtained through preparation is high in arrangement degree, large in preparation quantity and high in uniformity.

Owner:XI AN JIAOTONG UNIV

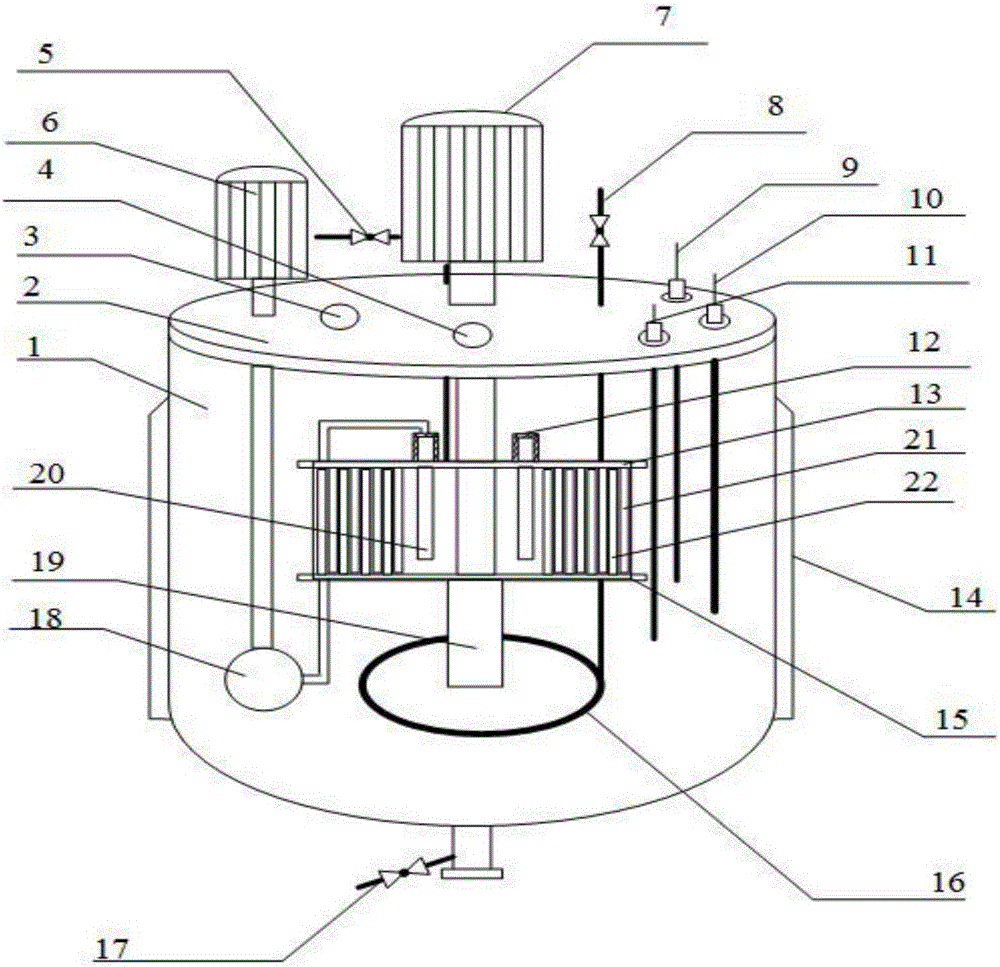

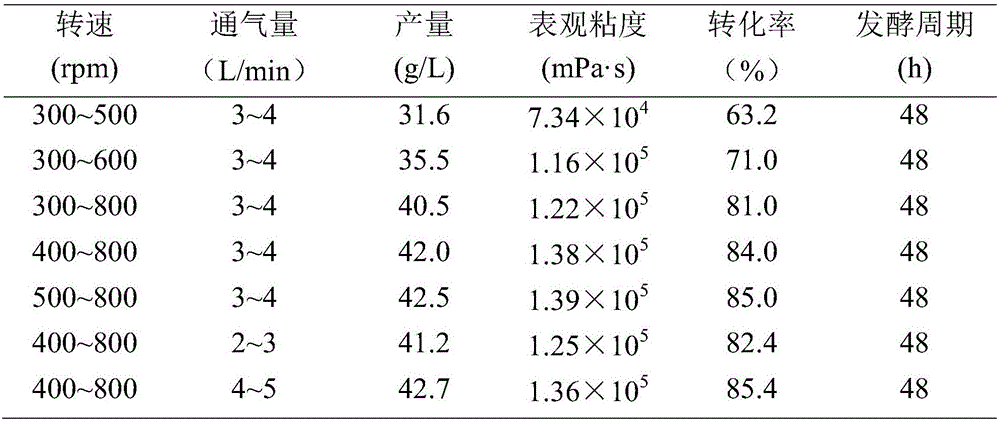

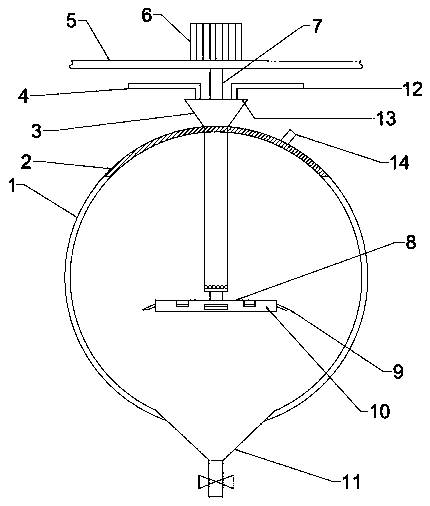

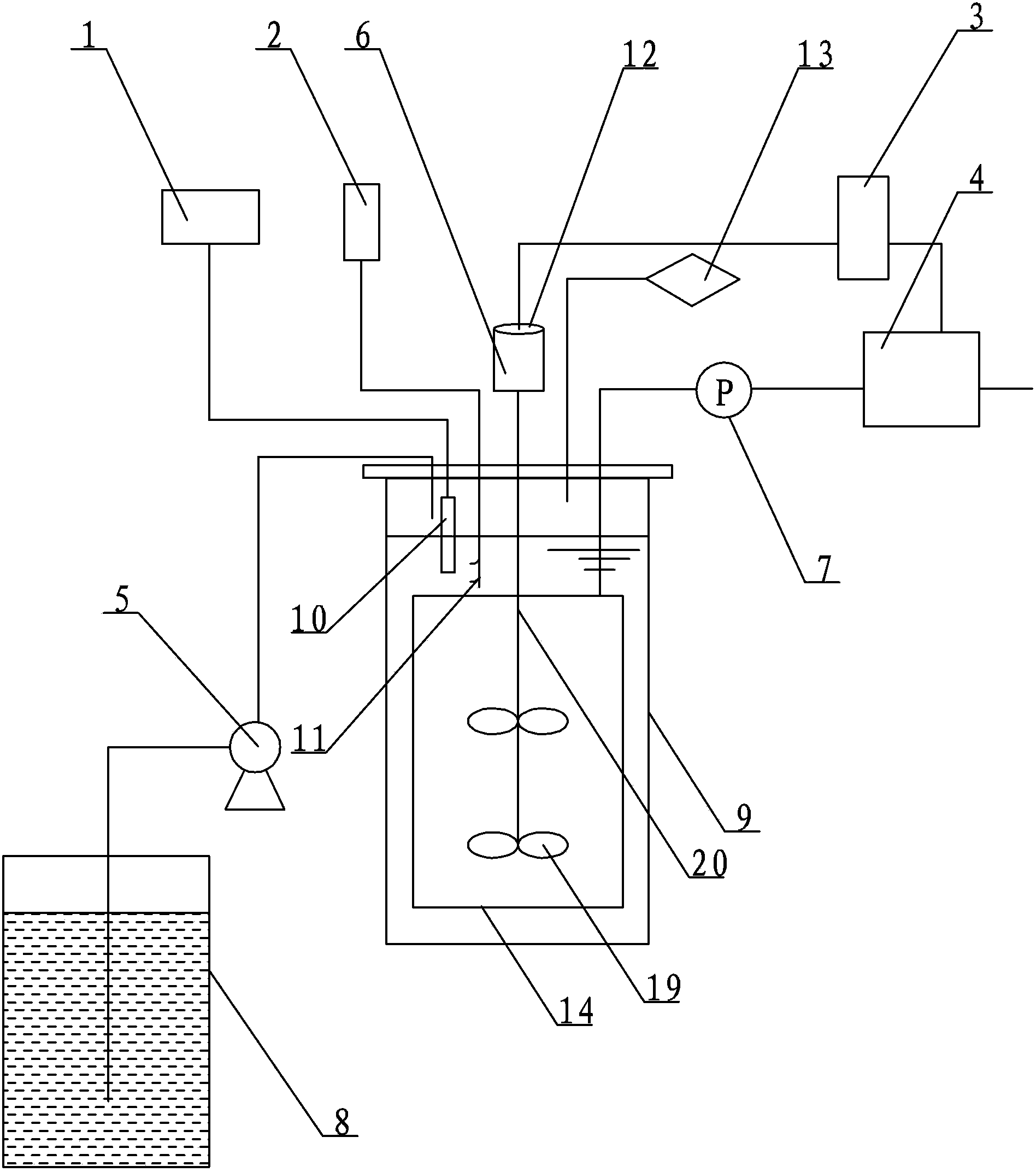

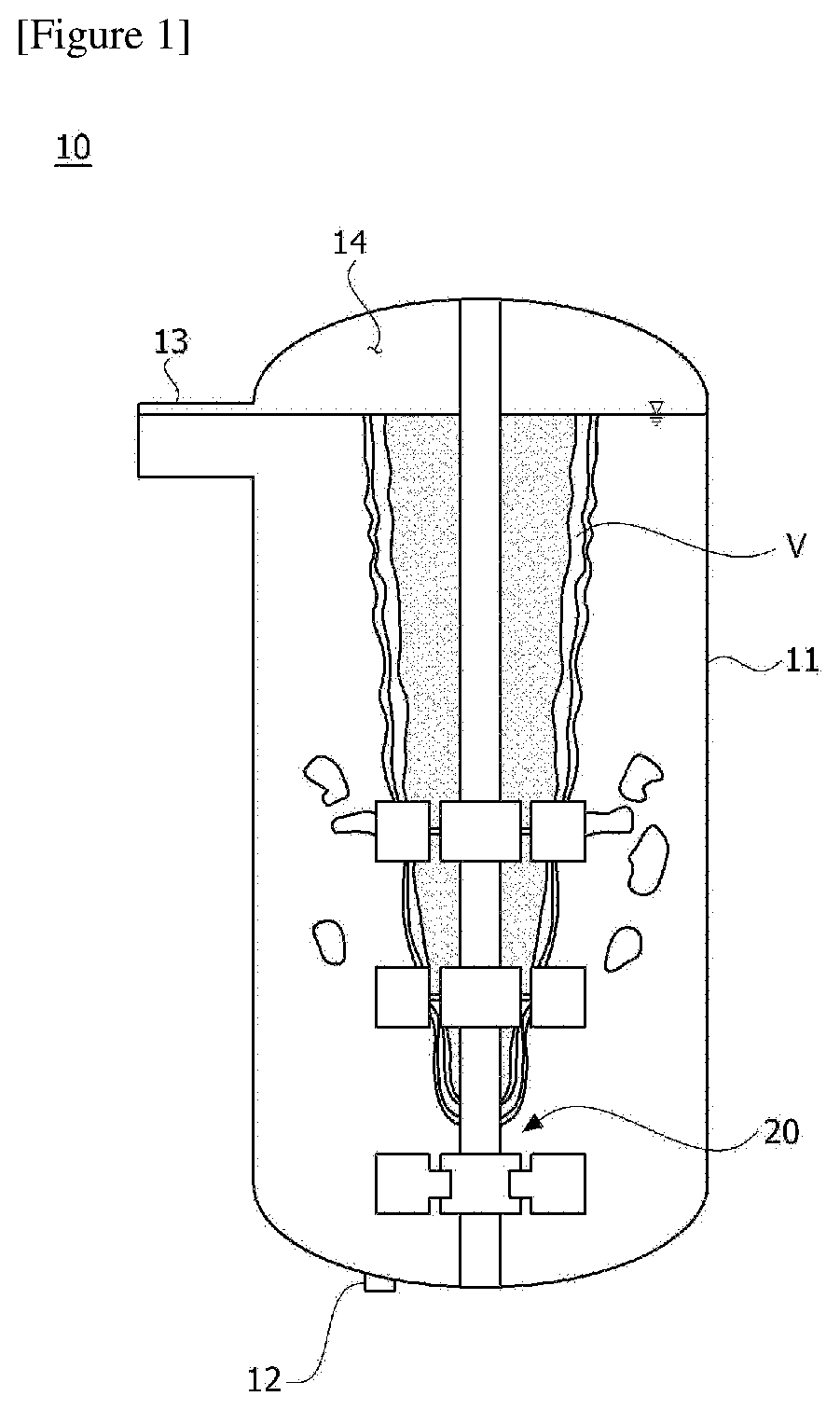

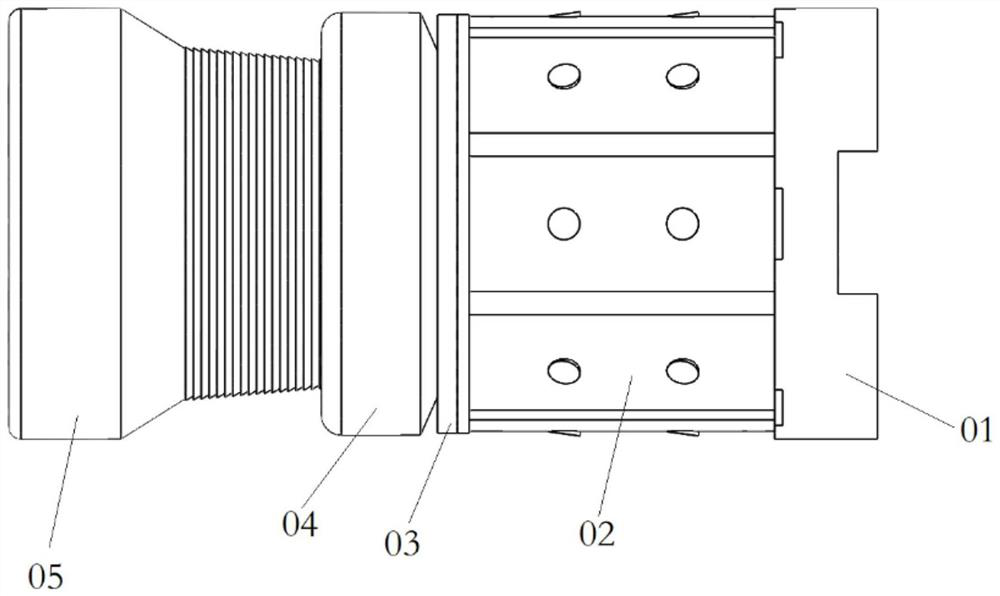

System device for strengthening high-viscosity microbial polysaccharide fermentation and application

InactiveCN106635753AGrow fastDissolved oxygen is goodBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringOxygen mass transfer

The invention discloses a system device for strengthening high-viscosity microbial polysaccharide fermentation. The system device comprises a tank body, a tank cover, a cooling interlayer, an air distributor, a first motor, a second motor, a supergravity revolving bed device and a high-temperature-resisting submerged pump. A rotary shaft is longitudinally arranged inside the tank body. The upper end of the rotary shaft penetrates through the tank cover to be in driven connection with the first motor, and the lower end of the rotary shaft extends into the tank body to be connected with the supergravity revolving bed device. The supergravity revolving bed device is transversely arranged at the center of the inside of the tank body. The air distributor is arranged at the lower end of the supergravity revolving bed device and is an annular pipeline. The high-temperature-resisting submerged pump is arranged on one side of the lower end of the inside of the tank body. One end of the high-temperature-resisting submerged pump is connected with the supergravity revolving bed device through a pipe, and the other end of the high-temperature-resisting submerged pump is connected with a rotary shaft of the second motor. The cooling interlayer is arranged outside the tank body. A fermentation period is greatly shortened by strengthening dissolved oxygen mass transfer, gas, liquid and solid phase mixing, rotating speed optimization, ventilatory capacity and other conditions, the yield and mass of high-viscosity polysaccharide are increased, and the cost is remarkably reduced.

Owner:BEIJING UNIV OF CHEM TECH

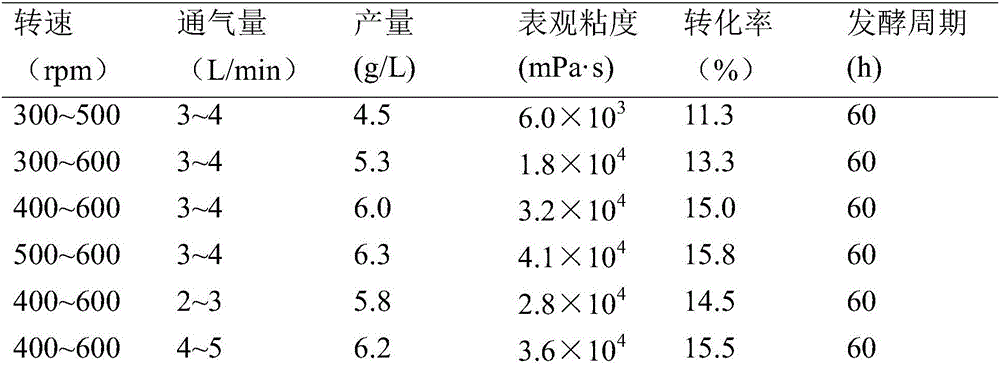

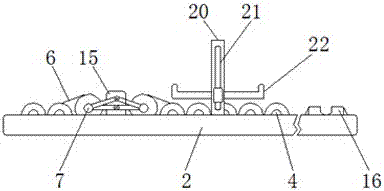

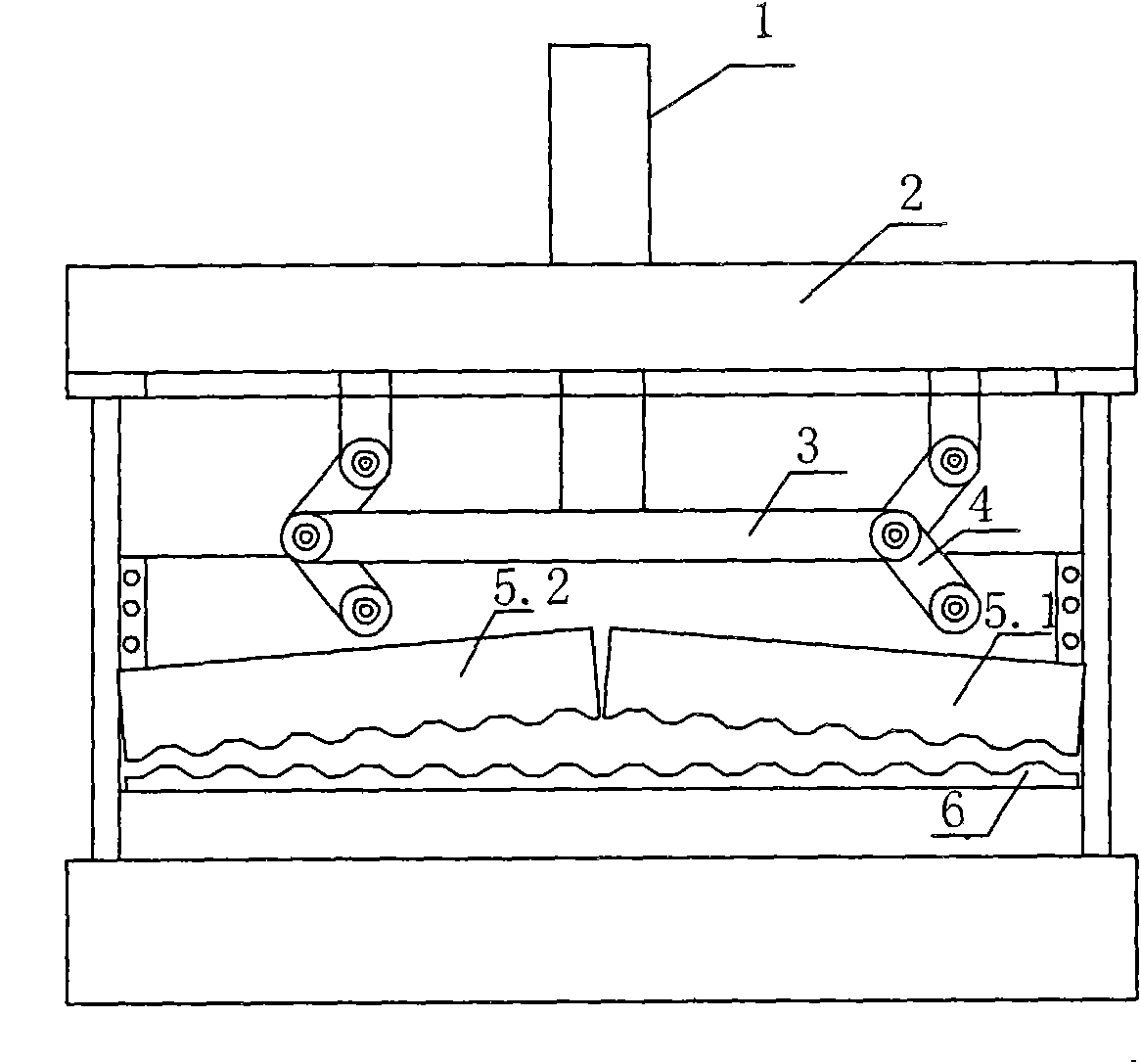

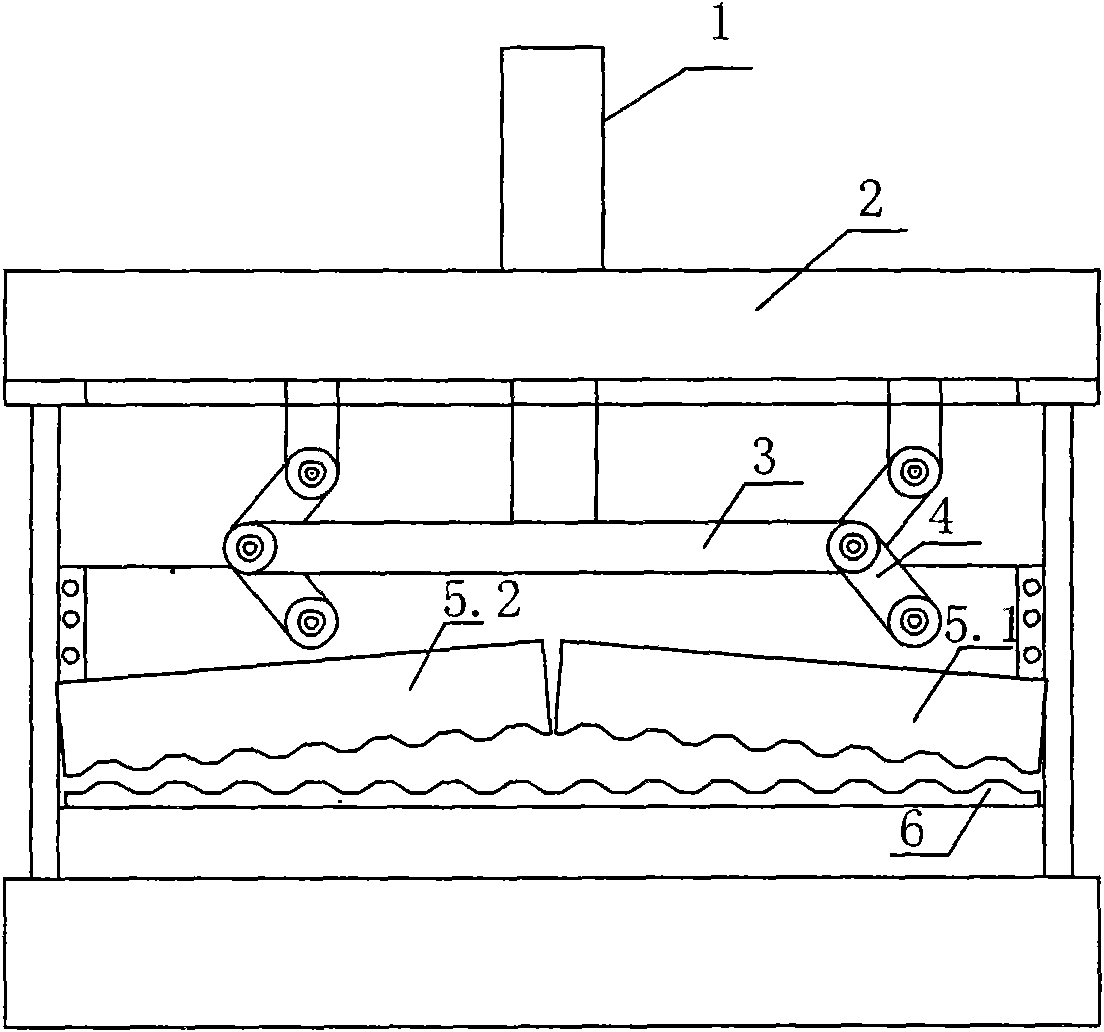

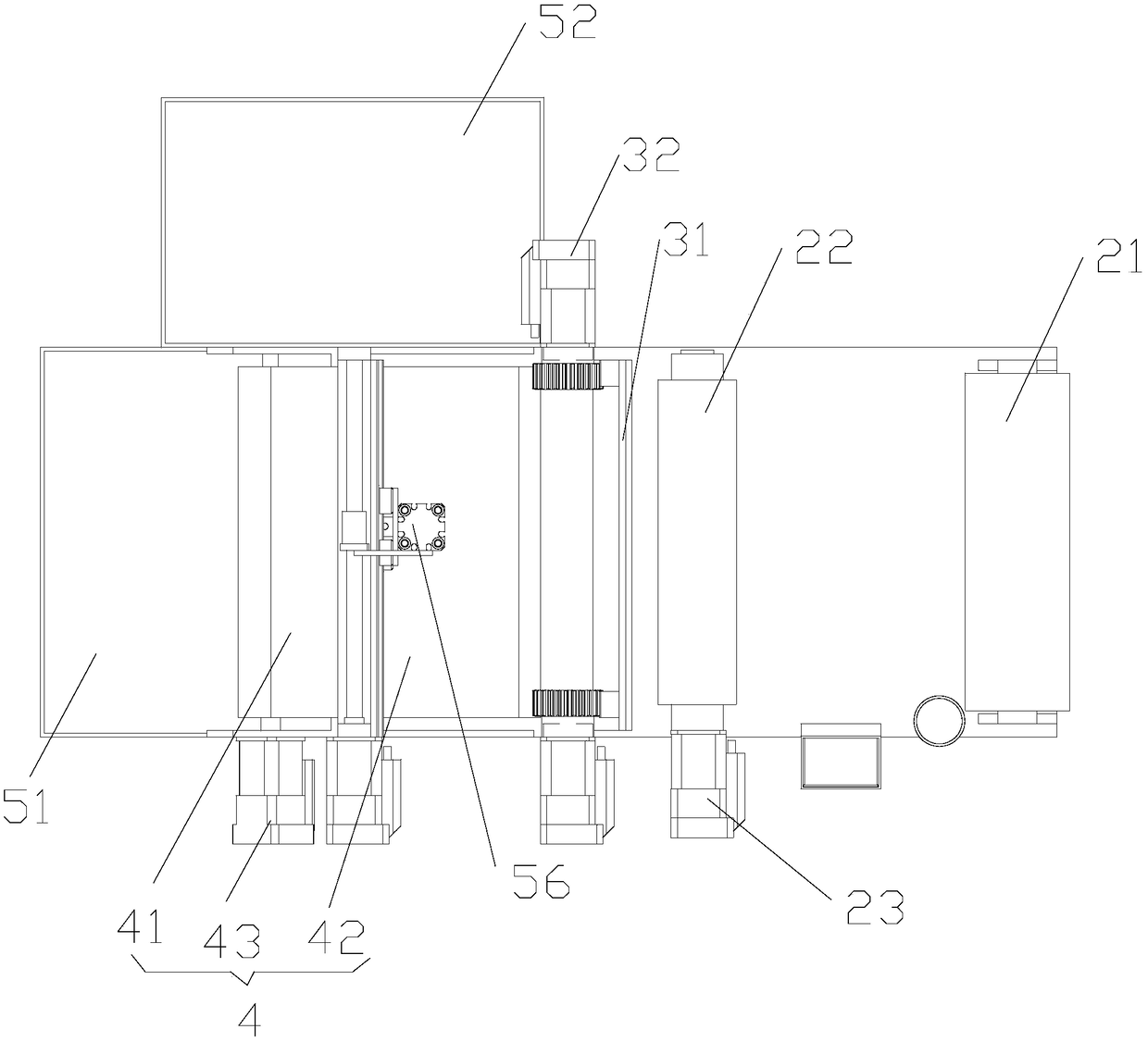

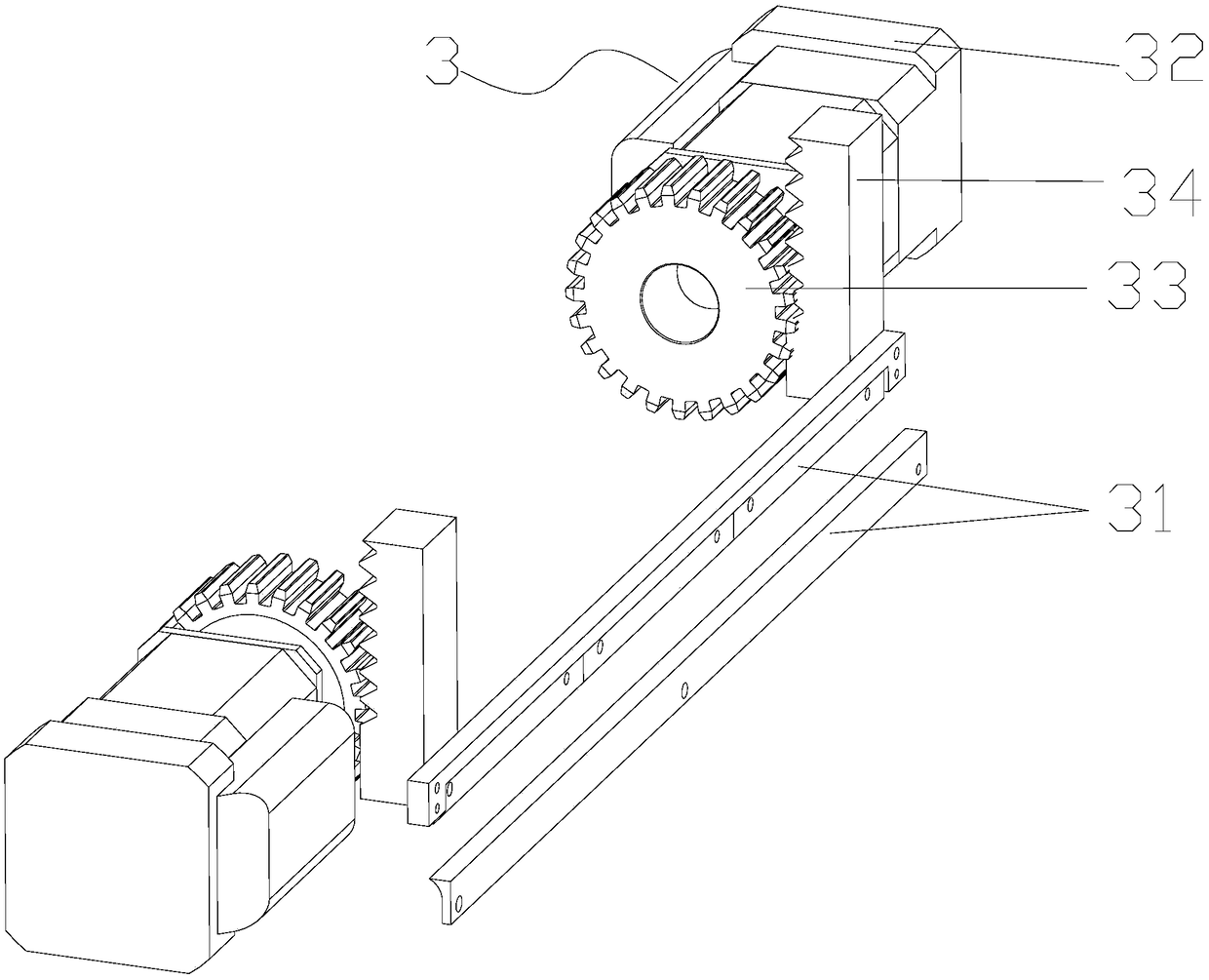

Shearing and bending equipment of thin metal plate

ActiveCN108000156AReduce deliveryEasy to cutShearing machinesOther manufacturing equipments/toolsThin metalMarine engineering

The invention discloses shearing and bending equipment of a thin metal plate. The shearing and bending equipment comprises a support, an upper cutter disc and a vertical rod, wherein a horizontal table is fixed above the support, and an operation table is arranged above the horizontal table; conveying rollers are installed above the operation table, and sand rings are welded on the surface of theconveying rollers; supporting plates are arranged above the sand rings, and rolling shafts are arranged above the supporting plates; baffles are fixedly arranged on the left side and the right side ofthe conveying rollers, and clamping plates are arranged above the baffles; a lifting rod is arranged on the outer side of the clamping plates, and a cross rod is arranged above the lifting rods; a cutting knife is arranged below the upper cutter disc, and the upper cutter disc is located in the middle of the cross rod; a grinding disc is arranged on the surface of the cutting knife, and a lower cutter disc is arranged below the cutting knife; a sliding groove is fixed in the middle of the vertical rod, and the vertical rod is located on the left side of a bending bottom plate. The shearing bending equipment of the thin metal plate can achieve continuous machining of shearing and bending, shear force is balanced, and the operation table can freely deflect the angle.

Owner:江苏磊澄智能机械装备有限公司

Method for food packaging

ActiveCN108408145AUniform shear forceAvoid wrinklesWrapper twisting/gatheringEngineeringFood packaging

The invention belongs to the technical field of packaging, and particularly relates to a method for food packaging. The method comprises the following steps that (1) preparation is made, wherein a rack is prepared, a conveying roller is installed on the rack, a planishing unit, a glue pasting unit and a cutting unit are sequentially installed above the rack, wherein the glue pasting unit comprisesa packaging tape, the cutting unit comprises a conveying belt and a cleaning box which are fixed to the rack, a cutter is fixedly connected to one side of the conveying belt, the blade direction of the cutter is parallel to the width direction of the packaging tape, and a cleaning zone used for cleaning the cutter is formed in the cleaning box; (2) feeding is carried out; (3) covering is carriedout; (4) glue pasting is carried out; (5) cutting is carried out; and (6) discharging is carried out. By means of the scheme, the packaging tape is prevented from being folded during sealing box packaging.

Owner:重庆勋勋商贸有限责任公司

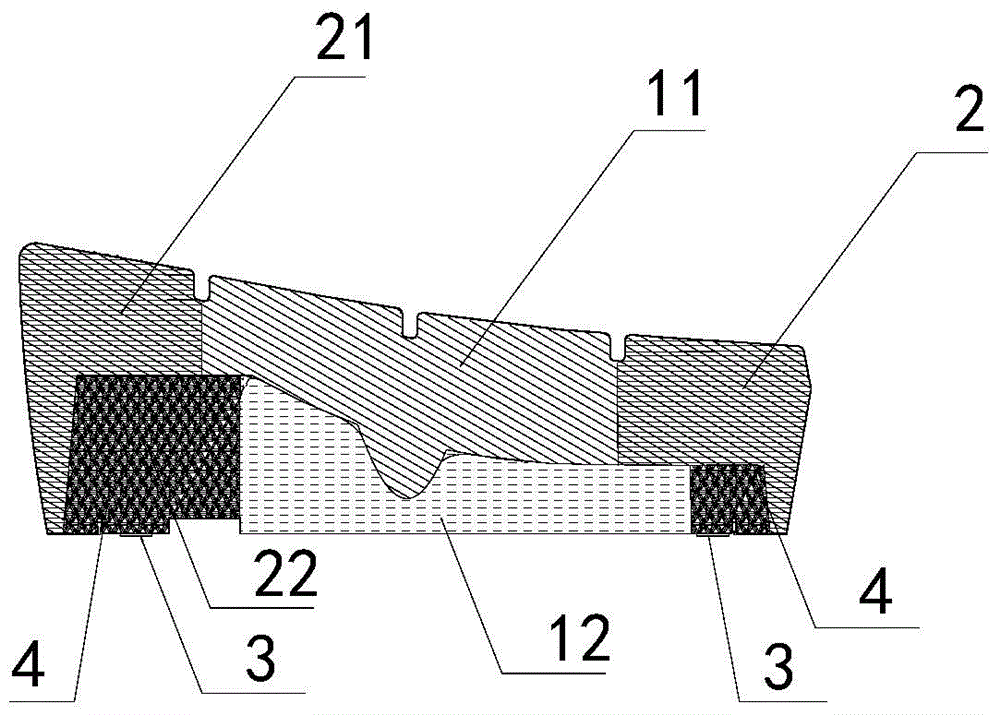

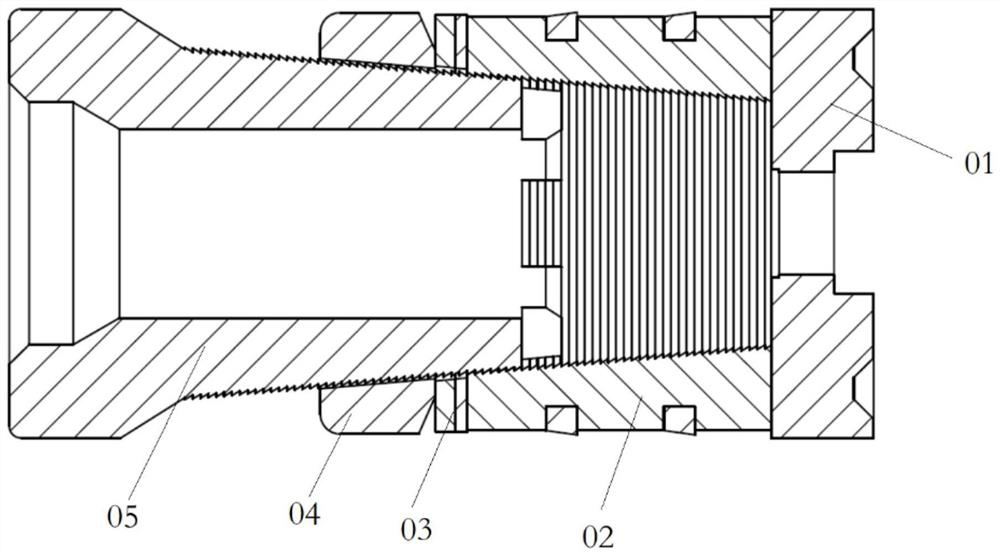

Lightweight ball seat

PendingCN109944571AShorten the overall lengthImprove drilling efficiencyFluid removalWell/borehole valve arrangementsHardnessEngineering

The invention provides a lightweight ball seat. The seat comprises a lower joint, a slip, a sealing member and a central tube, the central tube is in a truncated cone shape, the sealing member and theslip sequentially sleeve the outer side of one end with a smaller outer diameter of the central tube in a direction in which the outer diameter of the central tube is reduced, one end of the sealingmember abuts the one end of the slip, and the end of the one end with a smaller outer diameter of the central tube is located in the slip; the end of the lower joint abuts the other end of the slip, and the lower joint is internally provided with a sealing tool connecting structure; the sealing member adopts a two-stage structure, and the hardness of the first-stage sealing member is smaller thanthe hardness of the second-stage sealing member. The ball seat is provided with the two-stage sealing member, and improves the reliability of the sealing during work, the design of the ball seat is compact and short, the material is a lightweight magnesium-lithium alloy material, the drilling efficiency is improved, after the work is finished, it is easy to return out, and the risk of clogging a wellbore is eliminated.

Owner:VERTECHS OIL & GAS TECH CO LTD

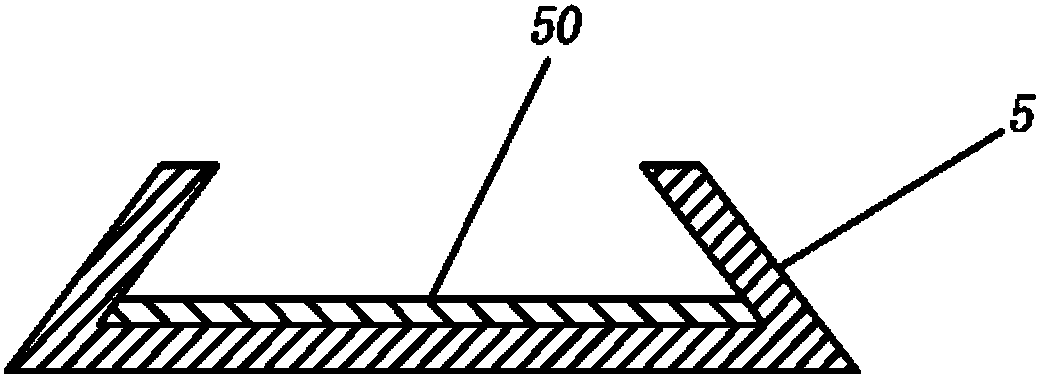

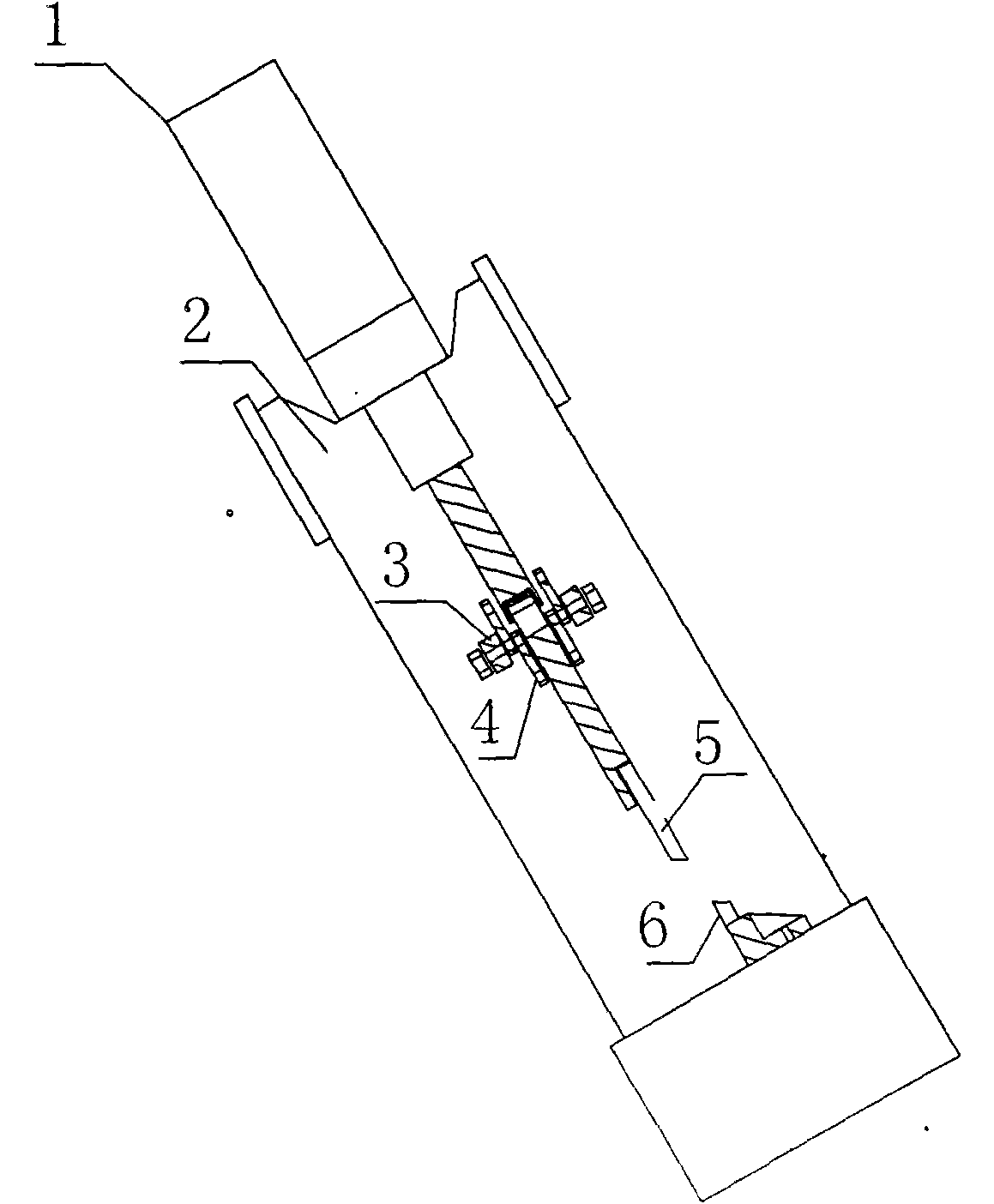

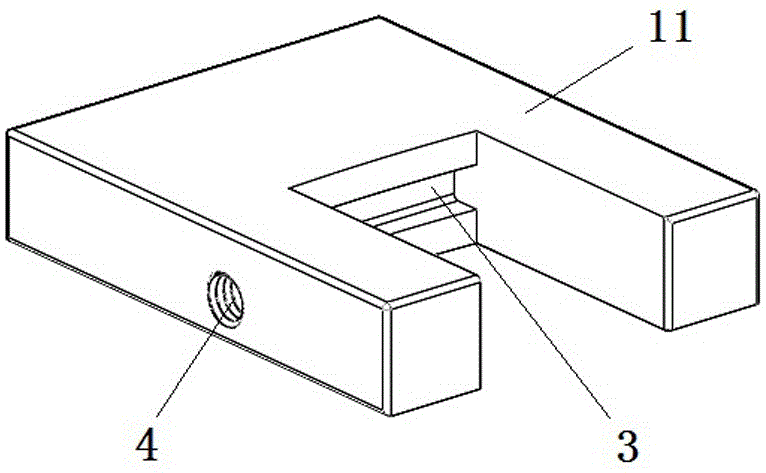

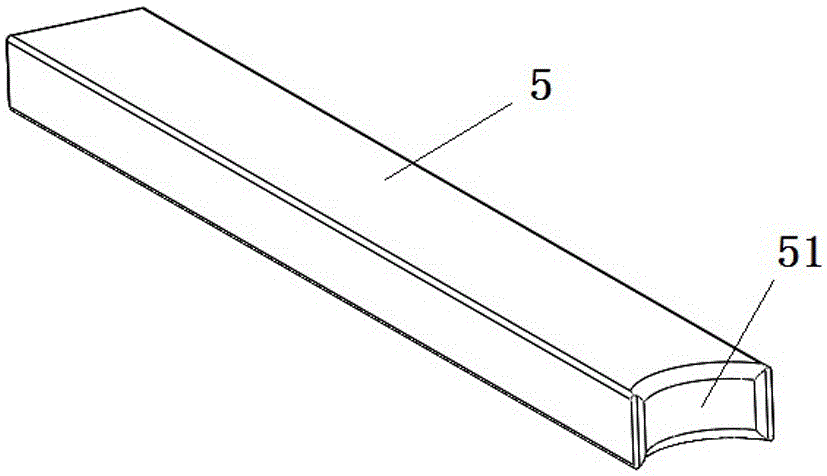

Method and device for cutting metal-moulded honeycomb thin wave plate

The invention relates to a method and a device for cutting a metal-moulded honeycomb thin wave plate, which are characterized in that: the cutting is performed from two sides to the middle part of the wave plate in a shearing way to make a shearing face at an oblique angle of 60+ / -10 degrees. The method and the device simply and obliquely cut the moulded honeycomb thin wave plate accurately at one time without additionally processing the oblique angle; at the same time, a cutting opening is flat and straight, has no burr edge and does not need to be deburred; and the cutting force in opposite direction is uniform and does not cause wave deformation, so secondary reshaping and processing are not needed. An upper cutter cuts at a high speed and with a high cutting efficiency while moving downwards and is used together with a wave plate continuously moulding machine; and equipment is simple and can obliquely cut at any oblique angle. A balance device arranged on the upper cutter can ensure that shearing on two sides is synchronous and that the shearing does not deform substantially. The cutting method of cutting from two sides to the middle part in the shearing way is weak in cutting force, simple in used equipment, low in requirement on the equipment and low in cost.

Owner:JIANGSU RUISHENG WATER TREATMENT

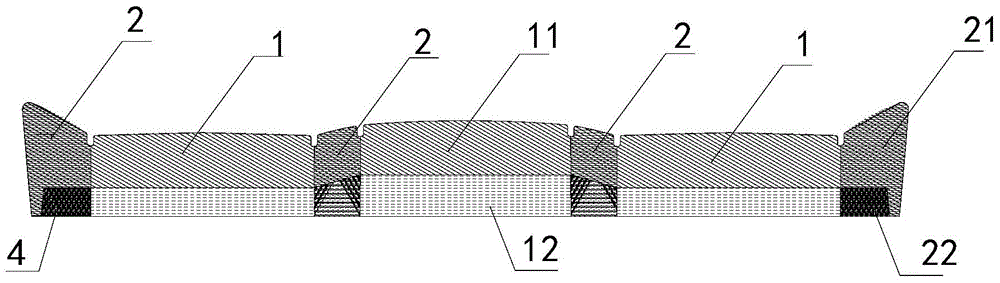

Automobile back-row cushion and machining-assembling method thereof

The invention discloses an automobile back-row cushion. The automobile back-row cushion comprises a sitting area and a peripheral area, wherein each area comprises a cushion core and a seat fabric; the cushion cores of the sitting area and the peripheral area are constructed by an upper layer foaming material and a lower layer foaming material respectively; the upper layer foaming materials and the lower layer foaming materials are connected in an embedding way through a complementary structure. The machining-assembling method for the automobile back-row cushion comprises the following steps: making a polyurethane foaming material according to the shape of the upper layer of each cushion, making a polypropylene foaming material according to the shape of the lower layer of each cushion core, and assembling corresponding polyurethane foaming materials and polypropylene foaming materials into each cushion core respectively; coating integrally, and fixing the fabric with an injection-molded clamping bar; fixing the cushion on a vehicle metal plate through a dual-layer mushroom hasp. By adopting the automobile back-row cushion, the collision safety index is increased, the weight is reduced, the buffering performance is improved, the passenger comfort is improved, and a sound-absorbing function is realized.

Owner:SHANGHAI HUAGU VEHICLE IND CO LTD

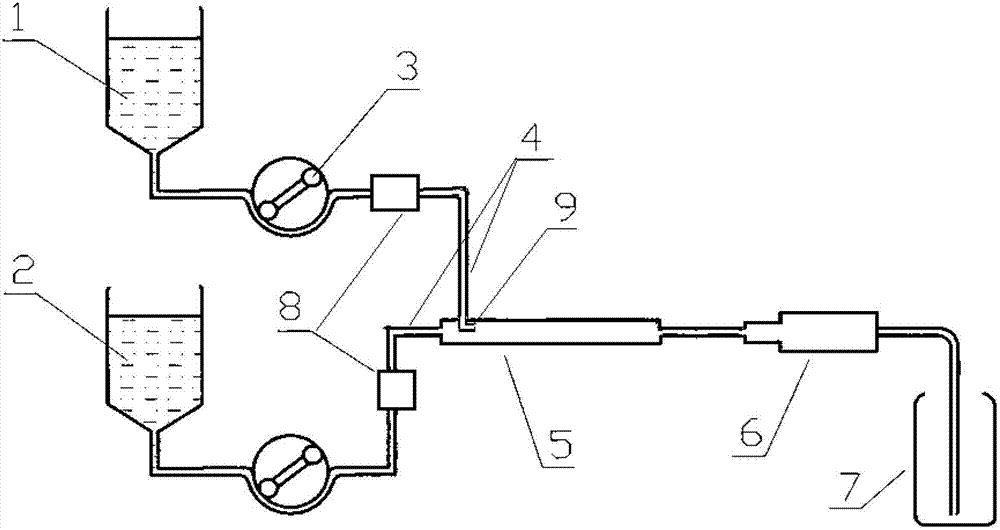

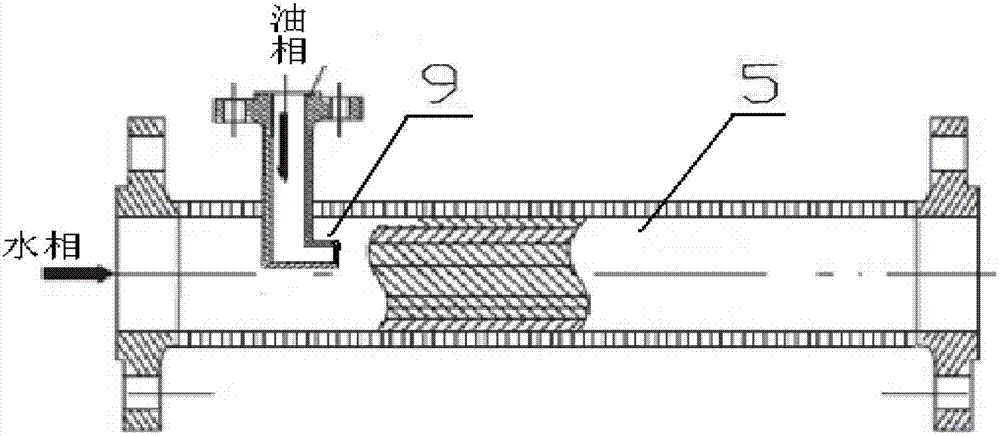

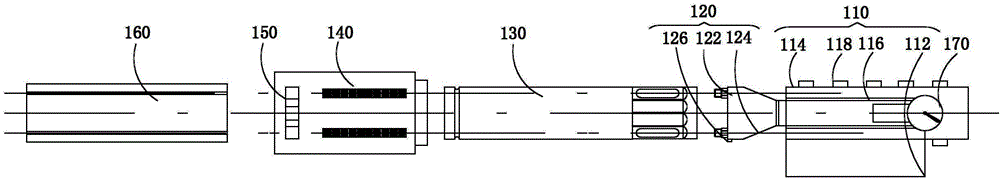

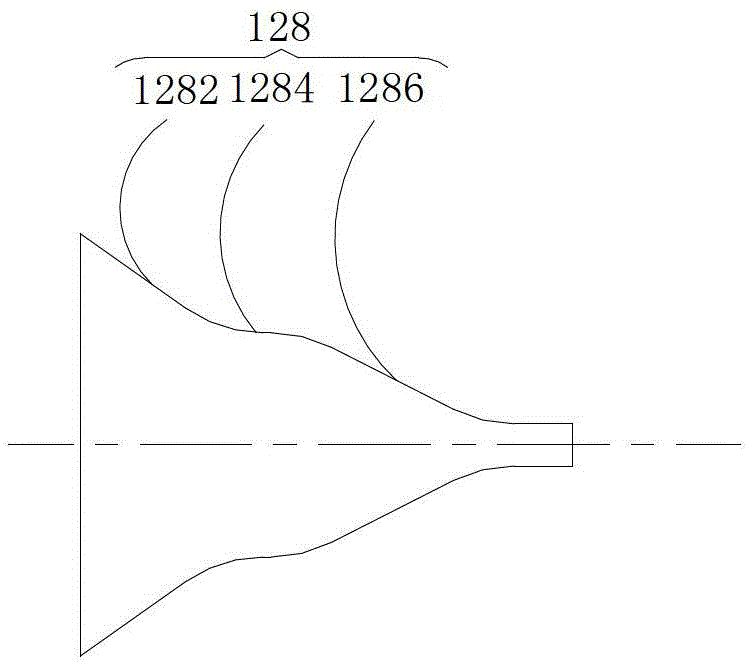

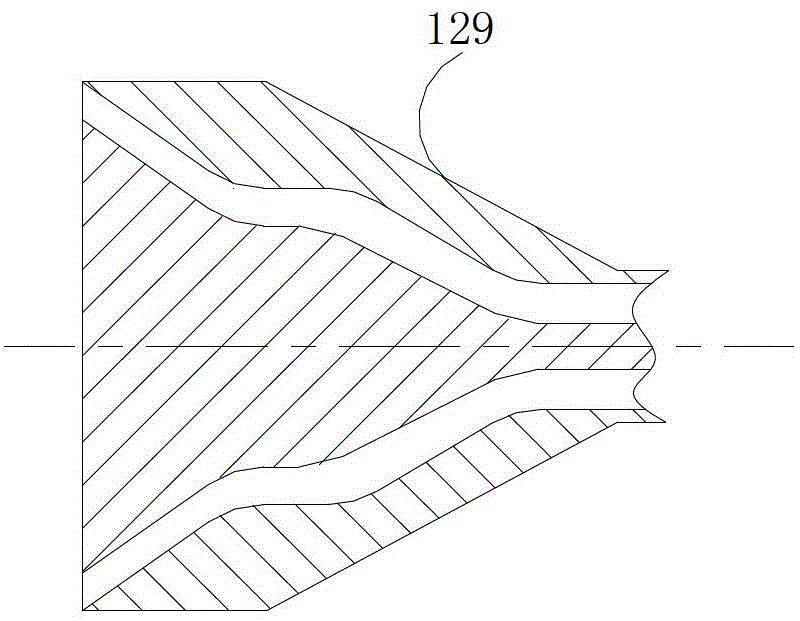

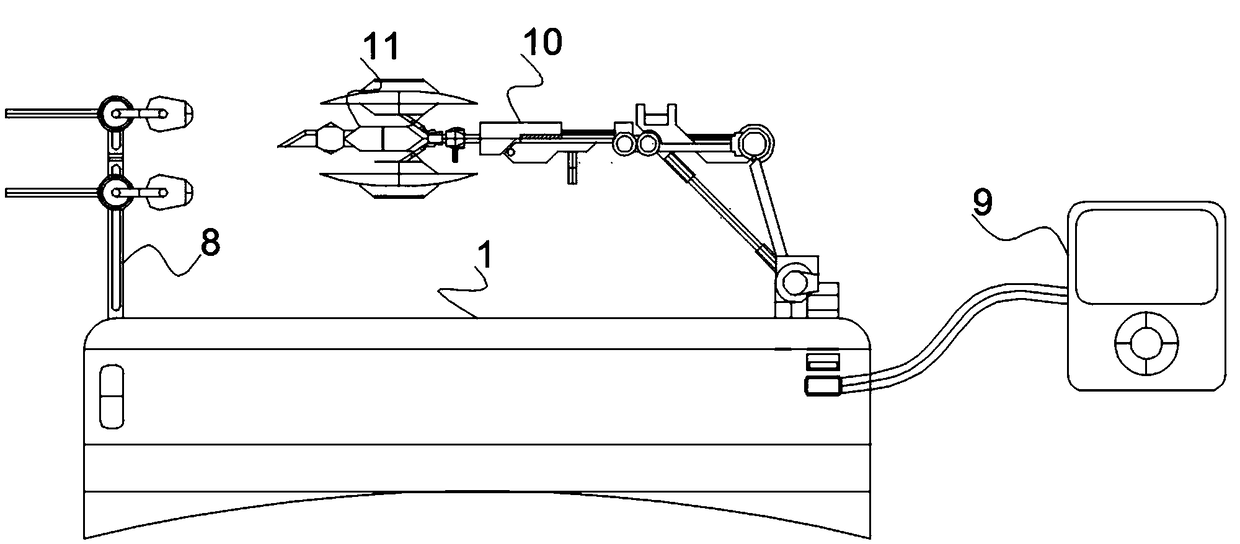

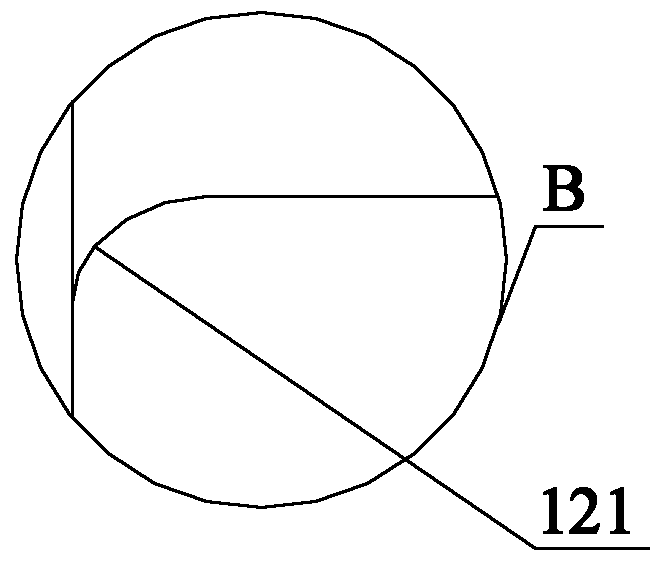

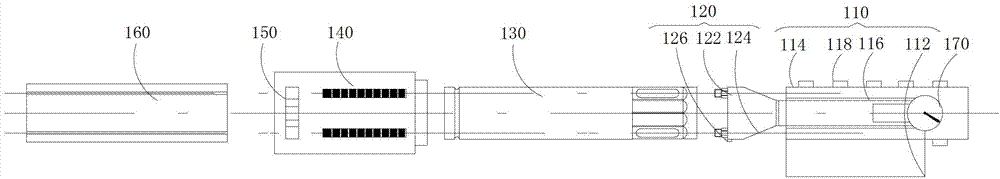

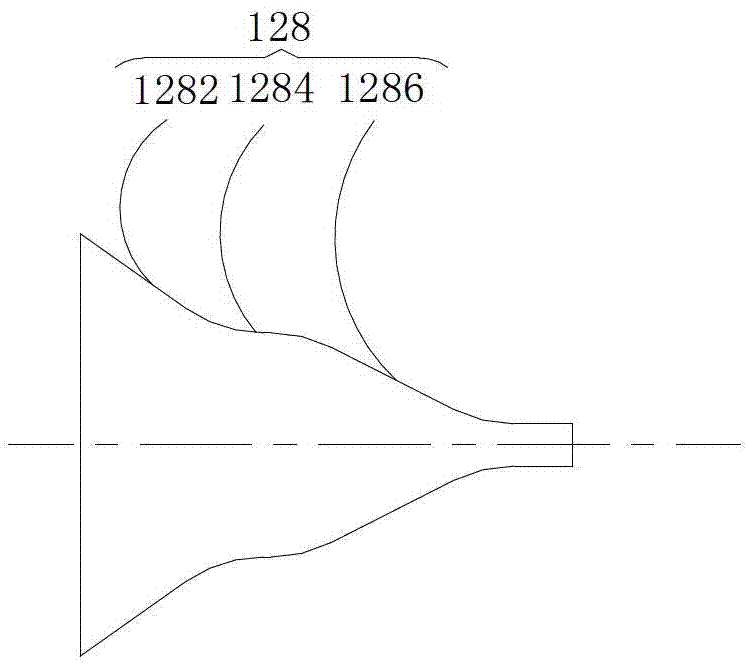

Equipment for continuously producing microspheres and application of equipment

InactiveCN103191021AImprove protectionReduce the temperaturePharmaceutical product form changeProcess equipmentMicrosphere

The invention relates to the field of medicinal preparations and provides new process equipment and a method for preparing microsphere preparations. According to the invention, the influence of the flow velocity on the grain diameter of the microspheres is reduced, the yield loss of products is reduced, the material transferring step is reduced, the processing time is reduced, and the production cost is reduced.

Owner:SHANDONG LUYE PHARMA CO LTD

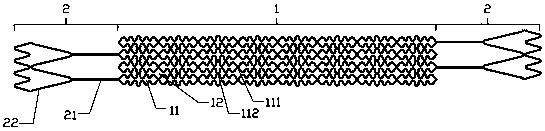

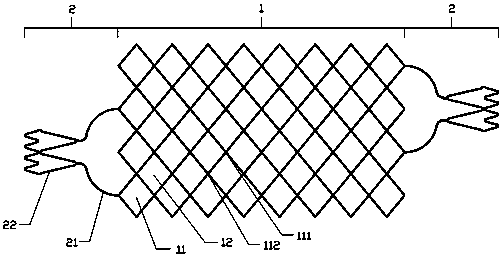

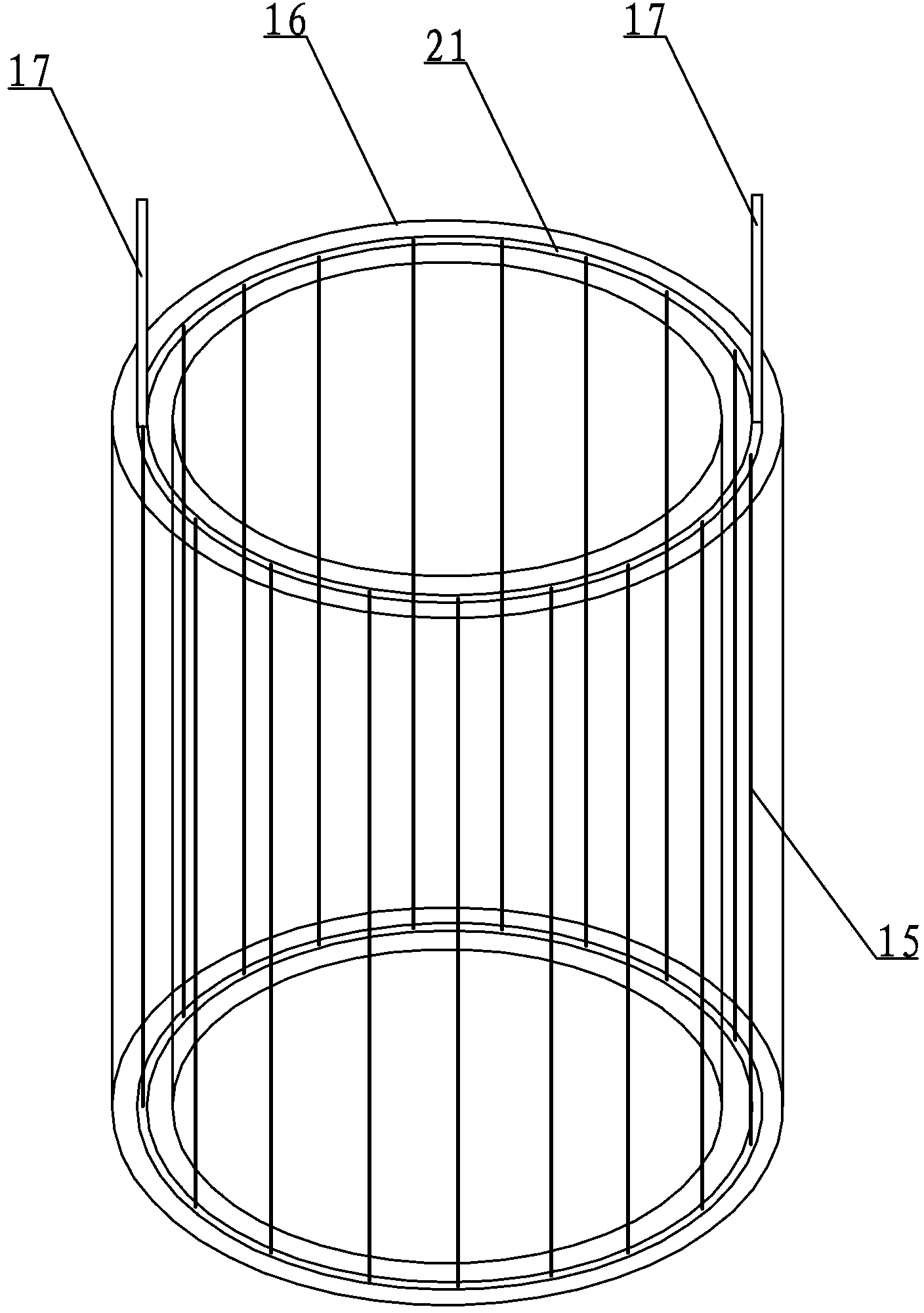

Non-implanted balloon-catheter constraint support and blood vessel expansion device with the same

PendingCN107582130AReduce rejectionSoft and even expansionSurgeryDilatorsTreatment effectMaximum diameter

The invention discloses a non-implanted balloon-catheter constraint support. The non-implanted balloon-catheter constraint support comprises a body part which is of a tubular structure and used for being arranged outside a balloon catheter in a coated mode and fixing parts connected to the two ends of the body part and used for being fixedly connected with the balloon catheter, and the constraintsupport is used for being expanded or shrunk along with the balloon catheter and inhibiting the maximum expanding volume of the balloon catheter. A non-implanted blood vessel expansion device comprises the balloon catheter, and also comprises the constraint support; the balloon catheter and the constraint support have the compressing forms used for being implanted into a blood vessel respectively,and have the expanding forms used for being expanded in the blood vessel, and the maximum diameter of the constraint support in the expanding form is smaller than the maximum diameter of the ballooncatheter in the expanding form. The non-implanted balloon-catheter constraint support and the non-implanted blood vessel expansion device are simple in structure and convenient to use, the treating effect is greatly improved, harm to the blood vessel is reduced, and the occurrence probability of complications is reduced.

Owner:HANGZHOU BARTY MEDICAL TECH CO LTD

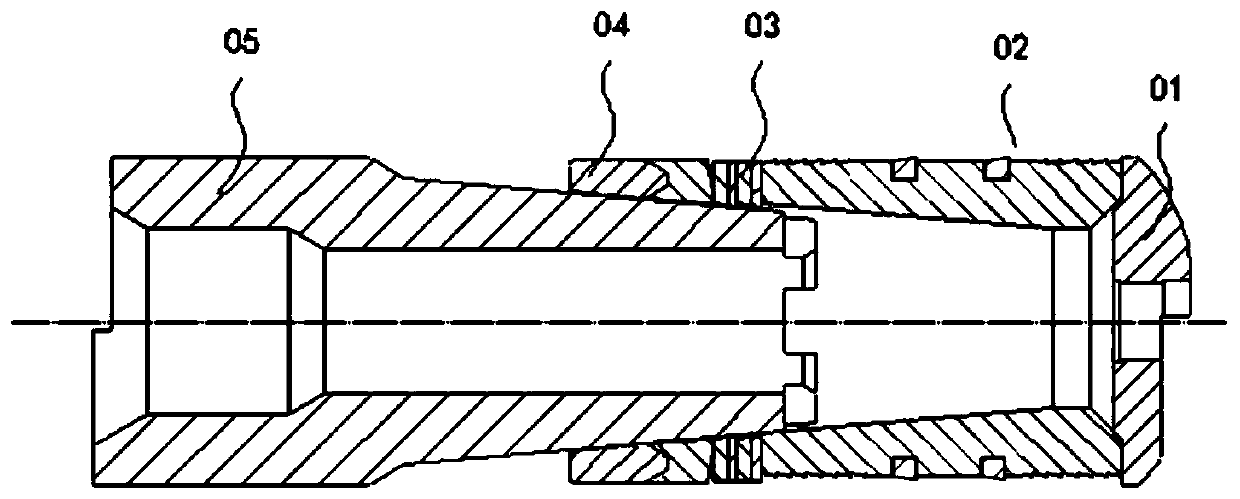

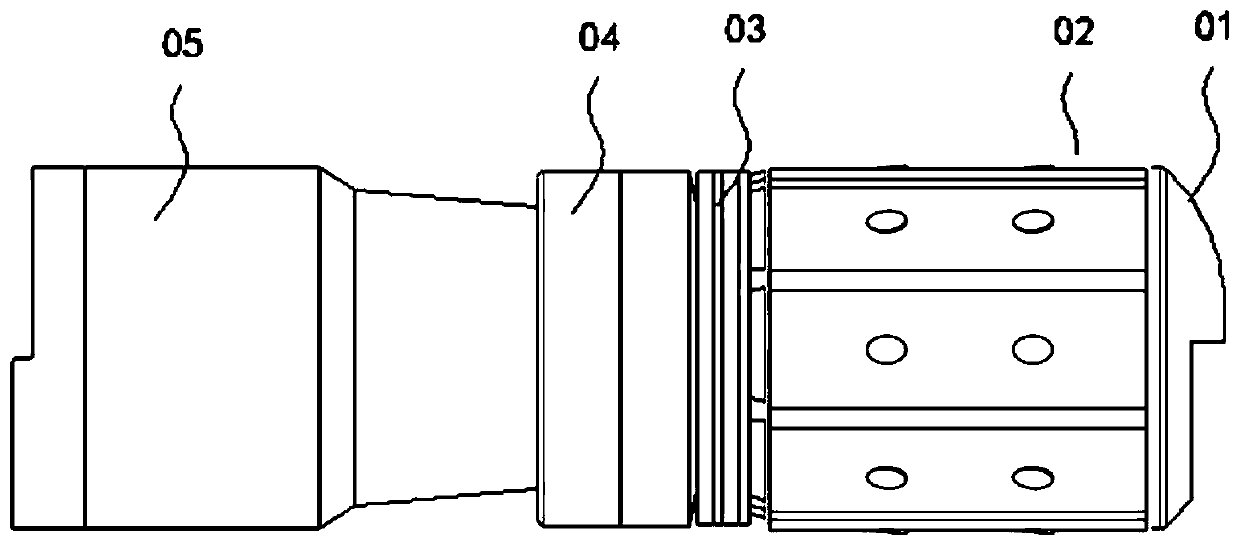

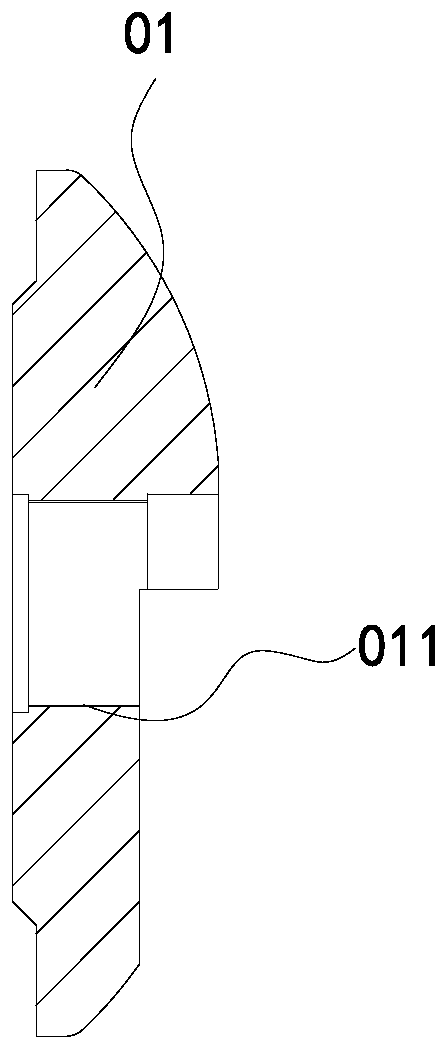

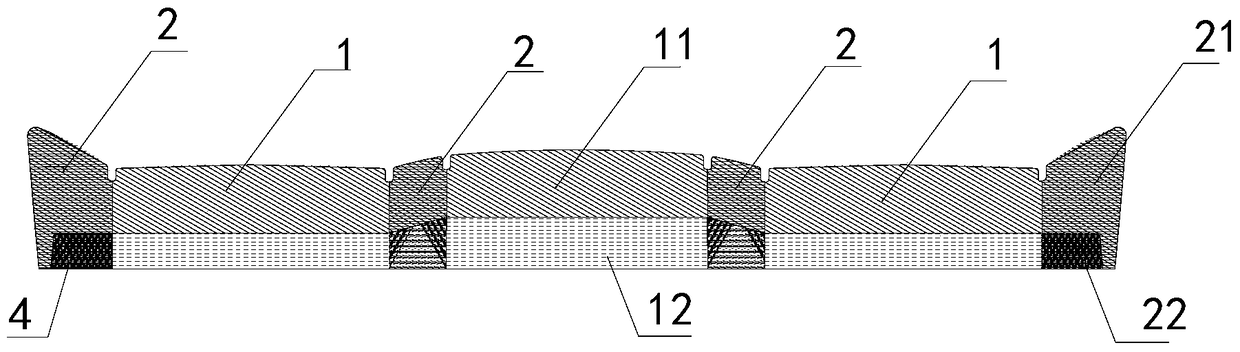

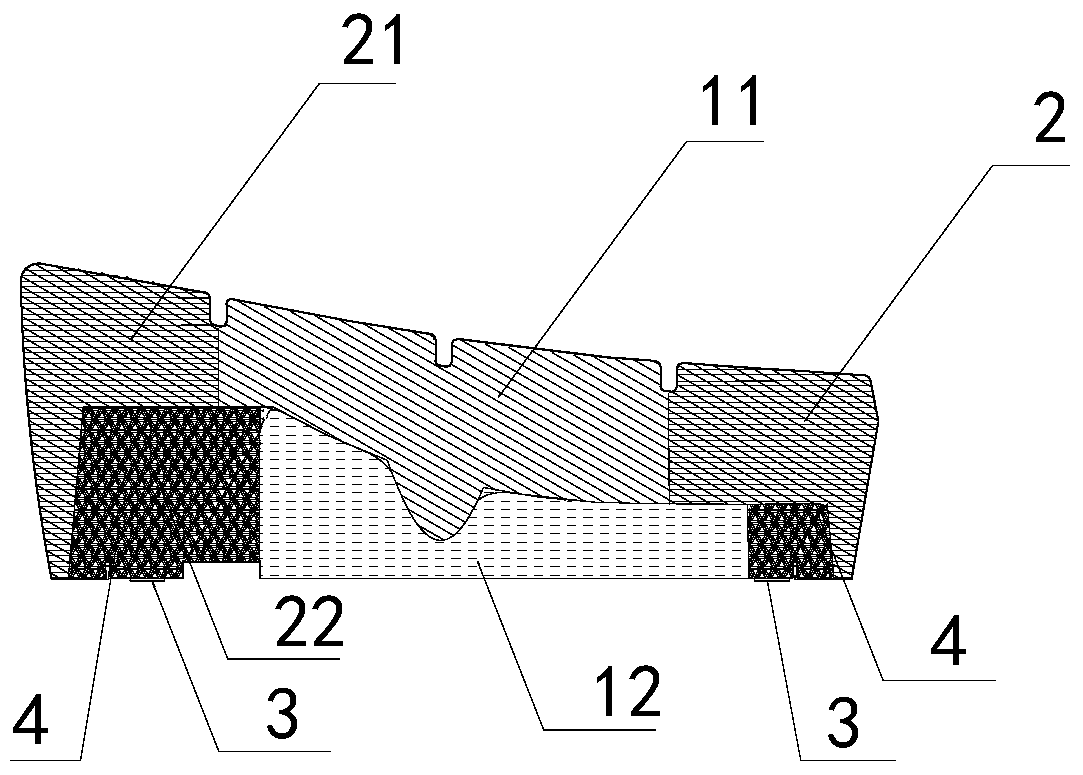

Pipe body uniform shear combination tool and working method thereof

InactiveCN106808012AExtend your lifeImprove shear efficiencyTube shearing machinesShearing toolsShear stressEngineering

The invention relates to a combined cutter for uniform shearing of a pipe body, comprising an upper shearing knife that can move up and down and a fixed lower shearing knife, the upper shearing knife includes an upper knife body and an upper blade, and the lower shearing knife The cutting knife includes a lower knife body and a lower knife edge, and both the upper knife edge and the lower knife edge have arc-shaped knife edges; the invention also relates to a working method for uniformly cutting a pipe body with a combined knife. In the tube body shearing combination tool of the present invention, the arc-shaped edge of the upper blade and the arc-shaped edge of the lower blade work together to make the shearing force more uniform, and it is easy to complete the cutting. The heat generated during the cutting process is small, the wear of the upper blade and the lower blade is small, and the phenomenon of chipping is avoided or reduced. Therefore, the structure design of the present invention is simple and reasonable, the cutting quality and cutting efficiency are high, the tool life is long, and the production cost is low. application prospects.

Owner:FUZHOU UNIV

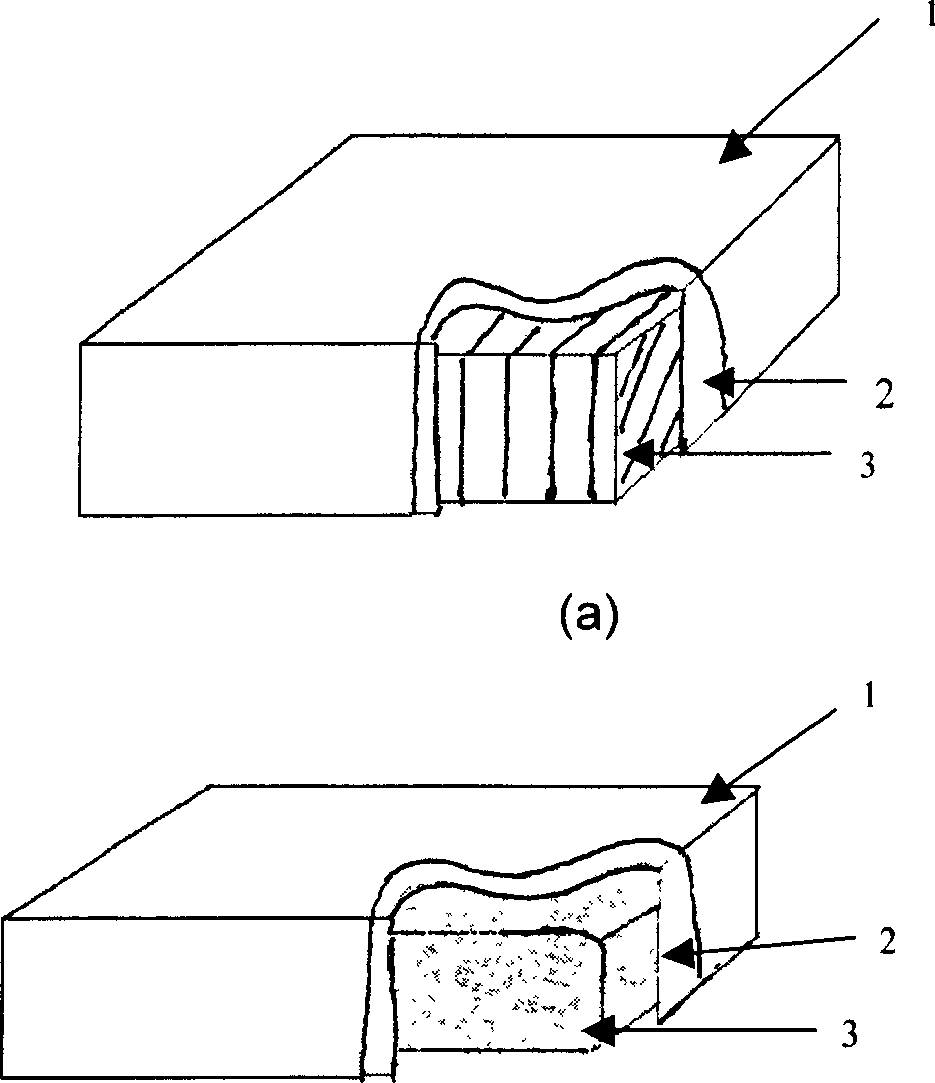

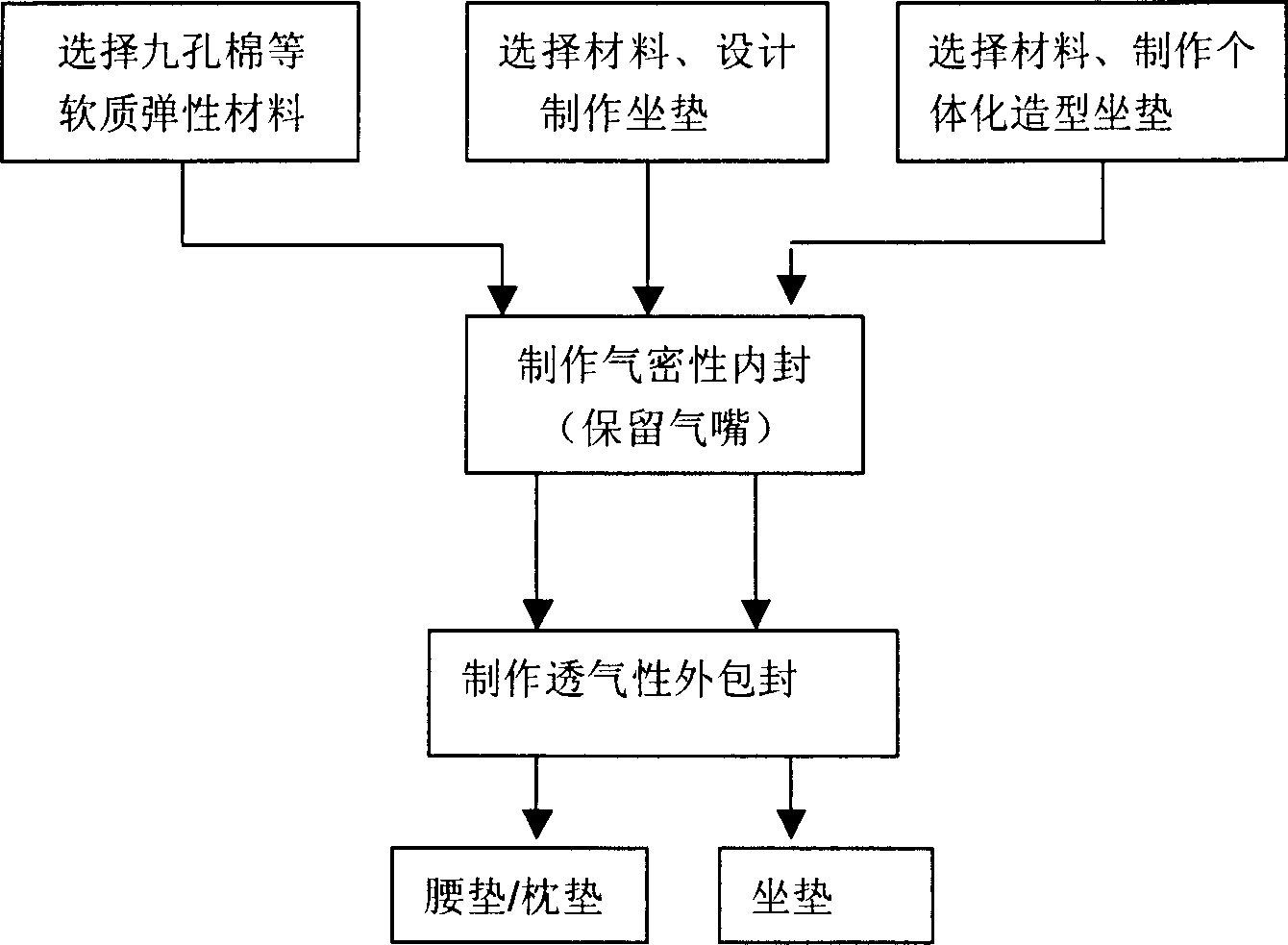

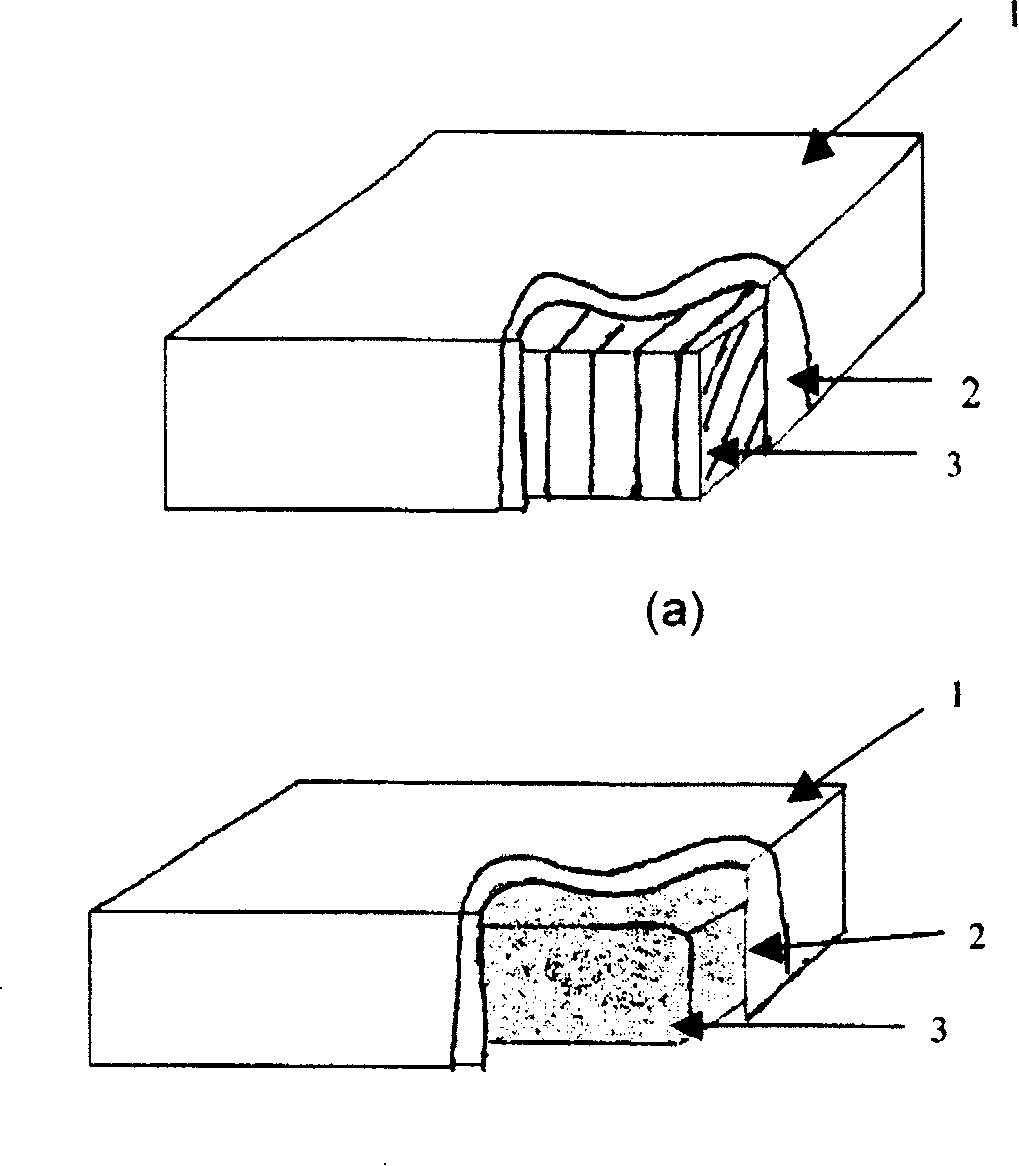

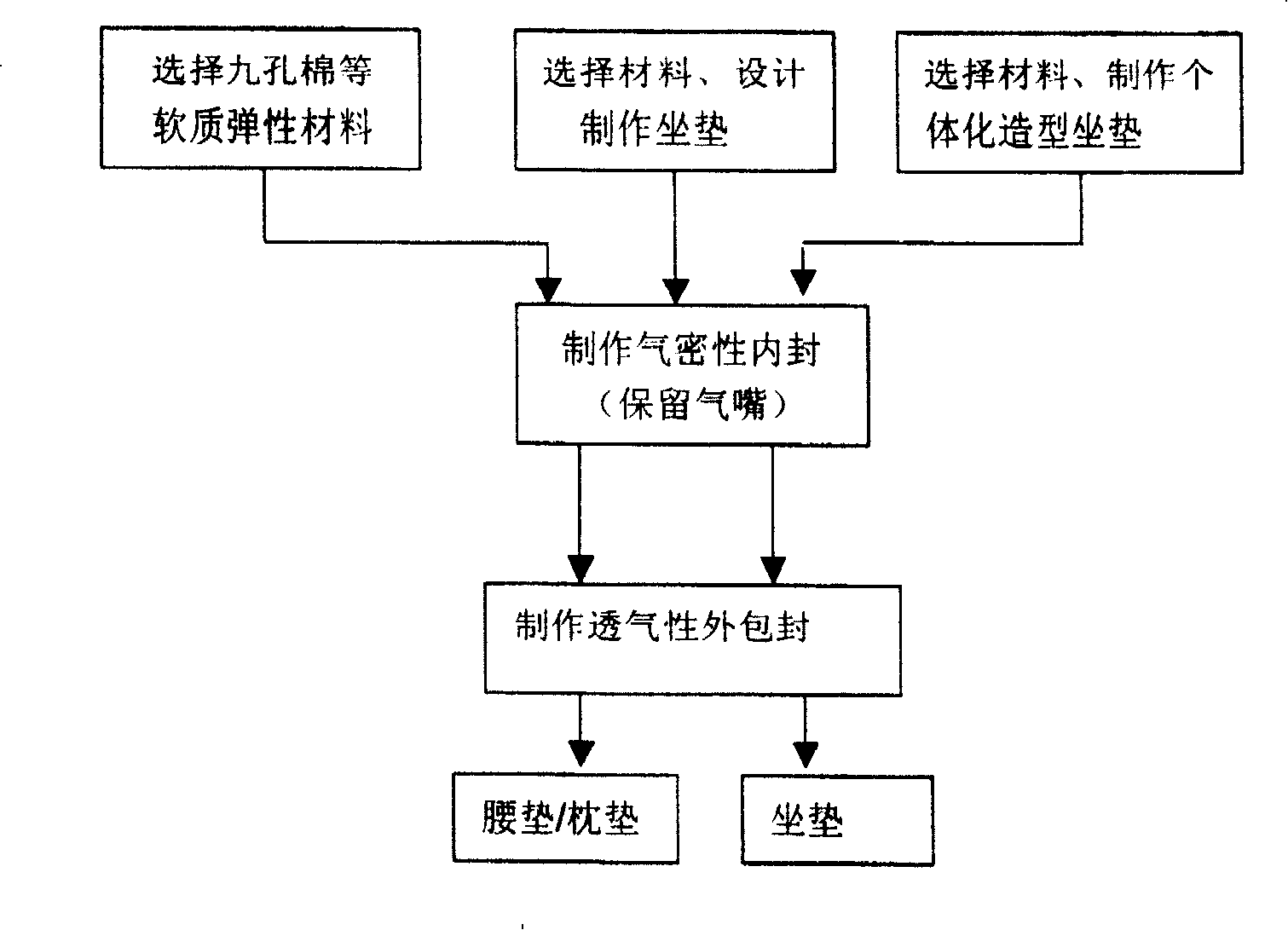

Passive self-adaptive memory cushion and its preparation method

InactiveCN1799457AImprove stabilityImprove comfortStuffed mattressesSpring mattressesMathematical modelEngineering

The invention discloses a non-source adaptive memorial cushion and the preparing method, the cushion mentioned comprising an air permeable enveloping closed shield, which is equipped with nylon button and air impermeable inner closed shield, which is equipped with air valve and filled with material of sponge of different material quality or composite sponge of different design or sponge of low shearing force produced specially or sponge, nine-pore sponge or seven-pore sponge designed by individual chosen according to individual parameter and demand, by controlling aerating and gas-discharging of the air valve to make the cushion interface shape memory the feature of the individual user. The preparing method comprises: establishing the mathematical model of reflecting the relation between the interfacial pressure, cushion deformation and shearing depth by checking and taking the individual feature parameter, and changing into CAD / CAM software preparing model, the non-source adaptive memorial cushion can be used in household soft furniture such as sofa cushion and bed cushion, and the sitting device, waist cushion and bolster in wheel chair, coach, train and plane.

Owner:XI AN JIAOTONG UNIV

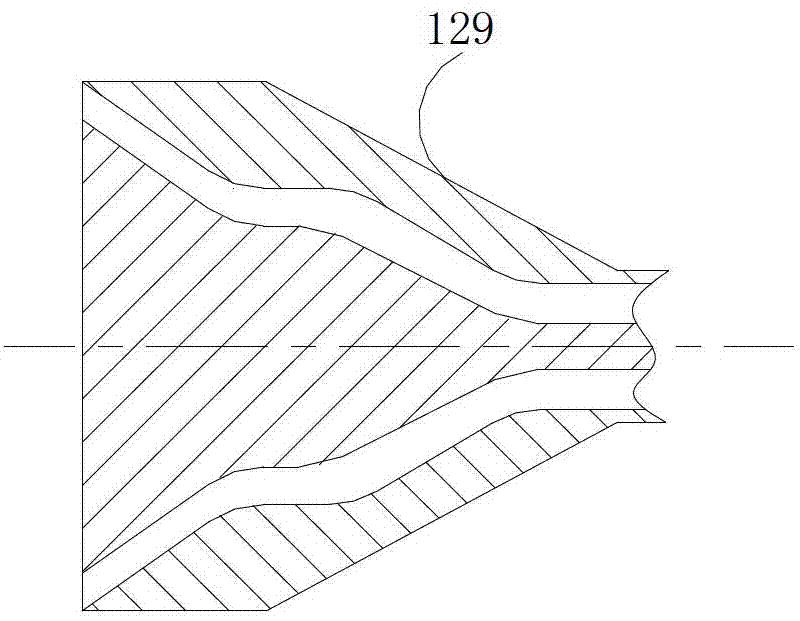

PPR pipe extruding production equipment

PPR pipe extruding production equipment comprises an extruding machine including a machine body and a machine barrel, and a forming die connected with the extruding machine, wherein a cone-shaped double screw is arranged inside the machine barrel of the extruding machine, and is in clearance fit with the machine barrel; temperature control device groups with different temperature are sequentially arranged on the outer wall of the machine barrel in the motion direction of material; the forming die comprises at least two die cavities; each die cavity is provided with an opening mould and a core rod; a temperature control device is arranged at the tail end of each opening mould. According to the PPR pipe extruding equipment, the defects that a plastic part generates residual stress and products are gloomy and reluster due to the temperature difference at various sections of the machine barrel are avoided; the temperature compensation or temperature reduction can be performed at different sections as per the property of material to better mix material and improve the yield of products; besides, each die cavity adopts a structure of one mould with two cavity or one mould with multiple cavities to increase the output; the temperature control devices arranged at the tail ends of the opening moulds can provide temperature compensation or temperature reduction to reduce the pipe diameter variation caused by sudden pressure release, volume expansion or cooling when products leave from the opening moulds, so that the yield of products is improved.

Owner:RIFENG ENTERPRISE GRP CO LTD +1

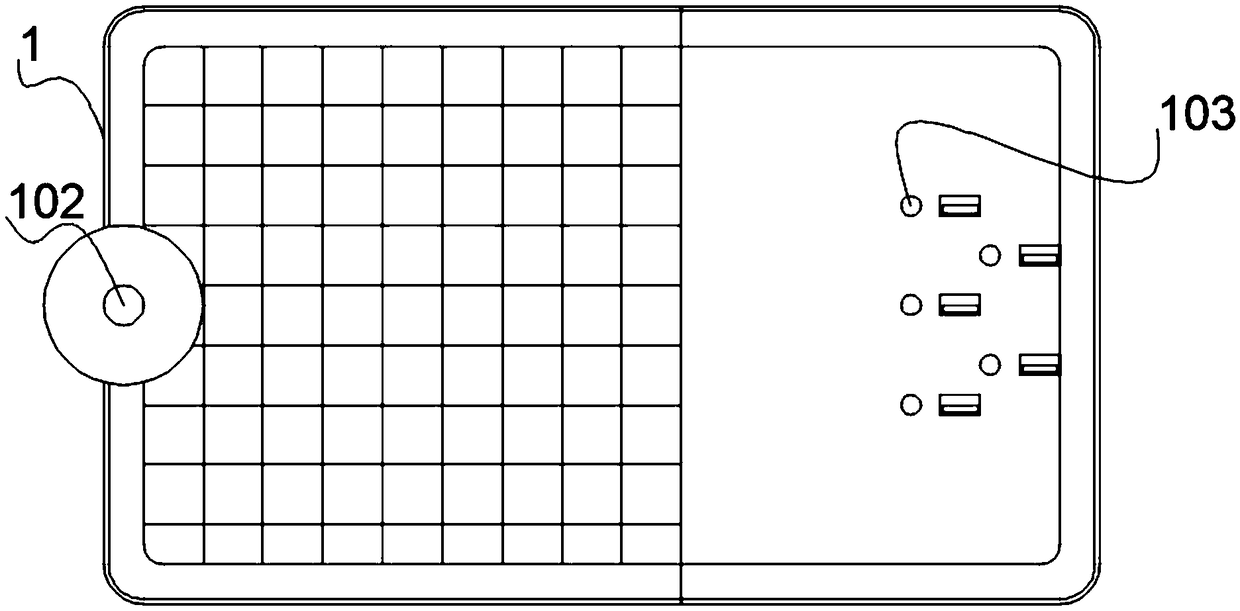

Integrated workbench used for model assembling and combining machining

InactiveCN108656038AHigh degree of automationImprove processing efficiencyWork benchesTweezersManipulator

The invention provides an integrated workbench used for model assembling and combining machining. The integrated workbench comprises a platform, a first pen knife, cutting pliers, polishing blocks, ahand drill, a clamping fixing arm, an inserted type control panel, a mechanical arm and a mechanical hand; the platform, the clamping fixing arm and the mechanical arm are three main components of thepersonal workbench, the plier-shaped mechanical arm capable of opening and closing left and right is installed at the front end of the mechanical arm, screw holes are formed inside the mechanical arm, the mechanical arm is connected and provided with the first pen knife, a second pen knife and the hand drill through the screw holes; the tail ends of the left and right pliers of the mechanical armare each provided with a bolt hole, the mechanical arm is connected with the cutting pliers and tweezers through the bolt holes, and the top ends of the left and right pliers of the mechanical arm are each provided with one polishing block; and the first pen knife, the second pen knife, the cutting pliers, the hand drill and the tweezers are all replaceable independent components. The inserted type control panel and the mechanical arm are arranged, and the problems that an existing model assembling tool is very scattered, a user needs to do switching repeatedly in use, and the using efficiency is low are solved.

Owner:屈珠丽

Nano-coating disperser

InactiveCN109248624AGood dispersion effectEvenly dispersedTransportation and packagingMixer accessoriesGastric tube feedingSolvent

The invention discloses a nano-coating disperser. The nano-coating disperser comprises a spherical opened container, an arc-shaped top cover, a feeding device, a feeding tube, a motor support, a motor, a rotating shaft, a stirring knife and a discharging port with a valve. The spherical container adopted by the nano-coating disperser makes the shearing force and the impacting force formed by the stirring device uniform during stirring, and the whole stirring system is sealed to make a high speed adopted during stirring in order to achieve a good dispersing effect; the amount of a nano-materialin the feeding device and the addition speed are respectively controlled through the feeding tube and a gas inlet tube, and is uniformly added into a solvent through small holes, so the dispersion isuniform; the stirring knife used in the invention can provide strong shearing force and impact force, so crushing, dispersing and mixing of the coating are efficient and uniform; and the dispenser also has the advantages of convenience in material feeding and discharging, simple structure, high reliability, and easiness in use.

Owner:贵州美工组科技有限公司

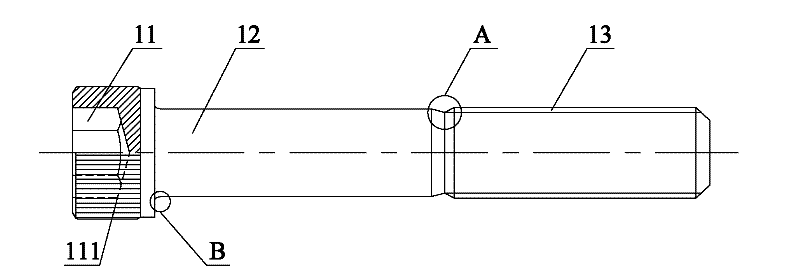

a bolt

InactiveCN102297188AHigh tensile strengthImprove fatigue lifeLoad modified fastenersScrewsEngineeringUltimate tensile strength

The invention discloses a bolt, which includes a nut and a screw rod. The outer circumferential surface of the screw rod has threads that match the nut; the end of the thread has a tooth mouth that engages with the nut, and the cross section of the tooth mouth is Oval. The threaded mouth with this kind of arc-shaped structure can significantly improve the bonding strength of the assembly structure after the threaded connection between the bolt and the nut, and reduce the tensile stress, shear force and other mechanical stresses that the tooth mouth is subjected to during use. The distribution is more uniform, so that the overall tensile strength of the bolt is correspondingly increased, and the overall fatigue life of the bolt is correspondingly extended.

Owner:SHANGHAI AUTOCRAFT

A ppr pipe extrusion production equipment

Owner:RIFENG ENTERPRISE GRP CO LTD +1

Shearing and bending equipment for thin metal plates

ActiveCN108000156BReduce deliveryEasy to cutShearing machinesOther manufacturing equipments/toolsThin metalMarine engineering

The invention discloses shearing and bending equipment of a thin metal plate. The shearing and bending equipment comprises a support, an upper cutter disc and a vertical rod, wherein a horizontal table is fixed above the support, and an operation table is arranged above the horizontal table; conveying rollers are installed above the operation table, and sand rings are welded on the surface of theconveying rollers; supporting plates are arranged above the sand rings, and rolling shafts are arranged above the supporting plates; baffles are fixedly arranged on the left side and the right side ofthe conveying rollers, and clamping plates are arranged above the baffles; a lifting rod is arranged on the outer side of the clamping plates, and a cross rod is arranged above the lifting rods; a cutting knife is arranged below the upper cutter disc, and the upper cutter disc is located in the middle of the cross rod; a grinding disc is arranged on the surface of the cutting knife, and a lower cutter disc is arranged below the cutting knife; a sliding groove is fixed in the middle of the vertical rod, and the vertical rod is located on the left side of a bending bottom plate. The shearing bending equipment of the thin metal plate can achieve continuous machining of shearing and bending, shear force is balanced, and the operation table can freely deflect the angle.

Owner:江苏磊澄智能机械装备有限公司

An anaerobic membrane bioreactor for domestic sewage treatment

ActiveCN103274525BGuaranteed uptimeReduce pollutionTreatment with anaerobic digestion processesPeristaltic pumpVacuum pressure

Owner:HARBIN INST OF TECH

A device and method for preparing aligned fibers using solution blow spinning technology

ActiveCN109537073BEase of mass productionFacilitate single batch preparationNew-spun product collectionNon-woven fabricsFiberSpinning

The invention discloses a device and a method for preparing directionally arranged fiber by a solution blow-spinning technology. The device comprises a solution blow-spinning system and a system for collecting fiber directionally arranged by airflow; the solution blow-spinning system comprises a spinning solution, an airflow control system and a blow-spinning device; the blow-spinning device, a spinning solution and the airflow control system are connected; a spinning collection system comprises a paving collection net; the paving collection net is connected with a negative pressure device; and the solution blow-spinning system collects directionally arranged nanometer fiber on the paving collection net by adjusting the angle of the spinning air flow and the paving collection net and by taking high-speed airflow as a directional driving force. The device and the method are relatively simple to operate, have many adjustable parameters and are high in precision; and the fiber obtained through preparation is high in arrangement degree, large in preparation quantity and high in uniformity.

Owner:XI AN JIAOTONG UNIV

Apparatus and Method for Producing Polymer Latex Resin Powder

PendingUS20200230525A1Uniform shear forceRotary stirring mixersTransportation and packagingFlocculationPolymer science

The present invention relates to an apparatus and a method for producing a polymer latex resin powder, and according to one aspect of the present invention, there is provided an apparatus for producing a polymer latex resin powder comprising a first flocculation tank to which a polymer latex and a flocculant are each supplied, wherein the first flocculation tank is provided with a stirring part including a rotation axis and one or more impellers mounted on the rotation axis, and a discharge line, and the first flocculation tank is configured to operate as a closed system upon operation of the stirring part.

Owner:LG CHEM LTD

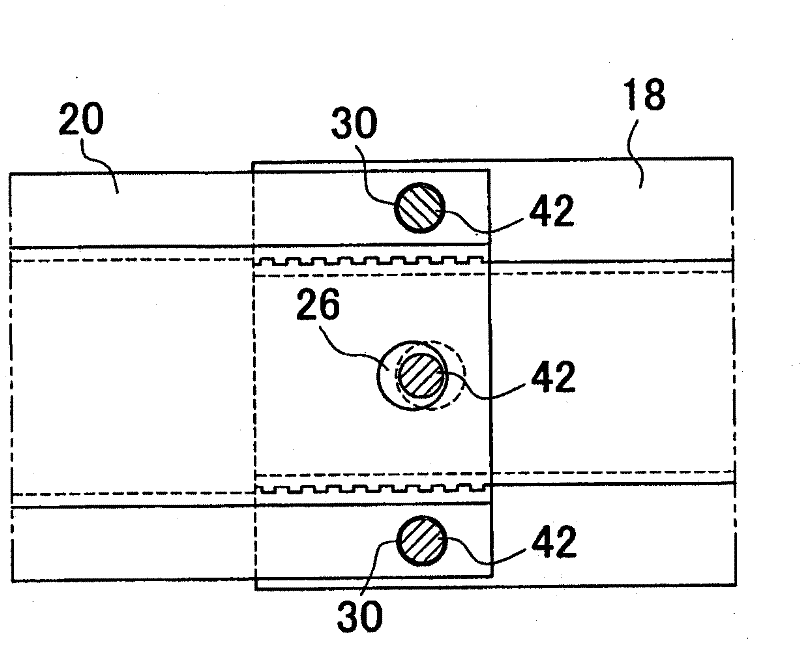

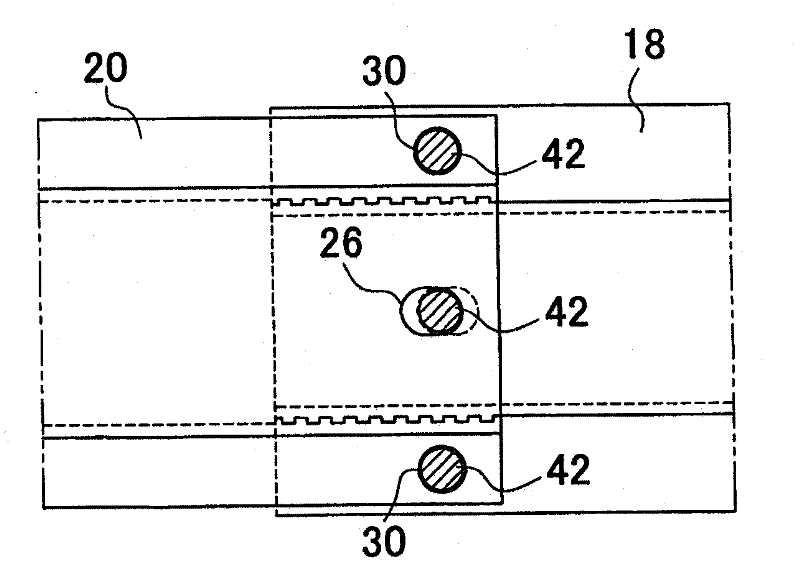

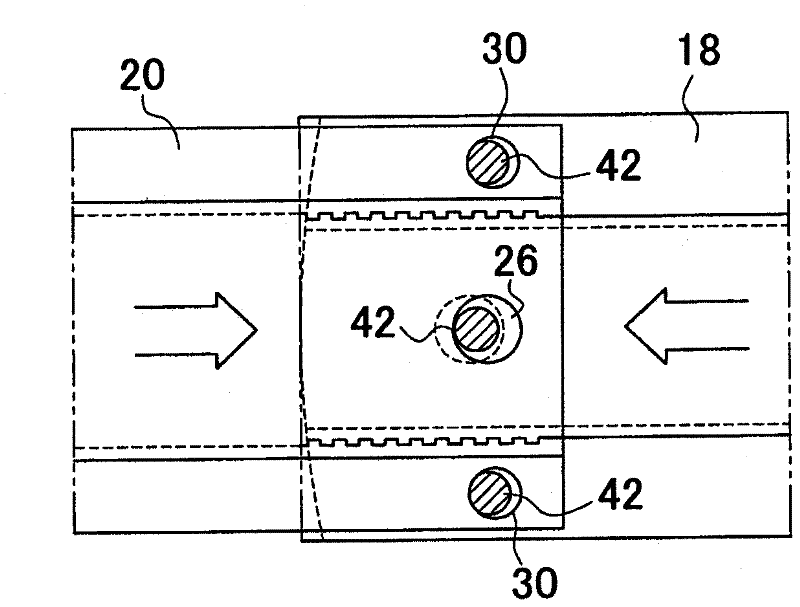

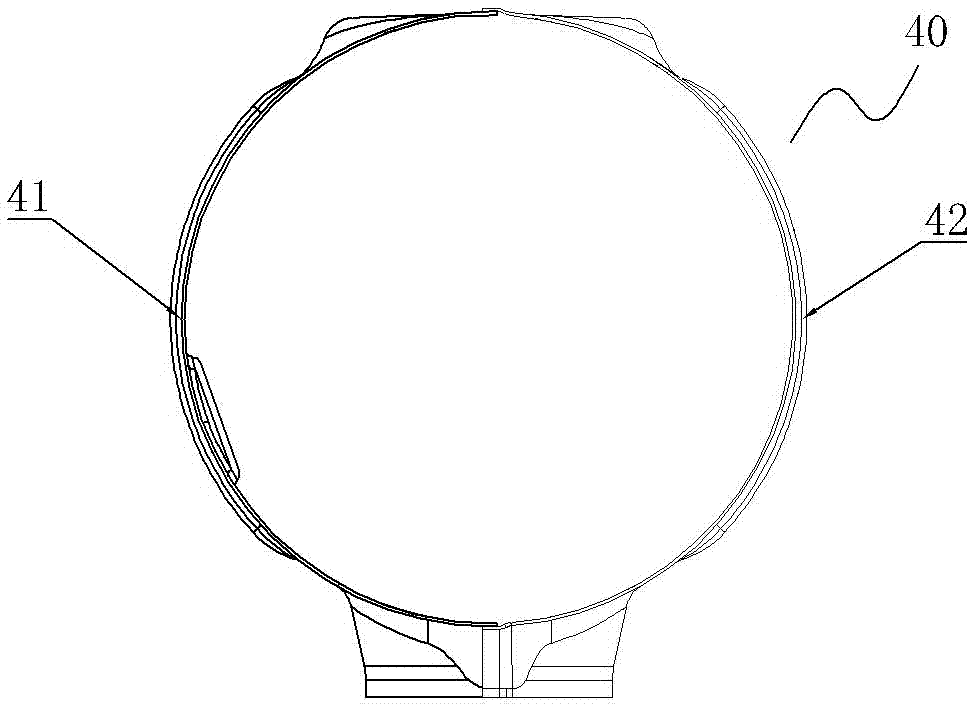

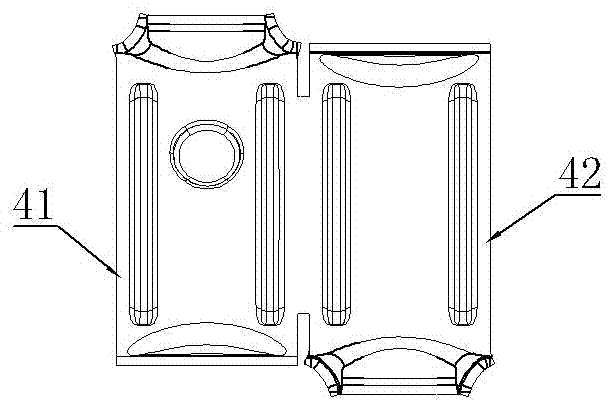

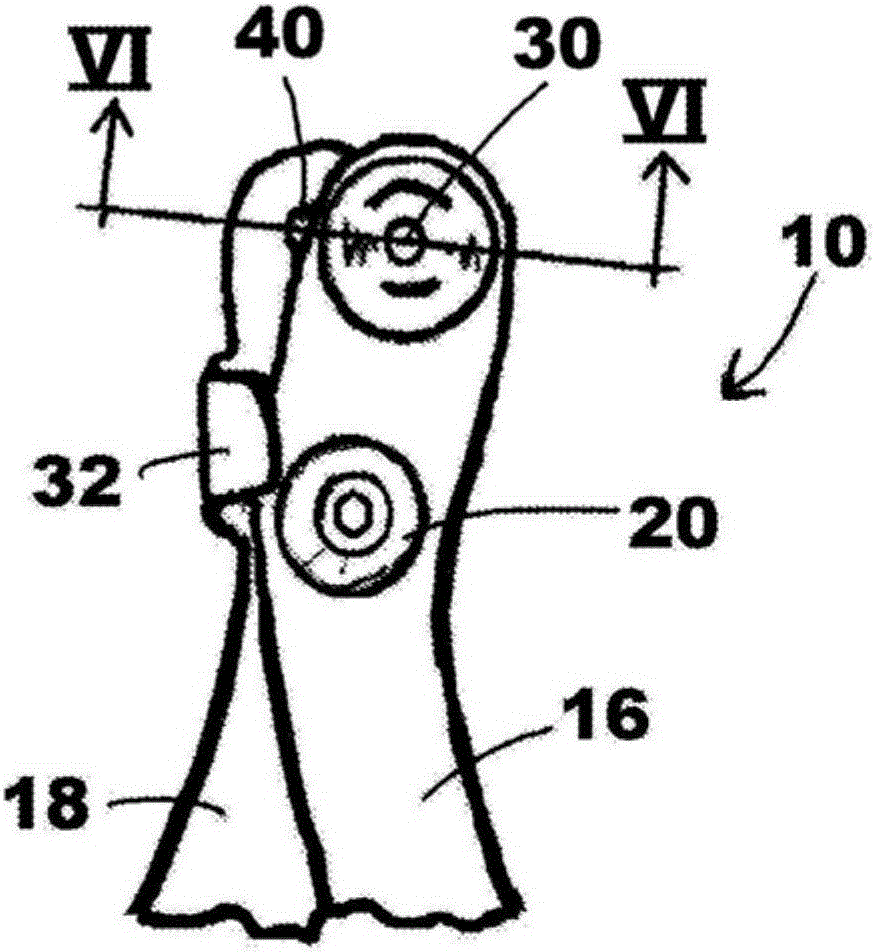

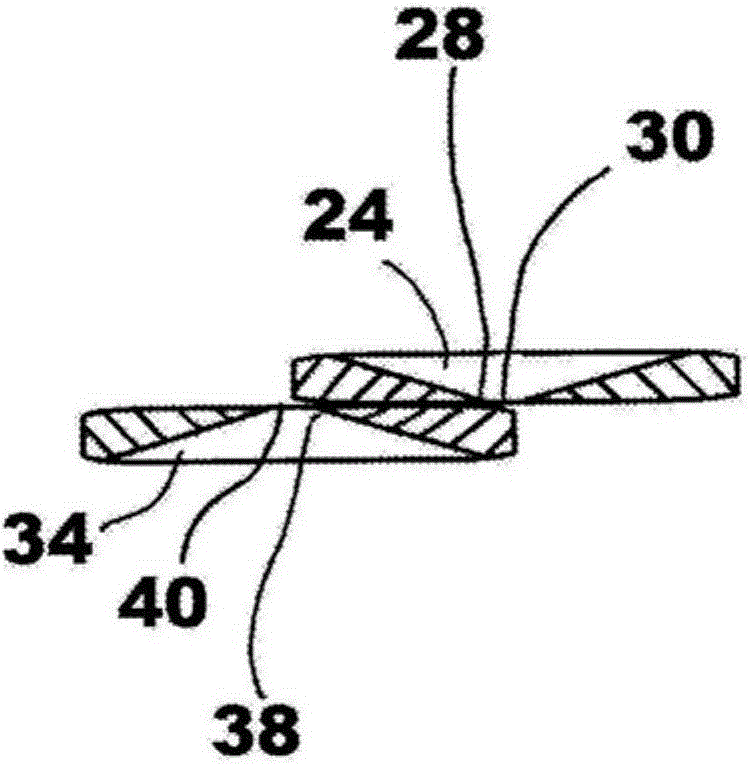

Structure that includes bolt fastening portion having higher resistance against external force

InactiveCN102245463AReduce displacementUniform shear forceUnderstructuresSuperstructure subunitsHigh resistanceShear force

Disclosed is a structure (14) in which two structural members (18, 20) that each include thick portion and that have a plurality of bolt holes (26, 28, 30, 32), wherein the two structural members are overlapped at the thick portion and fastened together with bolts (42) at the plurality of bolt holes. In this structure, a certain amount of play is provided respectively for the bolts (42) at the bolt holes (26, 28, 30, 32) so that a shear force resulting from an external force applied to the structure (14) acting on the bolts (42) is even after at least one of the two structural members is deformed by the external force.

Owner:TOYOTA JIDOSHA KK

Cutting mold for heat shield of automobile exhaust system

The invention discloses a trimming die for a thermal shield of an automobile exhaust system. The trimming die for the thermal shield of the automobile exhaust system is capable of solving the problems of easiness in wrinkling and cracking when a traditional integrally modular trimming die cuts off waste edges of four sides of a workpiece. The trimming die for the thermal shield of the automobile exhaust system comprises an upper die structure and a lower die structure, the upper die structure and lower die structure are closed by the guide of a rolling guide mechanism, the upper die structure comprises an upper template, an upper fixing plate is arranged on the bottom of the upper template through an upper lining plate, a press plate is arranged in the upper fixing plate, the lower die structure comprises a lower template, the lower template is provided with a convex die through a lower lining plate, cutter insert components are arranged in the upper fixing plate and around the four sides of the press plate, and each cutter insert component comprises a second cutter insert, a fifth cutter insert, a sixth cutter insert and a third cutter insert used for cutting off the waste edge of the outer side of the left half shell of the workpiece and a fourth cutter insert, a seventh cutter insert, an eighth cutter insert and a first cutter insert used for cutting off the waste edge of the outer side of the right half part of the workpiece.

Owner:WUXI DAWN DIE & STAMPING

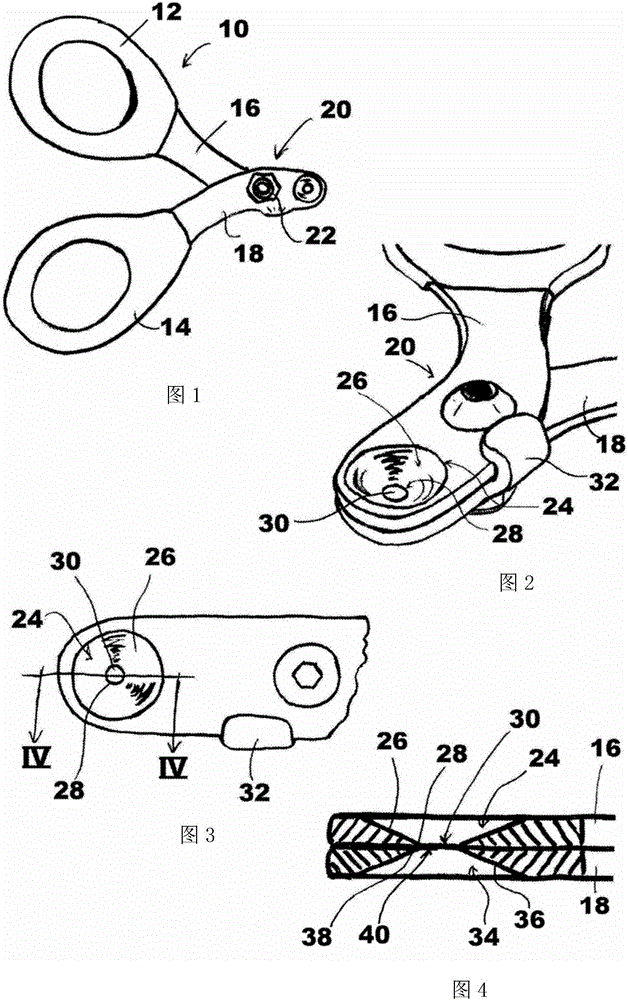

Animal claw shearing apparatuses and methods of using the same

InactiveCN106455522AEvenly trimmedUniform shear forceManicure/pedicureSurgical veterinaryEngineeringKnife blades

Owner:PET PROD INNOVATIONS

Light ball seat

PendingCN111749646AShorten the overall lengthImprove drilling efficiencyFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

The invention provides a light ball seat. The light ball seat comprises a central pipe, a sealing piece, a slip and a lower connector, the central pipe is in a circular truncated cone shape, an outerfriction layer is arranged on the outer side of the end, with the smaller outer diameter, of the central pipe, a plugging opening is formed in the end, with the larger outer diameter, of the central pipe, the sealing piece and the slip are sequentially connected to the outer side of the central pipe in a sleeving mode, the end part of the of the end, with the smaller outer diameter, of the centralpipe is located in the slip, a first inner friction layer matched with the outer friction layer is arranged on the inner side of the sealing piece, one end of the slip abuts against one end of the sealing piece, the other end of the slip is welded to one end of the lower connector, a second inner friction layer matched with the outer friction layer is arranged on the inner side face of the slip,a setting tool connecting structure is arranged in the lower connector, and the central pipe, the slip and the lower connector are made of light magnesium alloy materials. The provided ball seat is high in sealing reliability during working, the ball seat is compact, short and small in design and is made of the light magnesium alloy materials, so that the drilling and grinding efficiency is improved; and after work is finished, return is easy, and the risk of blocking a shaft is eliminated.

Owner:VERTECHS OIL & GAS TECH CO LTD

Column type extraction device for pipe bundle multi-channel phase-dispersing and extraction method thereof

InactiveCN102772913BLess prone to turbulenceSuitable for extraction operationLiquid solutions solvent extractionStraight tubeOil phase

The invention relates to a column type extraction device for pipe bundle multi-channel phase-dispersing; a main shaft is arranged inside the column type extraction device; two or at least three hollow thin tubes in parallel to the main shaft are distributed on the outer circumference of the main shaft; one end of each hollow thin tube is provided with a straight tube, and the other end of the hollow thin tube is bent to form a flanged bend; the bending direction of the flanged bend is the remote direction of a mounting shaft; the main shaft is connected with an electric motor, and drives the hollow thin tubes to carry out motion at a same speed with the main shaft when the main shaft rotates. The column type extraction device disclosed by the invention solves the difficult problems that a water phase or an oil phase with relatively small volume is difficult to disperse completely in the conventional mechanical stirring manner when the volume ratio of the water phase to the oil phase in an extraction process is large; and the difficult problems that the water phase and the oil phase are difficult to clarify and separate in an extraction system and the like caused by easy emulsification are also solved when the flow-rate ratio of the water phase to the oil phase is large.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Passive self-adaptive memory cushion and its preparation method

InactiveCN100407966CImprove stabilityImprove comfortStuffed mattressesSpring mattressesMathematical modelEngineering

The invention discloses a non-source adaptive memorial cushion and the preparing method, the cushion mentioned comprising an air permeable enveloping closed shield, which is equipped with nylon button and air impermeable inner closed shield, which is equipped with air valve and filled with material of sponge of different material quality or composite sponge of different design or sponge of low shearing force produced specially or sponge, nine-pore sponge or seven-pore sponge designed by individual chosen according to individual parameter and demand, by controlling aerating and gas-discharging of the air valve to make the cushion interface shape memory the feature of the individual user. The preparing method comprises: establishing the mathematical model of reflecting the relation between the interfacial pressure, cushion deformation and shearing depth by checking and taking the individual feature parameter, and changing into CAD / CAM software preparing model, the non-source adaptive memorial cushion can be used in household soft furniture such as sofa cushion and bed cushion, and the sitting device, waist cushion and bolster in wheel chair, coach, train and plane.

Owner:XI AN JIAOTONG UNIV

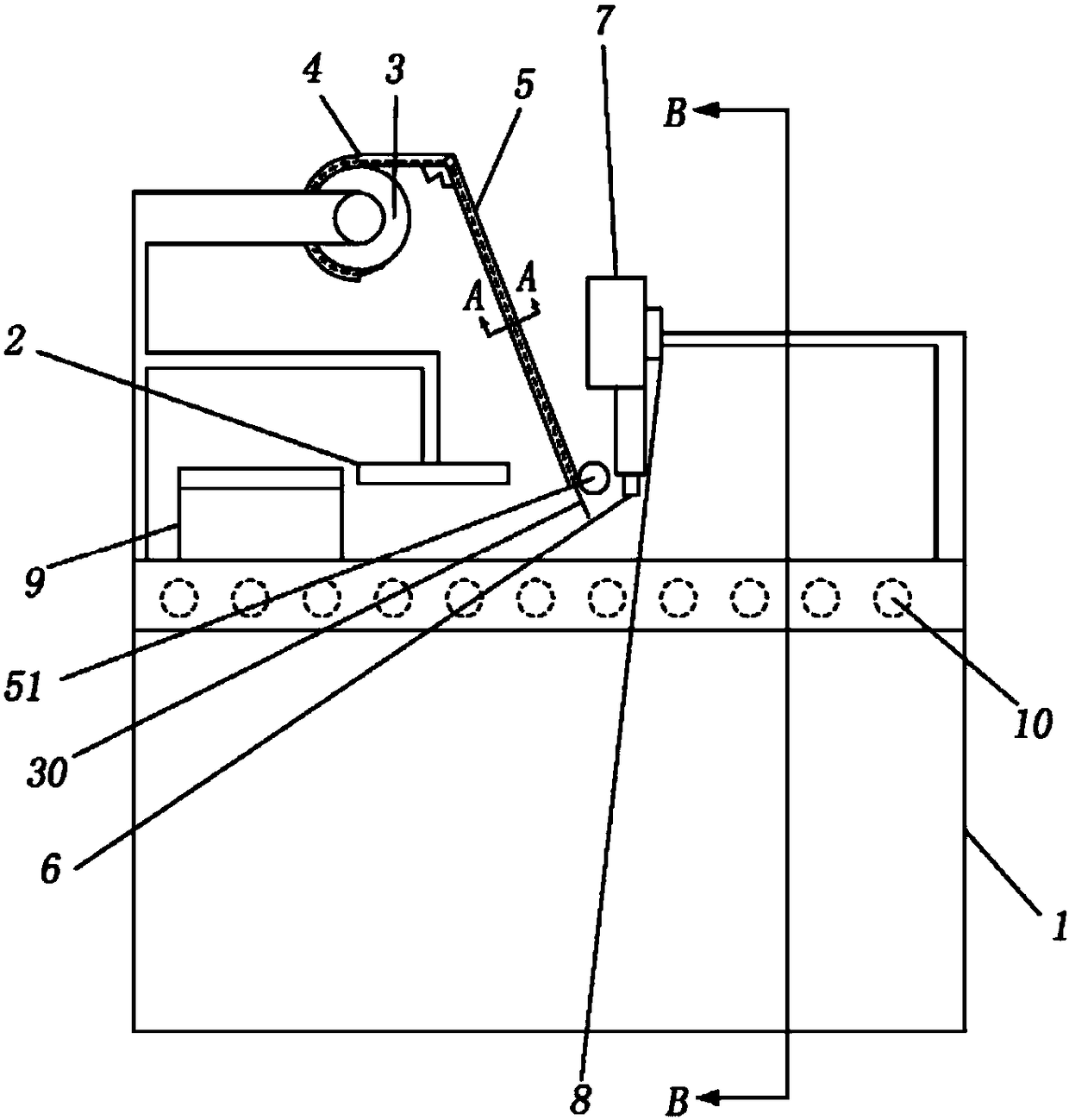

Automatic film cutting weighing machine

ActiveCN107053283BQuality assuranceGuaranteed to be smooth and flatSortingMetal working apparatusControl systemButt joint

The invention belongs to the technical field of silica gel raw material sheet cutting, and in particular relates to a fully automatic film cutting weighing machine, which includes a workbench, on which a feeding device, a material cutting device, a weighing Device and screening device, the film material is set on the feeding device, the feeding device flattens and transports the film material to the material cutting device, the cutting device is equipped with a cutter, and the weighing device is equipped with a weighing platform and a conveyor belt , the head end of the conveyor belt extends to the bottom of the film material at the material cutting device, and the tail end is docked with the screening device. The screening device includes a good product box, a waste product box and a screening material mechanism. The good product box is located at the tail end of the conveyor belt. The waste box is located on one side of the sieving mechanism, and the feeding device, material cutting device, weighing platform and sieving mechanism are all electrically connected to a control system. The automatic film cutting weighing machine of the present invention can automatically cut film, weigh and screen, and has a high degree of automation.

Owner:JIANGSU UNIV OF TECH

Automobile rear seat cushion and its processing and assembling method

The invention discloses an automobile back-row cushion. The automobile back-row cushion comprises a sitting area and a peripheral area, wherein each area comprises a cushion core and a seat fabric; the cushion cores of the sitting area and the peripheral area are constructed by an upper layer foaming material and a lower layer foaming material respectively; the upper layer foaming materials and the lower layer foaming materials are connected in an embedding way through a complementary structure. The machining-assembling method for the automobile back-row cushion comprises the following steps: making a polyurethane foaming material according to the shape of the upper layer of each cushion, making a polypropylene foaming material according to the shape of the lower layer of each cushion core, and assembling corresponding polyurethane foaming materials and polypropylene foaming materials into each cushion core respectively; coating integrally, and fixing the fabric with an injection-molded clamping bar; fixing the cushion on a vehicle metal plate through a dual-layer mushroom hasp. By adopting the automobile back-row cushion, the collision safety index is increased, the weight is reduced, the buffering performance is improved, the passenger comfort is improved, and a sound-absorbing function is realized.

Owner:SHANGHAI HUAGU VEHICLE IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com