An anaerobic membrane bioreactor for domestic sewage treatment

An anaerobic membrane biological and anaerobic reaction technology, applied in the field of sewage treatment, can solve the problems of limiting anaerobic membrane bioreactor, fast membrane fouling, short membrane fouling cycle, etc., to improve economic benefits, simple operation, guarantee The effect of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

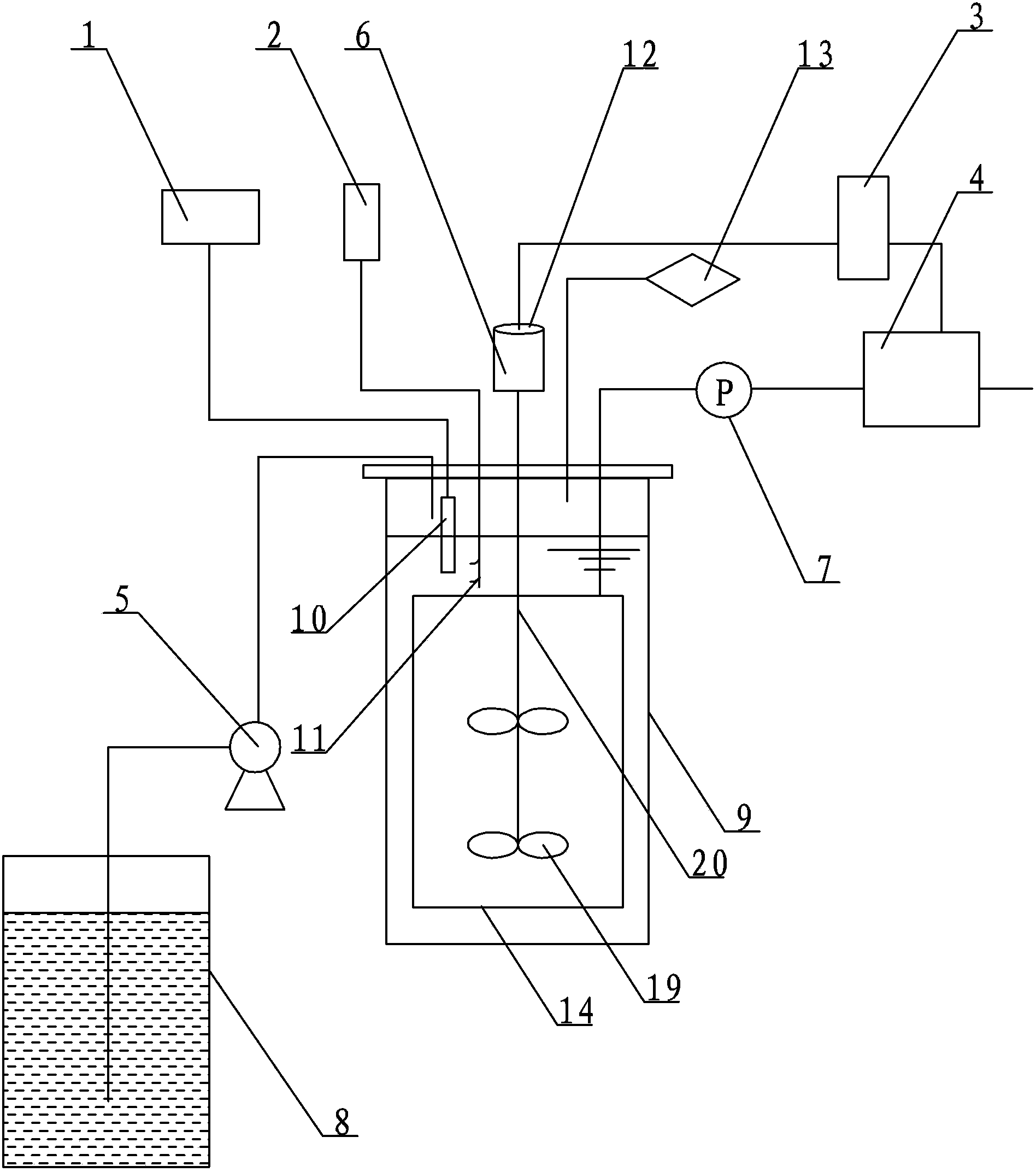

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises temperature controller 1, liquid level relay 2, time relay 3, peristaltic pump 4, water inlet pump 5 and vacuum pressure gauge 7, and described anaerobic membrane bioreactor also includes water inlet tank 8 , anaerobic reaction assembly 9, temperature probe 10, liquid level contact probe 11, stirring device 12, air collection bag 13 and circular membrane assembly 14,

[0017] The circular membrane assembly 14 is arranged in the anaerobic reaction assembly 9, and the water inlet box 8 is arranged on the outside of the anaerobic reaction assembly 9, and the water inlet box 8 is communicated with the water inlet of the anaerobic reaction assembly 9 by a conduit, and the water inlet box 8 is connected to the water inlet of the anaerobic reaction assembly 9. The conduit between the anaerobic reaction components 9 is provided with an inlet pump 5, the peristaltic pump 4 comm...

specific Embodiment approach 2

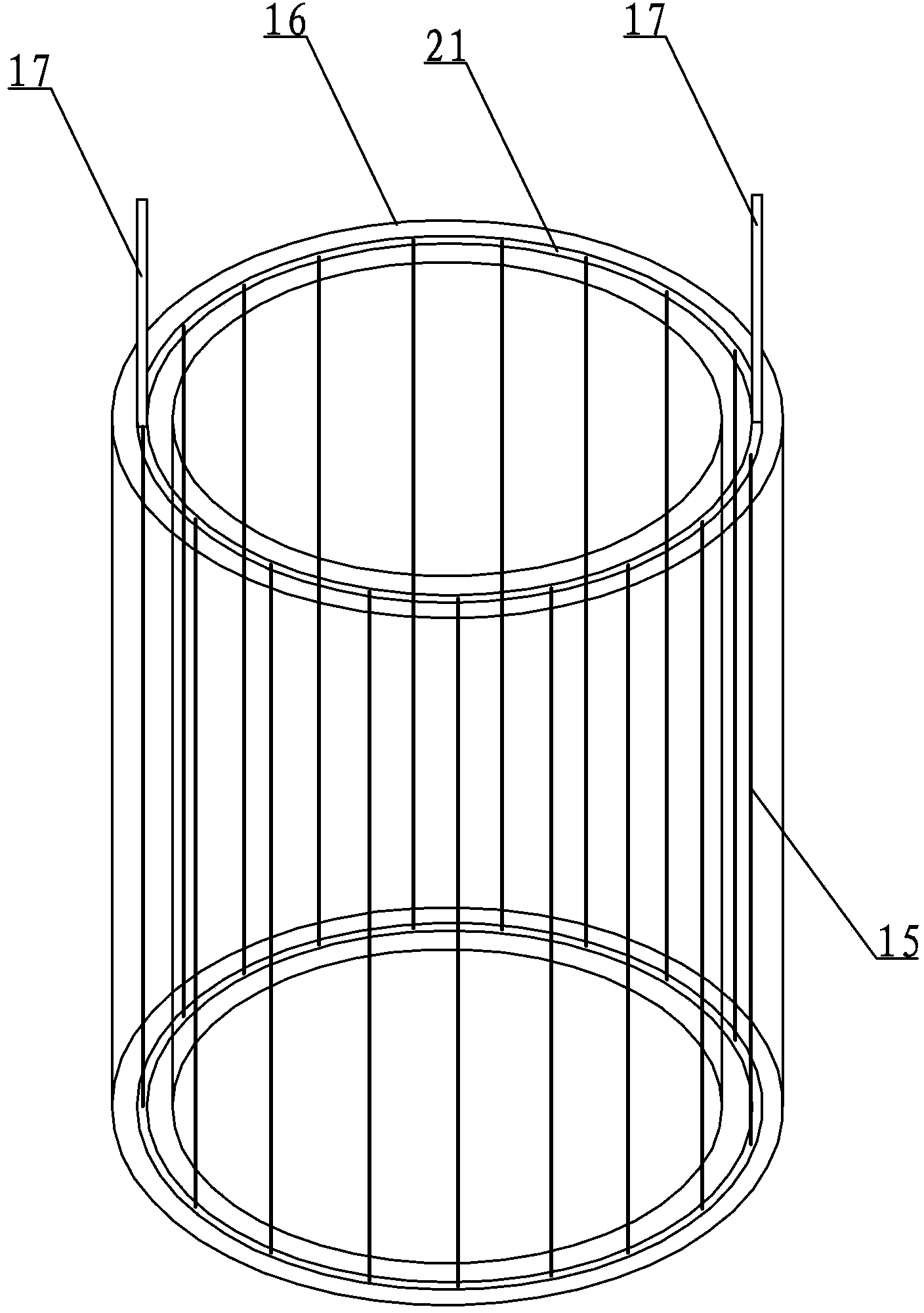

[0024] Specific implementation mode two: combination figure 2 Describe this embodiment, the circular membrane assembly 14 of this embodiment comprises hollow fiber membrane filament 15, water collecting pipe 16 and two water outlet pipes 17, and described water collecting pipe 16 is the circular plexiglass water collecting pipe, and the pipe of water collecting pipe 16 The lower end surface of the wall is provided with a circular slit 21, and the hollow fiber membrane 15 is vertically arranged in the circular slit 21 in a single layer. The two outlet pipes 17 are symmetrically arranged on the upper end surface of the pipe wall of the water collection pipe 16, and the outside of the lower end surface of the water collection pipe 16 is stuck on the protruding hook on the inner wall of the anaerobic reaction assembly 9, so that the entire circular membrane The component 14 is suspended in the cavity of the anaerobic reaction component 9 . Such setting overcomes the problem of u...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 2 To describe this embodiment, the width of the circular slit 21 at the center of the lower end surface of the pipe wall of the water collecting pipe 16 in this embodiment is 2 mm. Such setting satisfies the placement of the hollow fiber membrane filaments 15 . Other compositions and connections are the same as those in the second embodiment.

[0026] Specific implementation mode four: combination figure 1 Describe this embodiment, the stirring device 12 of this embodiment comprises stirring motor 6, double stirring paddle 19 and stirring shaft 20, and the upper end of stirring shaft 20 is connected with the stirring motor 6 that is arranged on anaerobic reaction assembly 9 tops, and the stirring shaft 20 The lower end extends into the inner ring space of the circular membrane module 14 , and the double stirring paddles 19 are arranged on the stirring shaft 20 in the circular membrane module 14 . Such setting me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com