Equipment for continuously producing microspheres and application of equipment

A kind of equipment and microsphere technology, which is applied in the field of preparation of microsphere preparations, can solve the problems of unrealizable production scale, enlargement of process parameters, increase of unpredictability, etc., and achieve the goal of being suitable for large-scale production, fully dispersed materials, and excellent cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

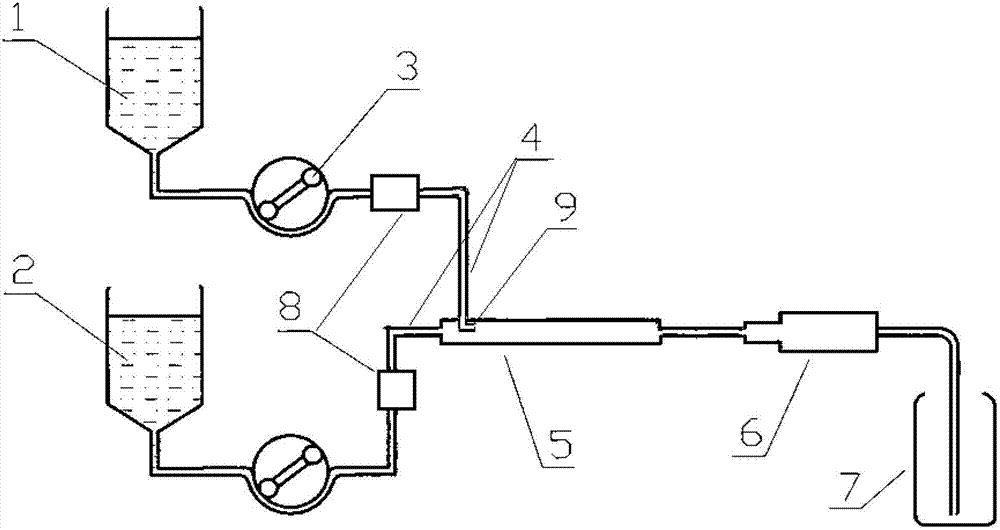

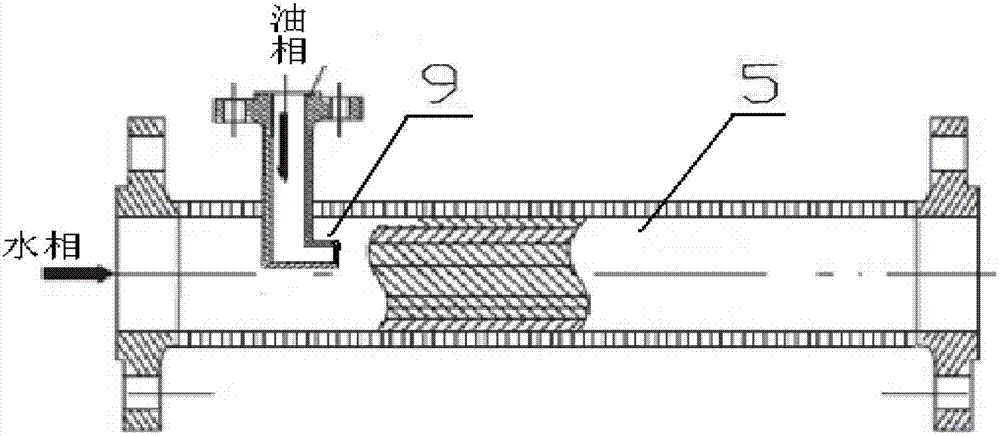

Method used

Image

Examples

Embodiment 1

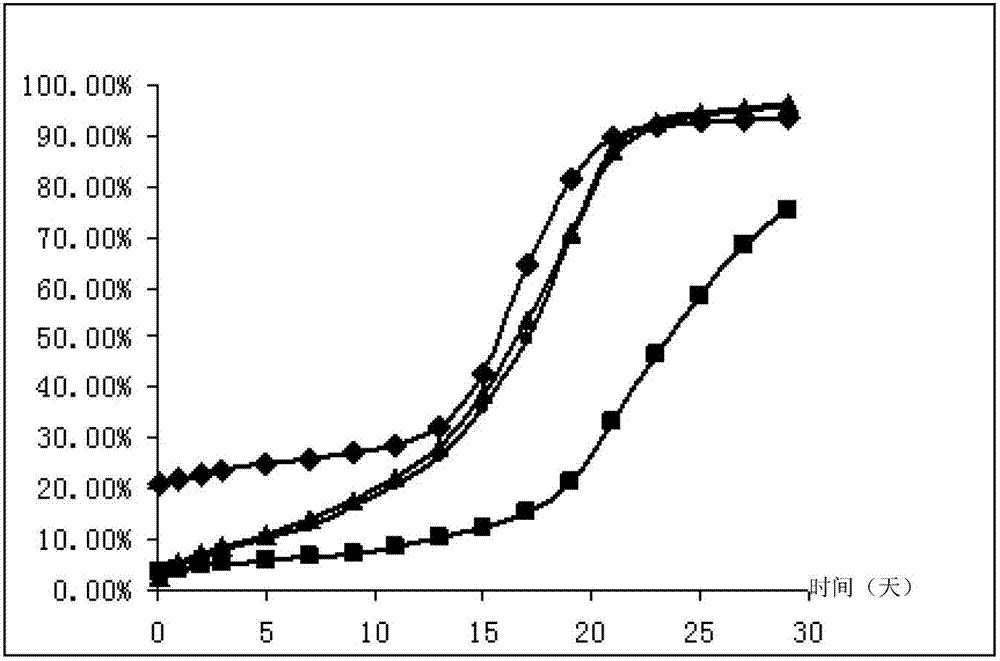

[0029] Weigh 0.6g of diazepam and 1.4g of PLGA (50 / 50, 0.24, 26000) into a 15ml vial, add 10ml of dichloromethane into it, stir and dissolve, as the oil phase; weigh 1.0g of polyvinyl alcohol ( Add PVA) to an appropriate amount of hot water at 80°C, stir until fully dissolved, add to 1000ml, and use it as the water phase; adjust the flow rate of the water phase metering pump 3 to 200-250ml / min, wait until the water phase is full of pipeline high-shear emulsification dispersion After the 6 working chambers of the homogenizer, open the homogenizing head and adjust the oil phase metering pump 3 to 2.0-2.5ml / min to ensure that the oil / water two phases are mixed according to the volume ratio of 1:100 until the oil phase and water phase Both are completely pumped into the pipeline type high-shear emulsification dispersing homogenizer 6, the pumped liquid is collected, stirred at room temperature to volatilize dichloromethane, filtered through a standard sieve, washed with water, and ...

Embodiment 2

[0031] Weigh 0.6g of diazepam and 1.4g of PLGA (50 / 50, 0.25, 26000) into a 15ml vial, adjust the flow rate of the water phase metering pump 3 to 450-500ml / min, and fill the water phase with pipeline high-shear emulsification After dispersing the 6 working chambers of the homogenizer, open the homogenizing head, adjust the oil phase metering pump 3 to 4.5-5.0ml / min, and prepare microspheres according to the method of Example 1; the encapsulation rate is 46.7%, and the average particle diameter It is 51.8μm, and the diameter is 1.418.

Embodiment 3

[0033] Weigh 0.6g of diazepam and 1.4g of PLGA (75 / 25, 0.5, 70000) into a 15ml vial, adjust the flow rate of the water phase metering pump 3 to 200-250ml / min, and fill the water phase with pipeline high-shear emulsification After dispersing the 6 working chambers of the homogenizer, open the homogenizing head, adjust the oil phase metering pump 3 to 2.0-2.5ml / min, and prepare microspheres according to the method of Example 1; the encapsulation rate is 53.1%, and the average particle diameter It is 57.6μm, and the diameter is 1.587.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com