PPR pipe extruding production equipment

A production equipment and pipe technology, applied in the field of PPR pipe extrusion production equipment, can solve the problems of low extrusion efficiency and slow production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

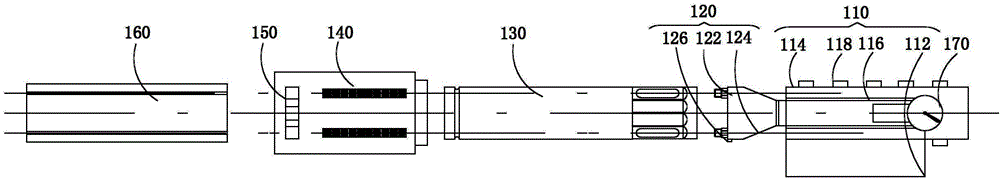

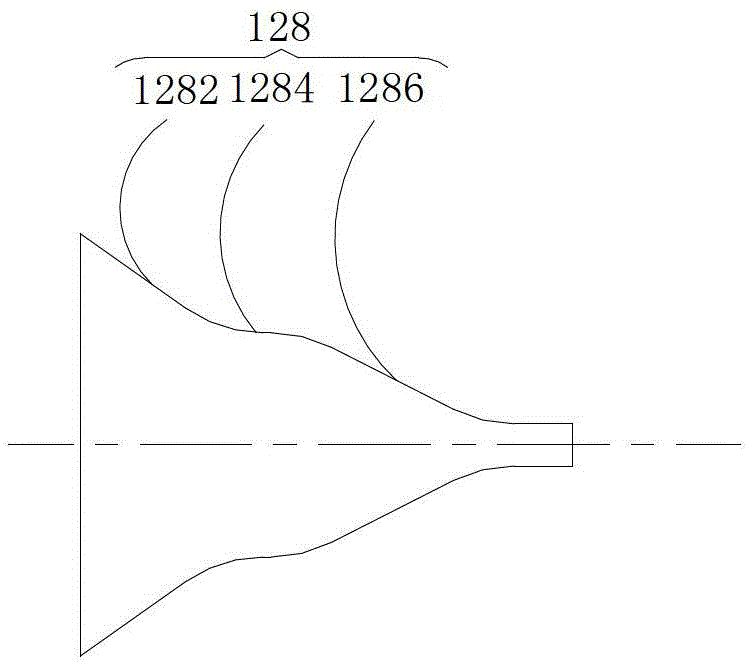

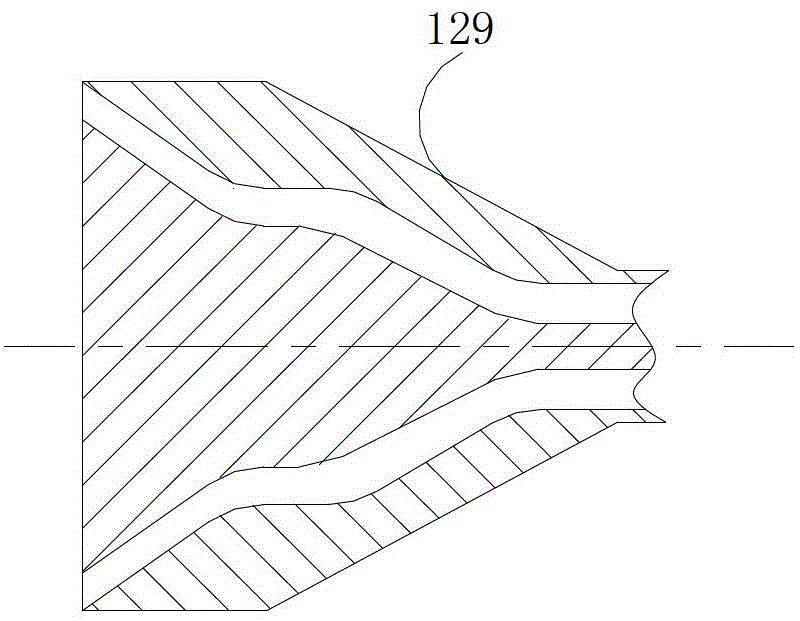

[0021] Such as figure 1 As shown, a PPR pipe extrusion production equipment includes an extruder 110 and a molding die 120. The extruder 110 includes a fuselage 112 and a barrel 114. A conical twin screw 116 is arranged in the barrel 114, and the barrel 114 The outer wall is successively provided with temperature control device groups 118 with different temperatures, and the molding die 120 includes at least two mold cavities, such as figure 1 In a specific embodiment shown, the molding die 120 includes two mold cavities, the first mold cavity 122 and the second mold cavity 124, and the first mold cavity 122 and the second mold cavity 124 are all provided with a die 129 and mandrel 128, die 129 ends are provided with temperature control device 126; Described equipment also comprises the splitter support and flow divider that are fixedly connected with extruder 110, and flow divider support is in order to support flow divider and mandrel 128, One end of the head of the extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com