Patents

Literature

122results about How to "Uniform plasticization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyethylene wood plastic and preparation method thereof

The invention relates to a polyethylene wood plastic and a preparation method thereof and belongs to the technical field of plastic compound modifying processing. The invention provides a formula of the polyethylene wood plastic and a preparation method for a section bar; extruding temperature and extruding speed are increased; a polyethylene wood plastic section bar produced according to the preparation method has excellent high-temperature resistance; and according to the technical scheme, the polyethylene wood plastic comprises the following raw materials in parts by weight: 30-40 parts of polyethylene, 50-70 parts of wood flour, 0.5-2 parts of maleic anhydride grafted polyethylene, 0.8-1.5 parts of polyethylene wax, 1-3 parts of zinc stearate, 2-6 parts of toner, 0.5-1 part of antioxidant, 0.4-0.9 part of anti-ultraviolet light absorber UV-531 and 0.5-1.2 parts of stearic acids. The preparation method provided by the invention is suitable for the extruding molding of the polyethylene wood plastic section bar.

Owner:山西峰岩新型建材股份有限公司

Coloured PVC waterproof roll and its preparation method

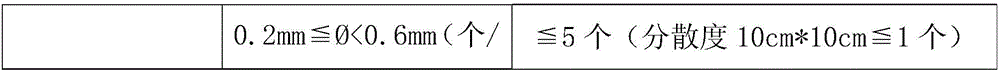

InactiveCN1844294AHigh tensile strengthUniform plasticizationOther chemical processesNitrile rubberPolyvinyl chloride

The invention relates to a colored polyvinyl chloride water-proof coiled material, which is prepared from the following constituents (by weight portions): PVC resin 100 parts, phthalandione dioctyl or tributyl citrate 35+-5 parts, powdered nitrile rubber or chlorinated polyethylene 10+-2 parts, calcium carbonate 30+-10 parts, rare earth heat stabilizer 1.5+-0.5 parts, barium stearate0.3+-0.1 part, stearic acid 0.2+-0.1 part. The invention also discloses its preparing process.

Owner:JIANGSU HUAHONG RUBBER & PLASTIC

Ultra-high molecular weight polyethylene tube and production technique thereof

InactiveCN102675715ARetain raw material propertiesIncrease productivityTubular articlesPolymer scienceGraphite

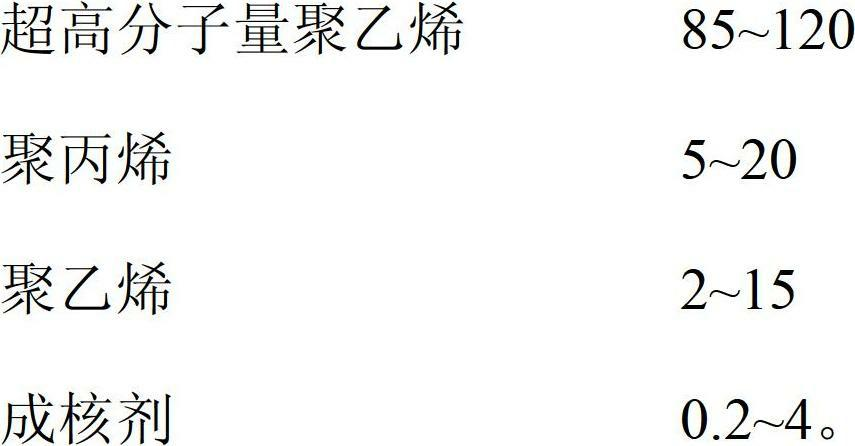

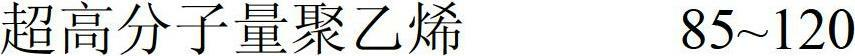

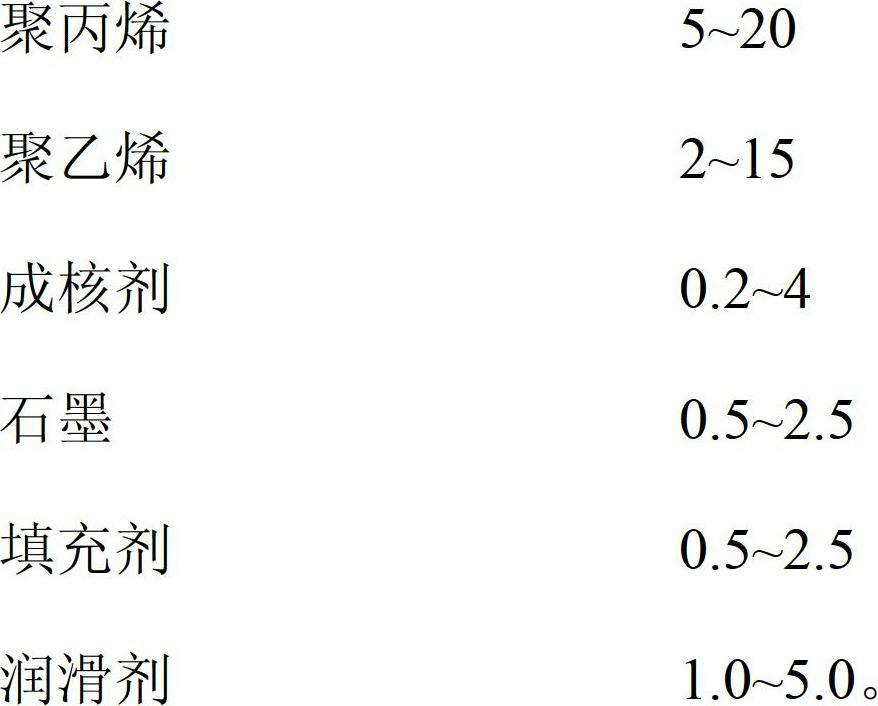

The invention relates to an ultra-high molecular weight polyethylene tube which is characterized by comprising the following components in parts by weight: 85-120 parts of ultra-high molecular weight polyethylene, 5-20 parts of polypropylene, 2-15 parts of polyethylene and 0.2-4 parts of nucleating agent. The tube can also comprise graphite and plastic assistants. The polypropylene and polyethylene are blended to modify the ultra-high molecular weight polyethylene, so the prepared ultra-high molecular weight polyethylene tube not only has the properties of the raw material, but also has the good characteristics of polyethylene and polypropylene; and thus, the ultra-high molecular weight polyethylene tube is easy to process, and has the advantages of favorable plastifying effect and high production efficiency.

Owner:HEBEI BEISU PIPE IND

Coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material and preparation method thereof

The invention discloses a coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material and a preparation method thereof. The coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material is prepared from the following raw materials: by weight, ultra high molecular weight polyethylene, a flow modifier, a compatibilizer, a lubricant, an antistatic agent, a flame retardant, pretreated calcium sulfate whisker, a nucleating agent and a coupling agent. Firstly, all the raw materials are mixed in a high speed, then the mixed materials are added into an extruder for extrusion forming, and then the coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material is obtained by sizing, cooling and final cutting of the formed material. The coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material prepared by the preparation method is well plasticized and is smooth in the inner wall, the wall thickness of the continuously produced coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material can reach 40mm, flame-retardant and antistatic functions can be improved, the cost is reduced, and the production efficiency and safety coefficient are improved. Products prepared by the preparation method can completely meet the safety technology requirements of coal mine-use pipe materials.

Owner:LUOHE KELAIBAO TECH CO LTD

Method for preparing supercritical fluid reinforced fluorine-containing polymer product

The invention relates to a method for preparing a supercritical fluid reinforced fluorine-containing polymer product, which comprises: preheating a region 1 and a region 2 in a double screw extruder, feeding the fluorine-containing polymer into the region 1, and injecting supercritical carbon dioxide at 31.1 to 70 DEG C and under 7.4 to 25MPa into a cylinder from a region 3; regulating the rotating speed of a screw melt pump to 1 to 10r / min, melting and blending the carbon dioxide and the fluorine-containing polymer in regions 4, 5, 6, and 7, releasing carbon dioxide, and reducing pressure ina cylinder in a region 9 to normal temperature; and extruding from a die head to form the fluorine-containing polymer product. According to the method disclosed by the invention, the pressure in the double screw cylinder is controlled by regulating the rotating speed of the melt pump to allow the carbon dioxide fluid to uniformly and stably plasticize and melt the polymer; and thus, the processing temperature is reduced to 5 to 20 DEG C, the fluorine-containing polymer is protected from decomposition, and processing window is enlarged. The method disclosed by the invention is environment-friendly, avoids solvent pollution and can ensure continuous production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

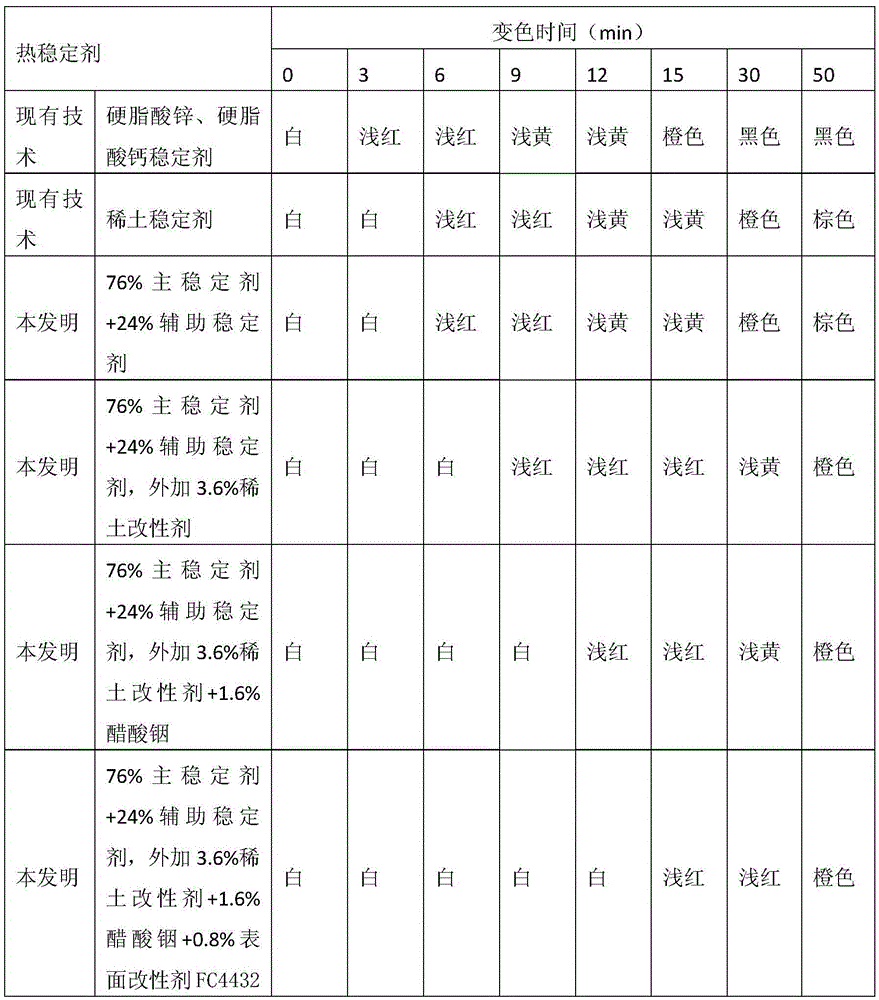

PVC compound stabilizer and preparation method

The invention provides a PVC compound stabilizer. The PVC compound stabilizer is characterized by being composed of, by mass, 85-90% of a main stabilizing agent and 5-15% of a subsidiary stabilizing agent; the main stabilizing agent is composed of polyvinylpyrrolidone, bis(5-oxo-L-prolinato-N1,O2) zinc, calcium disodium ethylenediamine tetraacetate and titanium tetraisopropanolate, and the subsidiary stabilizing agent is composed of N,N-ethylene bis-stearamide, pentaerythrityl tetrastearate, epoxidized linseed oil and mannitol. The invention further discloses a preparation method of the PVC compound stabilizer. The PVC compound stabilizer has the advantages of being free of toxin, environmentally friendly, good in lubricity and the like, is high in thermal stability, high in transparency, high in impact resistance and high in profile welded corner strength, can reduce damage to PVC molecules caused by ultraviolet light, improve outdoor aging performance of a product and further has good internal and external lubricating properties, and processing can be conducted stably.

Owner:SHENZHEN AIMSEA IND

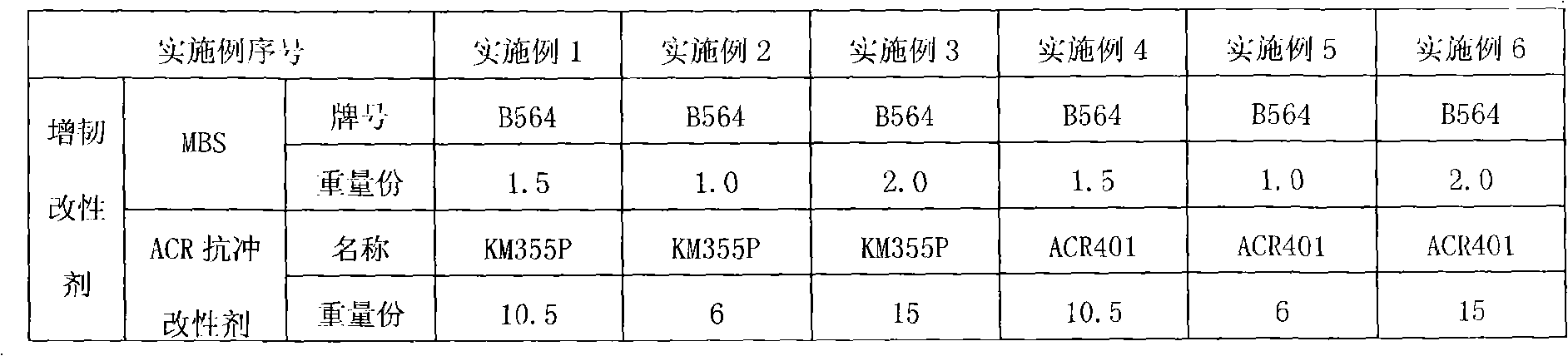

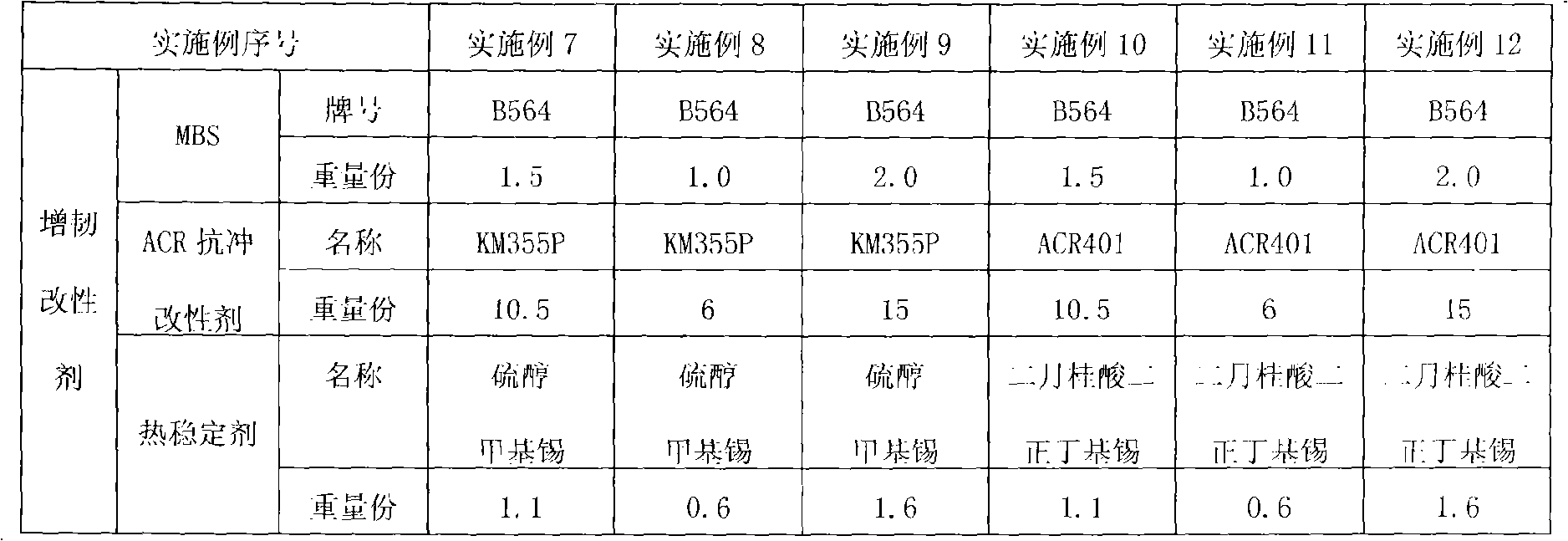

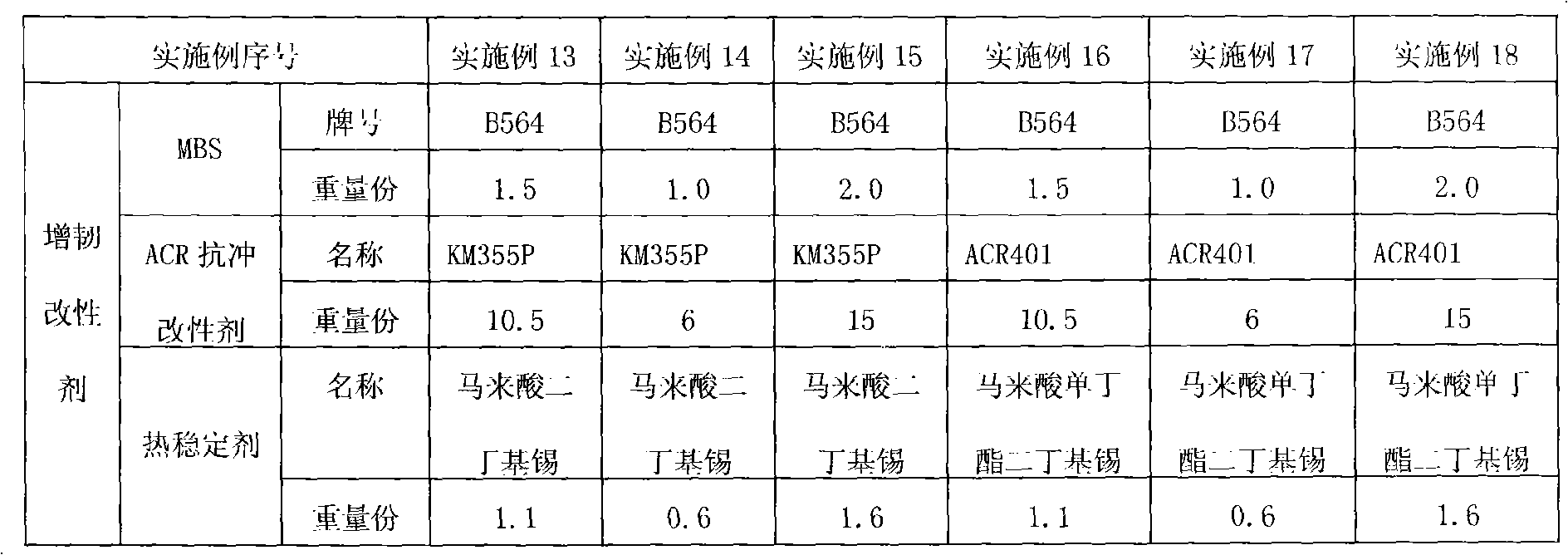

Polyvinyl chloride toughening modifier

InactiveCN101565530AImprove impact resistanceHigh surface glossRigid pipesMethylmethacrylatesPolyvinyl chloride

The invention discloses a polyvinyl chloride toughening modifier, which comprises 1.0 to 2.0 portions of methylmethacrylate butadine stryrene copolymer which is also called MBS, and 6 to 15 portions of acrylates impact modifier which is also called ACR impact modifier; and the portion of the compositions is weight portion. The polyvinyl chloride toughening modifier has good toughening and modification effects on polyvinyl chloride.

Owner:干方明

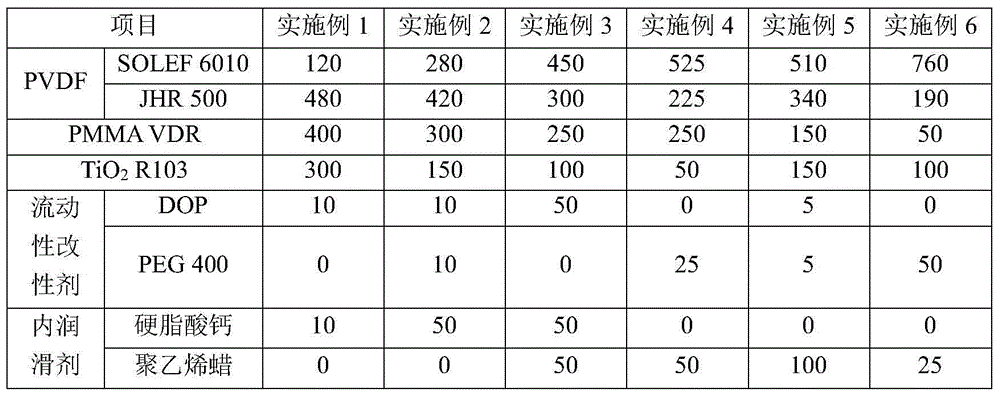

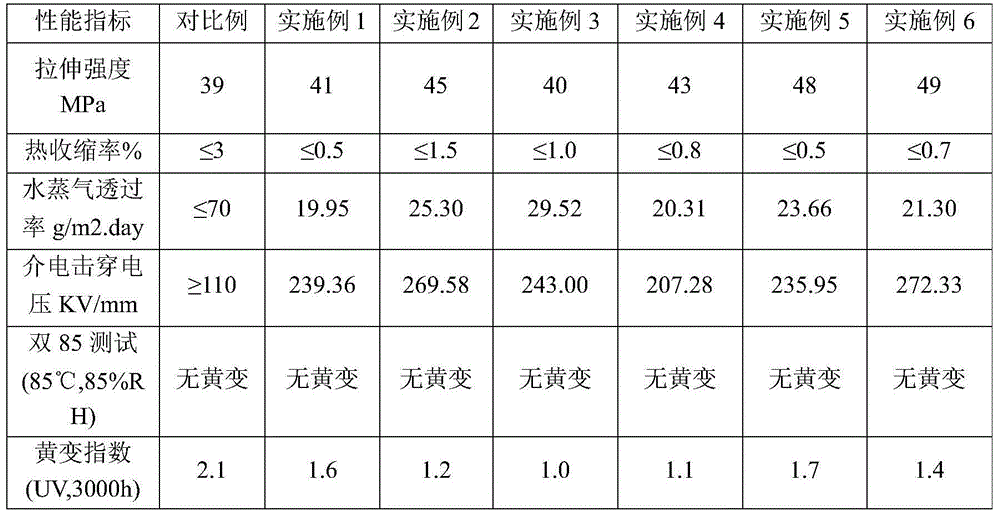

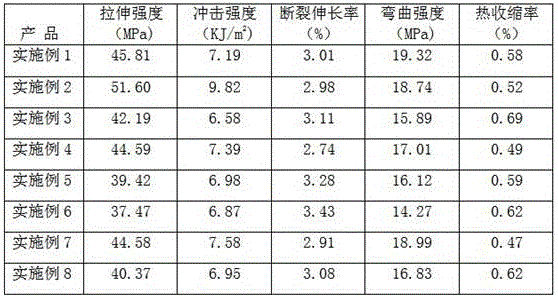

Preparation method and application of master batch used for polyvinylidene fluoride film

The invention discloses a preparation method of a master batch used for a polyvinylidene fluoride film. The preparation method comprises the steps of mixing a polyvinylidene fluoride A resin, a polyvinylidene fluoride B resin, polymethyl methacrylate, titanium dioxide, a mobility modifier and an inner lubricating agent at a room temperature until the materials are stirred uniformly, melt-extruding, cooling and granulating at a temperature of 150-250 DEG C, and drying to obtain the master batch. According to a standard of GB / T3682-2000, melt indexes of the polyvinylidene fluoride A resin and polyvinylidene fluoride B resin at a temperature of 230 DEG C and a load of 5 kg is 30-60 g / 10 min and 3-20 g / 10 min respectively. Performances such as tensile strength and thermal shrinkage of the film prepared by the preparation method provided by the invention are greatly improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

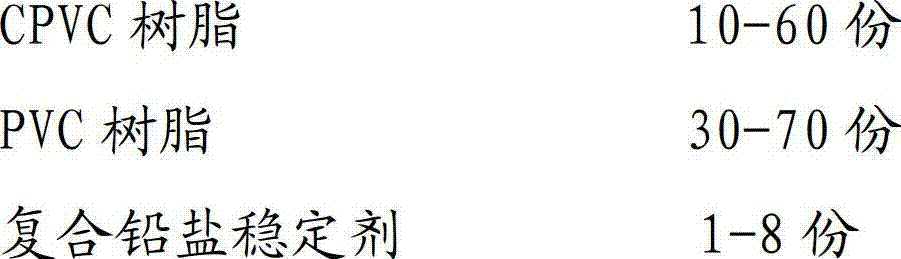

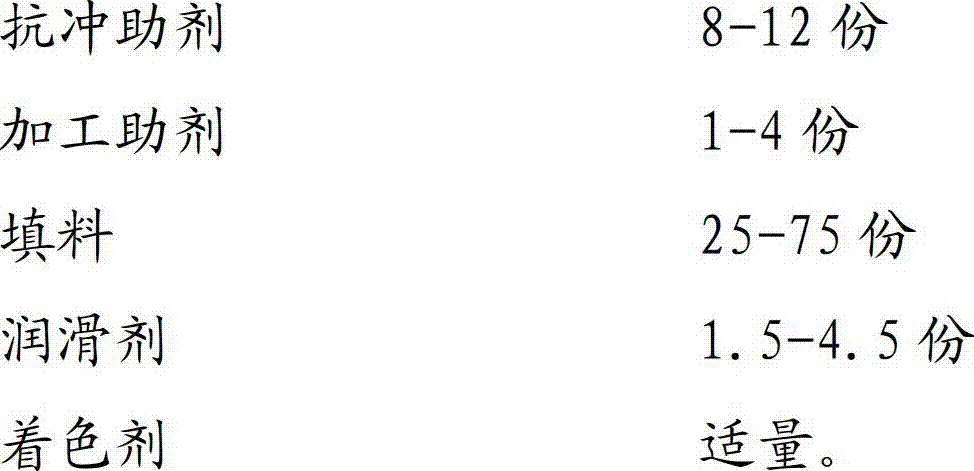

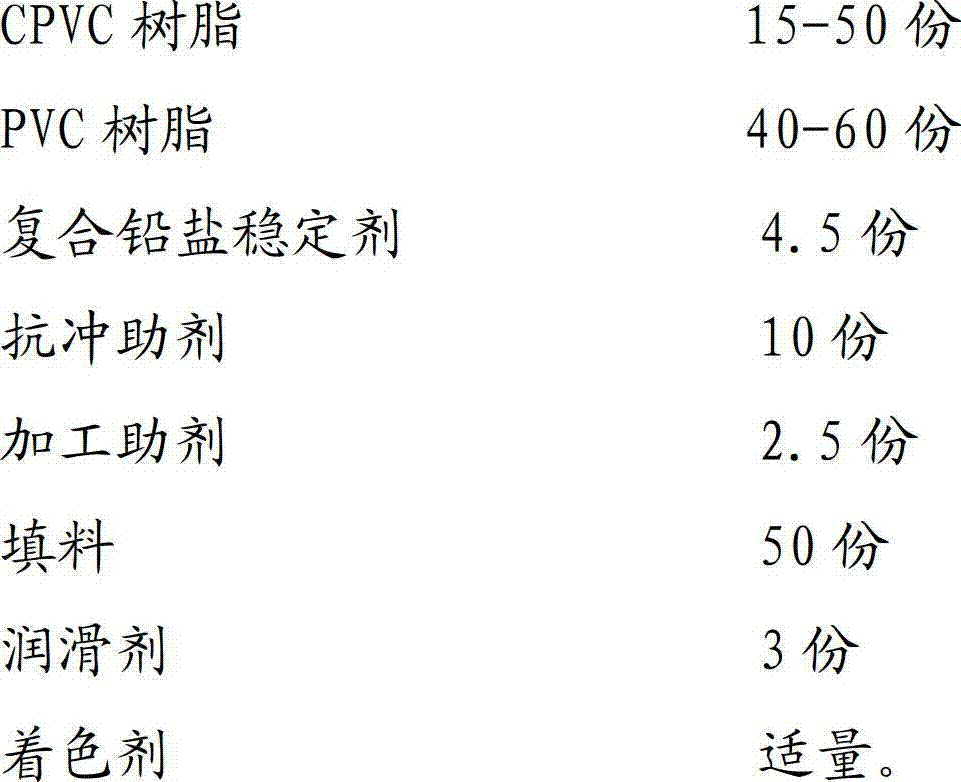

High-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and preparation method of chlorinated polyvinyl chloride (CPVC) corrugated board

ActiveCN102924851AImprove corrosion resistanceReduce thermal conductivity and heat absorptionStabilizing AgentsChemical stability

The invention discloses a high-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and a preparation method of the chlorinated polyvinyl chloride (CPVC) corrugated board. The corrugated board is prepared from the following raw materials by weight: 10-60 parts of CPVC resin, 30-70 parts of PVC (polyvinyl chloride) resin, 1-8 parts of composite lead salt stabilizer, 1-4 parts of processing aids, 8-12 parts of anti-impact aids, 25-75 parts of filler, 1.5-4.5 parts of lubricant, and a reasonable amount of colorant. The corrugated board has the advantages of high mechanical strength, excellent weatherability, high aging resistance and chemical stability and the like, and the formed raised corrugated board has higher thickness uniformity and uniform stress distribution, thereby being not easy to break due to stress concentration.

Owner:山东高信化学股份有限公司

High-barrier polyethylene material and preparation method thereof

InactiveCN108329564AImprove barrier abilityReduce chance of breakagePhosphoric acidHigh-density polyethylene

The invention discloses a high-barrier polyethylene material and a preparation method thereof. The preparation method comprises the following steps: subjecting 40 to 60 parts of polyethylene with highmolecular weight and high density, 2 to 3 parts of dilauryl thiodipropionate, 1 to 2 parts of ethoxyamide stearate, 2 to 4 parts of melamine aluminum polyphosphate, 2 to 5 parts of a compatibilizingagent and 8 to 12 parts of talcum powder to mixing under stirring for 5 to 8 minutes, adding an obtained mixture into the first-stage feed inlet of a double screw extruder through a feeding machine ata speed of 0.5 part of the mixture per minute, and carrying out plasticizing modification; and adding 20 to 50 parts of an ethylene-vinyl alcohol copolymer into the second-stage feed inlet of the extruder at a feeding speed of 0.128 to 0.423 part of the ethylene-vinyl alcohol copolymer per minute, wherein the rotating speed of the double screw extruder is 550 to 600 revolutions / minute; the temperature of the first, second and third stages of the extruder is controlled to be 210 to 235 DEG C; and the temperature of the fourth, fifth and sixth stages of the extruder is controlled to be 200 to 220 DEG C. The high-barrier polyethylene material provided by the invention is greatly improved in barrier performance and processing properties, and has excellent performance indexes.

Owner:贵州凯科特材料有限公司

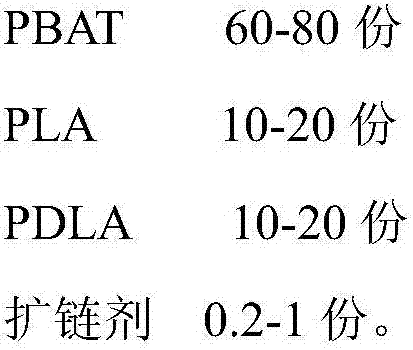

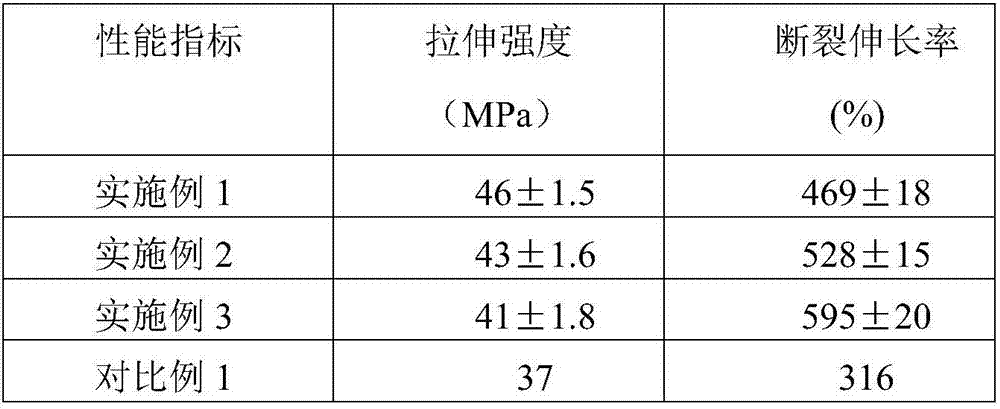

Enhanced poly(butylene terephthalate-co-butylene adipate) degraded material

The invention discloses an enhanced poly(butylene terephthalate-co-butylene adipate)degraded material, which belongs to the field of processing modification of a high-molecular material. The method comprises the following steps: pre-dried polybutylene terephthalate-co-butylene adipate, polylactic acid and dextrorotary polylactic acid are mixed according to certain mass ratio, a chain extender is added for being uniformly mixed, a double screw extruder is used for blending extrusion, wherein the temperature for each segment of the screw is 160-195 DEG C, and the screw rotating speed is 100-150 rpm, and extrusion granulation is carried out to obtain the enhanced PBAT fully-biodegraded material. The prepared poly(butylene terephthalate-co-butylene adipate) material has the advantages of high intensity and high toughness, and the method is simple.

Owner:CHANGZHOU UNIV

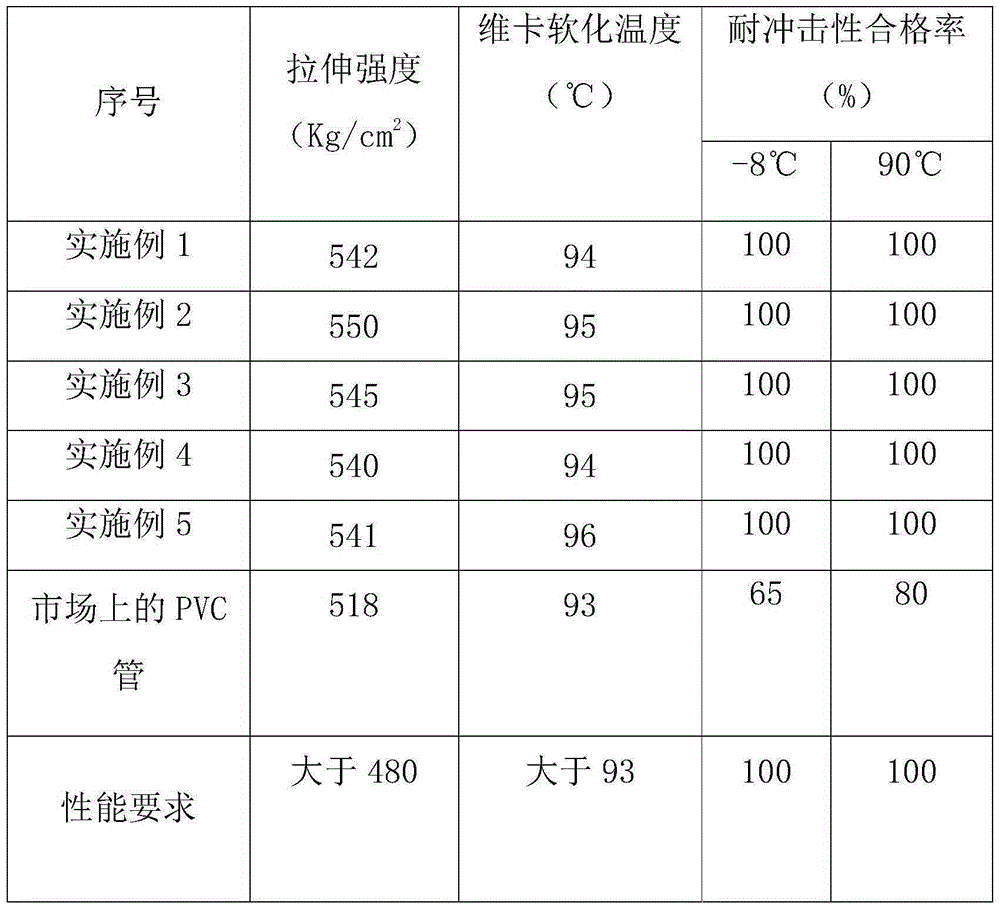

Polyvinyl chloride tubular product and preparation method thereof

The invention discloses a polyvinyl chloride tubular product and a preparation method thereof and relates to the field of plastic tubular products. The polyvinyl chloride tubular product is prepared from, by weight, 75 parts of PVC, 25 parts of light calcium carbonate, 3-5 parts of a heat stabilizer, 1-3 parts of a lubricant, 5-8 parts of CPE, 2-5 parts of ACR and 0.8-1.5 parts of molybdate red, and the preparation method comprises the seven process steps of raw material weighing, hot mixing, cooling mixing, extrusion, vacuum cooling, cutting and flaring for forming and packaging. The preparation method is simple, the production efficiency is high, the preparation process is simple, low in cost and high in preparation efficiency, the prepared polyvinyl chloride tubular product is good in tensile property and impact resistance, and brittle failure does not easily occur.

Owner:ANHUI RUIFENG PIPE IND CO LTD

PVC composite material suitable for extrusion molding and preparation method

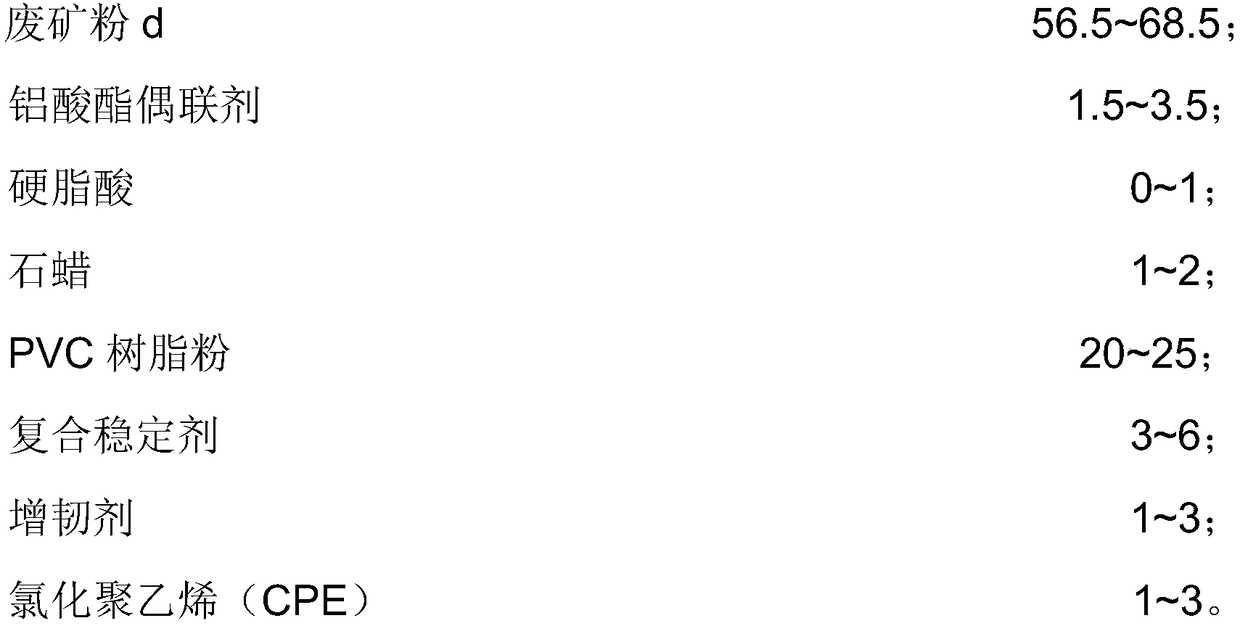

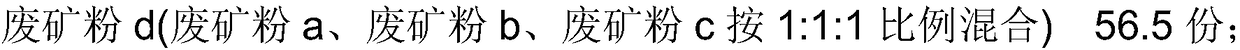

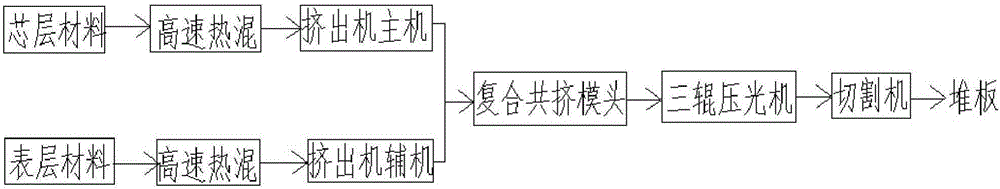

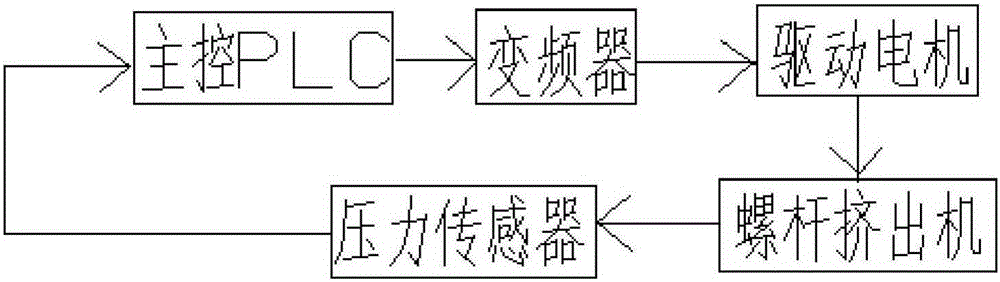

The invention relates to a PVC composite material suitable for extrusion molding and a preparation method. The preparation method comprises preparation of modified waste mineral powder, preparation ofa modified waste mineral powder premix and preparation of the PVC composite material. The modified waste mineral powder is obtained by performing grinding, screening and coupling activation treatmenton mixed waste mineral slag comprising tailings produced in mining of granites, wastes produced in marble processing and fired-coal coal ash produced in a smelting process; the modified waste mineralpowder premix is obtained by mixing the modified waste mineral powder with stearic acid and paraffin respectively; the PVC composite material is obtained by mixing the modified waste mineral powder premix with PVC resin, a composite stabilizer, a toughener and CPE under a heating condition. The composite material is suitable for extrusion molding, uniform in PVC plasticization and hard to decompose; the waste mineral powder is high in compatibility with PVC; no dust problem is caused; the defective rate is low; furthermore, a molded product is high in intensity, high in toughness and good inwater resistance and flame retardancy. The PVC composite material can replace a wood-plastic composite material and be widely applied to the field of buildings and home decoration.

Owner:SHAANXI SCI TECH UNIV +1

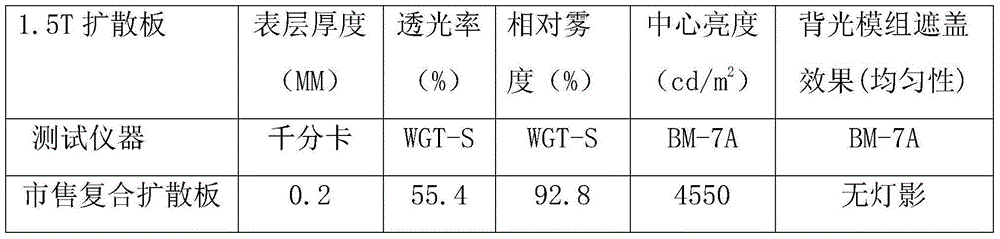

Production technology for composite co-extrusion PS diffuser plate

ActiveCN105175916AImprove optical performance indicatorsGuaranteed Diffusion EffectLuminescent compositionsSurface layerTransmittance

The invention relates to a production technology for a composite co-extrusion PS diffuser plate, and the technology mainly comprises steps of formula design, material mixing, extrusion, cutting, plate piling and the like. The material mixing step comprises high-speed hot mixing and sieving warehousing. The extrusion step employs a composite co-extrusion technology. A core-layer extruder is taken as a main machine, the main machine employs a screw with the diameter of 130 mm and the draw ratio of 38, and the main machine average rotation speed is 70 r / min. A surface-layer extruder is taken as an auxiliary machine, the auxiliary machine employs a screw with the diameter of 60 mm and the draw ratio of 33, and the auxiliary machine average rotation speed is 60 r / min. The main-machine material canister heating temperature is divided into seven stages, and the temperature is gradually raised. The auxiliary-machine material canister heating temperature is divided into five stages. Through formula design, equipment layout and technological parameter improvement, the diffuser plate is improved in light transmittance, relatively haze and center brightness, and the backlight module covering effect is good.

Owner:惠州市凯帝智光电科技有限公司

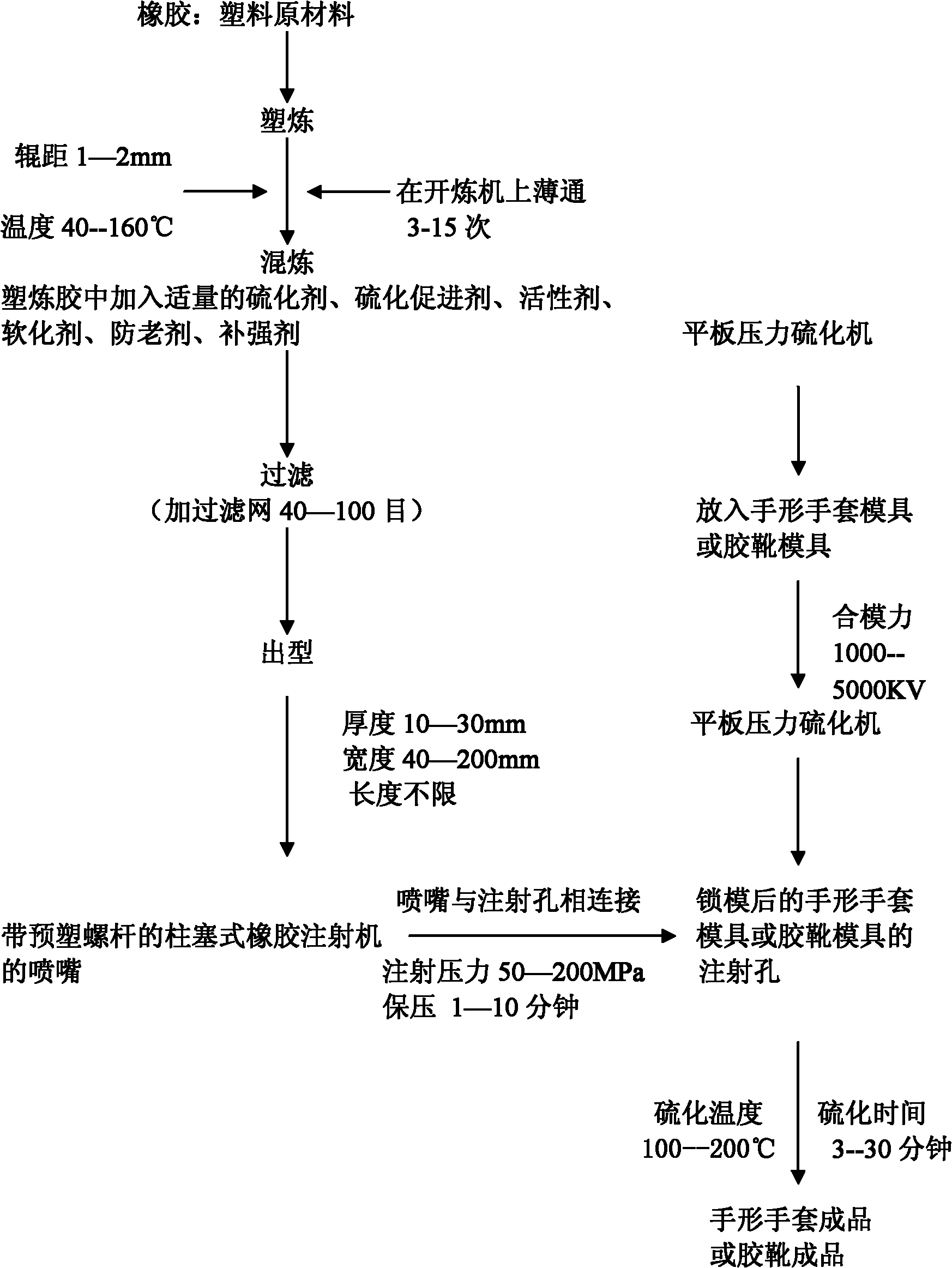

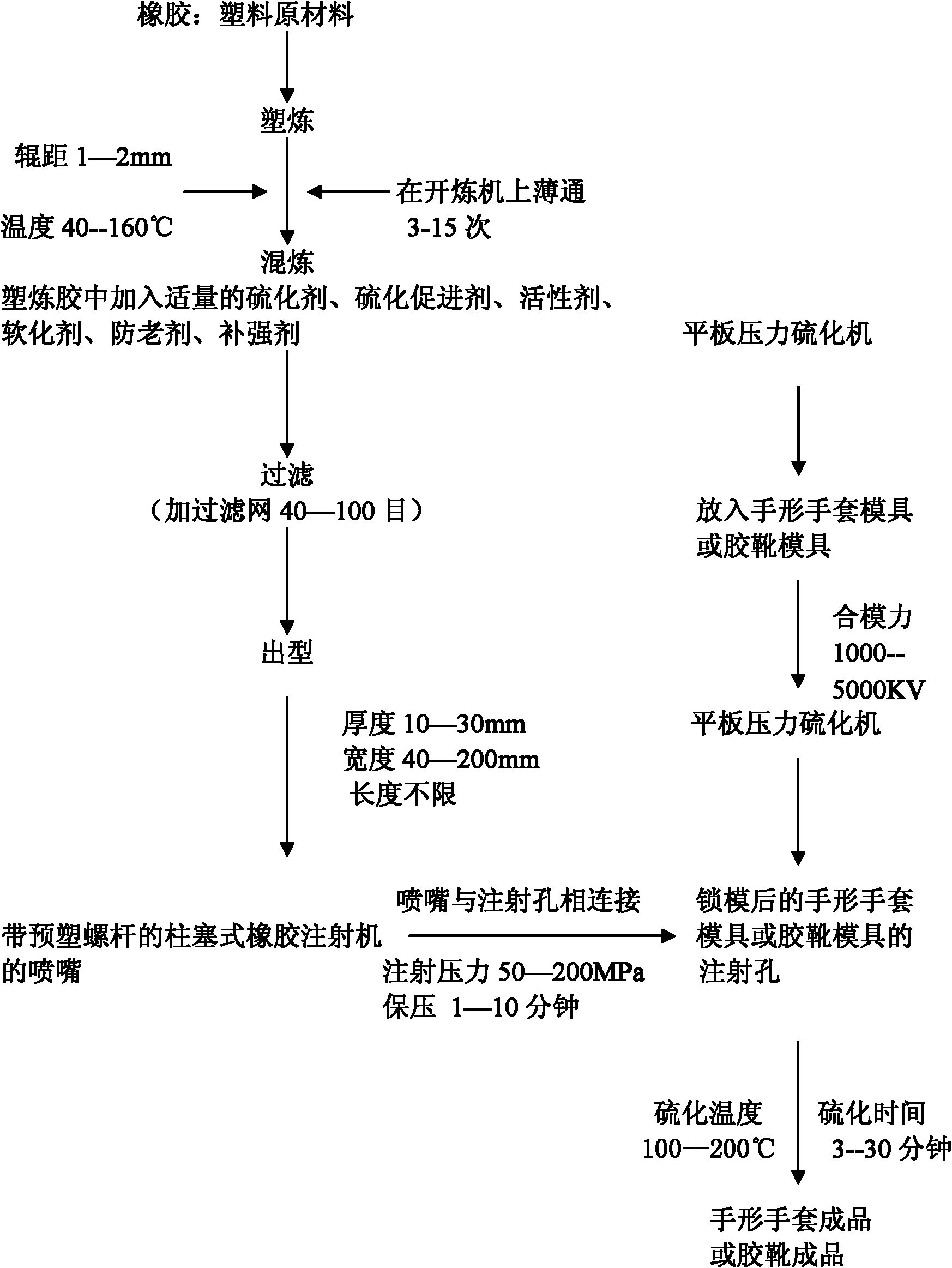

Injection moulding method of rubber and plastic electric insulation hand gloves and rubber boots

InactiveCN101913226AHigh densityHigh electrical insulationDomestic footwearPlate pressureVolumetric Mass Density

The invention relates to an injection moulding method of rubber and plastic electric insulation hand gloves and rubber boots, belonging to the technical filed of rubber and plastic moulding. The injection moulding method of the rubber and plastic electric insulation hand gloves and the rubber boots comprises the following steps: (1) taking rubber as a raw material; (2) plastication: thinly passing 3-15 times when the roller space on an open mill is 1-2mm; (3) mixing: mixing in the open mill or a banbury mixer; (4) filtering by a filter; (5) shaping to prepare rubber sheets the thickness of which is 10-30mm and the width is 40-200mm; (6) plasticizing: adding the rubber sheets to a plunger type rubber injection machine provided with a pre-plasticized screw rod to plasticize; (7) injection and sulfuration: connecting the nozzle of a movable plunger type rubber injection moulding machine provided with the performing screw rod with the injection hole of the mould locked in a flat-plate pressure vulcanizer, injecting size into a hand glove mould or a rubber boot mould for moulding, maintaining pressure and vulcanizing; and (8) demoulding products. The method of the invention has the advantages of simple process, accurate control, small equipment investment, low cost, high production efficiency, high product density, good comprehensive performance, high electric insulation degree and the like.

Owner:天津市腾盛橡塑制品厂(普通合伙)

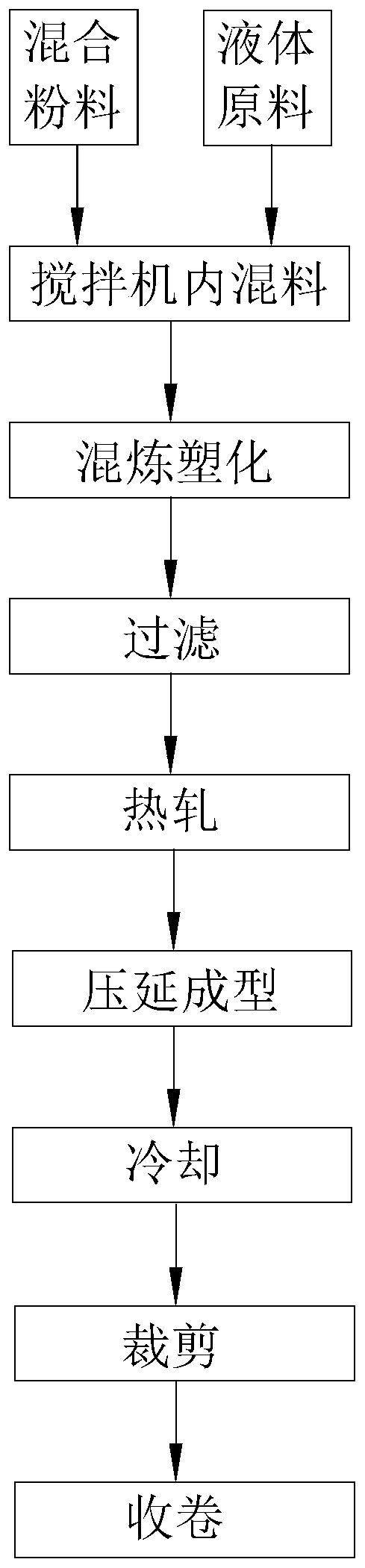

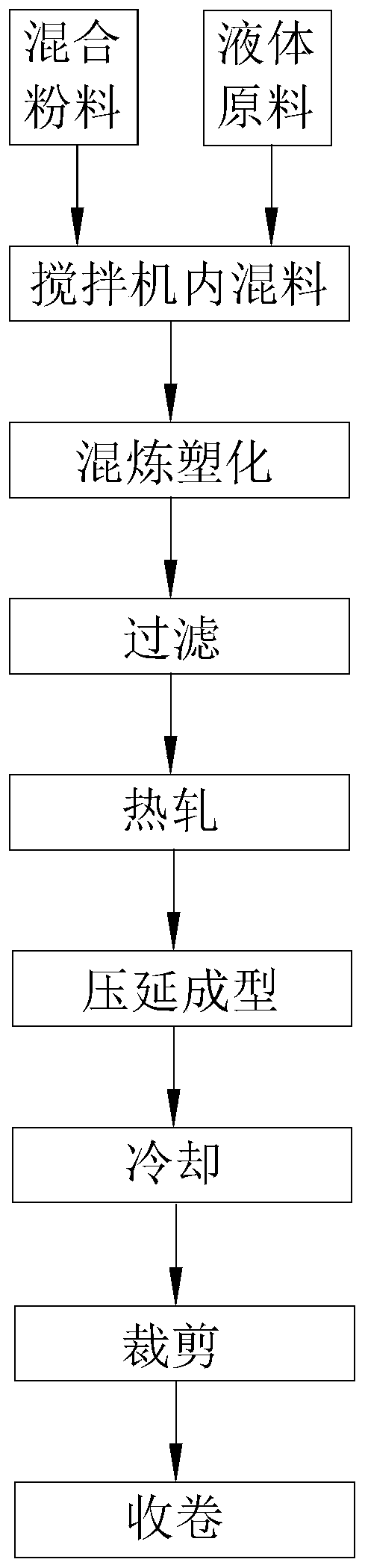

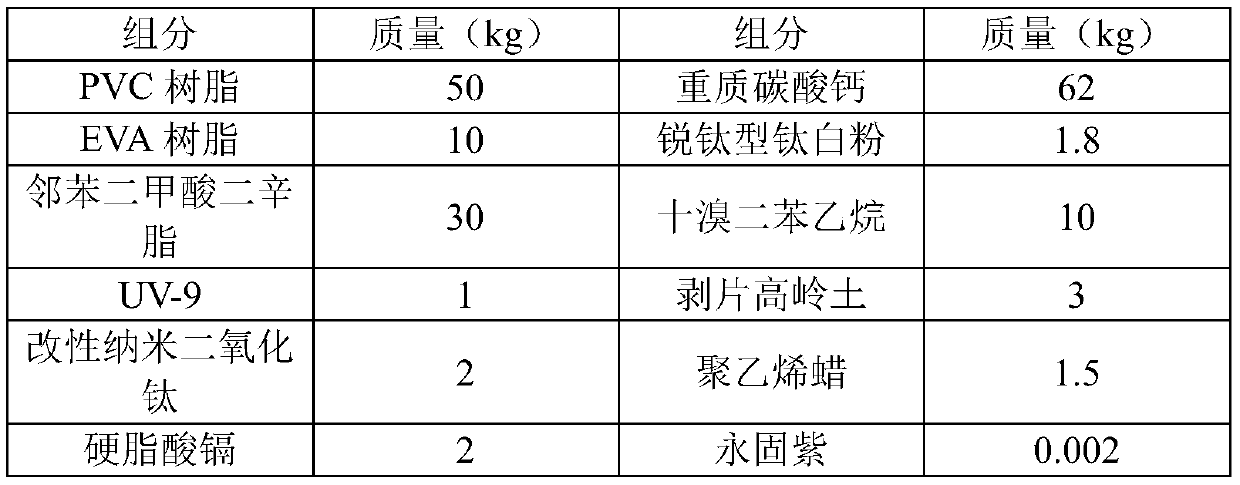

PVC lamp box film and preparation process thereof

The invention relates to a PVC lamp box film and a preparation process thereof, and relates to the technical field of lamp box films. The PVC lamp box film specifically comprises the following components in parts by weight: 50-60 parts of PVC resin, 5-10 parts of EVA resin, 28-35 parts of a plasticizer, 1-3 parts of an ultraviolet light absorber, 2-5 parts of modified nano titanium dioxide, 1-5 parts of a stabilizer, 62-70 parts of ground calcium carbonate, 1.8-2.5 parts of anatase titanium dioxide, 10-15 parts of a flame retardant, 2-3 parts of a flame retardant synergist, 1-3 parts of a lubricant and 0.002-0.007 part of a pigment. The aging of the PVC lamp box film is delayed, and the service life is prolonged.

Owner:上海蓝泉塑料制品有限公司

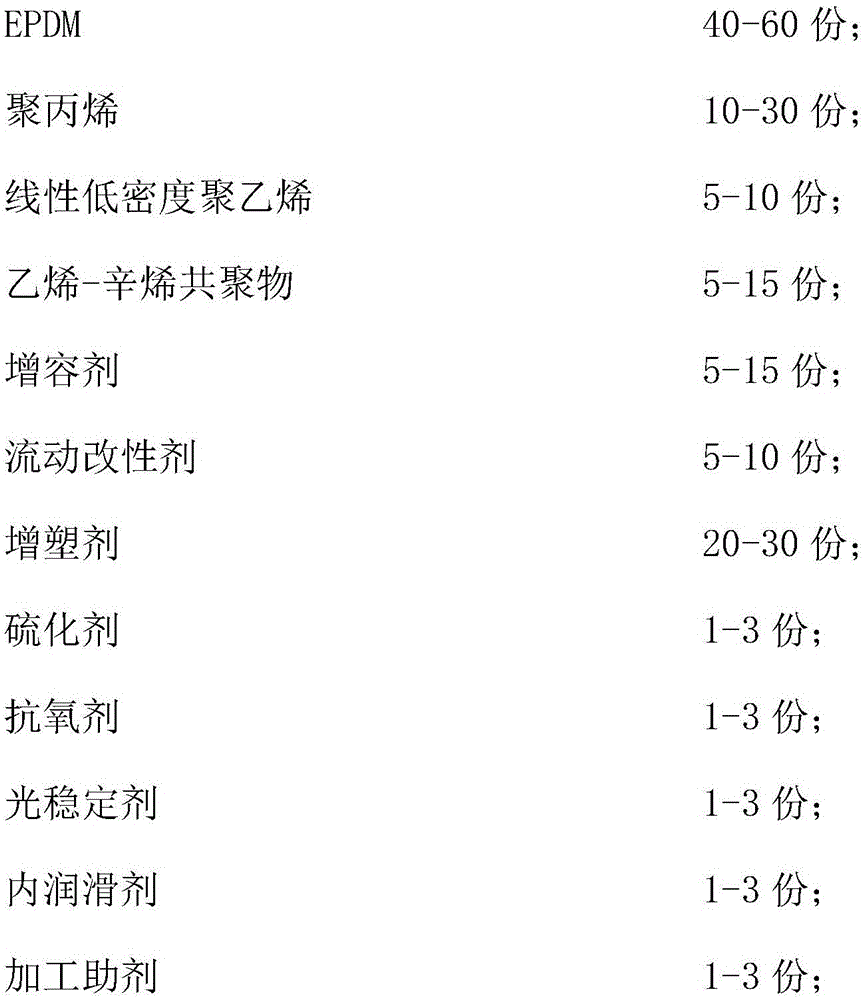

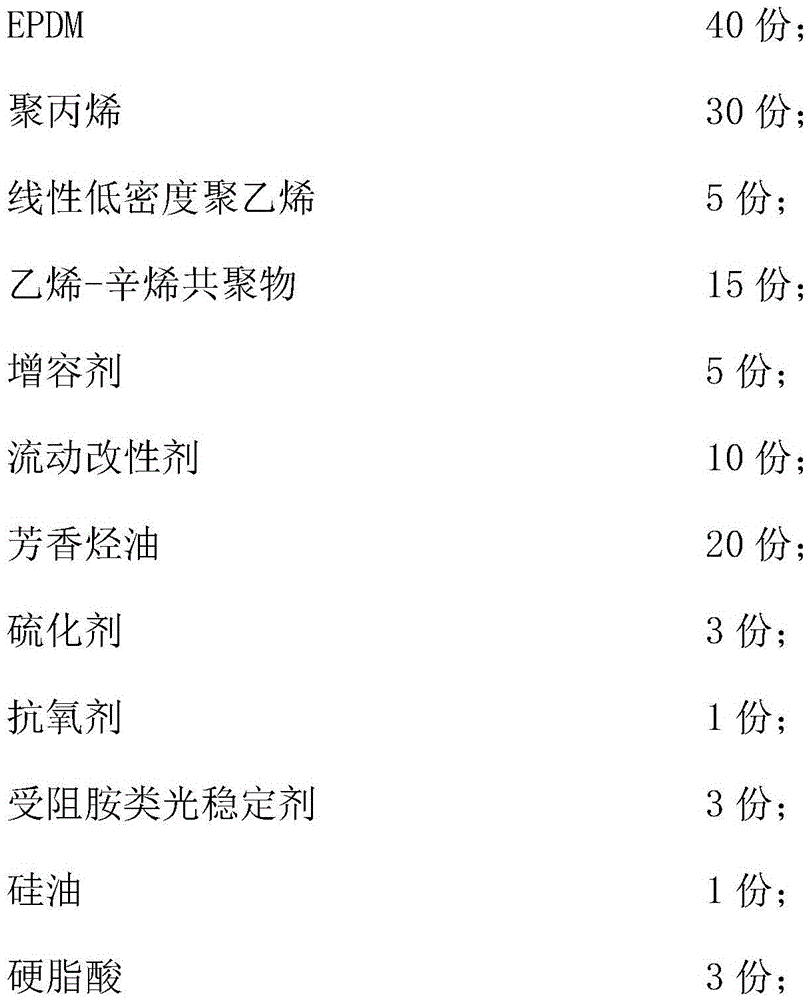

Blow-molding-grade TPV (thermoplastic vulcanizate) material for dust shields and preparation method thereof

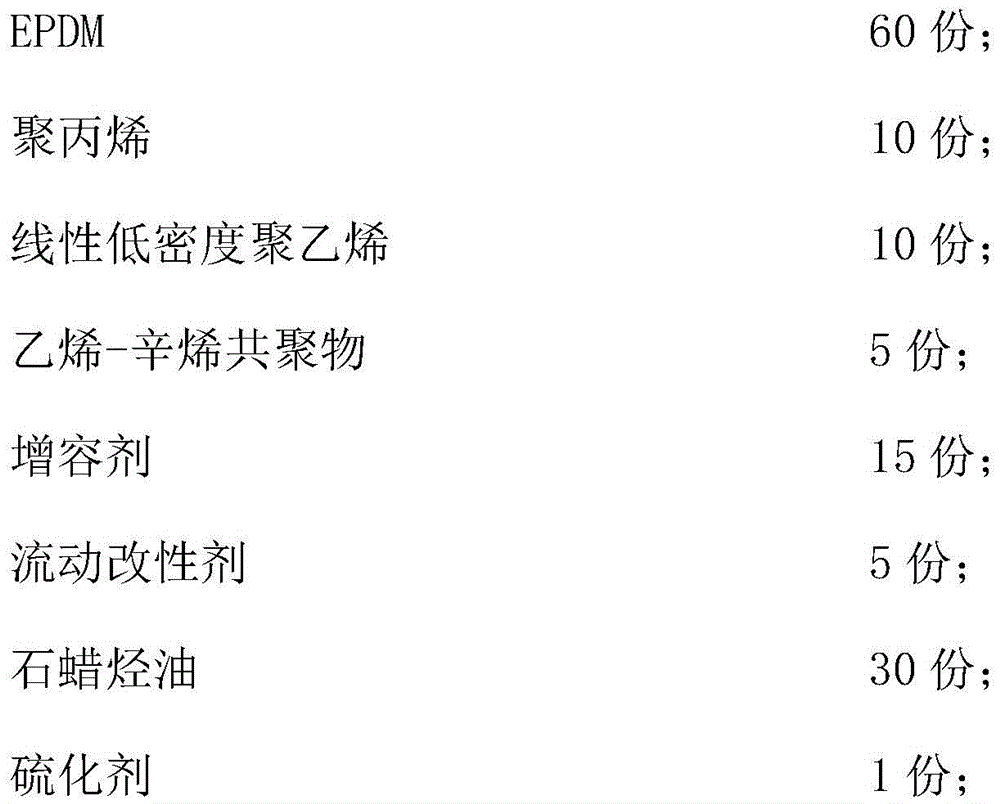

InactiveCN105670134AImprove melt strengthImprove blow molding processabilityThermoplasticLinear low-density polyethylene

The invention discloses a blow-molding-grade TPV (thermoplastic vulcanizate) material for dust shields. The blow-molding-grade TPV material for dust shields is prepared from the following raw materials in parts by weight: 40-60 parts of EPDM (ethylene-propylene-diene monomer), 10-30 parts of polypropylene, 5-10 parts of linear low density polyethylene, 5-15 parts of ethylene-octylene copolymer, 5-15 parts of compatibilizer, 5-10 parts of flow modifier, 20-30 parts of plasticizer, 1-3 parts of vulcanizing agent, 1-3 parts of antioxidant, 1-3 parts of light stabilizer, 1-3 parts of internal lubricant and 1-3 parts of processing aid. The TPV material has the advantages of favorable melt strength, excellent blow molding processability, favorable mechanical properties, excellent processability and favorable appearance.

Owner:安徽韧达高分子材料有限公司

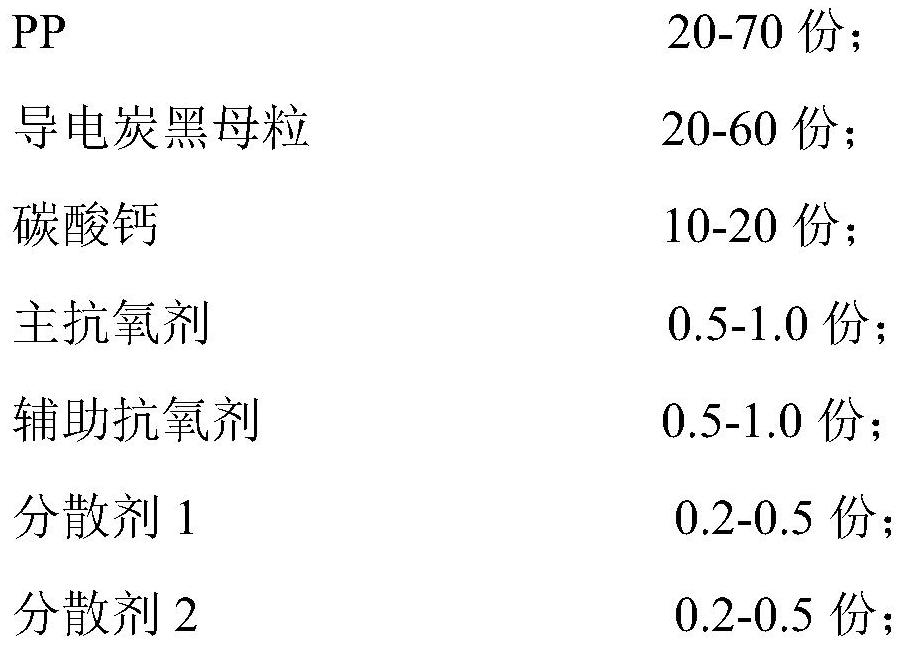

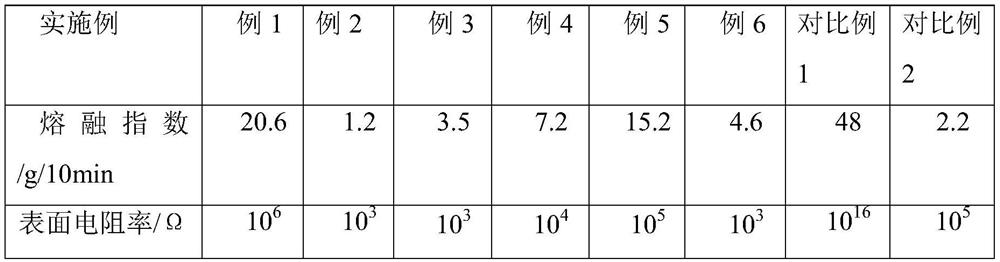

Conductive polypropylene material and preparation method thereof

InactiveCN111621088AEvenly dispersedImprove the processing environmentMasterbatchSurface resistivity

The invention discloses a conductive polypropylene material and a preparation method thereof. The conductive polypropylene material comprises the following components in parts by weight: 20-70 parts of PP; 20 to 60 parts of conductive carbon black master batch; 10 to 20 parts of calcium carbonate; 0.5 to 1.0 part of a main antioxidant; and 0.5 to 1.0 part of an auxiliary antioxidant; the preparation method comprises the following steps: mixing, extruding and granulating the raw materials. Wherein the conductive carbon black masterbatch is prepared from 40 parts of high-pressure low-density polyethylene; 25 parts of a lubricant; and 35 parts of conductive carbon black are internally mixed. The surface resistivity of the prepared conductive polypropylene material can be reduced to 103, and the conductivity of the conductive polypropylene material can be more uniform by using the conductive carbon black master batch.

Owner:HEFEI GENIUS NEW MATERIALS

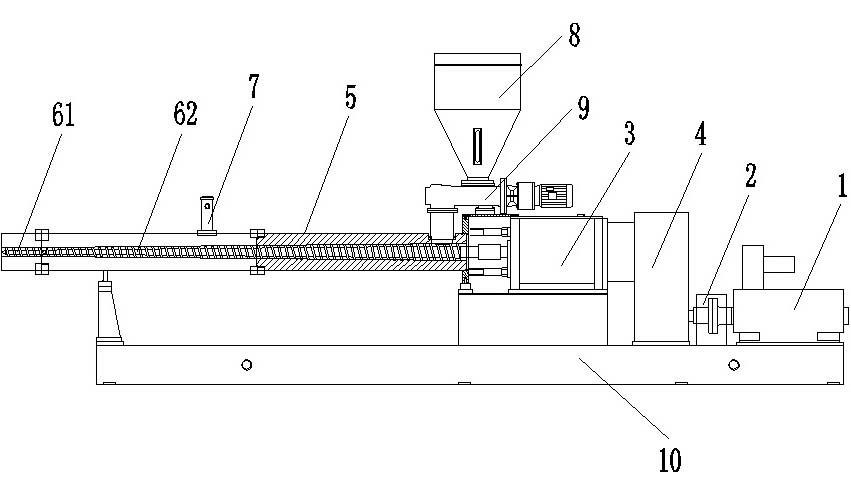

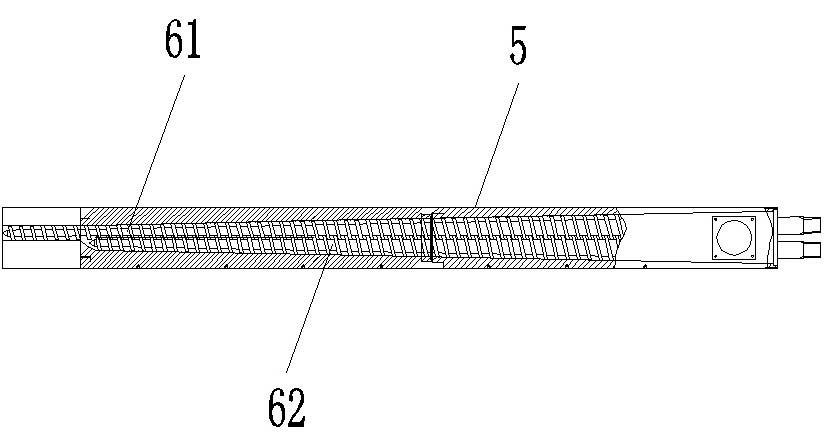

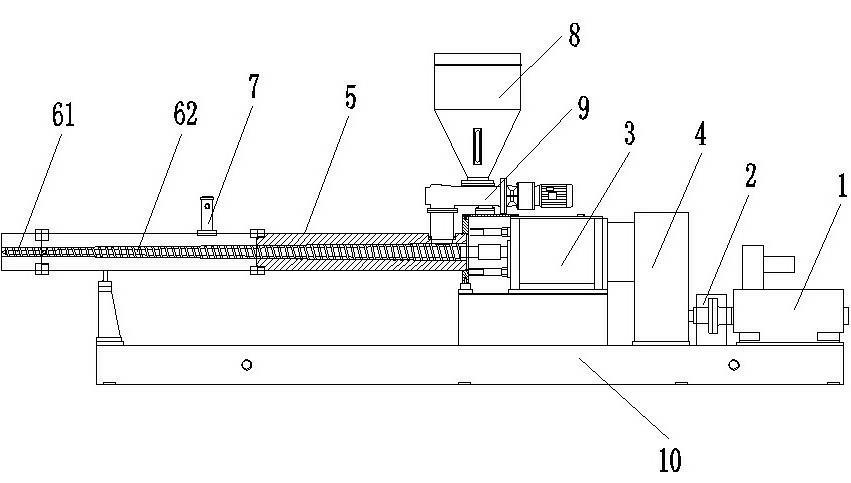

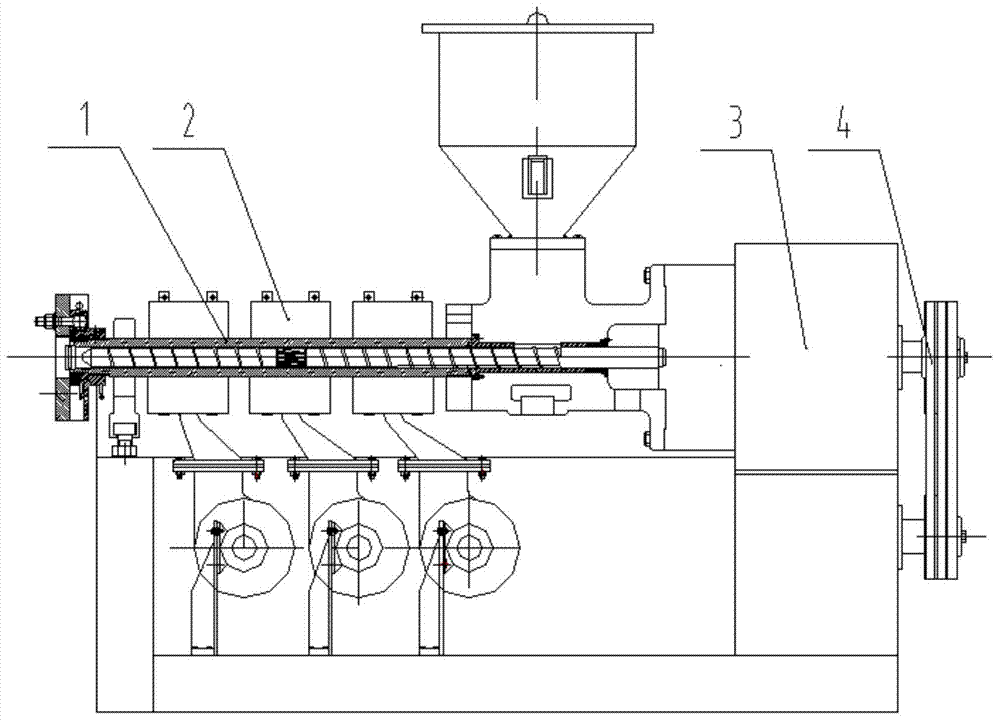

Double-screw extruder

The invention relates to a double-screw extruder, and belongs to the field of plastic mechanical manufacturing. At present, a double-screw extruder with simple structure, reasonable design and two screws of different lengths is unavailable. The double-screw extruder comprises a driving motor, a distribution box with a driving gear and a driven gear, a reduction box, a machine cylinder, an exhaust system, a hopper, a feed system and a machine frame, wherein the driving motor, the distribution box, the reduction box and the machine cylinder are arranged on the machine frame; the reduction box, is connected with the driving motor; the driving gear in the distribution box is connected with the reduction box, and is matched with the driven gear; the feed system is connected with the machine cylinder; and the exhaust system is arranged on the machine cylinder. The double-screw extruder is characterized by also comprising a long screw and a short screw which are arranged on the driving gear and the driven gear; and the long screw and the short screw are both positioned in the machine cylinder. The double-screw extruder has reasonable structural design, scientific layout, stable pressure and excellent extruding performance, and combines the advantages of a single-screw extruder and the double-screw extruder.

Owner:吴汉民

PVC (Polyvinyl Chloride) wood plastic foaming material and preparation method thereof

The invention discloses a PVC (Polyvinyl Chloride) wood plastic foaming material. The PVC wood plastic foaming material is prepared from the following raw materials in parts by weight: 20 to 70 parts of SG5 type PVC resin, 30 to 80 parts of SG7 type PVC resin, 10 to 60 parts of natural plant fiber, 30 to 80 parts of nano calcium carbonate, 5 to 30 parts of activated heavy calcium carbonate, 8 to 40 parts of modifier, 0.3 to 3 parts of polyethylene glycol, 0.5 to 3 parts of G60 type lubricant, 0.3 to 2 parts of maleic acid grafted PE (Poly Ethylene) wax compatibilizer, 2 to 6 parts of organic tin stabilizer, 5 to 10 parts of foam regulator, 1 to 8 parts of processing agent and 1 to 3 parts of composite foaming agent. All components in a formula of the PVC wood plastic foaming material provided by the invention are good in compatibility and have excellent dispersity and fluidity, so that the PVC wood plastic foaming material has good processing performance; meanwhile, the PVC wood plastic foaming material also is excellent in impact resistance, tensile strength, crack resistance, heat resistance and toughness, and has a wide market prospect.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

High molecular weight processing modifier for polyvinyl chloride low-foaming pipe

The invention relates to high molecular processing modifier used in a polyvinyl chloride low foaming tube, which is characterized in that: the total weight of polymeric monomer is calculated as 100 percent, which comprises 12-72 percent of methyl methacrylate, 21-66 percent of styrene and 7-22 percent of acrylonitrile. Chain extender is added into the compositions to carry out emulsion polymerization in redox system. The invention is characterized in that: the invention can improve plasticizing and the plasticizing can become more even, can improve melt strength to promote extending property, can improve surface quality to reduce melting pulsation and increase surface gloss and can improve processing property to reduce blooming and crazing, decrease the foaming density of the product and increase elongation and pulling speed. Because of higher relative molecular mass, the invention can greatly improve the melt strength. The invention is used for producing PVC foaming products which have dense and even stomata structure and lower density.

Owner:SHANDONG RUIFENG CHEM

Laminated tubular product for high-rise water drainage and manufacturing method thereof

ActiveCN106380735AImprove thermal stabilitySmall particle sizePotassium persulfatePolyvinyl chloride

The invention belongs to the technical field of plastic tubular products, and in particular, relates to a laminated tubular product for high-rise water drainage and a manufacturing method thereof. The laminated tubular product is composed of the following components: polyvinyl chloride resin, a stabilizer, stearic acid, modified ACR, titanium dioxide, modified nano calcium carbonate and the like; preparation of the modified ACR comprises the following steps: (1) seed emulsion preparation: with butyl acrylate and styrene as monomers, adding a lauryl sodium sulfate emulsifier and a potassium persulfate initiator, stirring and heating to prepare a seed emulsion; (2) inner core preparation: continuing to add the potassium persulfate initiator and the butyl acrylate and styrene monomers, and introducing tetrafluoroethylene gas, to prepare an inner core; and (3) outer shell preparation: continuing to add the lauryl sodium sulfate emulsifier and the potassium persulfate initiator, adding methyl methacrylate, and adding modified nano SiO2, to prepare an outer shell; and (4) carrying out spray drying, to prepare the modified ACR. The vinyl chloride tube has the advantages of good impact resistance and good pressure resistance.

Owner:HUZHOU JINJIE IND CO LTD

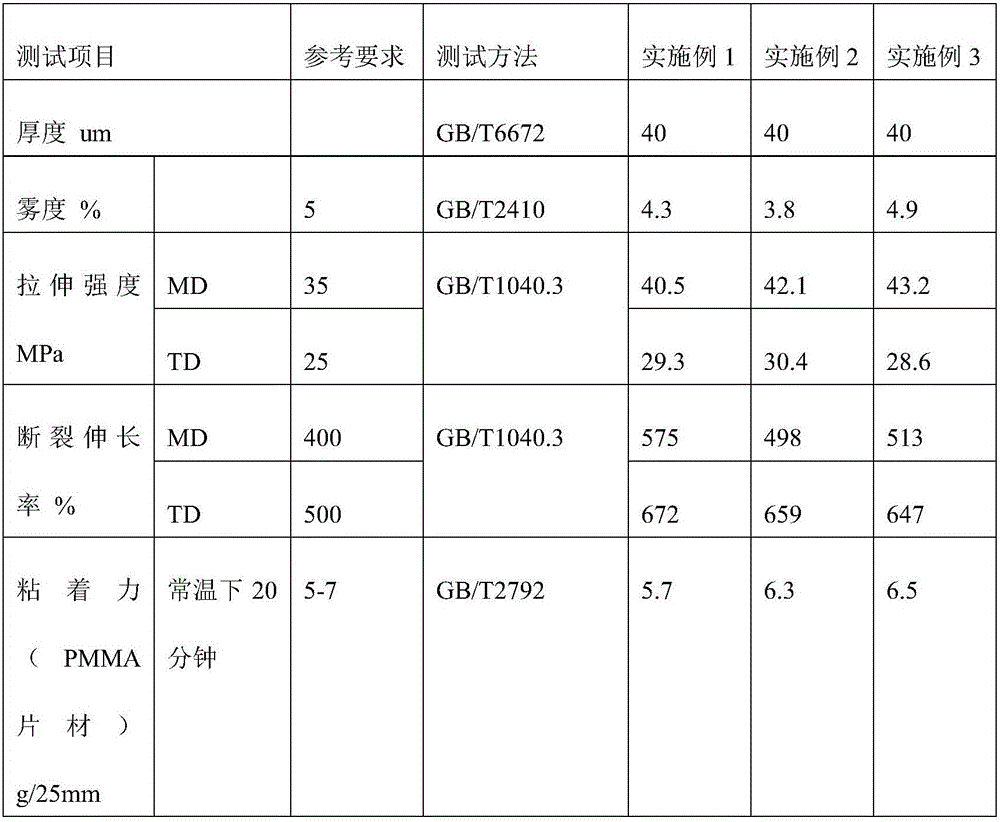

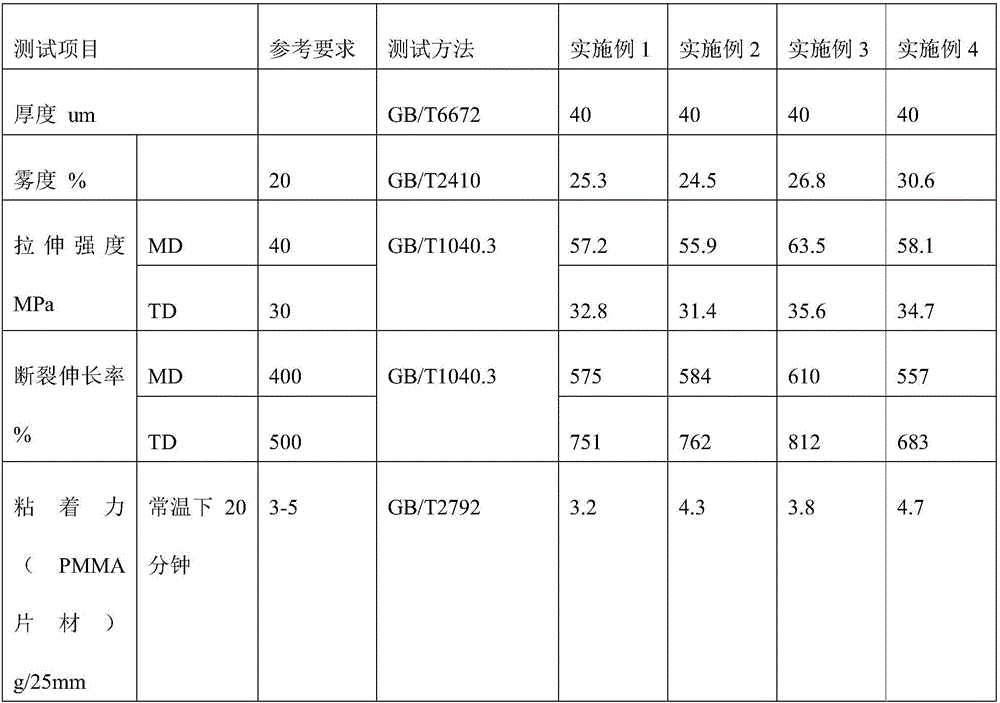

High transparency type self-adhesive surface protection film and manufacturing method thereof

ActiveCN105966024AUniform plasticizationGuaranteed cleanlinessSynthetic resin layered productsFlat articlesLow-density polyethyleneAutomatic control

The invention discloses a high transparency type self-adhesive surface protection film. The protection film comprises a self-adhesive layer, an intermediate layer and an anti-sticking layer, wherein the self-adhesive layer comprises ultra low density polyethylene and flexible polypropylene; the intermediate layer is prepared by high-transparency copolymerized polypropylene, and the anti-sticking layer is prepared by a ethylene-propylene random copolymer. The invention also discloses a method for manufacturing the high transparency type self-adhesive surface protection film. The method comprises the following steps in order: dedusting of raw materials, automatic weighing and metering of raw materials, heating and extrusion, high-efficiency filtering, co-extrusion and film formation, cooling and sizing, automatic gauge control, defect detection, trimming and rolling, aging treatment, and cutting and packaging. The high transparency type protection film has the characteristics of few fish-eyes, good self-adhesion, and high transparency. The film can be widely applied to surface protection fields of transparent optical sheet materials, high gloss paint surface, and other products.

Owner:永新股份(黄山)包装有限公司

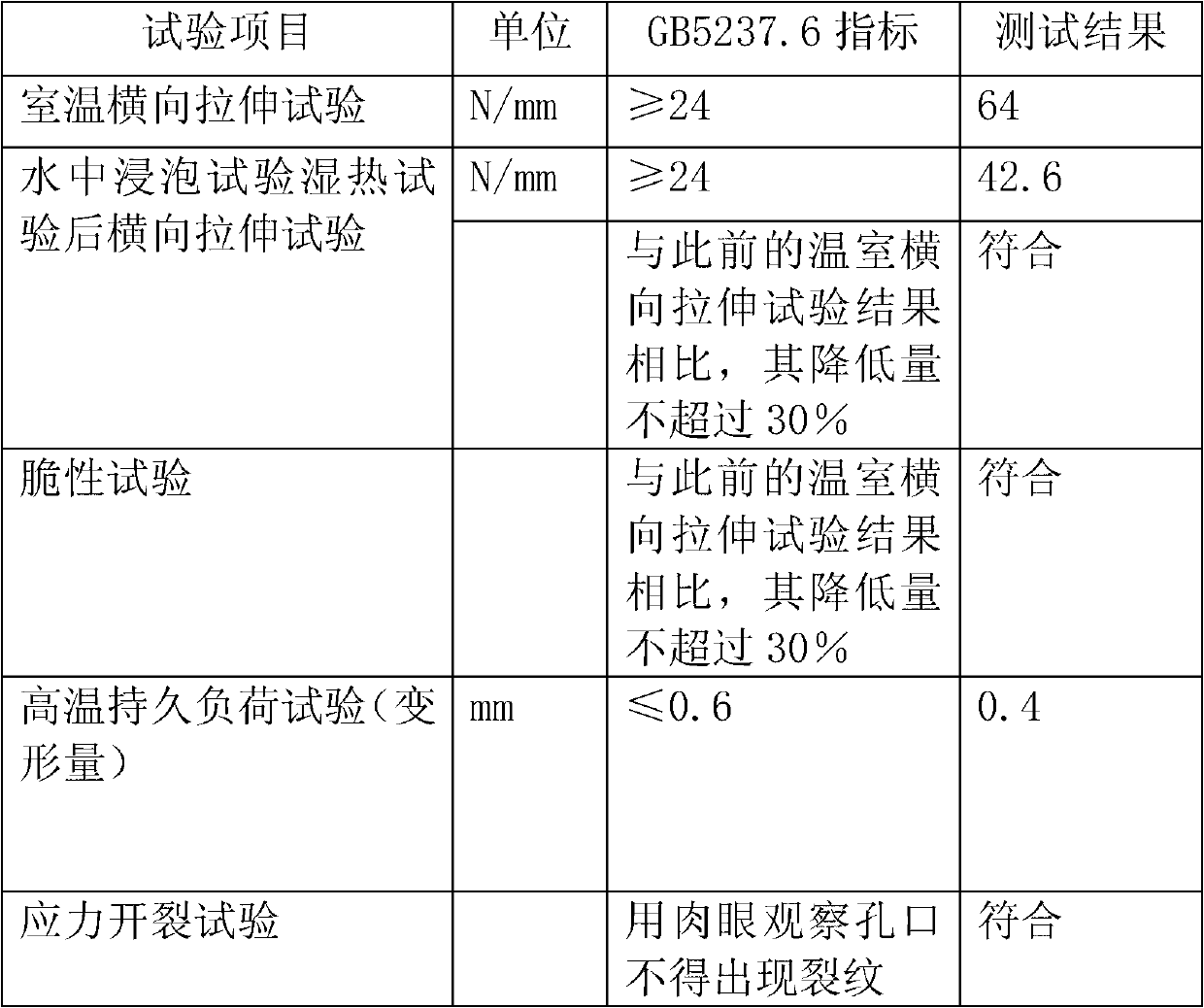

Bar inserting type heat insulation section material and preparation method thereof

InactiveCN102731932AComply with national standard performance requirementsExcellent processing and exterior decorationNylon 66Engineering

The invention discloses a bar inserting type heat insulation section material. Raw materials for the section material comprise polyvinyl chloride, high-heat-resistant resin, an impact modifier, a heat stabilizer, a lubricant, a processing aid, an anti-oxidant and a filler. The invention also discloses a preparation method for the bar inserting type heat insulation section material. The bar inserting type heat insulation section material provided in the invention is a novel environment-friendly material and can be used as a heat insulation section material to substitute imported glass fiber reinforced nylon 66. According to the invention, through the procedures of tooth punching, bar inserting and rolling, a bar-like heat insulation material is inserted into a bar inserting groove of an aluminum alloy section and is made to be firmly engaged with the aluminum alloy section, and performances of the bar inserting type heat insulation section material fully satisfy national standard performance requirements on heat insulation sections.

Owner:成都新兴富皇高分子材料科技有限公司

Decorative PVC (Polyvinyl Chloride) film

The invention discloses a decorative PVC (Polyvinyl Chloride) film. The decorative PVC film is prepared from the following raw materials in parts by weight: PVC440 resin powder, nano-tic, chitosan-grafted polyacrylic acid, polyoxyethylene sorbitan monostearate, tetrabutyl titanate, ethyl stearate, stearyl clcohol, titanium bis(triethanolamine)diisopropoxide, saturated fatty alcohol multiple carboxylic ester, sodium antimonate, zinc chromate, plasticizer, stabilizer and antioxidant. Through reasonable combination in a formula, the obtained decorative PVC film has the advantages of aging resistance, high toughness, good thermal stability and high flame resistance. Meanwhile, the decorative PVC film further has the characteristic of acid and alkali resistance.

Owner:黄山豪泰塑胶有限公司

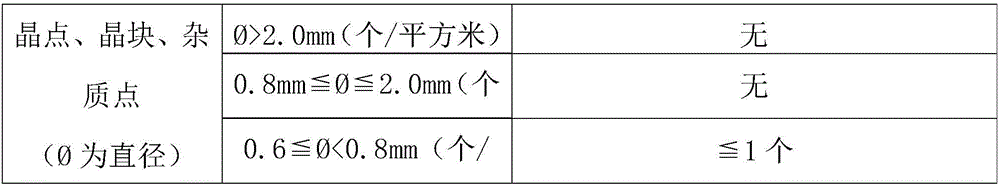

Extinction type self-adhesive surface protection film and manufacturing method thereof

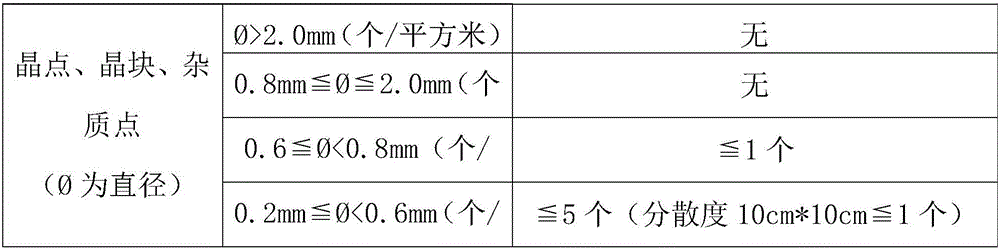

ActiveCN105966025AThe number of crystal points on the film surface is smallGood matting performanceSynthetic resin layered productsLaminationAutomatic controlPolypropylene

The invention discloses an extinction type self-adhesive surface protection film. The protection film comprises a self-adhesive layer, an intermediate layer and an anti-sticking layer, wherein the self-adhesive layer comprises ultra low density polyethylene which is used as a main material, and one or two materials which are selected from a copolymer of ethylene and methyl acrylate as well as flexible polypropylene; the intermediate layer comprises an ethylene-propylene copolymer with few fish-eyes or the ethylene-propylene copolymer with few fish-eyes and polyethylene; the anti-sticking layer comprises polypropylene and high density polyethylene or an extinction master batch. The invention also discloses a method for manufacturing the extinction type self-adhesive surface protection film. The method comprises the following steps in order: dedusting of raw materials, automatic weighing and metering of raw materials, heating and extrusion, high-efficiency filtering, co-extrusion and film formation, cooling and sizing, automatic gauge control, trimming and rolling, and cutting and packaging. The extinction type protection film has few fish-eyes and good self-adhesion, and residual adhesive or shadows are not remained on the surface of the products to be protected. The film can be widely applied to surface protection fields of optical sheet materials, household electrical appliances, electronic products, stainless steel and other products.

Owner:永新股份(黄山)包装有限公司

Calcium-zinc stabilizer for PVC, and preparation method thereof

The invention relates to a calcium-zinc stabilizer for PVC, and a preparation method thereof. The calcium-zinc stabilizer is prepared from, by mass, 5-7 parts of calcium stearate, 14-16 parts of zincstearate, 15-16 parts of zeolite, 5.5-6.5 parts of zinc laurate, 5-6 parts of a lubricant, 3.5-5 parts of beta-diketone, 1.5-2.5 parts of an antioxidant, 3-4 parts of 1,3-dimethyl-6-aminouracil, 3-4 parts of an ultraviolet light absorber and 4-5 parts of lanthanum maleamate. The 1,3-dimethyl-6-aminouracil is used for replacing unstable chlorine atoms in the PVC, so the stability of PVC is improved, and the color change phenomenon of PVC is reduced; and the lanthanum maleamate is used to solve problem of zinc burning of PVC containing the calcium-zinc stabilizer in the using process, so the good effect of inhibiting zinc burning is achieved.

Owner:惠州市兴邦新材料科技有限公司

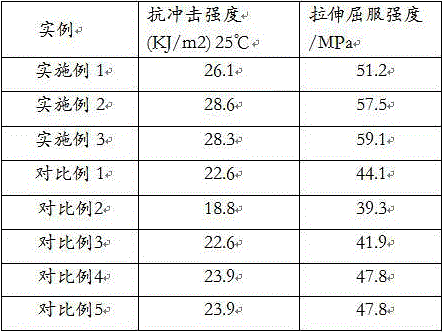

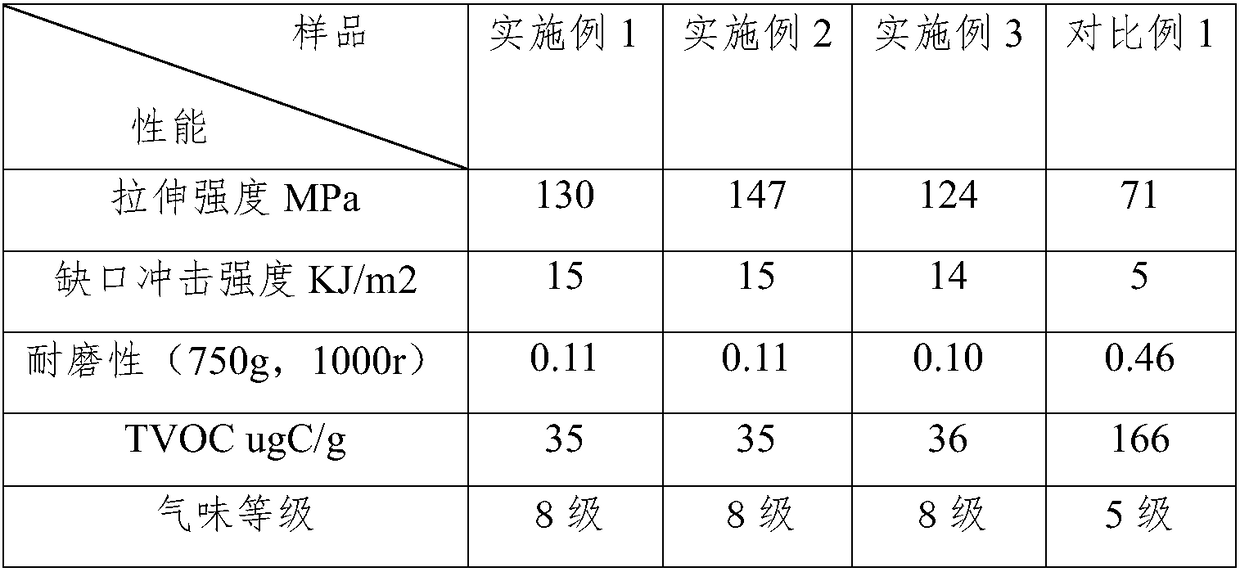

Modified nylon composition and preparation method thereof

The invention provides a modified nylon composition and a preparation method thereof, and relates to the technical field of macromolecular materials. The modified nylon composition is prepared from the following raw materials: nylon 6, nylon 66, POE grafted maleic anhydride, polytetrafluoroethylene modified glass fibers, an odor adsorption masterbatch, silicon carbide, a lubricant and an antioxidant. The modified nylon composition has the characteristics of low odor and good wear resistance. The nylon composition prepared by coordinating action of the raw materials has remarkable improvement in wear resistance and keeps excellent mechanical properties, and the forming and processing properties of the material are not affected.

Owner:HEFEI GENIUS NEW MATERIALS

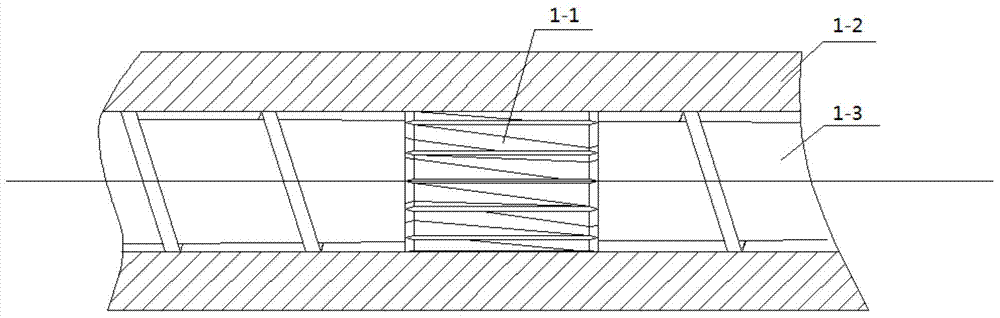

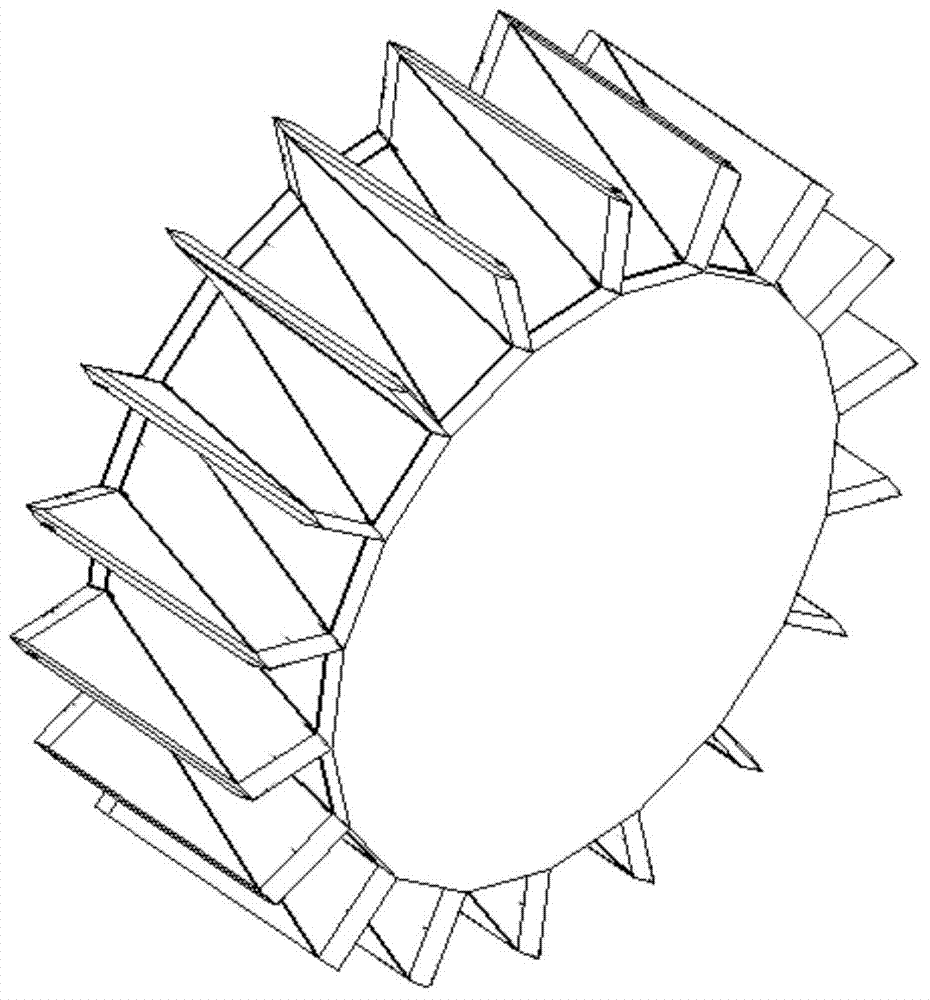

Polymer melt calculus heat transfer enhancement and mixing plasticization extruder

The invention discloses a polymer melt calculus heat transfer enhancement and mixing plasticization extruder. The polymer melt calculus heat transfer enhancement and mixing plasticization extruder mainly comprises a charged material plasticizing part, a heating and cooling part, a control system, a drive system and the like; the structures and the connection modes of the charged material plasticizing part, the heating and cooling part, the control system and the drive system are as the same as those of a common extruder; a screw rod of the charged material plasticizing part is provided with a mixing section which is provided with axial cutting edges (or forms an angle with the axial direction) with n equal divisions along the peripheral direction; adjacent cutting edges are parallel mutually; 90-degree torsional curve surfaces are additionally arranged in inner surfaces among the cutting edges, namely distributary torsion convergence sections. In the extruder provided by the invention, polymer melts rotate along with screws as well as twist by 90 degrees along the inner surfaces of the cutting grooves under the relative motion of the screws and machine barrels, so that the heat of the machine barrels is transmitted successively via each surface of the melts to enforce convection, and the heat transfer intensification and plasticization effects are achieved; additionally, the melts in the cutting grooves are subjected to distributary torsion convergence, and are mixed fully, so that the mixing effect is improved.

Owner:BEIJING UNIV OF CHEM TECH

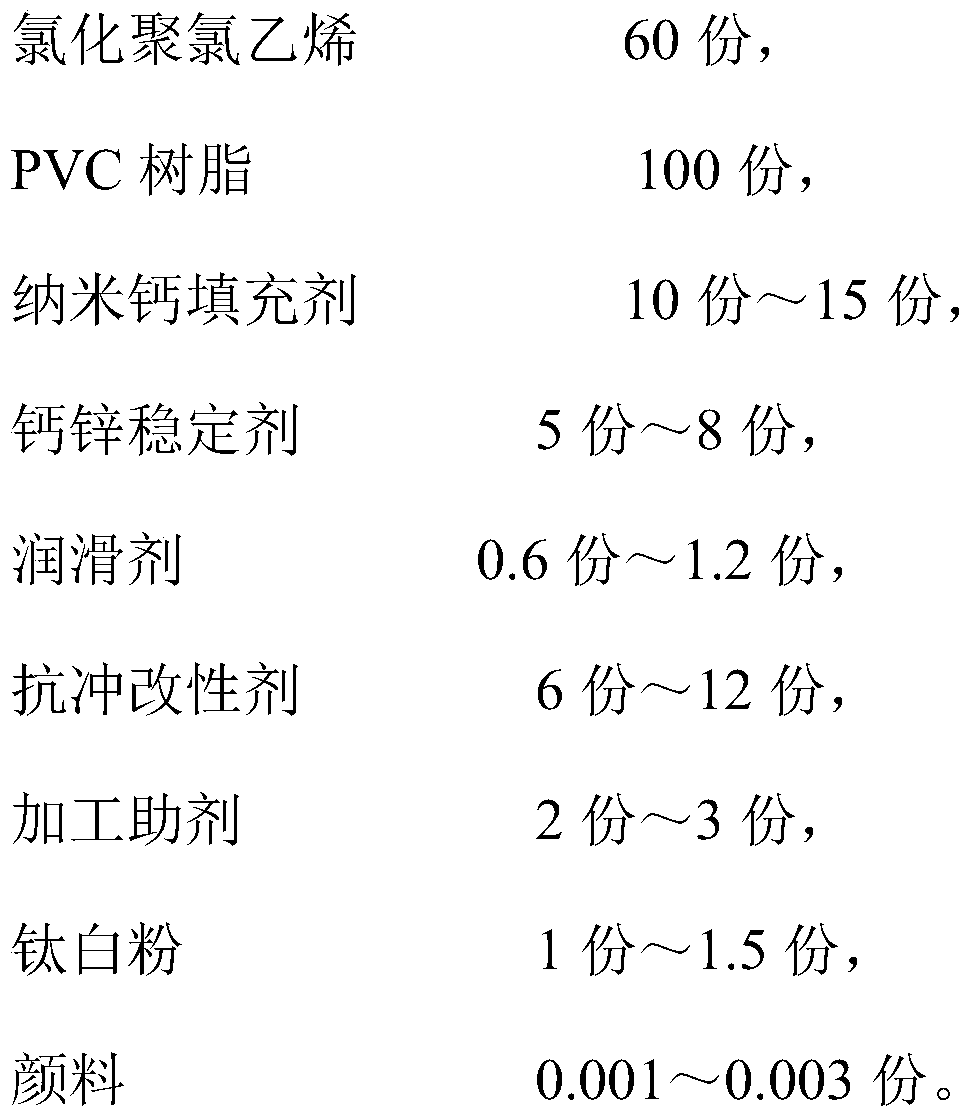

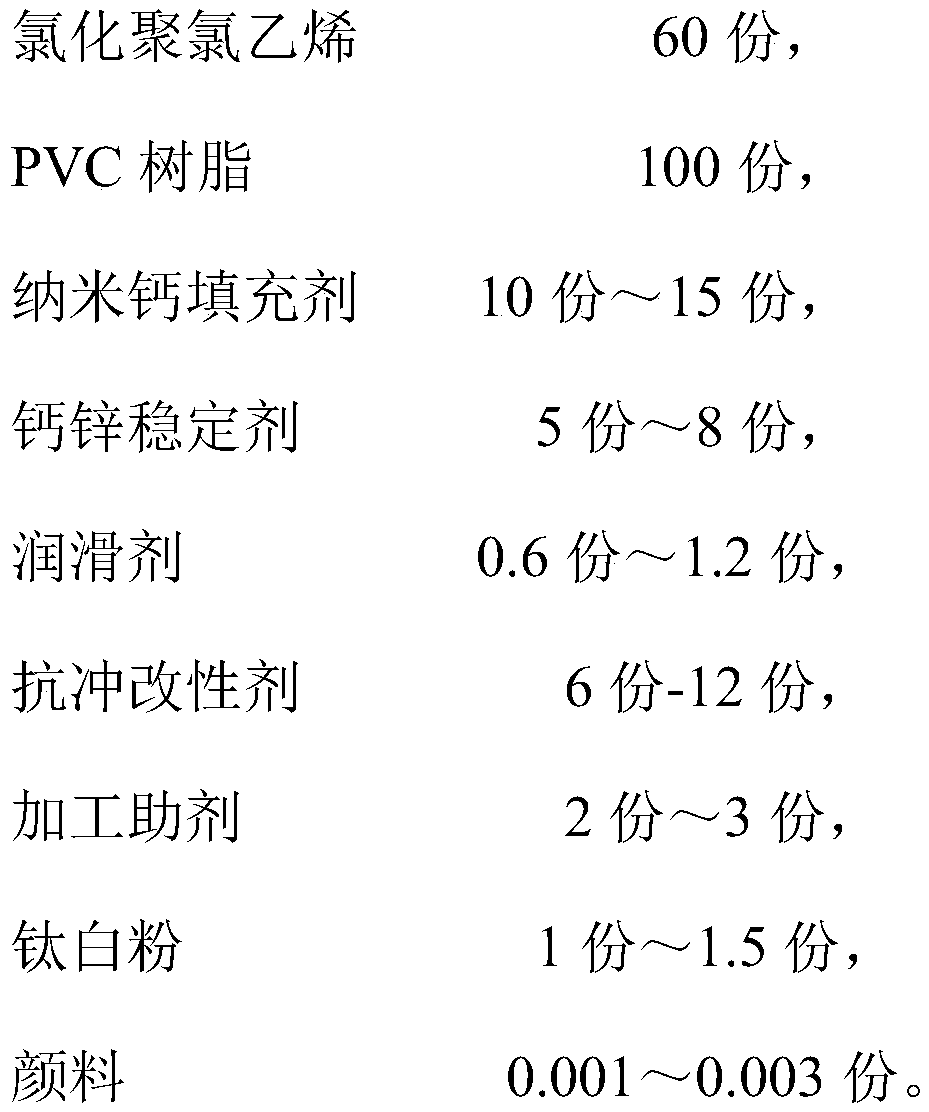

PVC heat-resistant pipe and preparation method thereof

InactiveCN111117114AImprove insulation performanceEfficient weather resistancePolymer scienceChlorinated polyvinyl chloride

The invention discloses a PVC heat-resistant pipe and a preparation method thereof. The PVC heat-resistant pipe is prepared from the following components in parts by mass: 60 parts of chlorinated polyvinyl chloride, 100 parts of PVC resin, 10-15 parts of nano calcium filler, 5-8 parts of calcium-zinc stabilizer, 0.6-1.2 parts of lubricant, 6-12 parts of anti-impact modifier, 2-3 parts of processing aid, 1-1.5 parts of titanium dioxide and 0.001-0.003 part of pigment. According to the formula, the components are properly selected, compatibility is reasonable, and the prepared PVC pipe is excellent in comprehensive performance in all aspects and particularly high in heat resistance.

Owner:SHANGHAI SHANGSU HLDG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com