PVC heat-resistant pipe and preparation method thereof

A technology of heat-resistant pipes and mass fractions, applied in the field of plastic processing, can solve the problems of insufficient heat resistance of PVC pipes, achieve the effects of shortening plasticizing time, improving impact strength and toughness, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

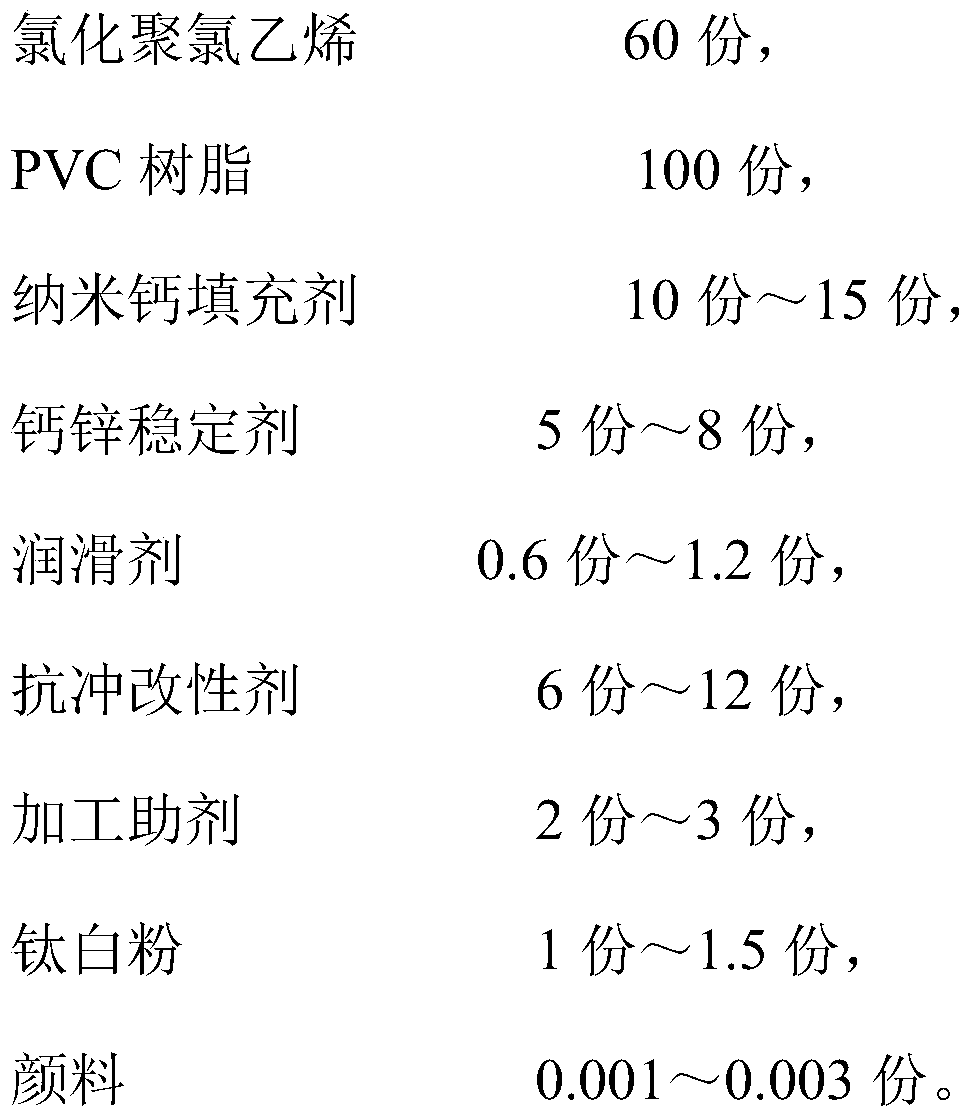

[0024] formula:

[0025]

[0026] Preparation:

[0027] Step 1: Weigh various raw materials according to the mass parts in the formula.

[0028] Step 2: Put other raw materials except the impact modifier into a high-speed mixer, and stir at a speed of 600 rpm for 5 minutes to make them fully stirred and mixed evenly.

[0029] Step 3: Add the impact modifier into the high-speed mixer again, and continue to stir at 300 rpm for 25 minutes to obtain a uniformly mixed blend.

[0030] Step 4: Put the homogeneously mixed blend into the extruder, plasticize and extrude at a temperature of 160°C.

[0031] Step 5: After cooling, solidifying and shaping, the PVC heat-resistant pipe is obtained.

Embodiment 2

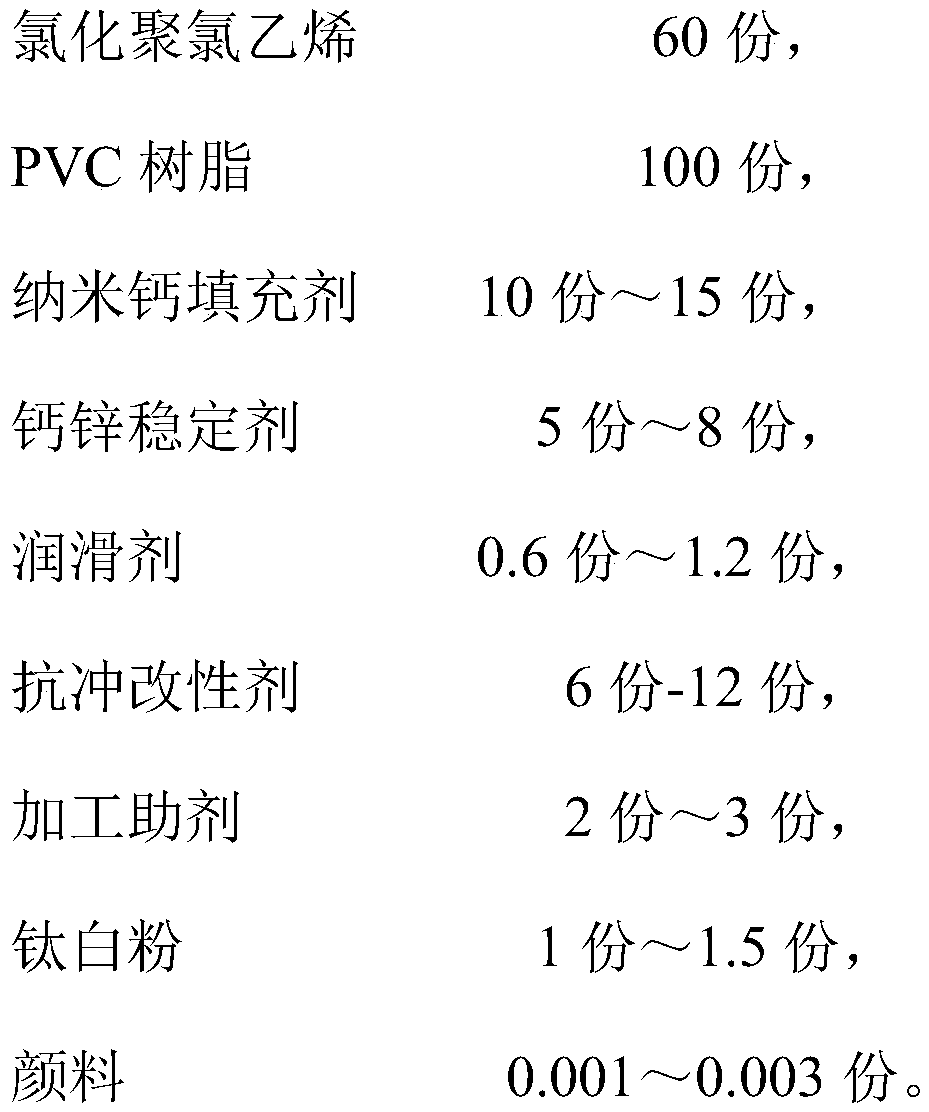

[0033] formula:

[0034]

[0035] Preparation:

[0036] Step 1: Weigh various raw materials according to the mass parts in the formula.

[0037] Step 2: Put other raw materials except the impact modifier into a high-speed mixer, and stir at a speed of 400 rpm for 10 minutes to make them fully stirred and mixed evenly.

[0038] Step 3: Add the impact modifier into the high-speed mixer again, and continue to stir at 450 rpm for 20 minutes to obtain a uniformly mixed blend.

[0039] Step 4: Put the homogeneously mixed blend into the extruder, plasticize and extrude at a temperature of 180°C.

[0040] Step 5: After cooling, solidifying and shaping, the PVC heat-resistant pipe is obtained.

Embodiment 3

[0042] formula:

[0043]

[0044] Preparation:

[0045] Step 1: Weigh various raw materials according to the mass parts in the formula.

[0046] Step 2: Put other raw materials except the impact modifier into a high-speed mixer, and stir for 15 minutes at a speed of 500 rpm to make them fully stirred and mixed evenly.

[0047] Step 3: Add the impact modifier to the high-speed mixer again, and continue to stir for 30 minutes at a speed of 350 rpm to obtain a well-mixed blend.

[0048] Step 4: Put the homogeneously mixed blend into the extruder, plasticize and extrude at a temperature of 220°C.

[0049] Step 5: After cooling, solidifying and shaping, the PVC heat-resistant pipe is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com