Patents

Literature

75 results about "PENTAERYTHRITYL TETRASTEARATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

About PENTAERYTHRITYL TETRASTEARATE: Pentaerythrityl Tetrastearate is a tetraester of pentaerythritol and stearic acid. Function(s): Binder; Skin-Conditioning Agent - Occlusive; Viscosity Increasing Agent - Nonaqueous; EMOLLIENT; VISCOSITY CONTROLLING.

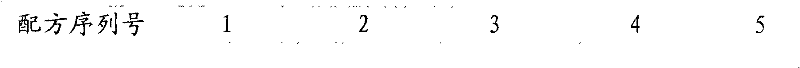

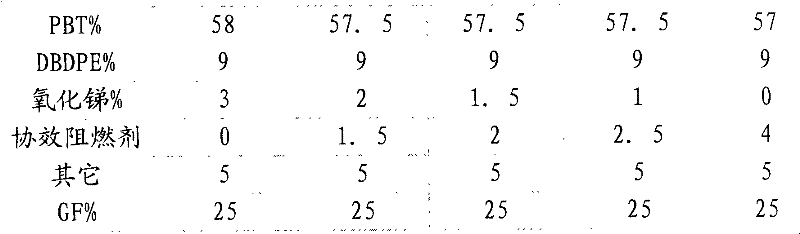

Novel environment-friendly synergistic flame retardant and preparation method thereof

The invention relates to an environment-friendly low-cost flame-retardant aid which is added into an organic synthetic material and a preparation method thereof. The synergistic flame retardant comprises the following components in percentage by weight: 10 to 15 percent of nanometer silicon dioxide, 70 to 80 percent of magnesium oxide, 3 to 5 percent of alumina, 1 to 2 percent of silane coupling agent, and 1 to 8 percent of pentaerythritol tetrastearate. The preparation method comprises the following steps of: 1, performing coating treatment on the silane coupling agent and the nanometer silicon dioxide by using organosilicon, wherein the treatment time is 2 to 3 hours; and 2, crushing the nanometer silicon dioxide which is subjected to coating treatment and other components, and mixing to form an uniform mixture. The flame-retardant aid can partially substitute antimony oxide in a halogen and antimony flame-retardant system, can ensure that materials have good flame-retardant properties, and reduces the total cost of material products at the same time; and the preparation method is simple.

Owner:GUANGZHOU QIYUAN CHEM

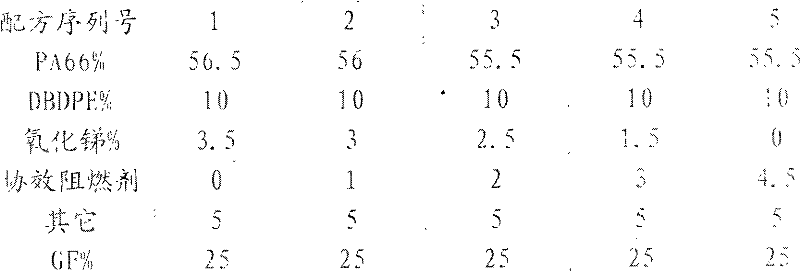

PVC compound stabilizer and preparation method

The invention provides a PVC compound stabilizer. The PVC compound stabilizer is characterized by being composed of, by mass, 85-90% of a main stabilizing agent and 5-15% of a subsidiary stabilizing agent; the main stabilizing agent is composed of polyvinylpyrrolidone, bis(5-oxo-L-prolinato-N1,O2) zinc, calcium disodium ethylenediamine tetraacetate and titanium tetraisopropanolate, and the subsidiary stabilizing agent is composed of N,N-ethylene bis-stearamide, pentaerythrityl tetrastearate, epoxidized linseed oil and mannitol. The invention further discloses a preparation method of the PVC compound stabilizer. The PVC compound stabilizer has the advantages of being free of toxin, environmentally friendly, good in lubricity and the like, is high in thermal stability, high in transparency, high in impact resistance and high in profile welded corner strength, can reduce damage to PVC molecules caused by ultraviolet light, improve outdoor aging performance of a product and further has good internal and external lubricating properties, and processing can be conducted stably.

Owner:SHENZHEN AIMSEA IND

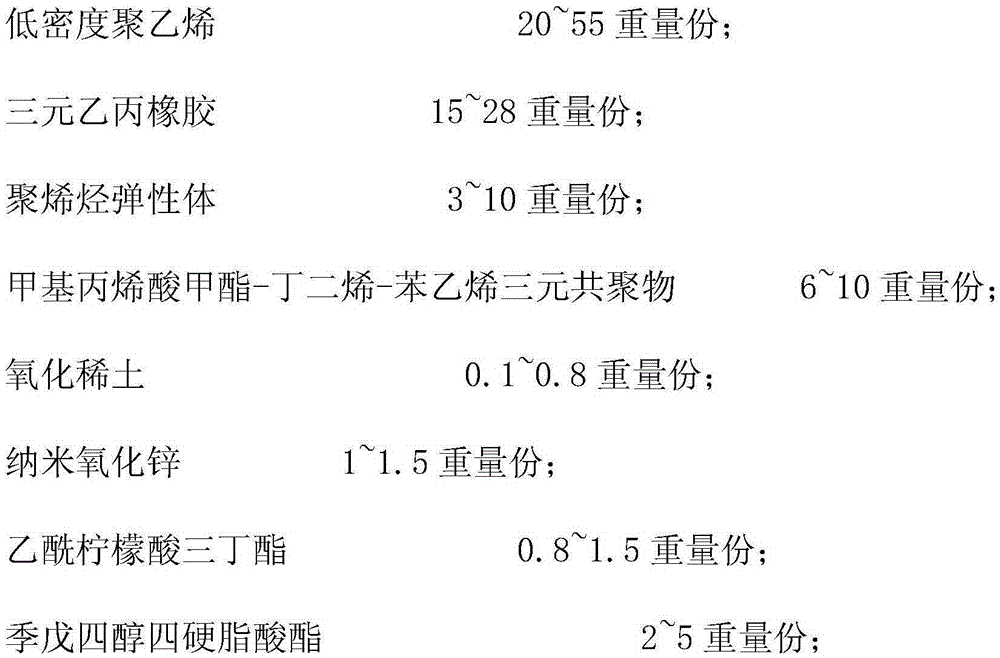

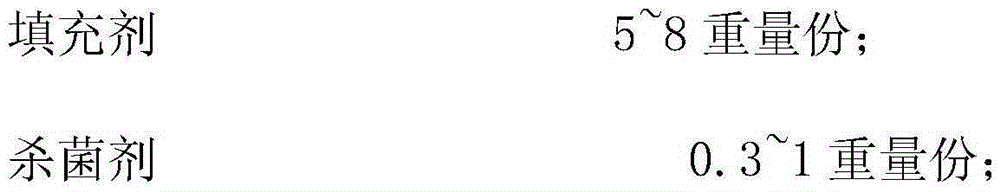

Antibacterial and mildewproof rubber-plastic shoe material and preparation method thereof

InactiveCN105400039AGuaranteed mechanical strengthGuaranteed heat resistanceInsolesLow-density polyethyleneElastomer

The invention discloses an antibacterial and mildewproof rubber-plastic shoe material. The antibacterial and mildewproof rubber-plastic shoe material comprises the following components: low density polyethylene, an ethylene-propylene-diene monomer, a polyolefin elastomer, a methyl methacrylate-butadiene-phenethylene terpolymer, rare earth oxide, nanometer zinc oxide, acetyl tributyl citrate, pentaerythrityl tetrastearate, calcium carbonate and a fungicide adopting a microcapsulate structure, wherein the particle size range of the microcapsulate structure is 10-100 microns, the ratio of a wall material to a sandwich layer is 1: (15-22), the sandwich layer is composite powder, and the wall material is polyester film. A shoe material prepared from the material provided by the invention is excellent in antibacterial and mildewproof effect, lasting in antibacterial effect, and long in effect time.

Owner:吴江市风尚鞋厂

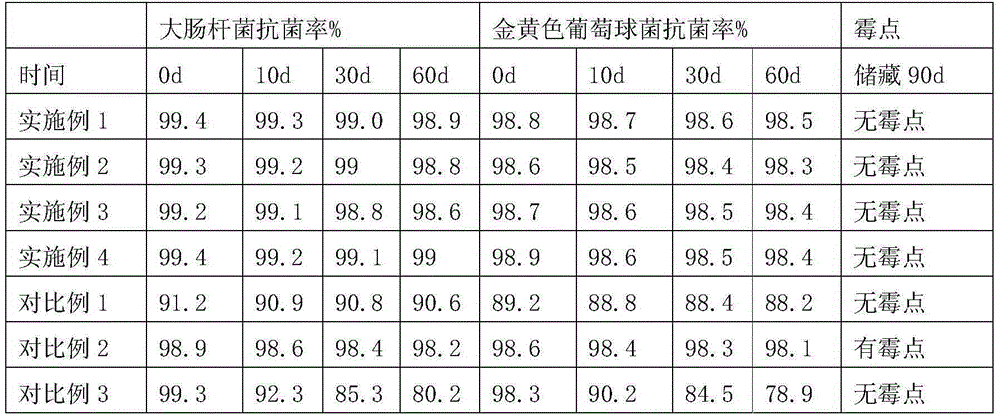

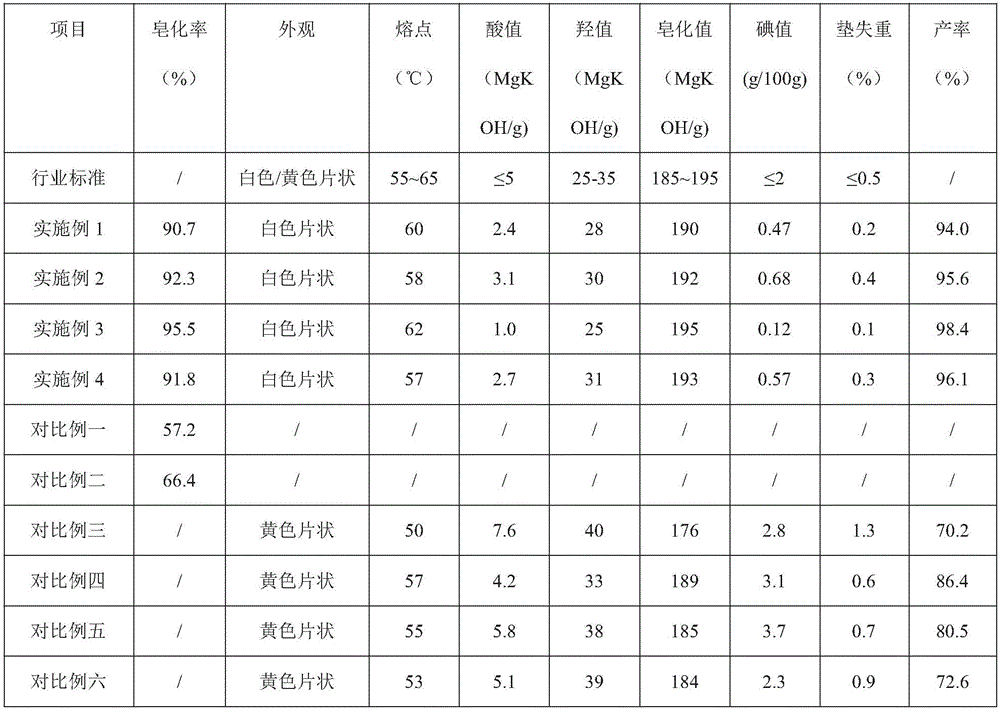

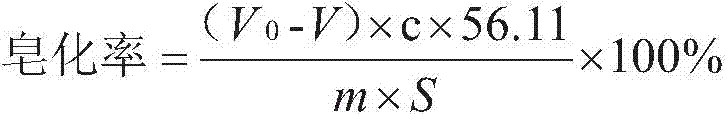

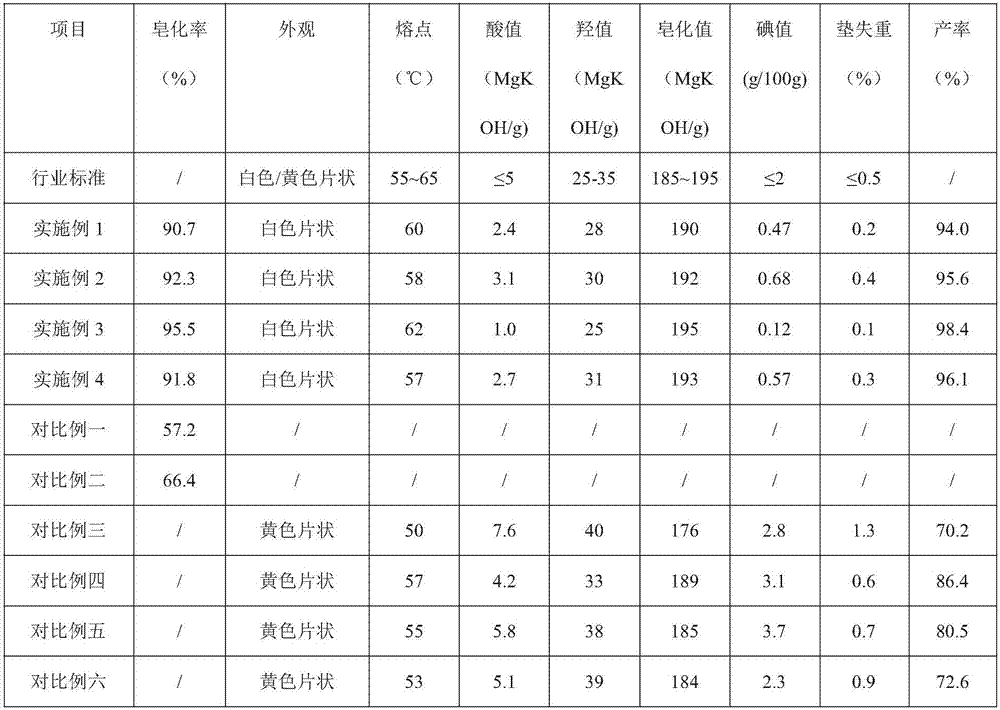

Method for preparing pentaerythritol stearate from hydrogenated oil

ActiveCN105753698AHigh saponification rateHigh acid valuePreparation from carboxylic acid saltsOrganic compound preparationDistillationStearic acid

The invention discloses a method for preparing pentaerythritol stearate from hydrogenated oil.The method includes the following steps that S1, a sodium hydroxide solution is added to hydrogenated palm oil, microwave processing is conducted, a reaction is conducted under stirring, and saponified matter is obtained; S2, a sulfuric acid solution is added to the saponified matter till the pH value is 1 to 2, the material is transferred into a distillation tower, and stearic acid is obtained after distillation is completed; S3, stearic acid, pentaerythritol and a catalyst are put, the material is heated, negative pressure is controlled, and a reaction is conducted; S4, then the vacuum degree is increased to 0.07-0.09 mpa, the material is heated to 155-165 DEG C, and a reaction is conducted for 130-150 min under heat preservation at constant pressure; S5, cooling is conducted after an esterification condensation reaction is completed, kieselguhr is added for decoloration and deordorization, the material enters a plate-and-frame filter press, filter cakes are removed, filtrate is taken and subjected to powder spraying, bead spraying and slicing, and packaging and storage are conducted.The method is stable, reliable, high in yield and capable of achieving industrial production, and the prepared pentaerythrityl tetrastearate product is good in whiteness, low in acid value and high in purity.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

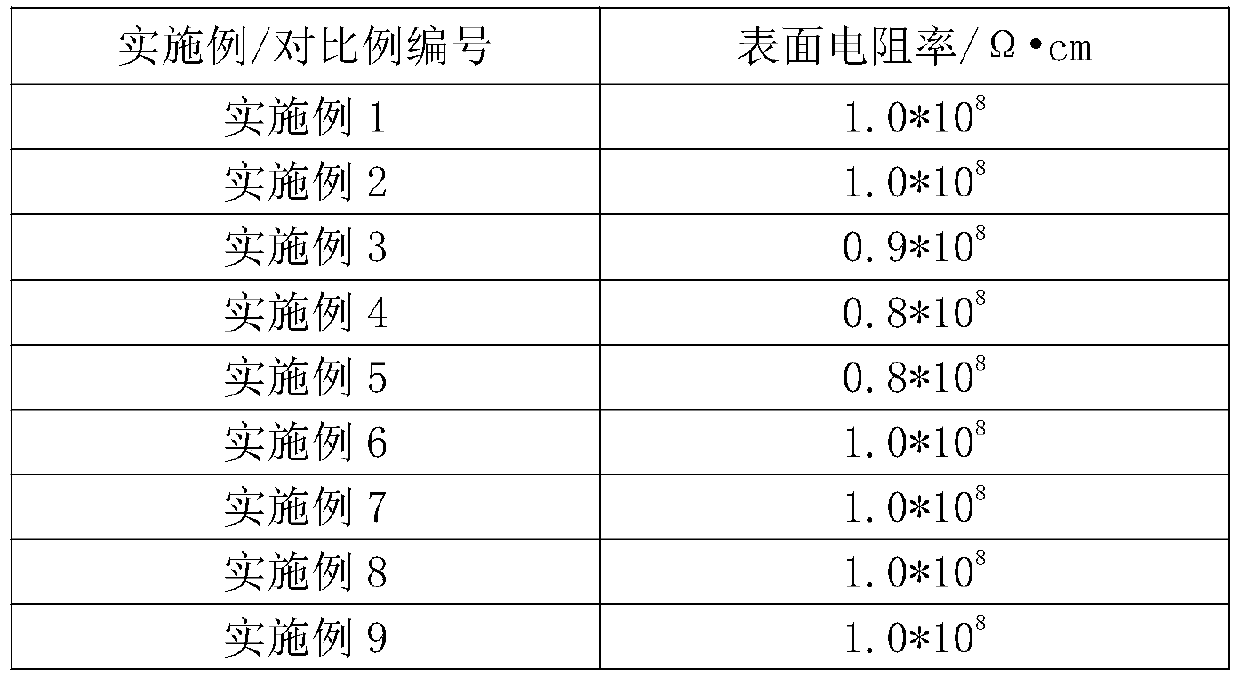

PET color master batch and preparation method thereof

InactiveCN109836785AReduce surface frictionImprove wear resistanceAntistatic agentPolyethylene terephthalate

The invention discloses a PET color master batch and a preparation method thereof, and relates to the technical field of plastic master batches. The PET color master batch comprises the following components in parts by mass: 70-90 parts of PET (polyethylene terephthalate); 10-20 parts of pentaerythritol tetrastearate; 10-20 parts of IncroMax 100 slipping agent; 1-3 parts of a dispersing agent and2-4 parts of an antistatic agent. The PET color master batch has the advantages of reducing friction force on the surface of a material and resisting static electricity.

Owner:厦门毅兴行塑胶原料有限公司

Plastic lubricant and preparation method thereof

Belonging to the technical field of plastics, the invention in particular relates to a plastic lubricant and a preparation method thereof. The plastic lubricant provided by the invention is prepared from the following raw materials: 100-120 parts of glyceryl tristearate, 60-80 parts of pentaerythrityl tetrastearate and 30-50 parts of polyethylene. The plastic lubricant provided by the invention can effectively improve plastic lubricity, reduce friction and lower the interface adhesion performance, improves fluidity and demoulding properties in plastic processing and the like, prevents the formation of fisheyes and other defects due to adhesion in a machine or mold, at the same time, the raw material cost is low, and the preparation method is simple.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

Enhanced polycarbonate extrusion grades

The present disclosure relates to thermoplastic compositions, methods of making thermoplastic compositions, and articles made from thermoplastic compositions. The disclosed compositions comprise a polycarbonate polymer and a triacylglyceride release agent. In an embodiment, a thermoplastic composition comprising: a melt polycarbonate polymer; and 0.01 to 0.05 weight percent of a release agent based on the total weight of the composition, wherein the release agent comprises triacylglyceride, and wherein the composition is free of stearyl stearate, glycerol monostearate, and pentaerythrityl tetrastearate.

Owner:SABIC GLOBAL TECH BV

Bath salt and preparation method

InactiveCN105687052AFormulation ScienceEasy to prepareCosmetic preparationsToilet preparationsGinkgo bilobaIn vivo

The invention discloses a bath salt, which is mainly prepared from the following raw materials in parts by mass: hazelnut oil 6-14, neroli essential oil 7-11, crystal salt 50-60, hydrolyzed gelatin 4-8, hydroxyl Ethyl urea 5-9, licorice 4-8, Chushi 2-6, fresh rehmannia 6-10, honeysuckle 3-7, ginkgo biloba 4-9, red peony 5-10, rhodiola 6-10, euphemum 6-9, Chuanxiong 3-8, Duhuo 2-7, Forsythia 4-9, Laureth Sulfate Sodium Salt 1-4, Polysorbate 20 1-3, Pentaerythritol Tetraisostearate 2-4. The invention can promote skin metabolism, eliminate body waste, effectively supplement body salt and minerals, promote skin nutrient absorption, rapidly improve skin water retention, and stimulate cell vitality.

Owner:韩存海

Filled and modified PBT powder and preparation method thereof

InactiveCN104845054AImprove mechanical propertiesImprove heat resistanceChemical industryPentaerythritol

The present invention discloses filled and modified PBT powder and a preparation method thereof, wherein the filled and modified PBT powder comprises, by mass, 50-80% of PBT, 5-25% of heavy calcium carbonate, 10-15% of a flame retardant agent, 0.1-0.5% of an aluminum-titanium composite coupling agent, 0.5-2% of a light stabilizer, 0.1-1% of erucylamide, 0.1-1% of pentaerythrityl tetrastearate, and 0.1-0.5% of an antioxidant, wherein the particle size of the heavy calcium carbonate is 0.1-20 [mu]m. The filled and modified PBT powder of the present invention has beneficial effects of good mechanical property, good heat resistance, excellent flame retardant property, good processability, simple preparation method, and cost reducing, can achieve the UL94V-0 grade, and has good practical values and prospects in the fields of electronic apparatuses, chemical industry, machinery and the like.

Owner:QINGDAO WANLI TECH

Polyethylene antistatic powder and preparation method thereof

InactiveCN104844883AGood permanent antistatic performanceImprove liquidityChemical industryAntioxidant

The present invention discloses polyethylene antistatic powder and a preparation method thereof. The polyethylene antistatic powder comprises, by mass, 60-80% polyethylene, 5-15% of glass fibers, 3-10% of a antistatic master batch, 0.5-2% of a light stabilizer, 0.1-1% of a slipping agent, 0.5-1% of pentaerythrityl tetrastearate, and 0.1-1% of an antioxidant, wherein the antistatic master batch comprises 30 wt% of a polyethylene resin, 40 wt% of sodium alkyl benzene sulfonate, 25 wt% of glycerol monostearate, and 5 wt% of ethylenebis(stearamide). The polyethylene antistatic powder of the present invention has beneficial effects of good permanent antistatic property, high mechanical strength, strong aging resistance, good mobility, excellent electrical performance, and the like, can be used in the fields of chemical industry, machinery, electrical apparatuses, pipelines, packaging and the like, and has good use effects.

Owner:QINGDAO WANLI TECH

High-strength two-way drawn polypropylene heat sealing film and preparation method thereof

InactiveCN106273958AEasy to prepareSynthetic resin layered productsLaminationEthyl hydroxybenzoatePolyethylene glycol

The invention discloses a high-strength two-way drawn polypropylene heat sealing film which sequentially comprises an upper layer, a middle layer and a lower layer from top to bottom. The upper layer comprises, by weight, copolymer polypropylene, polyethylene glycol terephthalate, ethylene acrylate copolymer, butyl stearate and synthetic silica; the middle layer comprises, by weight, homopolymer polyethylene, vinyl acrylate copolymer, ethylene glycol distearate, pentaerythrityl tetrastearate, methyl methacrylate, methyl cellulose and titanium dioxide; the lower layer comprises, by weight, polyacrylic acid, ethylene acrylate copolymer, ethyl parahydroxybenzoate and naphthenic acid glycerol ester. The invention further discloses a preparation method of the high-strength two-way drawn polypropylene heat sealing film. The prepared two-way drawn polypropylene heat sealing film is high in strength and can meet market demands.

Owner:HAINING CHANGKUN PACKAGING

High modulus carbon fiber modified polyethylene composite material

The present invention discloses a high modulus carbon fiber modified polyethylene composite material, which comprises, by mass, 80-90% of polyethylene, 5-15% of surface modified carbon fibers, 2-5% of nanometer talc powder, 1-3% of a styrene-maleic anhydride random copolymer, 0.1-0.5% of a silane coupling agent, 0.1-0.5% of an antioxidant 1010, 0.1-0.5% of an antioxidant 168, and 0.1-1% of pentaerythrityl tetrastearate, wherein the surface modified carbon fibers are carbon fibers with the surface treated by polyacrylonitrile. The high modulus carbon fiber modified polyethylene composite material of the present invention has beneficial effects of high strength, high modulus, high heat resistance, good dispersion, strong environmental stress resistance, and the like, and provides good prospects and economic benefits in the industries of electrical apparatuses, chemical industry, medicine, machinery and the like.

Owner:QINGDAO WANLI TECH

Smooth color master batch for PTT film

The invention discloses a smooth color master batch for a PTT film. The smooth color master batch comprises the following ingredients, by weight, 30%-80% of PTT resins, 2%-10% of antiblocking agent, 10%-30% of smooth agents, 0.1%-10% of pigments, 0.1%-1% of coupling agents, 0.5%-3% of dispersants, 5%-20% of PETG and 2%-10% of MBS. The antiblocking agent is lightweight synthetic silica with a particle size of 1-4 micrometers. The smooth agents are one or some selected from oleamide, erucamide, calcium stearate and pentaerythritol tetrastearate. The beneficial effects are that the smooth color master batch is applied in PTT film production, advantages of good impact resistance, excellent heat resistant stability, uniform coloring, good smooth effects, convenient usage, strong adaptability and the like are achieved, the PTT film performances and production environments are improved greatly, and the application effects are raised.

Owner:QINGDAO XINZHAN PLASTIC

Modified special material for manufacturing flame-retardant turnover box and preparation method of modified special material

The invention discloses a modified special material for manufacturing a flame-retardant turnover box and a preparation method of the modified special material. The modified special material is prepared from the following raw materials according to a ratio in parts by weight: HDPP, PVC resin, polyisoprene, pentaerythrityl tetrastearate, polyisobutene, PP-g-ST, polytetrafluoroethylene, glass fibers, ethylene glycol butyl ether, anhydrous calcium chloride, ethylene glycol, dioctyl adipate, activated calcium carbonate, titanium iso-propylate, hydroxypropyl methyl cellulose, a toughening agent, triphenyl phosphate, trimethylolpropane, a coupling agent, epoxy fatty acid butyl ester and chlorinated paraffin. According to the modified special material disclosed by the invention, the modification is performed by adding auxiliary components, and the flame resistance of products is improved to a larger extent on the premises that the properties of other materials are not influenced, and the cost is not increased; the modified special material obtained by the preparation method is good in toughness, and resistant to impact and facilitates processing of the turnover box with good flame retardance and the added values of the products are increased. With the adoption of the method disclosed by the invention, not only are qualified finished products effectively prepared, but also the operation process is very simple, and the mass production is facilitated.

Owner:SUZHOU DINGLI PACKAGING

A kind of method utilizing hydrogenated oil to prepare pentaerythritol stearate

ActiveCN105753698BHigh saponification rateHigh acid valuePreparation from carboxylic acid saltsOrganic compound preparationDistillationStearic acid

The invention discloses a method for preparing pentaerythritol stearate from hydrogenated oil.The method includes the following steps that S1, a sodium hydroxide solution is added to hydrogenated palm oil, microwave processing is conducted, a reaction is conducted under stirring, and saponified matter is obtained; S2, a sulfuric acid solution is added to the saponified matter till the pH value is 1 to 2, the material is transferred into a distillation tower, and stearic acid is obtained after distillation is completed; S3, stearic acid, pentaerythritol and a catalyst are put, the material is heated, negative pressure is controlled, and a reaction is conducted; S4, then the vacuum degree is increased to 0.07-0.09 mpa, the material is heated to 155-165 DEG C, and a reaction is conducted for 130-150 min under heat preservation at constant pressure; S5, cooling is conducted after an esterification condensation reaction is completed, kieselguhr is added for decoloration and deordorization, the material enters a plate-and-frame filter press, filter cakes are removed, filtrate is taken and subjected to powder spraying, bead spraying and slicing, and packaging and storage are conducted.The method is stable, reliable, high in yield and capable of achieving industrial production, and the prepared pentaerythrityl tetrastearate product is good in whiteness, low in acid value and high in purity.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

PBT powder with characteristics of high toughness, high strength and high fire retardation

InactiveCN104845059AImprove impact toughnessHigh mechanical strengthChemical industryMixed materials

The present invention discloses a PBT powder with characteristics of high toughness, high strength and high fire retardation, wherein the PBT powder comprises, by mass, 55-80% of PBT, 10-15% of a composite filler, 8-15% of a composite fire retardation agent, 3-8% of a toughening agent, 0.5-2% of an anti-aging agent, 0.1-1% of erucylamide, 0.1-1% of pentaerythrityl tetrastearate, and 0.1-0.5% of an antioxidant, wherein a mixed material comprising heavy calcium carbonate and precipitated barium sulfate according to a mass ratio of 2:1 is subjected to an aluminum titanium composite coupling agent activation treatment so as to obtain the composite filler. The PBT powder of the present invention has beneficial effects of high impact resistance toughness, high mechanical strength, high fire retardation, good processability, strong aging resistance, excellent electrical property, excellent heat resistance, excellent corrosion resistance, and good application prospects, and can be used in the application fields of vehicles, chemical industry, machinery, electrical apparatuses, and the like.

Owner:QINGDAO WANLI TECH

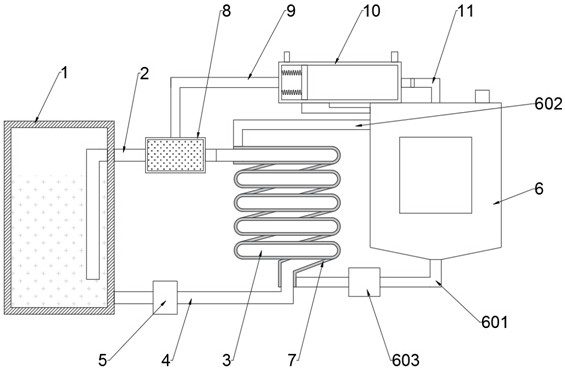

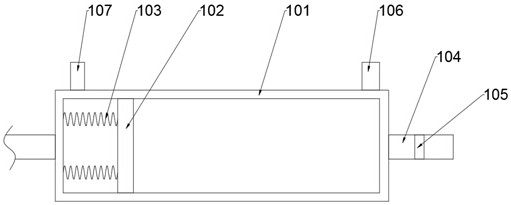

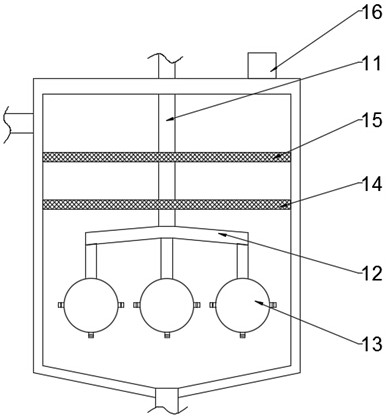

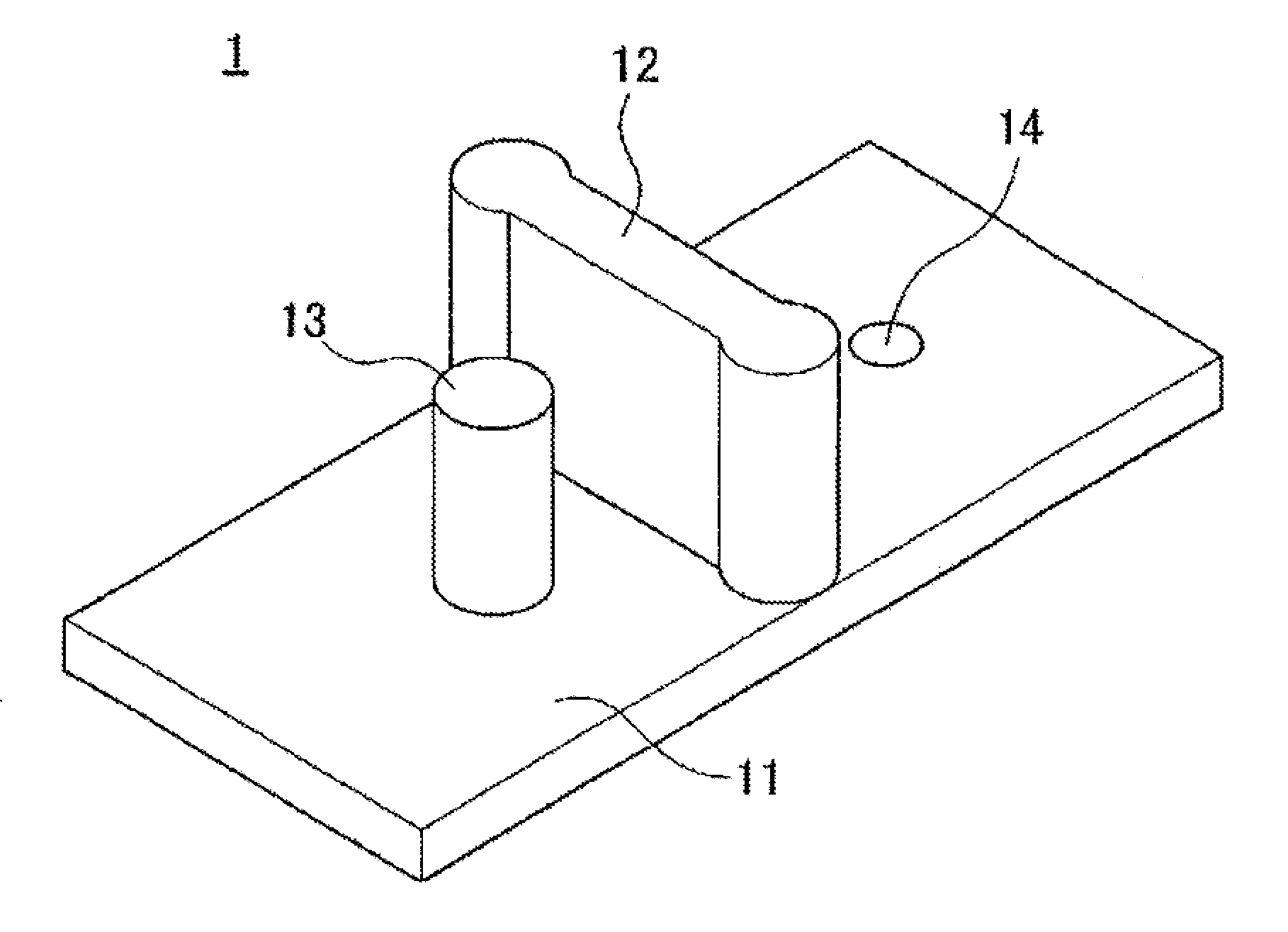

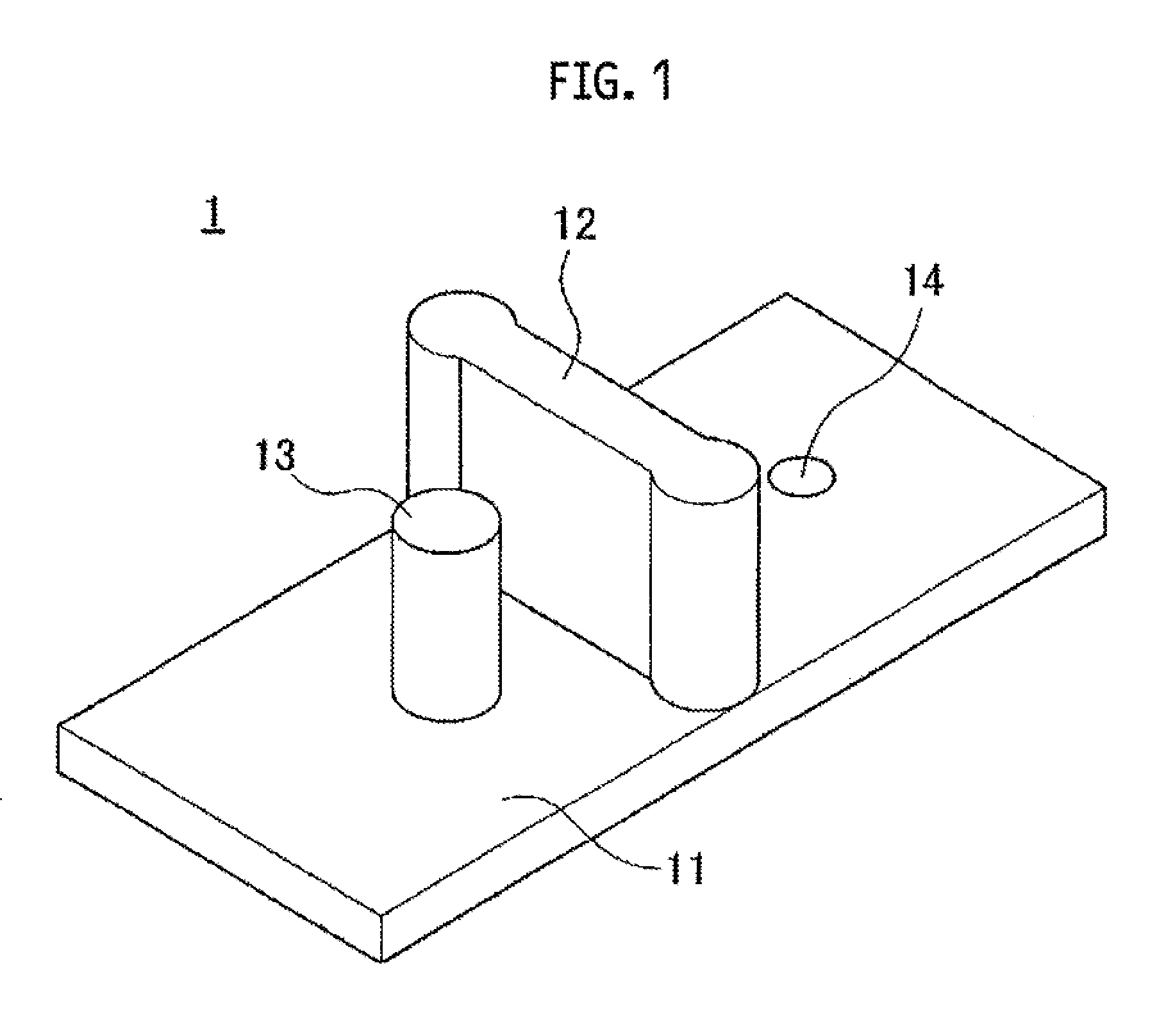

Heat conducting oil cooling device for preparing pentaerythrityl tetrastearate

PendingCN111895722ARealize automatic coolingRealize automatic controlLighting and heating apparatusCooling fluid circulationChemical reactionCooling effect

The invention discloses a heat conducting oil cooling device for preparing pentaerythrityl tetrastearate and belongs to the technical field of chemical production. The heat conducting oil cooling device comprises a heat conducting oil storing barrel; the top end and the bottom end of the conducting oil storing barrel are connected with an oil discharging pipeline and an oil feeding pipeline separately; the oil discharging pipeline extends to the interior bottom of the conducting oil storing barrel; a spiral cooling pipeline is connected between the oil discharging pipeline and the oil feedingpipeline; the oil feeding pipeline is connected with a circulating oil pump; a spiral cooling water pipe sleeve wraps the outer wall of the spiral cooling pipeline; and a cooling water cylinder is arranged on the right side of the spiral cooling pipeline, circulating cooling water can be utilized to rapidly cool heat conducting oil, and a heat absorption effect generated through chemical reactionbetween acetic acid solution and ammonium bicarbonate is utilized to rapidly cool cooling water, so that the cooling effect of cooling water can be effectively ensured, stable cooling of heat conducting oil can be effectively improved, and effective control over the cooling process of cooling water is realized.

Owner:JIANGXI ZHILIAN PLASTIC TECH CO LTD

Polycarbonate/polybutylene terephthalate fire retardation composition

InactiveCN104845314AImprove mechanical propertiesImprove flame retardant performancePolytetramethylene terephthalateAntioxidant

The present invention discloses a polycarbonate / polybutylene terephthalate fire retardation composition, which comprises, by mass, 40-60% of a bisphenol A type aromatic polycarbonate, 20-40% of polybutylene terephthalate, 1-4% of a styrene grafted maleic anhydride copolymer, 0.1-1% of triphenyl phosphite, 5-15% of a fire retardation agent, 3-8% of thermoplastic polyether ester TPEE, 0.1-0.5% of an antioxidant, and 0.1-1% of pentaerythrityl tetrastearate. The polycarbonate / polybutylene terephthalate fire retardation composition of the present invention has beneficial effects of excellent mechanical property and excellent fire retardation, and meets the halogen-free, smoke suppression, environmental protection and UL94V-0 grade fire retardation requirements, wherein the limiting oxygen index achieves more than or equal to 38%.

Owner:QINGDAO TONGCHUANG ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

High-strength PC optical cable connect

The invention relates to a high-strength PC optical cable connect, which comprises the following components, by weight part, 50-75 parts of modified polycarbonate, 45-60 parts of polyvinyl chloride, 30-50 parts of modified carbon fibers, 1-3 parts of a lubricant, 1-2 parts of a nucleating agent, 5-7 parts of benzoyl peroxide, 4-6 parts of pentaerythrityl tetrastearate, 20-35 parts of calcium carbonate powder, 1-3 parts of an antioxidant, 6-10 parts of an ultraviolet screening agent, 3-7 parts of modified graphene, 1-3 parts of nanometer silicon carbide and 5-10 parts of nanometer chromium carbide. The high-strength PC optical cable connect is flame-retardant, waterproof and shockproof, is high in strength, and is good in toughness, ultraviolet resistance, aging resistance and weathering resistance.

Owner:BOND GRP CO LTD +1

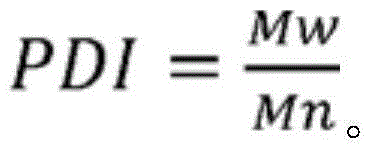

Skin care cream and preparation method thereof

InactiveCN107929145AThe formula is scientific and rigorousEffectivenessCosmetic preparationsAntipyreticPurslane extractChamomile extract

The invention provides skin care cream which comprises the following components: water, glycerin, propylene glycol, butanediol, ethylhexylglycerin, Carbomer, isohexadecane, polydimethylsiloxane, hydrogenated polydecene, cetearyl glucoside, isopropyl myristate, PEG-100 glyceryl stearate, trehalose, cetostearyl alcohol, pentaerythritol tetrastearate, methylparaben, propyl hydroxybenzoate, beta glucan, panthenol, triethanolamine, methylisothiazolinone, pearl powder, herba houttuyniae extract, chamomile extract, purslane extract, salvia extract, albizia flower extract and jasmine extract. The skincare cream disclosed by the invention is scientific and strict in formula and exact in effects, and the preparation process of the skin care cream is very simple. The prepared use equipment and packaging materials do not need to be specially treated, characters are stable, and use is convenient. In addition, the skin care cream disclosed by the invention is enriched in plant extract components, does not have any toxic or side effect and is safe to use.

Owner:青岛铭芳莲商贸有限公司

Detergent for glass curtain wall and preparation method therefor

ActiveCN105018244AClean thoroughlyLess cleaningOrganic detergent compounding agentsNon-ionic surface-active compoundsDihexyl sulfosuccinateMethylene bisacrylamide

The invention discloses a detergent for a glass curtain wall and a preparation method therefor. The detergent comprises the following materials: sodium dihexyl sulfosuccinate, N- N' methylenebisacrylamide, lauroyl diethanolamine, diatomite, polyepoxysuccinic sodium, nanometer BaTiO3, ethanol, water, sodium polyacrylate, trithiocyanuric acid trisodium salt, sodium alginate, glyceryl monostearate, glyceryl laurate and pentaerythrityl tetrastearate. Beneficial effects of the invention are that a cleaning objective can be quickly achieved, time of cleanness kept after the cleaning is long, the number of times of cleaning of the glass curtain wall is effectively reduced, labors are saved, and the cleaning cost is reduced.

Owner:广东智洋城市服务有限公司

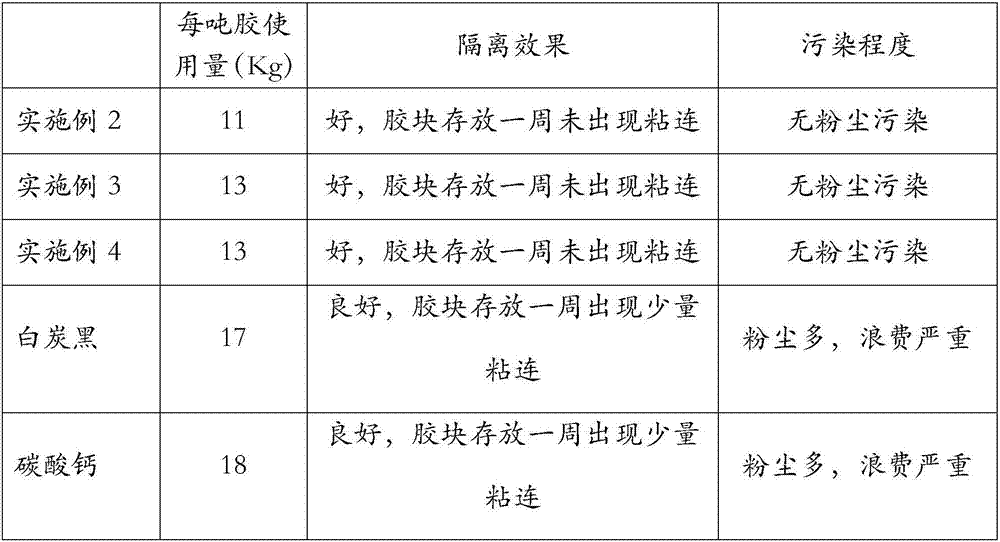

Hydrogenated rosin-modified aging-resistant sheathing material for building optical cables, and preparation method of sheathing material

InactiveCN106084419AImprove flame retardant performanceImprove toughnessLow-density polyethyleneMaterials science

The invention discloses a hydrogenated rosin-modified aging-resistant sheathing material for building optical cables. The sheathing material is prepared from the following raw materials in parts by weight: 80-100 parts of low-density polyethylene, 2-4 parts of hydrogenated rosin, 3-5 parts of methyl-phenyl silicon resin, 4-6 parts of magnesium hydroxide, 2-4 parts of white carbon black, 0.5-1 part of tetraethyl orthosilicate, 1.5-2.5 parts of vinyl triethoxysilane, 3-5 parts of triphenyl phosphate, 0.3-0.5 part of pentaerythrityl tetrastearate, 0.3-0.5 part of antioxidant 1010, 0.5-1 part of oleamide, and 0.5-1 part of white mineral oil. The optical cable sheathing material has both excellent mechanical performance and flame-retardant performance, and is good in tensile resistance and bending resistance, as well as aging-resistant property, the service life is long, the environmental suitability is good, and the hydrogenated rosin-modified aging-resistant sheathing material is suitable for the field of building optical sheaths.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

Modified PTFE anti-dripping agent and preparation method thereof

The invention relates to a modified PTFE anti-dripping agent. The anti-dripping agent comprises, by weight, 50-90 parts of PTFE resin and 10-50 parts of a lubricant, wherein the lubricant is one or acombination of montan wax, pentaerythritol tetrastearate and ethylene bis-stearamide. The PTFE resin and the micron-sized lubricant can be sufficiently mixed, the mixture is heated, the lubricant is melted and adsorbed by the PTFE resin, and the fiber-forming property of the PTFE resin at normal temperature is greatly reduced after cooling, so that fibration is not likely to happen during transportation, storage and mixing of polytetrafluoroethylene resin, and the polytetrafluoroethylene resin can be uniformly dispersed in engineering plastics.

Owner:NANJING TIANSHI NEW MATERIAL TECH

Heat-resistant, reinforced and modified PBT powder and preparation method thereof

InactiveCN104845078AImprove heat resistanceImprove flame retardant performanceChemical industryDiphenylmethane

The present invention discloses heat-resistant, reinforced and modified PBT powder and a preparation method thereof, wherein the heat-resistant, reinforced and modified PBT powder comprises, by mass, 60-80% of PBT, 5-15% of glass fibers, 2-10% of talc powder, 8-15% of a flame retardant agent, 3-8% of TPU, 0.1-0.3% of an aluminum titanium composite coupling agent, 0.1-1% of pentaerythrityl tetrastearate, 0.1-1% of a heat-resistance stabilizer, and 0.1-0.5% of an antioxidant, wherein the heat-resistance stabilizer is N,N-4,4-diphenylmethane bismaleimide. The heat-resistant, reinforced and modified PBT powder of the present invention has beneficial effects of high heat resistance, high flame retardant property, good mechanical property, excellent electrical performance, good processability, strong chemical resistance, stable performance, good appearance quality, low cost, and the like, and can be used in the fields of electronic appliances, chemical industry machinery, and the like.

Owner:QINGDAO WANLI TECH

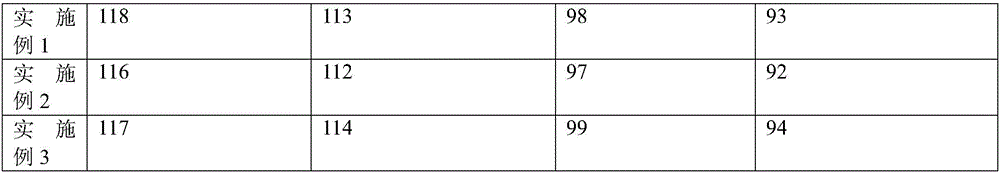

Rubber block isolating agent for breaking natural rubber, and preparation method thereof

The invention discloses a rubber block isolating agent for breaking natural rubber, and a preparation method thereof. The rubber block isolating agent comprises the following components in parts by weight: 10 to 20 parts of fatty acid ester, 10 to 20 parts of fatty acid, 1 to 10 parts of organic filler, and 60 to 75 parts of an inorganic carrier, wherein the fatty acid ester is one or more of pentaerythritol tetrastearate, glyceryl stearate and propylene glycol stearate; the fatty acid is one or more of stearic acid, palmitic acid and lauric acid; the organic filler is one or combination of fatty acid calcium and fatty acid zinc; the inorganic carrier is one or combination of silicate filler and calcium carbonate filler. The rubber block isolating agent can be combined with a broken rubber block quickly to isolate the rubber block so as to prevent adhesion again, dust cannot be generated during spraying, the usage of the isolating agent is reduced, and the working environment is improved.

Owner:青岛福凯橡塑新材料有限公司

PBT modified powder and preparation method thereof

The present invention discloses PBT modified powder and a preparation method thereof, wherein the PBT modified powder comprises, by mass, 60-80% of PBT, 5-20% of heavy calcium carbonate, 5-10% of TPU, 1-3% of a compatilizer, 0.5-1.5% of carbodiimide, 0.5-1% of pentaerythrityl tetrastearate, 0.1-0.5% of pyromellitic dianhydride, 0.1-0.5% of a silane coupling agent, and 0.1-0.5% of an antioxidant, wherein the compatilizer is an ethylene-methyl acrylate-glycidyl methacrylate copolymer. The PBT modified powder of the present invention has the following beneficial effects that: on the basis of the PBT, the toughness, the rigidity and the heat resistance are substantially improved while the good mechanical strength is maintained, the hydrolysis resistance is good, the size is stable, the processability is good, the electrical property is excellent, the preparation process is simple and easy to operate, the cost is low, and the industrial production is easily achieved.

Owner:QINGDAO WANLI TECH

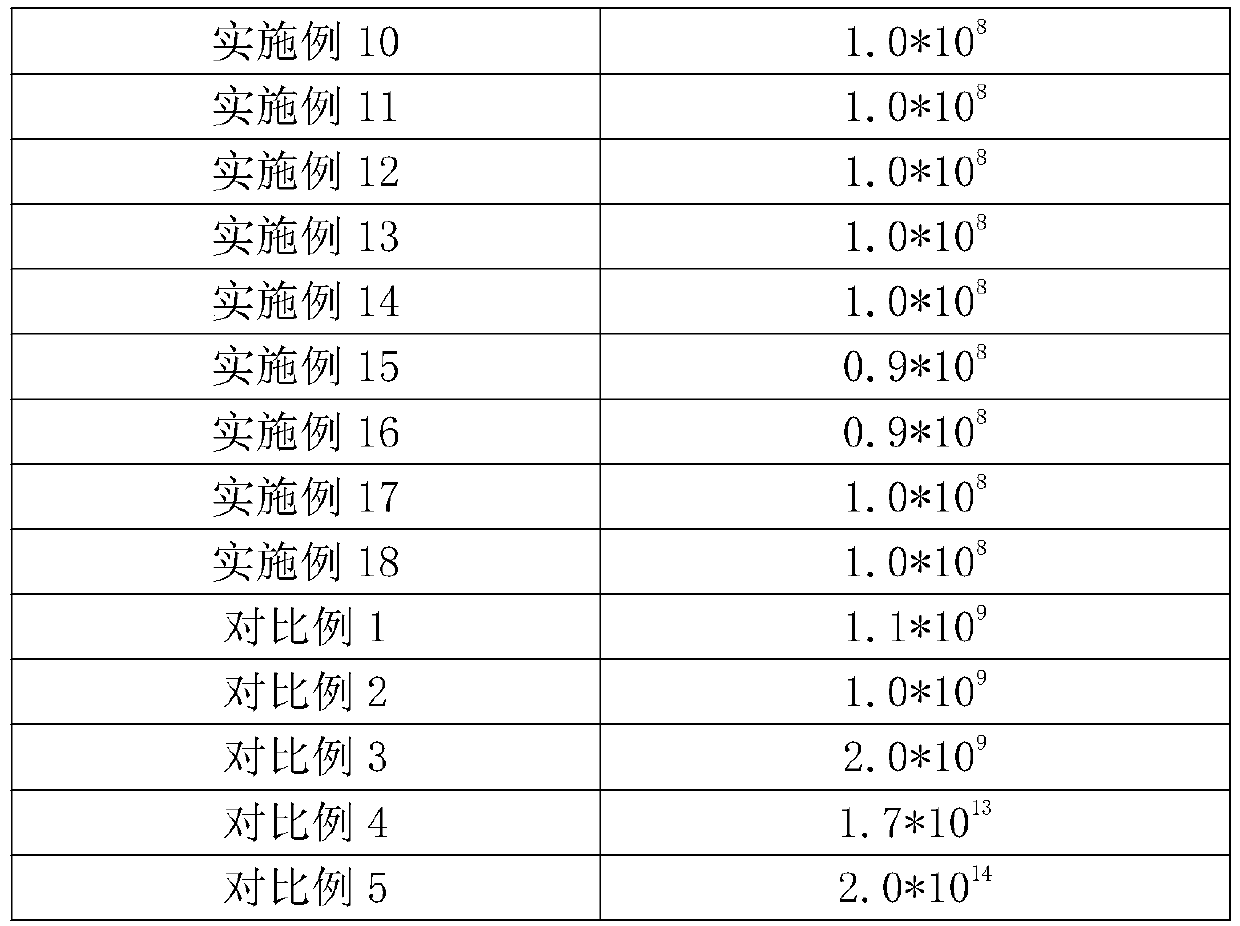

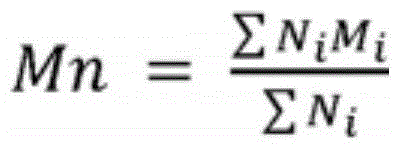

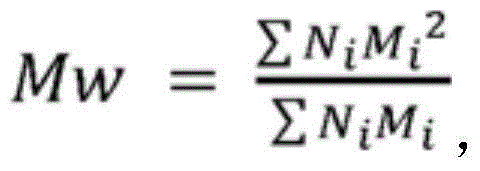

Polybutylene terephthalate resin composition

ActiveUS20170002194A1Improve hydrolysis resistanceExcellent mold releasabilityPolytetramethylene terephthalatePentaerythritol

Provided is a polybutylene terephthalate resin composition having excellent mold releasability, measurement stability and hydrolysis resistance, and exhibiting minimal discoloration under high-temperature conditions. The polybutylene terephthalate resin composition contains: (A) a polybutylene terephthalate resin, (B) a higher fatty acid ester of pentaerythritol, and (C) a low-molecular weight polyethylene having a number-average molecular weight of 3,000 to 7,000. It is preferable that the component (B) is pentaerythritol tetrastearate, and that the component (C) is a low-molecular weight polyethylene having a number-average molecular weight of 4,500 to 5,500.

Owner:POLYPLASTICS CO LTD

Anti-aging PC (polycarbonate) sun board and preparation method thereof

The invention provides an anti-aging PC (polycarbonate) sun board and a preparation method thereof. The PC sun board is prepared from raw materials including PC, polyethylene, butadiene styrene rubber, polyethylene glycol, glass fiber, stearic acid, a plasticizer, a dispersant, a filling material, an antioxidant, a silane coupling agent and pentaerythritol tetrastearate. The preparation method comprises steps as follows: firstly, PC, polyethylene, the butadiene styrene rubber, polyethylene glycol, the glass fiber, stearic acid, the plasticizer, the dispersant, the filling material, the antioxidant, the silane coupling agent and pentaerythritol tetrastearate are added to a stirrer, heated and subjected to thermal insulation, then an obtained mixture is introduced to a double-screw extruder and subjected to melt blending extrusion, traction, granulation and injection molding and the anti-aging PC sun board is obtained. Polyethylene, the butadiene styrene rubber and PC are matched to serve as a matrix, the glass fiber is added, the prepared PC sun board has excellent anti-aging performance, and the color difference and the notch impact strength retention rate are relatively high after the PC sun board is aged for 400 h.

Owner:句容市恒鑫遮阳科技有限公司

Toughened and anti-aging PBT powder

The present invention discloses toughened and anti-aging PBT powder, which comprises, by mass, 70-85% of PBT, 5-10% of MBS, 5-10% of glass fibers, 0.5-3% of a benzotriazole light absorbing agent, 0.1-1% of erucylamide, 0.1-1% of pentaerythrityl tetrastearate, and 0.1-0.5% of an antioxidant, wherein the glass fibers are the alkali-free short cut glass fibers with the surface treated by a silane coupling agent KH560. The toughened and anti-aging PBT powder of the present invention has beneficial effects of good impact resistance toughness, good tensile strength, good heat resistance, strong aging resistance, good appearance, easy processing, and low cost, and can be used in the fields of electronic appliances, vehicles, chemical industry, machinery and the like.

Owner:QINGDAO WANLI TECH

Compression and ageing resistant automobile sealing strip

The invention discloses a compression and ageing resistant automobile sealing strip. The compression and ageing resistant automobile sealing strip comprises, by weight, 20-30 parts of ethylene propylene diene monomer, 25-28 parts of nitrile butadiene rubber, 3-5 parts of tert-butyl peroxybenzoate, 2-4 parts of semi-reinforcing carbon black N660, 2-4 parts of silica, 2-5 parts of pentaerythritol tetrastearate, 1-3 parts of paraffin oil, 2-3 parts of an antioxidant, 3-5 parts of a silane coupling agent KH550, 1.2-1.8 parts of a vulcanizing agent, 3-4 parts of stearic acid, 4-6 parts of zinc borate, 8-10 parts of a filler and 0.4-0.6 parts of a vulcanizing agent. The above formula has the advantages of reasonable ratio and low cost, and the above produced product has ageing resistance, so the long service life of the product is guaranteed; and silica and the filler are adopted as reinforcing agents, so the product has the advantages of high tensile strength, high compression deformation resistance, excellent heat resistance, reduction of pollution to environment, and suitableness for wide popularization.

Owner:王颖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com