High-strength PC optical cable connect

An optical cable splice box and high-strength technology, applied in the field of high-strength PC optical cable splice boxes, can solve the problems of low weather resistance and insufficient strength of the splice box, and achieve the effects of good weather resistance, good toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

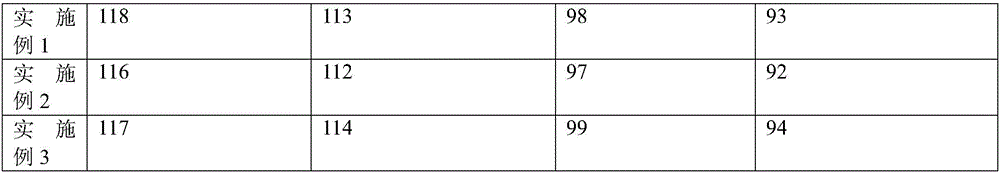

Embodiment 1

[0022] A high-strength PC optical cable splice box, the PC optical cable splice box contains the following components in parts by weight: 50 parts of modified polycarbonate, 45 parts of polyvinyl chloride, 30 parts of modified carbon fiber, 1 part of lubricant, and 1 part of nuclear agent, 5 parts of benzoyl peroxide, 4 parts of pentaerythritol stearate, 20 parts of calcium carbonate powder, 1 part of antioxidant, 6 parts of UV protection agent, 3 parts of modified graphene, 1 part of nano-silicon carbide 5 parts with nanometer chromium carbide.

[0023] The modification method of modified graphene is: 25 parts by weight of graphene oxide are dispersed in 300 parts by weight of trishydroxymethylaminomethane buffer solution and ultrasonically treated for 2h to obtain a suspension; then 200 parts by weight of dicyclohexyl Carboimide, 155 parts by weight of dimethyl siloxane and 120 parts by weight of dibutyl sebacate, heated to 280°C for 2 hours after ultrasonication for 20 minu...

Embodiment 2

[0029] A high-strength PC optical cable splice box, the PC optical cable splice box contains the following components in parts by weight: 63 parts of modified polycarbonate, 58 parts of polyvinyl chloride, 36 parts of modified carbon fiber, 2 parts of lubricant, and 1.5 parts of nucleating agent, 6 parts of benzoyl peroxide, 5 parts of pentaerythritol stearate, 25 parts of calcium carbonate powder, 2 parts of antioxidant, 7 parts of UV protection agent, 4 parts of modified graphene, 2 parts of nano silicon carbide 6 parts with nanometer chromium carbide.

[0030]The modification method of modified graphene is: 25 parts by weight of graphene oxide are dispersed in 300 parts by weight of trishydroxymethylaminomethane buffer solution and ultrasonically treated for 2h to obtain a suspension; then 200 parts by weight of dicyclohexyl Carboimide, 155 parts by weight of dimethylsiloxane and 120 parts by weight of dibutyl sebacate, heated to 300°C for 3 hours after ultrasonication for ...

Embodiment 3

[0036] A high-strength PC optical cable splice closure, the PC optical cable splice closure contains the following components in parts by weight: 75 parts of modified polycarbonate, 60 parts of polyvinyl chloride, 50 parts of modified carbon fiber, 3 parts of lubricant, and 2 parts of nuclear agent, 7 parts of benzoyl peroxide, 6 parts of pentaerythritol stearate, 35 parts of calcium carbonate powder, 3 parts of antioxidant, 10 parts of UV protection agent, 7 parts of modified graphene, 3 parts of nano-silicon carbide parts and 10 parts of nano-chromium carbide.

[0037] The modification method of modified graphene is: 25 parts by weight of graphene oxide are dispersed in 300 parts by weight of trishydroxymethylaminomethane buffer solution and ultrasonically treated for 2h to obtain a suspension; then 200 parts by weight of dicyclohexyl Carboimide, 155 parts by weight of dimethylsiloxane and 120 parts by weight of dibutyl sebacate, heated to 320°C for 4 hours after ultrasonica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com