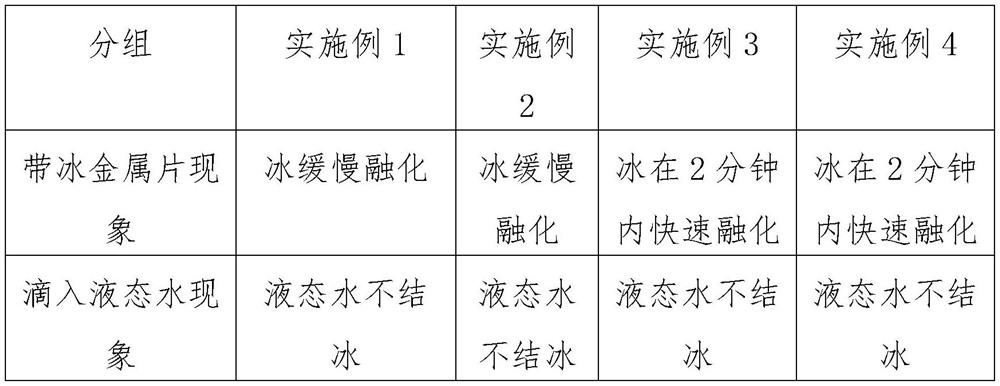

Patents

Literature

33results about How to "Wide liquid temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

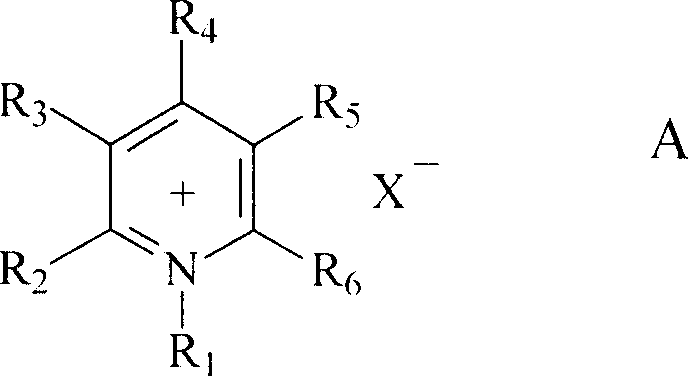

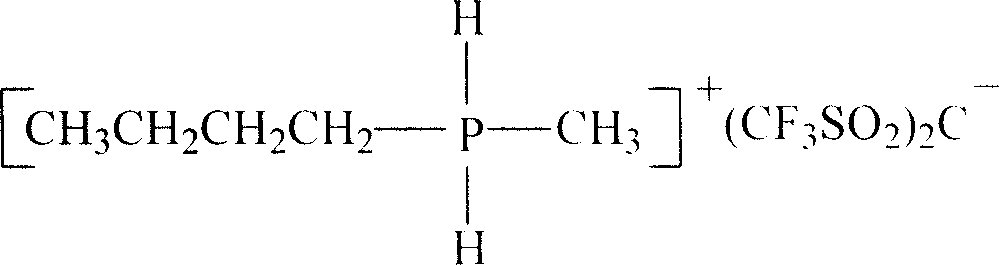

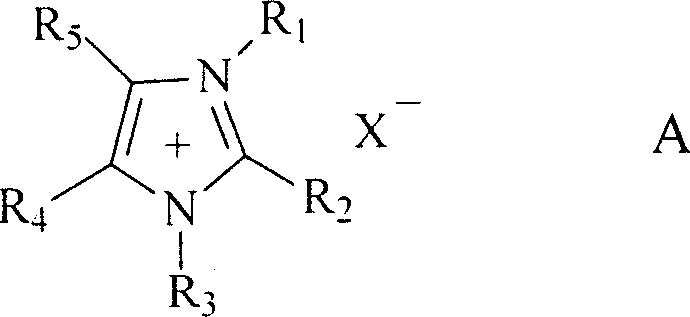

Lithium ion battery electrolyte and lithium ion battery containing the same

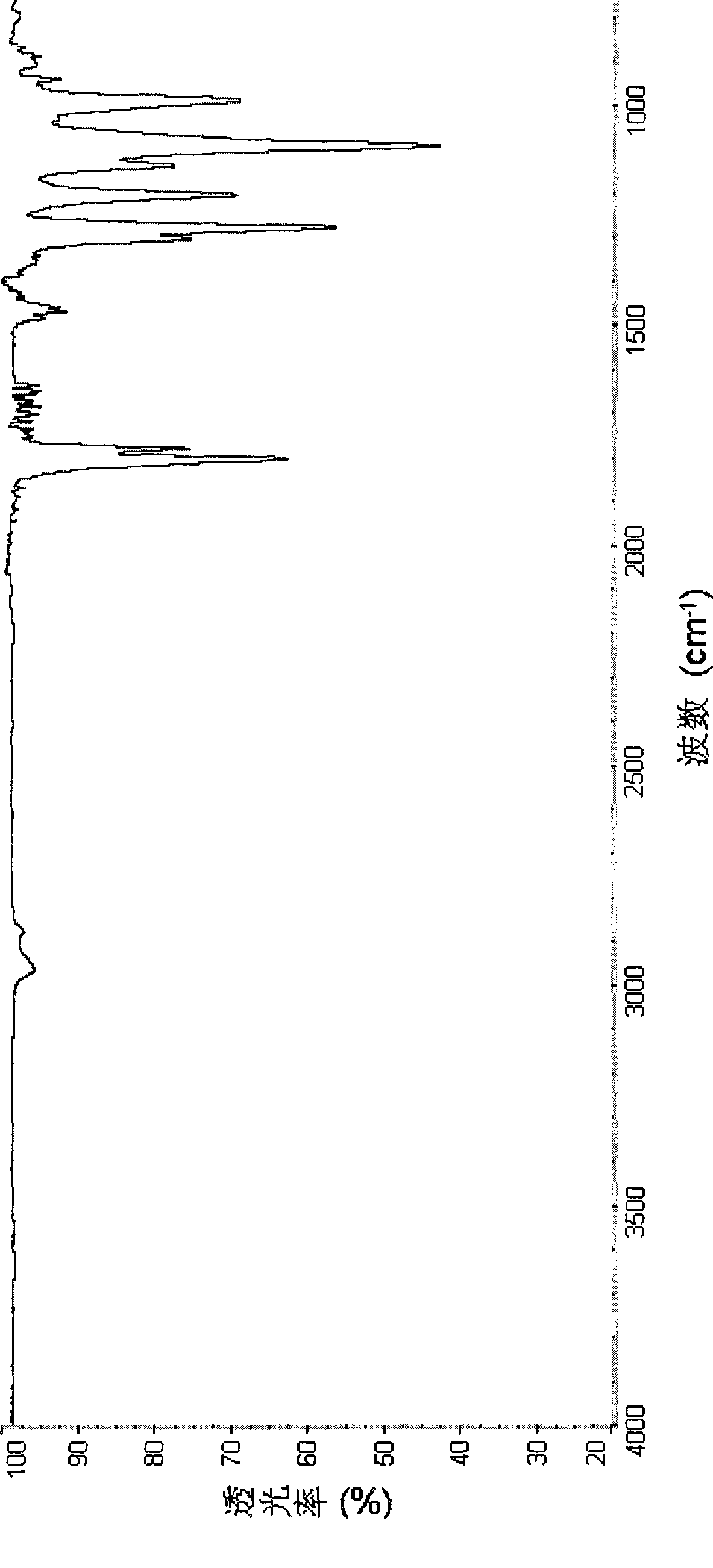

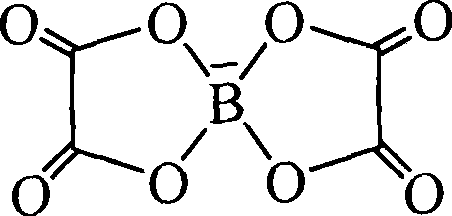

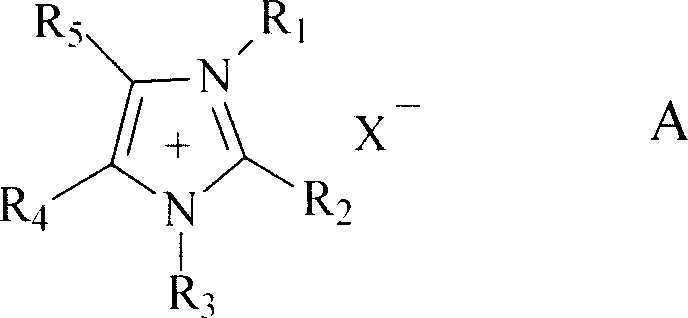

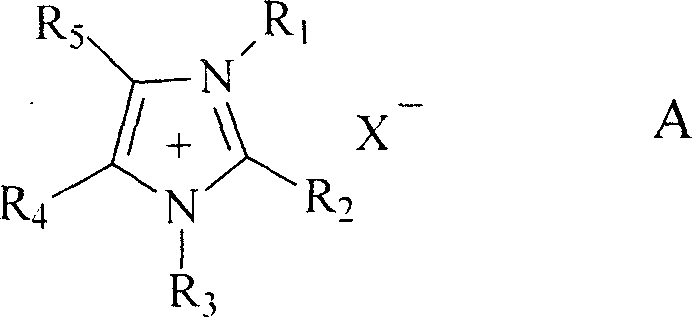

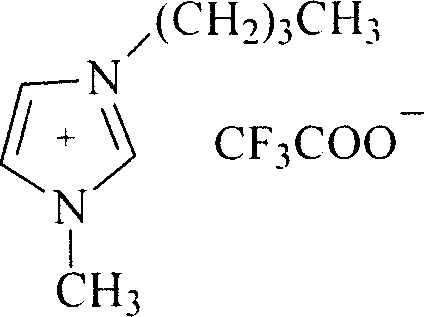

ActiveCN101471454AWide liquid temperature rangeFlame retardantSecondary cellsElectrolytic agentCombustion

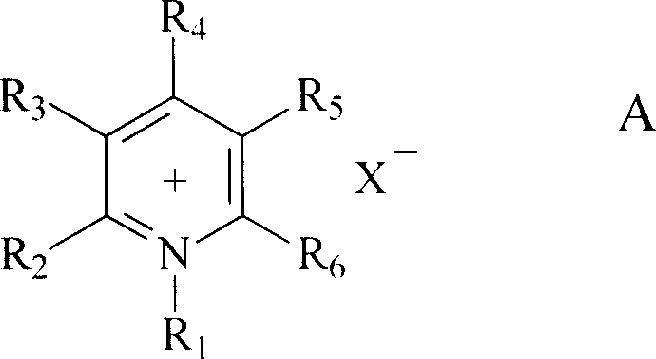

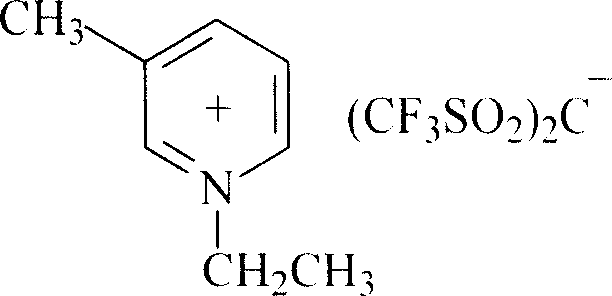

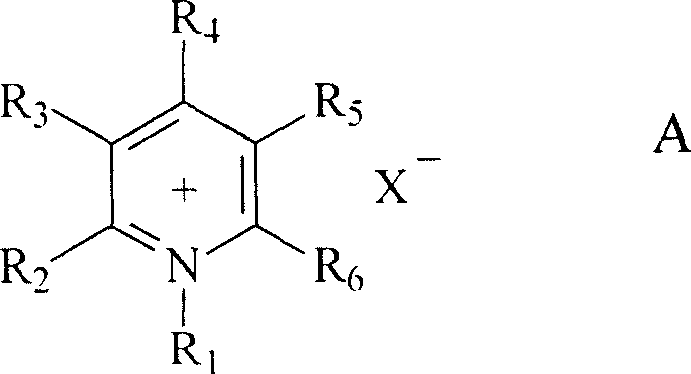

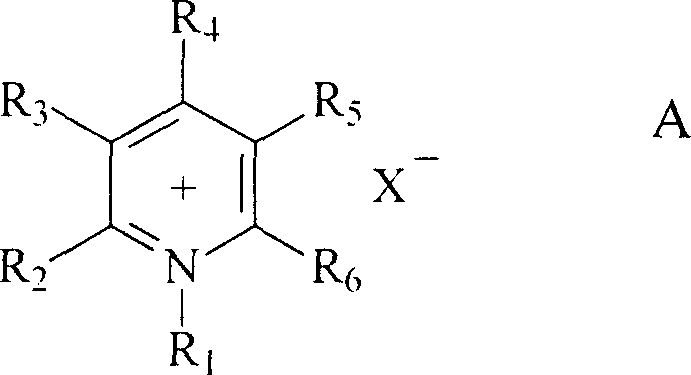

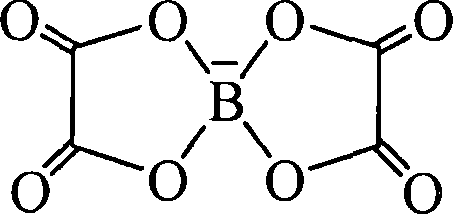

A Li-ion battery electrolyte contains lithium salt, ionic liquid and a non-aqueous solvent, wherein the anion contained in the ionic liquid is showed by formula (1). A Li-ion battery comprises an electrical core and the above electrolyte, which can retard combustion of organic solvents. The Li-ion battery using the electrolyte can suppress capacity fade at low temperature, and can reduce the amount of gas generated by the electrolyte at high temperature, thereby effectively preventing battery expansion and improving the high-temperature performance of the battery.

Owner:BYD CO LTD

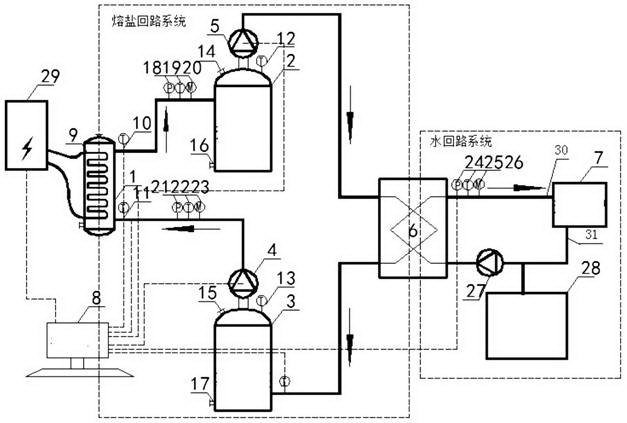

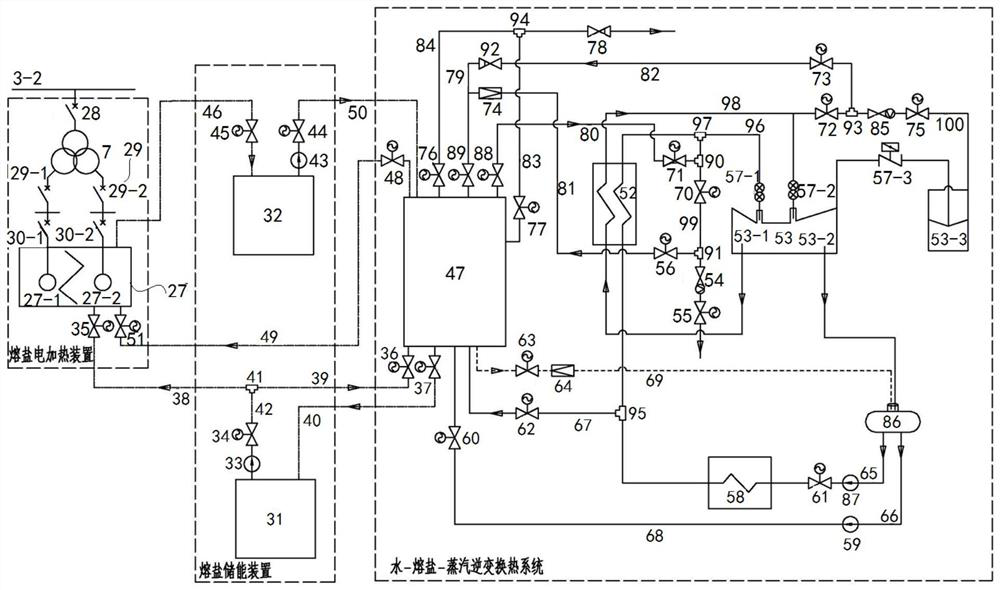

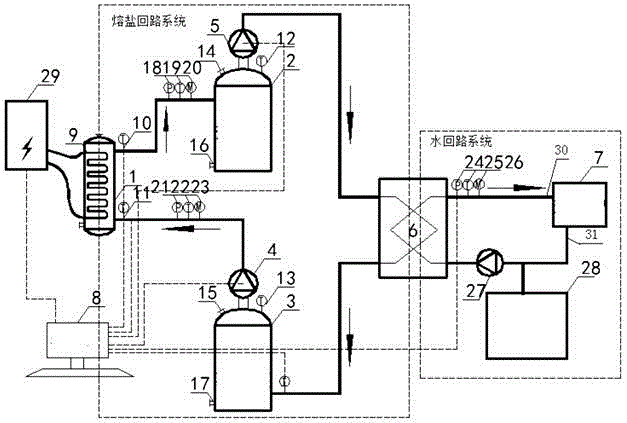

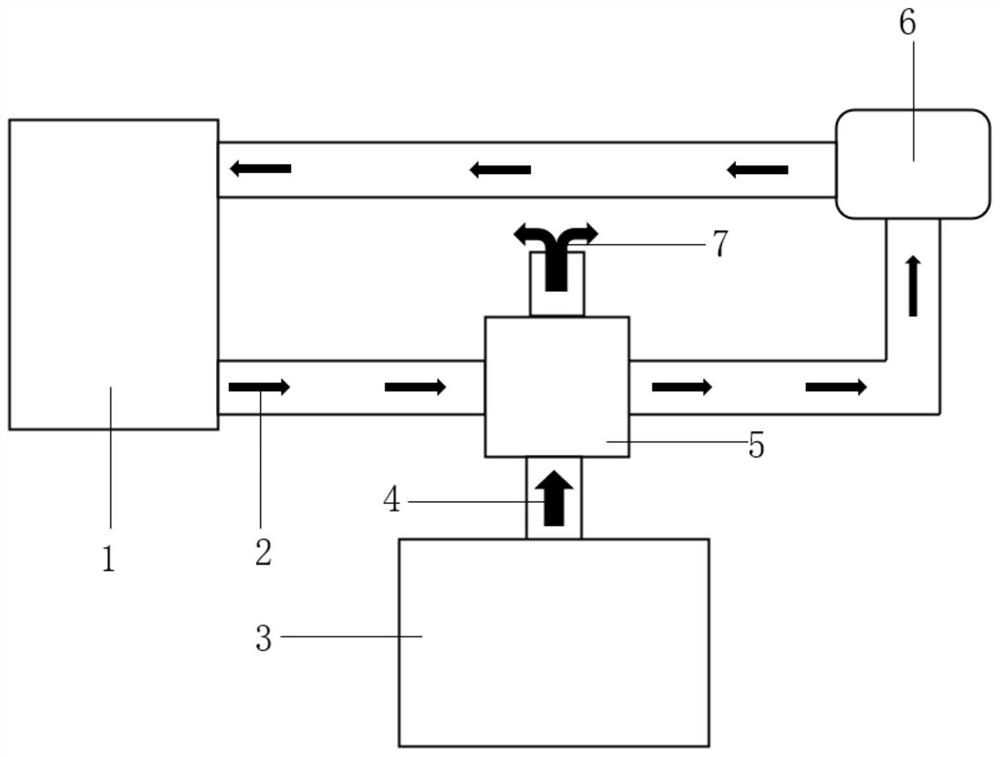

Molten salt heat storage type electric heating central heating system

ActiveCN103836703AAlleviate the peak-to-valley differenceReduce usageLighting and heating apparatusElectric heating systemWater useMaterials science

The invention relates to a molten salt heat storage type electric heating central heating system, and belongs to the technical field of heat storage. The molten salt heat storage type electric heating central heating system comprises a molten salt electric heater, a high-temperature hot salt tank, a low-temperature cold salt tank, a molten salt pump, a molten salt-water heat exchanger and a heat user. During the time period of low-price low off-peak electricity at night, the molten salt in the cold salt tank is pumped out through the molten salt pump to be conveyed to the molten salt electric heater for heating, and enters the hot salt tank after being heated up to high temperature. During the time period of a power utilization peak, the high-temperature molten salt, with accumulated heat, in the hot salt tank is pumped put through the molten salt pump to be conveyed to the molten salt-water heat exchanger and heats water used for municipal heating to produce hot water for supplying heat to residents. On the basis of a coal-fired boiler central heating system which is in general use at present, only a boiler room of the central heating system needs to be transformed into the molten salt heat storage type electric heating system, and neither a municipal heat supply pipe network nor heat supply terminal equipment needs to be transformed. Besides, the molten salt heat storage type electric heating central heating system can cut down a peak to supplement a trough and reduce the usage amount of coal, thereby playing a role in protecting the environment.

Owner:中投亿星新能源投资有限公司

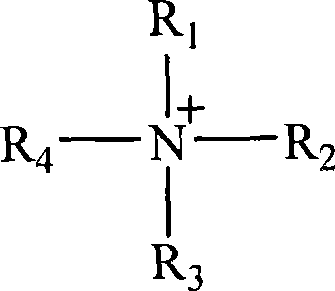

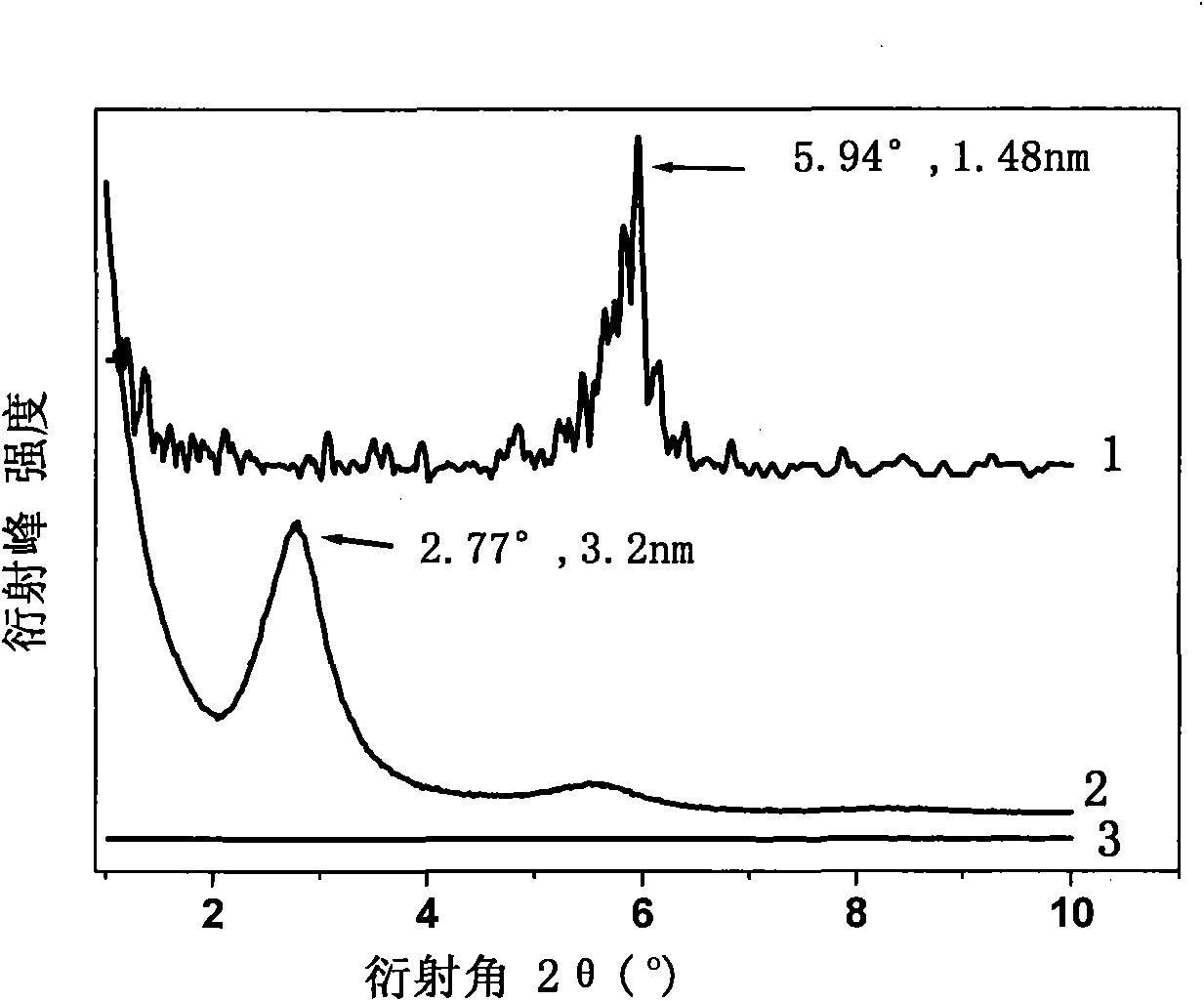

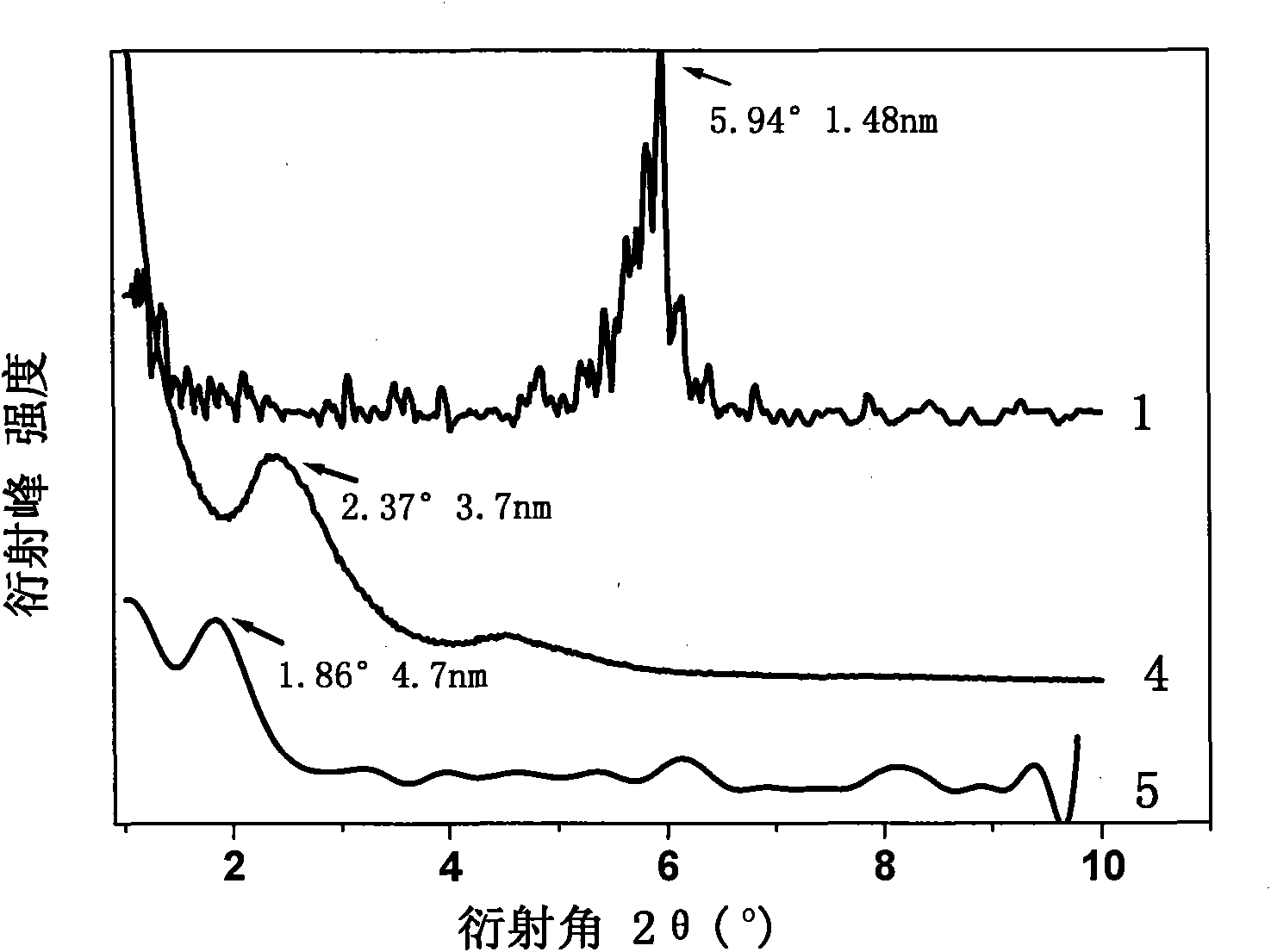

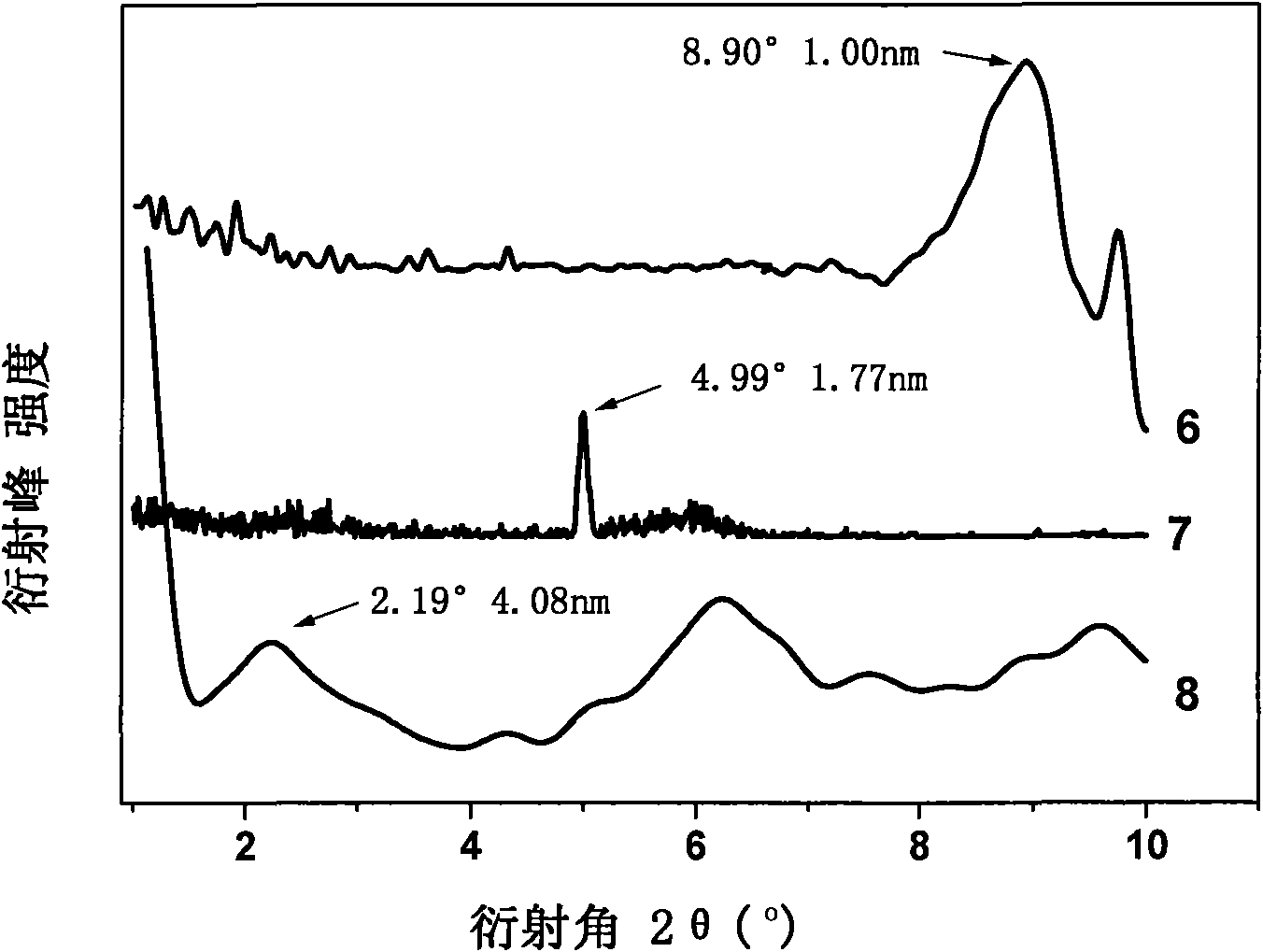

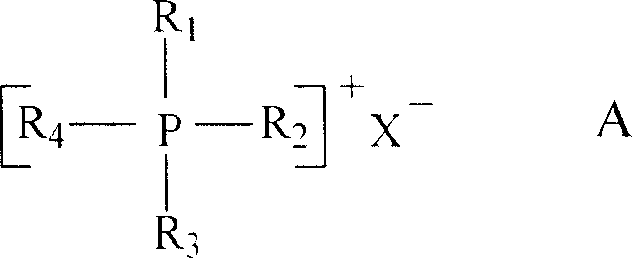

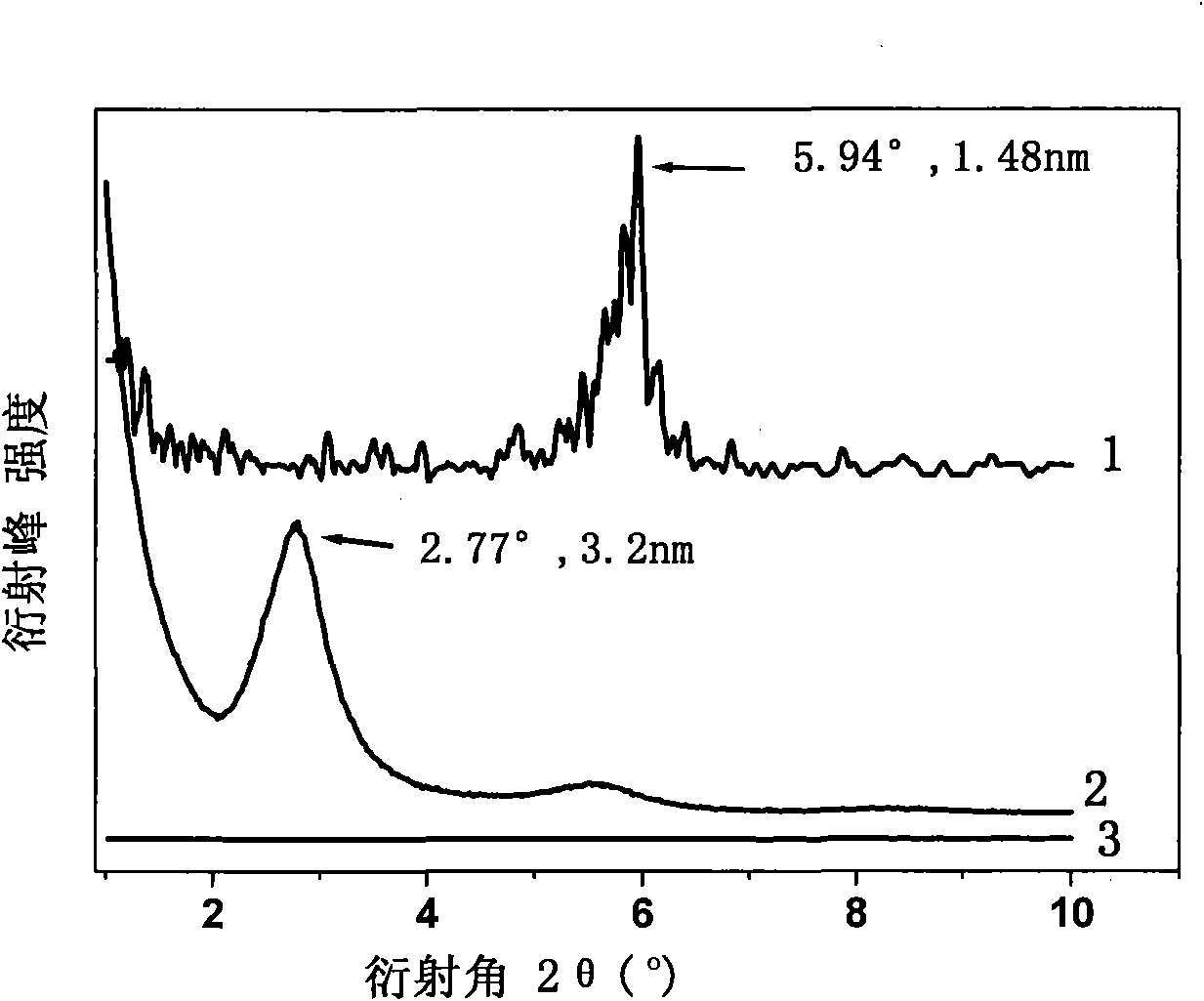

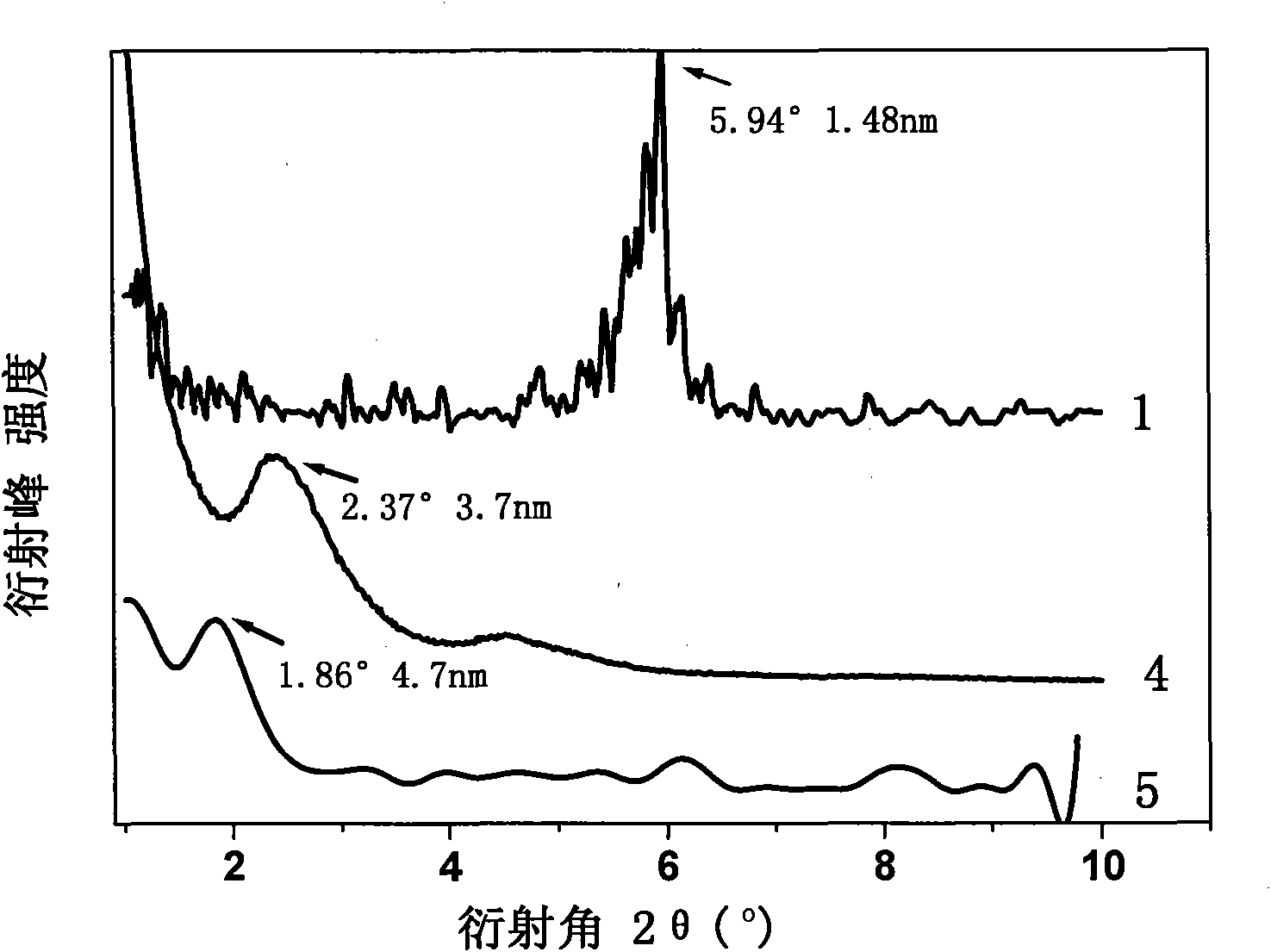

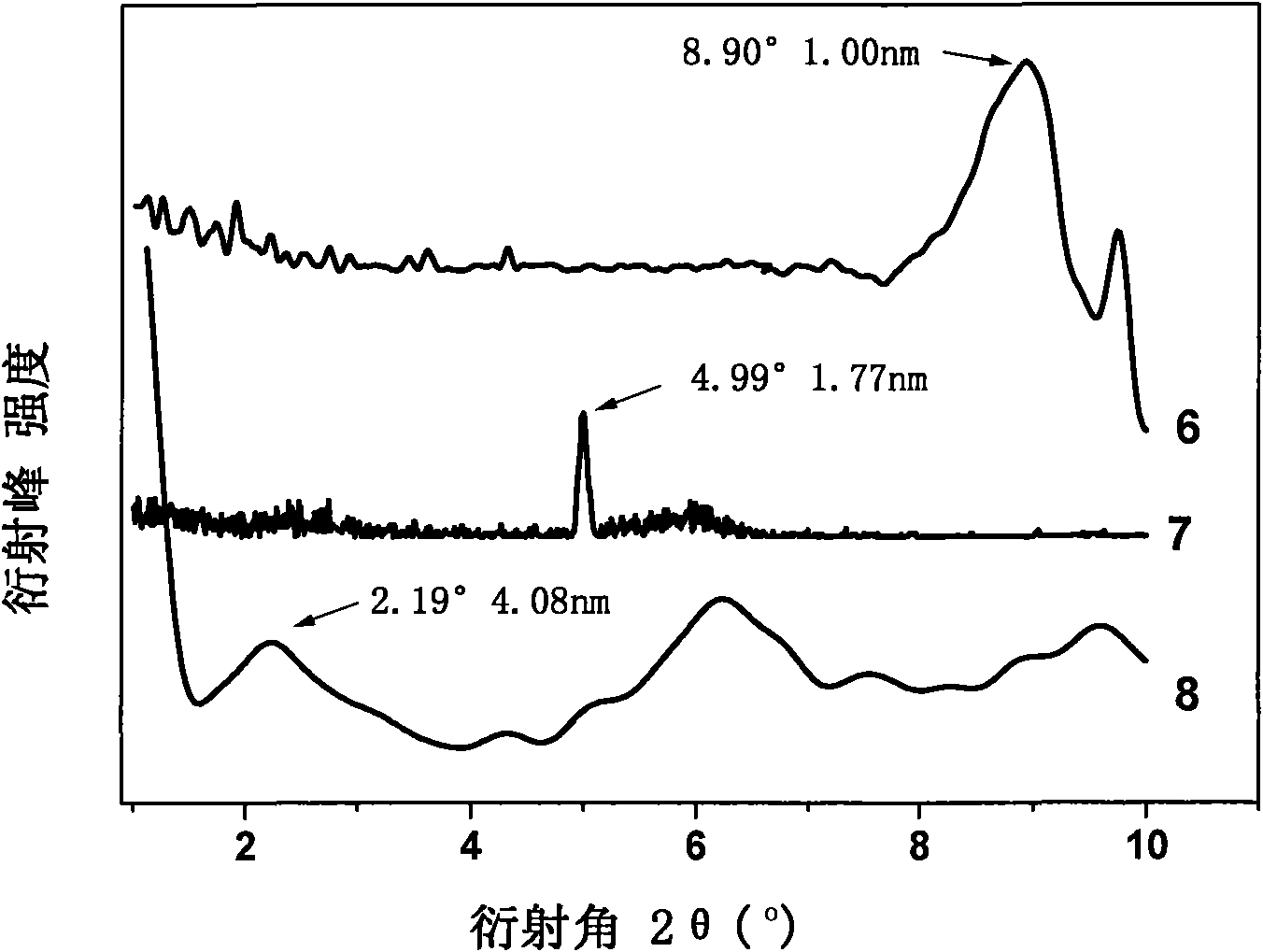

Methods for preparing quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and polymer/montmorillonite nanocomposite

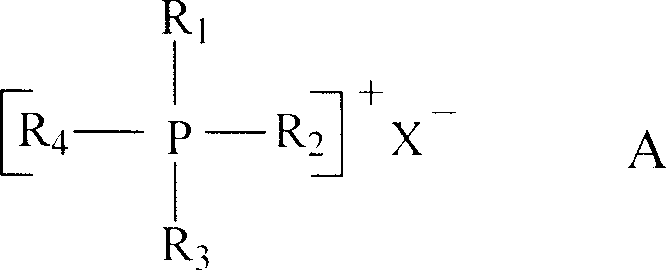

InactiveCN101979444AGood physical and chemical stabilityGreen chemical reagents are goodFibre treatmentCoatingsPhosphonium saltEngineering plastic

The invention relates to the field of polymer / montmorillonite nanocomposites, and discloses methods for preparing quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and the polymer / montmorillonite nanocomposite. The method for preparing the polymer / montmorillonite nanocomposite comprises the steps of performing pillaring-modification on montmorillonite by using quaternaryphosphonium salt ionic liquid and then intercalating the quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and a polymer or a polymeric monomer. In the methods, the montmorillonite is pillaring-modified directly by the quaternary phosphonium salt ionic liquid without water and any other solvent, and the ionic liquid can be recycled; the methods are simple, convenient to operate and environmentally-friendly, reduces the cost and saves energy consumption; and the quaternary phosphonium salt ionic liquid has more stable chemical properties and higher thermal stability, greatly improves the mechanical properties of the polymer material, can be applied to engineering plastics and heat-resisting polymers, and greatly expands the application range of the montmorillonite.

Owner:SOUTH CHINA UNIV OF TECH

Wet spinning method for polyacryl-nitrile fibre

InactiveCN1752302AEasy to recycleImprove protectionWet spinning methodsMonocomponent synthetic polymer artificial filamentIonSolvent

The wet spinning method of polyacrylonitrile fibre includes the following steps: dissolving fibre-grade polyacrylonitrile resin in the solvent to obtain spinning solution, making the spinning solution the passed through spinneret component to form primary fibre, then making the primary fibre be passed through a coagulating bath and coagulated to form the invented fibre. Said invention also provides the chemical structure formula of said solvent, and the polyacrylonitrile resin content in the spinning solution is 10-35 wt%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Anhydrous cooling liquid for engines and preparation method thereof

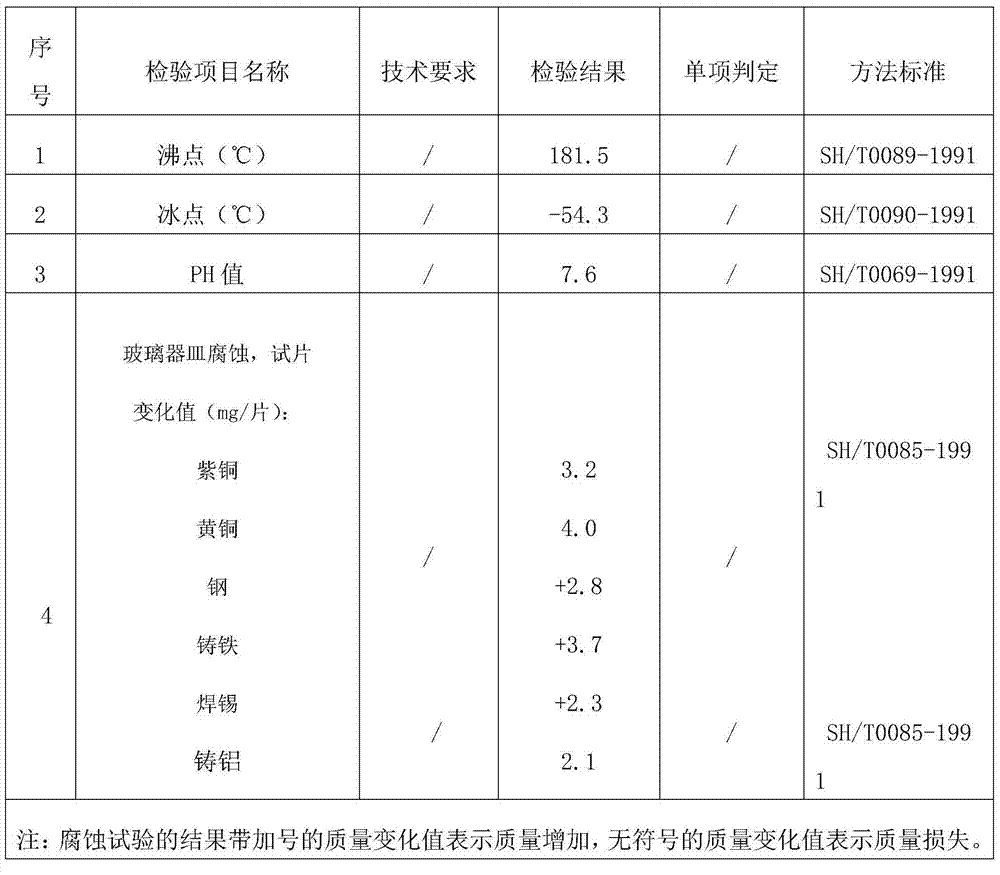

InactiveCN104513649ALow toxicityFast biodegradationHeat-exchange elementsSodium metasilicateGlycerol

The invention puts forward an anhydrous cooling liquid for engines. The anhydrous cooling liquid is composed of the following components by weight: 10-50% of an AST polymer; 20-70% of propylene glycol; 1-10% of triethanolamine; 0.1-3% of coconut oil diethanolamide; 10-30% of glycerol; 0.05-1% of sodium metasilicate; 0.05-3% of benzotriazole; 0.01-0.3% of sodium borate; 0.01-1% of an organic silicon defoamer; and 0.05-3% of sodium benzoate. The invention also discloses a preparation method of the anhydrous cooling liquid for engines. The anhydrous cooling liquid provided by the invention has the advantages of environmental protection and no toxicity, low freezing point, high boiling point, high ignition point, no scale, fuel oil saving, and good heat conductivity, thereby solving the problems of unhealthiness and no environmental protection in the prior art. In addition, the production process is simple and the cost is low, so that the anhydrous cooling liquid is of great popularization performance.

Owner:江门市江海区一言科技有限公司

Wet spinning method for polyacryl-nitrile fibre

InactiveCN1752305AEasy to recycleImprove protectionWet spinning methodsMonocomponent synthetic polymer artificial filamentChemical structureSolvent

The wet spinning method of pelyacrylonitrile fibre includes the following steps: dissolving fibre-grade polyacrylonitrile resin in the solvent to obtain spinning solution, making the spinning solution be passed through spinneret component to form primary fibre, then making the primary fibre be passed through a coagulating bath and coagulated to form the invented fibre. Said invention also provides the chemical structure formula of said solvent, and the polyacrylonitrile resin content in the spinning solution is 10-35 wt%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Method for trivalent chromium electroplating of non-micro-crack crystalline chromium and chromium alloy coating in ionic liquid

The invention discloses a method for trivalent chromium electroplating of a non-micro-crack crystalline chromium and chromium alloy coating in a 1-butyl-3-methyl imidazole hydrosulfate ([BMIM]HSO4) ionic liquid system, relating to a surface engineering and surface treatment technology. The method comprises the configuration of a novel ionic liquid plating solution, an electroplating technological process and the like. The current efficiency of the electroplating chromium and chromium alloy coating of a plating solution system can reach more than 95%, and is 45% higher than that of a conventional aqueous solution system; moreover, the defects that the plating solution of a normal aqueous solution system is poor in stability, easy in combustion, short in service life and high in toxicity and volatility, and an additive brightening agent and a stabilizing agent are easy to be out of operation can be overcome by using the method. The prepared non-micro-crack crystalline chromium and chromium alloy coating disclosed by the invention is compact and smooth in surface, has a strong combining capacity with a substrate, is excellent in corrosion resistance and high in hardness, is suitable for the demands on corrosion prevention, decoration and the like of the surfaces of metals and alloys, is easy in operation, and has the characteristics of economic practicality and low toxicity.

Owner:HUNAN UNIV OF TECH

Wet spinning method for polyacryl-nitrile fibre

InactiveCN1752304AEasy to recycleImprove protectionMonocomponent synthetic polymer artificial filamentWet spinning methodsChemical structureSolvent

The wet spinning method of pelyacrylonitrile fibre includes the following steps: dissolving fibre-grade polyacrylonitrile resin in the solvent to obtain spinning solution, making the spinning solution be passed through spinneret component to form primary fibre, then making the primary fibre be passed through a coagulating bath and coagulated to form the invented fibre. Said invention also provides the chemical structure formula of said solvent, and the polyacrylonitrile resin content in the spinning solution is 10-35 wt%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Polyalkylcyclopentane lubricating oil composition, and preparation method and application thereof

ActiveCN111019744AWide liquid temperature rangeReduce volatile lossLubricant compositionSide chainPhosphoric acid

The invention provides a polyalkylcyclopentane lubricating oil composition, and a preparation method and an application thereof, and belongs to the field of liquid lubrication. Guerbet alcohol Guerbetacid ester and tricresyl phosphate are ester compounds and can be well mixed and dissolved to form a composite additive; and the base oil and the Guerbet alcohol Guerbet acid ester have similar longside chain structures, so the polyalkylcyclopentane lubricating oil composition has the advantages of good compatibility, extremely wide liquid temperature range, extremely low volatilization loss, excellent lubricating performance and excellent high and low temperature performances, and can be used for liquid lubrication under harsh conditions such as a micro electro mechanical system and space machinery.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

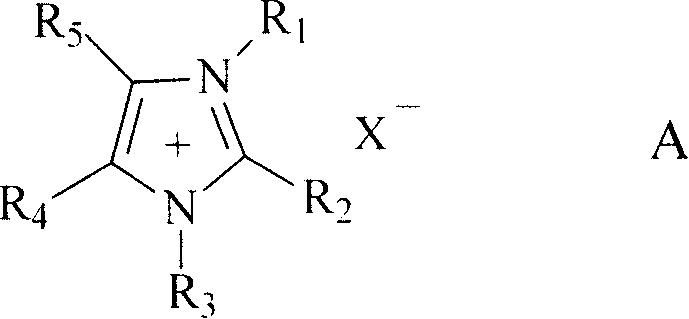

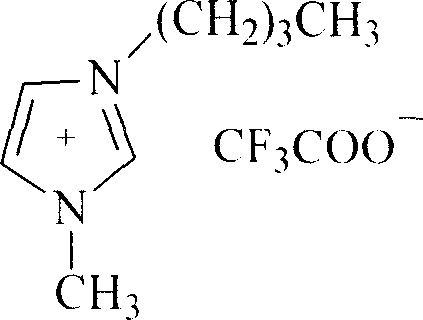

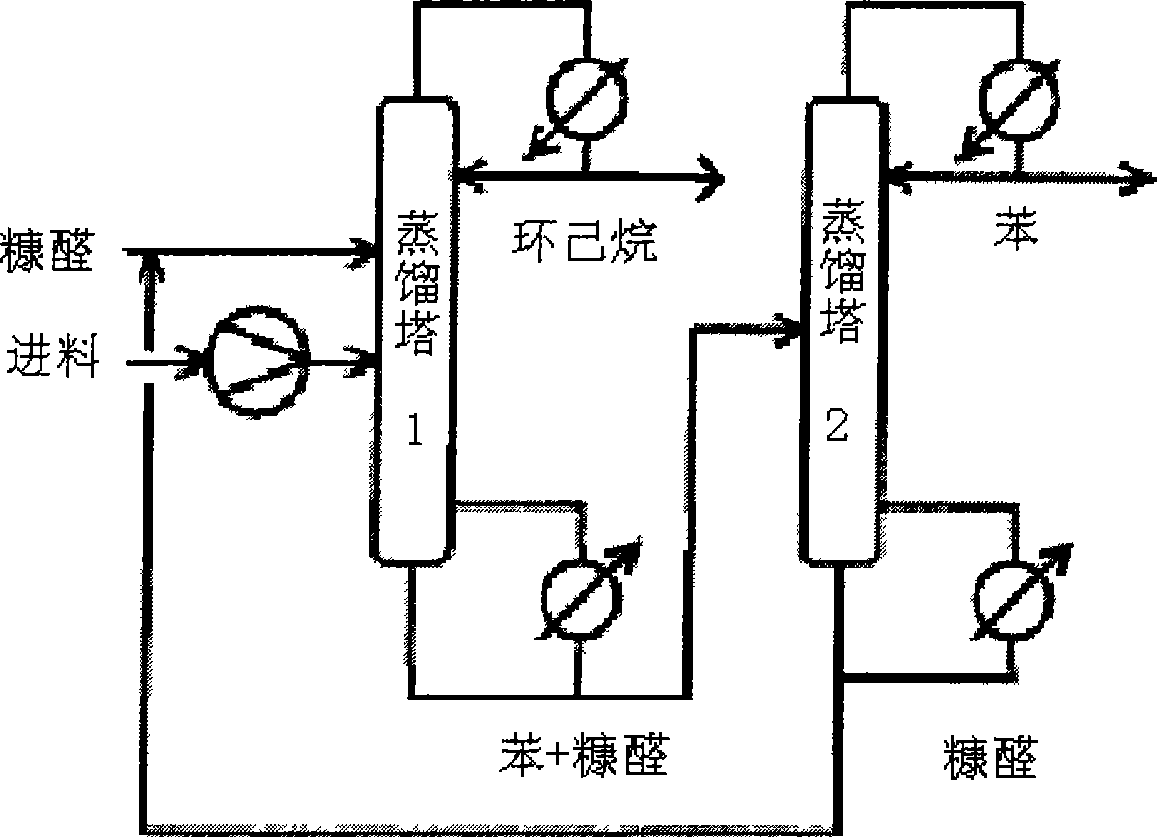

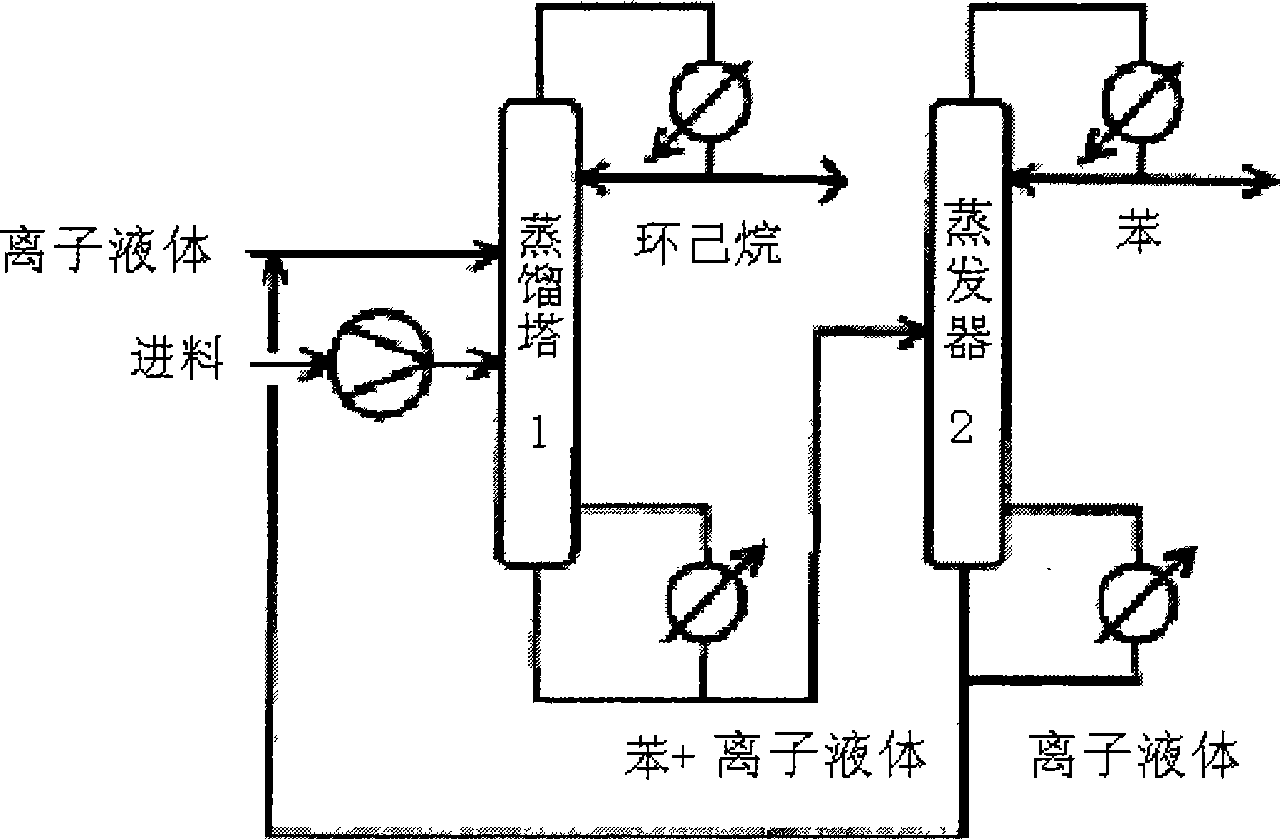

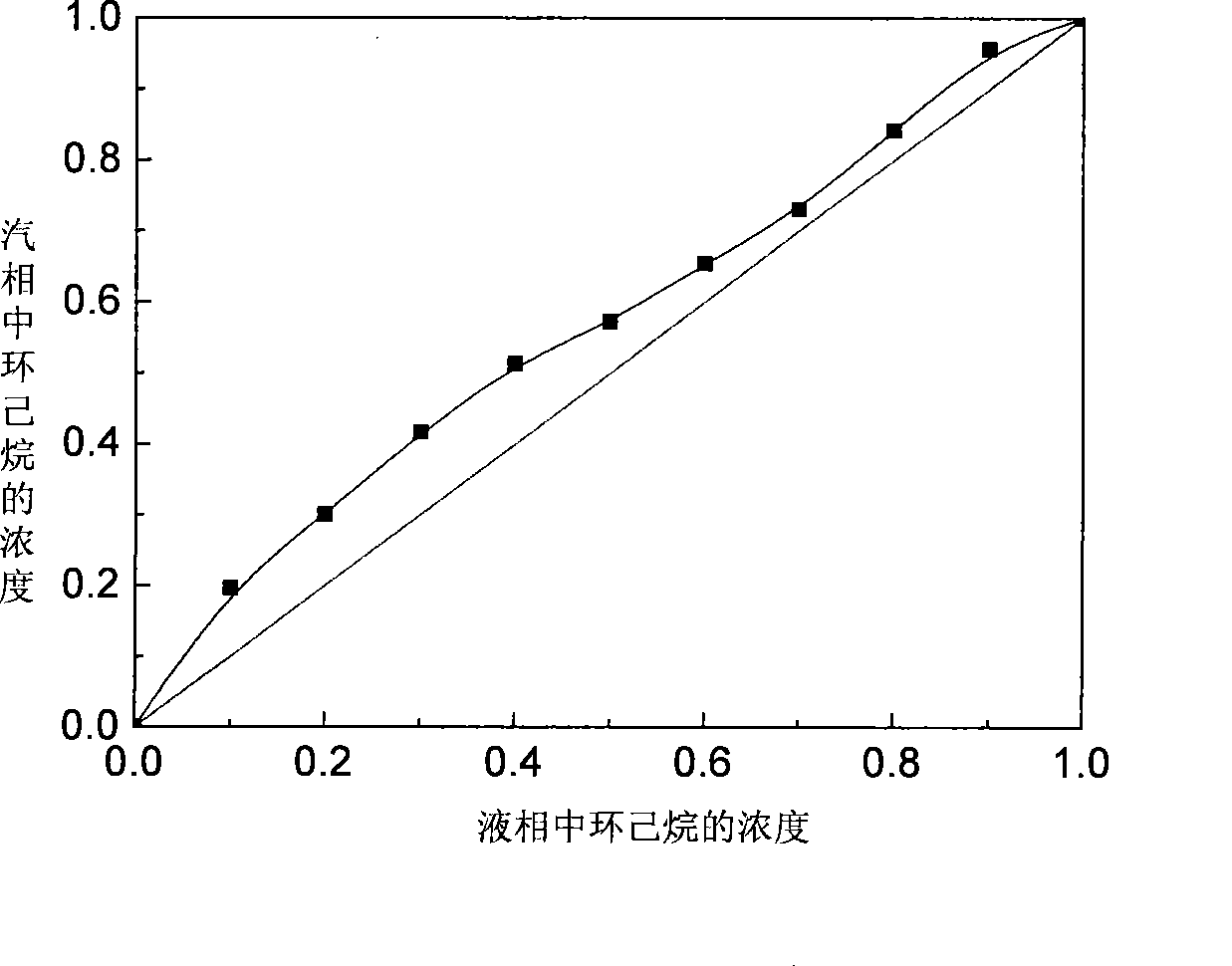

Application of ionic liquid used as solvent in benzene and cyclohexane extraction, rectification and separation

InactiveCN101265152BAdjustable solubilityIncrease relative volatilityDistillation purification/separationBulk chemical productionExtractive distillationIonic liquid

The invention discloses the application of ionic liquid which is used as a solvent for separating benzene and cyclohexane by extractive distillation, and relates to the application that the ionic liquid is used as the solvent during the process of separating the benzene and the cyclohexane by extractive distillation. Cationic in the ionic liquid is imidazole cationic, anion in the ionic liquid isfluorophoshoric acid anion or halide anion, and ionic liquid solvent is one ionic liquid or two or more than two compounded ionic liquid; the water content of the ionic liquid is 0 percent to 20 percent, and the addition amount ranges in the molar concentration from 5 percent to 90 percent; light-component cyclohexane with low boiling point is obtained at the top of a rectification column and themixture of the ionic liquid and the benzene is obtained in a column reactor during the separating process; the mixture passes through an evaporator or is performed through steam stripping separation.The extractive distillation technology of the ionic liquid solvent increases the separation precision, and obviously simplifies process flow agents, reduces equipment investment and lowers the separation energy consumption at the same time, thereby getting very remarkable economic benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Methods for preparing quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and polymer/montmorillonite nanocomposite

InactiveCN101979444BGood physical and chemical stabilityGreen chemical reagents are goodFibre treatmentCoatingsPolymer sciencePhosphonium salt

The invention relates to the field of polymer / montmorillonite nanocomposites, and discloses methods for preparing quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and the polymer / montmorillonite nanocomposite. The method for preparing the polymer / montmorillonite nanocomposite comprises the steps of performing pillaring-modification on montmorillonite by using quaternaryphosphonium salt ionic liquid and then intercalating the quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and a polymer or a polymeric monomer. In the methods, the montmorillonite is pillaring-modified directly by the quaternary phosphonium salt ionic liquid without water and any other solvent, and the ionic liquid can be recycled; the methods are simple, convenient to operate and environmentally-friendly, reduces the cost and saves energy consumption; and the quaternary phosphonium salt ionic liquid has more stable chemical properties and higher thermal stability, greatly improves the mechanical properties of the polymer material, can be applied to engineering plastics and heat-resisting polymers, and greatly expands the application range of the montmorillonite.

Owner:SOUTH CHINA UNIV OF TECH

Wet spinning method for polyacryl-nitrile fibre

InactiveCN100362149CEasy to recycleImprove protectionWet spinning methodsMonocomponent synthetic polymer artificial filamentChemical structureSolvent

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

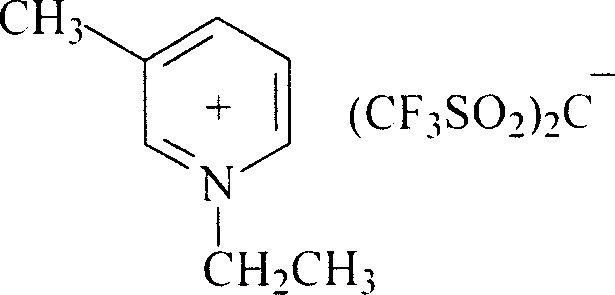

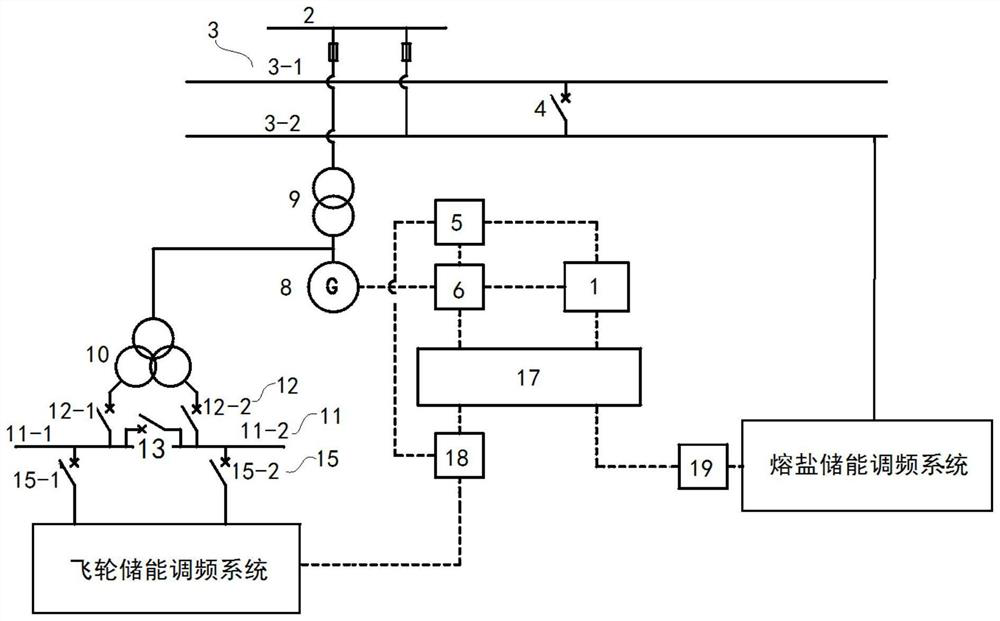

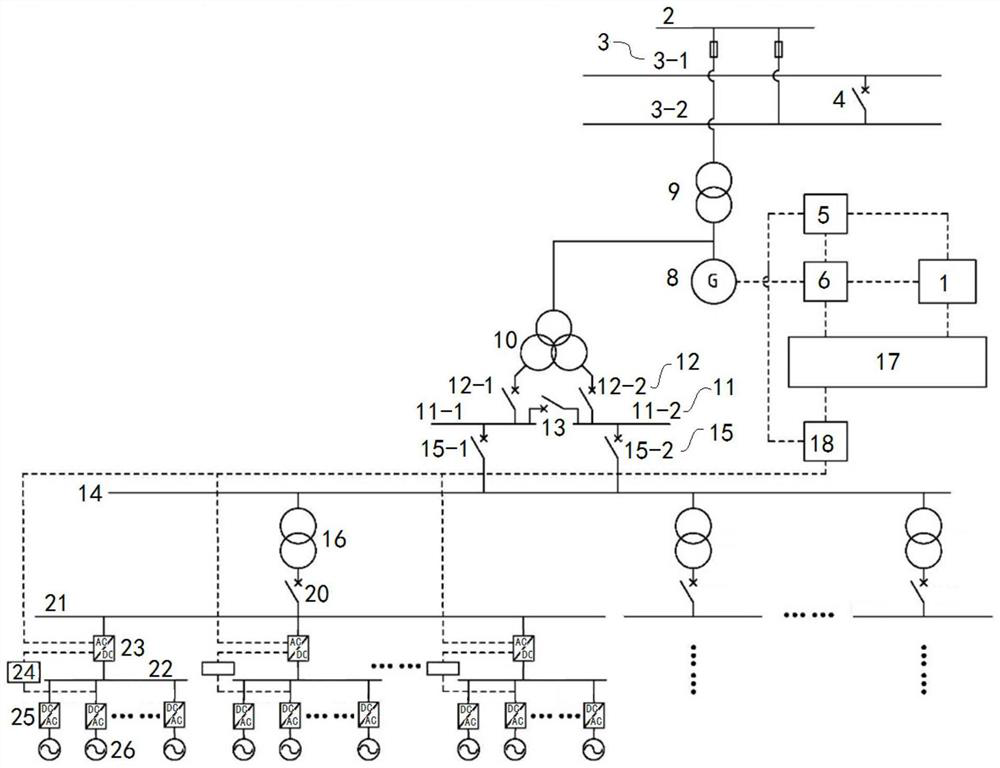

Application method of thermal power flexibility multi-source coordination active balance process system

PendingCN114597977AImprove performance qualityImprove standardsElectrical storage systemHeat storage plantsThermodynamicsFlywheel energy storage

The invention relates to an application method of a thermal power flexibility multi-source coordination'active balance 'process system, which is characterized by comprising the following steps of: setting a thermal power flexibility multi-source coordination'active balance service' process system which comprises a flywheel energy storage frequency modulation system, a fused salt energy storage frequency modulation system and a thermal power flexibility'active balance 'process monitoring control system; controlling a flywheel energy storage frequency modulation system to provide rotational inertia or primary frequency modulation active balance service of the thermal power plant; a flywheel energy storage frequency modulation system and a fused salt energy storage frequency modulation system are fused with a thermal power generating unit to form a virtual frequency modulation power supply so as to provide a multi-source coordination active balance service. The method can be widely applied to the technical field of active balance service of thermal power flexibility transformation.

Owner:吉林省众鑫能源服务有限公司

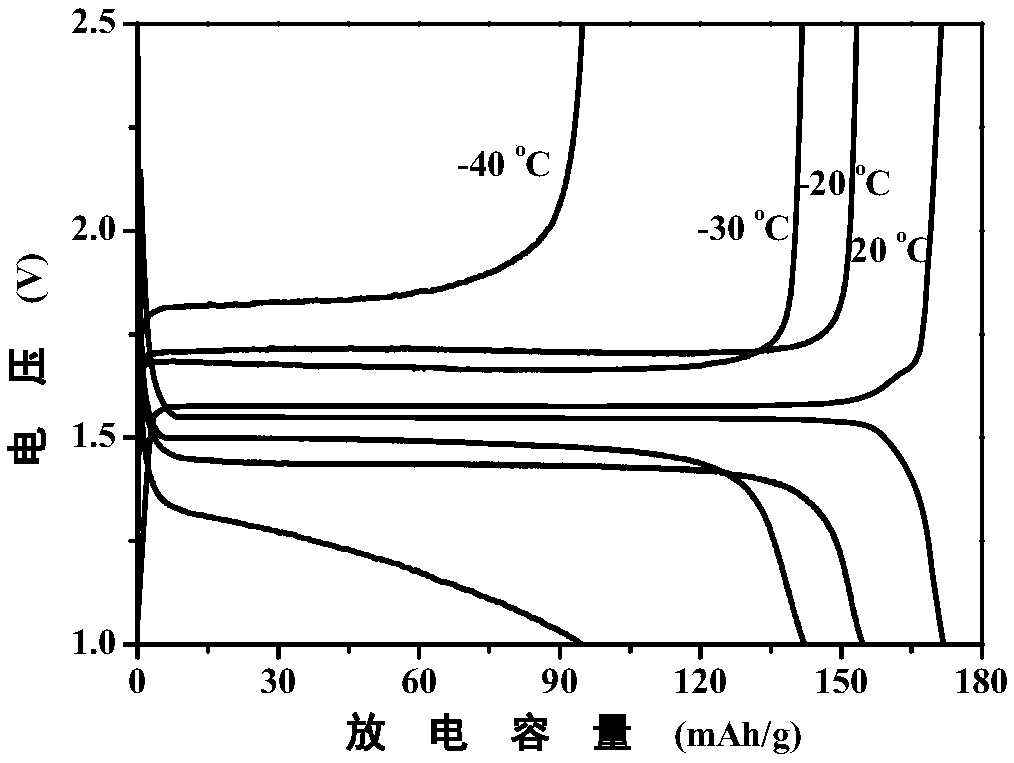

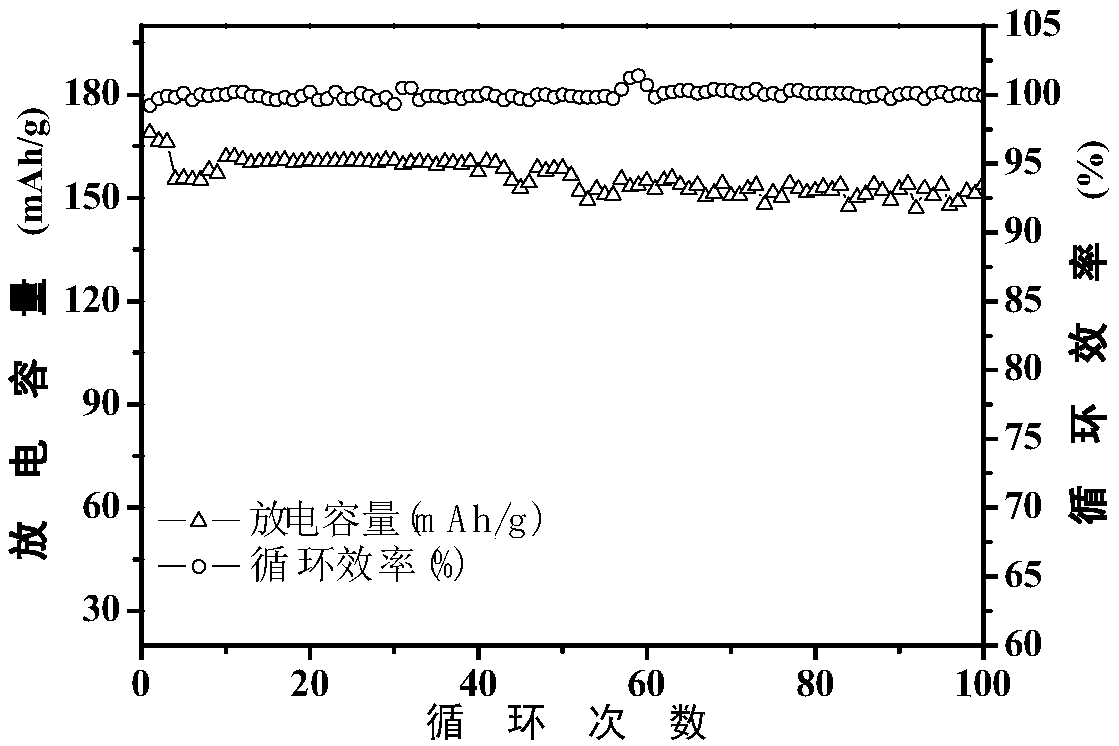

A lithium ion battery wide temperature electrolyte

InactiveCN109167097AImprove conductivityWide liquid temperature rangeSecondary cellsIonLithium electrode

The invention discloses a wide-temperature electrolyte for lithium ion battery, which is characterized in that the electrolyte is composed of an ionic liquid like ether solvent, an auxiliary organic solvent and a low-temperature additive. The electrolyte has low viscosity and freezing point and can maintain high ionic conductivity at ultra-low temperature. Forming a thin and dense solid electrolyte membrane on the surface of the negative electrode; On the premise of maintaining good cycling performance at room temperature, the charge-discharge capability at low temperature and safety performance at high temperature are effectively improved, and the application range of lithium battery is effectively expanded.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Conductive polymer-coated silicon-based negative electrode sheet, and preparation method and application thereof

ActiveCN110767878AImprove interface performanceImprove cycle stabilityNegative electrodesSecondary cellsMetallic lithiumPtru catalyst

The invention discloses a conductive polymer-coated silicon-based negative electrode sheet, and a preparation method and an application thereof. The silicon-based negative electrode sheet is used as amatrix, ionic liquid is used as a reaction medium, a polymer monomer generates an electrochemical self-polymerization reaction in a gap and on the surface of a matrix through an electrochemical polymerization reaction, and a conductive polymer film with a controlled thickness is formed on the surface of the matrix to improve the interfacial properties and the cycling stability of the silicon-based negative electrode sheet; and then the electrode sheet is used as a positive electrode, a metal lithium sheet is used as a negative electrode, an external circuit is connected to control the currentto perform electrochemical pre-lithium, so as to improve the first-time coulombic efficiency of the matrix, and the conductive polymer-coated silicon-based negative electrode sheet is prepared. During the electrochemical polymerization reaction, the thickness of the conductive polymer film can be controlled by electric quantity, no catalyst is needed, and mass production can be realized; and thereaction medium is the ionic liquid, which has almost no vapor pressure and a wide liquid temperature range, so compared with other organic / inorganic solvents, it is more environmentally friendly, green and pollution-free.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

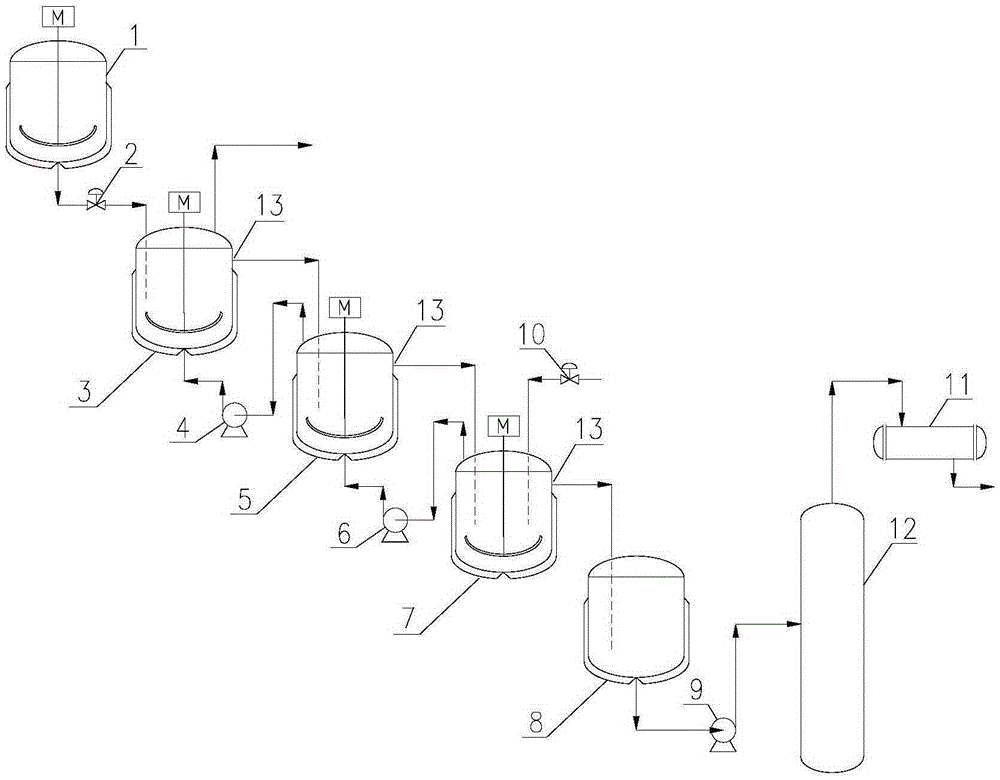

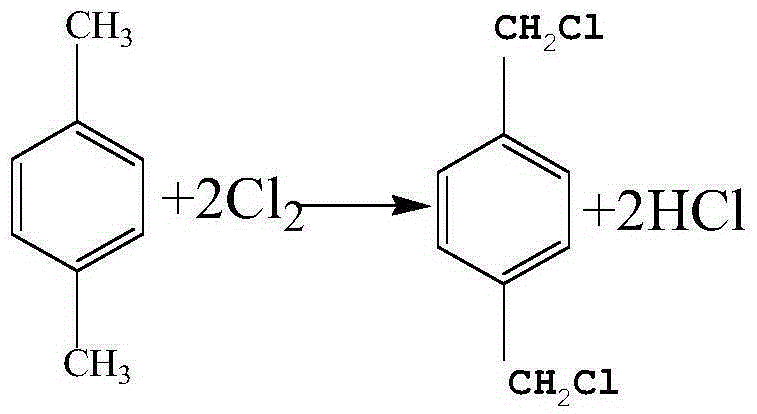

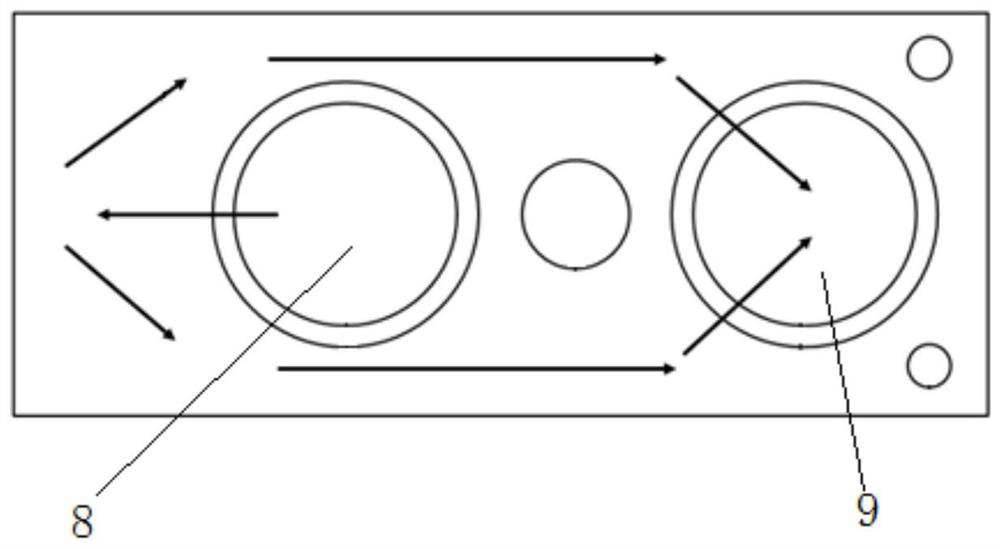

Continuous production process of p-xylylene dichloride and device

ActiveCN105348036AWide liquid temperature rangeImprove physicsHalogenated hydrocarbon separation/purificationXylyleneChemical synthesis

The invention relates to a continuous production process of p-xylylene dichloride and a device, and belongs to the technical field of organic chemical synthesis. The device provided by the invention comprises a feed tank, wherein the feed tank is successively connected with a third order chloride kettle, a second order chloride kettle, a first order chloride kettle, a knockout drum and a rectifying tower; the first order chloride kettle is connected with the second order chloride kettle in parallel, and the second order chloride kettle is connected with the third order chloride kettle in parallel; the continuous production process comprises the steps of mixing paraxylene and an ionic liquid catalyst, then introducing chlorine to the mixture under the irradiation of an LED (light-emitting diode) light source, obtaining p-xylylene dichloride reaction liquid after the third order chlorine reaction, cooling and separating the p-xylylene dichloride reaction liquid, performing vacuum distillation, then collecting cut fraction to obtain the p-xylylene dichloride. The continuous production process of the p-xylylene dichloride solves the problem in the existing process that the production is discontinuous, the product yield is low and the production cost is high, has the characteristics of simple technological process, short production cycle and high product purity, and the device is simple in structure and is liable to operate.

Owner:SHANDONG KAISHENG NEW MATERIALS

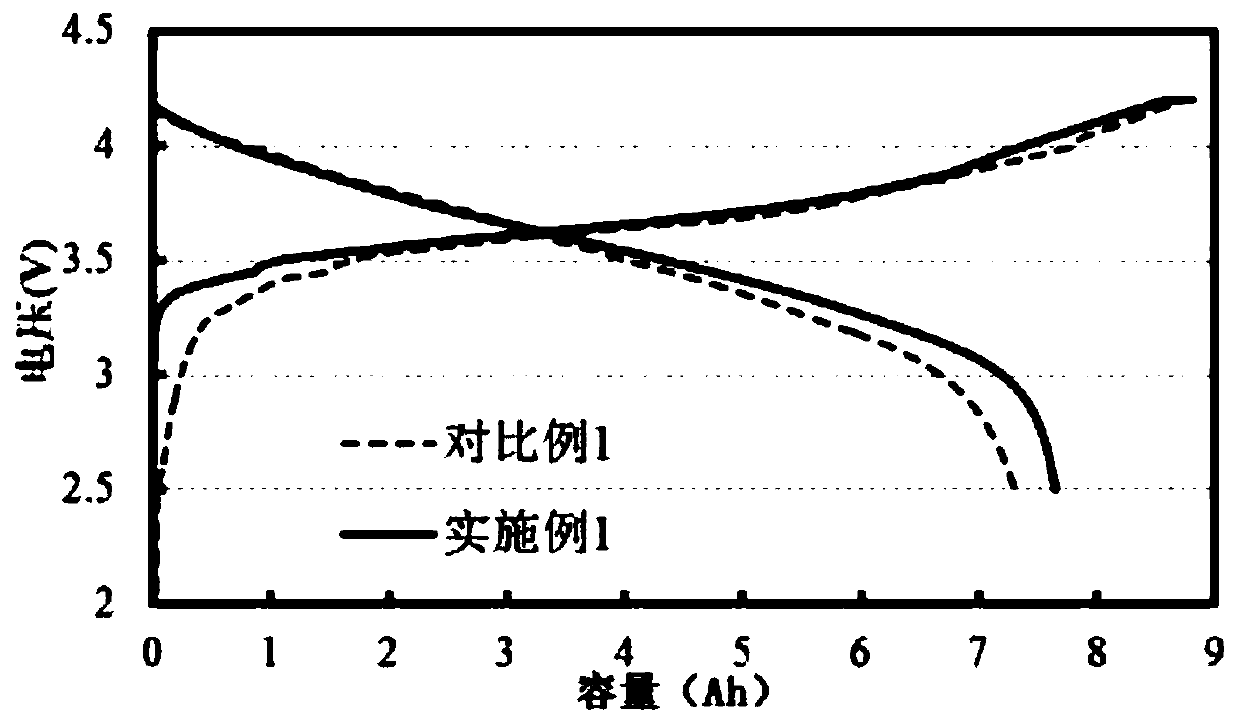

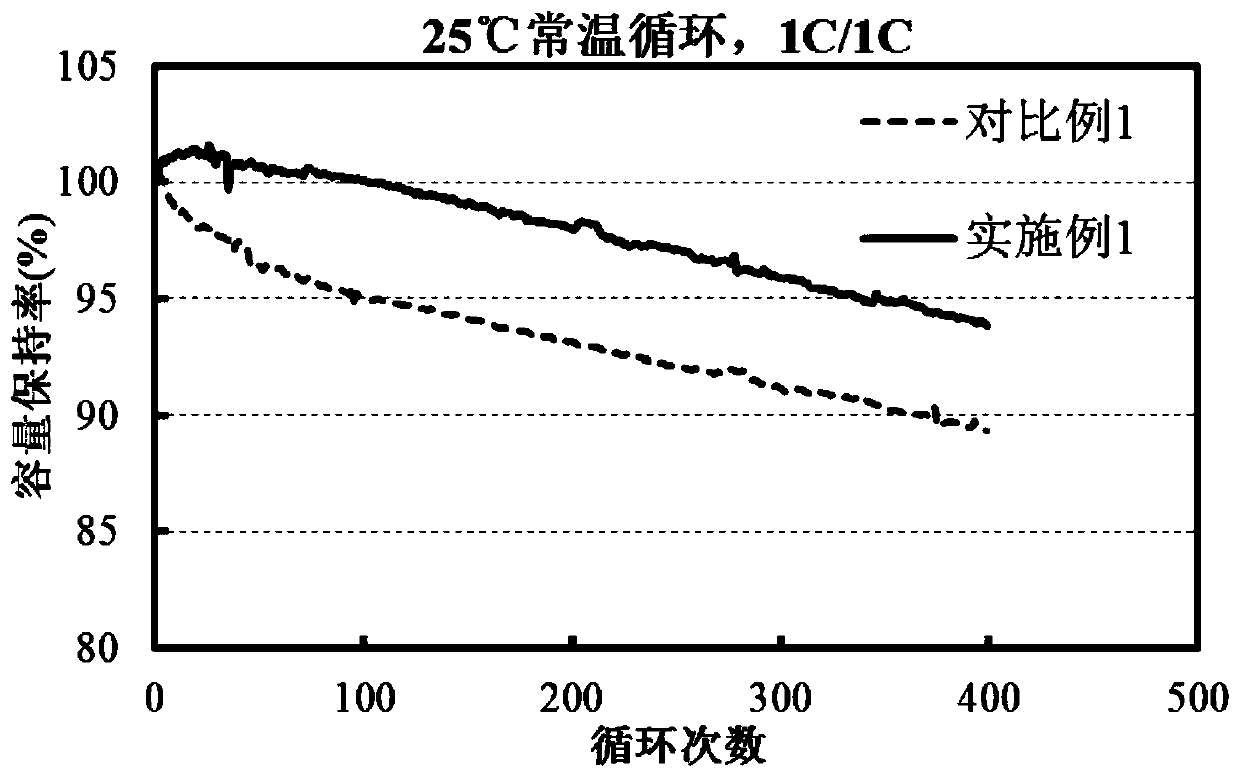

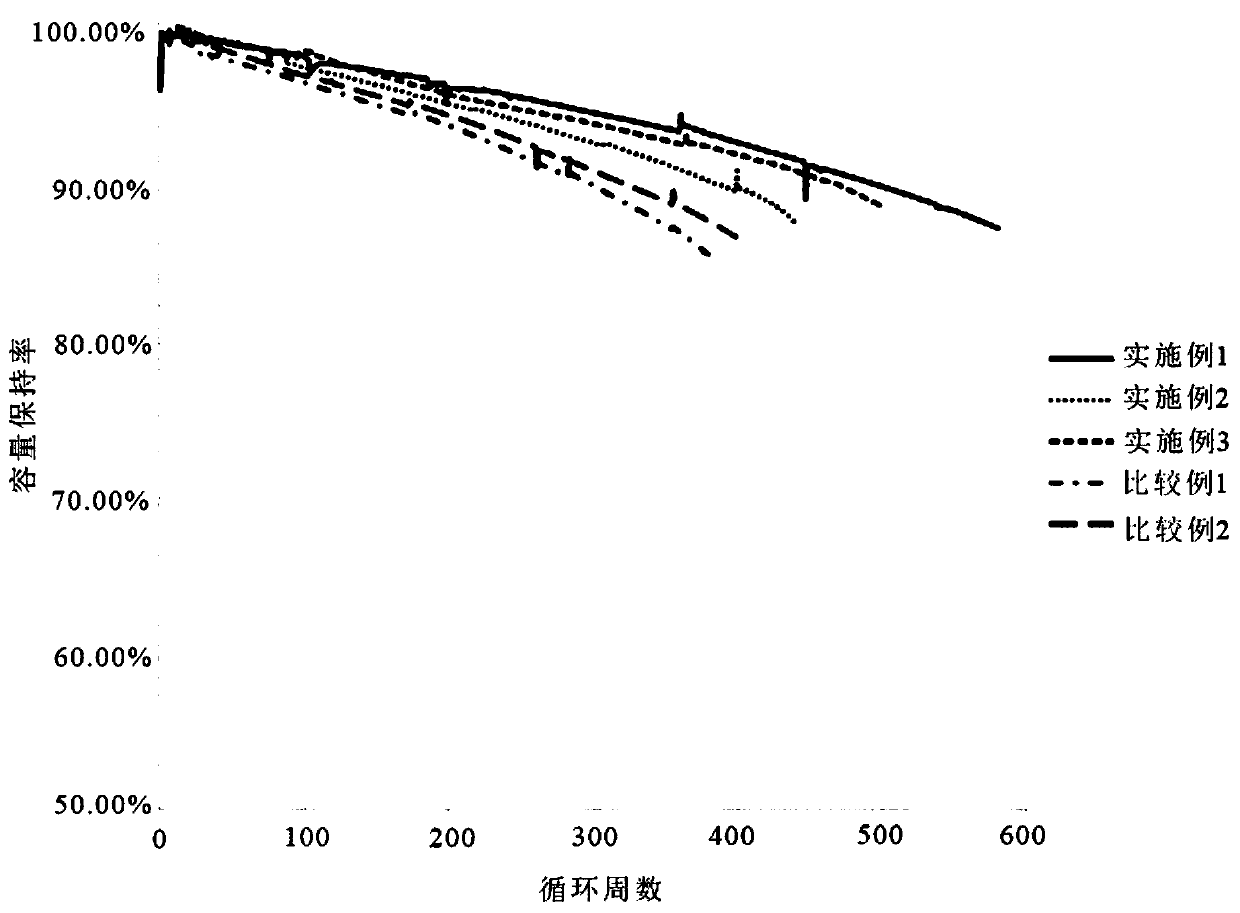

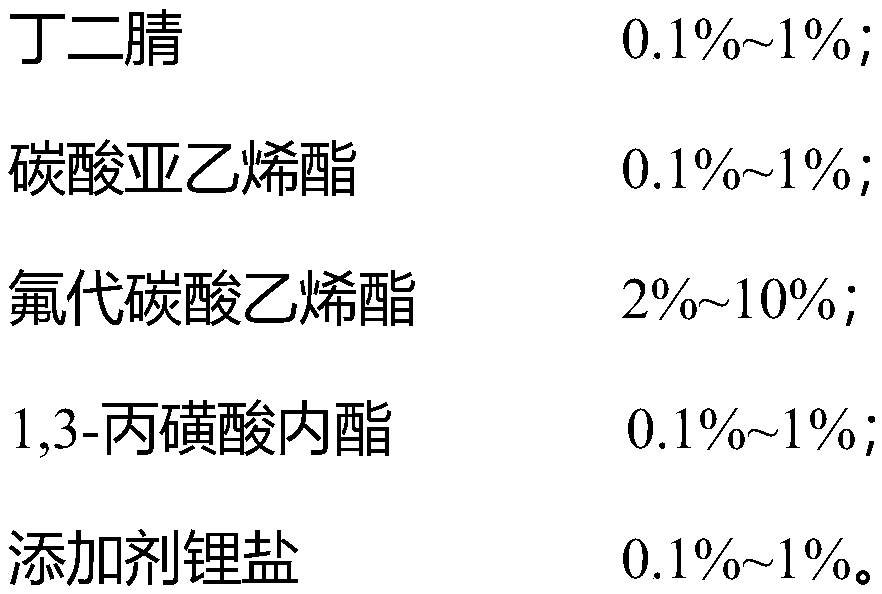

Lithium ion battery electrolyte and lithium ion battery

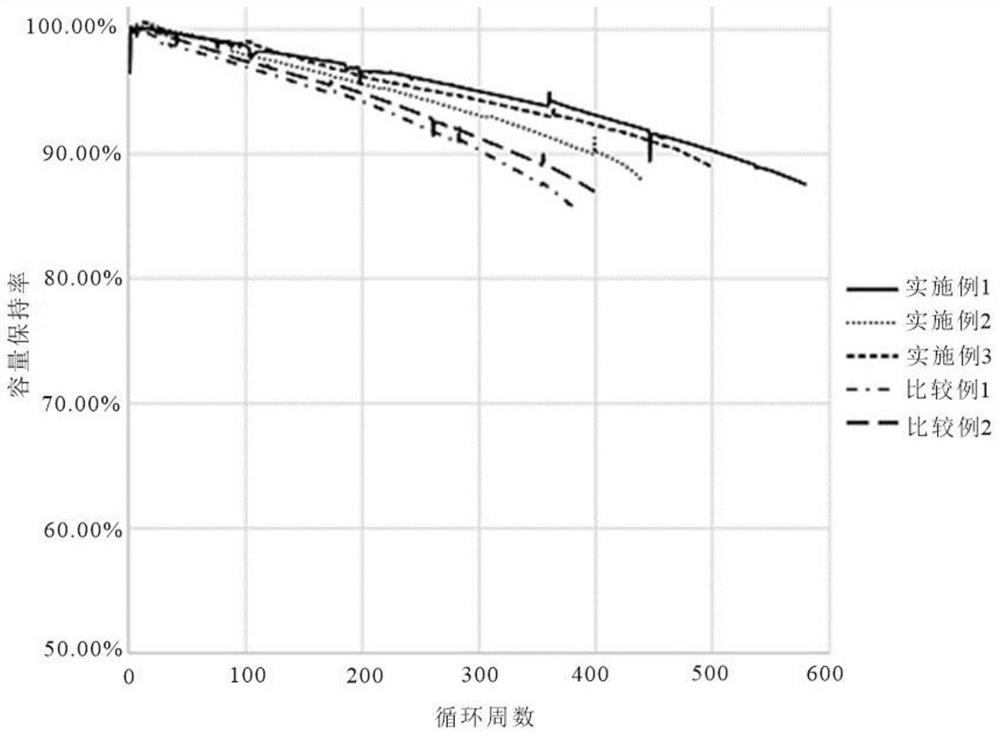

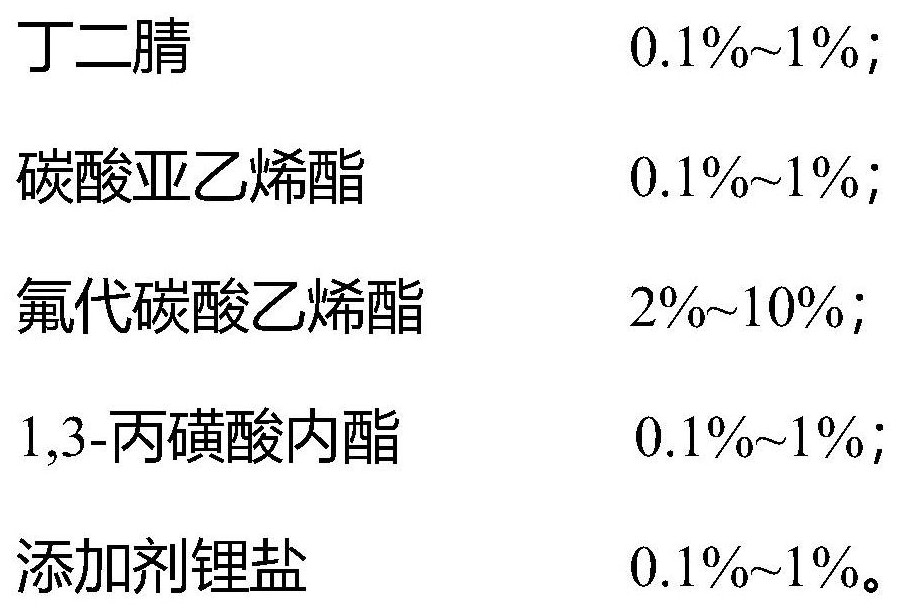

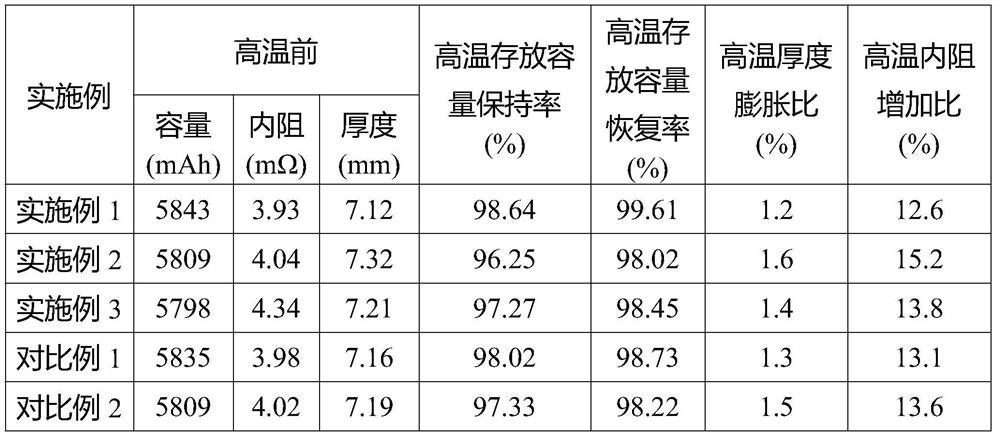

ActiveCN111048840AIncrease high temperature cycleImprove high temperature storage performanceElectrolytesSecondary cells servicing/maintenanceCarboxylic esterVinylene carbonate

The invention provides a lithium ion battery electrolyte and a lithium ion battery. The lithium ion battery electrolyte comprises a solvent, an electrolyte lithium salt and an additive, wherein the solvent comprises a carbonic ester solvent and a carboxylic ester solvent. According to the total amount of the electrolyte being 100%, the additive comprises the following components in percentage by mass: 0.1-1% of butanedinitrile; 0.1%-1% of vinylene carbonate; 2%-10% of fluoroethylene carbonate; 0.1%-1% of 1, 3-propane sultone; and 0.1%-1% of additive lithium salt. The lithium ion battery electrolyte composed of the mixed solvent, the mixed additive and the electrolyte lithium salt in a specific ratio is adopted so that the high-temperature cycle and high-temperature storage performance of the lithium ion battery can be remarkably improved.

Owner:湖南领湃鼎芯电池研究院有限公司

Molten salt regenerative electric heating central heating system

ActiveCN103836703BAlleviate the peak-to-valley differenceReduce usageLighting and heating apparatusElectric heating systemWater useMaterials science

The invention relates to a molten salt heat storage type electric heating central heating system, and belongs to the technical field of heat storage. The molten salt heat storage type electric heating central heating system comprises a molten salt electric heater, a high-temperature hot salt tank, a low-temperature cold salt tank, a molten salt pump, a molten salt-water heat exchanger and a heat user. During the time period of low-price low off-peak electricity at night, the molten salt in the cold salt tank is pumped out through the molten salt pump to be conveyed to the molten salt electric heater for heating, and enters the hot salt tank after being heated up to high temperature. During the time period of a power utilization peak, the high-temperature molten salt, with accumulated heat, in the hot salt tank is pumped put through the molten salt pump to be conveyed to the molten salt-water heat exchanger and heats water used for municipal heating to produce hot water for supplying heat to residents. On the basis of a coal-fired boiler central heating system which is in general use at present, only a boiler room of the central heating system needs to be transformed into the molten salt heat storage type electric heating system, and neither a municipal heat supply pipe network nor heat supply terminal equipment needs to be transformed. Besides, the molten salt heat storage type electric heating central heating system can cut down a peak to supplement a trough and reduce the usage amount of coal, thereby playing a role in protecting the environment.

Owner:中投亿星新能源投资有限公司

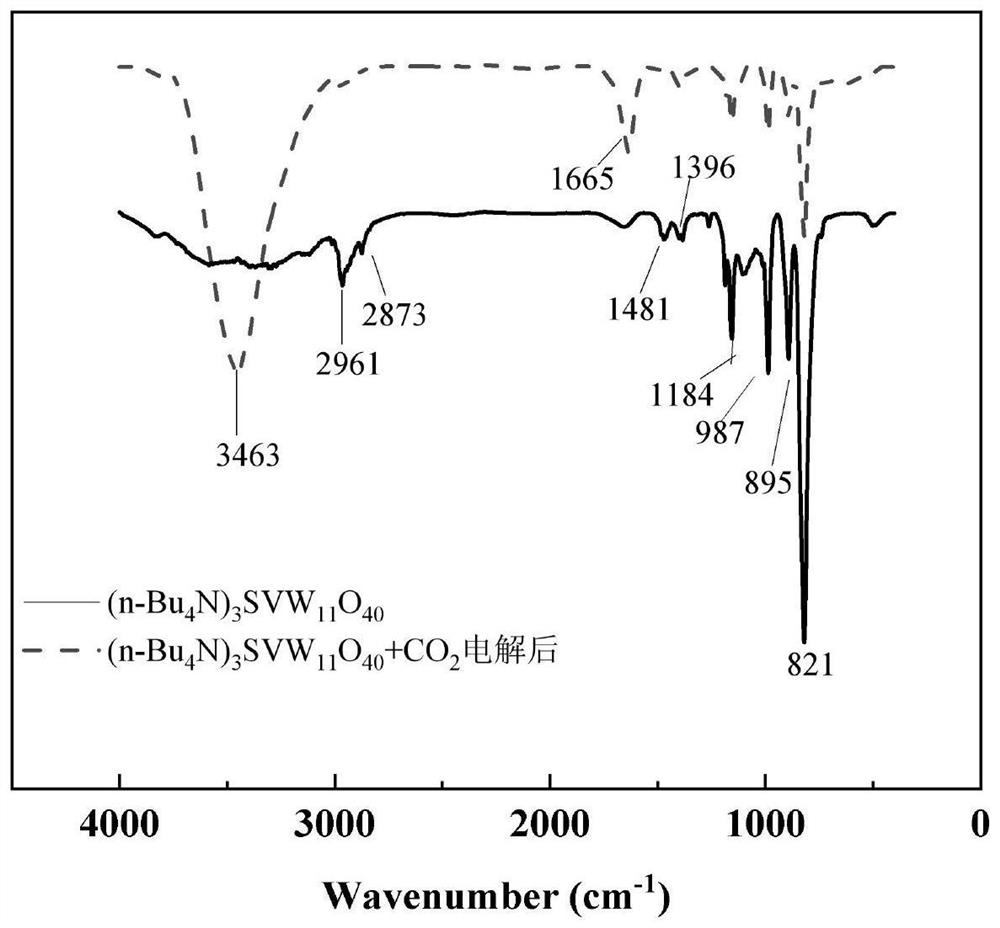

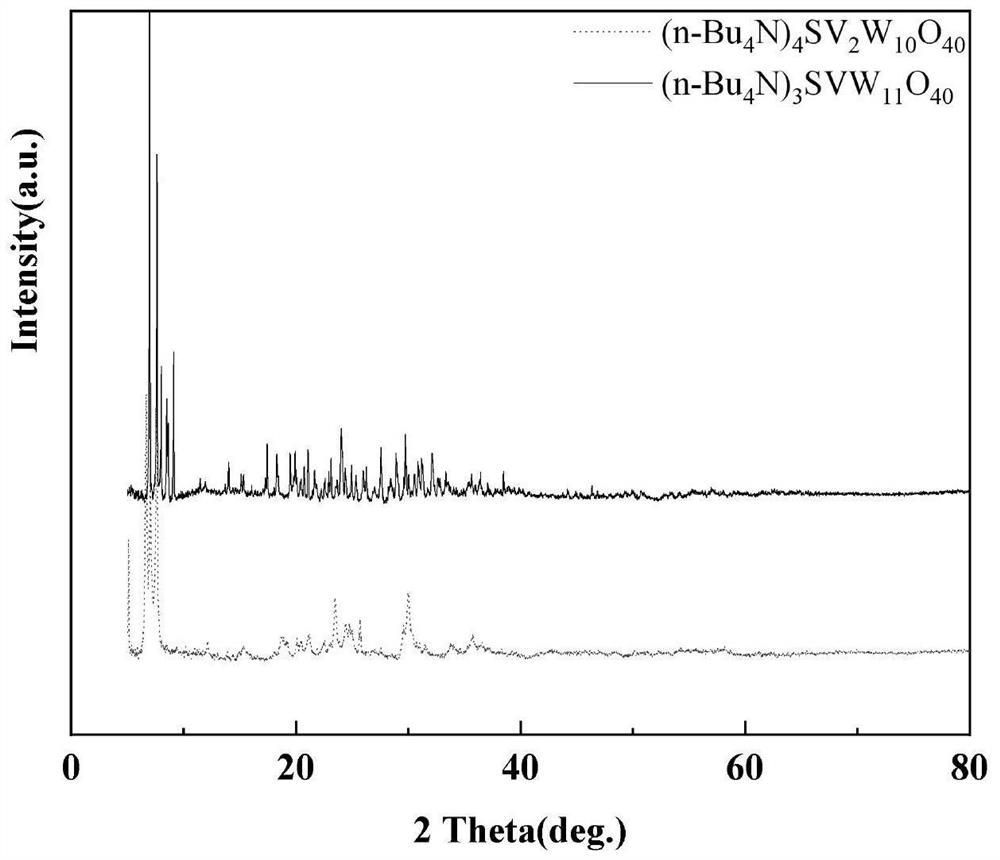

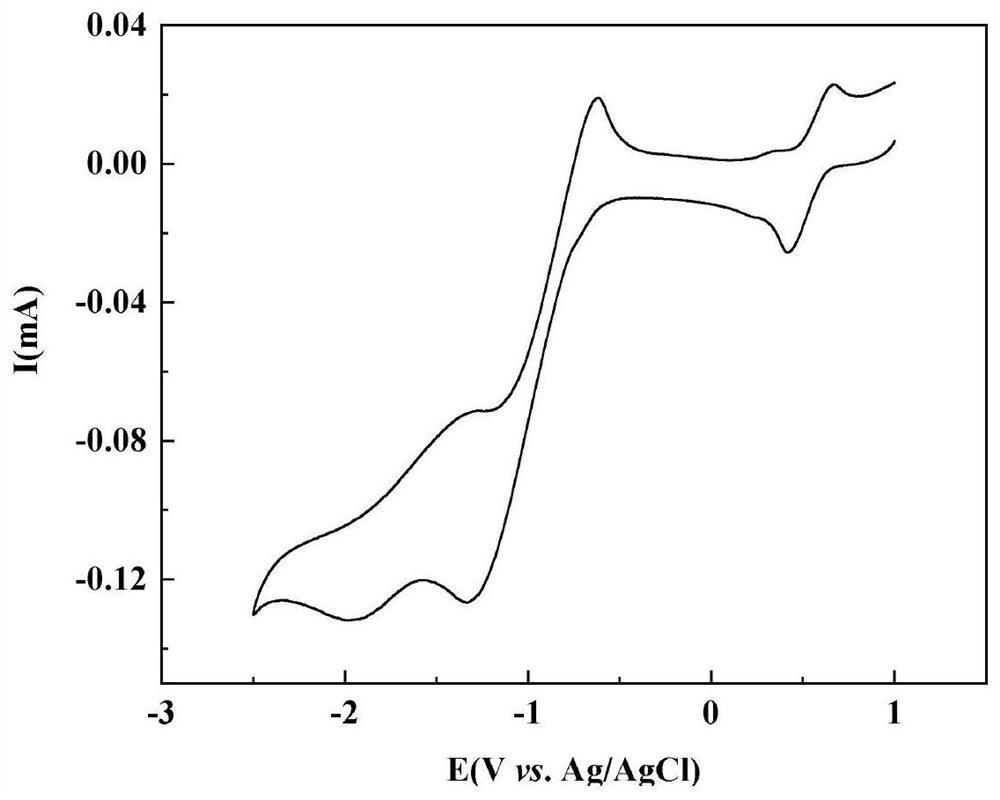

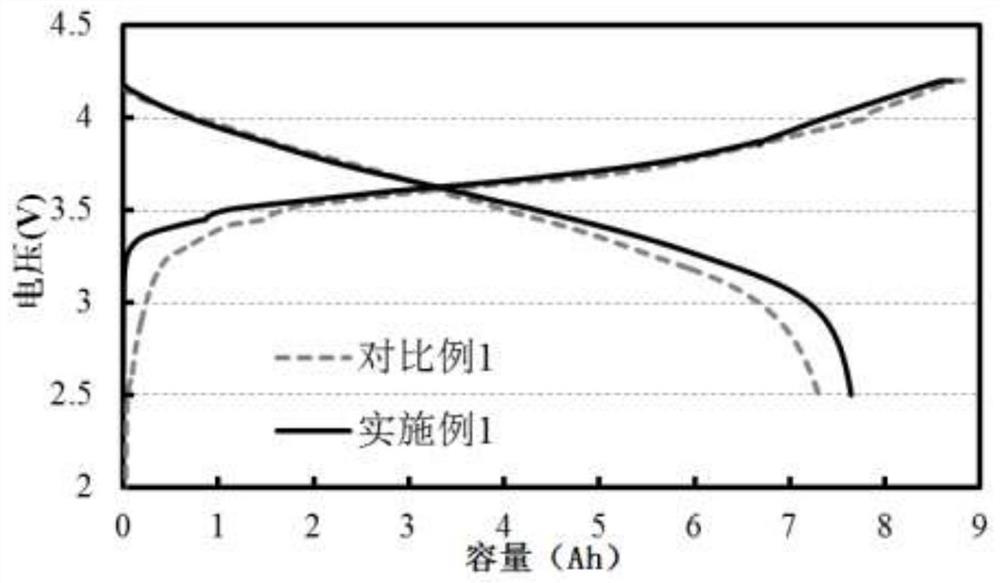

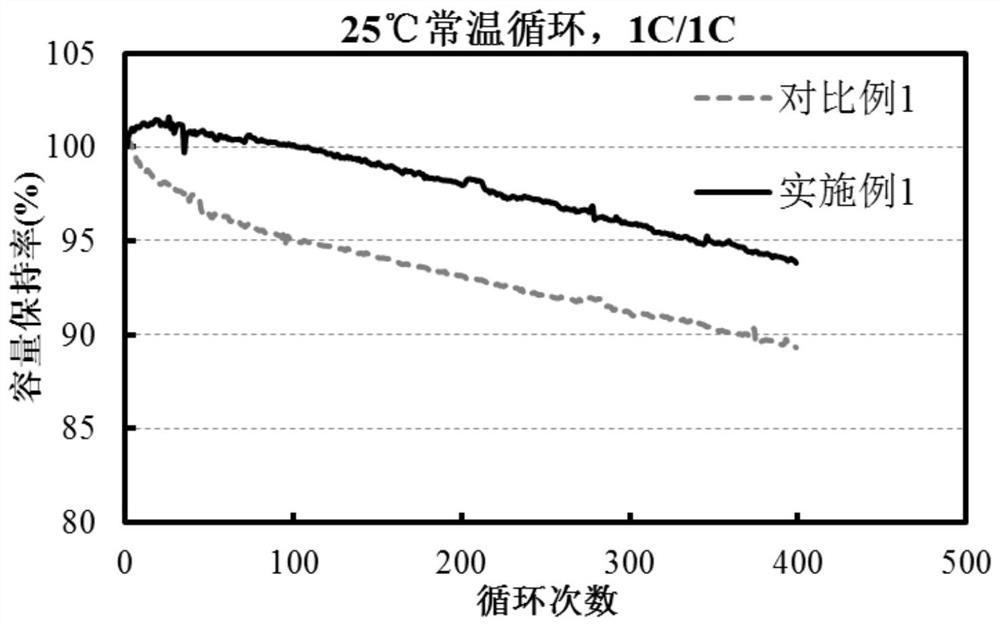

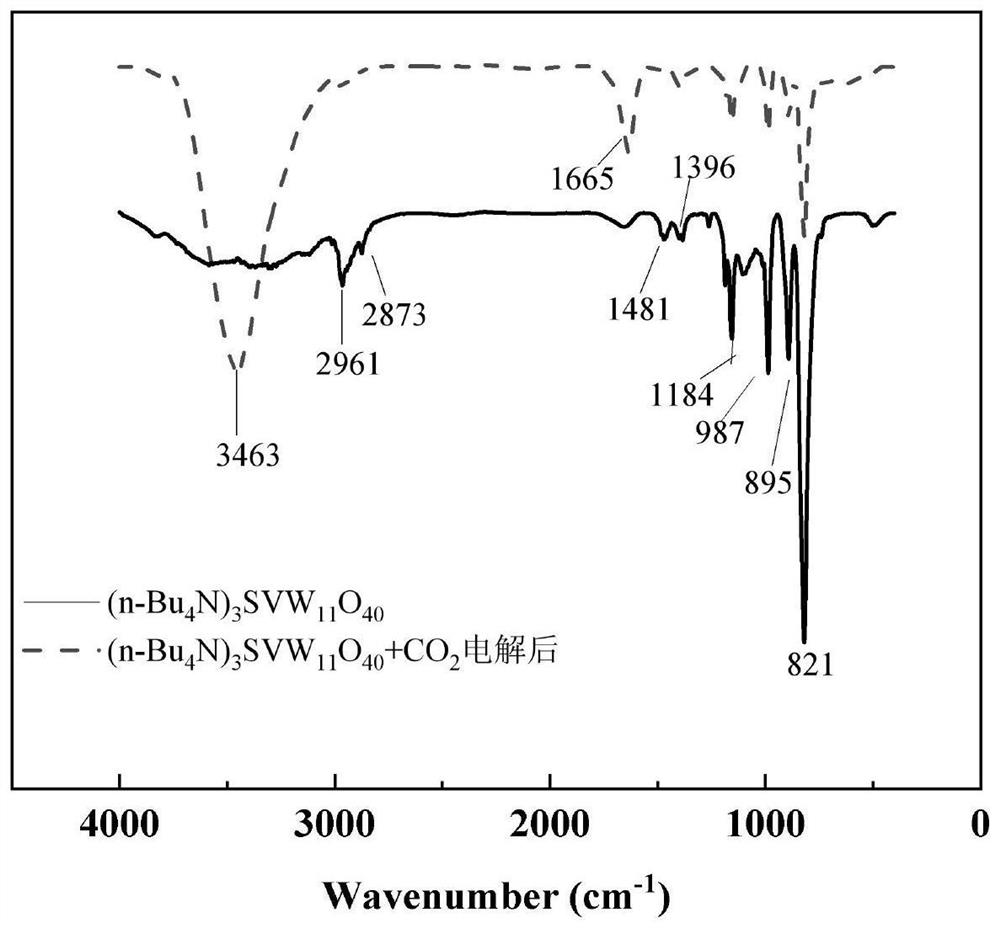

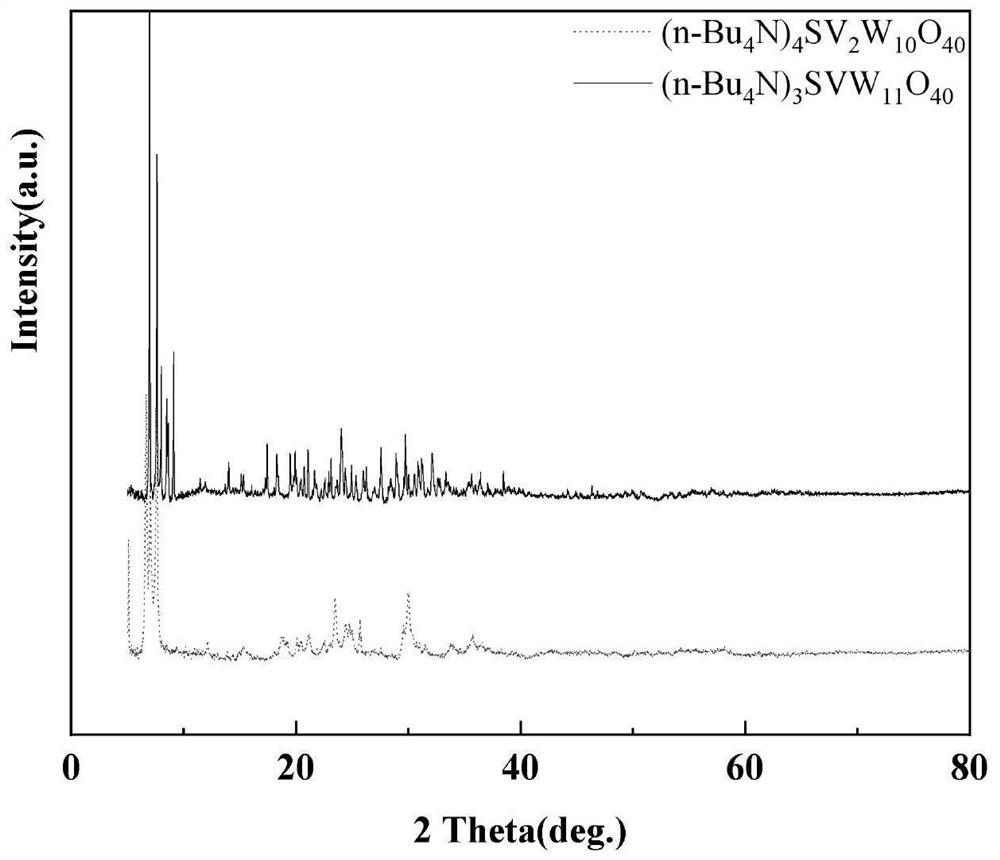

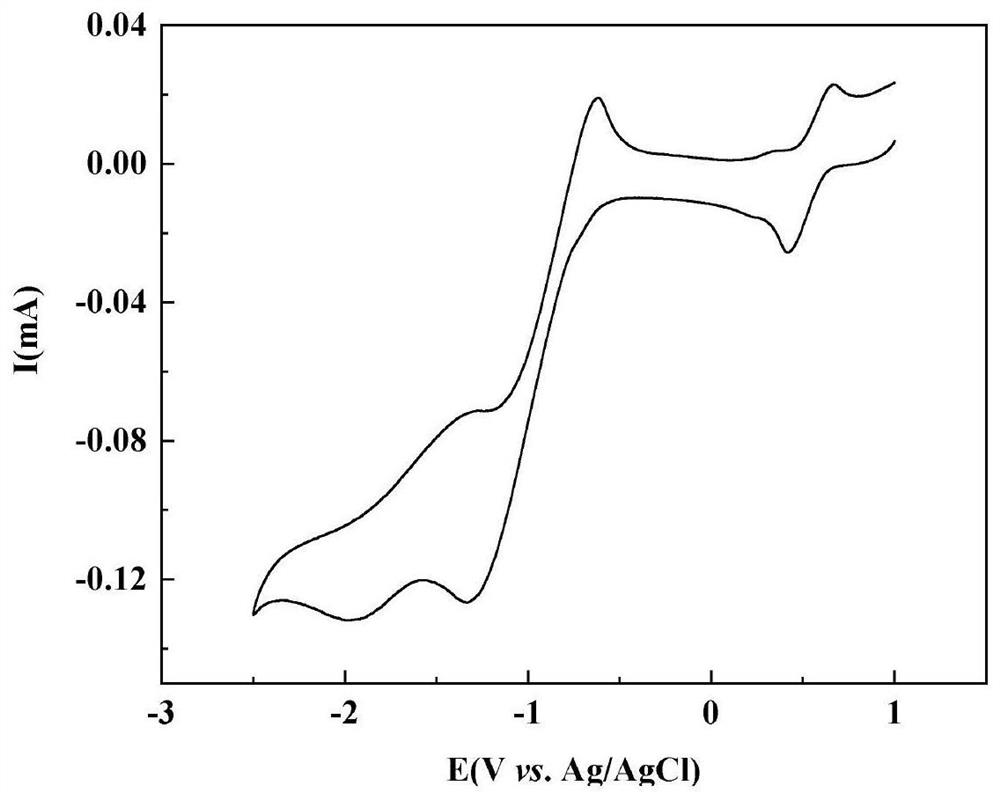

Method for preparing glycolic acid by electrocatalytic reduction of CO2 in heteropolyacid ionic liquid-indium dual-catalytic system

ActiveCN112144073ASolve the scarcitySolve the problem of quantity shortageOrganic-compounds/hydrides/coordination-complexes catalystsElectrolytic organic productionElectrolytic agentAcetic acid

The invention relates to a method for preparing glycolic acid by electrocatalytic reduction of CO2 in a heteropolyacid ionic liquid indium dual-catalytic system. The invention belongs to the field ofpreparation of glycolic acid by electrocatalytic reduction of CO2. The invention aims to solve the technical problems that the existing CO2 reduction reaction is generally 2e-, 4e- transfer reaction,the deep reduction of CO2 cannot be realized, and the ionic liquid preparation process of the existing reaction system is complex. The method comprises the following steps: preparing polyoxometallateionic liquid (n-Bu4N) 3SVW11O40, dissolving the polyoxometallate ionic liquid (n-Bu4N) 3SVW11O40 in acetonitrile to obtain a catholyte, and carrying out electrocatalytic reduction on carbon dioxide byusing dilute sulfuric acid as an anolyte to prepare liquid-phase products ethanol and acetic acid which are greater than or equal to C1. The method provided by the invention is simple, effectively solves the problems that the existing polyacid ionic liquid is rare in variety and short in quantity, is mild in reaction condition and low in economic cost, and can improve the energy efficiency to 4-5times, and the Faraday efficiency of the obtained ethanol is 7-16%, and the Faraday efficiency of the obtained acetic acid is 14-67%.

Owner:HARBIN INST OF TECH

Wet spinning method for polyacryl-nitrile fibre

InactiveCN100362151CEasy to recycleImprove protectionWet spinning methodsMonocomponent synthetic polymer artificial filamentChemical structureSolvent

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Secondary refrigerant and preparation method thereof, cooling structure, semiconductor laser bar and heat sink system

PendingCN113717697AWide liquid temperature rangeEffectively regulate working temperatureLaser detailsHeat-exchange elementsHeat sinkFluoride

The invention discloses a secondary refrigerant and a preparation method thereof, a cooling structure, a semiconductor laser bar and a heat sink system. The secondary refrigerant for operating the semiconductor laser bar at low temperature comprises the following components in parts by volume: 100 parts of fluoride; and 1-50 parts of alcohol. The secondary refrigerant has the characteristics of no corrosion, low toxicity, safety, stability, excellent thermal conductivity, wide liquid temperature range and the like, is suitable for a semiconductor laser bar micro-channel heat sink cooling structure running at low temperature, effectively adjusts the working temperature of a semiconductor laser bar, and improves the electro-optical efficiency of the semiconductor laser bar. According to the secondary refrigerant, the freezing point of impurity water in the secondary refrigerant can be reduced to be lower than the working temperature, and ice particles are prevented from being generated to block a heat sink microchannel. The secondary refrigerant has certain conductivity, can prevent accumulation of static charges in the working process, and avoids the problem of static sparking.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A lithium ion battery electrolyte and a lithium ion battery containing the electrolyte

ActiveCN101471454BWide liquid temperature rangeFlame retardantSecondary cellsOrganic solventCombustion

A Li-ion battery electrolyte contains lithium salt, ionic liquid and a non-aqueous solvent, wherein the anion contained in the ionic liquid is showed by formula (1). A Li-ion battery comprises an electrical core and the above electrolyte, which can retard combustion of organic solvents. The Li-ion battery using the electrolyte can suppress capacity fade at low temperature, and can reduce the amount of gas generated by the electrolyte at high temperature, thereby effectively preventing battery expansion and improving the high-temperature performance of the battery.

Owner:BYD CO LTD

A conductive polymer-coated silicon-based negative electrode sheet and its preparation method and application

ActiveCN110767878BImprove interface performanceImprove cycle stabilitySecondary cellsNegative electrodesMetallic lithiumPtru catalyst

The invention discloses a conductive polymer-coated silicon-based negative pole piece and its preparation method and application. The silicon-based negative pole piece is used as a substrate and an ionic liquid is used as a reaction medium to make polymer monomers Electrochemical self-polymerization reaction is carried out between the voids and the surface of the substrate, and a conductive polymer film with controllable thickness is formed on the surface of the substrate to improve the interface performance and cycle stability of the silicon-based negative electrode sheet; then use the electrode sheet as the positive electrode, metal lithium The sheet is the negative electrode, and the external circuit is connected to control the current to carry out electrochemical pre-lithium to improve the first Coulombic efficiency of the matrix, and to prepare a conductive polymer-coated silicon-based negative electrode sheet. In the electrochemical polymerization process, the thickness of the conductive polymer film can be controlled by electricity, no catalyst is needed, and it can be produced on a large scale; and the reaction medium is an ionic liquid, which has almost no vapor pressure and a wide range of liquid temperatures. Compared with other organic / Inorganic solvent, more friendly to the environment, green and pollution-free.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

An electrocatalytic reduction of CO in a heteropolyacid ionic liquid-indium dual catalyst system 2 Process for the preparation of ethanol acetic acid

ActiveCN112144073BThe reaction steps are simpleSimple methodOrganic-compounds/hydrides/coordination-complexes catalystsElectrolytic organic productionElectrolytic agentAcetic acid

Owner:HARBIN INST OF TECH

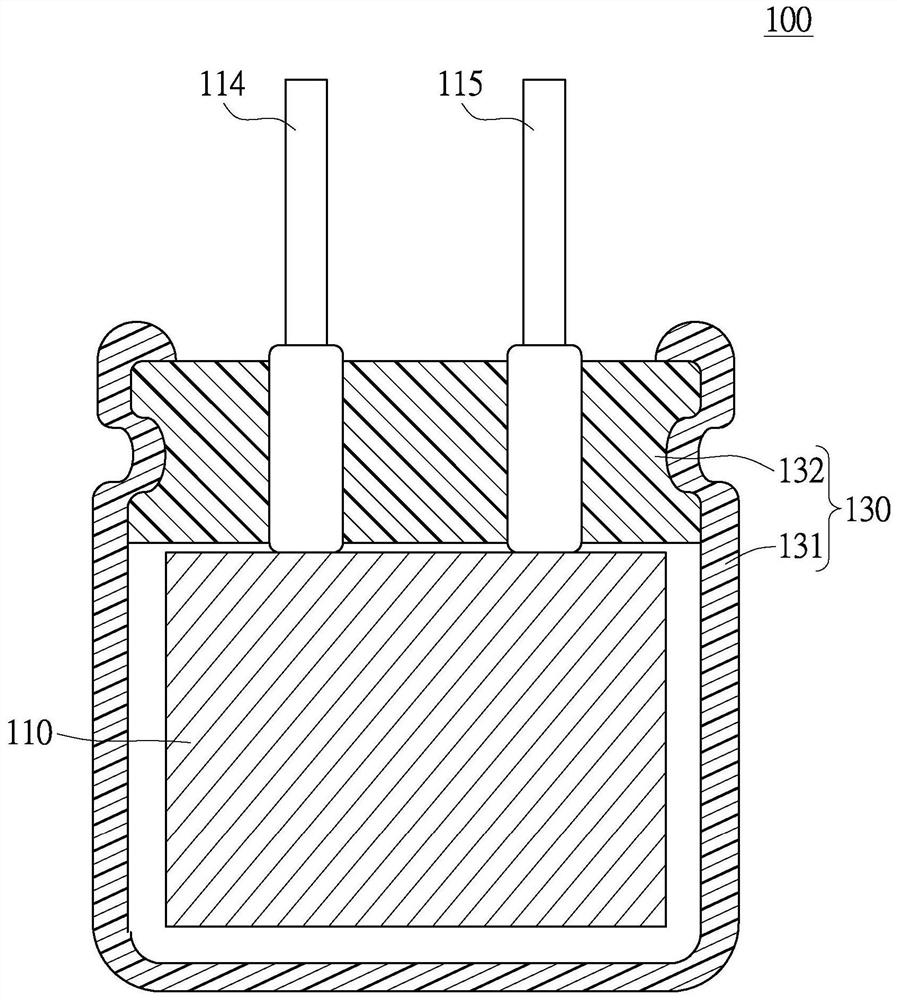

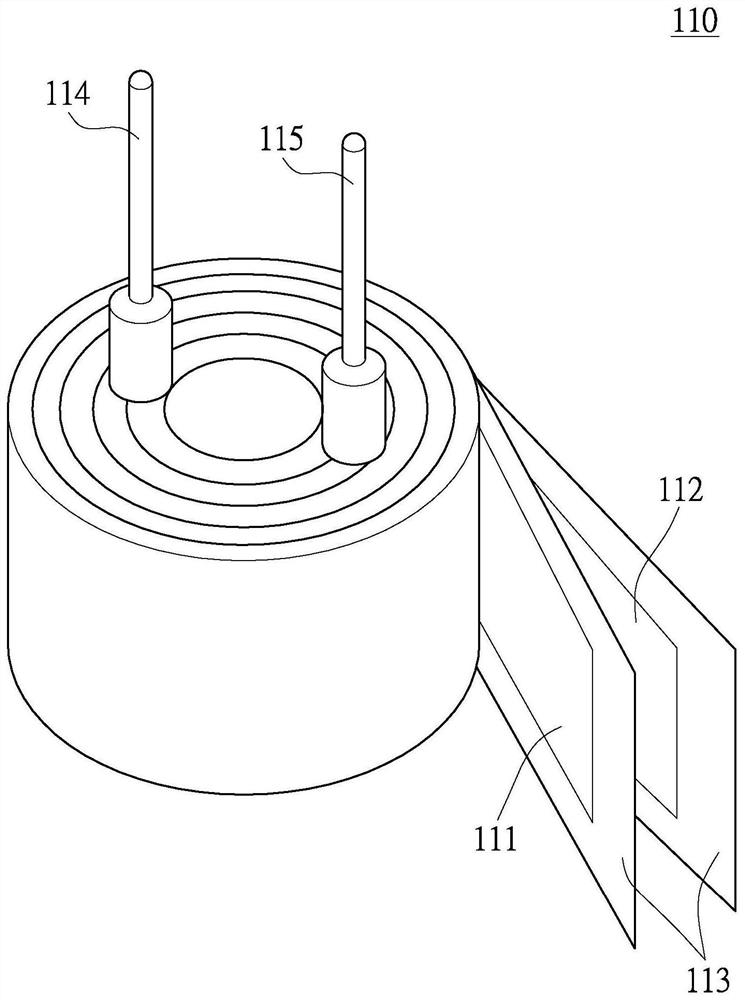

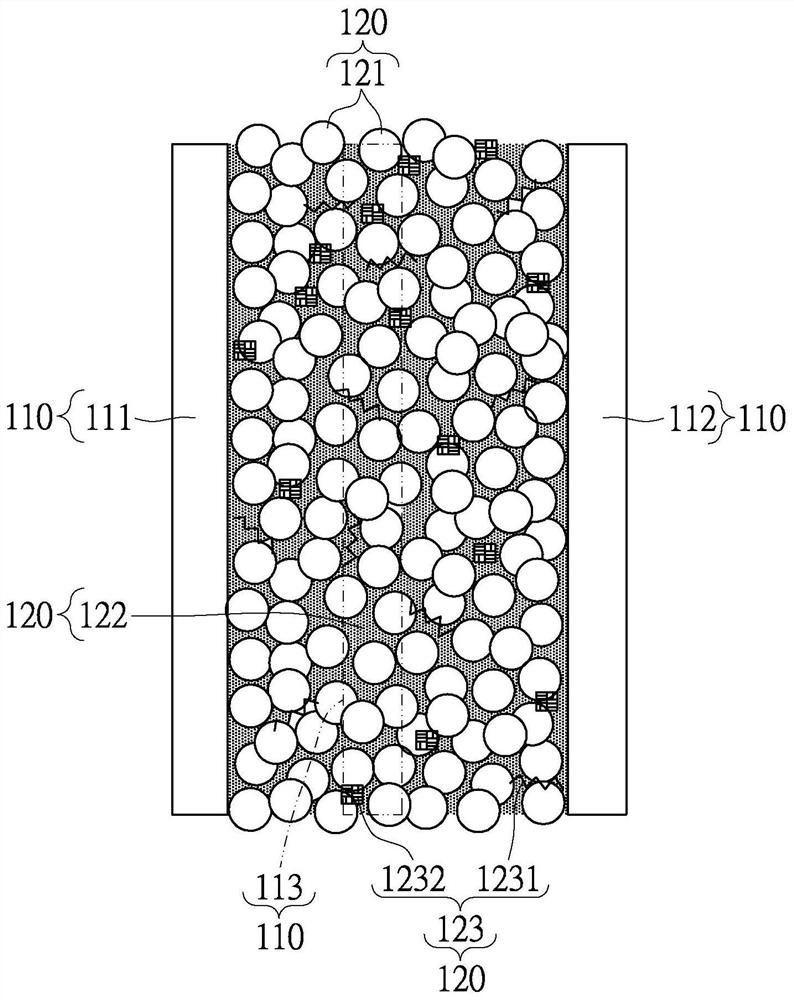

Low Leakage Electrolytic Capacitors

ActiveCN108597877BHigh mechanical strengthImprove electrical performanceCapacitor electrolytes/absorbentsElectrolysisConductive polymer

The invention discloses a low-electric leakage electrolytic capacitor. The capacitor comprises a wound type capacitor assembly, a mixed type conductive medium and a packaging body; an anode foil, a cathode foil and an isolating membrane between the anode foil and the cathode foil are wound so as to form the wound type capacitor assembly; the mixed type conductive medium is impregnated in the woundtype capacitor assembly; the mixed conductive medium contains a conductive polymer and an ionic liquid; and the packaging body completely wraps the wound type capacitor assembly and the mixed type conductive medium. The low-electric leakage electrolytic capacitor of the invention has the superior characteristics of a solid-state low-electric leakage electrolytic capacitor and can alleviate an electric leakage condition.

Owner:APAQ TECH

Lithium-ion battery electrolyte and lithium-ion battery

ActiveCN111048840BGood effectImprove conductivityElectrolytesSecondary cells servicing/maintenanceHigh temperature storageElectrolytic agent

The present application provides a lithium ion battery electrolyte and a lithium ion battery. The lithium-ion battery electrolyte includes a solvent, an electrolyte lithium salt and an additive, and the solvent includes a carbonate solvent and a carboxylate solvent; the total amount of the electrolyte is 100%, and the additive is in mass percent, including: D Dinitrile 0.1%~1%; Vinylene carbonate 0.1%~1%; Fluoroethylene carbonate 2%~10%; 1,3-propane sultone 0.1%~1%; Additive lithium salt 0.1%~ 1%. The application adopts a lithium-ion battery electrolyte composed of a specific proportion of mixed solvent, mixed additives and electrolyte lithium salt, which can significantly improve the high-temperature cycle and high-temperature storage performance of the lithium-ion battery.

Owner:湖南领湃新能源研究院有限公司

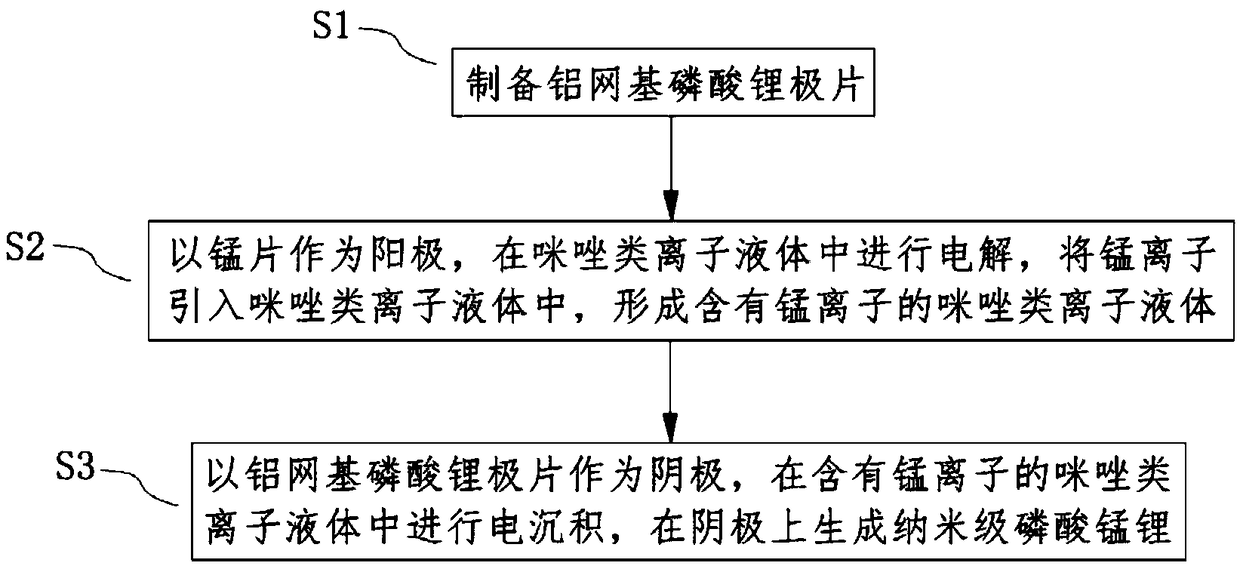

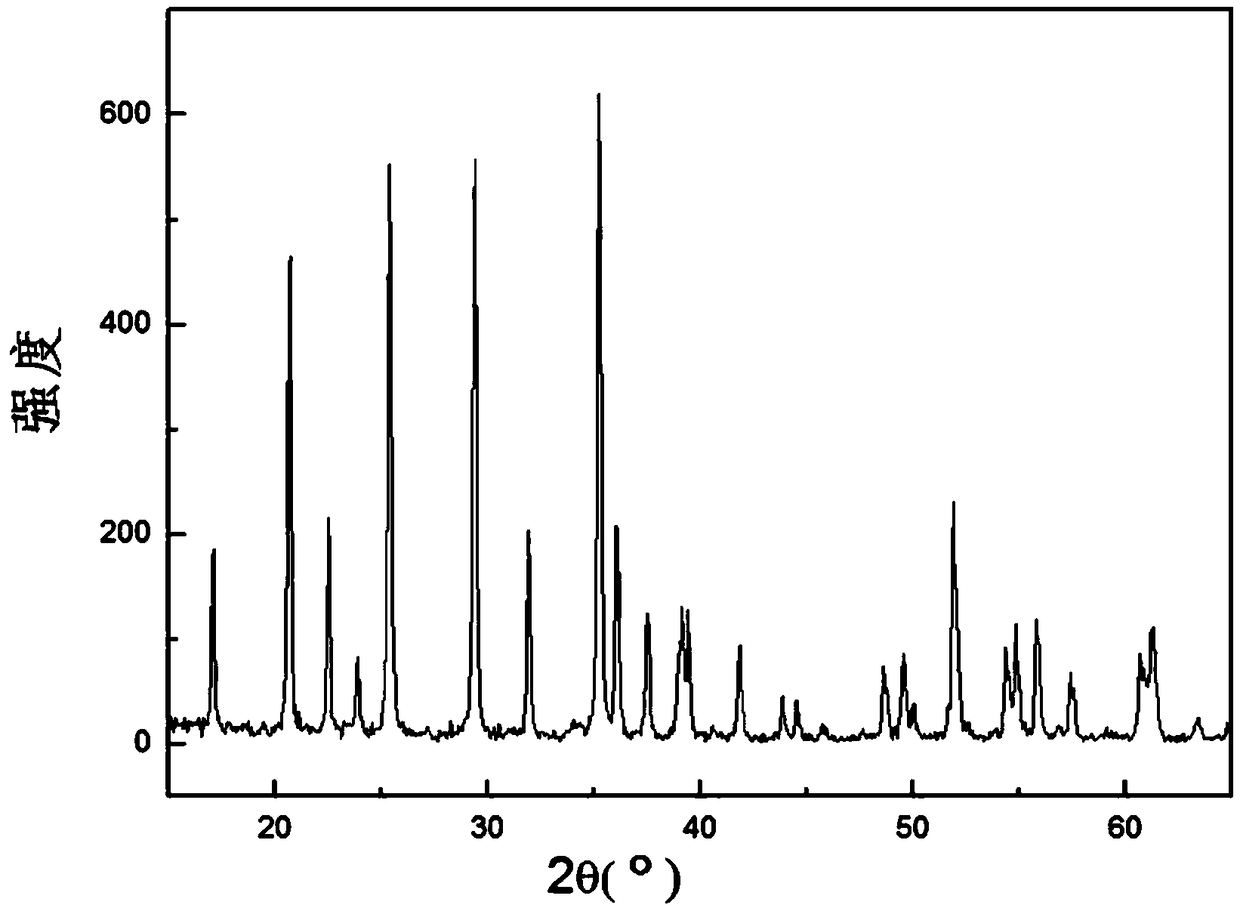

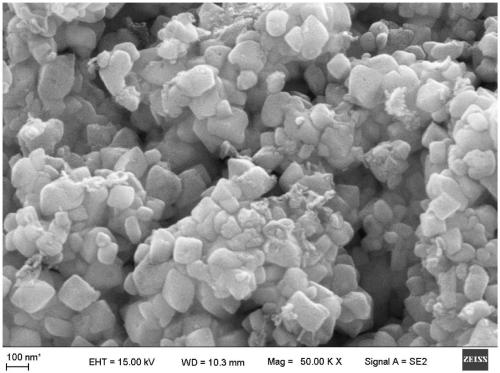

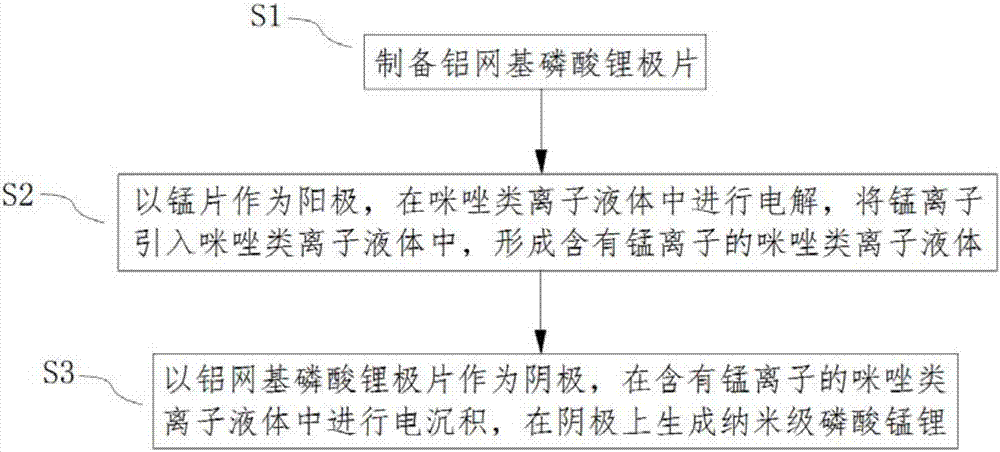

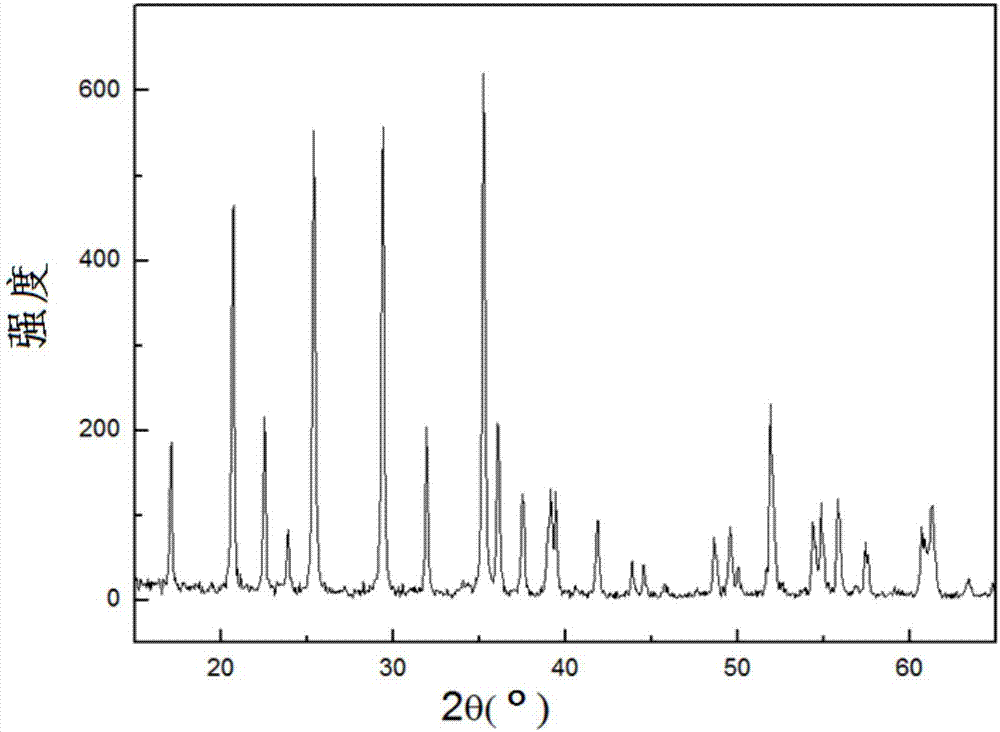

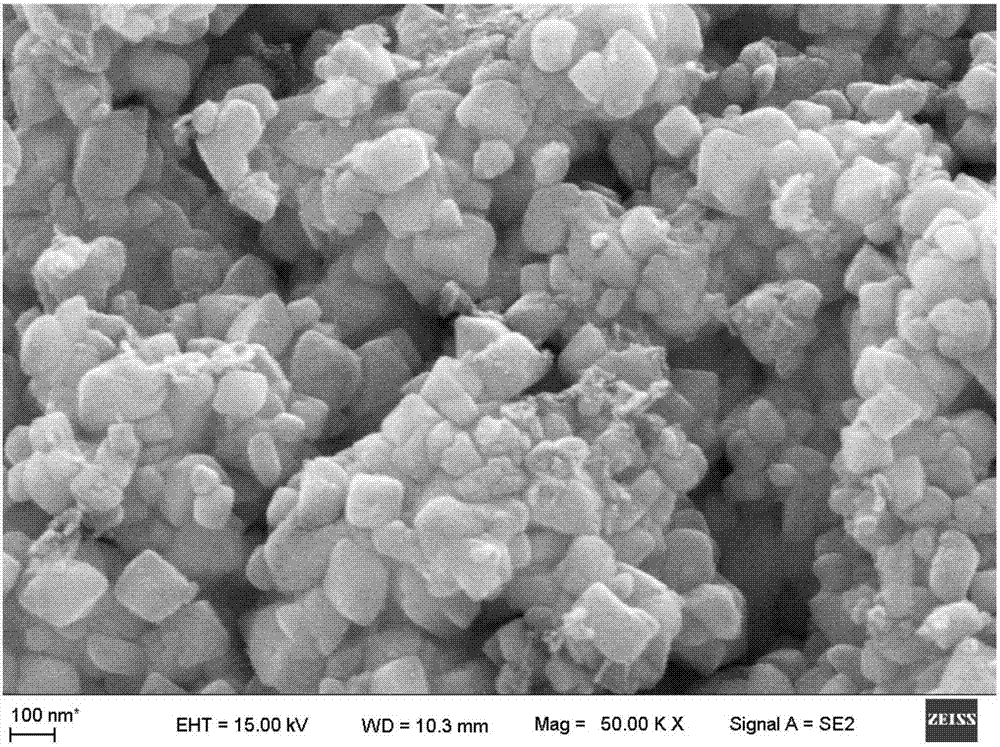

A method for preparing nanoscale lithium manganese phosphate

ActiveCN106957049BEasy to controlControl shapeMaterial nanotechnologyCell electrodesElectrolysisManganese

The invention relates to a method for preparing nanoscale lithium manganese phosphate. The method includes: S1, preparing an aluminum mesh-based lithium phosphate electrode piece; S2, using a manganese piece as an anode, performing electrolysis in an imidazole ionic liquid, introducing manganese ions into the imidazole ionic liquid, and forming imidazole ions containing manganese ions. Liquid; S3. Use the aluminum mesh-based lithium phosphate pole piece as a cathode, conduct electrodeposition in the imidazole ionic liquid containing manganese ions, and generate nanoscale lithium manganese phosphate on the cathode. This invention uses imidazole ionic liquid electrodeposition for the first time to prepare lithium manganese phosphate that can be used as a positive electrode material for lithium ion batteries. The source of raw materials is simple, the cost is low, and the particle size of the nanoscale lithium manganese phosphate is more uniform. Moreover, imidazole ionic liquids can be recycled multiple times without producing side reactions. The preparation process is green, environmentally friendly, simple, easy to control, and consumes low energy.

Owner:NORTHEASTERN UNIV LIAONING

Method for preparing nano-scale lithium manganese phosphate

ActiveCN106957049AEasy to controlControl shapeMaterial nanotechnologyPhosphorus compoundsElectrolysisManganese

The invention relates to a method for preparing nano-scale lithium manganese phosphate. The method comprises the following steps of S1, preparing an aluminum mesh based lithium phosphate pole piece; S2, using a manganese sheet as an anode, carrying out electrolysis in imidazole ionic liquid, and introducing a manganese ion into the imidazole ionic liquid, so as to form manganese ion-containing imidazole ionic liquid; S3, using the aluminum mesh based lithium phosphate pole piece as a cathode, carrying out electrodeposition in the manganese ion-containing imidazole ionic liquid, and generating the nano-scale lithium manganese phosphate on the cathode. According to the method, lithium manganese phosphate which can be used for a positive-pole material of a lithium-ion battery is prepared for the first time by utilizing the electrodeposition in the imidazole ionic liquid; the sources of raw materials are simple; the cost is low; the granularity of the made nano-scale lithium manganese phosphate is more uniform. Moreover, the imidazole ionic liquid can be circularly used for multiple times; further, a side reaction is not generated; the preparation process is green and environment-friendly; the technique is simple; the process is easily controlled; the energy consumption is low.

Owner:NORTHEASTERN UNIV

A kind of polyalkyl cyclopentane lubricating oil composition and its preparation method and application

ActiveCN111019744BWide liquid temperature rangeReduce volatile lossLubricant compositionSide chainPhosphoric acid

The invention provides a polyalkylcyclopentane lubricating oil composition, and a preparation method and an application thereof, and belongs to the field of liquid lubrication. Guerbet alcohol Guerbetacid ester and tricresyl phosphate are ester compounds and can be well mixed and dissolved to form a composite additive; and the base oil and the Guerbet alcohol Guerbet acid ester have similar longside chain structures, so the polyalkylcyclopentane lubricating oil composition has the advantages of good compatibility, extremely wide liquid temperature range, extremely low volatilization loss, excellent lubricating performance and excellent high and low temperature performances, and can be used for liquid lubrication under harsh conditions such as a micro electro mechanical system and space machinery.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

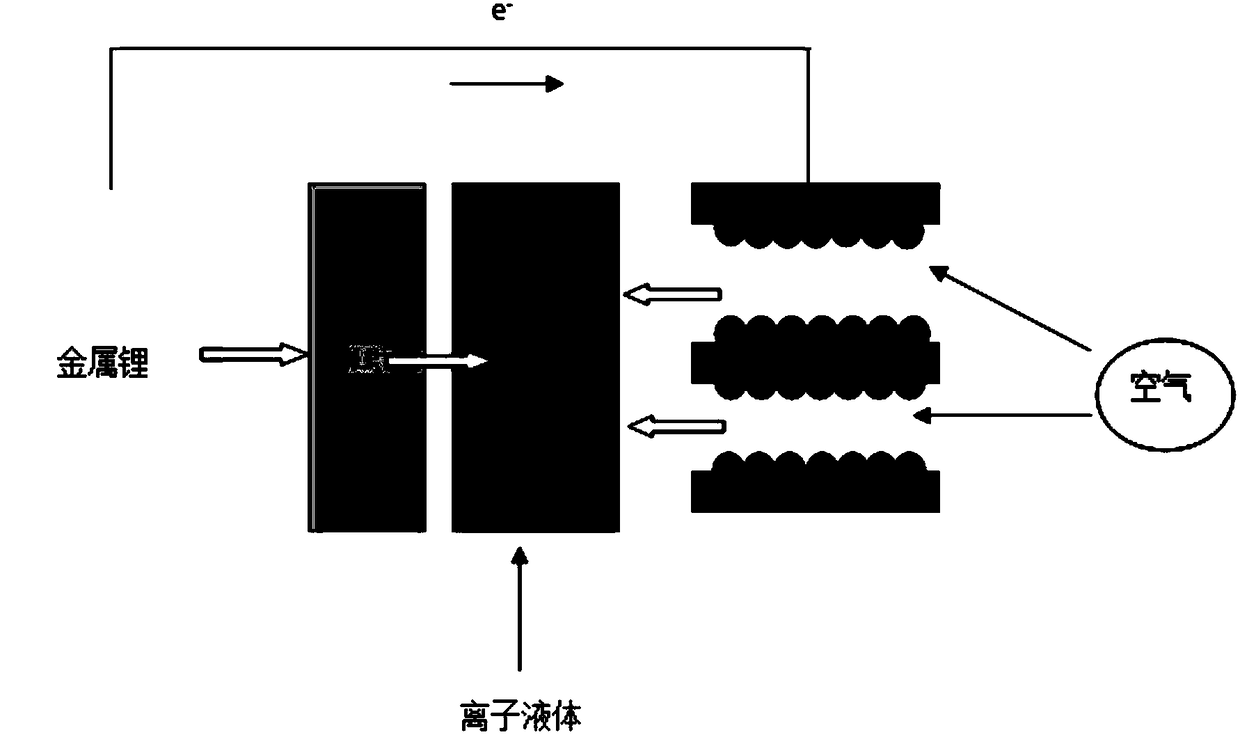

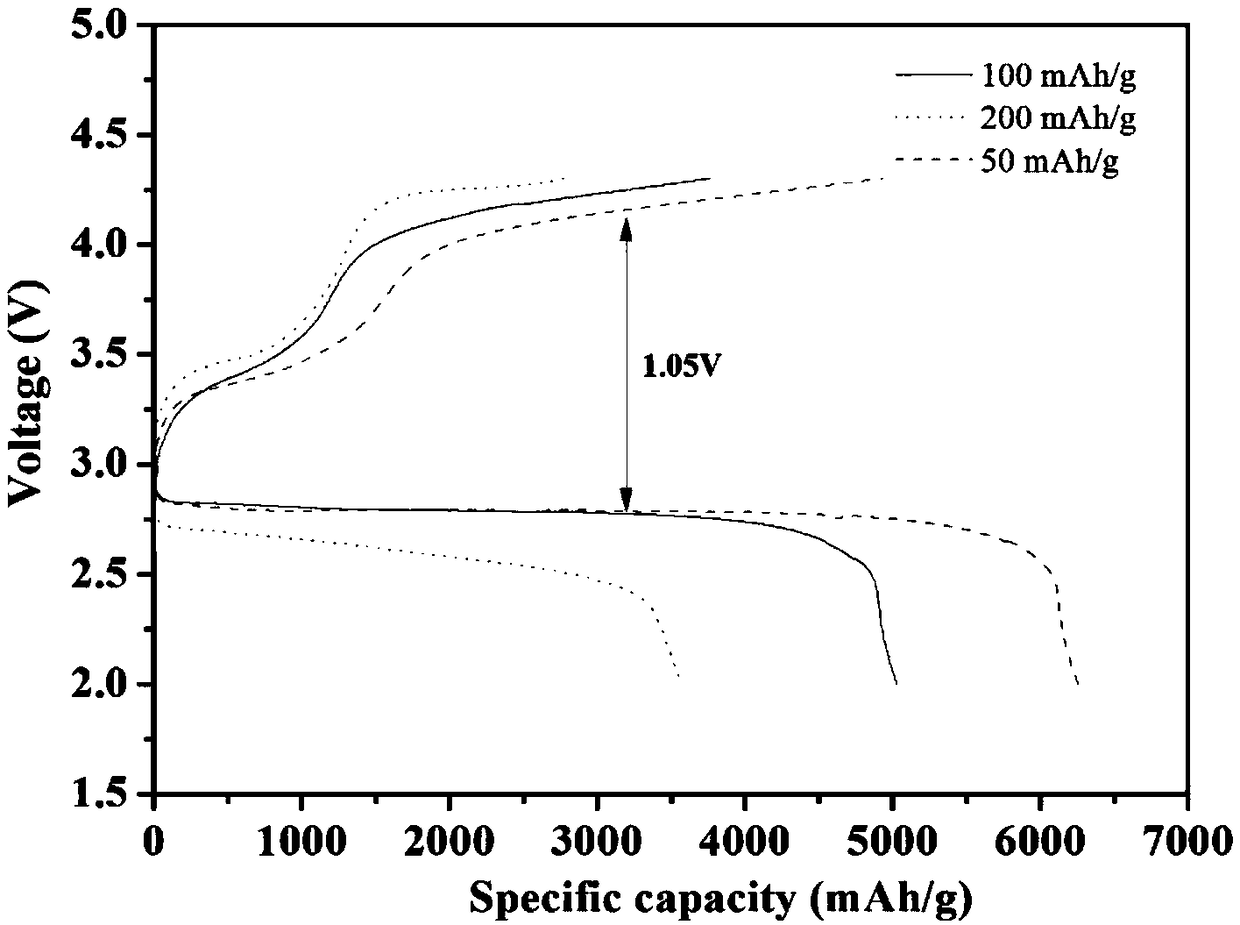

Lithium air battery ionic liquid electrolyte and air battery preparation method

InactiveCN108933289AImprove securityWide liquid temperature rangeFuel and secondary cellsSecondary cellsNew energyElectrochemical window

The invention relates to an electrolyte and an air battery preparation method, which belong to the technical field of new energy, and in particular to a lithium air battery ionic liquid electrolyte and an air battery preparation method. The electrolyte of the invention has good material compatibility, does not react with other structures of the battery; has wide electrochemical window and high electrochemical stability, and can meet the application of high voltage and high capacity battery systems; has low toxicity, and is environmentally friendly. The lithium air battery made of electrolyte improves the specific capacity and safety of the battery, has strong practicability, and establishes a foundation for the next large-scale production.

Owner:武汉霖泉环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com