Methods for preparing quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and polymer/montmorillonite nanocomposite

A nanocomposite material and ionic liquid technology, which is applied in the field of polymer/clay nanocomposite materials, can solve the problems of low thermal decomposition temperature of quaternary ammonium salts, restrictions on the application of organic montmorillonite, difficulties in organic solvent recovery, etc., and reach the liquid temperature range Wide, easy to operate, highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

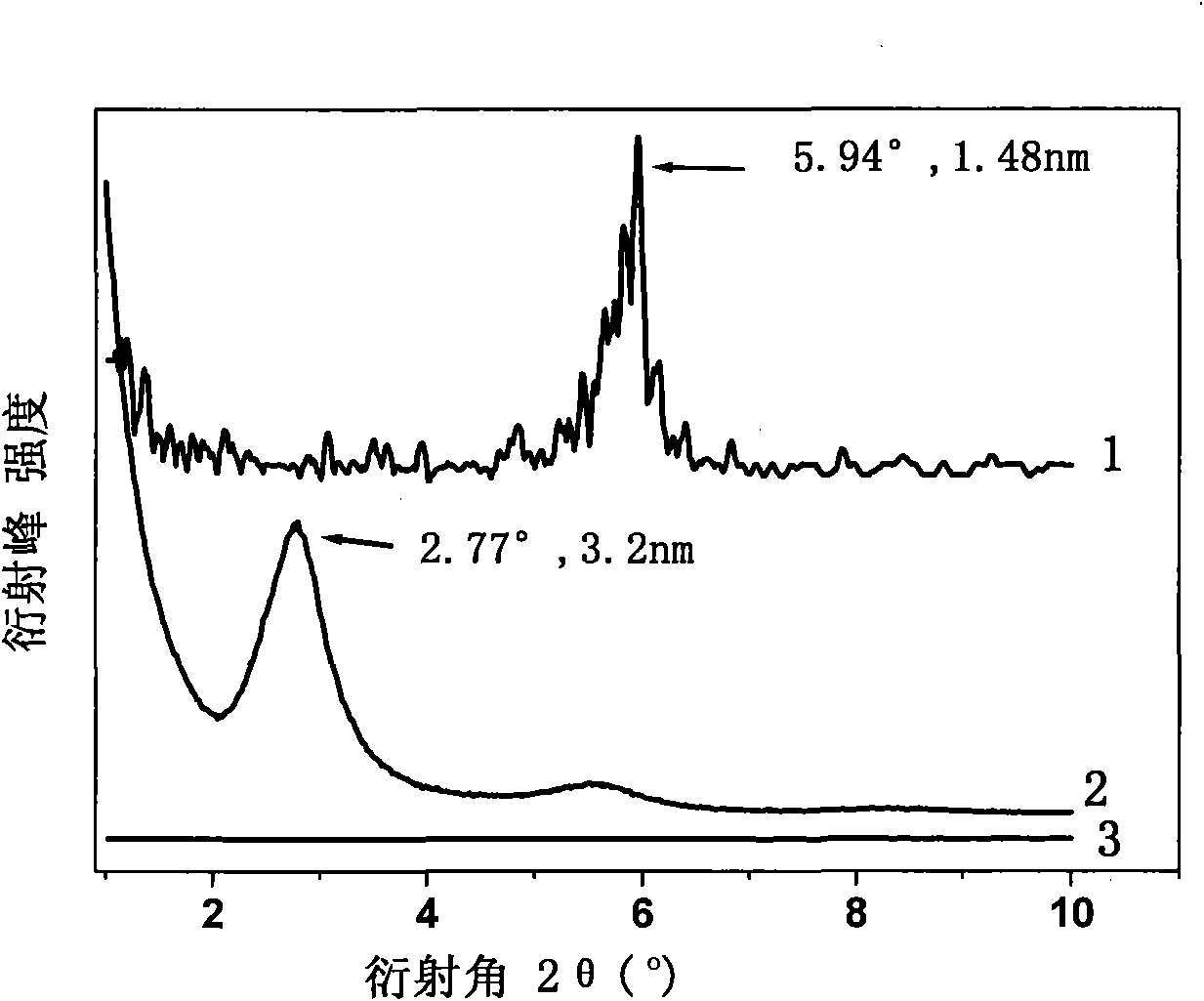

Embodiment 1

[0035] (1) Weigh 30g of sodium montmorillonite powder, add it to 100g of trihexyltetradecylphosphonium chloride ionic liquid at room temperature, and heat to 200°C;

[0036] (2) Stir the above solution at 200° C. for 30 minutes to carry out organic pillaring reaction modification of montmorillonite;

[0037] (3) The above solution is vacuum filtered, solid and liquid are separated, and the liquid is recovered and reused. The obtained solid is washed with deionized water, vacuum dried, ground, and passed through a 300-mesh sieve. The obtained solid is the quaternary phosphonium salt ionic liquid column Supported modified montmorillonite;

[0038] (4) Take by weighing 25g of the above-mentioned quaternary phosphonium salt ionic liquid pillar-supported modified montmorillonite, join in 475g polypropylene resin, mix uniformly, plasticize with two-roller open mill, pull sheet after mixing uniformly and take off, then Molded on a flat vulcanizing machine. The molding temperature i...

Embodiment 2

[0045] (1) Take by weighing 50g sodium montmorillonite powder, join in 10g triphenyldodecylphosphonium bromide ionic liquid;

[0046] (2) Stir the above solution for 480 min at 30° C. to carry out organic pillaring reaction modification of montmorillonite;

[0047] (3) The above solution is filtered, the solid and liquid are separated, and the liquid is recovered and reused. The obtained solid is washed with deionized water, vacuum-dried, ground, and passed through a 300-mesh sieve. The obtained solid is a modified quaternary phosphonium salt ionic liquid pillar. sex montmorillonite;

[0048] (4) Take by weighing 25g of the above-mentioned quaternary phosphonium salt ionic liquid pillared modified montmorillonite, join in 500g polyvinyl chloride resin, add 25g of rare earth stabilizer of polyvinyl chloride, mix uniformly, melt on the two-roller mixer Kneading, after mixing evenly, take off the tab, and mold it on a flat vulcanizing machine. The molding temperature is 175°C a...

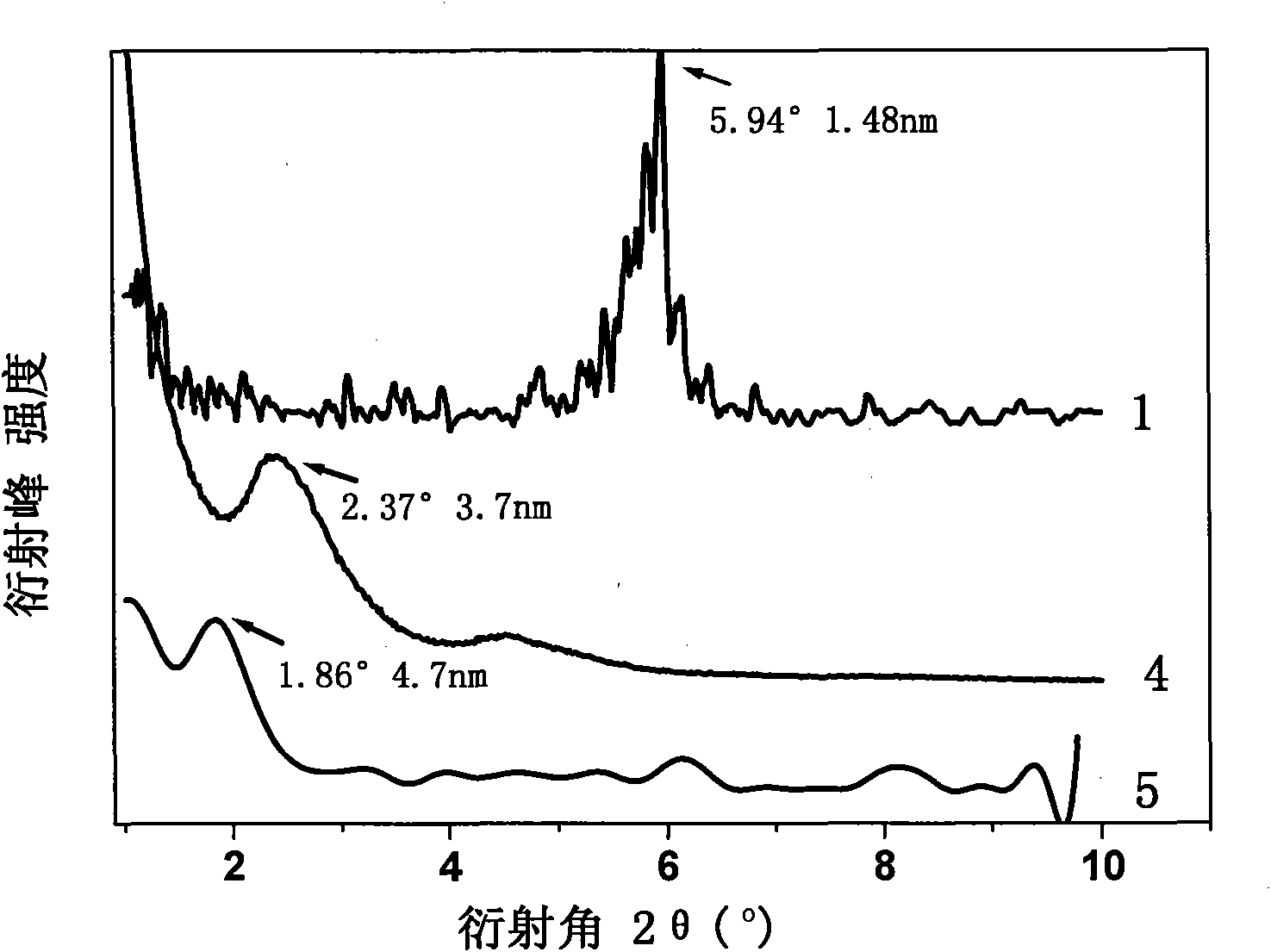

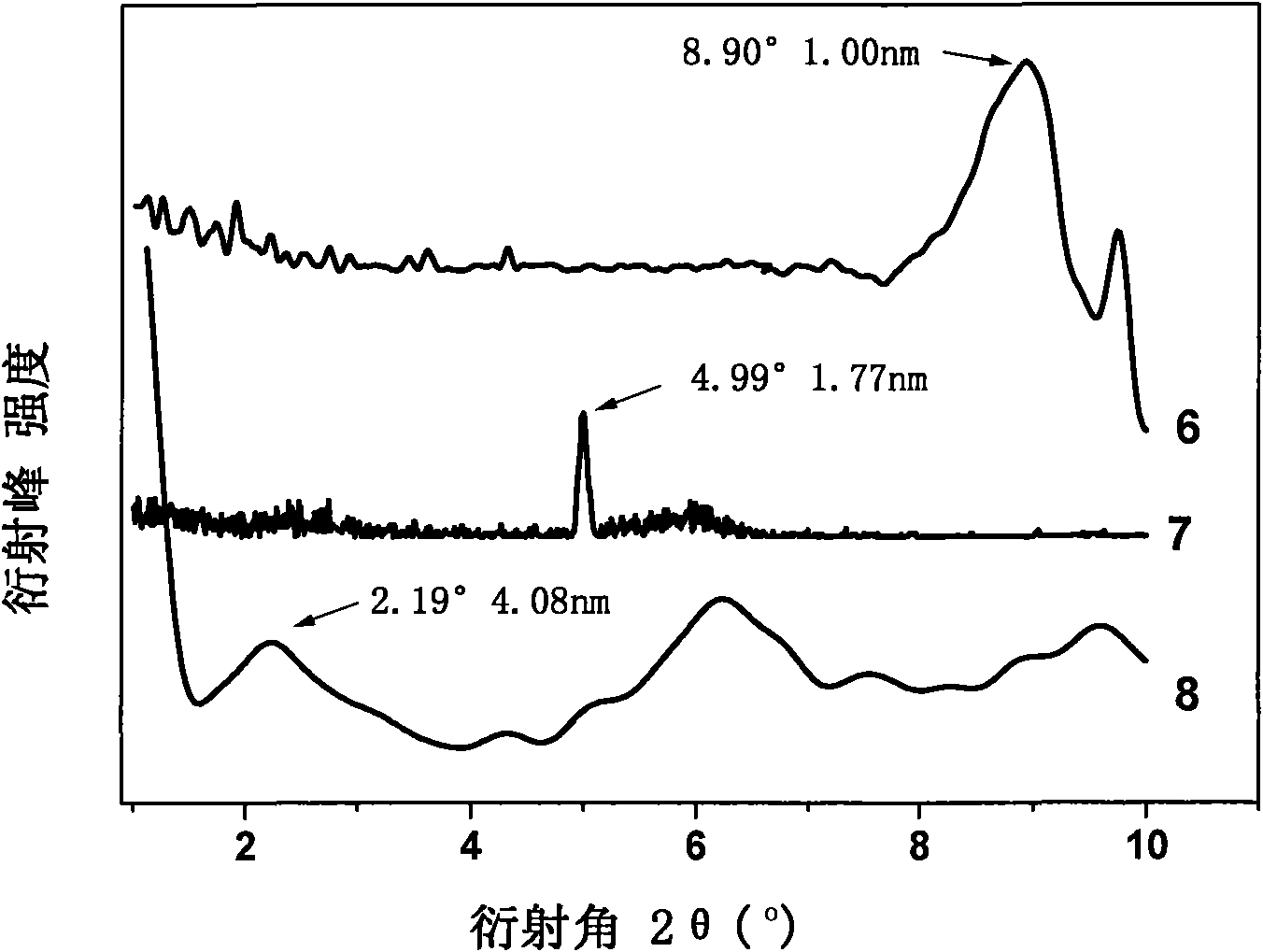

Embodiment 3

[0054] (1) Weigh 300g of calcium-based montmorillonite powder and add it to 300g of trihexyloctadecylphosphonium tetrafluoroborate ionic liquid at room temperature;

[0055] (2) Stir the above solution at 120° C. for 240 min to carry out organic pillaring reaction modification of montmorillonite;

[0056] (3) The above solution is filtered, the solid and liquid are separated, and the liquid is recovered and reused. The obtained solid is washed with deionized water, vacuum-dried, ground, and passed through a 300-mesh sieve. The obtained solid is the quaternary phosphonium salt ionic liquid pillar Modified montmorillonite;

[0057] (4) Weigh 200g of the above-mentioned quaternary phosphonium salt ionic liquid pillared modified montmorillonite, add 200g of natural rubber to it, mix it on a two-roller mixer, remove the tab after mixing evenly, and obtain natural rubber / montmorillonite Masterbatch for destoned nanocomposites.

[0058] (5) Take 50g of the above-mentioned masterbat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com