Citric acid loofah sponge preparation method and application

A loofah and citric acid technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of small adsorption capacity of adsorbents, and achieve conditions that are easy to control, fast, and desorption good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

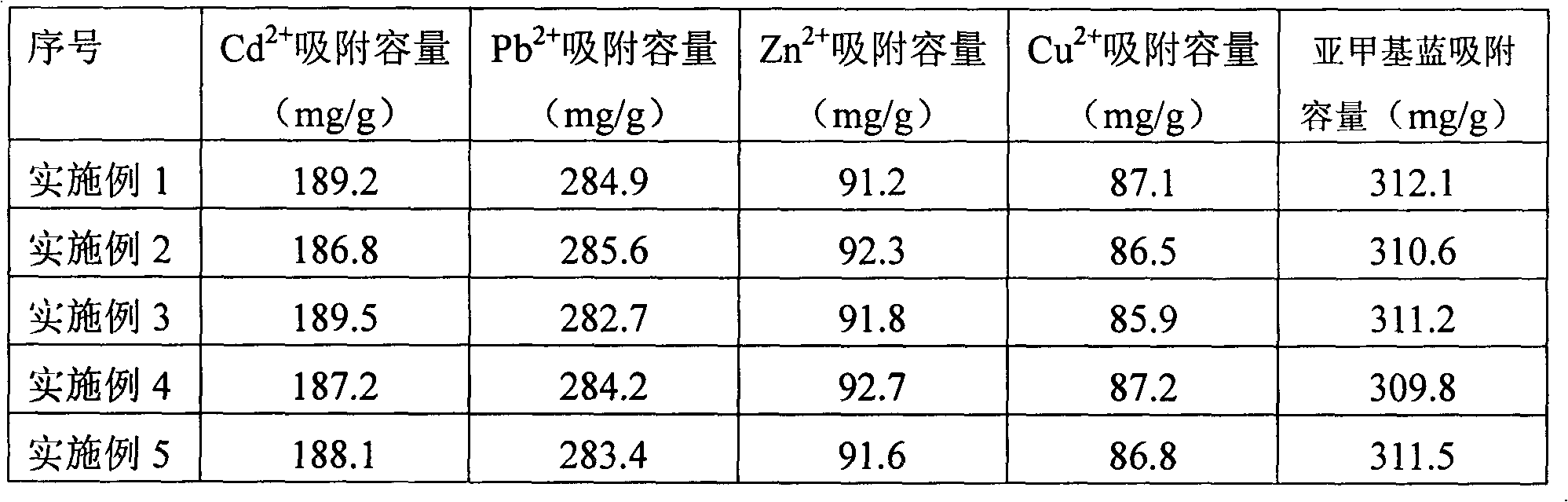

Examples

Embodiment 1

[0013] (1) Loofah pretreatment: loofah is derived from loofah fruit, obtained by peeling and removing the core, cutting loofah into small pieces, washing with water, drying, crushing, and sieving with a 60-mesh sieve;

[0014] (2) saponified loofah: the loofah of pulverizing is pressed 50% of gross mass, is that the NaOH solution of 0.5mol / L and 1% OP solution are mixed and immersed in azeotropic 1h with concentration, constantly adds water during azeotropic period, to keep The volume of the solution is constant, after cooling, it is washed with deionized water until the pH is about 7, then soaked in isopropanol for 3 hours, filtered by suction and dried at 75°C to obtain saponified loofah.

[0015] (3) Add 20g of citric acid and 100mL of distilled water into a stoppered Erlenmeyer flask, mix well, add 20g of saponified loofah, stopper, reflux at 70°C for 2h with stirring, then heat up to 110°C for 2h, after cooling , washed with deionized water, suction filtered until the fil...

Embodiment 2

[0017] (1) Loofah pretreatment: loofah is derived from loofah fruit, obtained by peeling and removing the core, cutting loofah into small pieces, washing with water, drying in vacuum, crushing, and sieving with a 50-mesh sieve;

[0018] (2) saponification loofah: the loofah of pulverizing is by 45% of gross mass, is that the NaOH solution of 0.4mol / L and 0.8% OP solution mix immersion azeotropy 1.5h with concentration, constantly add water during azeotropy, with Keep the volume of the solution constant, wash it with deionized water until the pH is about 7 after cooling, soak it in isopropanol for 2.5 hours, filter it with suction and dry it at 70°C to obtain saponified loofah.

[0019] (3) Add 25g of citric acid and 110mL of distilled water into a stoppered Erlenmeyer flask, mix well, add 25g of saponified loofah, stopper, at 60°C, reflux with stirring for 3h, then heat up to 120°C for 3h, after cooling , washed with deionized water, suction filtered until the filtrate is neut...

Embodiment 3

[0021] (1) Loofah pretreatment: loofah is derived from loofah fruit, which is obtained by peeling and removing the core, cutting loofah into small pieces, washing with water, vacuum drying, crushing, and sieving with a 40-mesh sieve;

[0022] (2) saponified loofah: 50% of the total mass of the pulverized loofah is mixed with NaOH solution and 0.8% OP solution with a concentration of 0.4mol / L and submerged in azeotropic 2h, and water is constantly added during the azeotropic period to keep The volume of the solution is constant, after cooling, it is washed with deionized water until the pH is about 7, then soaked in isopropanol for 3 hours, filtered with suction, and dried at 75°C to obtain saponified loofah.

[0023] (3) Add 18g of citric acid and 100mL of distilled water into a stoppered Erlenmeyer flask, mix well, add 20g of saponified loofah, stopper, reflux at 65°C for 3h with stirring, then heat up to 120°C for 2h, after cooling , washed with deionized water, suction filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com