Amino-terminated modified cellulose, and preparation method and application thereof

A technology of amino-terminated cellulose, which is applied in the field of amino-terminated cellulose and its preparation, can solve the problems of single adsorption type, difficult adjustment, and great influence on adsorption effect, so as to reduce production cost, increase added value, and source broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The method for preparing the amino-terminated modified cellulose, its processing steps are:

[0065] (1) Raw material pretreatment: the bagasse raw material washed and dried to a constant weight in 3% (Wt%) lithium hydroxide concentrated alkali solution; the bath ratio of the concentrated alkali and bagasse raw material is 5 (V / W)) Soaked in more than 10 hours, washing, suction filtration, drying to obtain alkali bagasse fiber;

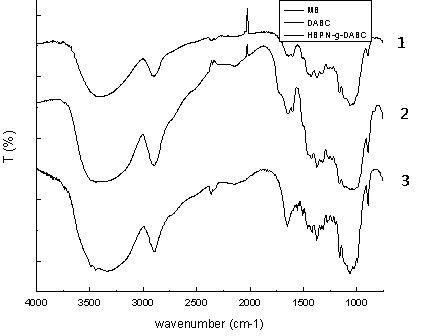

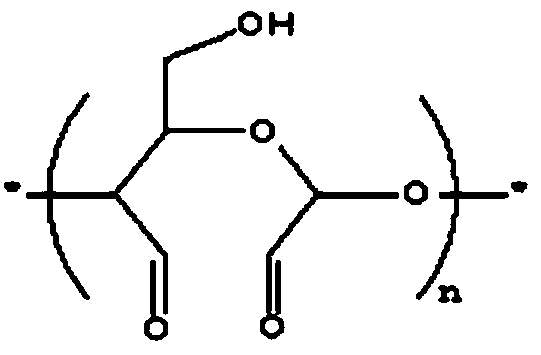

[0066] (2) Preparation of dialdehyde bagasse cellulose: Alkali bagasse fiber and strong oxidant (KIO 4 ) Oxidation reaction occurs under dark conditions to obtain dialdehyde bagasse cellulose;

[0067] (3) Synthesis of amino-terminated hyperbranched polymers: using methyl methacrylate and ethylenediamine as raw materials, under the condition of avoiding light and oxygen in methanol (introducing N 2 ) stirring and polymerizing to obtain an amino-terminated hyperbranched polymer;

[0068] (4) Synthesis of dialdehyde cellulose grafted with ami...

Embodiment 2

[0077]The method for preparing the amino-terminated modified cellulose, its processing steps are:

[0078] (1) Raw material pretreatment: the bagasse raw material that has been washed and dried to constant weight is placed in a 5% (Wt%) sodium hydroxide concentrated alkali solution; the bath ratio of the concentrated alkali to the bagasse raw material is 8 (V / W )) for more than 15 hours, washed, filtered and dried to obtain alkali bagasse fiber;

[0079] (2) Preparation of dialdehyde bagasse cellulose: Alkaline bagasse fiber and strong oxidant H 5 IO 6 Oxidation reaction occurs under dark conditions to obtain dialdehyde bagasse cellulose;

[0080] (3) Synthesis of amino-terminated hyperbranched polymers: using methyl methacrylate and ethylenediamine as raw materials, stirring in ethanol under light-proof and oxygen-proof conditions (introducing helium gas during the reaction) to undergo polymerization reaction to obtain end-amino-terminated hyperbranched polymers. Amino hyp...

Embodiment 3

[0086] The method for preparing the amino-terminated modified cellulose, its processing steps are:

[0087] (1) Raw material pretreatment: Put the bagasse raw material washed and dried to constant weight in 10% (Wt%) potassium hydroxide concentrated alkali solution; the bath ratio of the concentrated alkali and bagasse raw material is 10 (V / W )) for more than 20 hours, washed, filtered and dried to obtain alkali bagasse fiber;

[0088] (2) Preparation of dialdehyde bagasse cellulose: Alkaline bagasse fibers and a strong oxidant (NaIO 4 ) Oxidation reaction occurs under dark conditions to obtain dialdehyde bagasse cellulose;

[0089] (3) Synthesis of amino-terminated hyperbranched polymers: using methyl methacrylate and ethylenediamine as raw materials, stirring and polymerizing in propanol under the condition of avoiding light and oxygen (neon gas is introduced into the reaction) to obtain Amino-terminated hyperbranched polymers;

[0090] (4) Synthesis of dialdehyde cellulo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com