Patents

Literature

144results about How to "Low added value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

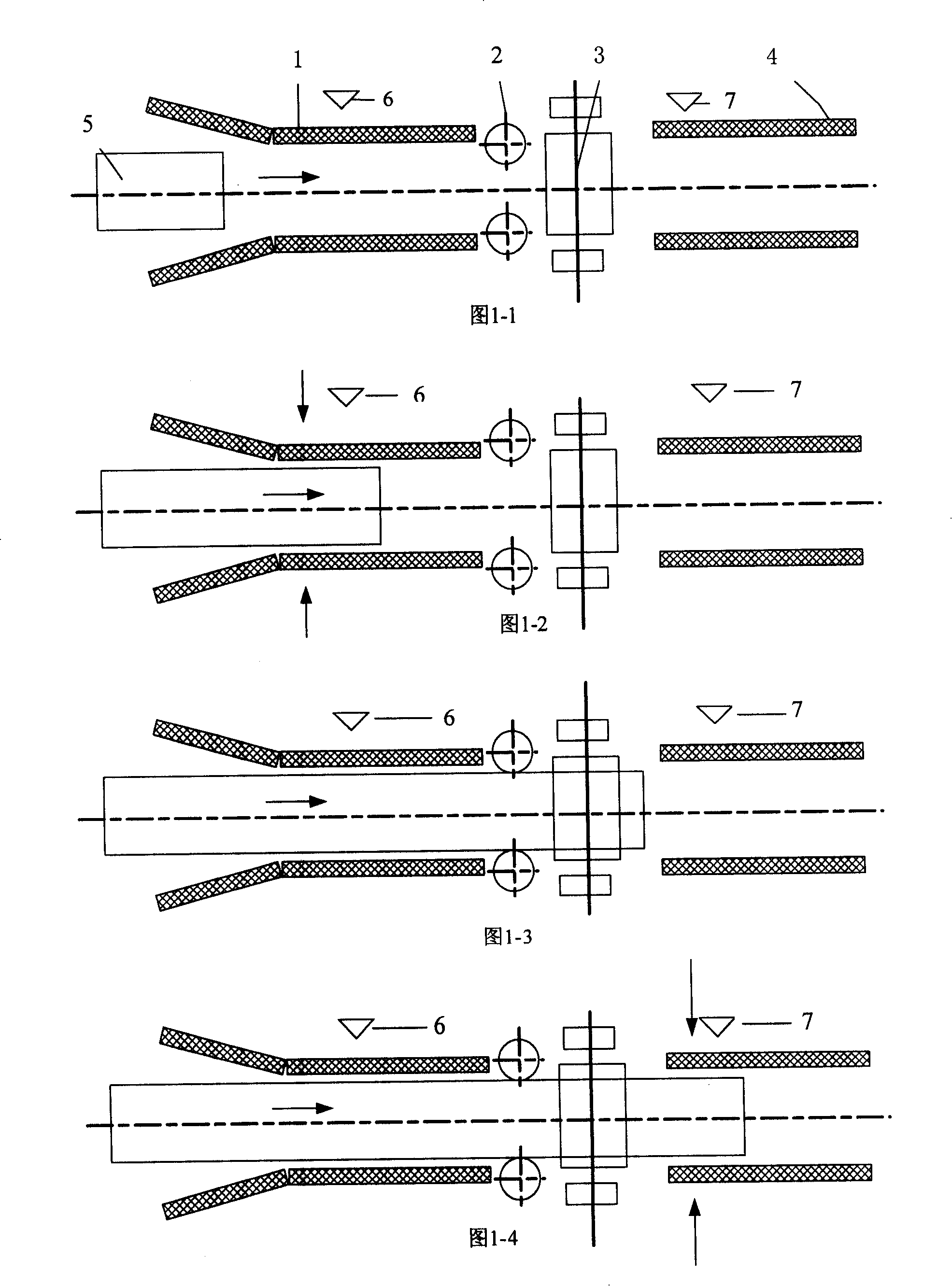

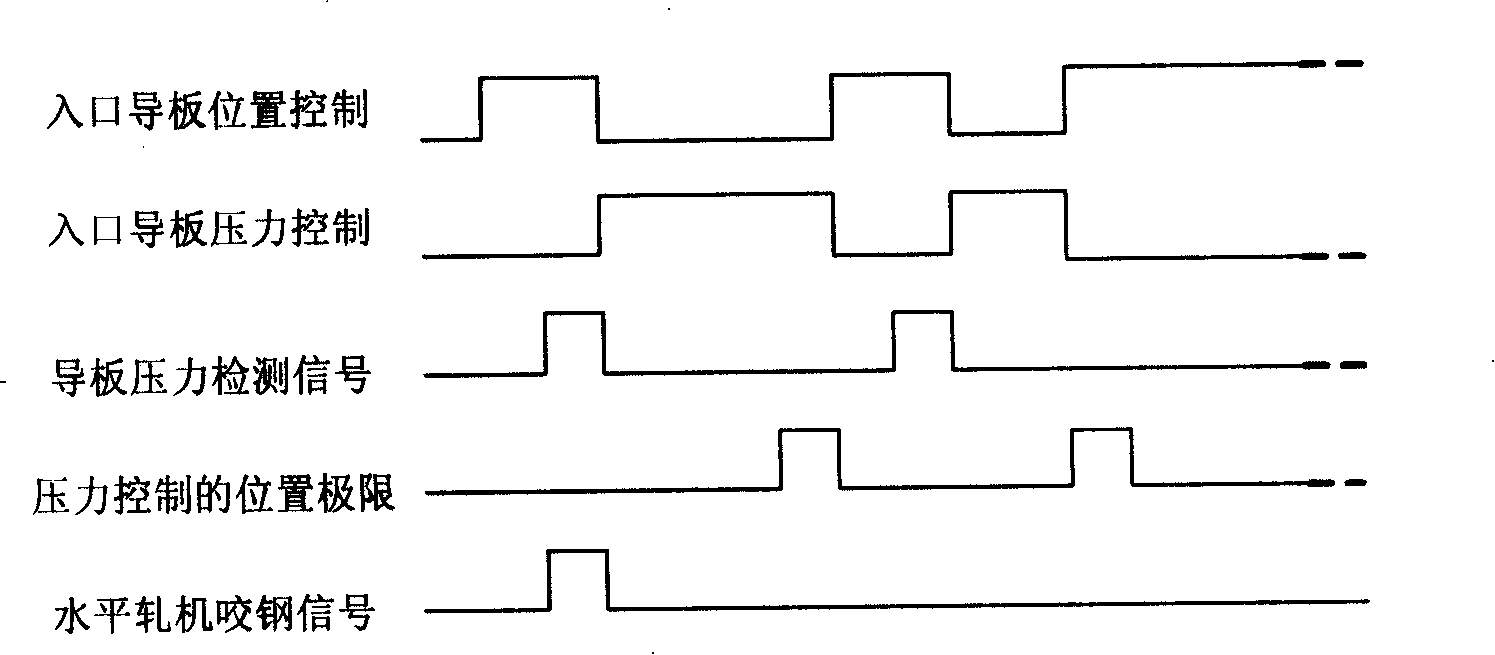

Controlling method of rough rolling breakdown bar camber

ActiveCN101224471APlay a guiding roleLow added valueGuiding/positioning/aligning arrangementsTension/compression control deviceAdditional valuesPosition control

The invention relate to a control technique of the rolling process of a rolling steel. The invention discloses a control method of a rough rolling intermediate billet camber. The control method combines a position control with a pressure control; in a multi-pass rolling of the positive-pass and reverse-pass of a roughing mill, the camber generation of the intermediate billet is restricted. The control method of the invention can reduce the additional value of the openness of a side guide plate, leads the flexible deformation of the intermediate billet between the inlet and the outlet of the roughing mill in the horizontal direction to be restricted by the side guide plate, reduces the camber of the intermediate billet, and prevents the severe abrasion which is caused by the long-term contact of the side guide plate and the intermediate billet.

Owner:BAOSHAN IRON & STEEL CO LTD

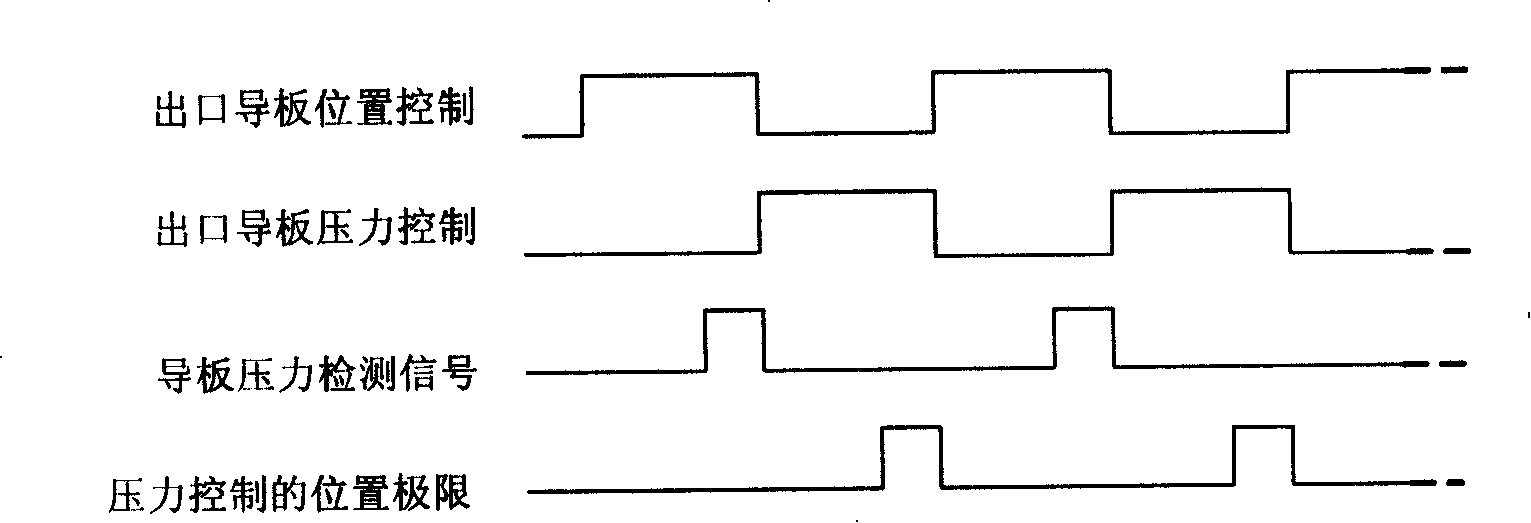

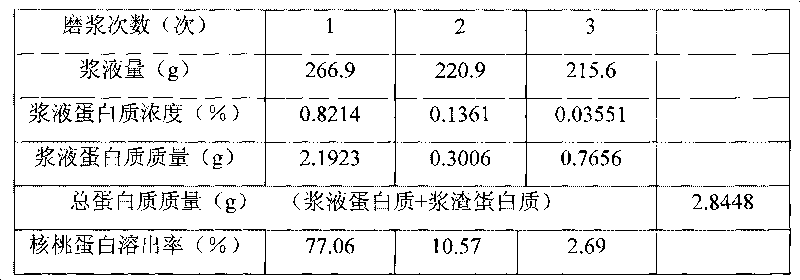

Walnut powder and production method thereof

InactiveCN101690596AReduce the degree of protein denaturationRealize comprehensive utilizationFood preparationSocial benefitsSolubility

The invention provides walnut powder and a production method thereof; walnut kernel is peeled by high pressure water spraying, bubble water stream impact and ultrasonic wave vibration after being soaked by compound alkaline liquid, and then second-grade cold pressing is carried out to the peeled walnut kernel after the peeled walnut kernel is dried and crushed, the walnut kernel is crushed, filtered, batched and colloid-milled to be refined, and then a complex stabilizer is added in the walnut kernel to be sterilized, concentrated, homogenized and dried to obtain the walnut powder. The method has low damage degree, can effectively prevent protein denaturation and reduce alkaline liquid amount; the second-grade cold pressing technology is adopted, the denaturation degree of the protein of the walnut cake is reduced, and the walnut powder is prepared by high-pressure homogeneity and spraying drying; the visual color and luster, solubility and the content of the protein and other indexes of the product are superior to the similar products in the current market. The invention realizes the comprehensive utilization of the walnut resource, the technology is advanced, simple and practical and is easy to popularize, thereby having good economic and social benefits.

Owner:石家庄市丸京干果有限公司

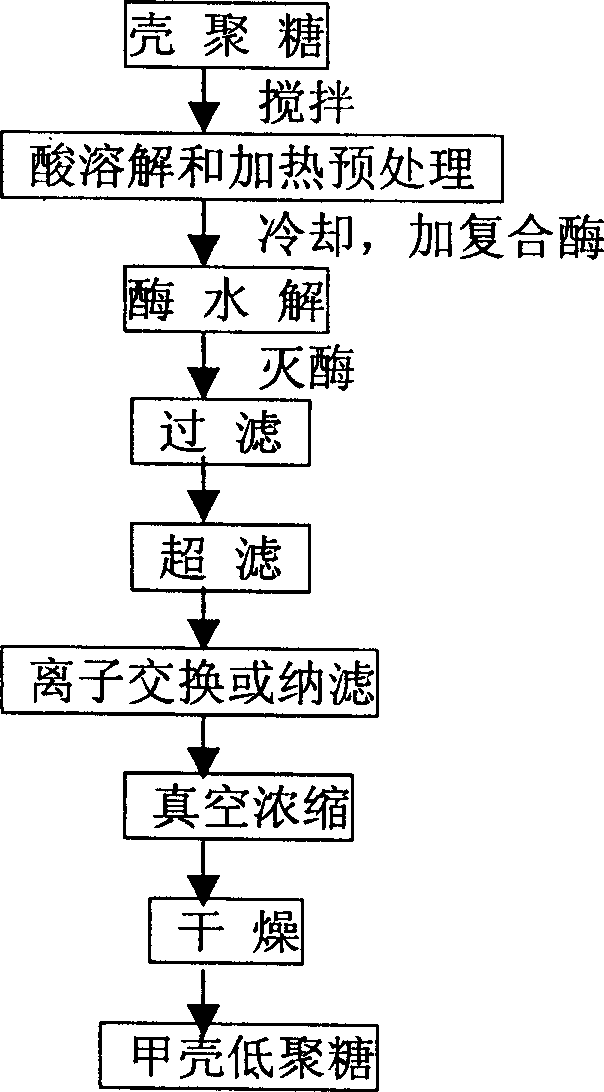

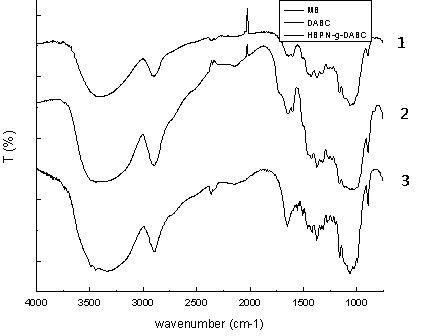

Preparation of crust oligosaccharide and use

The present invention relates to preparation and application of crust oligosaccharide and belongs to the field of deep chitin processing technology. Non-specific enzyme is used to raise the hydrolysis degree of chitosan and the separation and purification of hydrolytic product. The key point of the present invention is that the chitosan material is produced into crust oligosaccharide powder through acid dissolving, heating, enzymolysis and hydrolysis with compoiste, enzyme comprising polysaccharide hydrolase, proteinase and lipase, deactivating enzyme, filtering, ultrafiltering, ion exchange or nanometer filtering, vacuum concentration and drying. The product is used in producing various functional health foods with the functions of immunological regulation and blood fat regulation.

Owner:上海华宝孔雀香精有限公司

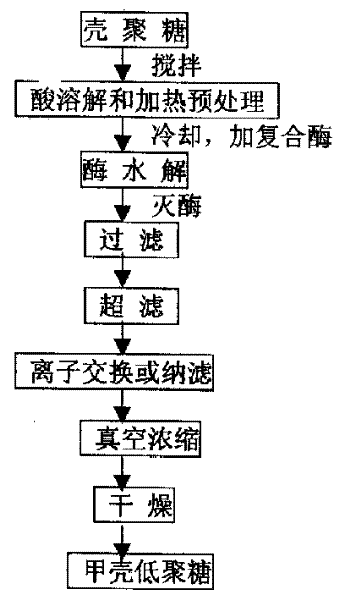

Amino-terminated modified cellulose, and preparation method and application thereof

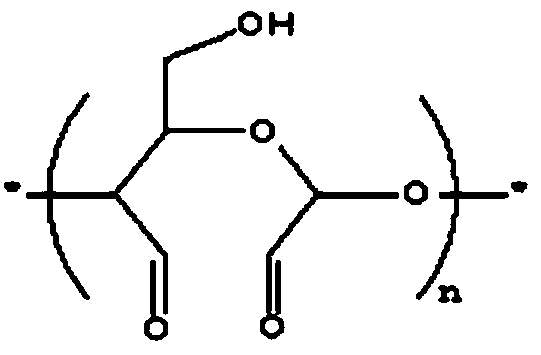

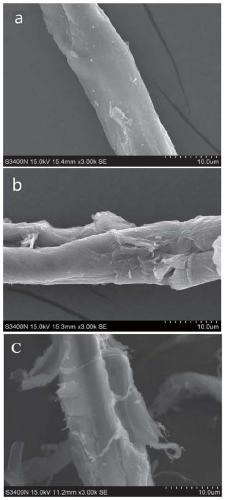

InactiveCN103554510AIncrease added valueLow added valueWater contaminantsWater/sewage treatment by sorptionEthylenediamineFiber

The invention discloses amino-terminated modified cellulose, and a preparation method and application thereof. The method comprises the following steps: firstly, soaking a bagasse material which is cleaned and dried into constant weight in concentrated alkaline for over 10 hours; washing, carrying out suction filtering and drying to obtain alkaline bagasse fibers; then carrying out an oxidation reaction on the alkaline bagasse fibers and a strong oxidant in a dark condition, so as to obtain dialdehyde bagasse cellulose; with methyl methacrylate and ethanediamine as raw materials, stirring in an organic solvent under dark and oxygen-isolated conditions to carry out a polymerization reaction, so as to obtain an amino-terminated hyperbranched polymer; and finally carrying out a reflux reaction after dissolving the dialdehyde bagasse cellulose and the amino-terminated hyperbranched polymer into the organic solvent, so as to obtain the amino-terminated hyperbranched grafted dialdehyde cellulose. The modified cellulose not only has good adsorptive property on heavy metal ions in a wastewater solution, but also is easy to separate after adsorption. Thus, the amino-terminated modified cellulose has the water purification effects of simple method and low cost.

Owner:GUANGXI UNIV FOR NATITIES

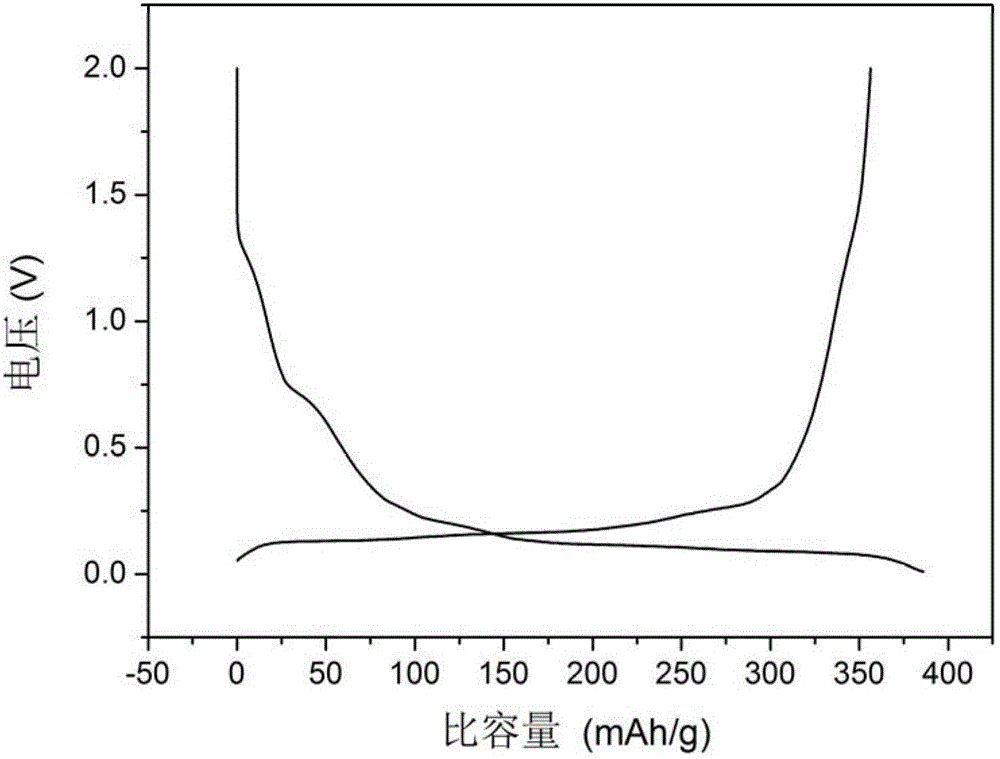

Coke powder-based cathode material of lithium ion power battery and preparation method thereof

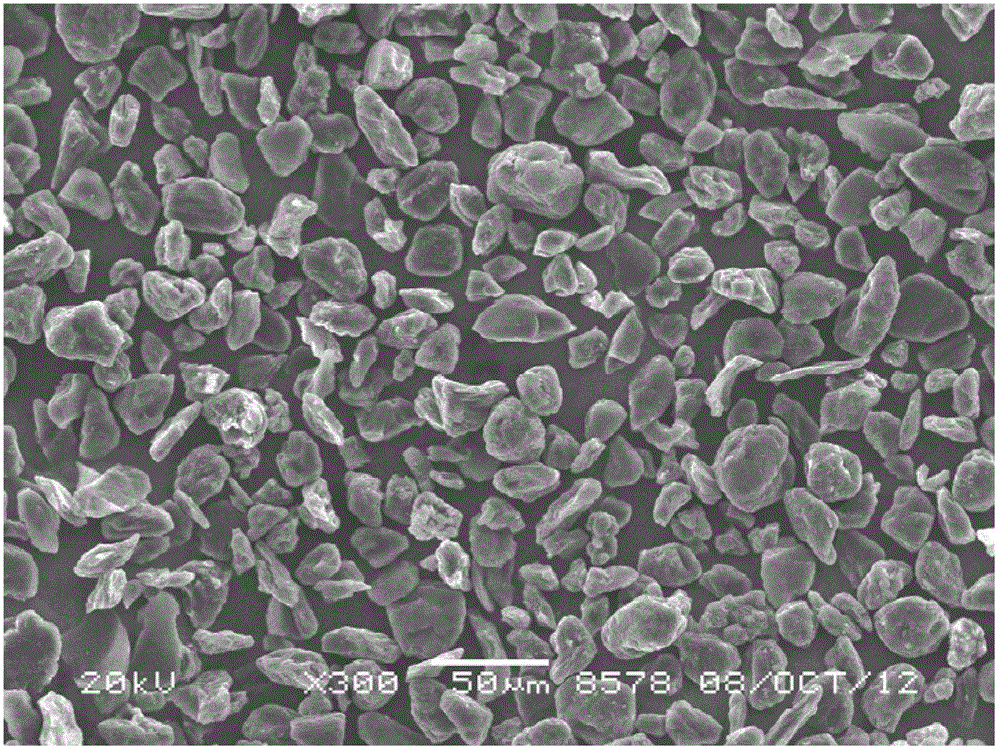

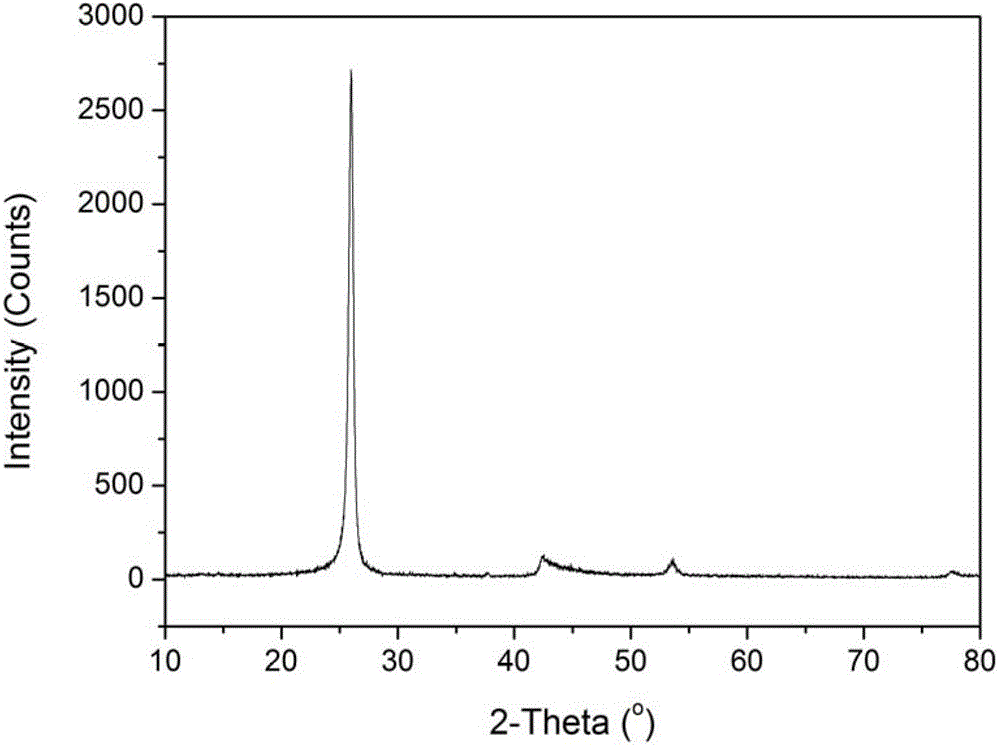

ActiveCN103066243AShort processReduce manufacturing costCarbon compoundsCell electrodesSolid carbonPower battery

The invention discloses a coke powder-based cathode material of a lithium ion power battery and a preparation method thereof. The cathode material has a D50 of 10-30 [mu]m, a minimum granularity of 5 [mu]m, a maximum granularity of 30 [mu]m, and a tap density of 1.1-1.5 g / cm<3>. The cathode material has a core-shell structure, wherein a core is graphitized coke powder, and a shell is composed of coal pitch pyrolytic carbon and metal particles. The cathode material contains 95.00-99.00 % of solid carbon and 1-5 % of metal or metal oxide particles by mass percent. The preparation method comprises crushing, grading and purifying the coke powder, cladding coal pitch on the coke powder particles, graphitizing under a high temperature, attaching metal or metal oxide on the particles, etc. The cathode material is excellent in rate performance, good in high-temperature and low-temperature performances, low in manufacture cost and suitable for large-scale industrialization.

Owner:CENT SOUTH UNIV +1

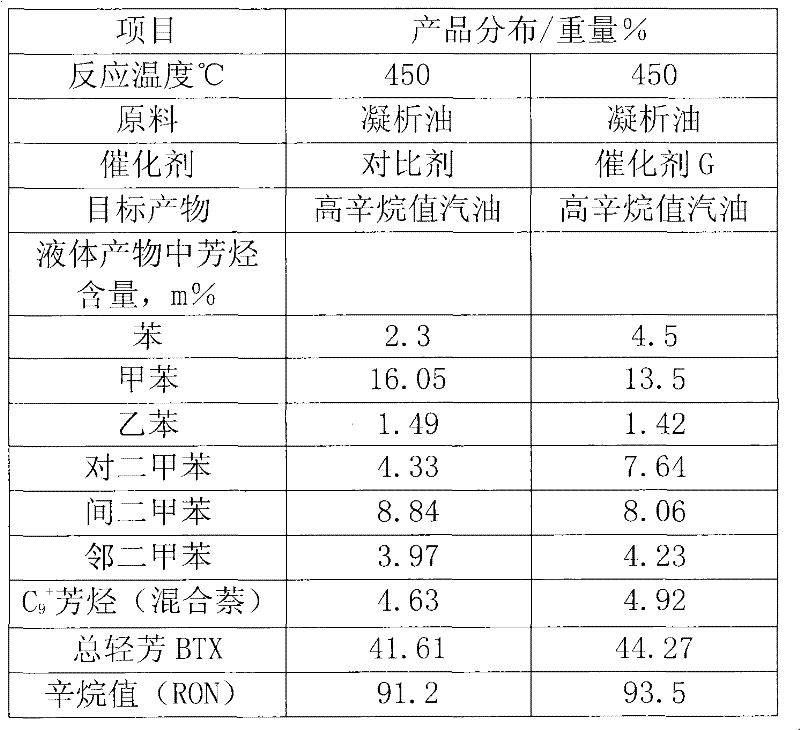

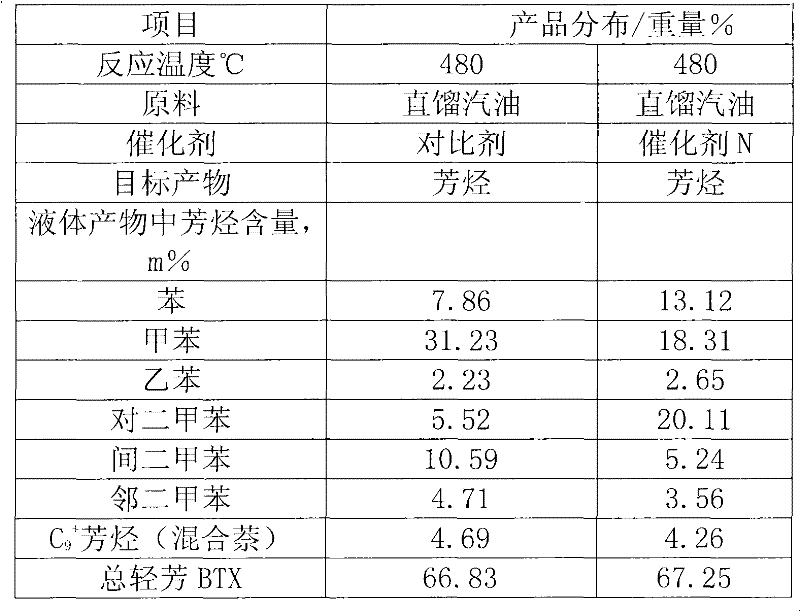

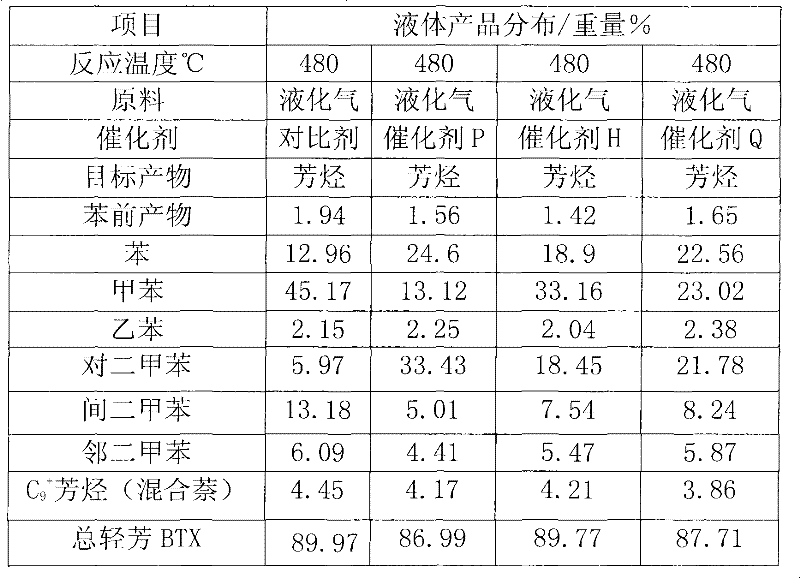

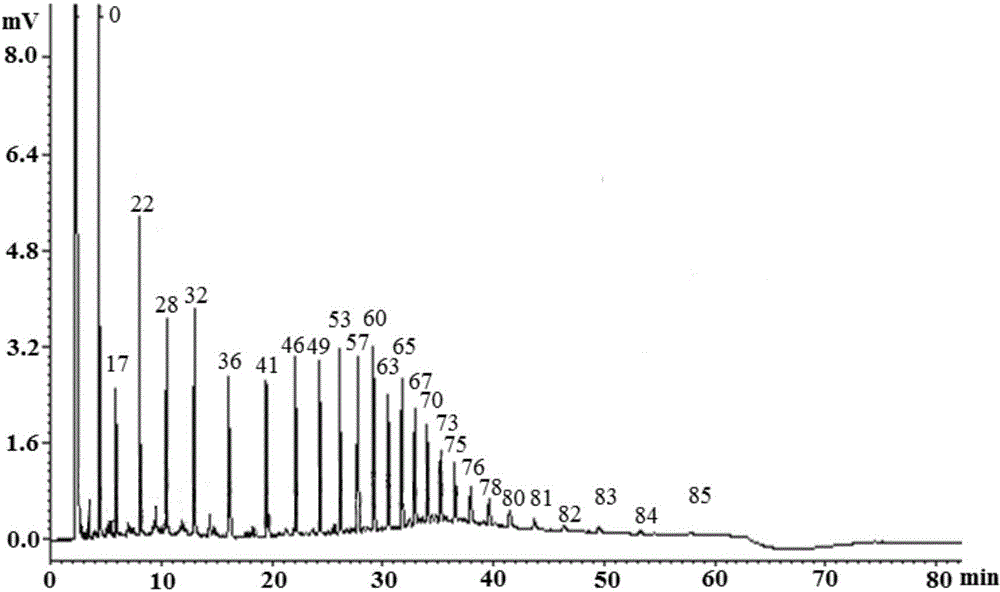

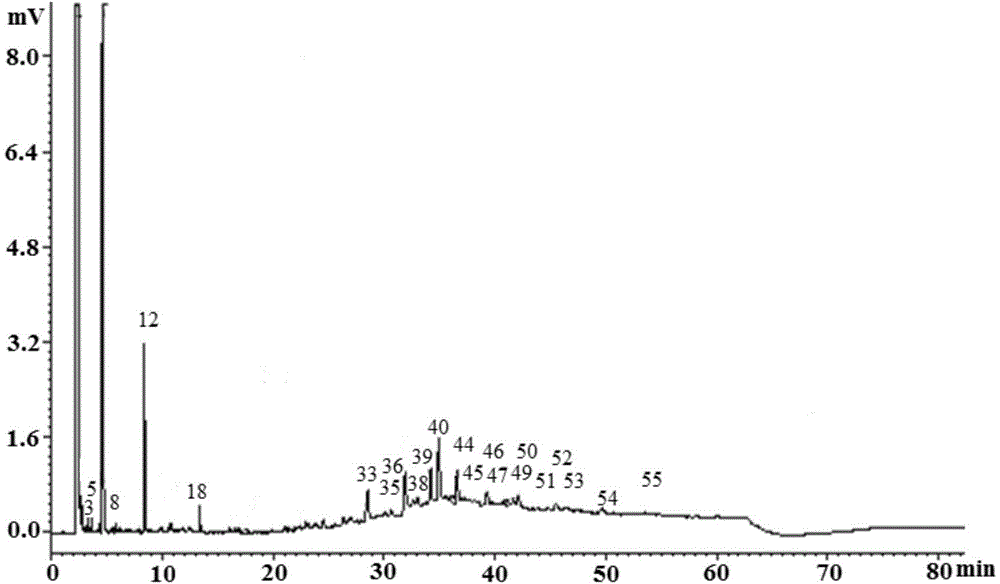

Aromatization catalyst and applications thereof

ActiveCN102218341AAdjust acid distributionIncrease total acidMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumAdhesive

The invention discloses an aromatization catalyst and applications thereof, and aims at solving the problems such as low yield of benzene and mixed xylene in the liquid outcomes and the like during the existing hydrocarbon aromatization reaction. The catalyst comprises the following components by weight percentage of 30-90wt% of molecular sieves, 0-60wt% of carriers and 10-20 wt% of adhesives, wherein the molecular sieves are mixtures of a molecular sieve I, a molecular sieve II, a molecular sieve III and a molecular sieve IV; the molecular sieve I is at least one modified HZSM-5 molecular sieve out of modified elements zinc, gallium and lanthanum; the molecular sieve II is at least one modified HZSM-5 molecular sieve out of modified elements bismuth, molybdenum, silver, copper, zirconiumand rhenium; the molecular sieve III is the HZSM-5 molecular sieve formed by modifying polysiloxane; and the molecular sieve IV is a modified hydrogenated mercerization type molecular sieve, a modified hydrogenated Beta-type molecular sieve, a hydrogenated ZSM-11 molecular sieve and a hydrogenated MCM-22 molecular or mixtures thereof.

Owner:CHINA PETROCHEMICAL CORP +1

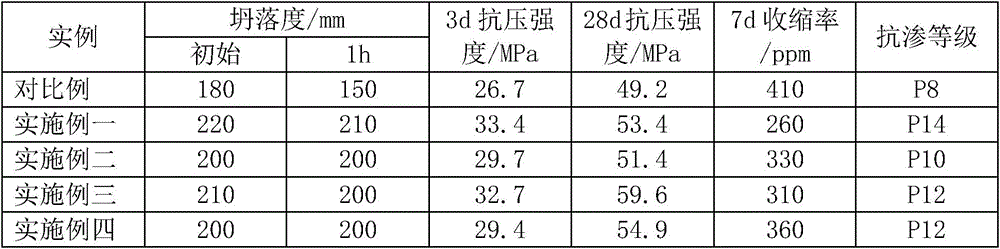

Composite mineral admixture for concrete

The invention discloses a composite mineral admixture for concrete. The admixture is prepared by mixing and grinding the following raw materials in percentage by weight: 40 to 60% of lithium slag, 10 to 30% of mineral slag, 5 to 20% of nickel slag, 5 to 10% of aerated concrete waste, 5 to 10% of sulfoaluminate cement clinker, and 0.1 to 0.5% of super plasticizer powder. The industrial wastes are fully utilized, the concrete production cost is reduced, and the admixture has a high activity, barely influences the early and late strength of concrete, has a shrinkage-compensating function and good anti-permeability property, and can improve the service life of concrete.

Owner:SOUTHEAST UNIV

Method for synthesizing p-acetamido benzene sulfonyl chloride by phosphorus pentachloride

InactiveCN101613308AHigh yieldReduce dosageSulfonic acid preparationSulfonyl chlorideChlorosulfuric acid

The invention relates to a method for synthesizing p-acetamido benzene sulfonyl chloride by phosphorus pentachloride, relating to the preparation method for sterilization and mould inhibition midbody of sulfonamides. The invention takes acetanilide and chlorosulfonic acid as raw materials, uses phosphorus pentachloride as chlorinating agent; under the action of organic dissolvent, the raw materials are sulfonated, chloridized, separated, and washed to obtain the product. The invention has the effects of little chlorosulfonic acid usage, high product yield, few generated waste acid,, completely cycling dissolvent, recycled by-products, low manufacturing cost, being convenient to popularize and apply, and the like. The products prepared by the method can be widely applied to the preparation of the sterilization and mould inhibition of sulfonamides and industries such as coating, plastics, pesticides, etc.

Owner:CHONGQING UNIV

Preparation method of petroleum-degrading acinetobacter junii bacillus

InactiveCN104450583ALow priceReduce degradation costBacteriaContaminated soil reclamationCooking & bakingMicrobial agent

The invention discloses a preparation method of petroleum-degrading acinetobacter junii bacillus, relates to a preparation method of a petroleum-degrading bacterial agent, and is used for solving the problems that transportation and storage are inconvenient due to the fact that the petroleum is directly degraded by using the bacterial fermentation liquor, the injuries to human bodies are relatively large, and a traditional microbial agent is low in cost. The method comprises the following steps: 1, selecting acinetobacter junii, inoculating into a culture medium, and cultivating to obtain a first-stage seed solution; 2, adding the first-stage seed solution into a fermentation culture medium, and cultivating to obtain a bacterial fermentation liquor; and 3, sterilizing corncob powder, rice bran and wheat bran, mixing any two of the corncob powder, the rice bran and the wheat bran, adding the bacterial fermentation liquor, sodium chloride and monopotassium phosphate to the mixture, mixing evenly, baking, and hermetically storing, so as to obtain the petroleum-degrading acinetobacter junii bacillus. The petroleum-degrading acinetobacter junii bacillus has the advantages of being low in price, easy to degrade, and free of secondary pollution; meanwhile, the soil fertility can be improved; and the method is applied to degradation of petroleum.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

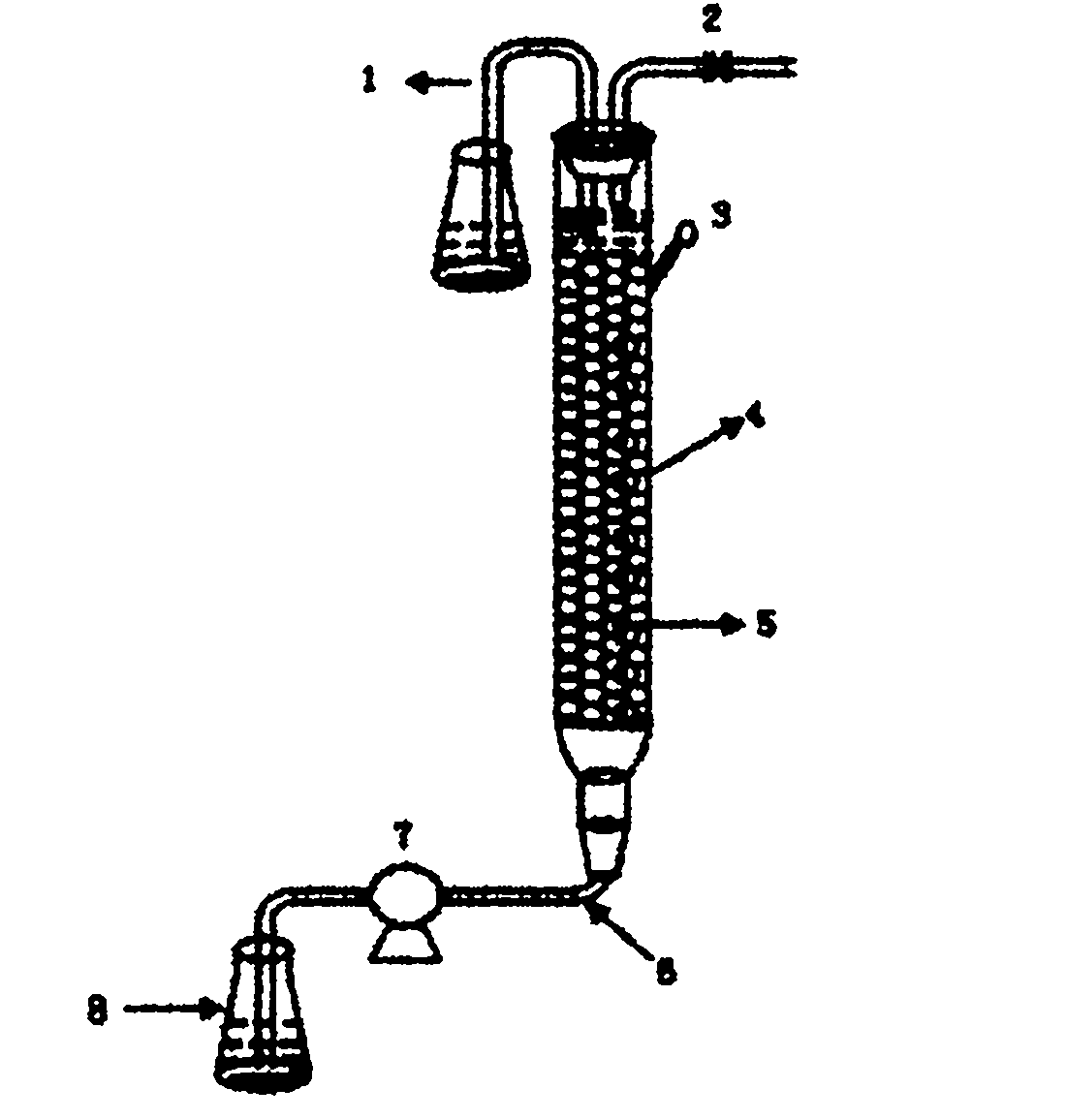

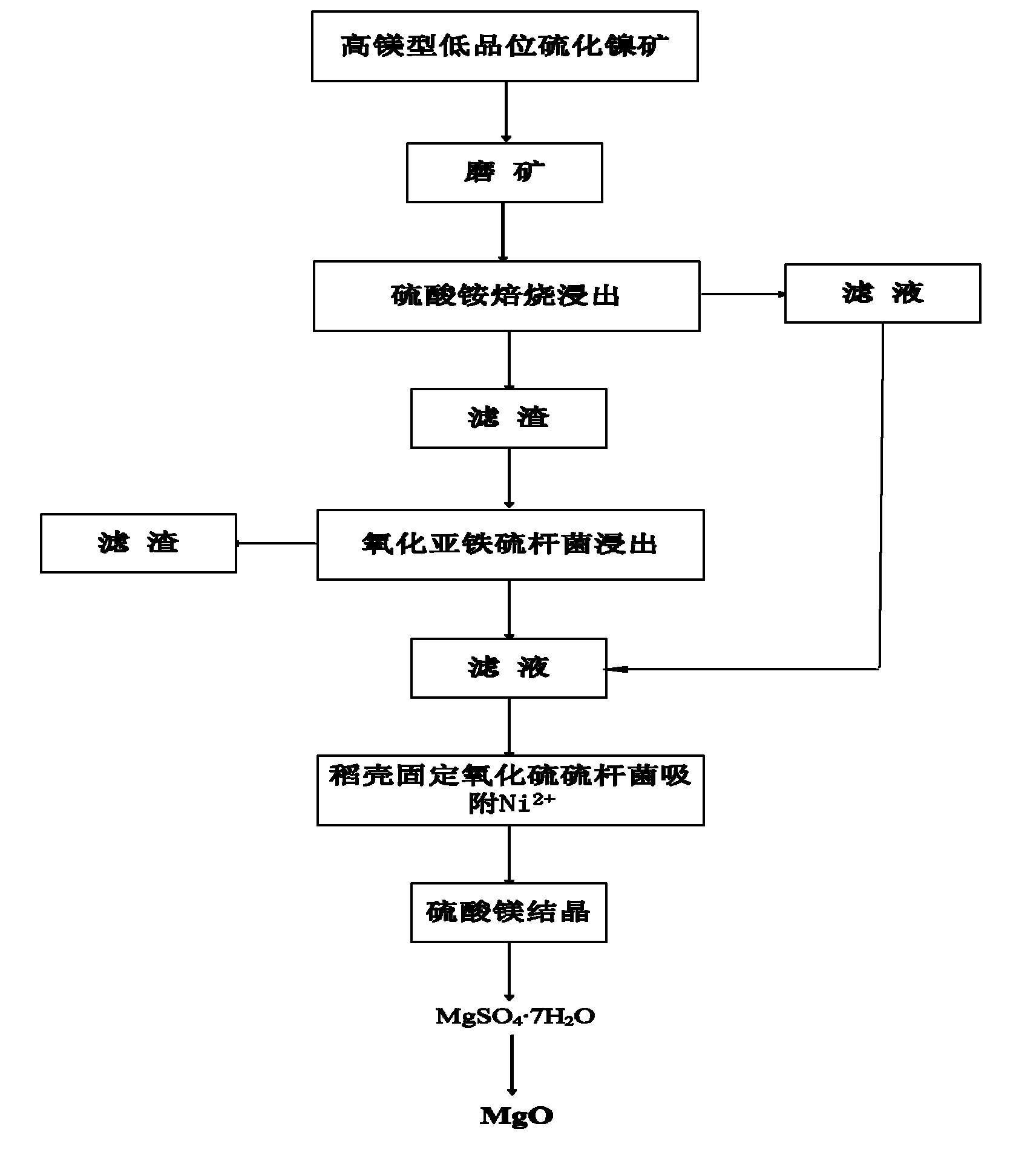

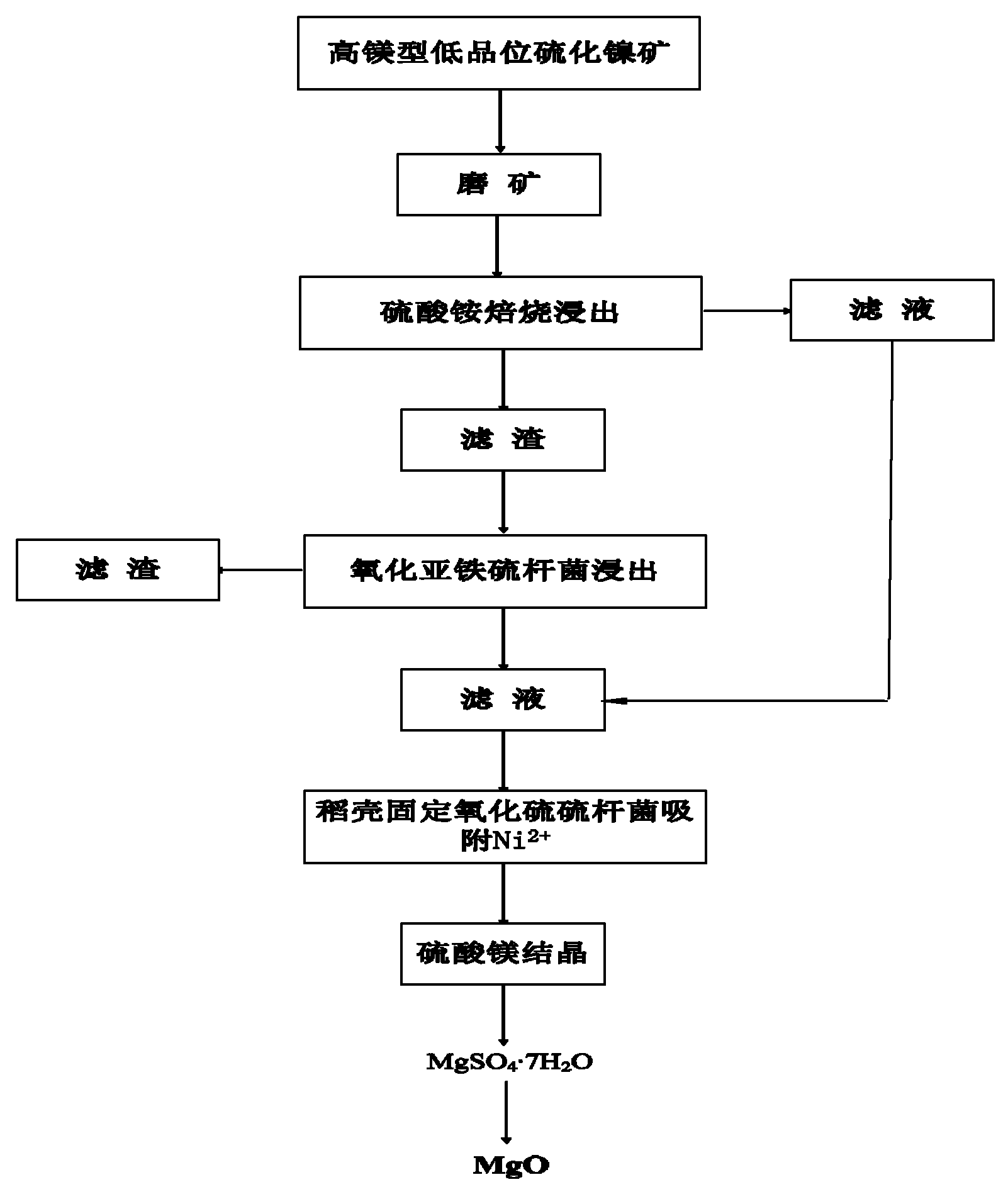

Method for recovering nickel and magnesium elements from high-magnesium low-grade nickel sulfide ore

InactiveCN102094127AHigh magnesium type with low added valueLow added valueProcess efficiency improvementSulfate-reducing bacteriaFixed bed

The invention belongs to the field of nonferrous metallurgy, and relates to a method for recovering nickel and magnesium elements from a high-magnesium low-grade nickel sulfide ore. The method comprises the main steps of ammonium sulfate roasting and leaching, bacterial leaching, Ni<2+> and Mg<2+> separation, solution crystallization, high-purity magnesium oxide preparation and the like. The method is characterized in that: nickel and magnesium in the high-magnesium low-grade nickel sulfide ore are leached by the two-section leaching process of ammonium sulfate roasting and bacterial leaching, sulfate reducing bacteria are fixed by rice hull, an upflow fixed bed reactor is constructed to adsorb and recover Ni<2+> in solution, magnesium sulfate in the solution is recovered by a solution crystallization method, and high-purity magnesium oxide is prepared by pyrolyzing the obtained magnesium sulfate. By the method, the nickel and magnesium elements in the high-magnesium low-grade nickel sulfide ore can be fully recycled, and the process is simple, low in energy consumption and environmental-friendly.

Owner:UNIV OF SCI & TECH BEIJING

Method for producing SiF4 from Na2SiF6 through pyrolysis

ActiveCN102398906ASolve the waste of fluorine resourcesAbundant sources of raw materialsHalogenated silanesChemistryActivated carbon

The invention discloses a method for producing SiF4 from a phosphorus fertilizer industry by-product Na2SiF6 through pyrolysis. The method comprises steps that: Na2SiF6 is dried in a vacuum dryer, and is delivered into a fixed-quantity feeder through a material guiding groove; Na2SiF6 is mixed with NaF in the fixed-quantity feeder, and the mixture is delivered into a high-temperature reaction vessel or a high-temperature circulating fluidized bed; the mixture is subject to pyrolysis for 1-3 hours under a temperature of 600-750 DEG C, wherein the pressure in the high-temperature reaction vessel or the high-temperature circulating fluidized bed is controlled at 10-50mmH2O, such that NaF and SiF4 gases are produced through pyrolysis; NaF is delivered back into the fixed-quantity feeder and is reused; the SiF4 gas is condensed in a condenser, processed though a dust-removing treatment, and purified by using two stages of activated carbon adsorbing columns; the SiF4 gas is then processed through refrigeration compression; the SiF4 gas is delivered into a cylinder, and is stored in the cylinder. The production method provided by the invention is advantaged in low production cost. No waste is generated during the production process, such that clean production is realized. The quality of the produced silicon tetrafluoride gas is stable, and the purity of the silicon tetrafluoride gas reaches 99.9%.

Owner:河南省氟基新材料科技有限公司

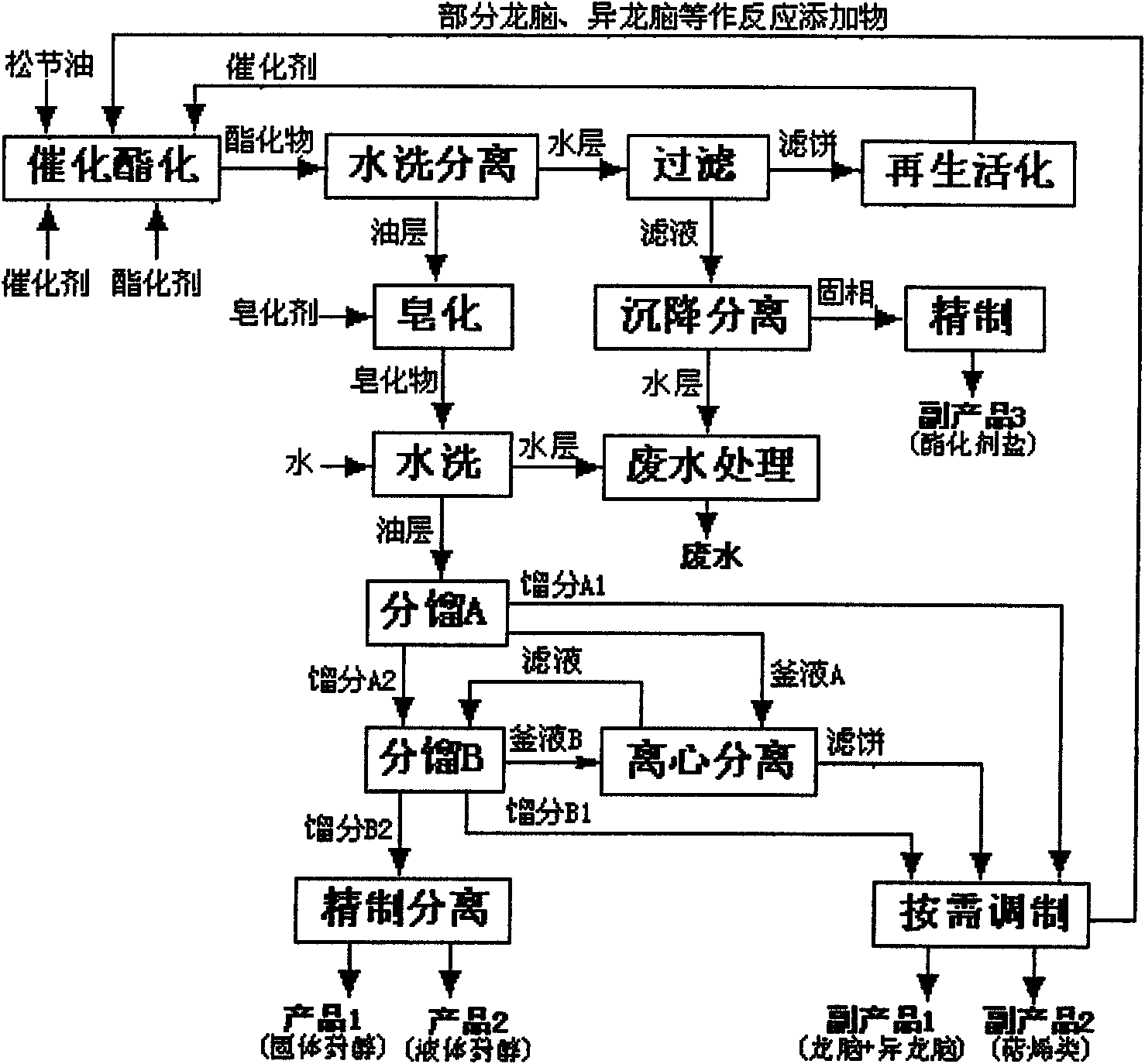

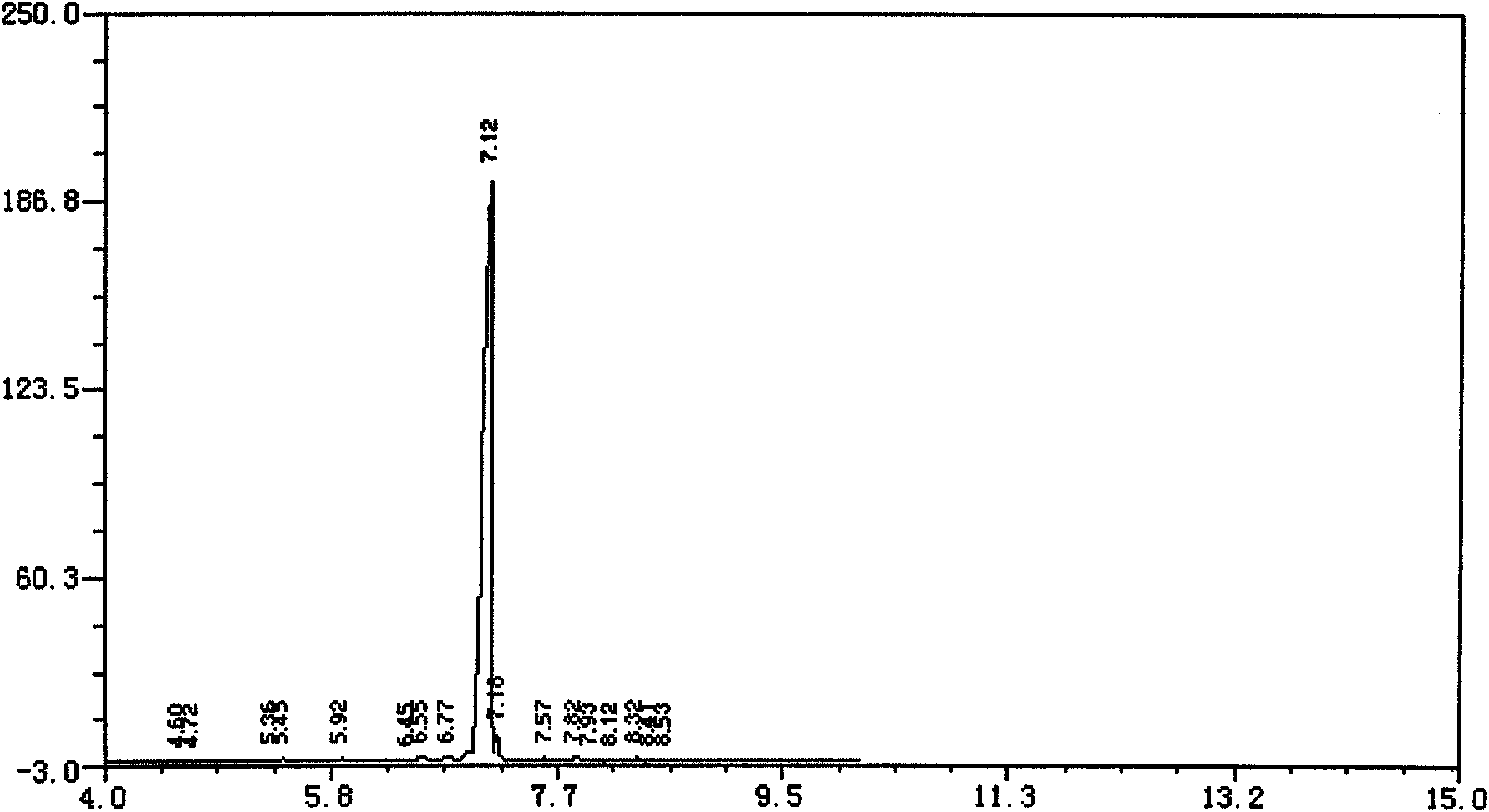

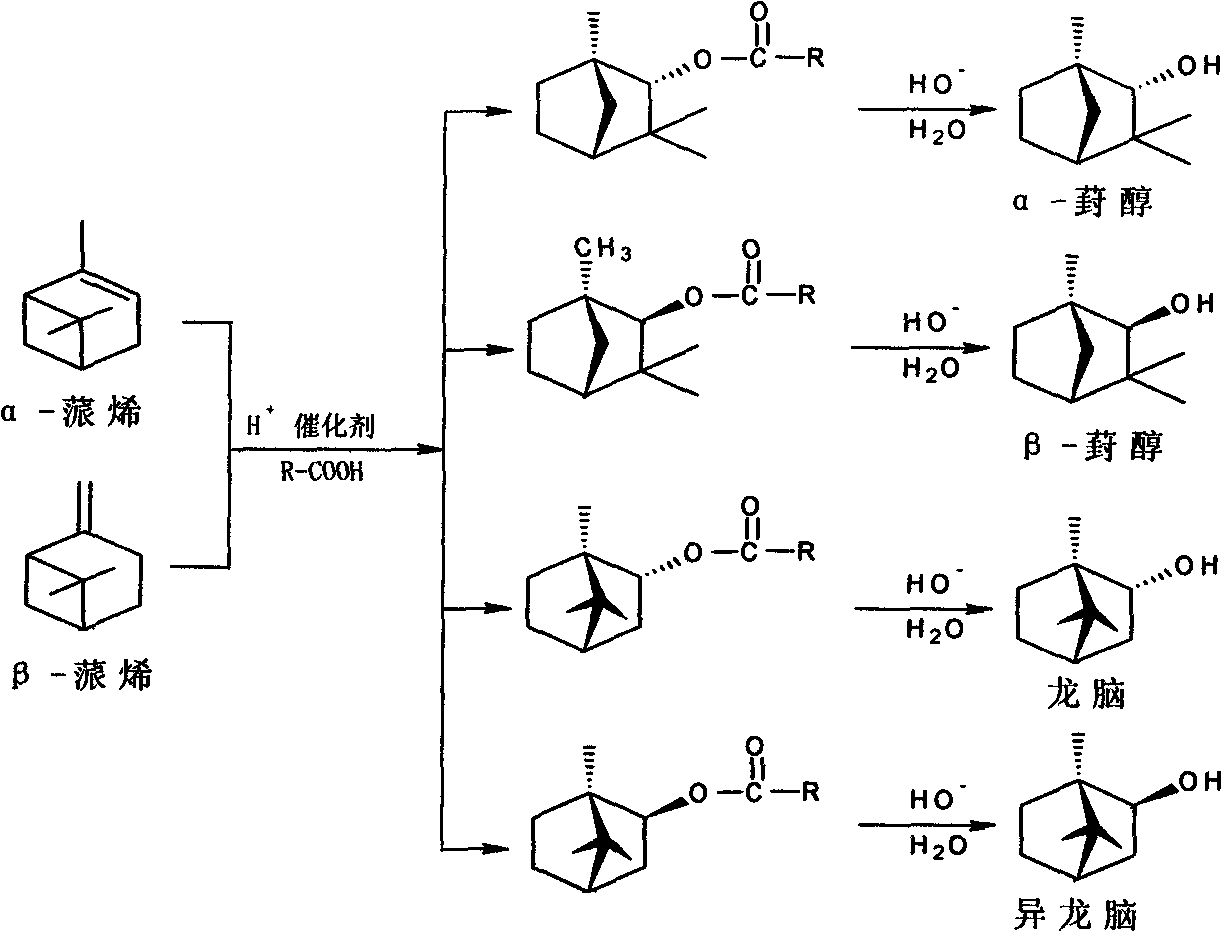

One-step method for synthesizing fenchol with turpentine

InactiveCN102241567ARich deep processing varietiesExtend the industrial chainOxygen-containing compound preparationOrganic compound preparationIsomerizationSeparation technology

The invention discloses a one-step method for synthesizing fenchol with turpentine. In the method, turpentine is used as a raw material, CHKC-4 is used as a catalyst, the catalytic characteristics of the catalyst, namely high activity and selectivity are utilized to perform catalytic isomerization and hydration on pinene (terpene), isomerization and hydration are completed in one step, and then physical methods and chemical methods are combined, and various advanced separation technologies such as efficient vacuum fractionation and melt crystallization are utilized to perform assembly and integration and prepare the fenchol product of which the yield is no less than 50% and purity is 99%. The method has the following advantages: turpentine is used as a raw material which is abundant, is easy to obtain and has low cost, the synthesis and separation technologies are simple, the method is convenient to operate, the product has high purity and lower production cost, etc. The technology and cost of the method are obviously superior, and the competition of the product in international markets can be increased.

Owner:广西辰康生物科技有限公司

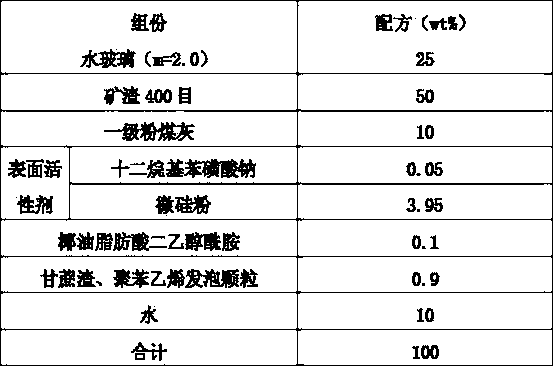

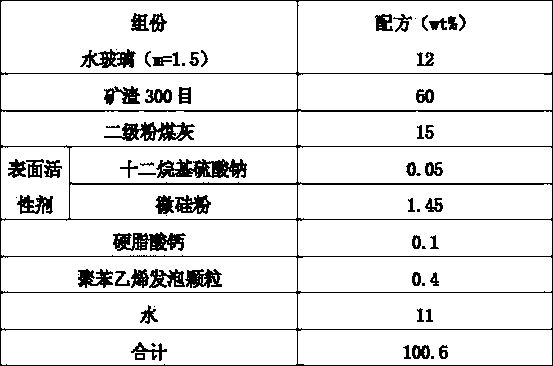

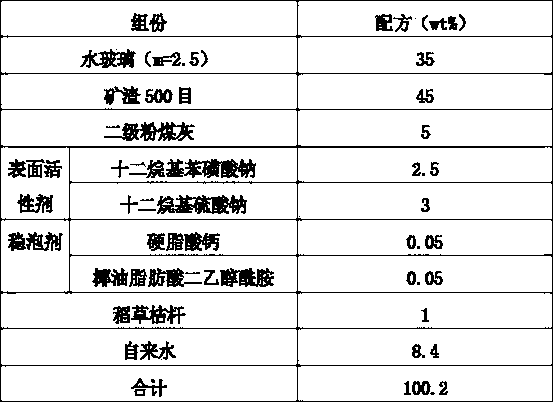

Sandwich layer used for making light partition wall batten

InactiveCN103482950ALow thermal conductivityReduce weightSolid waste managementSlagAdditional values

The invention discloses a sandwich layer used for making a light partition wall batten. The sandwich layer mainly comprises 12-35 parts of water glass, 45-60 parts of superfine slag powder, 1-15 parts of coal ash, 1.5-5.5 parts of surfactants, 0.02-0.1 part of foam stabilizer, 0.03-1 part of light packing and 10-20 parts of water. The invention further discloses a method for making the light partition wall batten through the sandwich layer. The method mainly includes the steps of evenly mixing raw materials, stirring, placing a model, grouting the model, carrying out maintenance and the like. The main raw materials of the sandwich layer are ground polymer, the ground polymer raw materials are rich in source and environmentally friendly, the light partition wall batten made through the sandwich layer made of the ground polymer is low in heat conductivity coefficient, light in weight, good in sound insulation and high in production efficiency, and the product is low in cost and high in additional value, can be planed, nailed and drilled, is convenient to install and construct and meets the national energy-saving and emission-reduction policy. After fiber reinforcement is carried out, the sandwich layer can be further used for making various GRC components.

Owner:刘海锋 +1

Multi-injection molding process one-time molding method for high-toughness home appliance panel

The invention discloses a multi-injection molding process one-time molding method for a high-toughness home appliance panel. The multi-injection molding process one-time molding method is characterized by comprising the following steps of preparing materials for injection molding; inputting relative parameters of the four-stage injection molding process on a control panel of an injection molding machine; pushing a manual / automatic change-over switch on an electric control cabinet to the automatic position; inputting location parameters and pressure holding parameters of a screw rod on a touchinput screen when completion of filling meeting process switching conditions; closing a safety door of the injection molding machine, pressing an on / off switch in an on position to start the injectionmolding machine; and opening a mold and taking out workpieces after completion of injection molding. According to the multi-injection molding process one-time molding method, the injection molding machine is controlled by a PLC to conduct regulation to adopt different injection molding processes at different injection molding stages according to data stored from the control panel of the injectionmolding machine. Meanwhile, compared with a bonded panel, the panel manufactured through multi-injection molding one-time molding has the good integrity and toughness and is not likely to get bent and fall off.

Owner:太仓意欣智能科技有限公司

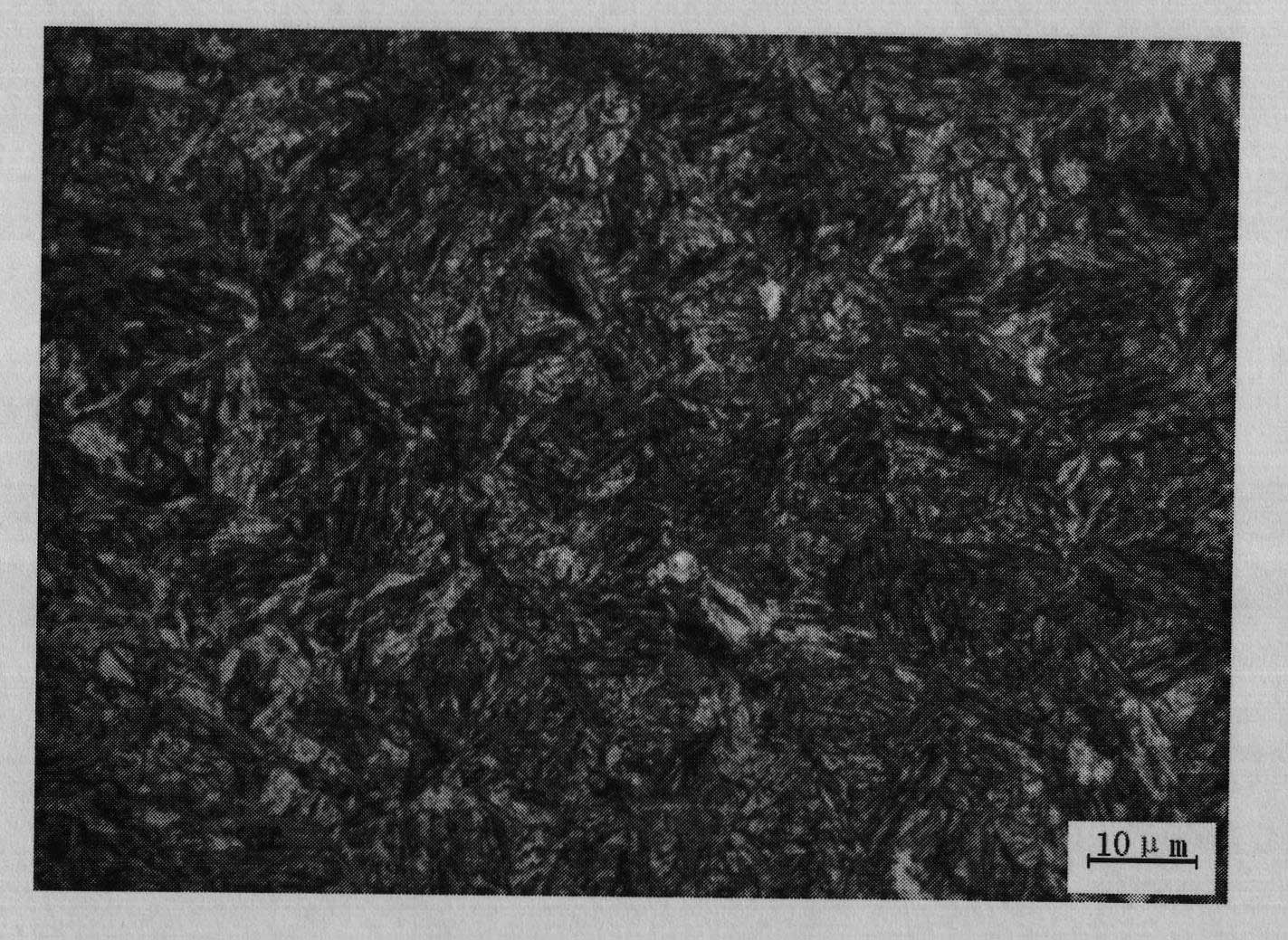

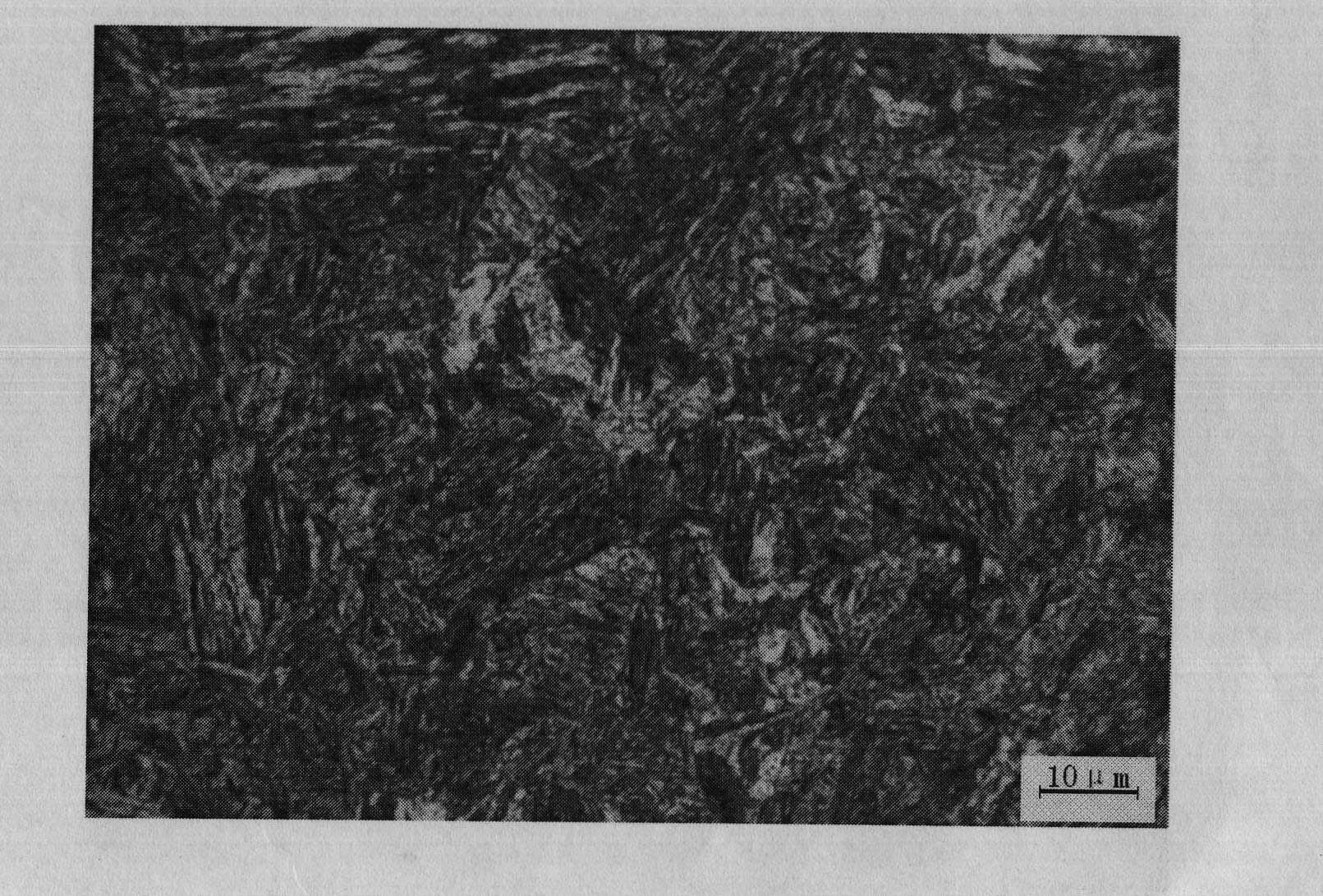

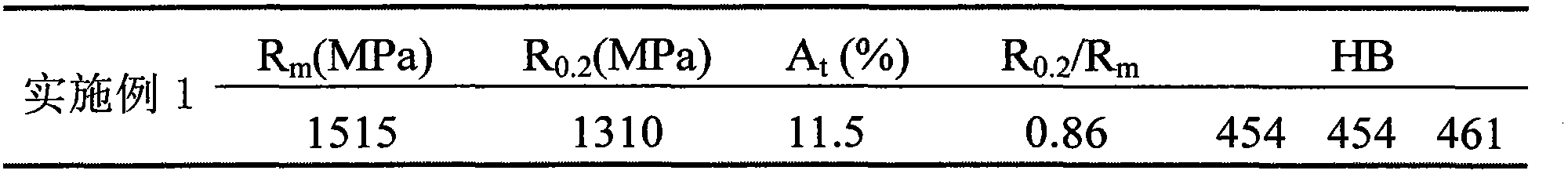

High-strength steel plate containing rare earth (RE) and heat treatment process thereof

The invention provides a high-strength steel plate containing rare earth (RE) and a heat treatment process thereof, and belongs to the metallurgical technical field. The RE-containing high-strength heat-treated steel plate comprises the following chemical components by weight percentage: 0.15%-0.25% of C, 1.5%-1.85% of Mn, 0.7%-1.0% of Si, not more than 0.015% of P, not more than 0.003% of S, 0.01%-0.06% of Ti, 0.0005%-0.035% of B, 0.001%-0.09% of RE and the balance of Fe and unavoidable impurities. The heat treatment process comprises the following steps: austenitizing at the temperature of 900-950 DEG C, keeping the temperature for 0.5-2.5 hours and then performing water quenching; and tempering at the temperature of 190-240 DEG C and then keeping the temperature for 1-10 hours. The heat-treated steel plate produced by the heat treatment process has the advantages of excellent mechanical properties and low production cost, wherein, the tensile strength reaches 1500-1700MPa, the elongation is 10-15% and the yield ratio is not more than 0.9; and the heat treatment process is applicable to industrial production of the steel plate with the thickness of 5-25mm.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

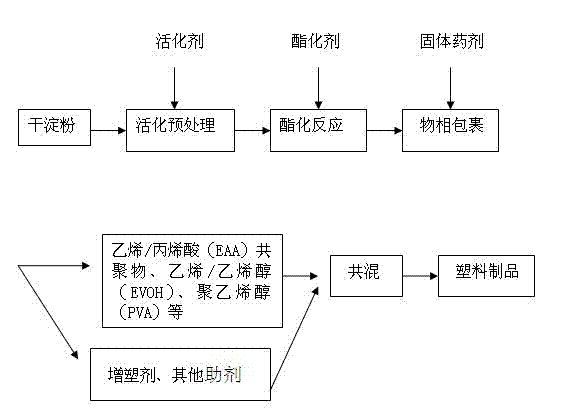

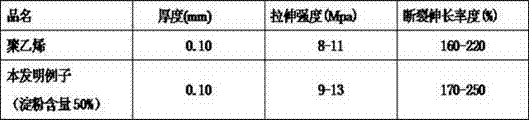

Starch-based biodegradable plastic and preparation method thereof

ActiveCN103044718ASignificant progressBiodegradation is completePolymer scienceBiodegradable plastic

The invention provides a method for preparing starch-based biodegradable plastic. The starch-based biodegradable plastic is prepared by using cassava starch as a raw material and using a modified starch and biodegradable high-molecular polymer blending technology line. The modified starch is prepared by activating dry starch, adding an esterification reagent to the pretreated activated starch, and then adding a solid coupling agent. The biodegradable plastic products are prepared by blending the modified starch, an ethane / vinyl alcohol copolymer, polyvinyl alcohol, a plasticizer and an auxiliary agent.

Owner:广西农垦明阳生化有限公司

Ginseng polysaccharide chewable tablet and preparation method thereof

The invention provides a ginseng polysaccharide chewable tablet and a preparation method thereof. The ginseng polysaccharide chewable tablet is prepared by using a ginseng polysaccharide extract through a modern preparation technology. Animal function test and human body test demonstrate that the ginseng polysaccharide chewable tablet has a health-care function of immunoregulatory.

Owner:BEIJING YILING PHARMA

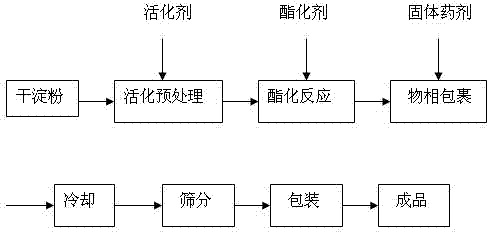

Method for preparing composite modified starch for biodegrading plastic

The invention provides a method for preparing composite modified starch for biodegrading plastic, comprising: adding an activator in dry starch, for pretreatment under 95-100 DEG C for 30min; adding an esterification reagent into the starch after activation, for making esterification reaction under 120-125 DEG C for 1h, wherein the whole press is carried out in a solid phase state; adding a solid coupling agent into the material after esterification, for making a phase coating reaction in case of stirring under 125-130 DEG C for 40-50min, wherein the whole press is carried out in a solid phase state; cooling the material until to room temperature, screening the material with 60 mesh sieves, and then packaging the material to obtain the finished product.

Owner:广西农垦明阳生化有限公司

Changeable imitation fur and linen face fabric and its processing technique

InactiveUS20090269545A1Application area is limitedComfort level is also poorLayered productsProtective fabricsFiberPolyester

This invention makes public a kind of changeable imitation fur and linen face fabric weaved together from warp and weft yarns. The warp yarn uses mixed spun yarn with bamboo fiber and fine polyester as raw materials. The weft yarn uses mixed spun multiple color changeable yarn with allotropic and anisotropic polyester and adhesives as raw materials. The processing technique of this changeable imitation fur and linen is also made public. This invention features soft tactility, abrasion resistance, good drapability, air permeability, flexibility, anti-static and anti-bacterial ability.

Owner:XU REN LIANG

High-efficiency pretreatment separation of hemicellulose from fiber-based biomass raw material and comprehensive utilization method

ActiveCN110272509ARealize comprehensive utilization of high quality and high valueEfficient separationLignin derivativesPulping with organic solventsFiberDistillation

The invention provides high-efficiency pretreatment separation of hemicellulose from a fiber-based biomass raw material and a comprehensive utilization method. The method comprises the following steps: the forest biomass resource fiber-based biomass raw material is used as a raw material, and the fiber-based biomass raw material is firstly subjected to slurry method pretreatment: the fiber-based biomass raw material is ground by a ball mill, sieving is performed to obtain fiber-based biomass raw material powder with a certain mesh, and the powder and water are mixed according to a ratio at a room temperature to obtain a fiber-based biomass raw material powder slurry premixed liquid; through regulation and control of the reaction temperature, time and water quantity, high-efficiency hydrothermal removal of the hemicellulose in the fiber-based biomass raw material powder in the slurry fiber-based biomass raw material powder premixed liquid system is realized; after the mixed liquid is filtered, the filtrate is subjected to gradient precipitation to separate low-dispersion hemicellulose, the precipitate is dried, and the dried material is stored; after the filter residues, a polar aprotic solvent and water are mixed, the mixture is heated and stirred in a pressurized reaction kettle for a certain period of time, filtering separation is performed to obtain high-purity cellulose, the high-purity cellulose is washed by using water, drying is performed, and the dried high-purity cellulose is stored; the filtrate and water are mixed, the mixture is allowed to stand, the precipitated powder is filtered, drying is performed, and the dried material is stored; and the filtrate is subjected to reduced-pressure distillation to recover water, the solvent and a small amount of small-molecular chemicals, and recycling is performed. The method provided by the invention adopts the fast-growing forest fiber-based biomass raw material unique in China as the raw material, and has a green and environmentally-friendly process and low costs, the hemicellulose has a low dispersion degree and a high yield, the solvent used in the method can be efficiently recycled, and the method is friendly to the environment, and suitable for industrial production.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

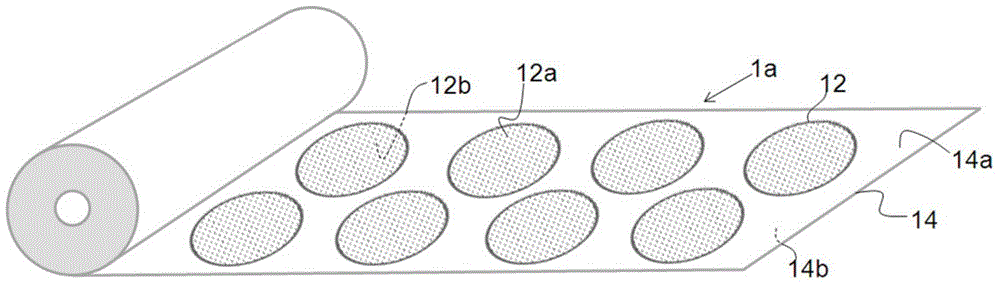

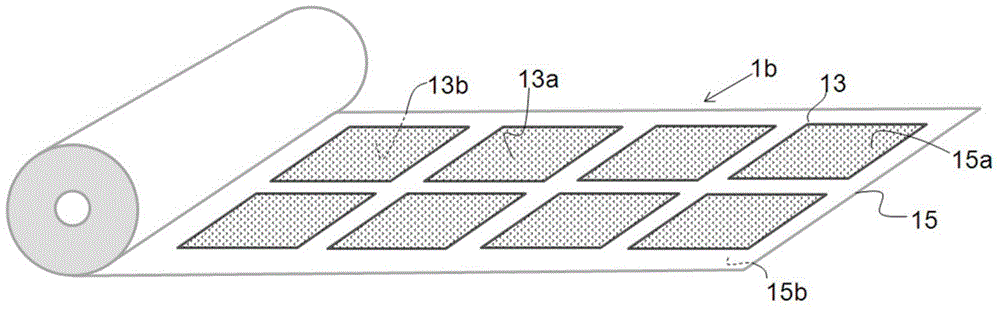

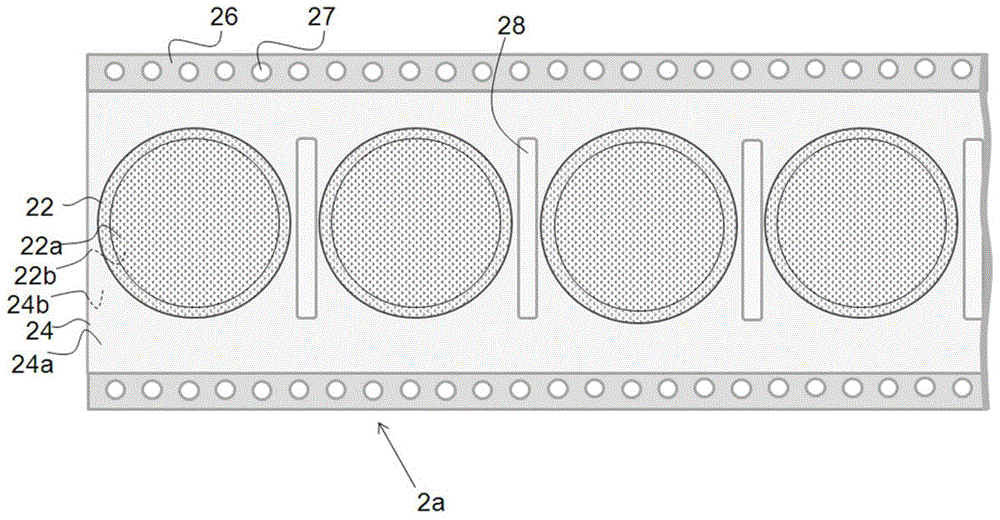

Glass substrate strip

ActiveCN104602908ALow added valueSmall sizeGlass forming apparatusElectrical equipmentEngineeringEdge region

The invention relates to a glass substrate strip made of a multiplicity of thin-glass segments which are positioned and fixed on an adherent foil. The thin-glass segments are fixed on the adherent foil over the entire area thereof, by way of the entire edge region thereof or by way of parts of the edge regions thereof. The glass substrate strip can comprise lateral transport bands or else coding fields. For storage, it is plated in meandering fashion or is rolled up, and it serves not only for transport and storage but also as a carrier strip in processing steps for the thin-glass segments.

Owner:SCHOTT AG

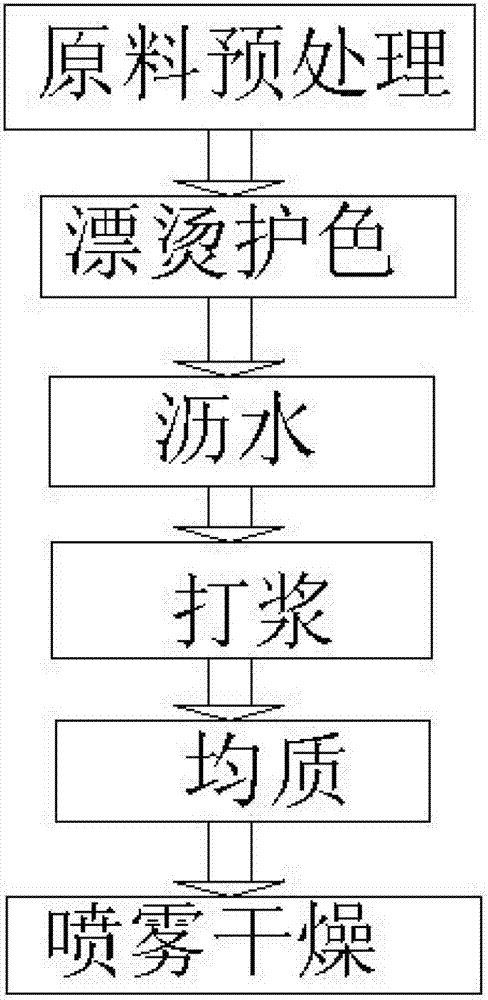

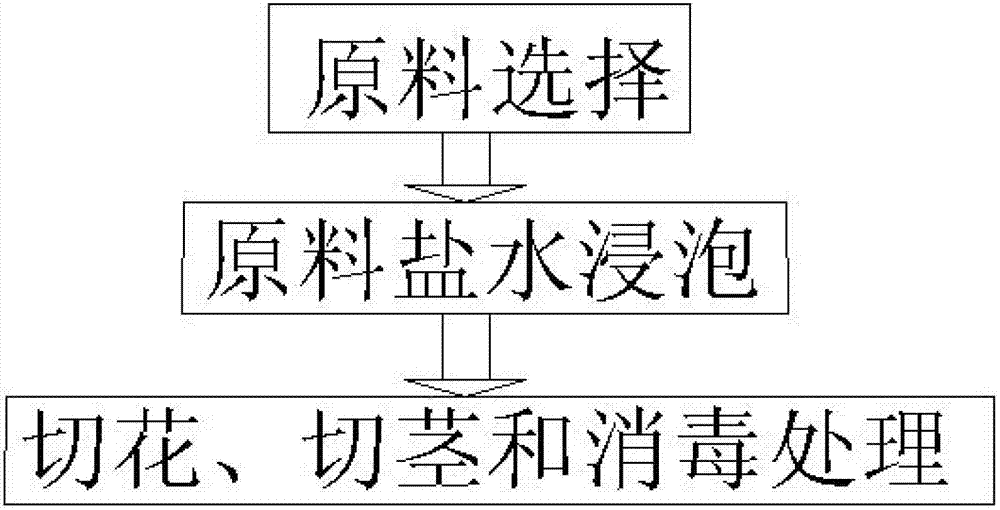

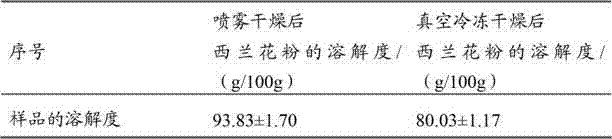

Spray-drying method of broccoli powder

InactiveCN102763816ASmall color differenceGood color protectionFood preservationFood preparationPre treatmentSpray drying

The invention discloses a spray-drying method of broccoli powder. The spray-drying method of broccoli powder sequentially includes the steps of pretreatment of raw material, blanching and color protection, draining, pulping, homogenizing and spray-drying. During blanching and color protection, 0.25mg / l Cu(AC)2 is used as color fixative, the blanching and color protection is performed at 95 DEG C for 90s, resultant color difference is small, and color protection for a finished product is effective. Parameters in the spray-drying include 50% of broccoli liquid, 150 DEG C of temperature, and 800ml / h of compressed air flow. Color difference of the spray-dried product (greenish) is small, and yield of the product is high. In addition, dispersiblity and solubility of the broccoli powder can be improved by the spray-drying method, the broccoli powder is less easy to cake and fast to dissolve, and the broccoli power can be added in other foods without generating rough taste in oral cavity.

Owner:ZHEJIANG WANLI UNIV

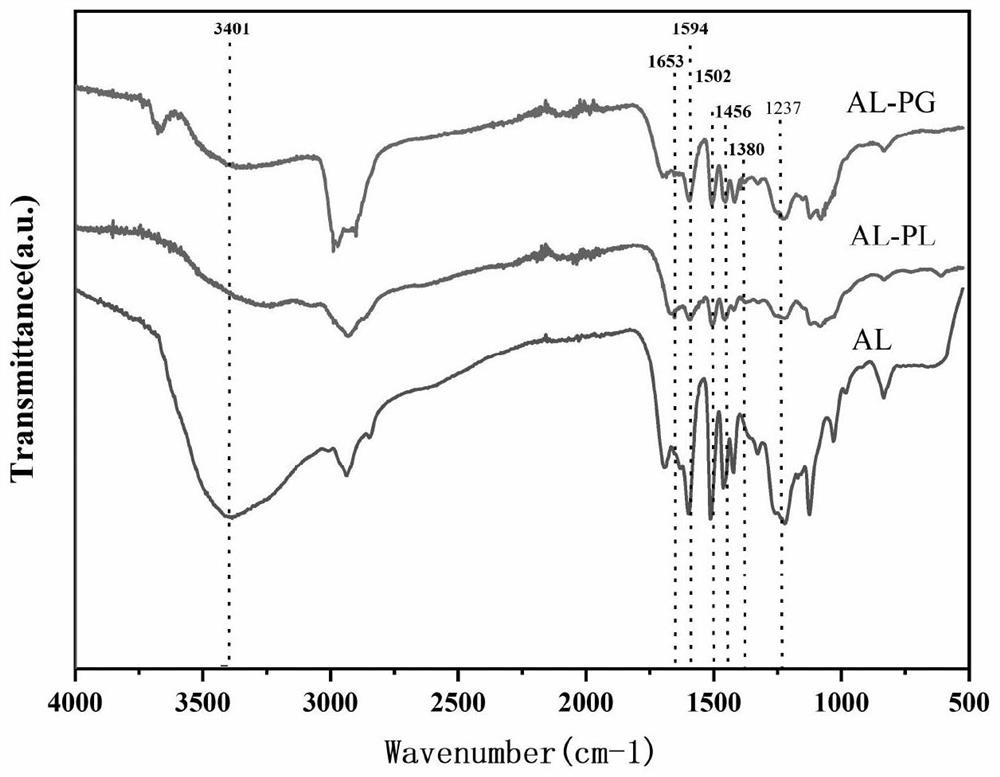

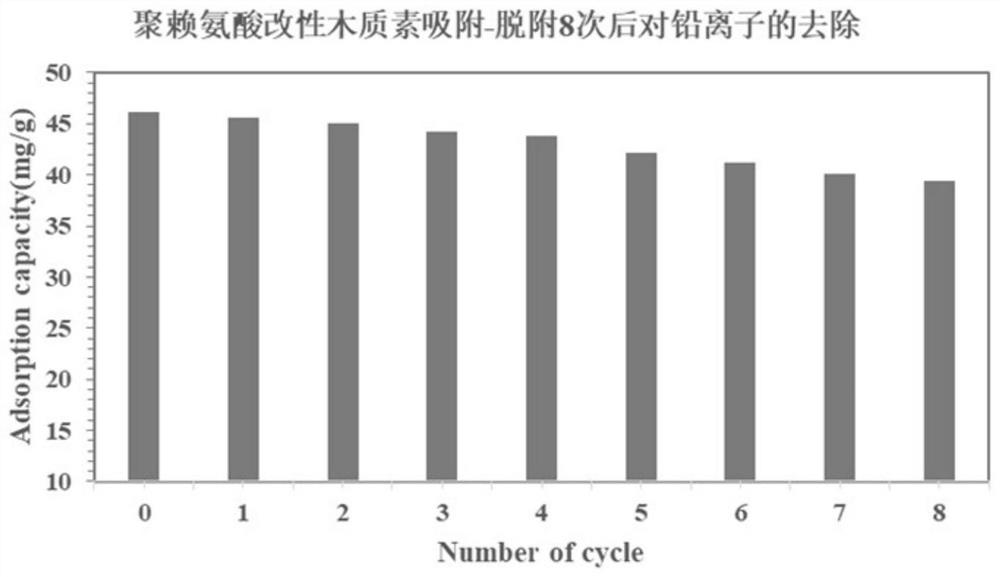

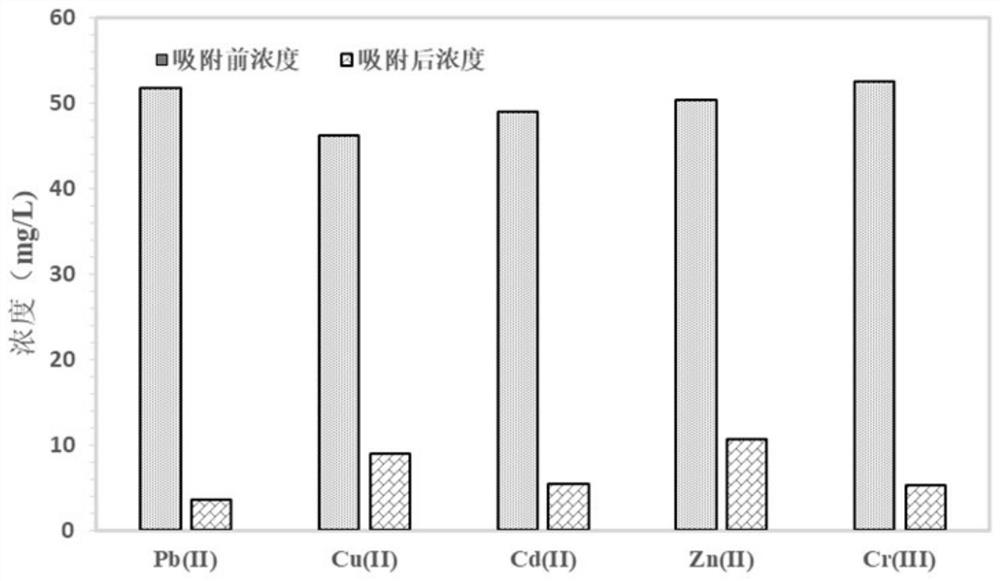

Lignin grafted polyamino acid type heavy metal adsorbent as well as preparation method and application thereof

InactiveCN112915971AImprove adsorption capacityLow added valueOther chemical processesWater contaminantsEnvironmental chemistryEnvironmentally friendly

The invention discloses a lignin grafted polyamino acid type heavy metal adsorbent and a preparation method and application thereof.The adsorbent is stable in structure, adsorption-desorption can be conducted for multiple times, metal recovery and repeated utilization of the adsorbent are facilitated, and meanwhile lignin and polyamino acid have the advantages of being safe, non-toxic, green, environmentally friendly and the like; and the lignin grafted polyamino acid type heavy metal adsorbent has good economic and environmental benefits.

Owner:NANJING UNIV OF TECH

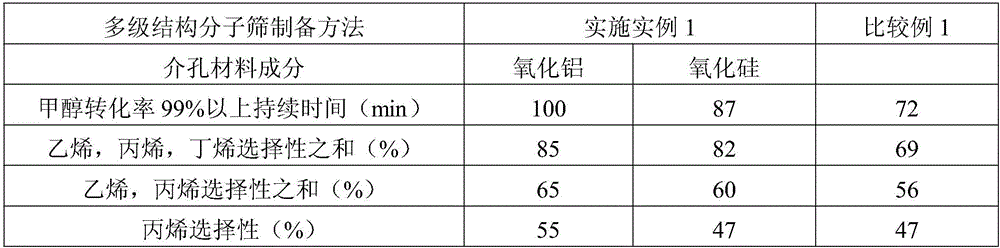

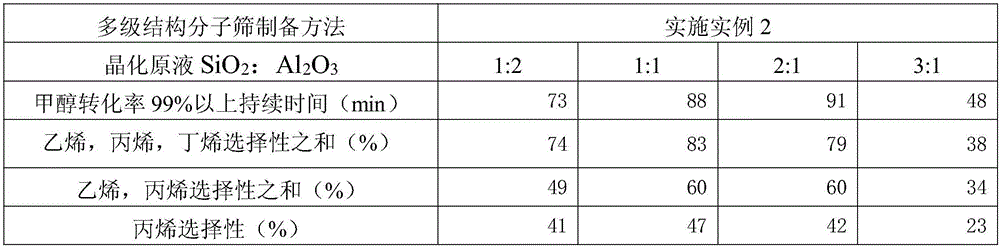

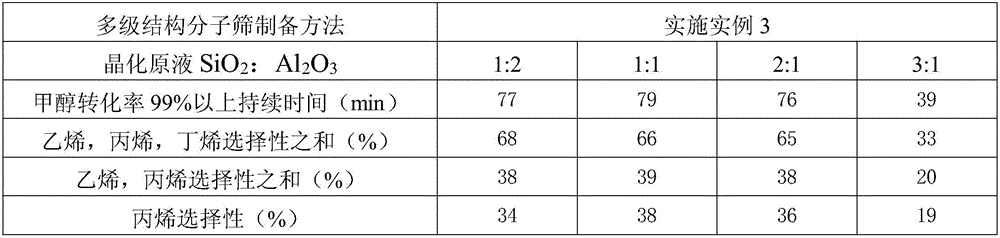

Method for preparing multi-level-structured molecular sieve by taking mesoporous material as indirect template agent

ActiveCN106430229AGood carbon deposition resistanceHigh selectivityMolecular sieve catalystsMolecular sieve catalystLevel structureMicrosphere

The invention discloses a method for preparing a multi-level-structured molecular sieve by taking a mesoporous material as an indirect template agent. The method comprises the following steps: mixing aluminum oxide spheres or silicon oxide microspheres, an external silicon source or an aluminum source, phosphoric acid, a template agent and water to form a crystallization raw solution; transferring the uniformly mixed crystallization raw solution into a hydrothermal kettle taking tetrafluoroethylene as a lining, and ageing; after ageing, putting the hydrothermal kettle into a homogeneous reactor for crystallization; cooling a crystallized solution, taking out the crystallized solution and carrying out washing and centrifuging treatment; filtering an obtained solid-liquid mixture, washing and drying; and roasting to remove the template agent to obtain the multi-level-structured molecular sieve. The molecular sieve comprises mesopores and micropores; generation and diffusion of isobutylene in pore channels can be inhibited very well; isomeric hydrocarbon and aromatic hydrocarbon, which have relatively great molecules, can be subjected to more serious diffusion limitation; and meanwhile, the diffusion resistance of a target product, low-carbon olefin, particularly propylene, is reduced due to the presence of the mesopores, so that the prepared multi-level-structured molecular sieve is used as a catalyst, is not easy to inactivate and has good stability.

Owner:CHINA HUANENG GRP CO LTD +1

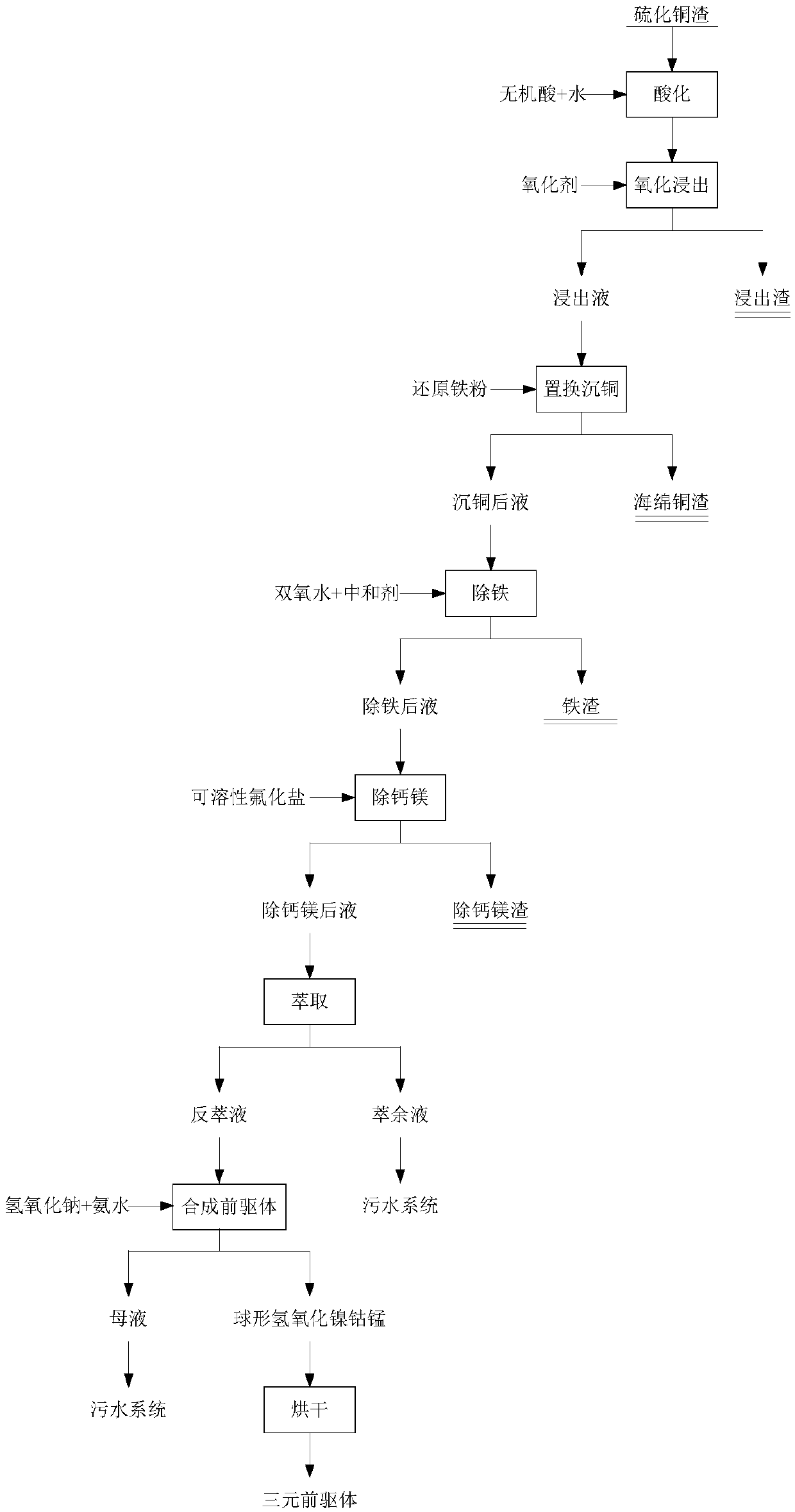

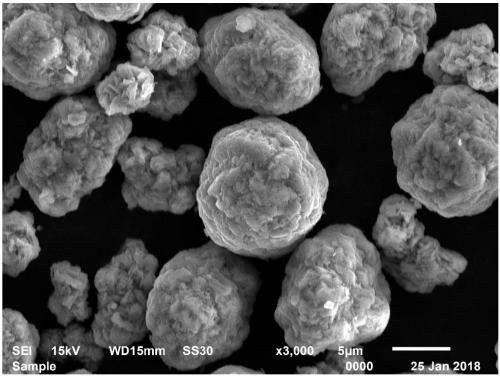

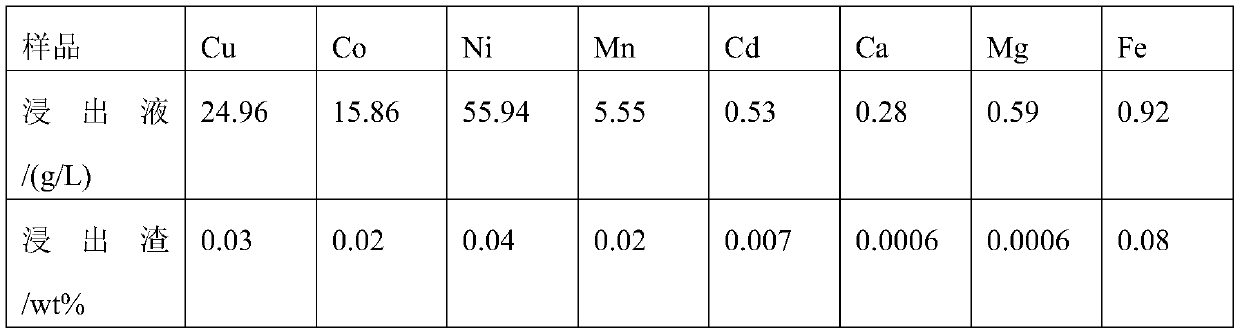

Method for preparing ternary precursor material by recycling copper sulfide slag

The invention discloses a method for preparing a ternary precursor material by recycling copper sulfide slag. The copper sulfide slag is subjected to acidification, oxidation leaching, replacing and copper precipitating, iron removing, calcium and magnesium removing, cobalt-nickel-manganese extracting, nickel-cobalt-manganese precipitating and calcining to prepare the ternary precursor material; and according to the method, the defects that in the prior art, the requirement of leaching equipment is high, the processing flow is long, the product additional value is low, the energy consumption is large, and the waste gas is prone to generate to pollute the environment are overcome. The method has the advantages that the process is simple, the cost is low, the method is green and environment-friendly, the comprehensive recovery of valuable metals can be realized, and the total recycling rate of the nickel-cobalt-manganese is up to 97%.

Owner:江西赣锋循环科技有限公司

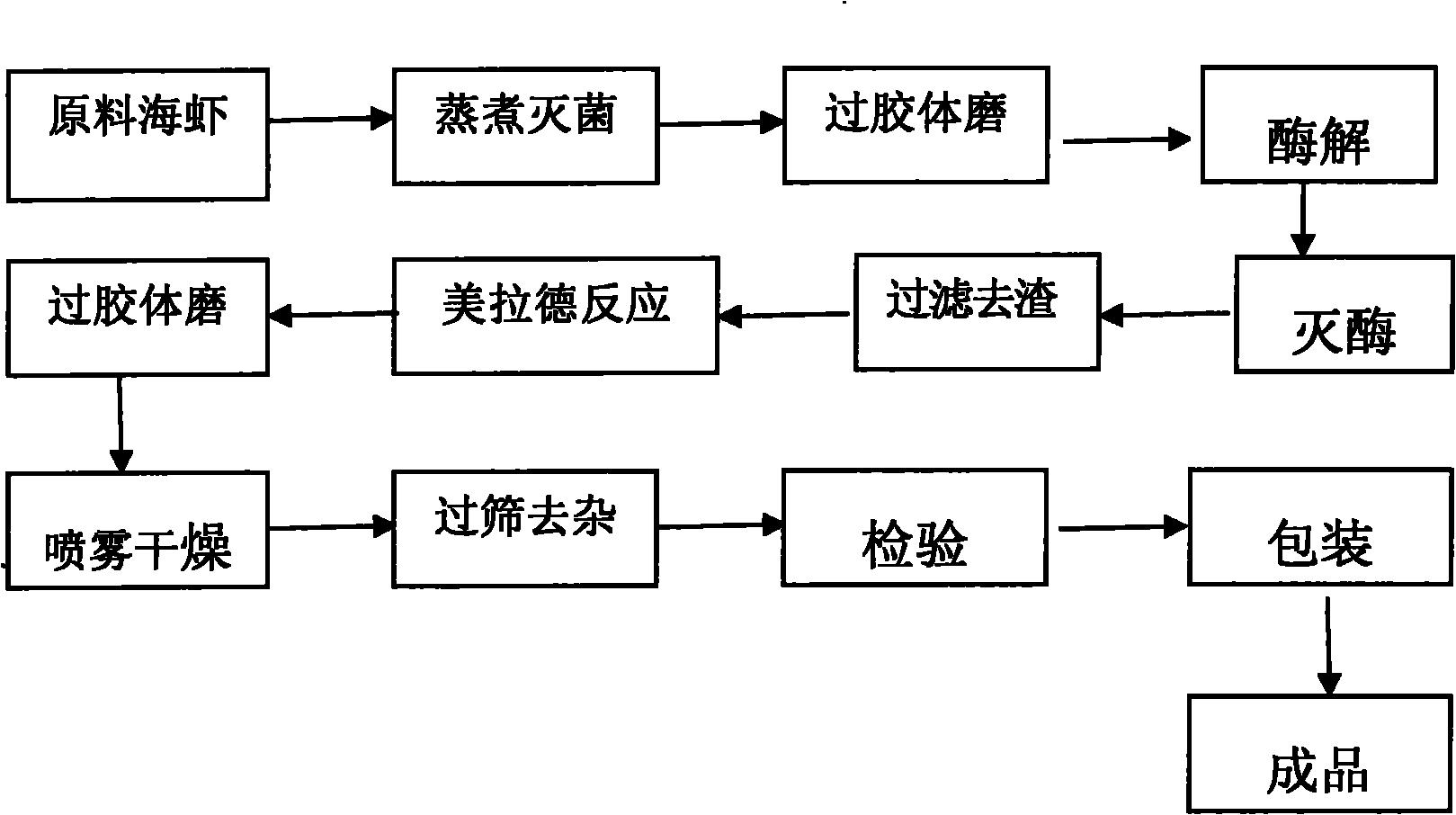

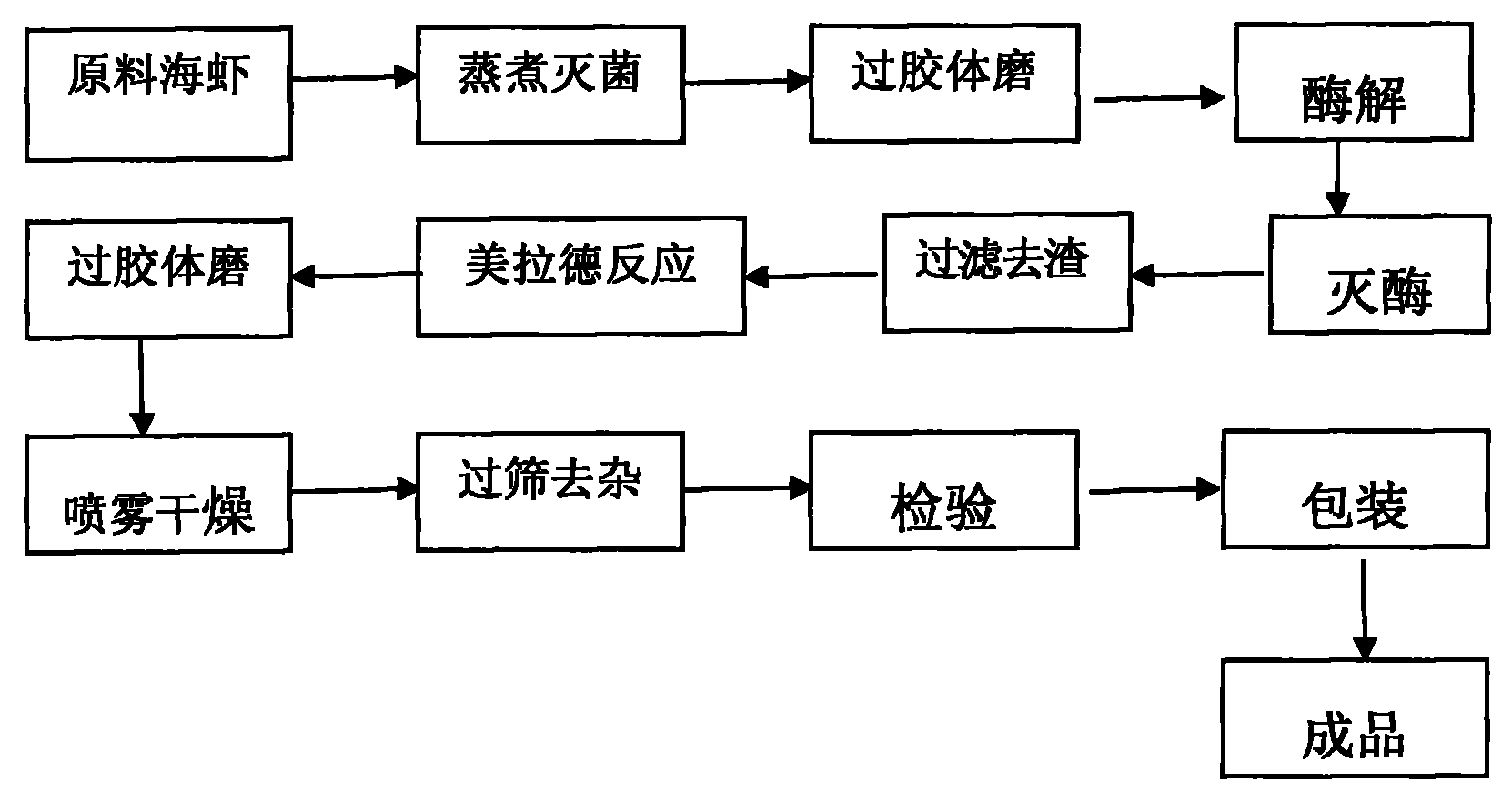

Shrimp protein extraction essence and manufacturing process thereof

The invention discloses a shrimp protein extraction essence and a manufacturing process thereof. The powdery shrimp protein extraction essence is obtained by using natural shrimps as the raw material through the steps of cooking, grinding, carrying out enzymolysis for destroying enzyme, performing maillard reaction, spraying and drying. The invention prevents deterioration of shrimps, improves the conversion rate of changing protein into amino acid through enzymolysis, better prevents oil oxidation and rancidity phenomenon and has the characteristic of aromatic flavor. The produced shrimp protein extraction essence has low water content and complete sterilization, ensures that the microbiological indicator is better than that of the similar products, has long quality guarantee period and is widely applied to the food processing industries of instant noodles, puffed food, cooked meat, and the like. Besides, the invention improves the additional value of aquatic products, solves the problem that the low-value aquatic products are hard to sell, increases income for fisherman and reduces side effect on the environment resulting from discarding low-value aquatic products.

Owner:ZHEJIANG DINGWEI FOOD

Attapulgite nickel-plated composite material and preparation method thereof

InactiveCN102295473AIncrease added valueGood economic benefits and social significanceNanometreChemistry

The invention discloses a nickel-plated attapulgite composite material and a preparation method thereof. The nickel-plated attapulgite composite material comprises attapulgite as a matrix, and a nickel layer coated on the surface of attapulgite. The preparation method comprises the following steps: preparing attapulgite deionized water suspension with the concentration of 10-50 g / L, successively carrying out a treatment with surfactant dodecyl benzene sulphonic acid, sensitizing agent and activating agent and a treatment with surfactant dodecyl benzene sulphonic acid under conditions with ultrasonic or stirring, then plating under homeothermic condition at the temperature of 35-60 DEG C for 20-50 min, when finishing plating, carrying out centrifugation, washing and drying to obtain the nickel-plated attapulgite composite material. The invention opens up a new way for the utilization of nano mineral materials in the high technical field, and provides a new direction of the development of absorbing material, thus bringing potential applications of attapulgite.

Owner:HEFEI UNIV OF TECH

Method for producing silicon dioxide and alumina by using fly ash

This invention discloses a method for extracting SiO2 and Al2O3 from fly ashes. The method comprises: activating fly ashes, leaching with more than 40 wt. % NaOH solution so that Si is stripped out in the form of sodium cilicate, introducing CO2 to prepare SiO2, adding CaO or CaCO3 into the leaching residue, calcining to obtain a clinker, preparing Al2O3 by Bayer method, and preparing cement from the waste residue. The method extracts Si at first, thus increasing the Al / Si ratio in the leaching residue. Treated leaching residue can be directly subjected to Bayer method to extract Al2O3, which largely simplify Al2O3 extraction process and increase Al2O3 utility. The method has such advantages as simple process, low investment, and high product added value.

Owner:PINGSHUO INDAL

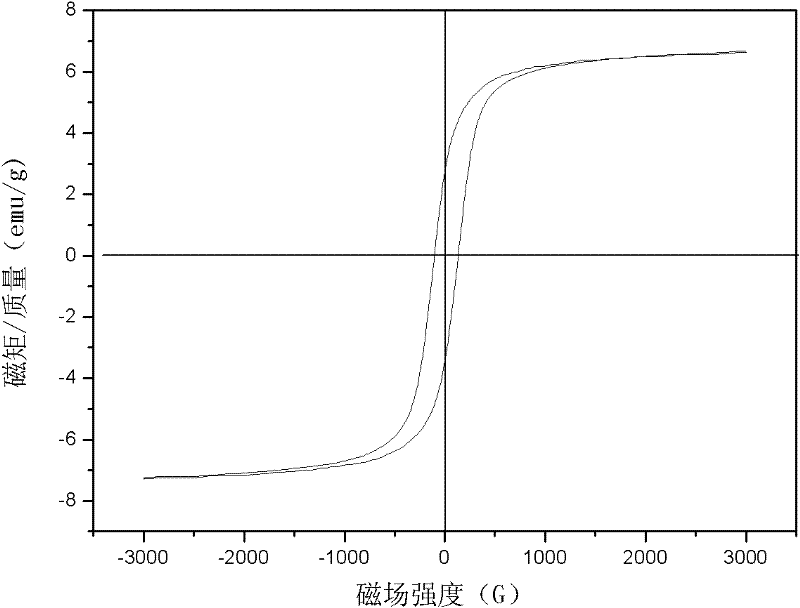

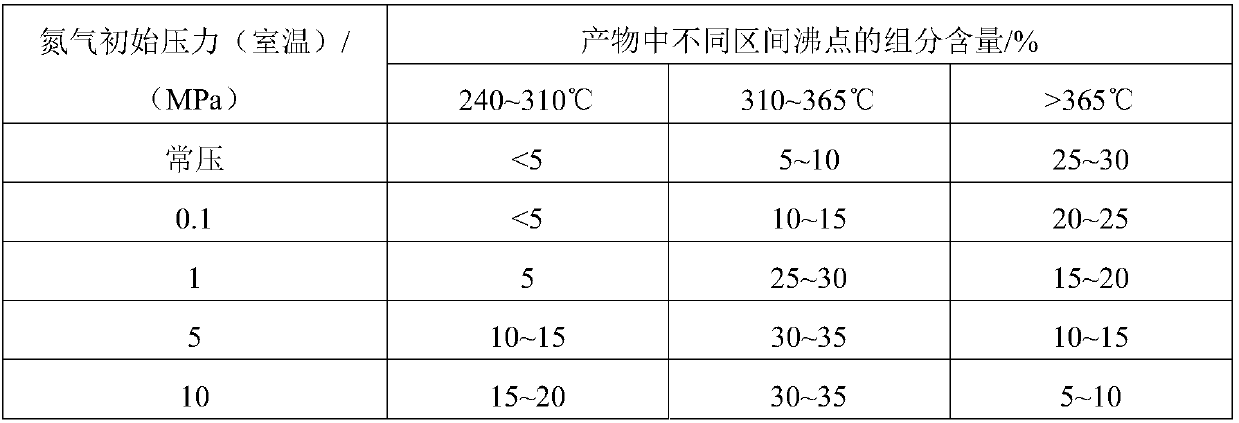

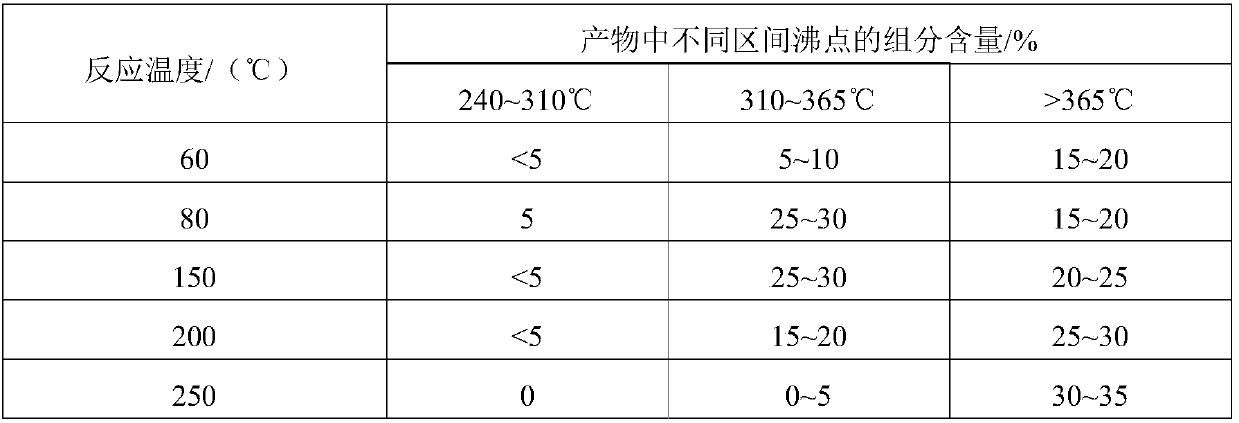

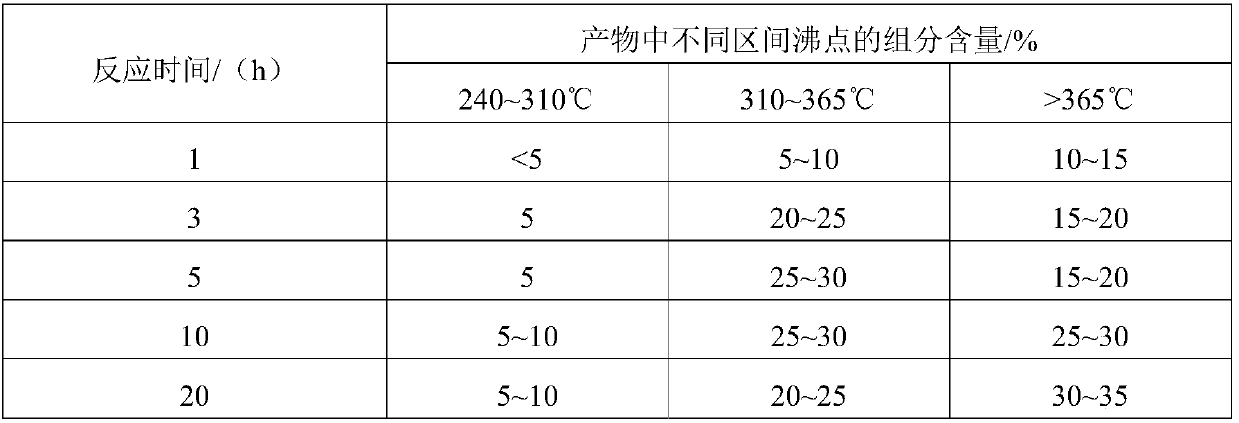

Method for preparing high-boiling aromatics used as heat carrier oil from heavy aromatics

InactiveCN107903938AImprove utilization efficiencyEasy accessLiquid hydrocarbon mixtures productionHydrocarbon oils treatment productsLiquid productHeat carrier

The present invention provides a method for preparing high-boiling aromatics used as heat carrier oil from heavy aromatics. According to the method, monocyclic aromatic hydrocarbons or bicyclic and polycyclic aromatic hydrocarbons obtained from whole fractions of heavy aromatics or by rectification of heavy aromatics are respectively used as raw materials to be stirred with an olefin in a closed reaction kettle or to undergo a flowing reaction with an olefin in a fixed-bed reactor, a liquid inorganic acid or solid acid catalyst or a mixed acid catalyst is employed, at a reaction temperature of60 DEG C or more and under the condition that the nitrogen initial pressure at room temperature is normal pressure or above, one-step catalytic conversion is performed, so that alkylation of the aromatic hydrocarbon with the olefin is achieved to prepare the high-boiling aromatic hydrocarbon used as the heat carrier oil. Compared with existing industrial synthetic routes of mineral heat carrier oil, the method of the invention has the advantages of wide range of sources of raw materials for reaction, low cost, highly efficient use of fossil resources, less waste and reduction of environmentalpollution, and has a wide range of reaction catalyst sources, mild reaction conditions, separation easiness between a liquid product and the catalyst.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

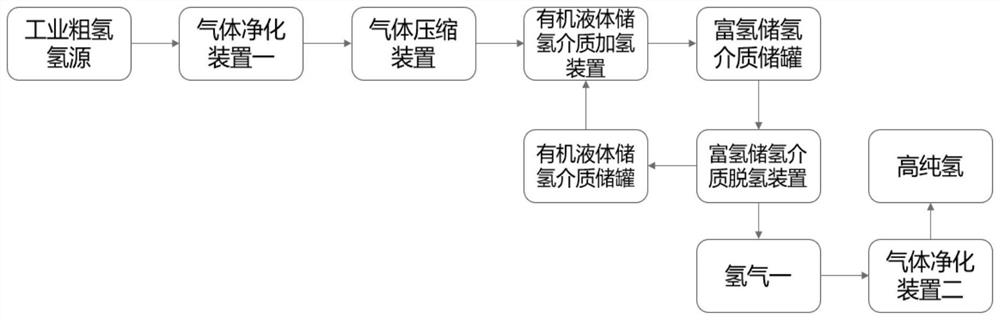

Hydrogen storage and release system and method for organic liquid hydrogen storage medium and industrial crude hydrogen source

PendingCN112093775AAchieve purificationFix security issuesHydrogen separationOrganic liquidsDehydrogenation

The invention discloses a hydrogen storage and release system and method for an organic liquid hydrogen storage medium and an industrial crude hydrogen source, and belongs to the technical field of organic liquid hydrogen storage. The system comprises a first gas purification device, a gas compression device, an organic liquid hydrogen storage medium hydrogenation device, an organic liquid hydrogen storage medium storage tank, a hydrogen-rich hydrogen storage medium storage tank, a hydrogen-rich hydrogen storage medium dehydrogenation device and a second gas purification device, an industrialcrude hydrogen source is introduced into the first gas purification device, is purified, then introduced into the gas compression device and is compressed, the compressed hydrogen source enters the organic liquid hydrogen storage medium hydrogenation device, is subjected to catalytic hydrogenation, is fed into a hydrogen-rich hydrogen storage medium storage tank, then is fed into the hydrogen-richhydrogen storage medium dehydrogenation device, and is subjected to dehydrogenation, and hydrogen obtained after passing through the hydrogen-rich hydrogen storage medium dehydrogenation device enters the second gas purification device and is purified again to obtain high-purity hydrogen. The high-purity hydrogen is obtained, and meanwhile, the problems of purification of an industrial crude hydrogen source and safe storage and transportation of hydrogen can be effectively solved.

Owner:陕西氢易能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com