Glass substrate strip

A technology of glass substrates and substrates, which is applied in glass molding, glass molding, glass manufacturing equipment, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

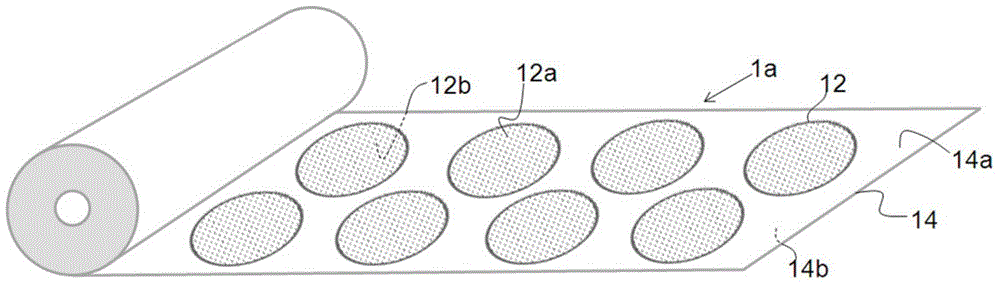

[0056] Figure 1a Shown by way of example is a glass substrate ribbon 1 a with positioned and fixed circular thin glass segments 12 for making wafers. The thin glass segment 12 has been fixed on an adhesive foil 14 in contact with the entire area of the first thin glass surface 12b. The second thin glass surface 12a is uncovered, directed upwards, and comes into contact with the adhesive foil 14, ie with the surface 14b of the adhesive foil, only when the glass substrate strip 1a is wound. The thin glass segments have a thickness of 0.06 mm. The adhesive foil 14 is a coextruded polyethylene adhesive foil, provided as an example by PE-CLING Protect from Molco GmbH, Schwertter. The thickness of the adhesive foil is 110 microns, so the location of the neutral phase between tensile and compressive stresses in the rolled state is in the adhesive layer between the surface 14a of the adhesive foil and the surface 12b of the thin glass segment. The adhesive foil 14 has an adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com