Shrimp protein extraction essence and manufacturing process thereof

A manufacturing process and technology of shrimp protein, which is applied in the field of food seasoning, can solve the problems of fishery economy and fishermen's income decline, fishery structure is not ideal, etc., and achieve the effect of preventing sea shrimp from deteriorating, reducing adverse effects, and rich in amino acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

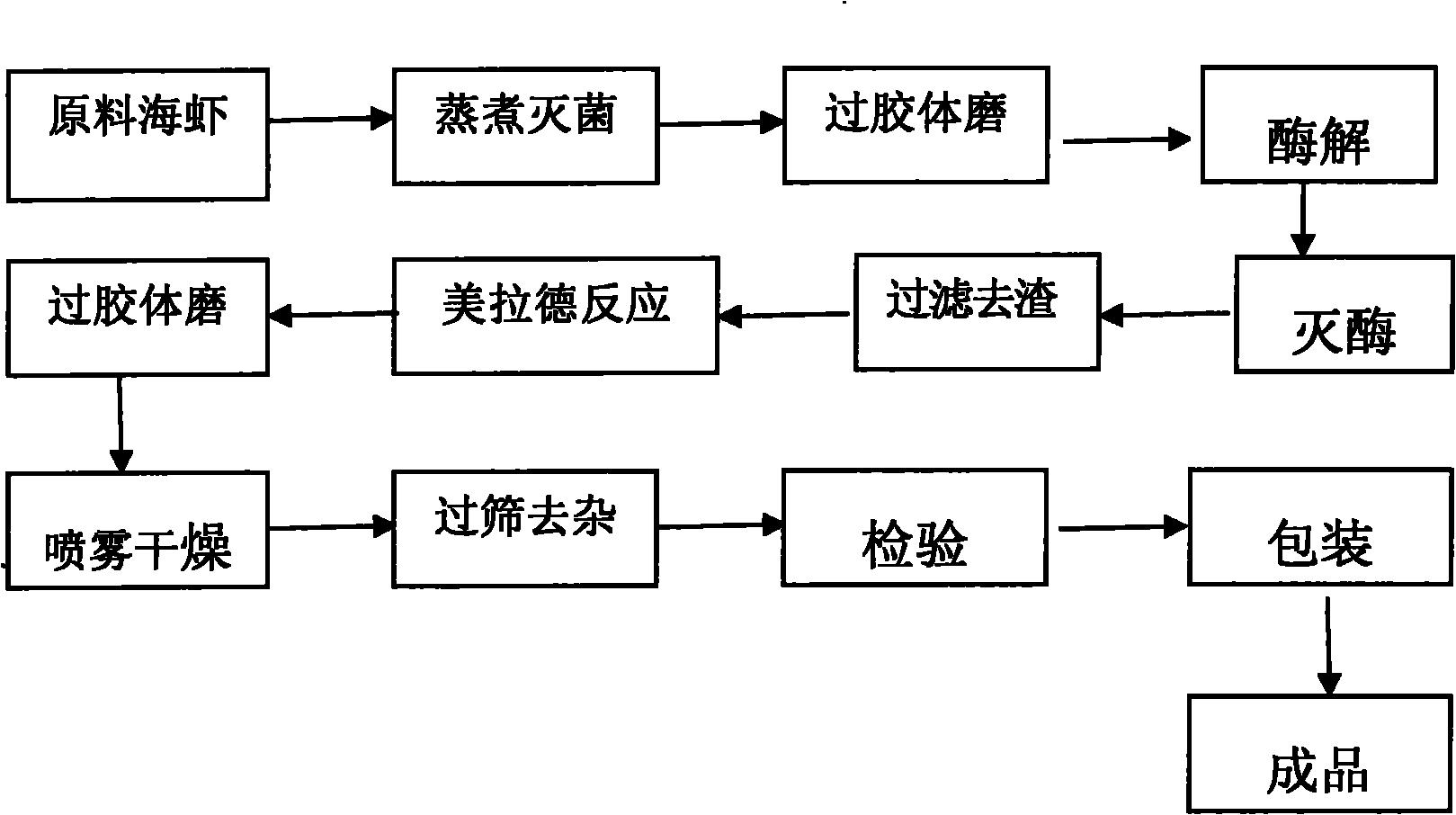

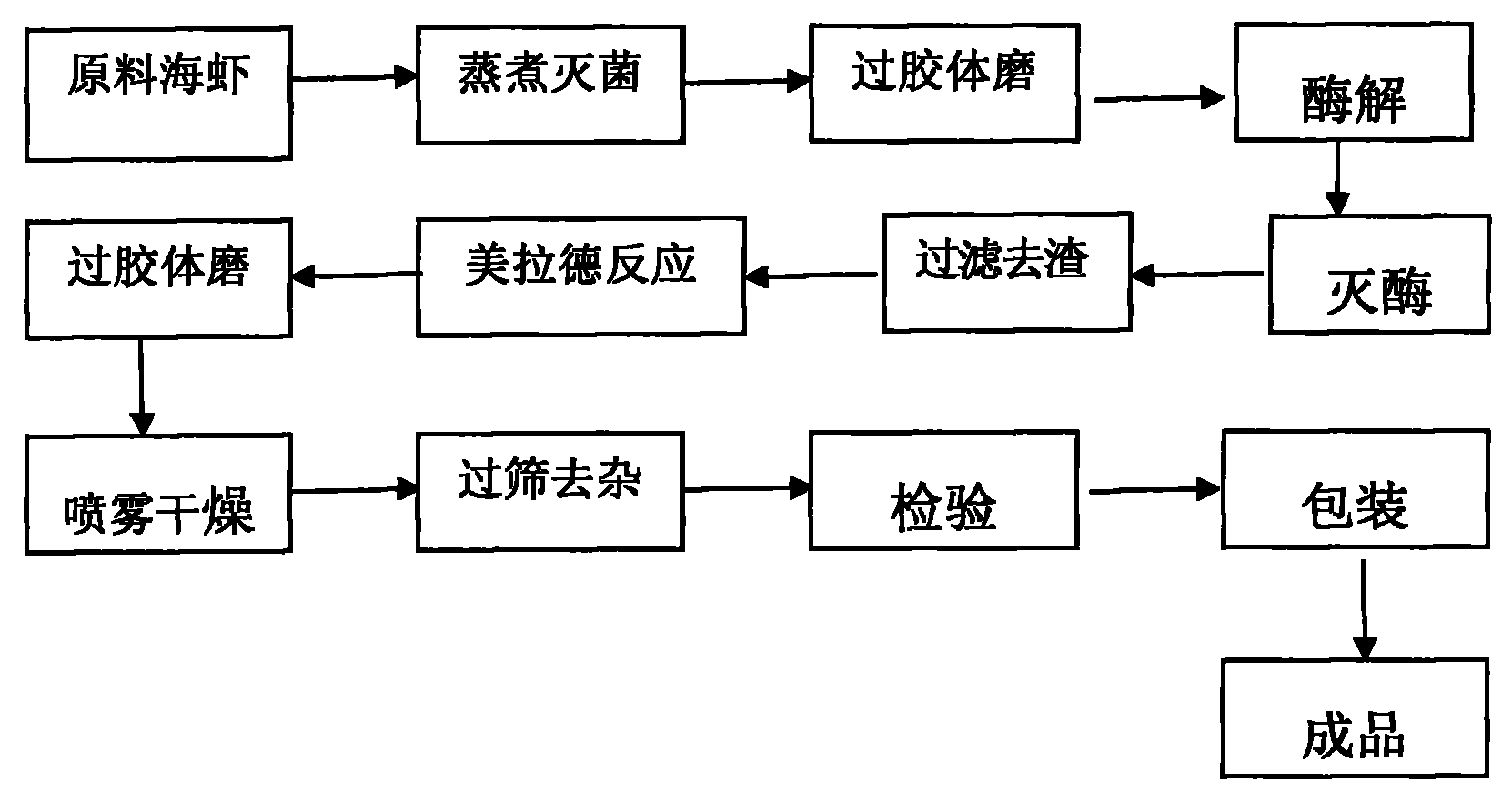

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Get 1000Kg of fresh low-value sea prawns and mix them with water of equal quality, add them to the reaction tank, then seal them up, then raise the temperature to 110°C, and keep the temperature unchanged for half an hour, steam and sterilize After finishing, the cooking liquid is finely ground into 10-25μm shrimp paste on JM130 colloid mill, put the shrimp paste into the enzymolysis pot, heat up to 50-60°C while stirring, adjust the pH to 5.5-6.5, and then Add 1Kg compound protease (enzyme activity 1.11×10 5 u / g) and 2Kg flavor protease (enzyme activity 6.4×10 4 u / g), stirring and maintaining this temperature for enzymolysis for 4-5 hours, adding 10g of antioxidants, then raising the temperature to 90°C for enzymatic deactivation treatment for 10 minutes, and then filtering to remove slag; adding 12 Kg of sodium chloride, 12 kg of sodium glutamate, 4 kg of glucose, 5 kg of white sugar, 0.16 kg of vitamin C, 0.32 kg of sodium inosinate, 0.32 kg of sodium gua...

Embodiment 2

[0020] Example 2: Get 1000Kg of fresh low-value sea prawns and mix them with water of equal quality, add them to the reaction tank, then seal them up, then raise the temperature to 110°C, keep the temperature unchanged for half an hour, cook and sterilize After finishing, the cooking liquid is finely ground into 10-25μm shrimp paste on JM130 colloid mill, put the shrimp paste into the enzymolysis pot, heat up to 50-60°C while stirring, adjust the pH to 5.5-6.5, and then Add 1Kg compound protease (enzyme activity 1.11×10 5 u / g) and 2Kg flavor protease (enzyme activity 6.4×10 4 u / g), stirring and maintaining this temperature for enzymolysis for 4-5 hours, adding 10g of antioxidants, then raising the temperature to 90°C for enzymatic deactivation treatment for 10 minutes, and then filtering to remove slag; adding 15 Kg of sodium chloride, 15 kg of sodium glutamate, 6 kg of glucose, 7 kg of white sugar, 0.2 kg of vitamin C, 0.4 kg of sodium inosinate, 0.4 kg of sodium guanylate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com