Patents

Literature

129 results about "Fish resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

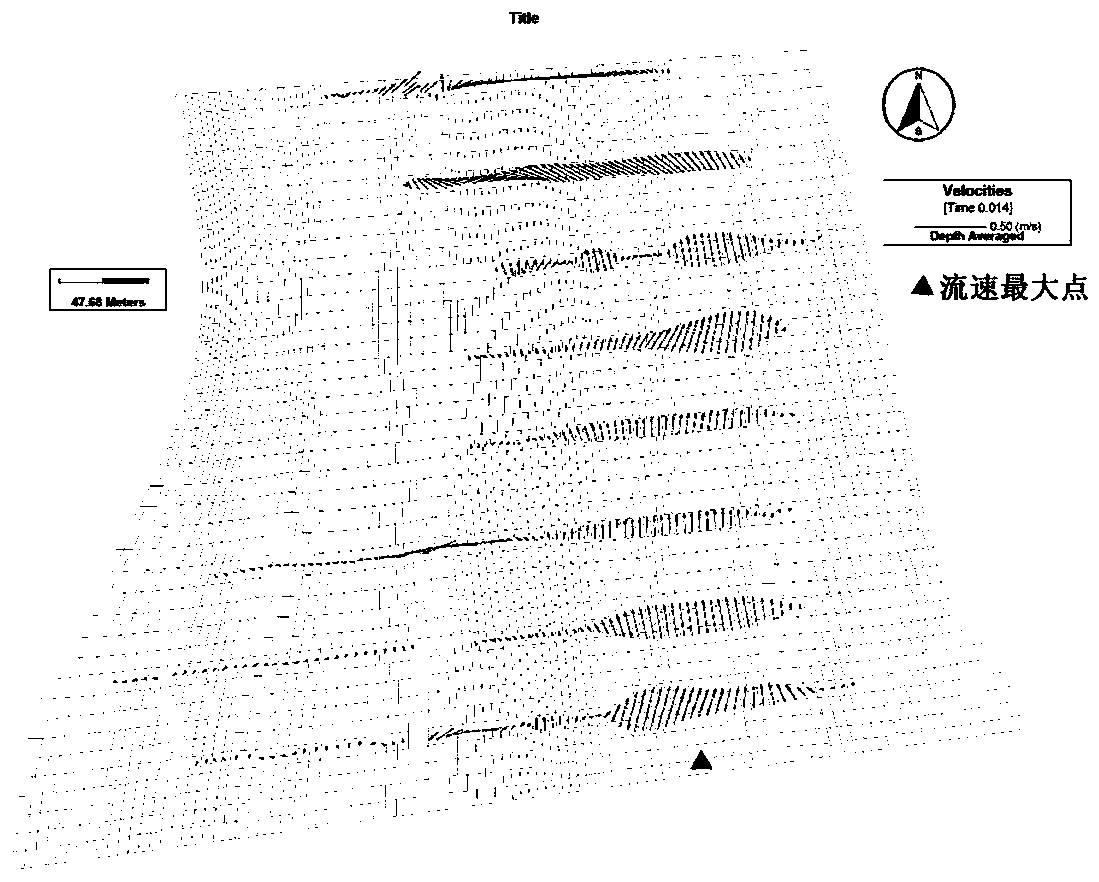

Seine object fish shoal tracking method based on horizontal fishgraph images

InactiveCN105572676AEasy to detectImprove tracking performanceAcoustic wave reradiationShoalFish resources

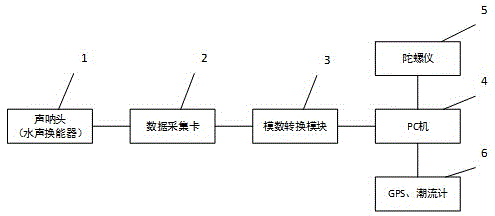

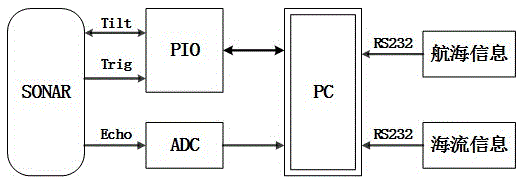

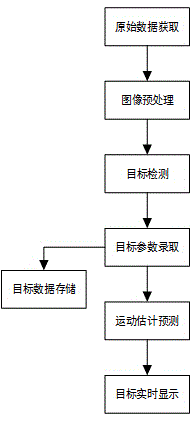

The invention discloses a seine object fish shoal tracking method based on horizontal fishgraph images. Through obtaining echo signals of a fishgraph, a seine object fish shoal is tracked, a movement locus is predetermined, and thus the success rate of seine fishing is improved. According to the invention, through adjusting the inclination angle of a sonar, changing the emission direction of sound waves and performing 360-degree rotation, underwater three-dimensional space can be scanned, three-dimensional images are drafted, the quantity of fish shoals is estimated in a stereo mode, and effective help is provided for development of fish resources.

Owner:ZHEJIANG UNIV

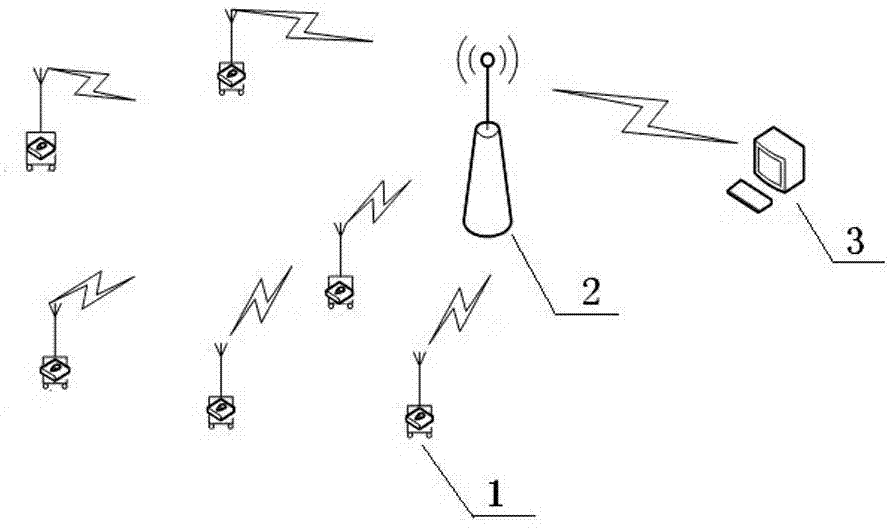

Yangtze River endemic fish oviposition habitat monitoring method and system based on Internet of things

ActiveCN103190365ALow costOperableClimate change adaptationPisciculture and aquariaThe InternetData acquisition

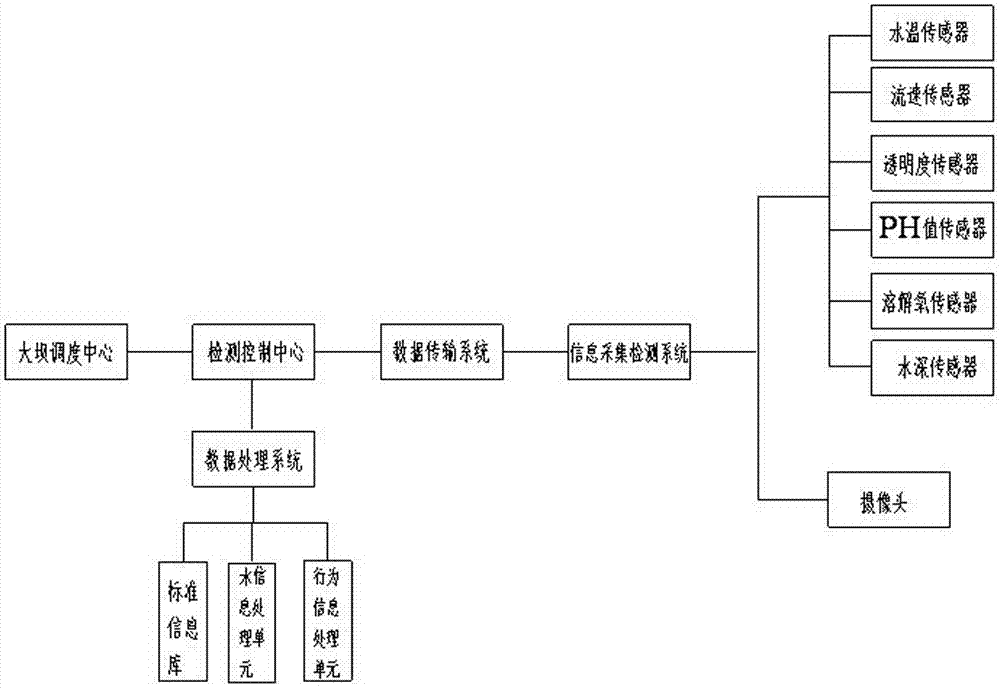

The invention discloses a Yangtze River endemic fish oviposition habitat monitoring method and system based on the Internet of things. The method comprises the steps of performing optimized arrangement of a sensor assembly within a Yangtze River endemic fish breeding inhabitation range, collecting water environment information and fish behavior information of the Yangtze River endemic fish breeding inhabitation range in real time, utilizing a technology of the Internet of things to transmit the collected information to a monitoring control center, enabling the control center to evaluate the monitored water environment in real time by combination with a endemic fish oviposition habitat evaluation model, sending ecologic early warning to a dam dispatching center when the habitat water environment exceeds a fish fitness value, and enabling the dispatching center to adjust a dam running mode timely according to early warning signals so as to improve the oviposition habitat fitness value and protect endemic fish resources. The system comprises a data collecting system, a data transmission system and a data processing system. Automatic positioning, automatic monitoring record and wireless network technologies are adopted, and the goal of real-time monitoring and analysis of the habitat water environment is achieved.

Owner:CHINA YANGTZE POWER +1

Fishbone sauce and processing method thereof

ActiveCN101971970AAvoid pollutionGuaranteed reasonablenessFood preparationHigh pressureProduct processing

The invention relates to a processing method for fishbone sauce, and belongs to the technical field of fish byproduct processing. The fishbone sauce is characterized by comprising the following components in percentage by mass: 60 to 80 percent of fishbone paste, 4 to 6 percent of edible salt, 3 to 5 percent of soft sugar, 0.3 to 0.5 percent of cooked white sesame seed, 0.5 to 2 percent of red chilli powder, 1 to 2 percent of cooked ground peanut, 1 to 3 percent of fermented soy sauce, 0.2 to 0.4 percent of thickener, 0.1 to 0.5 percent of dried shallot powder, 0.1 to 0.5 percent of dried ginger powder, 0.1 to 0.5 percent of five spice powder, 5 to 8 percent of wheatmeal, 3 to 10 percent of soybean flour and the balance of water. The processing method comprises the following steps of: 1, processing raw materials; 2, removing fishy smell of the fishbone, and adjusting pH; 3, performing vacuum centrifugal defatting; 4, crushing, and homogenizing under high pressure; 5, seasoning; 6, heating and pressurizing for sterilization; and 7, cooling and packaging. The processing method has the advantages that: the fish resources can be fully utilized, and deteriorated fishbone is prevented from polluting the environment. The fishbone sauce produced by the technology has fine and smooth mouthfeel, unique flavor, a little sediment and uniform color, and is easy to store.

Owner:PENGLAI JINGLU FISHERY

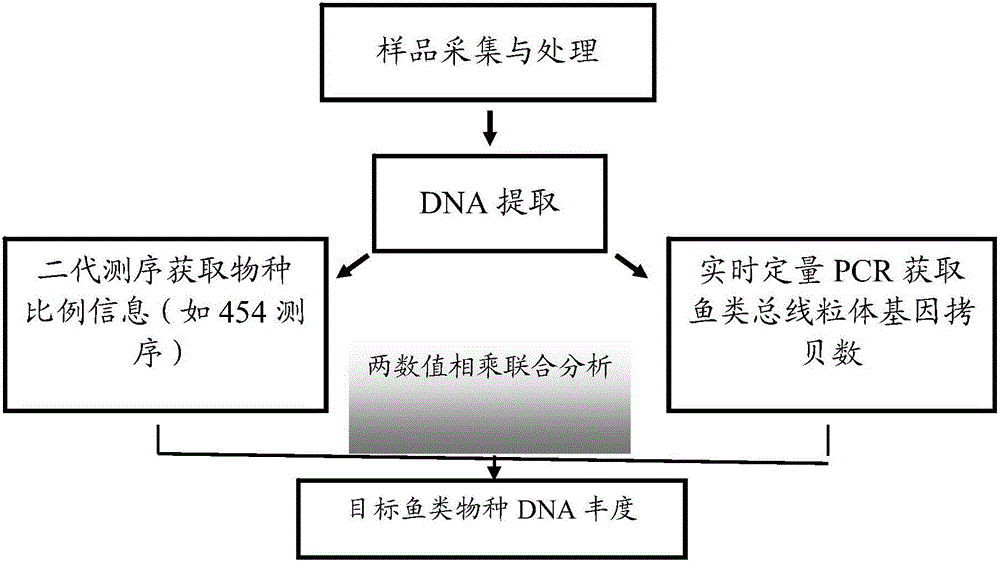

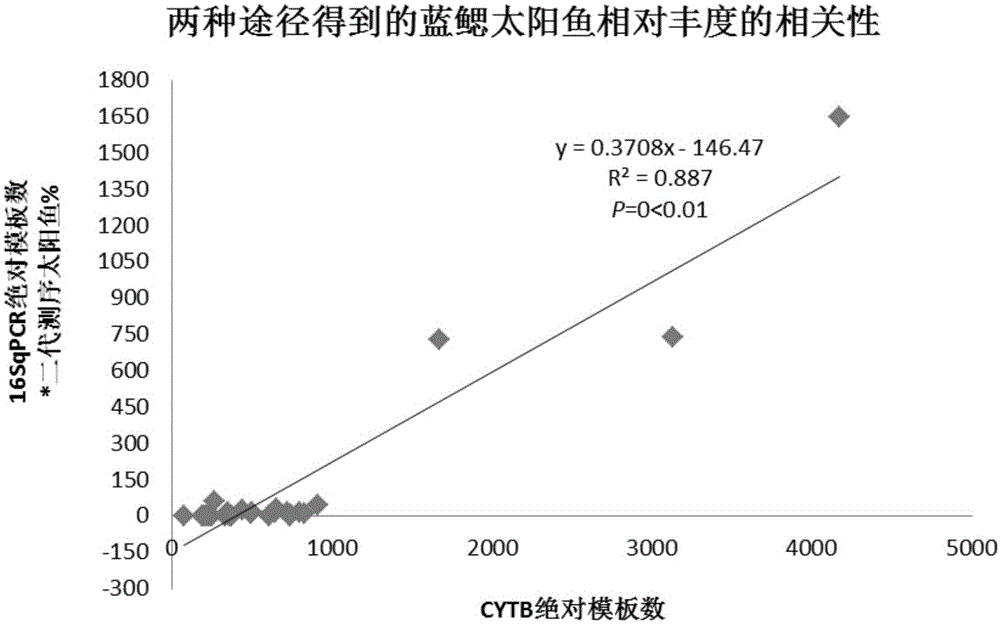

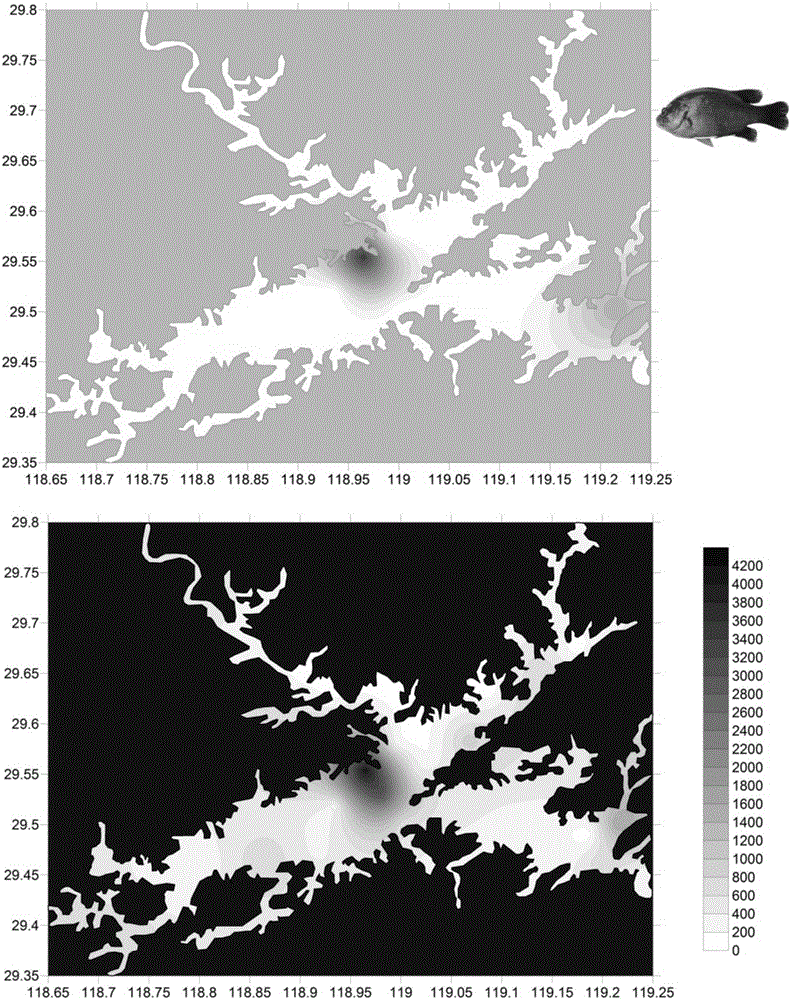

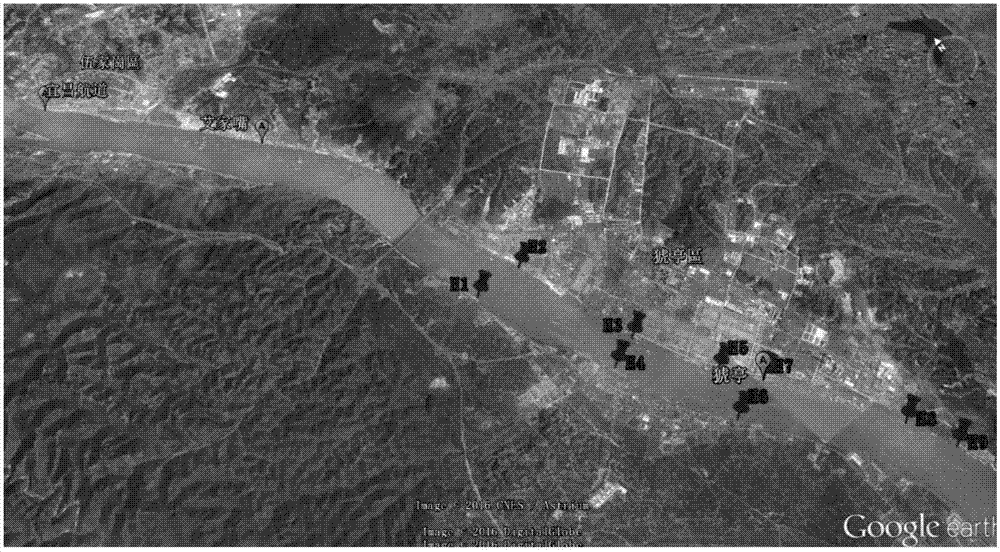

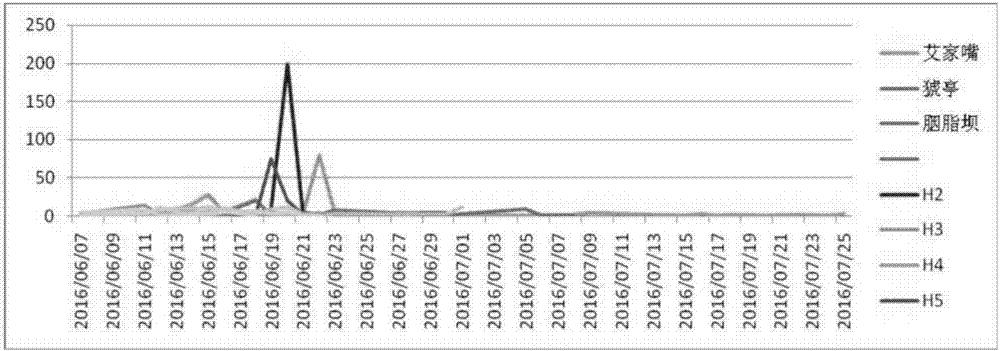

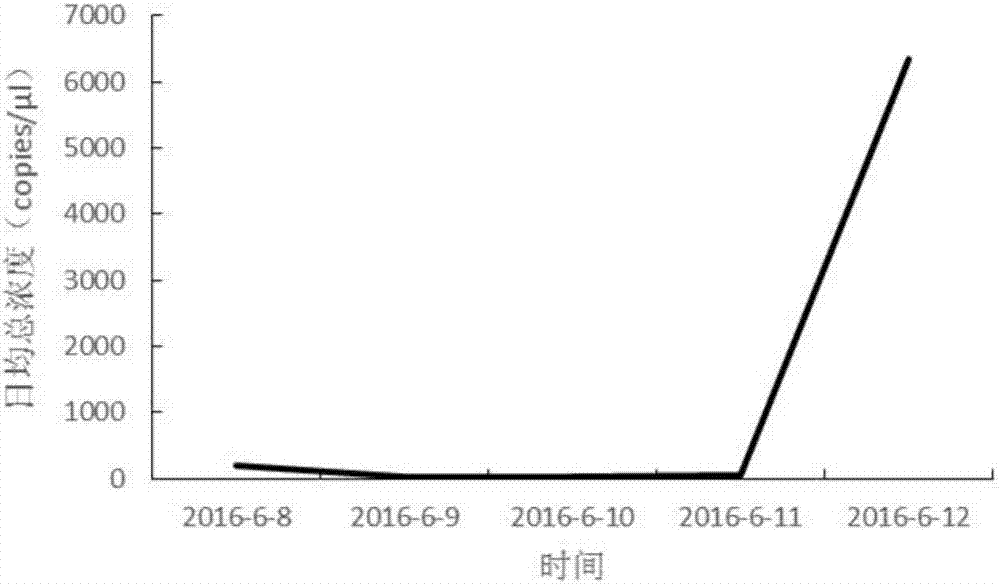

Conjoint analysis method for estimating DNA abundance of fishes based on environment DNA technology

ActiveCN105154564ASampling method is simpleProtect resourcesMicrobiological testing/measurementSequence analysisConjoint analysis

The invention relates to a conjoint analysis method for estimating the DNA abundance of fishes based on an environment DNA technology. The conjoint analysis method includes the steps that the total DNA abundance of the fishes is acquired through timed and quantified PCR; the species composition proportion of the fishes is acquired through 454 GS-FLX Titanium sequencing analysis; conjoint analysis of target species is performed through sequencing data and timed and quantified PCR data; a relative distribution diagram of mitochondrial DNA of the fishes in an environment is drawn through sufer 8.0 software. Based on the environment DNA identification technology, weather species exist and how many species exist can be analyzed just by collecting water samples without depending on fish species capturing, a sampling method is simple, and fish resources can be protected to the maximum degree; meanwhile, for some species which are rarely distributed and difficult to capture, the method is still more effective than traditional fishing investigation, the method can effectively solve the problem that effective species specificity primers are difficult to obtain when multiple closely related species exist in samples, and NDA abundance information of all species can be known just by conducting experiment once respectively through the two technologies.

Owner:SHANGHAI OCEAN UNIV

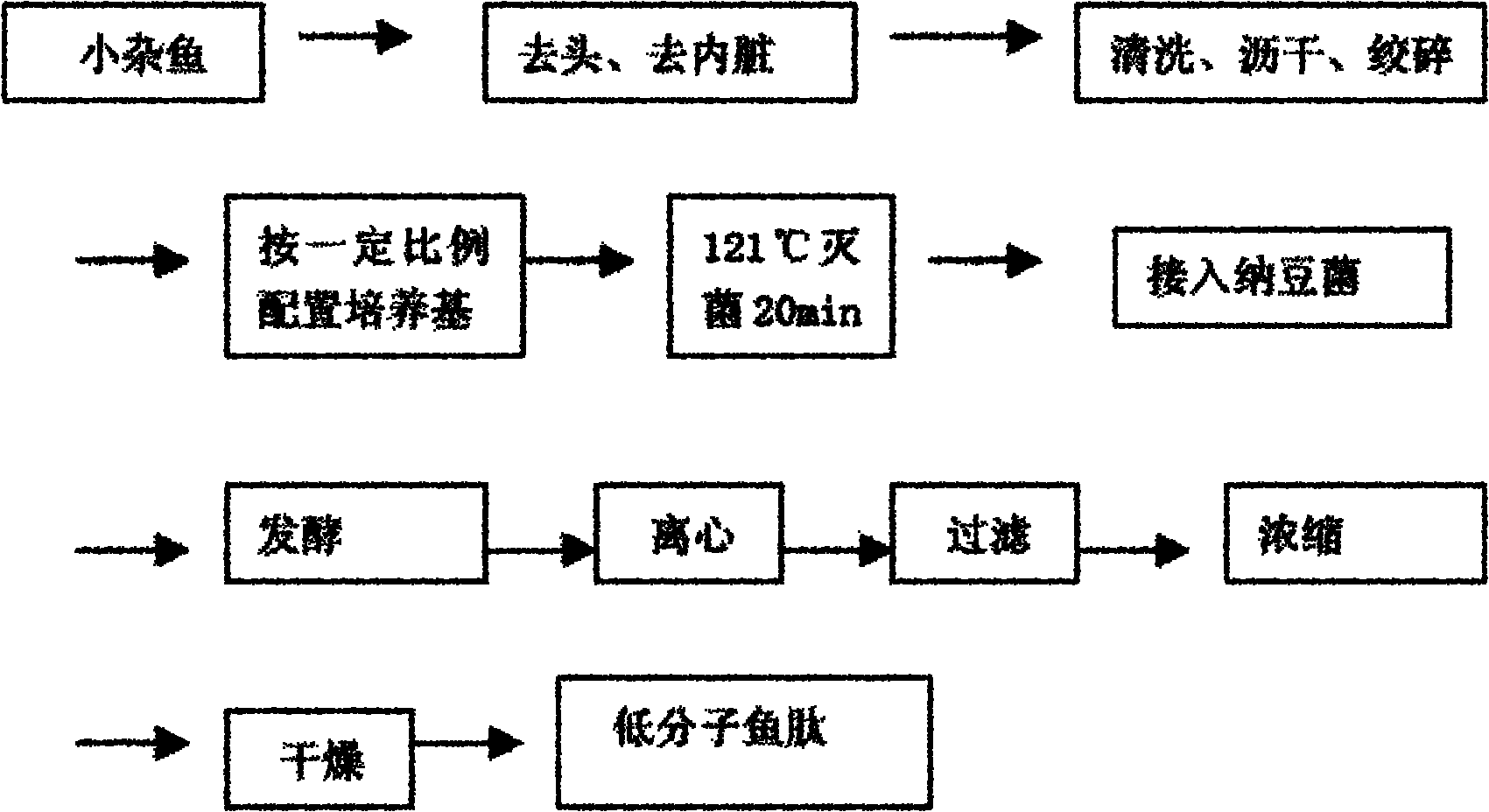

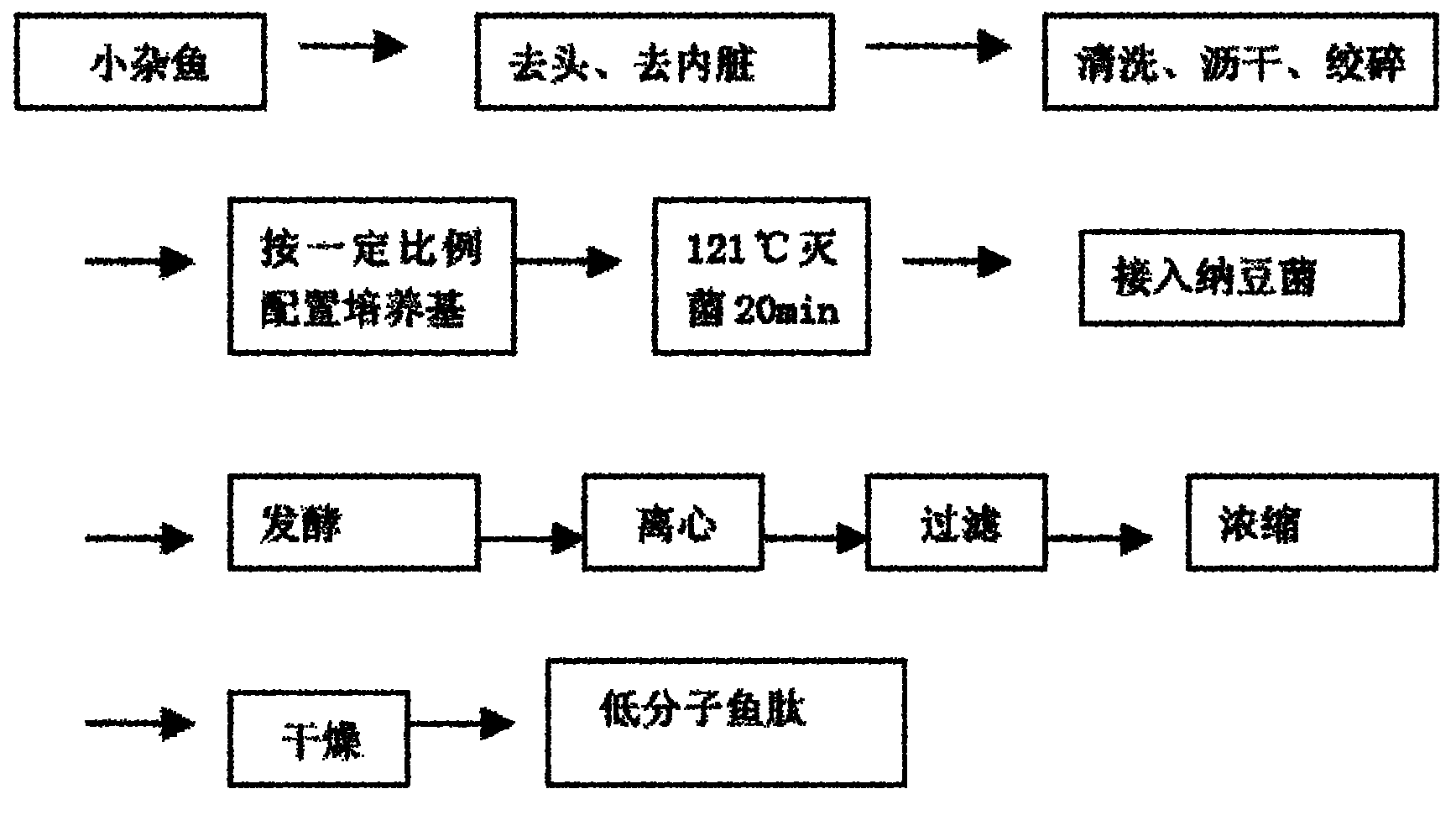

Method for preparing low molecular weight fish peptide through Bacillus natto fermentation method

ActiveCN102028091AWith viscosityWith fresh fragranceProtein composition from fishAnimal feeding stuffCholesterolTreatment hypertension

A method for preparing a low molecular weight fish peptide through a Bacillus natto fermentation method comprises the following steps: taking fish to mince, adding water, adding maltose, glucose, lactose or sucrose to obtain a mixture; adjusting the pH value of the mixture, sterilizing at high temperature; cooling, inoculating Bacillus natto seed liquor to ferment; and centrifuging fermentation liquor, filtering, concentrating, drying and grinding to obtain a low molecular weight fish peptide product. The method uses fish as the raw material and utilizes the Bacillus natto fermentation technology to obtain the low molecular weight fish peptide. The product in the invention is very soluble in water, is digested and absorbed easily by human body and has various functions of reducing cholesterol in the blood, promoting lipid metabolism, preventing and curing hypertension and the like. The technology in the invention is also suitable for other low value aquatic product and high-grade aquatic product machine leftover pieces, thus fish resources can be fully utilized; and the technology is simple and easy, the investment is less, the cost is low, the effect can be realized fast, the added value is high and the method is suitable for large-scale industrial production.

Owner:全然之心(大连)商贸有限公司

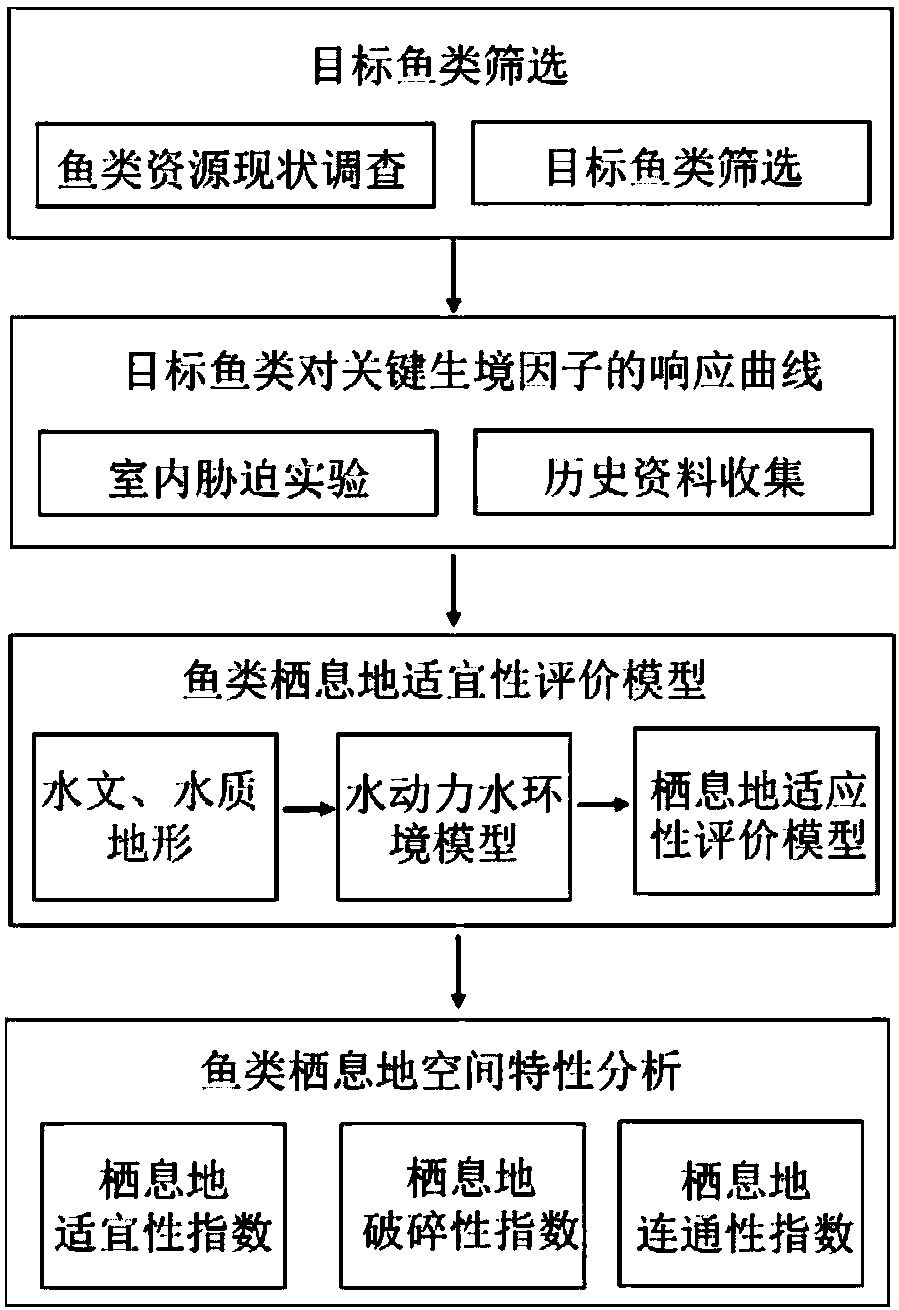

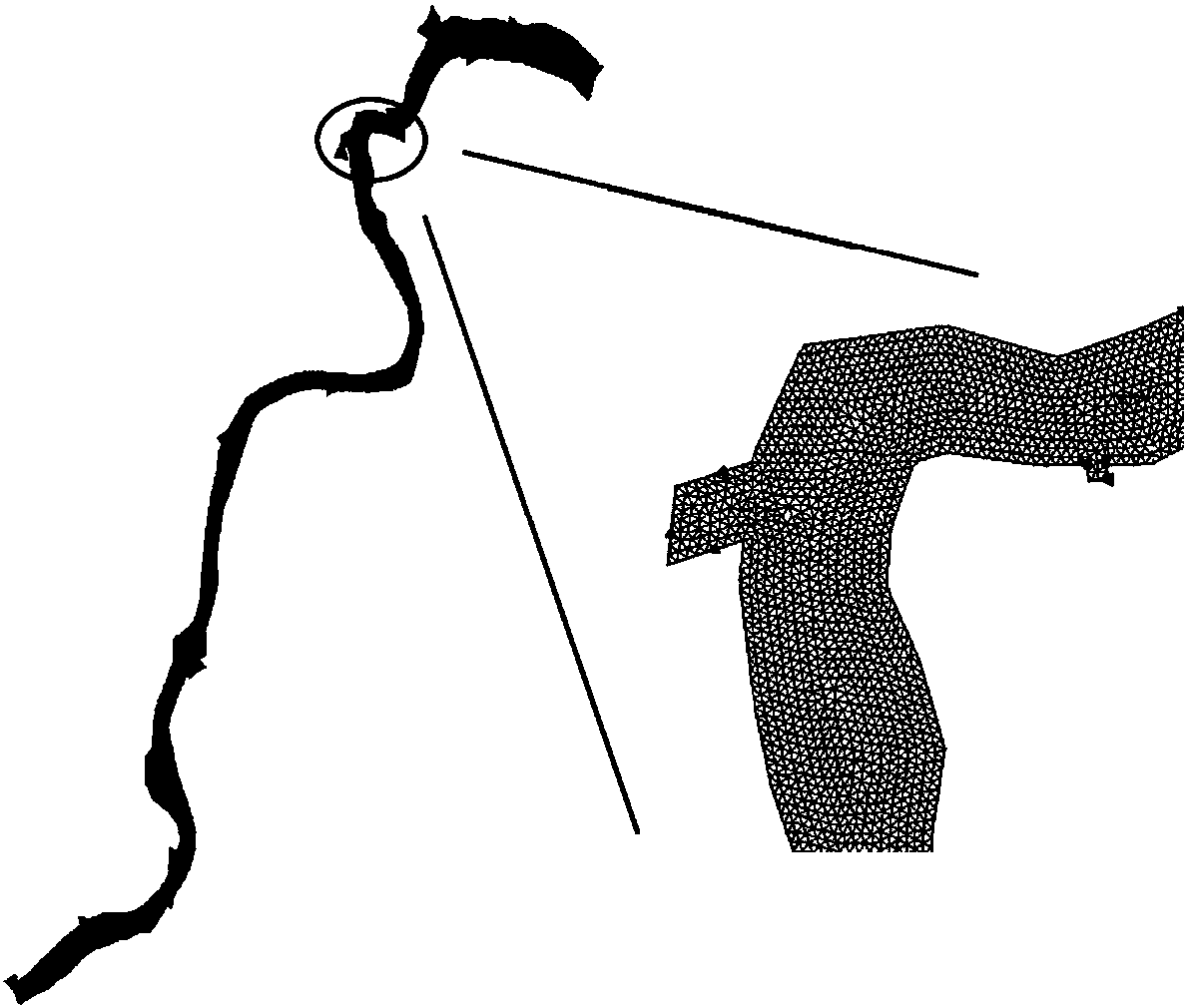

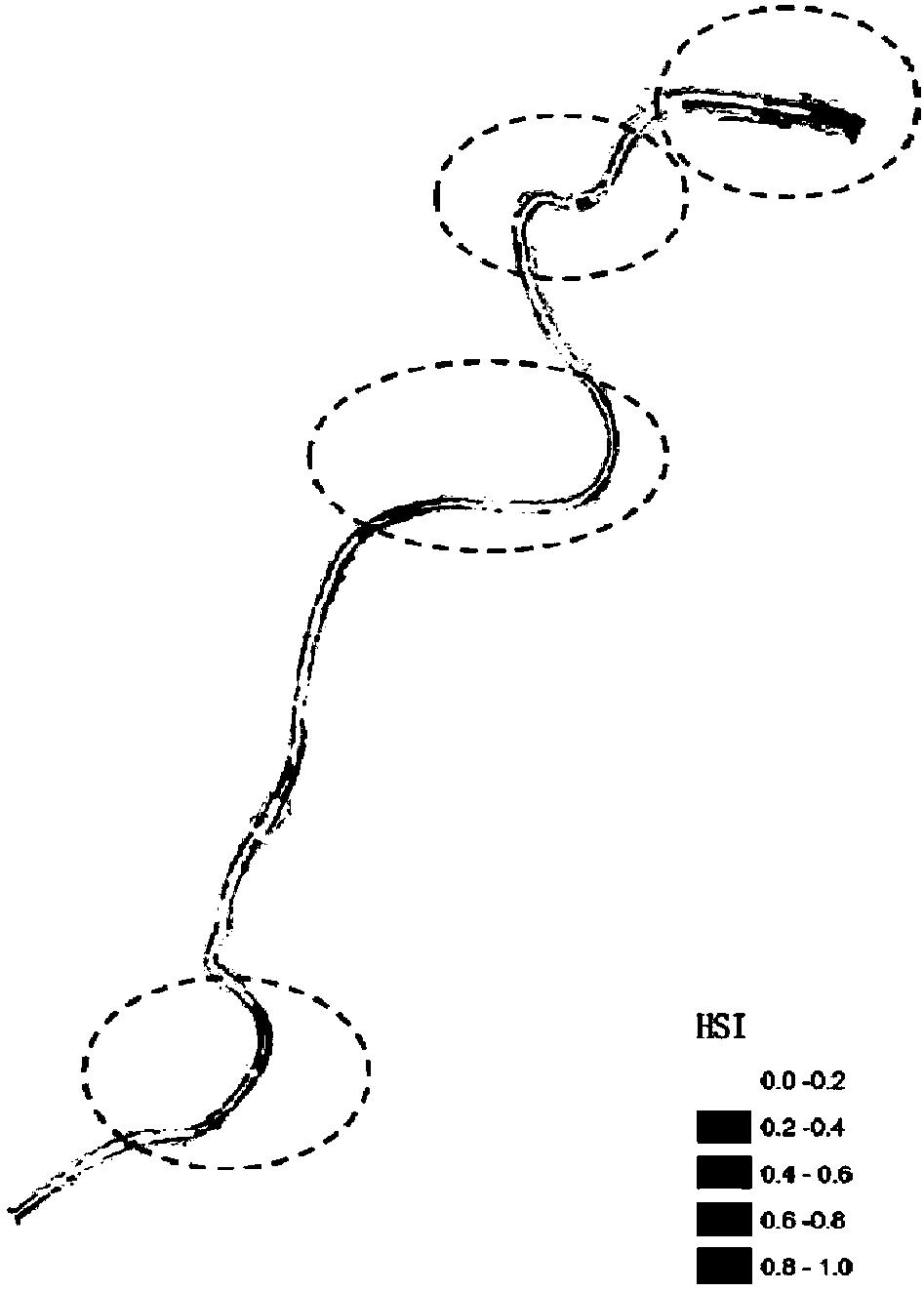

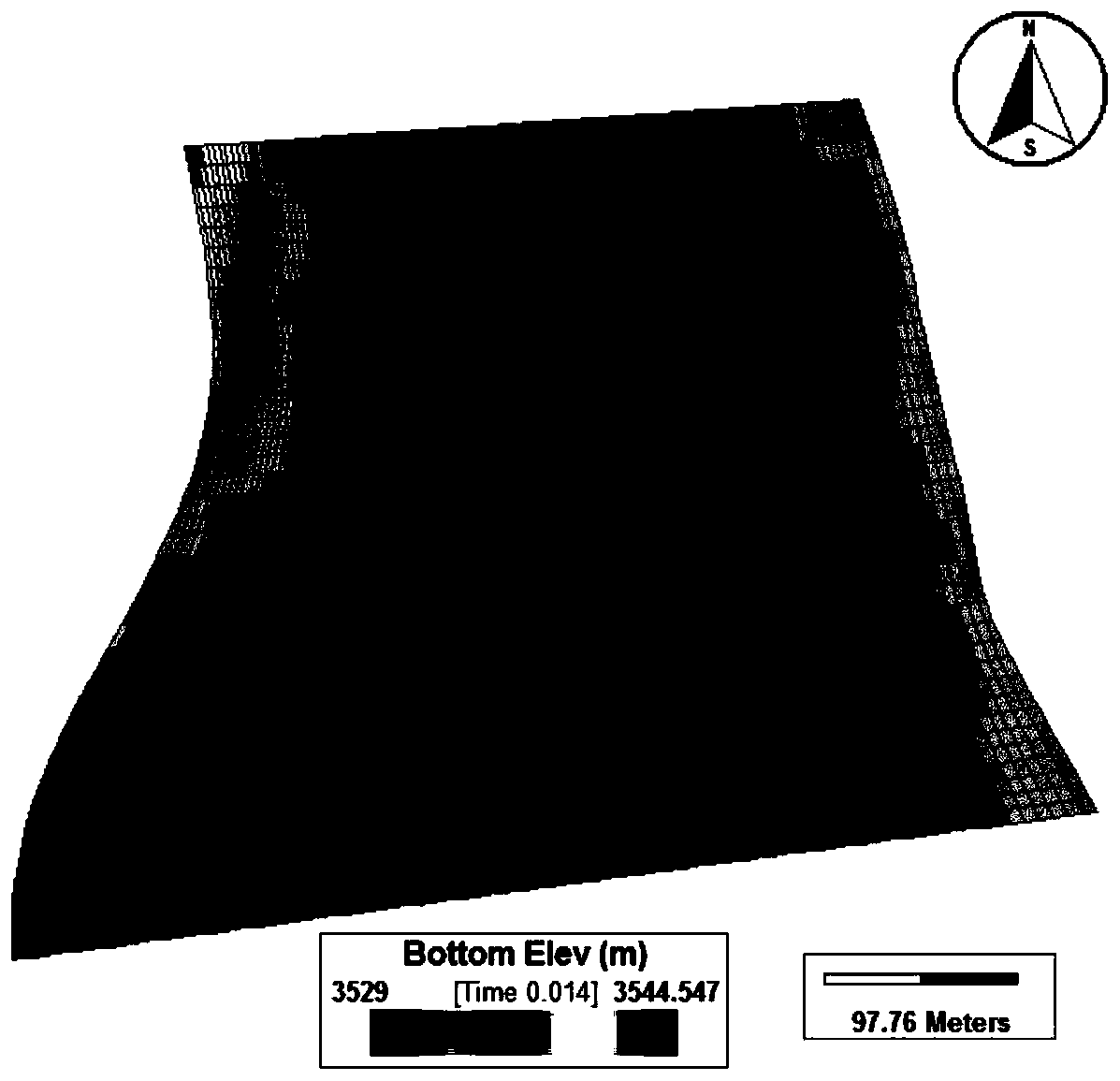

Quantification analysis method of fish habitat space characteristic influenced by gate dam regulation and control

ActiveCN107563610AReflect habitat statusWater resource protectionPisciculture and aquariaWater resource planningEcological study

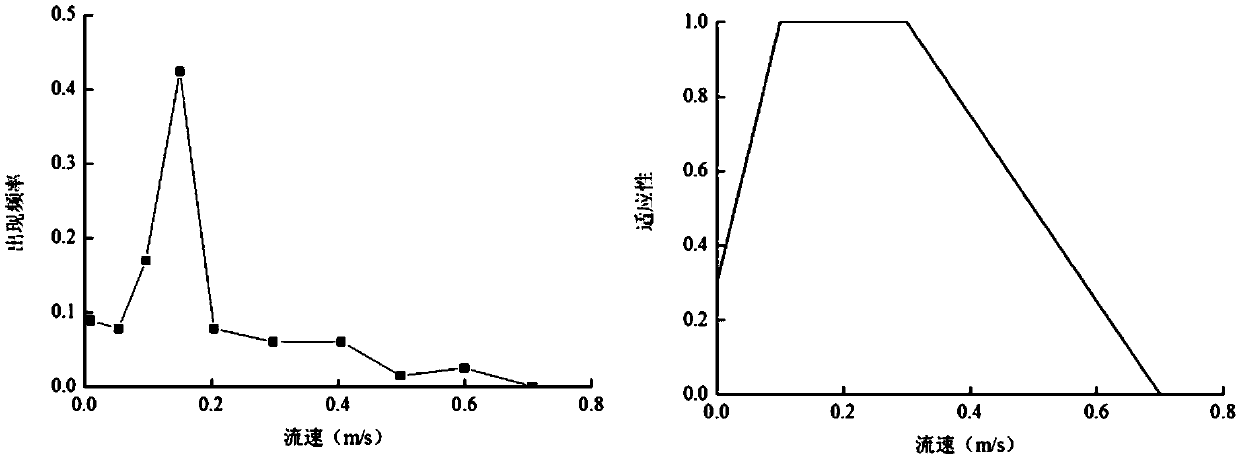

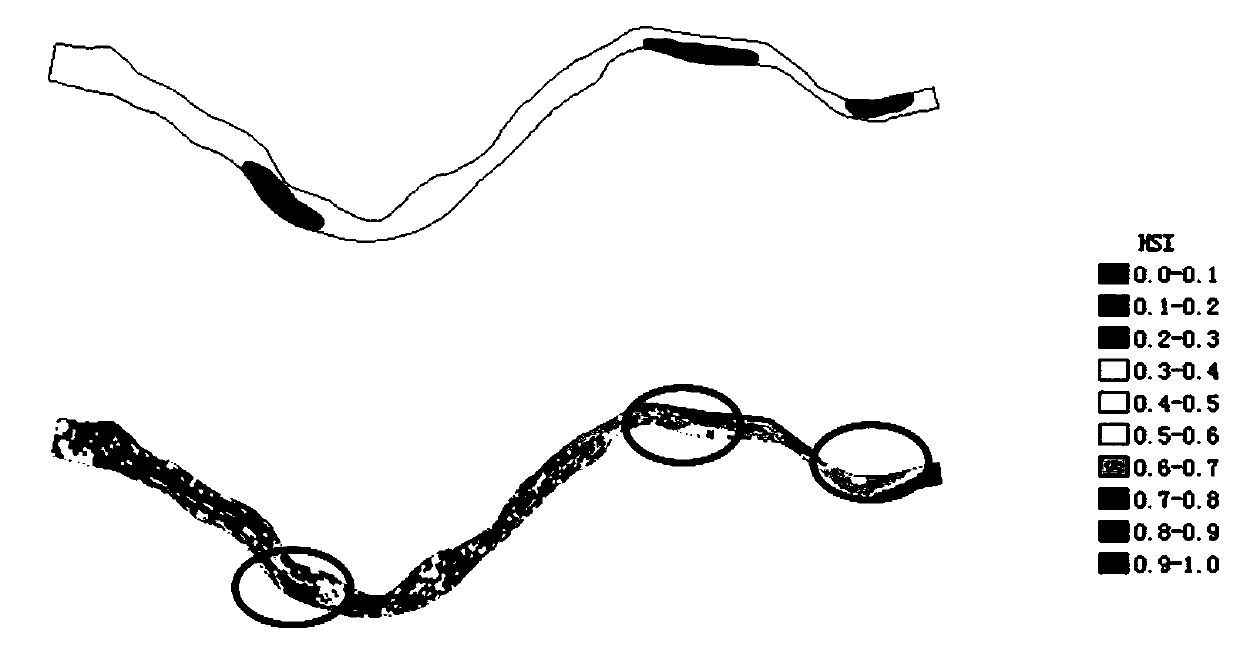

The invention discloses a quantification analysis method of fish habitat space characteristics influenced by gate dam regulation and control; the method comprises the following steps: investigating fish resource present situations in a research area, and screening a target fish; aiming at the screened target fish, and using indoor stress experiments and history data to build a quantification response relation curve of the target fish with respect to key habitat factors; gathering research area basic hydrology and landform data so as to build a water-power water environment model, and combiningthe quantification response relation curve of the target fish with respect to key habitat factor so as to build a habitat model facing fish habitats; introducing a landscape ecology theory and methodso as to evaluate the space characteristics of the habitat simulation result facing the fish habitat, and quantitatively analyzing the influences on the fish habitat space characteristics by the gatedam operations. The method can guide multi-gate dam river ecology restorations and protections, thus providing important theory and practice meanings for basin water resource planning and configurations.

Owner:NANJING HYDRAULIC RES INST

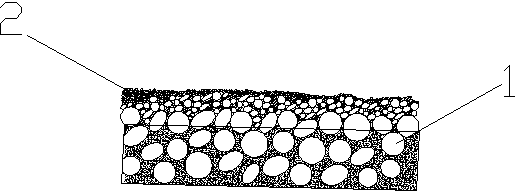

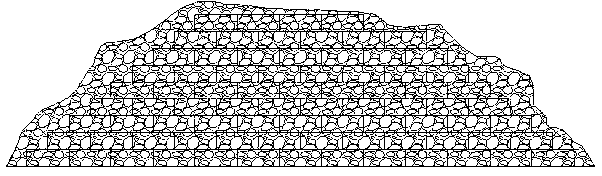

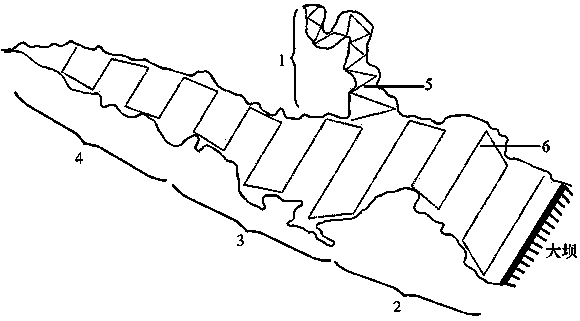

Method for constructing schizothoracinae artificial spawning site in natural river

InactiveCN103270983ABreed smoothlySuitable spawning siteClimate change adaptationAgricultural fishingHydroelectric developmentFishery

The invention provides a method for constructing a schizothoracinae artificial spawning site a natural river. The method comprises a first step of carrying out previous preparation, a second step of selecting a construction site of the spawning site, a third step of determining parameters, a fourth step of determining the scale and the structure of the spawning site, a fifth step of determining the paving method of a structural unit, a sixth step of constructing auxiliary facilities and a seventh step of managing and maintaining. According to the method, under the condition that normal operation of a hydropower station is not affected, a shoal can be constructed manually in an appropriate river reach to provide the site of egg reproduction for the schizothoracinae, and the schizothoracinae can be successfully multiplied. The contradiction between river hydroelectric development and ecological protection can be effectively relieved. The scale and the appropriate river reach of the artificial spawning site can be determined according to reach fish resource quantity, labor management serves as an auxiliary means, and the sustainable utilization of the reach fish resources can be well maintained.

Owner:YANGTZE RIVER FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

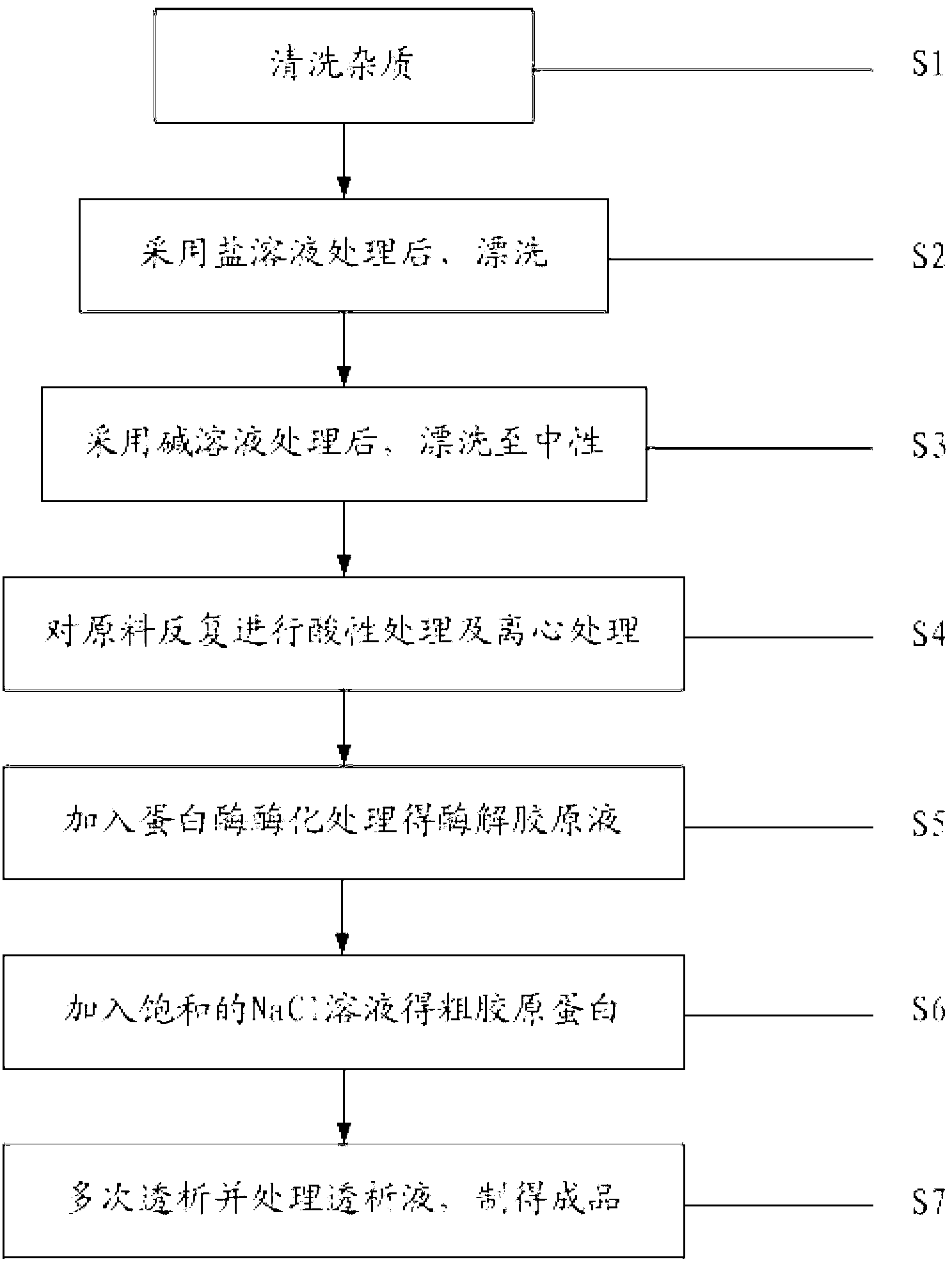

A method for preparing tuna skin gelatin

InactiveCN103289576AImprove qualityScientific and reasonable processGlue/gelatin preparationActivated carbon filtrationIon exchange

The present invention discloses a method for preparing tuna skin gelatin, belonging to the technical field of fish resources utilization. According to the invention, skin tuna skin is subjected to pretreatment, degreasing, acid and alkali treatment, and then is subjected to gelatin extraction, and deodorization by filtering through activated carbon, and ion-exchange purification to remove heavy metal ions, and then concentration under vacuum and spray-drying to obtain finished products of tuna skin gelatin with quality meeting the edible gelatin standards specified in national standards. The tuna skin gelatin of the invention can be further processed for use and can be used in medicine, food and cosmetic industries, achieving the purposes of turning waste into treasure, and comprehensively and efficiently developing high value-added tuna by-products. The method of the invention has advantages of: 1, a scientific and reasonable process is adopted, the temperature in the reaction process is low and easy to control, which saves energy and controls the molecular weight of the skin gelatin in a relatively narrow range, and the quality of obtained gelatin is high; and 2, activated carbon is used for filtering for deodorization, improving the taste of the product.

Owner:BEIHAI GOFAR MARINE BIOLOGICAL IND CO LTD

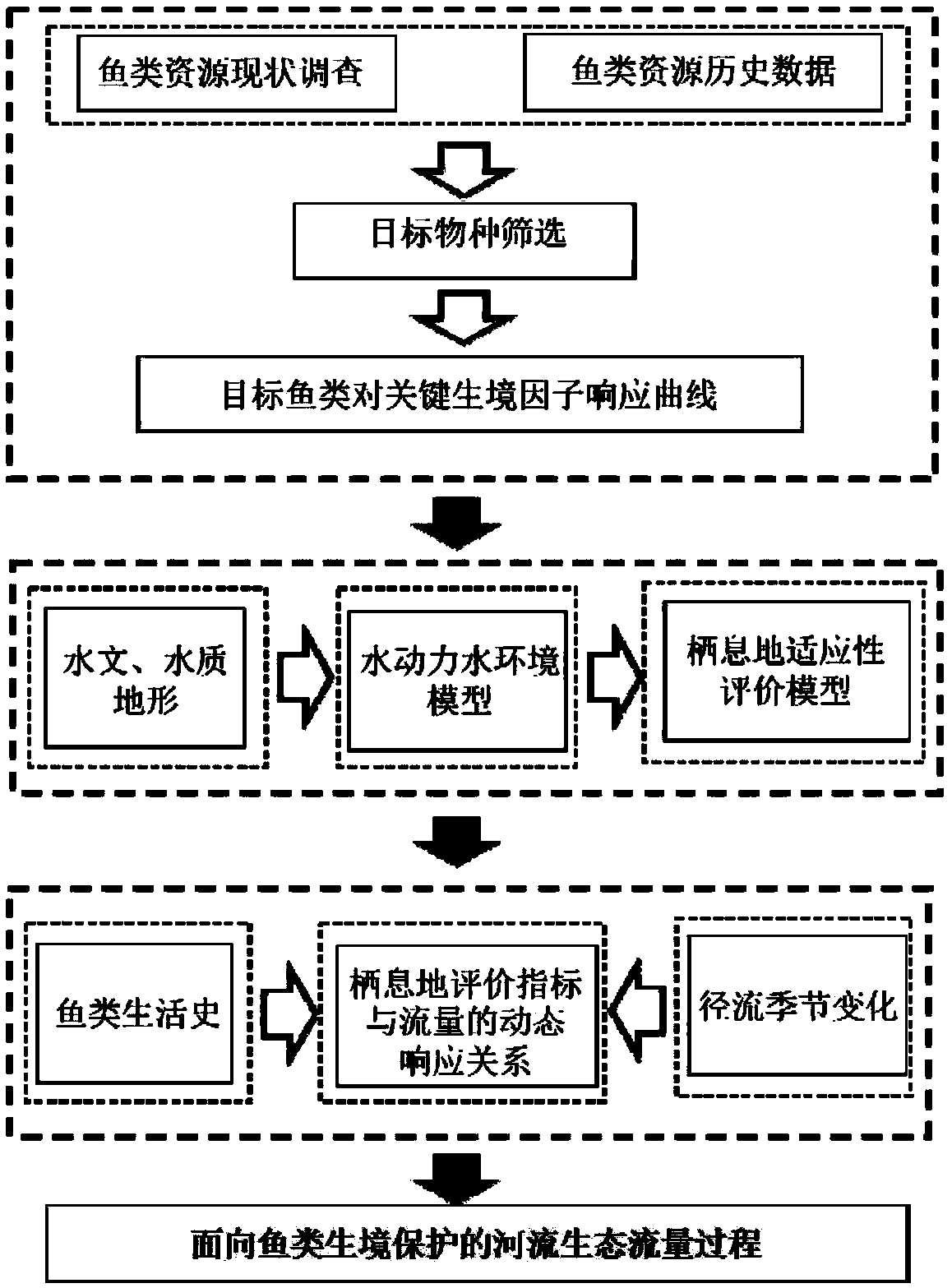

River ecological flow process derivation method for fish habitat protection

InactiveCN109615076AUniversalData processing applicationsFuzzy logic based systemsHydrometryExperimental laboratory

The invention discloses a river ecological flow process derivation method for fish habitat protection, and the method specifically comprises the steps: carrying out the investigation of the current situation of fish resources in a research region, and determining a target fish obtained through the ecological flow derivation; the method comprises the following steps: carrying out targeted survey ontarget fishes, carrying out a laboratory stress experiment, screening key water environment factors, and establishing a quantitative response relationship between different life stages of the targetfishes and the key environment factors by utilizing data obtained by the laboratory and field survey; Basic data of hydrology, water quality, topography, meteorology and the like of a research area are collected, a fish habitat model is established by adopting a fuzzy mathematics principle and is coupled with a water environment model, a fish habitat evaluation system is established, and a dynamicresponse relation between the habitat and flow is obtained; and determining a reference system for river ecological flow process calculation, comprehensively considering habitat demands of target fishes at different life stages and seasonal changes of natural runoff, and deducing a complete hydrological annual ecological flow process of the river. Constraint conditions can be provided for reservoir-oriented eco-friendly scheduling, and a practical and reliable basis is provided for drainage basin water resource distribution and management.

Owner:NANJING HYDRAULIC RES INST

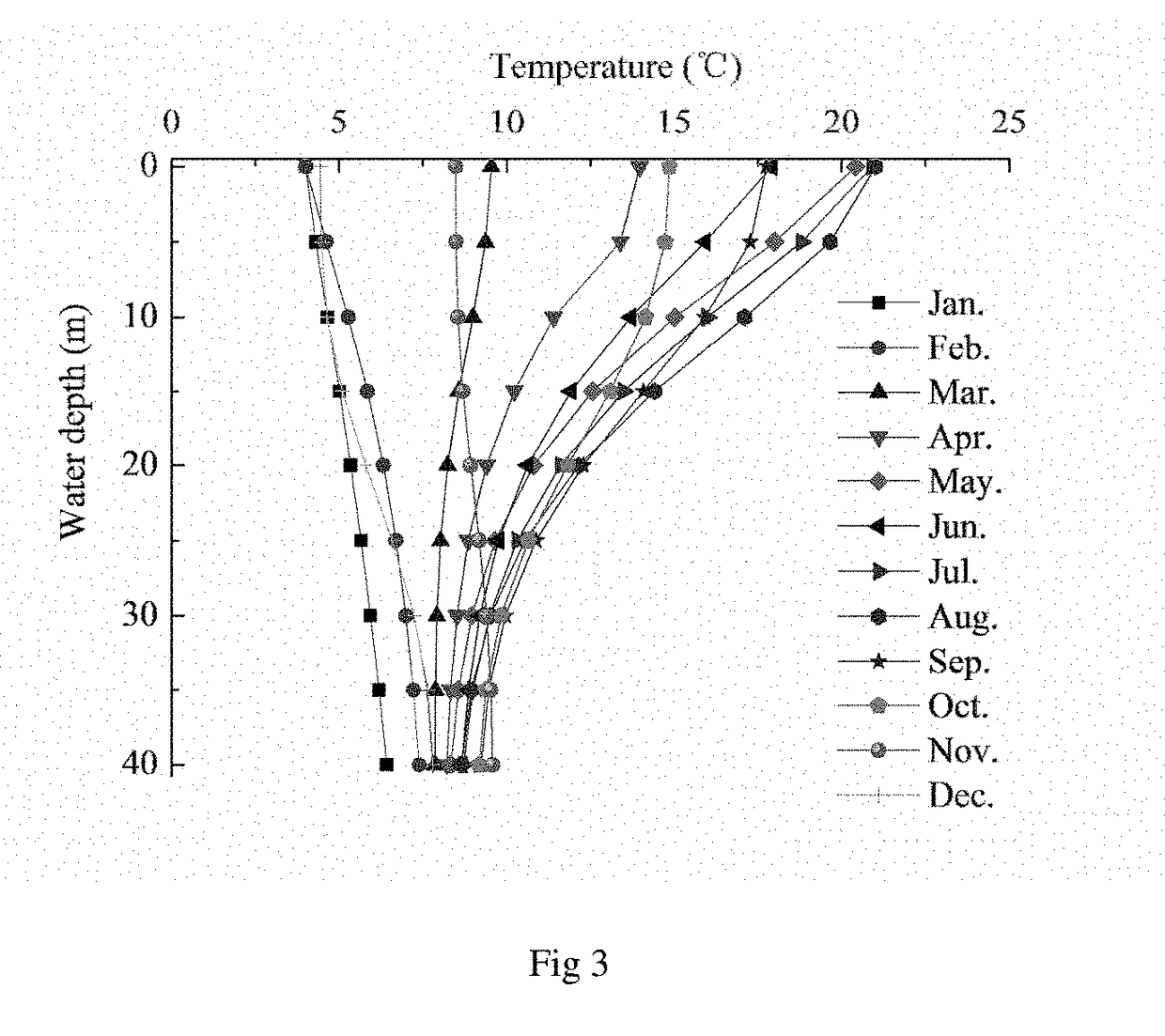

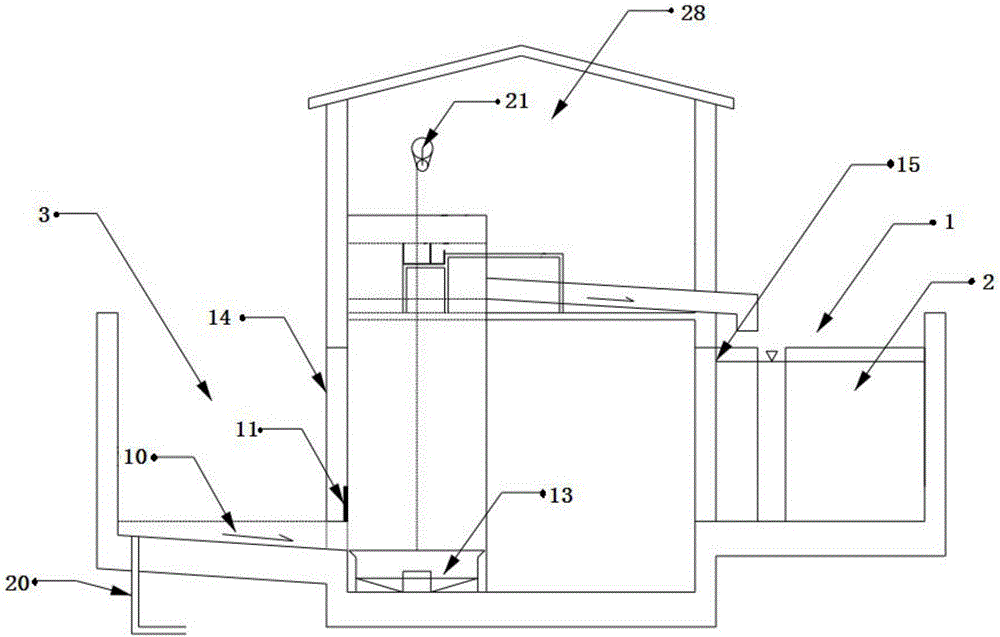

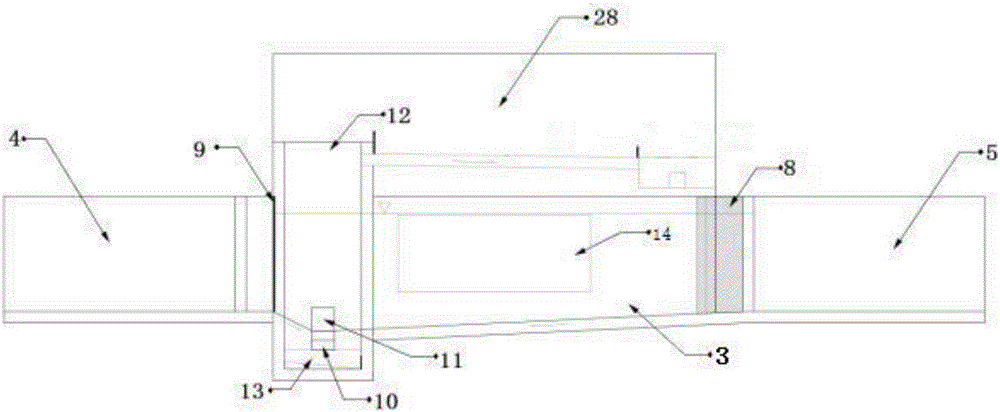

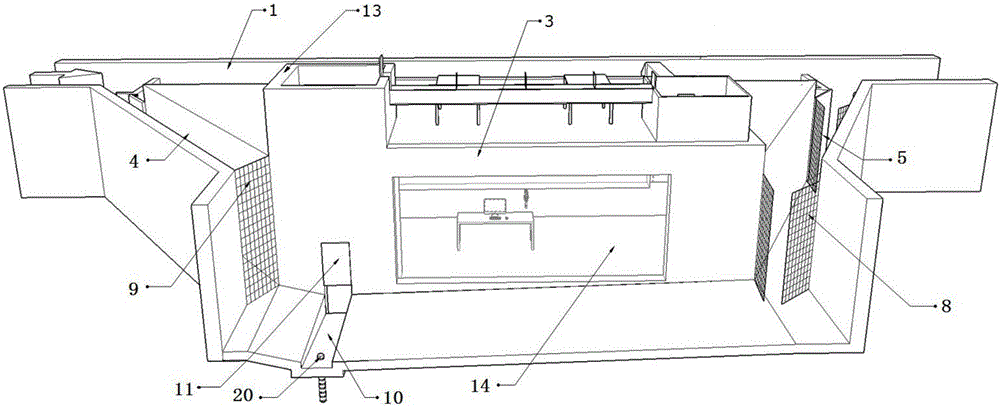

Method for controlling the gate based on the habitat requirement for fish overwintering in rives

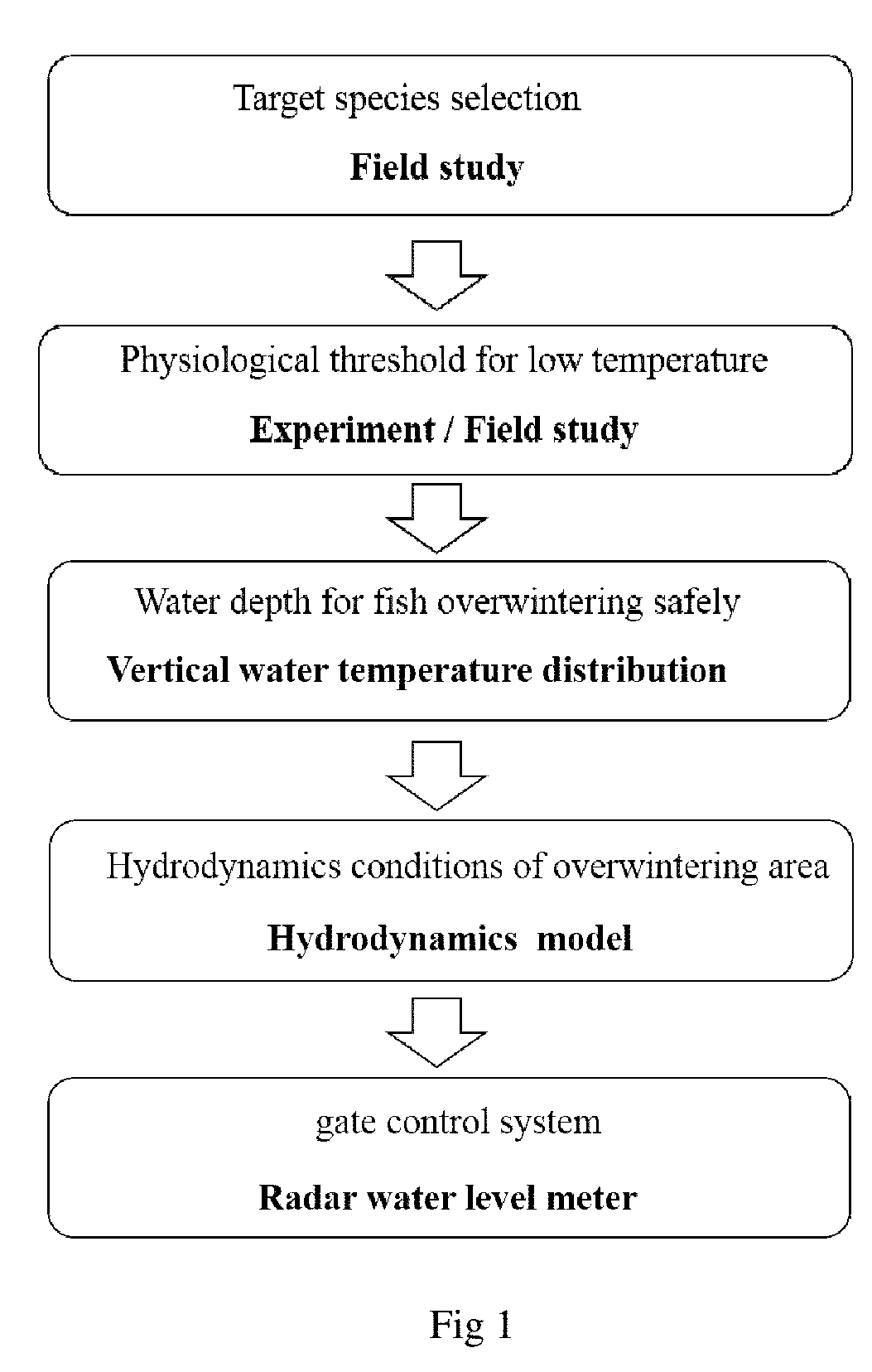

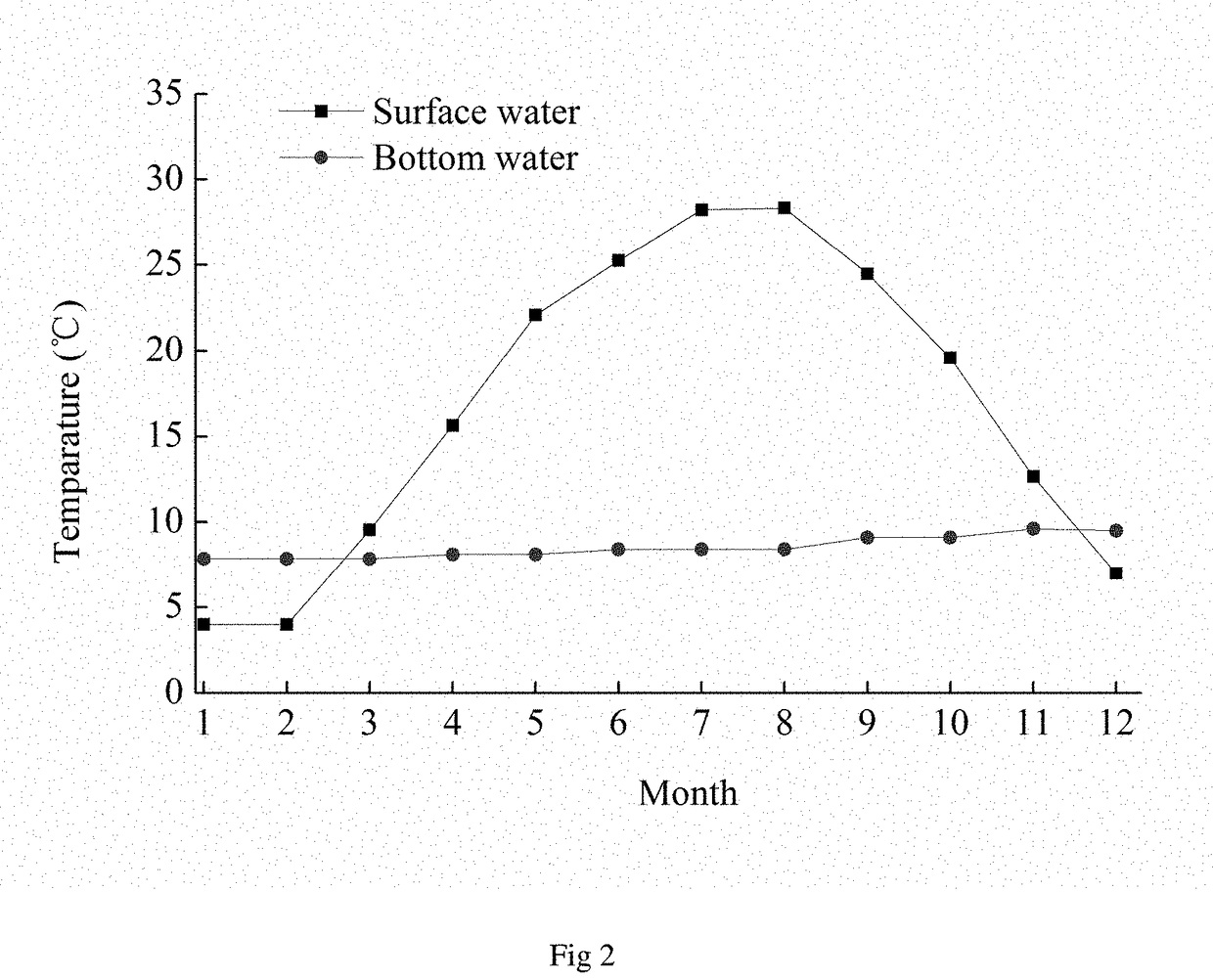

A method for controlling the gate based on the habitat requirement for fish overwintering in rivers. According to the characteristics of biological habitat of the river and the habitat demand of fishes during overwintering, the method specifically comprises the steps of: firstly, determining candidate fishes for ecological flow calculation though fish resources investigating and historical data, and then screening out the target fish by adopting hierarchical analysis method; Secondly, establishing a quantitative response relationship curve between target fish physiological adaptions and water temperature, obtaining ecological water level which ensures the target fish overwintering safely according to the vertical temperature distribution, and establishing the relation between water depth and discharge using hydrodynamic model; finally, setting up a gate control system including a radar water level meter in the overwintering areas and an ecological water level management system in a gate control room.

Owner:NANJING HYDRAULIC RES INST

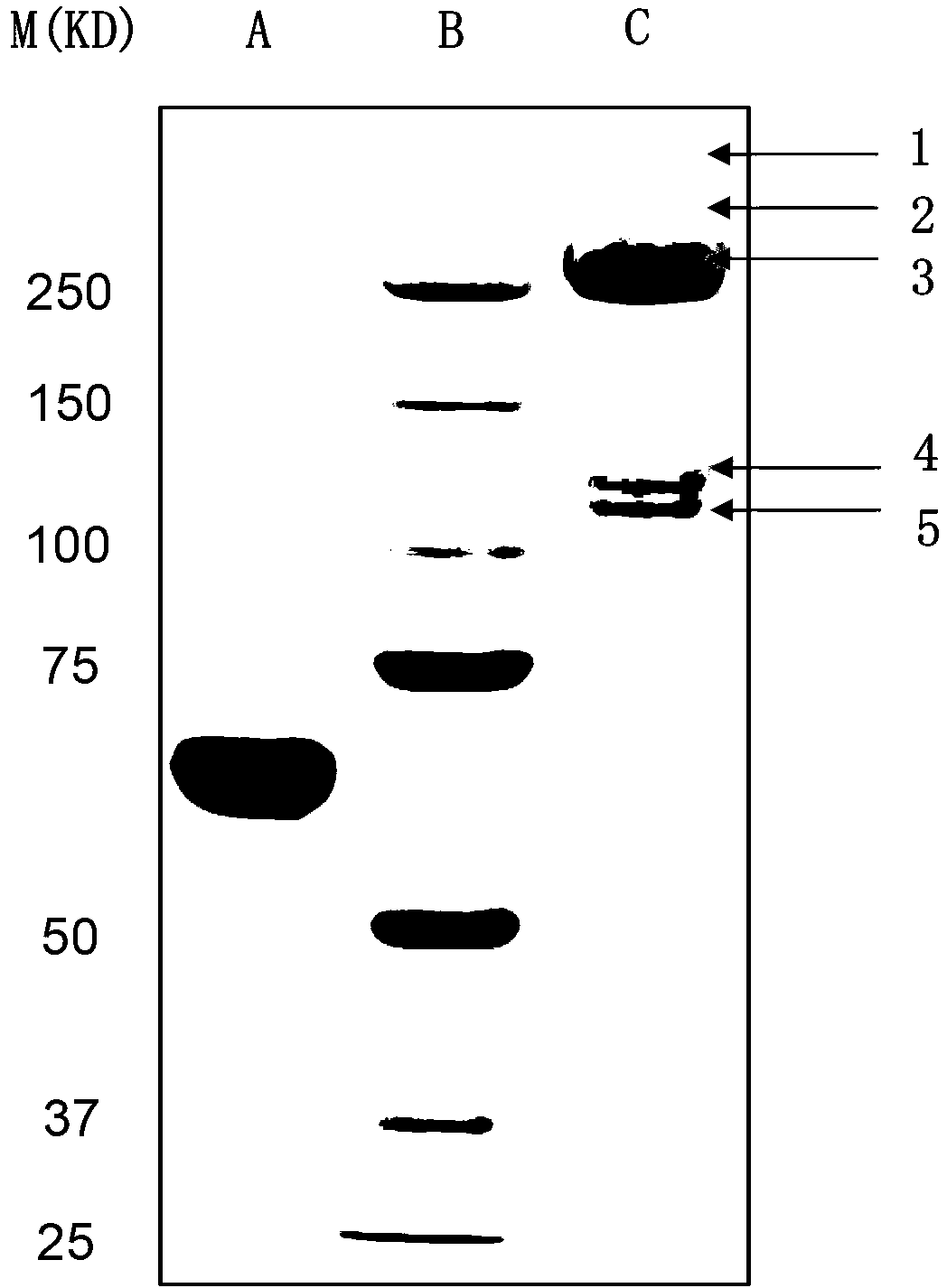

Preparation method of fish-skin collagen for medical biomaterial

ActiveCN103320485AFully and effectively removeEfficient removalConnective tissue peptidesPeptide preparation methodsHydroxyprolineNon collagenous protein

The invention provides a preparation method of fish-skin collagen for a medical biomaterial. The preparation method provided by the invention comprises steps of raw material treatment, collagen extraction, extract purification and the like. By the adoption of the preparation method of fish-skin collagen for a medical biomaterial, non-collagen components of fish-skin can be fully and effectively removed; high-purity collagen with the content of obtained hydroxyproline being greater than or equals to 9%, the content of non-collagen being less than or equals to 1% and the content of ash being less than or equals to 1% is obtained; and fish resources can be utilized within a larger range. The preparation method has advantages of simple technology, easy operation, short processing time and obvious biocompatibility effect, and is suitable for industrial production.

Owner:烟台德胜海洋生物科技有限公司

Fishing system assembly and method based on network video remote control

The invention discloses a fishing system based on network video remote control and a method breaking through the defects in a traditional mode for realizing the fishing under the condition that people are not at the scene. The fishing system comprises a customer display terminal, a customer management center, a cabled and wireless network system, a local area network management station, a fishing operation remote control system, a power supply and a video sound collecting transmission system. During the operation, a remote control cloud deck power supply is started, a fishing rod can remotely control the cloud deck to realize the horizontal rotation and the vertical displacement, one end of a fishing data wire assembly is fixed on the fishing rod, the other end of the fishing data wire assembly is provided with a fishing hook assembly and an underwater illumination and video sound collecting playing assembly, the fishing hook adopts a remote control bait hanging assembly for hanging bait, a buoy adopts a space bean for realizing the position limitation, the displacement of the space bean is realized through a space bean displacement assembly, and the harvested fish is contained into an antitheft fish basket assembly. The invention provides action games really combining the virtuality and the reality, requirements of fishermen with the fishing desire but without the in-site fishing time can be greatly met, the fishermen can realize the remote control fishing by a computer through sitting at home, the wild fish resource development benefits are improved through adopting a mode of fishing large fish and breeding fish fry, and the sustainable development of fish resources is promoted.

Owner:杨文宇

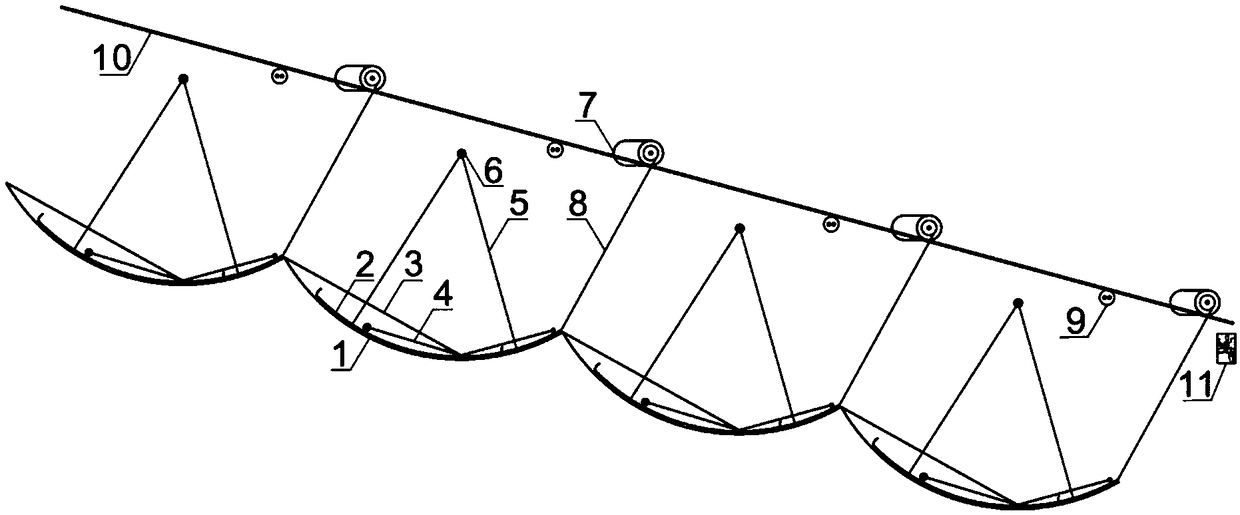

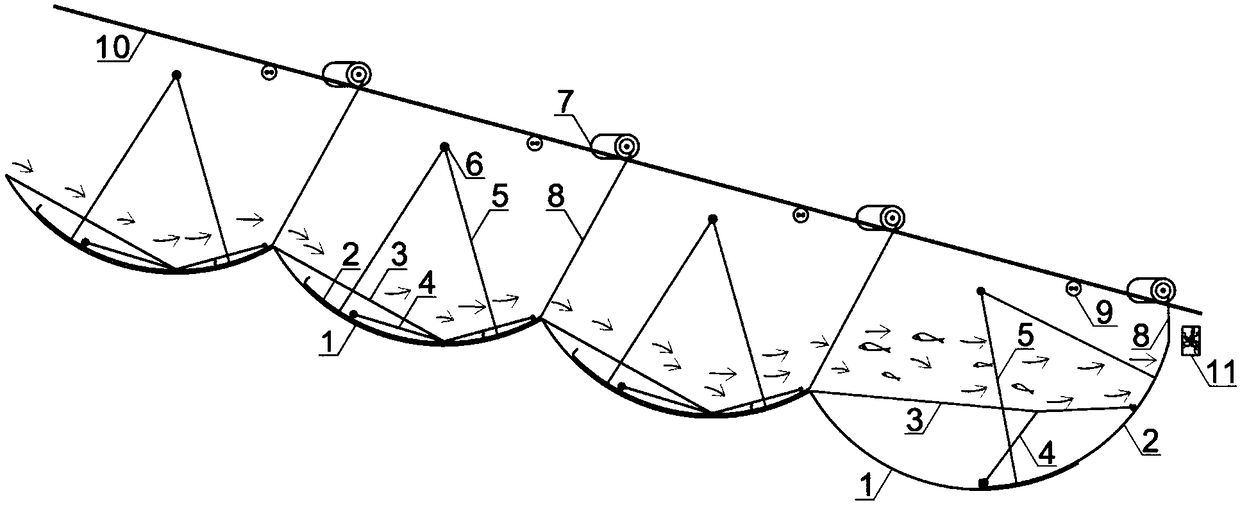

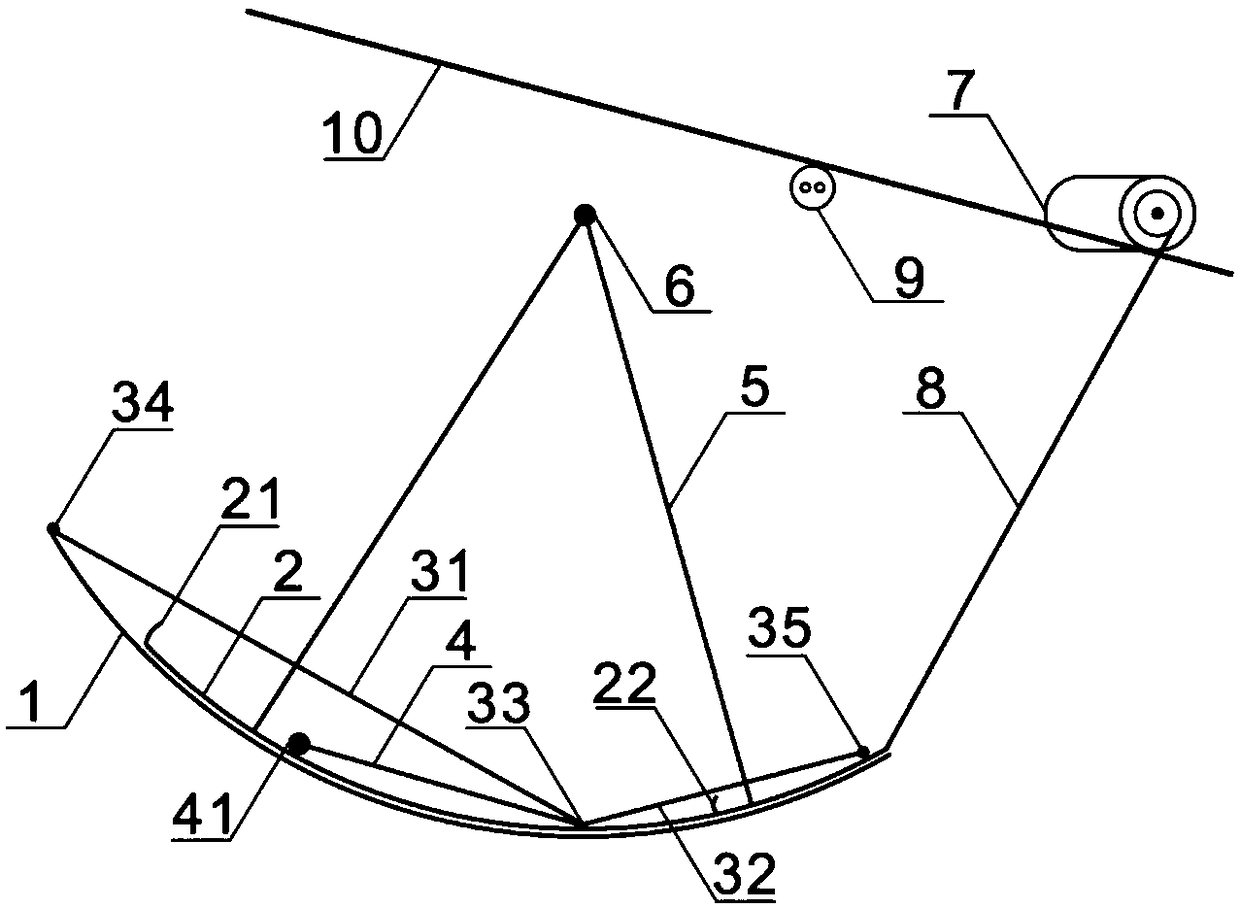

Multi-level overlapping arc fishway and fish passing method

ActiveCN106702979BReduce distractionsGood for internal energy dissipationBarrages/weirsClimate change adaptationEcological environmentControl system

The invention discloses a multi-stage superimposed arc type fish passage and a fish passing method and belongs to the field of ecological environment of fish passing buildings and hydraulic and hydroelectric engineering. The multi-stage superimposed arc type fish passage comprises a plurality of stages of fish passage units, a fish passage two-wing wall and a control system, wherein bottom plates and gates of the fish passage units are arc-shaped panels to form a superimposed arc type structure; foldable plates in the fish passage units can tend to be straight along the opening process of the gates and can cooperate with the gates to form water flow condition beneficial for upstream movement of the fishes. Compared with the conventional fish passage, the length of the fish passage can be reduced; the water flow condition of the fish passage can be adjusted; the fish passage is high in intelligent level, is applied to fish passing of dams with different water heads, is also applied to fishes with different swimming capabilities, and is capable of effectively protecting fish resources and maintaining the diversity of river ecosystems.

Owner:ANHUI UNIV OF SCI & TECH

Monitoring method for natural reproduction of fish based on environmental DNA technology

InactiveCN107099595AEasy accessFishing Survey ValidMicrobiological testing/measurementDNA extractionFish species

The invention relates to a monitoring method for natural reproduction of fish based on environmental DNA technology. The method comprises the following steps: acquisition of a water sample; DNA extraction; ddPCR amplification of a target fragment; and concentration analysis. The monitoring method provided by the invention is based on environmental DNA identification technology, does not depend on traditional fishing technology for roe and fries and traditional anatomical technology for oophagous fish and can determine the oviposition behavior of a target species and the position of an oviposition site only through reasonable design of a sampling point, acquisition of a water sample and concentration analysis of the target species. The method maximally protects fish resources and avoids inconvenience caused by restrictive factors like long time for traditional fishing and difficulty in fishing of a part of fish fingerlings.

Owner:CHINESE STURGEON RES INST CHINA THREE GOR

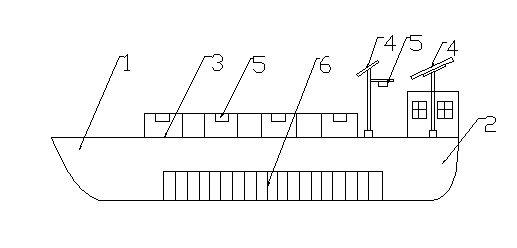

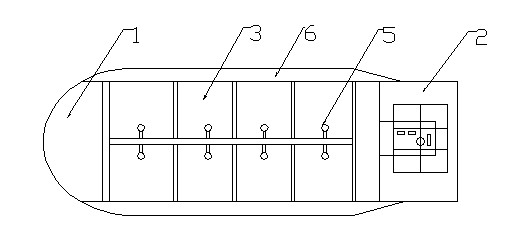

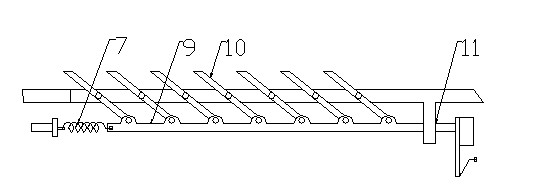

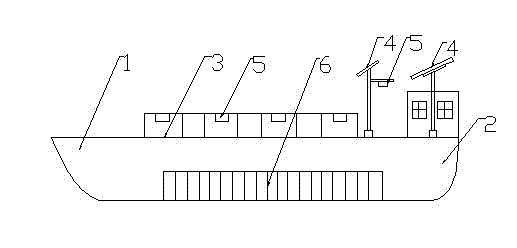

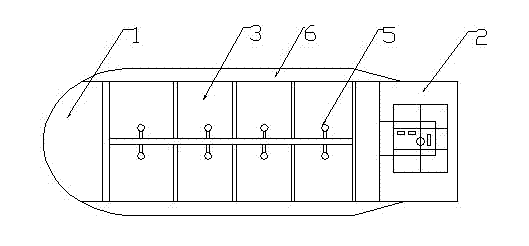

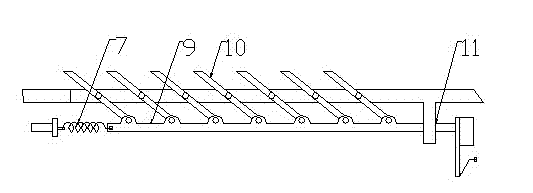

Boat-type solar fish-farming net cage in river

ActiveCN101933484ATo satisfy the market's needsProtect resourcesClimate change adaptationAgricultural fishingAutomatic controlNormal growth

The invention discloses a boat-type solar fish-farming net cage in river, comprising a flow rate regulation device. The flow rate regulation device comprises a flow rate measurement cabin, the inner of the flow rate measurement cabin is provided with a tension spring, a flow rate measurement board, a draw bar, and a plurality of regulation pieces for controlling the opening and closing of the flow rate measurement cabin. One end of the tension spring is fixed on the flow rate measurement cabin, and the other end is connected with the draw bar. The draw bar passes through a draw bar sleeve arranged on the flow rate measurement cabin and is fixedly connected with the flow rate measurement board, and the regulation pieces are arranged on the flow rate measurement cabin in revolving and are movably connected with the draw bar. The net cage of the invention is free of the limitation of the power supply, achieves the illumination, the insect killing and automatic feed of bait by using the solar energy. The net cage can automatically control the flow entering the net cage and ensure the reasonable flow-resisting capability of the fishes in the fish-farming, and is suitable for the normal growth of the fishes. In addition, the net cage can kill the injurious insects when illuminating, thereby protecting the wild fish resources in the rivers and developing the farming production of the wild fishes.

Owner:攀枝花市银江金勇工贸有限责任公司

Method for artificial domestication and cultivation of semilabeo notabilis

InactiveCN105028273AMaintain ecological balanceMaintain diversityClimate change adaptationPisciculture and aquariaBalance of natureDrainage basin

The invention relates to a method for artificial domestication and cultivation of semilabeo notabilis. The method comprises the steps of 1, building a semilabeo notabilis cultivation pond; 2, collecting and selecting parent fish fry; 3, conducting food habit conversion; 4, conducting artificial domestication of fry; 5, observing gonad development; 6, conducting domestication management. By the adoption of the method, massive cultivation and population continuation of semilabeo notabilis are facilitated, native commercial fish aquaculture and new species are added, ecological balance of a water area is maintained, local native fish resources are protected, population quantity is increased, biodiversity and ecological balance are maintained, and conditions are provided for semilabeo notabilis cultivation and considerable economic benefits are obtained by means of the natural resources in the Dabang river drainage basin.

Owner:安顺汇成特色农业科技发展有限责任公司

Fish way design method

The invention discloses a fish way design method. The fish way design method comprises the steps of: step 1, collecting data; step 2, determining a fish passing target object; step 3, determining a fish passing scheme; step 4, establishing a dam front section hydrodynamic model and simulating a flow field; step 5, fish way overall design; and step 6, determining an optimal separation board distance. According to the invention, the fish passing target and the fish passing scheme are determined according to the fish resource current situation, the water environment current situation investigation is performed, and the hydrology and water quality conditions of the research area are analyzed. After the current situation analysis is completed, a flow field of a river channel at a dam site is simulated by utilizing an EFDC model, an appropriate living flow velocity range of local fishes is determined, preliminary design of the fish passing channel is performed, and flow field conditions of the fish passing channel under different design schemes are simulated. Simulation results of the fish passing channel flow field are analyzed and compared under different design schemes, and an optimalfish passing channel scheme is determined by combining the simulation results of the river channel flow field in the research area. The overall design of the fish passing channel is completed, and adaptive design and management are implemented.

Owner:HOHAI UNIV

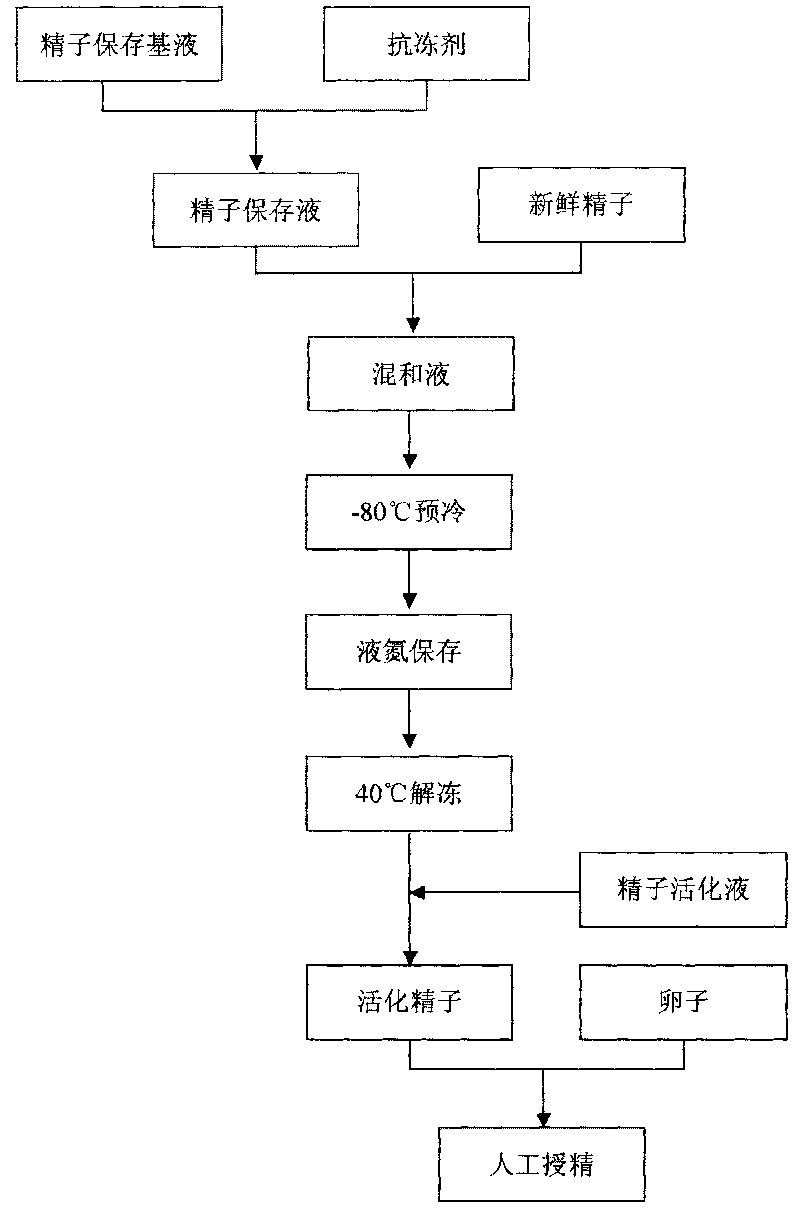

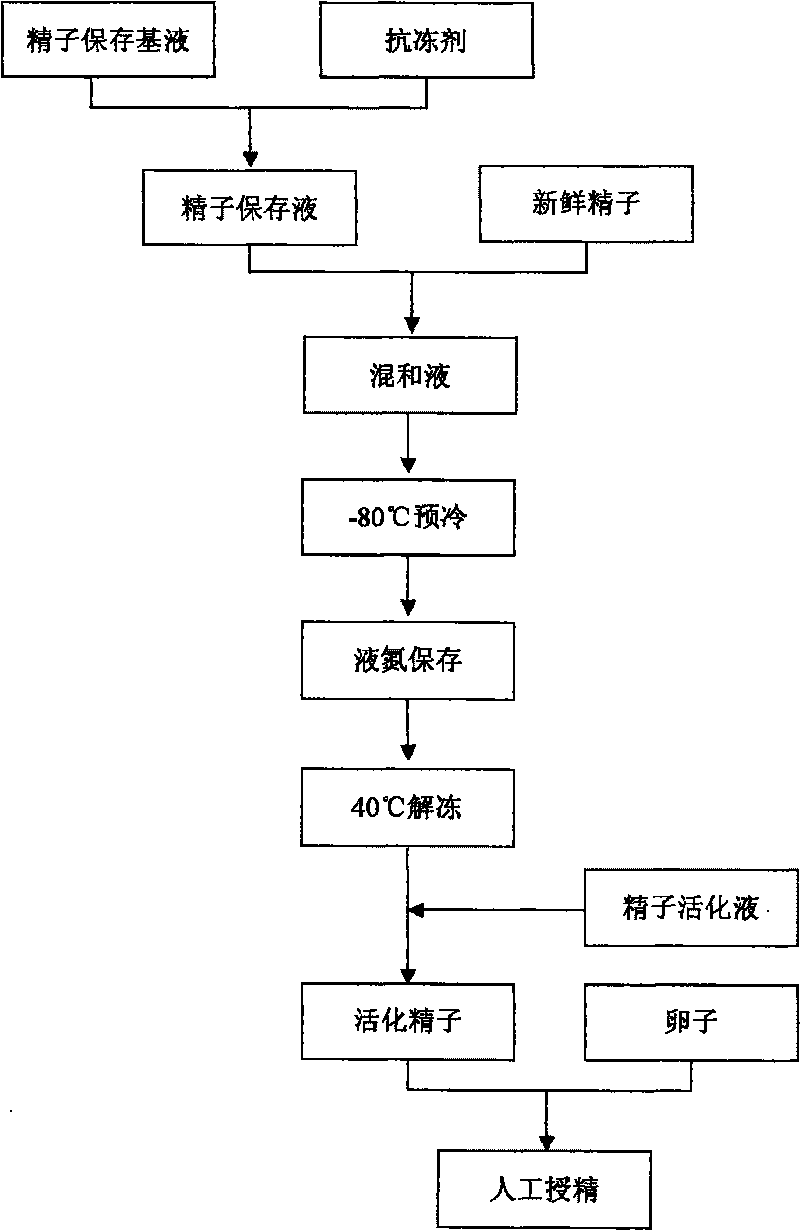

Ultralow-temperature preservation method of rachycentron canadum spermia

InactiveCN101711522AIncrease profitLarge breeding capacityClimate change adaptationDead animal preservationEconomic benefitsBiological activation

The invention belongs to the technical field of aquaculture, in particular to an ultralow-temperature preservation method of rachycentron canadum spermia, comprising the following steps of: diluting and uniformly mixing the collected fresh seminal fluid and spemium preserving fluid step by step according to the volume ratio of 1:3 within 20 seconds, placing the mixture on the liquid level of liquid nitrogen for precooling for 5 minutes at the precooling temperature of 70 DEG C below zero to80 DEG C below zero, and then placing the mixture in the liquid nitrogen with 196 DEG C below zero for long-time preservation. When in use, the preserved spermia are unfrozen at the temperature of 37 to 40 DEG C for 3 to 4 seconds, are immigrated into a spermium activating fluid for activation and then are inseminated. The ultralow-temperature preservation method of the rachycentron canadum spermia in the invention contributes to enhancing the utilization rate of the rachycentron canadum spermia so as to increase the fingerling breeding quantity and enhance the economic benefits. The technology can be used for the artificial breeding of fish, and also has the important significance on developing the recovery and reestablishment of fish resources.

Owner:GUANGDONG OCEAN UNIVERSITY

Crispy popcorn fish snack food prepared from minced fish and preparation method thereof

The invention relates to the technical field of aquatic product processing, in particular to a crispy popcorn fish snack food prepared from minced fish and a preparation method thereof. The technicalscheme includes: conducting thawing, rinsing, fishy smell elimination, antioxidation treatment, mincing and fine filtering on a fish processing by-product minced fish, then conducting mixing and kneading, adhesive bonding, mixing and seasoning, and molding, and then carrying out slurry wrapping, powder wrapping (in corn flakes), frying and nitrogen-filled packing, thus obtaining the fried powder wrapped leisure aquatic snack food. Through scientific recombination and reasonable seasoning, the crispy popcorn fish prepared by the invention has a golden bright appearance, also is crispy outside and soft inside, and is delicious in taste, so that consumers can enjoy the double delicacy of fried popcorn and delicious fish at the same time. The crispy popcorn fish snack food provided by the invention not only meets the nutritional and delicious leisure food development needs, but also solves the problem of comprehensive utilization of fish processing by-products, and improves the fish resource utilization rate and the added value of product.

Owner:BOHAI UNIV

Boat-type solar fish-farming net cage in river

ActiveCN101933484BTo satisfy the market's needsProtect resourcesClimate change adaptationAgricultural fishingAutomatic controlWater flow

Owner:攀枝花市银江金勇工贸有限责任公司

System and method for observing and collecting migratory fishes in fish way

ActiveCN106172274AWith observationWith monitoringImage enhancementImage analysisWater flowRed mullet

The invention discloses a system for observing and collecting migratory fishes in a fish way. The system comprises an observing system and a collecting system, the observing system is arranged beside or in a fish way body, and the collecting system is arranged beside the observing system. The system overcomes the defect that an observing chamber directly arranged on the side wall of the fish way is only supportive of observing and counting and cannot collect fishes or is small in collection quantity and low in efficiency and the defect of influence on normal fish passing of the fish way due to proneness to fish death caused by the fact that several times of fishing are needed for complete counting in the prior art. The system has observing, monitoring, counting and sampling functions, and is free of influence on normal running of the fish way, high in fish collecting efficiency, little in damage to fishes and free of influence on fish resources and supportive of cleaning and maintaining a glass window of the observing chamber by opening and closing different gates to adjust flowing direction of water. The invention further discloses a method for observing and collecting the migratory fishes in the fish way.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Fish milk and its producing process

InactiveCN1473481AIncrease profitNutrient Fortified and BalancedMilk preparationFood preparationCow milkingAdditive ingredient

Fish milk is milk-like matter comprising fish slurry 10-85 wt%, cow milk 10-85 wt%, emulsifier 1-5 wt%, destinking agent 0.1-5 wt% and corrective 0.1-5 wt%. The fish slurry is prepared with fish without gall bladder and water and through coarse milling and fine milling and fish accounts for 12.5 wt% of the material. The production process includes making fish slurry, blending, emulsifying, correcting taste, instantaneous heating to sterilize, heating and pressurizing to homogenize and packing. Compared with available cow milk, the fish milk has higher calcium and protein content, EPA and DHA content higher than 7 %, similar taste and storage period at normal temperature over 6 months. The present invention makes it possible to utilize fish resource and fish nutrients fully.

Owner:陆巧琴

Steamed fish belly product with rice flours and preparation method thereof

The invention discloses a steamed fish belly product with rice flours and preparation method thereof. The steamed fish belly product with rice flours, which is delicious in taste and fat but not greasy, is obtained by preparing fish bellies, preparing seasonings, preparing flours and packaging the product and is edible only through being simply boiled. The steamed fish belly product with rice flours, disclosed by the invention, has the advantages of rich raw material source, convenience in processing, easiness for realizing industrialization and contribution to deep development to sufficiently utilize fish resources and increase additional values of fish products; meanwhile, the gaps of the steamed fish products with rice flours in the market are also filled.

Owner:BAIYANG INVESTMENT GRP INC

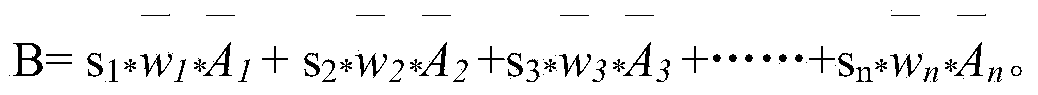

Reservoir fish resource acoustics investigation method

InactiveCN104268786ANo damageAvoid damageData processing applicationsFishing netsInvestigation methodsData acquisition

The invention discloses a reservoir fish resource acoustics investigation method. The method comprises the steps that (1), multi-mesh combination gill nets are designed; (2), the length of cruising paths is designed; (3), the cruising paths are designed; (4), net points are designed and laid, water surface sub-areas are designed, and the multi-mesh combination gill nets are laid in all the sub-areas; (5), underwater acoustics data are collected, and acoustics evaluation data of a reservoir fish resource are obtained; (6), fish samples are collected, the multi-mesh combination gill nets are laid in all the sub-areas before the sun sets, and statistics is carried out on the species, the body length, the body mass, the quantity and the proportion of catches in all the sub-areas; (7), the reservoir fish resource is evaluated comprehensively, and the underwater acoustics evaluation data and fish sample data are combined for obtaining a result of the reservoir fish resource. The effects of path planning and fish sample collecting in the acoustics investigation of the reservoir fish resource are achieved; the reliable basis is provided for reasonable utilization and management of the reservoir fish resource, and the condition of the reservoir fish resource is evaluated efficiently and fast.

Owner:INST OF AQUATIC LIFE ACAD SINICA

A method for preparing fish protein from fish processing waste

InactiveCN102277404AEasy to operateReduce dosagePeptide preparation methodsFermentationSide effectTrypsin

The invention relates to a method for preparing fish protein from fish processing waste. The method of the invention comprises the following steps: pretreatment, enzymatic hydrolysis, acid hydrolysis and posttreatment. Wherein, the protease used in the acid hydrolysis step is a composite enzyme of papain and trypsin. The preparation method of the invention has mild reaction conditions, few side reactions, does not destroy amino acids, and requires simple experimental equipment, is environmentally friendly and safe in operation, and can further effectively utilize fish resources.

Owner:BEIJING FISHERIES RES INST

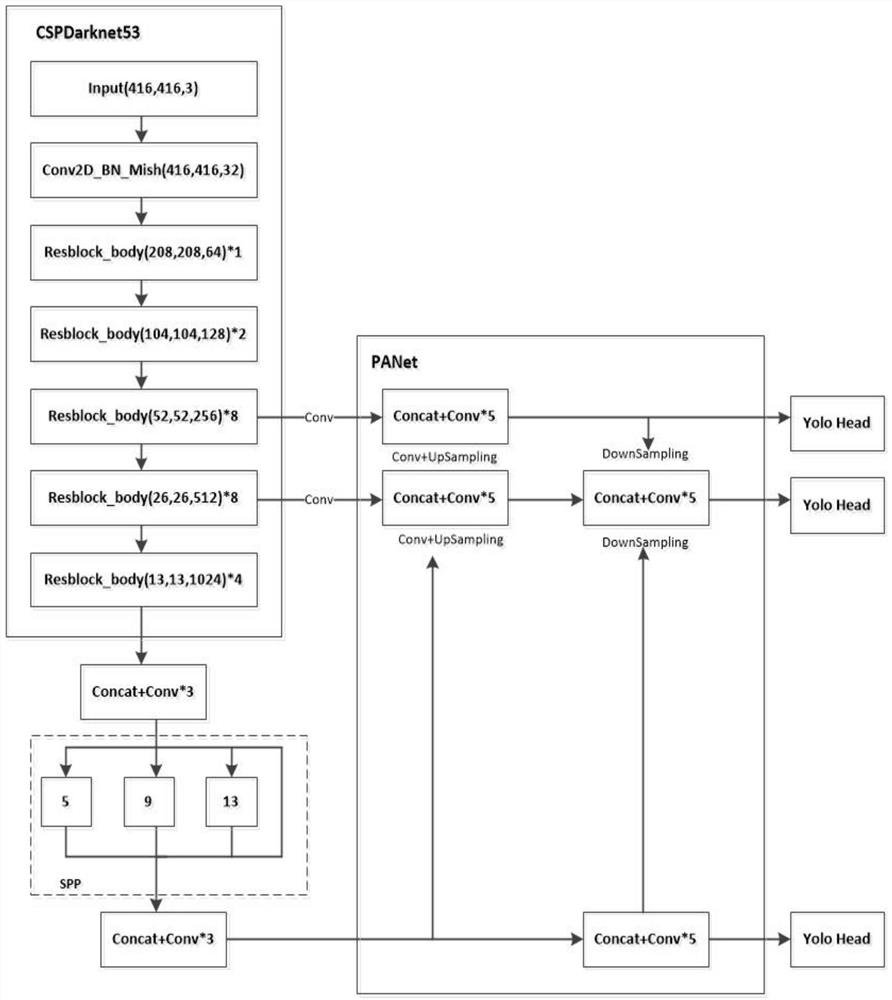

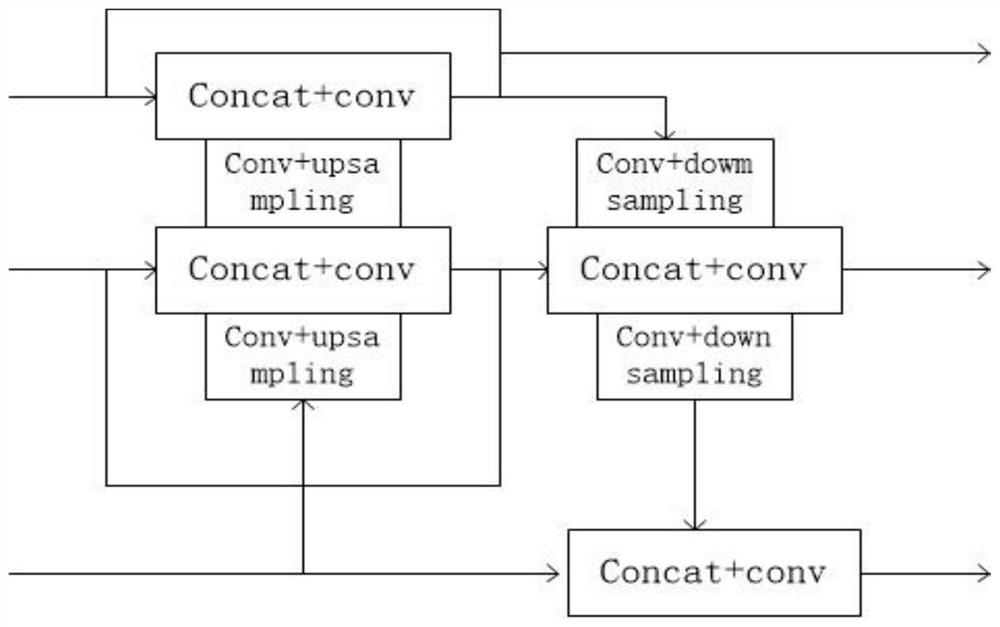

Multi-scale underwater fish school detection method based on attention module

PendingCN114170497AAdd attention mechanismImprove feature extractionCharacter and pattern recognitionNeural architecturesMarine fishFeature extraction

The invention discloses a multi-scale underwater fish school detection method based on an attention module, and belongs to the technical field of marine fish resource detection. Firstly, underwater fish school images are obtained, fish school images are selected from the underwater fish school images, enhancement preprocessing is conducted on the underwater images according to the characteristics that the underwater environment is dark, the background is complex and the fish school images are small and dense, based on an optimized YOLO V4 detection framework, an ECA attention mechanism is added to enable a network to focus on fish body feature learning, background interference is overcome, and the fish school images are obtained. PANet connection is improved, multi-scale information is added, feature extraction is enhanced, and the detection precision is improved. According to the method, automatic detection of underwater fish schools is realized; scientific theory and technical support are provided for automatic fish detection, scientific fishing is specified, ocean resources can be better protected, and sustainable and healthy development of an ocean system is promoted; and a reference scheme can be provided for detection of other marine organisms.

Owner:CHINA AGRI UNIV

Ultra-low temperature cryopreservation and recovery methods for sperms of sinocyclocheilus grahami

InactiveCN102763641AIncrease vitalityImprove fertilization rateDead animal preservationGerm cellsWater bathsRecovery method

The invention relates to ultra-low temperature cryopreservation and recovery methods for the sperms of the sinocyclocheilus grahami, belonging to the technical field of cryobiology. The ultra-low temperature cryopreservation method comprises the following steps: selecting a manure high-quality protospecies or improved variety, anesthetizing for 5 minutes by 100ppm of MS-222, squeezing the dried abdomen to make the manure semen flow into a 1.5ml centrifuge tube, detecting the vitality of the fresh semen, freezing the fresh semen with the vitality of more than 85%, diluting the semen and the antifreeze liquid (D-15 and 7.5% ethylene glycol) according to the volume ratio of 1:2, subpackaging, balancing at 4 DEG C for 60 minutes, balancing in the position of 6cm above the liquid nitrogen surface for 2 minutes, balancing on the liquid nitrogen surface for 20 seconds and putting in the liquid nitrogen to preserve. The recovery method comprises the following steps: shaking the semen rapidly in the water bath of 37 DEG C to unfreeze, and mixing the sinocyclocheilus grahami sperms squeezed out with the unfreezed semen so that the ovums are fertilized. The methods have low cost, are easy and convenient to operate, ensure that the sperms of the sinocyclocheilus grahami can be preserved for a long time, the recovered sperms have high vitality and the artificially propagated sinocyclocheilus grahami has high fertilizing rate and hatching rate, can realize the large-scale production and are of great significance to the fish resource recovery and reconstruction.

Owner:KUNMING INST OF ZOOLOGY CHINESE ACAD OF SCI

Artificial taming method of pond with wild bagarius yarrelli

InactiveCN101574068AImprove survival rateRealize artificial domesticationClimate change adaptationPisciculture and aquariaConchShrimp

The invention relates to an artificial taming method of a pond with wild bagarius yarrelli, belonging to the technical field of fish culture. The method comprises the following steps of designing the environment of a fish pond, sterilizing the fish pond, sterilizing before putting the bagarius yarrelli and casting baits for taming eating. The method comprises the following detailed steps of: dividing the fish pond into a plurality of ponds which are provided with water inlets and water outlets and have different volumes, then manufacturing water flow and arranging hidden places and activity places in the pond; pumping water from the pond to be dry before putting the bagarius yarrelli for taming, leading calcium lime to form pulp, splashing the pulp in the whole pond according to 10 to 300kg per mu and sterilizing; before putting the bagarius yarrelli, using antibiotic solution of 10 to 100IU / L for soaking each bagarius yarrelli for 15 to 30 minutes for sterilization; before putting the bagarius yarrelli for taming, putting living shrimps, living little fishes and conches in the pond by 10 to 30kg per mu, after putting the bagarius yarrelli for 30 days, putting fish meat of 1 to 3kg on a food table every day, and leading the bagarius yarrelli to be capable of intaking food gradually at fixed time and place. The artificial taming method has simple and convenient operation, low cost and high survival rate of bagarius yarrelli, realizes artificial taming of the wild bagarius yarrelli in the pond and lays the foundation for developing and utilizing native fish resource, namely bagarius yarrelli.

Owner:云南省渔业科学研究院

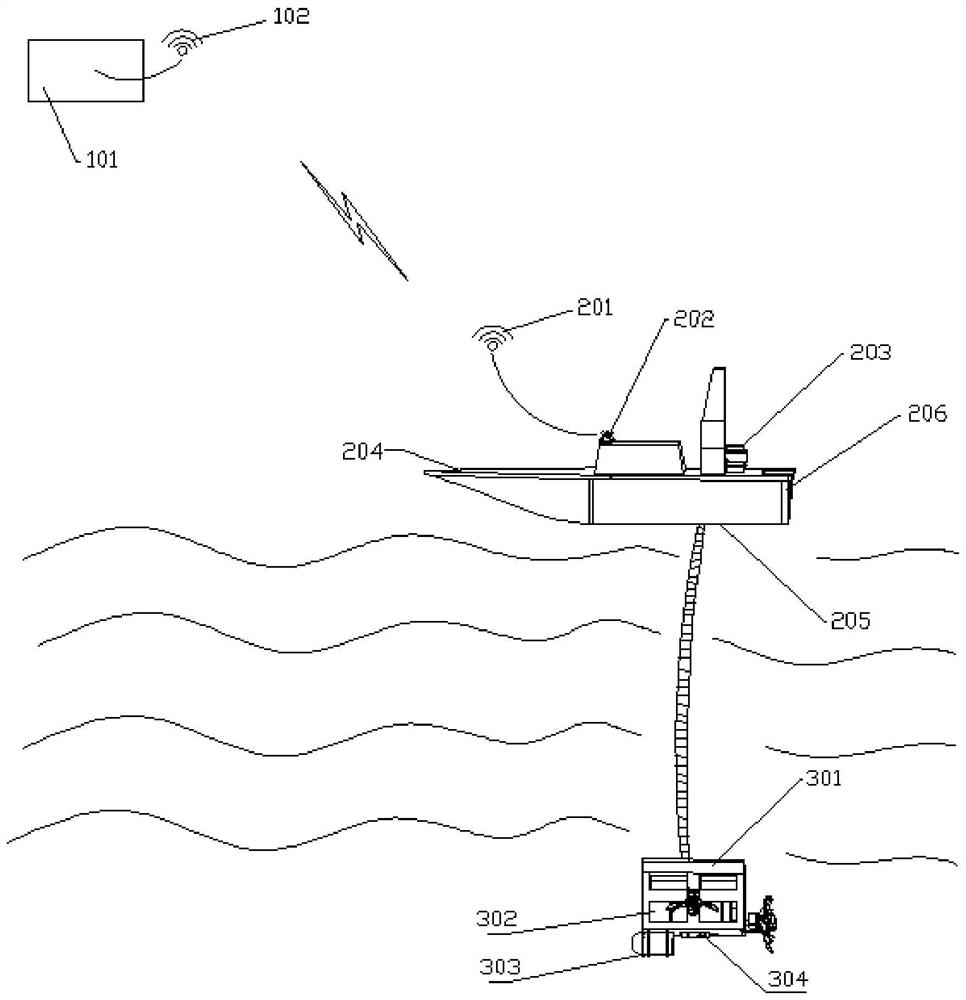

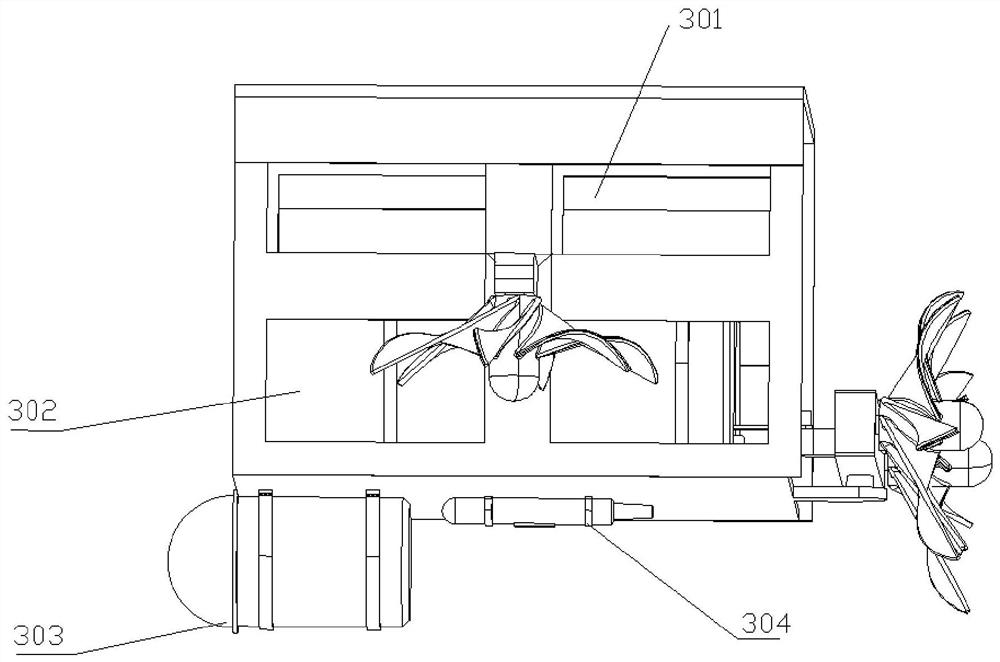

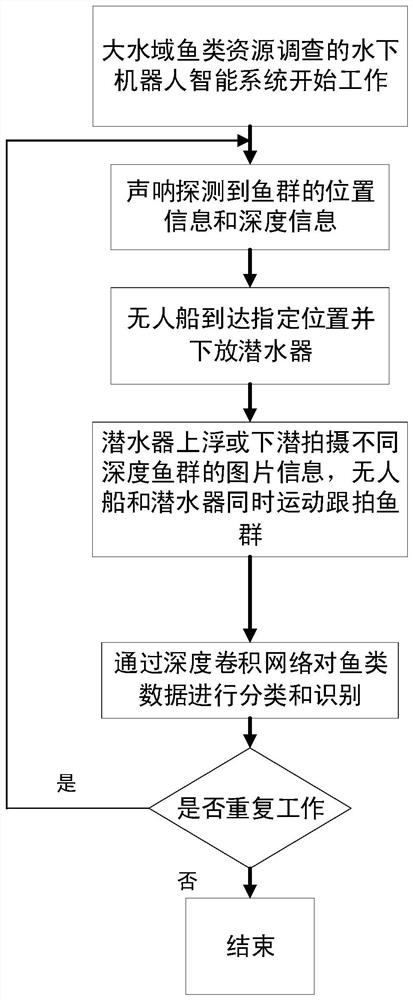

Underwater robot intelligent system for large-water-area fish resource investigation, and working method thereof

InactiveCN112644646AImprove survey accuracyAvoid harmUnmanned surface vesselsWater resource assessmentMarine engineeringUnderwater vision

The invention belongs to the technical field of underwater robots. The invention aims to provide the underwater robot system for large-water-area fish resource investigation based on underwater vision assistance, so as to realize high-precision, high-efficiency and low-destructiveness large-water-area fish resource investigation and remarkably reduce the labor cost of fish investigation. According to the technical scheme, the underwater robot intelligent system for large-water-area fish resource investigation is characterized by comprising a shore-based console and an underwater intelligent investigation system, wherein the shore-based console and the underwater intelligent investigation system are arranged on a shore-side base; the shore-based console comprises a shore-based server and a shore-based wireless communication module in information communication with the shore-based server, and is used for carrying out classification processing on image information returned by the unmanned ship and recording fish school position, depth and motion information, and processing and analyzing the obtained information so as to calculate fish data; and the wireless communication module is also used for real-time communication with the unmanned ship.

Owner:ZHEJIANG SCI-TECH UNIV

Deep-sea fish image classification and recognition method

ActiveCN111523612AAccurate assessmentEffective development and utilizationCharacter and pattern recognitionNeural architecturesAlgorithmFish fin

The invention discloses a deep-sea fish image classification and recognition method, and the method is characterized in that the method comprises the following steps: 1, building a fish state multi-source information database according to the fin position information amount, fish size information amount, fish tail shape information amount and body color information amount of deep-sea fishes, and dividing the state similarity of the fishes into 0-1; 2, establishing a three-layer neural network based on a BP algorithm; and 3, setting various parameters on the basis of the neural network tool, and training and verifying the neural network. According to the invention, four types of information scoring rules for fish type state evaluation are respectively formulated; a neural network is adoptedas an evaluation algorithm in combination with scoring of the four types of information; the comprehensive score is used as the basis of fish classification, various types of data and parameters areintegrated, the category of deep-sea fishes is comprehensively and accurately evaluated, a scientific basis is provided for deep-sea fish classification, deep-sea fish resources can be effectively developed and utilized, and the strategic significance of long-term development is achieved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com