Patents

Literature

143results about How to "With viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromagnetic shielding conductive coating and preparation method thereof

InactiveCN102618145AReduce dosageImprove shielding effectEpoxy resin coatingsElectrically-conductive paintsConductive coatingElectromagnetic shielding

The invention provides an electromagnetic shielding conductive coating and a preparation method thereof. The electromagnetic shielding conductive coating comprises film-forming substances, conductive powder, thickening agents, coupling agents and curing agents. The mass ratio of the film-forming substances to the conductive powder to the thickening agents to the coupling agents to the curing agents is 5-20:50-75:5-30:0.7-4:6.5-15. Auxiliaries are added into the film-forming substances and stirred to be completely dissolved, the thickening agents are added into mixture, the coupling agents are then added into the mixture, the conductive powder is added into the mixture after stirring, and the curing agents are added into the mixture, so that the electromagnetic shielding conductive coating is obtained. By means of composition and proportioning for the conductive coating, the prepared coating is excellent in electric conductivity and resistant to acid, alkaline and oxidization. Besides, the resistivity of the conductive coating prepared by the preparation method is continuously reduced, and conductive high molecular polymer for the conductive powder in the conductive coating is well compatible with organic resin, so that air bubbles and needle holes in the coating can be decreased.

Owner:KUNMING UNIV OF SCI & TECH

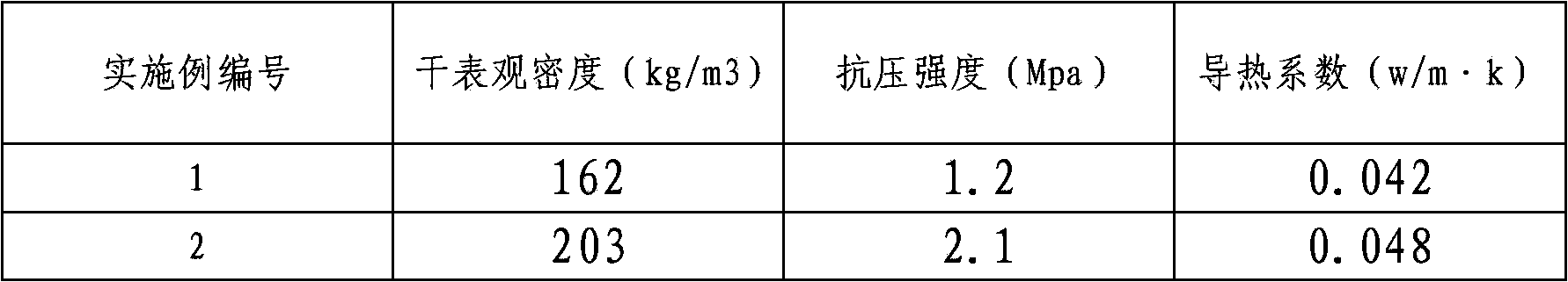

High-performance foam concrete insulation board and preparation method thereof

The invention belongs to the field of an external wall insulation material of a building, and particularly relates to a high-performance foam concrete insulation board and a preparation method thereof. The high-performance foam concrete insulation board is prepared from the following raw materials in parts by weight: 45-250 parts of cement, 10-125 parts of admixture, 6-30 parts of foaming agent, 40-130 parts of water, 0.8-5.5 parts of additive, and 2-11 parts of modifier in a mixed casting manner. The insulation board provided by the invention is light in weight, high in strength and excellent in waterproofness.

Owner:沈阳红姗石新型建材有限公司

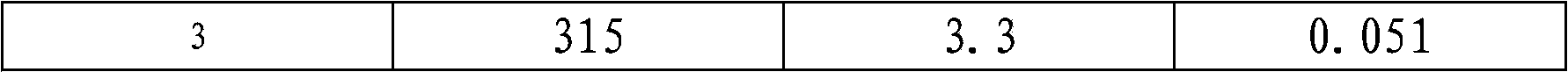

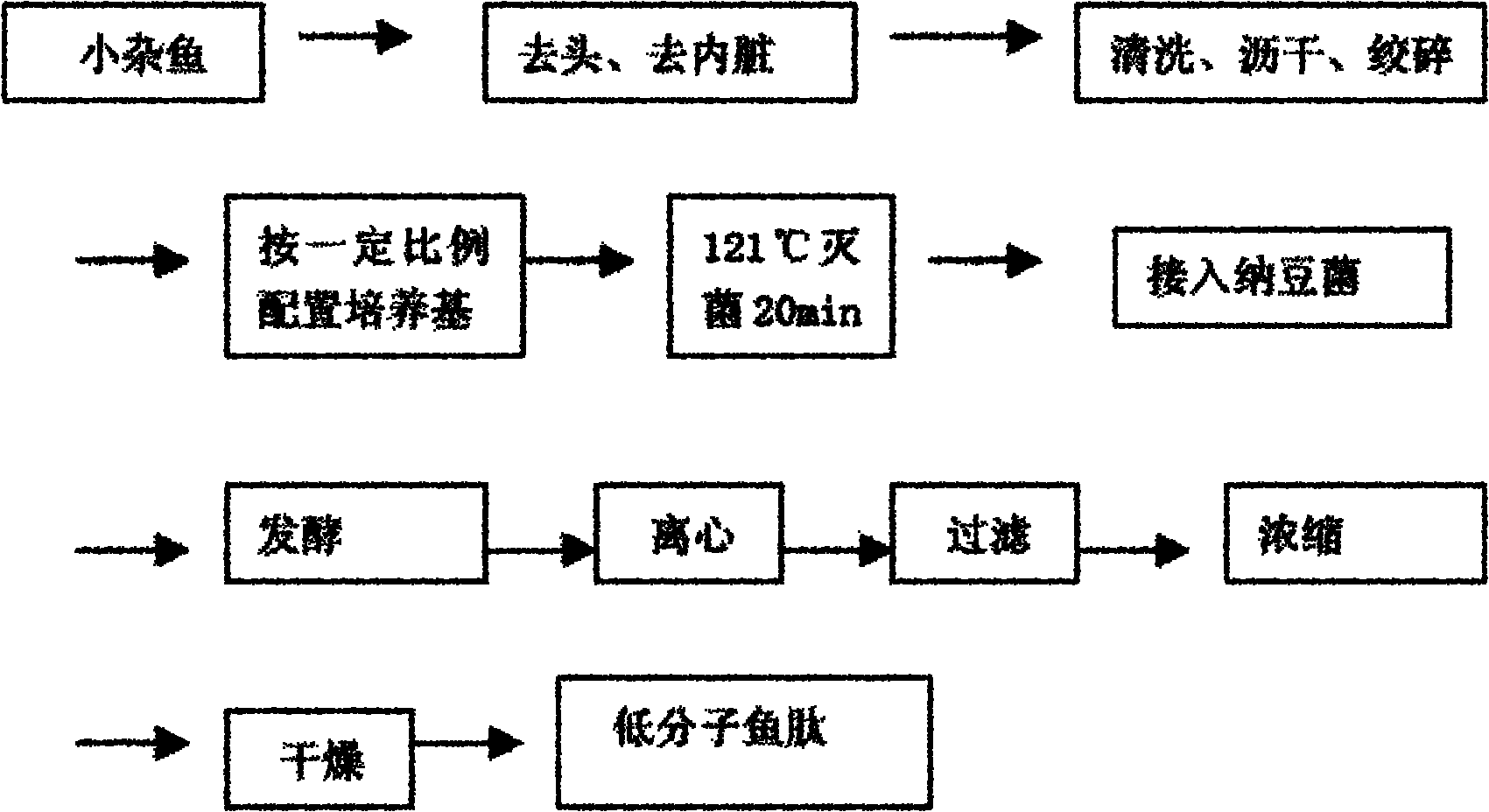

Method for preparing low molecular weight fish peptide through Bacillus natto fermentation method

ActiveCN102028091AWith viscosityWith fresh fragranceProtein composition from fishAnimal feeding stuffCholesterolTreatment hypertension

A method for preparing a low molecular weight fish peptide through a Bacillus natto fermentation method comprises the following steps: taking fish to mince, adding water, adding maltose, glucose, lactose or sucrose to obtain a mixture; adjusting the pH value of the mixture, sterilizing at high temperature; cooling, inoculating Bacillus natto seed liquor to ferment; and centrifuging fermentation liquor, filtering, concentrating, drying and grinding to obtain a low molecular weight fish peptide product. The method uses fish as the raw material and utilizes the Bacillus natto fermentation technology to obtain the low molecular weight fish peptide. The product in the invention is very soluble in water, is digested and absorbed easily by human body and has various functions of reducing cholesterol in the blood, promoting lipid metabolism, preventing and curing hypertension and the like. The technology in the invention is also suitable for other low value aquatic product and high-grade aquatic product machine leftover pieces, thus fish resources can be fully utilized; and the technology is simple and easy, the investment is less, the cost is low, the effect can be realized fast, the added value is high and the method is suitable for large-scale industrial production.

Owner:全然之心(大连)商贸有限公司

Bone cement containing calcium citrate and preparation method of bone cement

ActiveCN105396175AImproved ability to resist collapseStrong plasticityTissue regenerationProsthesisSolid phasesOrthopedic department

The invention belongs to the field of bone damage repair medicinal materials and particularly relates to a preparation method and application of bone cement containing calcium citrate. The bone cement containing calcium citrate is composed of a solid phase part and a liquid phase part, the solid phase part is formed by compounding the calcium citrate and calcium phosphate salt, and the mass ratio of the calcium citrate to the calcium phosphate salt is (2-5):1; the liquid-solid ratio is (0.5-1.5):1. The bone cement containing the calcium citrate has comprehensive biomedical properties such as good plasticity, bone guidance, bone induction activity, cell activity and good degradation rate and is applicable to the orthopedics department, the thoracic surgery department and shaping and restoration of skull and jaw surfaces.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Conductive coating and preparation method thereof

InactiveCN101792634AWith viscosityPrevent subsidenceEpoxy resin coatingsElectrically-conductive paintsAluminiumMetallic Nickel

The invention provides a conductive coating, comprising the following raw materials in parts by weight: 5-20 parts of film-forming materials, 20-75 parts of conductive powder and coupling agents in a ratio of 100:2-10 and 5-30 parts of thickening agents. The conductive powder is one or more of nickel powder, aluminum powder, zinc powder, titanium powder, manganese powder, chromium powder, silver-plated nickel powder, silver-plated aluminum powder, nickel-plated copper powder and silver-plated copper powder. The conductive coating can be used on the shells of computers, mobile phones, GPS, electromedical equipment, electronic instruments and electronic and electrotechnical communication products and has obvious electromagnetic shielding effect.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

Method for preparing flavored fermented milk by stirring type heat treatment

InactiveCN103828915AGuaranteed viscosityGuarantee that the product has viscosityMilk preparationFlavorWhey protein

The invention discloses a method for preparing flavored fermented milk by stirring type heat treatment. The flavored fermented milk is prepared from the following ingredients in parts by weight: 50-100 parts of white granulated sugar, 10-15 parts of whey protein powder, 20-25 parts of a stabilizer, 0.03-0.1 part of strains, 0.1-1 part of essence, and 1000 parts of milk without antibiotics. The flavored fermented milk stored at normal temperature is normal in texture without whey being separated out and is normal in flavor within the shelf life; within the shelf life, the acidity and the pH value of the flavored fermented milk do not change fundamentally, and an appropriate sour-sweet ratio as well as normal texture and mouthfeel of the flavored fermented milk are maintained, so that yogurt can be stored, sold and drunk at normal temperature; besides, the method can be performed under existing technical conditions without extra equipment investment, and consequently, the method has a significant business value and a big market efficiency space.

Owner:KUNMING XUELAN MILK

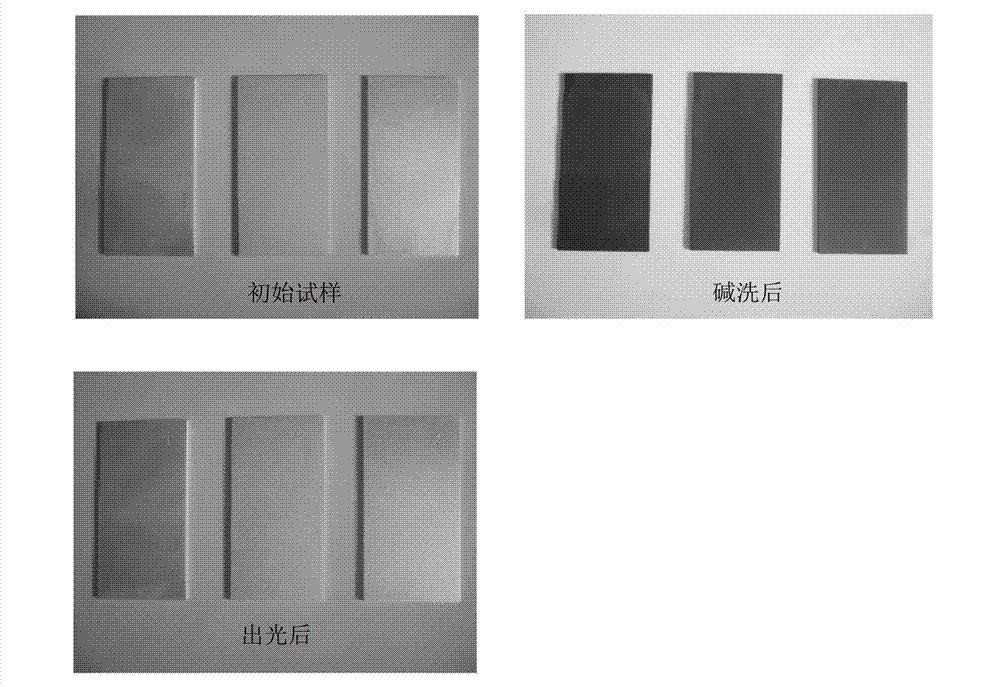

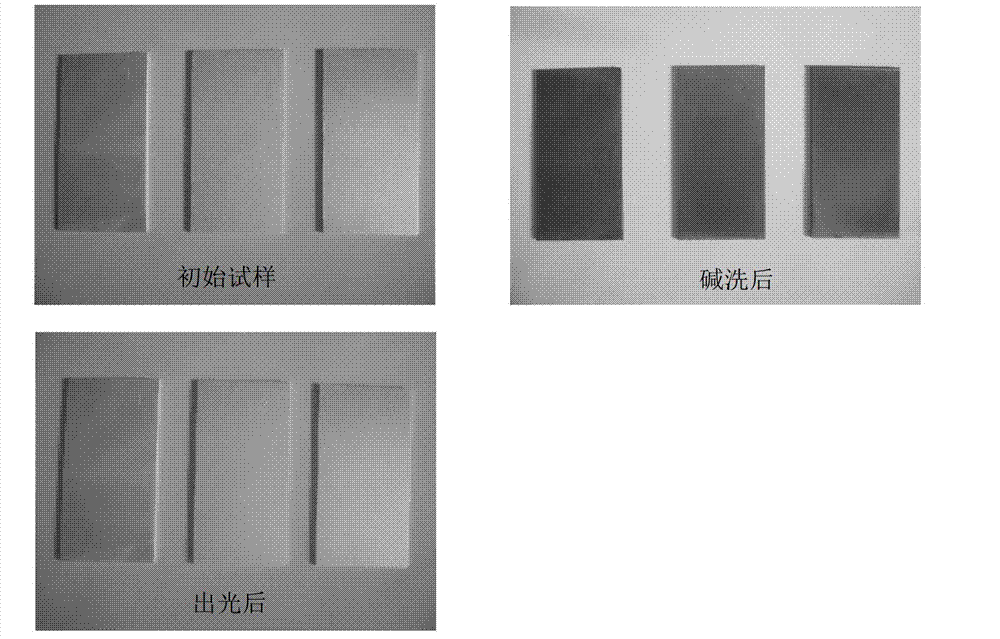

Environmental long-term pre-treatment process for surface anodization of aluminum alloy

ActiveCN102965709AIncrease temperatureProlong the alkaline etching timeSurface reaction electrolytic coatingSodium phosphatesAlkaline etching

The invention discloses an environmental long-term pre-treatment process for surface anodization of aluminum alloy. A pre-treatment solution comprises two parts: an alkali etching solution and a brightening liquid, wherein the alkali etching solution is composed of sodium hydroxide and an alkaline etching agent consisting of sodium phosphate, sodium carbonate, D-sodium gluconate, sodium benzoate and sodium dodecanesulphonate; and the brightening liquid is composed of sulfuric acid and sodium molybdate. The technology comprises the following steps: 1, etching by alkali; 2, washing by hot water; 3, washing by cold water; 4, brightening; and 5, washing by the cold water. The alkali etching solution provided by the invention has long using period, is stabile in performance and not easy to produce insoluble aluminum fouling; the brightening liquid does not contain fluorinion and hexavalent chromium, does not emit toxic gases, is green and safe, and meets environmental requirements. The aluminium processed by the pre-treatment method can be directly anodized.

Owner:BEIHANG UNIV

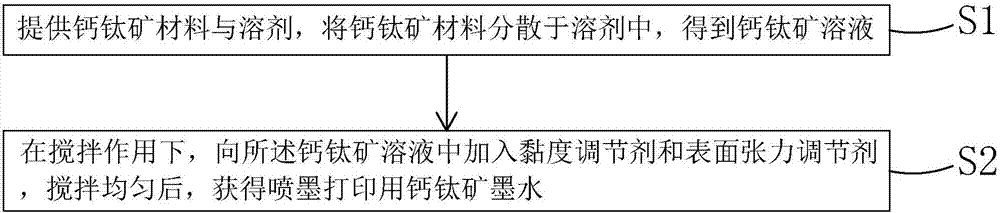

Perovskite ink for ink-jet printing and preparation method of perovskite ink

The invention provides a perovskite ink for ink-jet printing and a preparation method of the perovskite ink. The preparation method of the perovskite ink for ink-jet printing has a simple preparation process; and the prepared perovskite ink for ink-jet printing has certain viscosity, surface tension and volatilization performance, and can meet the requirement on the preparation process of ink-jet printing to realize an ink-jet printing mode of a perovskite luminescent layer. The perovskite ink for ink-jet printing is prepared by adopting the method, can meet the requirement on the preparation process of ink-jet printing, and realizes the ink-jet printing mode of the perovskite luminescent layer.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Industrial secondary refrigerant

The invention relates to an industrial secondary refrigerant. The industrial secondary refrigerant is composed of, by weight, 80 to 99% of glycol alkyl ether or propylene glycol alkyl ether compounds, 0.1 to 5% of a corrosion scale inhibitor and 0.9 to 10% function-adjusting liquid. According to the invention, the secondary refrigerant is added with the environment-friendly corrosion scale inhibitor which is harmless to the environment and human body, and the corrosion scale inhibitor can adsorb on metal surface and forms a physical adsorption protective film, so dissolved oxygen is blocked from diffusion to the metal surface; meanwhile, a compact passivation antirust film is generated through oxidation reduction reaction of the corrosion scale inhibitor with the metal surface, so metal oxidation is inhibited; moreover, the industrial secondary refrigerant provided by the invention also selects and uses the glycol alkyl ether or propylene glycol alkyl ether compounds with low viscosity, so effects of cold carrying and heat exchanging are guaranteed. The industrial secondary refrigerant in the invention is suitable for being used as the secondary refrigerant applied in industry under minus 80 to 200 DEG C, and an indirect heat transfer system in chemical industrial production and medicinal synthesis process. The secondary refrigerant is non-toxic and harmless, has excellent and safe heat transfer property and good fluidity at low temperature, does not precipitate and scale, and has the characteristics of environmental protection, cold carrying, heat transfer, corrosion inhibition, bacterial inhibition, low viscosity, corrosion resistance, etc.

Owner:CHAOYANG GUANGDA CHEM

Preparation method of high capacity rare earth magnesium base hydrogen storage alloy

The invention relates to high volume rare earth magnesium group hydrogen storage alloy manufacturing method. It features are adding raw material and its 0.1-20% protective cover into intermediate frequency furnace; pumping vacuum degree to less than 10-1pa; inputting argon or nitrogen to 0.03-0.1MPa; melting; keeping for 3-30 minutes after full melting; cooling alloy solution to gain alloy pig or alloy piece with thickness 0.05-1mm; doing heat preservation heat treatment for 2-24h at 700-1150 centigrade degree; cooling to room temperature; crushing to 100-300 order rare earth magnesium group hydrogen storage alloy. The AB3 type rare earth magnesium group hydrogen storage alloy has high volume, good cycle performance, and good sucking-discharging hydrogen performance. The cost is low. The technique is simple; process is easy to control; and it is adapted to large-scale industrial production.

Owner:GUANGDONG INST OF RARE METALS

Preparation method of nano silicon dioxide/ hydroxyl silane coupling agent composite modified polyurethane super-hydrophobic membrane

PendingCN113248755AIncrease the degree of cross-linkingFavor molecular weightPolyurethane membraneCyanate ester

The invention discloses a preparation method of a nano-silica / hydroxysilane coupling agent composite modified polyurethane super-hydrophobic membrane. The nano-silica / hydroxysilane coupling agent composite modified polyurethane super-hydrophobic membrane is prepared from the following main raw materials: polyol, isocyanate, a catalyst, a hydrophilic chain extender, a neutralizer, a micromolecule chain extender, a silane coupling agent, nano-silica, deionized water and a post-chain extender. According to the invention, a synthesized polyurethane system is modified by introducing nano silicon dioxide particles modified by a hydroxyl silane coupling agent. A hydroxyl group of the hydroxyl silane coupling agent can chemically react with an isocyanate group of a waterborne polyurethane system, and silane is introduced to modify the hydrophobicity of the polyurethane membrane from the chemical aspect. The hydrophobicity of the polyurethane membrane is modified from the physical aspect by a micro-nano structure formed after the membrane is formed by the nano silicon dioxide particles treated by the hydroxyl silane coupling agent. The water contact angle of the prepared polyurethane super-hydrophobic membrane can reach 145-155 degrees, the rolling angle is 5-7 degrees, and the application field of the polyurethane membrane is widened.

Owner:CHANGCHUN UNIV OF TECH

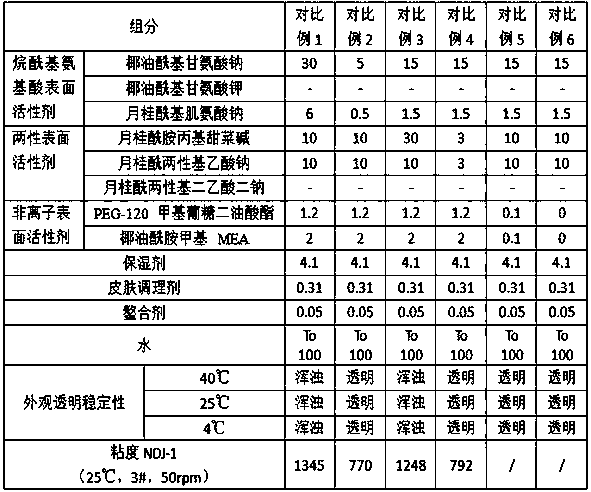

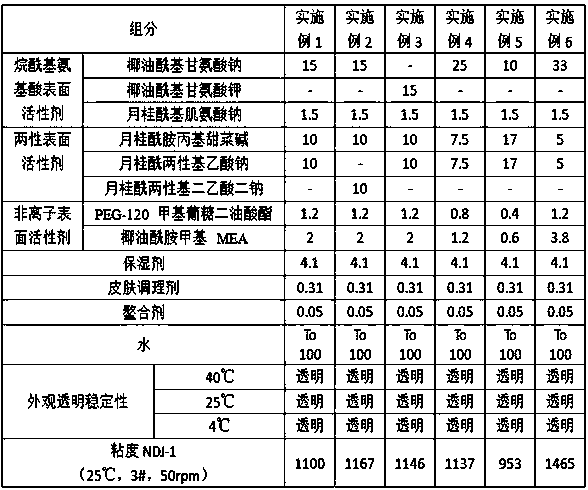

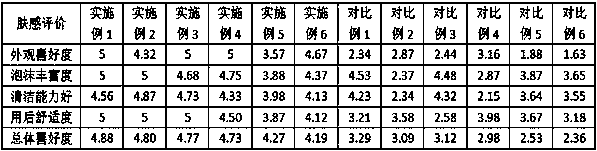

Cleansing gel and preparation method thereof

ActiveCN108653168AAppearance is clear and transparentWith viscosityCosmetic preparationsToilet preparationsN acylaminoacidIrritation

The invention discloses cleansing gel. The cleansing gel is prepared from the following components in parts by weight: 10-35 parts of an alkyl acyl amino acid surfactant, 10-35 parts of an ampholyticsurfactant and 1-5 parts of a nonionic surfactant. According to the cleansing gel, the non-ionic surfactant with the specific content is added to the alkyl acyl amino acid surfactant with the specificcontent and the ampholytic surfactant with the specific content, and by virtue of the synergistic interaction of the components, the prepared cleansing gel is clear and transparent in appearance, hascertain viscosity, is good in stability, is fine and exquisite in foam, has good cleaning capability, does not cause skin allergy and irritation, gives comfortable and non-tight feelings to consumersafter being used, is convenient to use, can well meet the quality pursuit of the consumers on the appearance, can effectively clean the skin and can meet the mild and inirritative requirements. The preparation technology is simple, the implementation is easy and large-scale production can be realized.

Owner:HUAANTANG BIOTECH GRP CO LTD

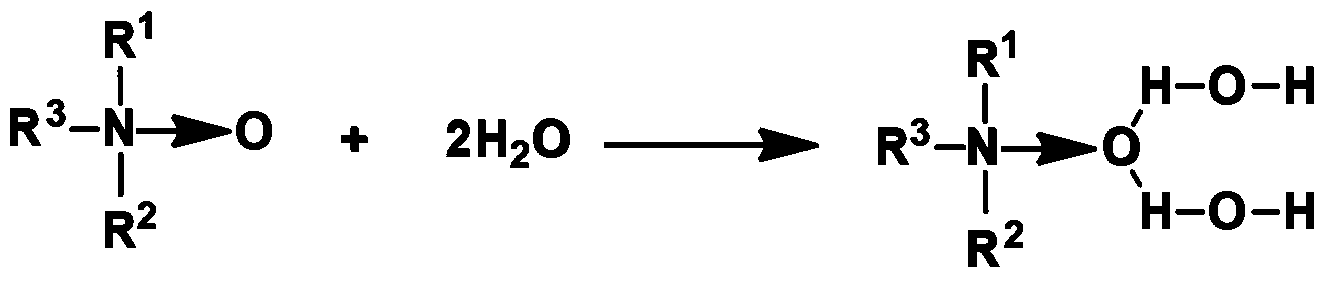

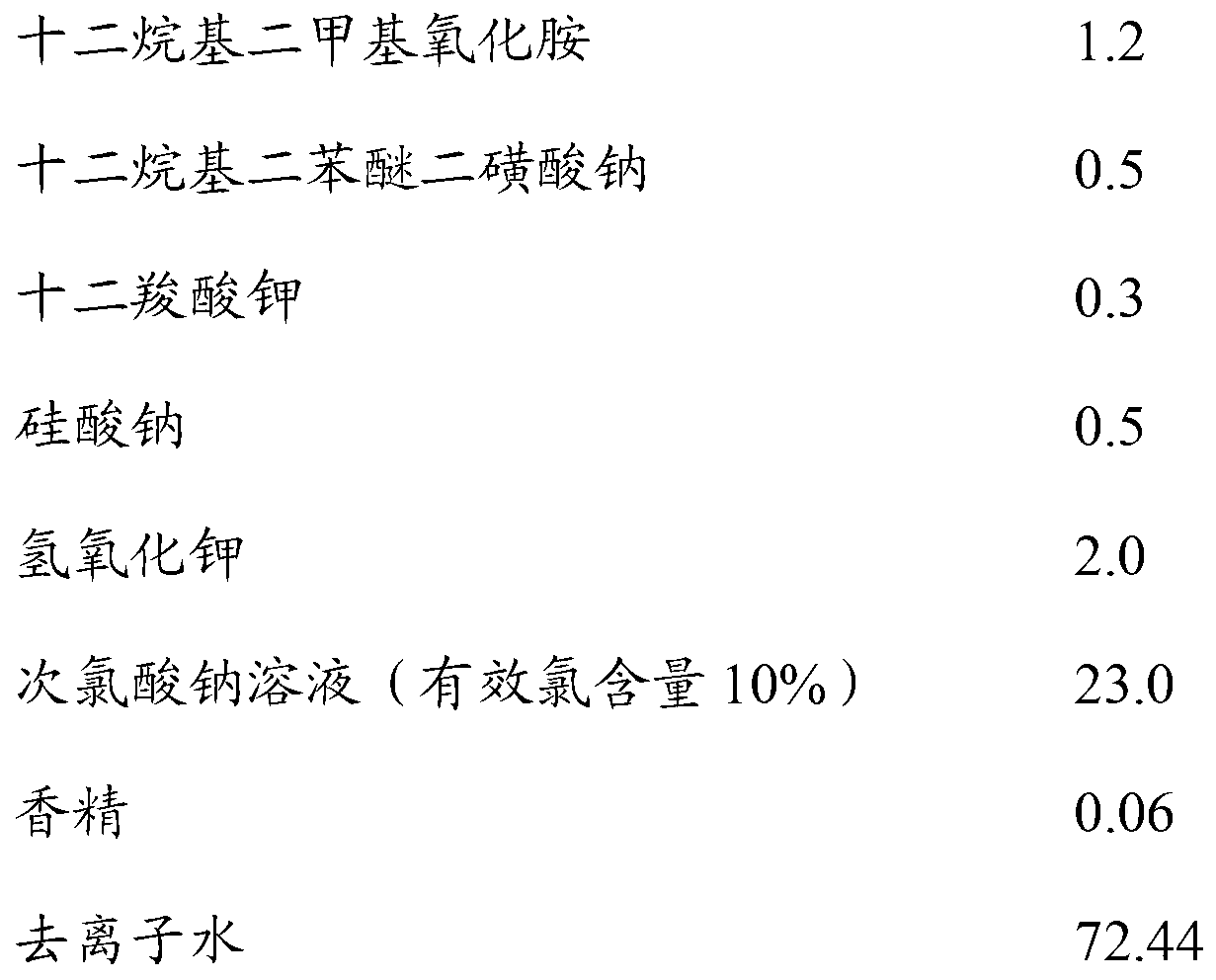

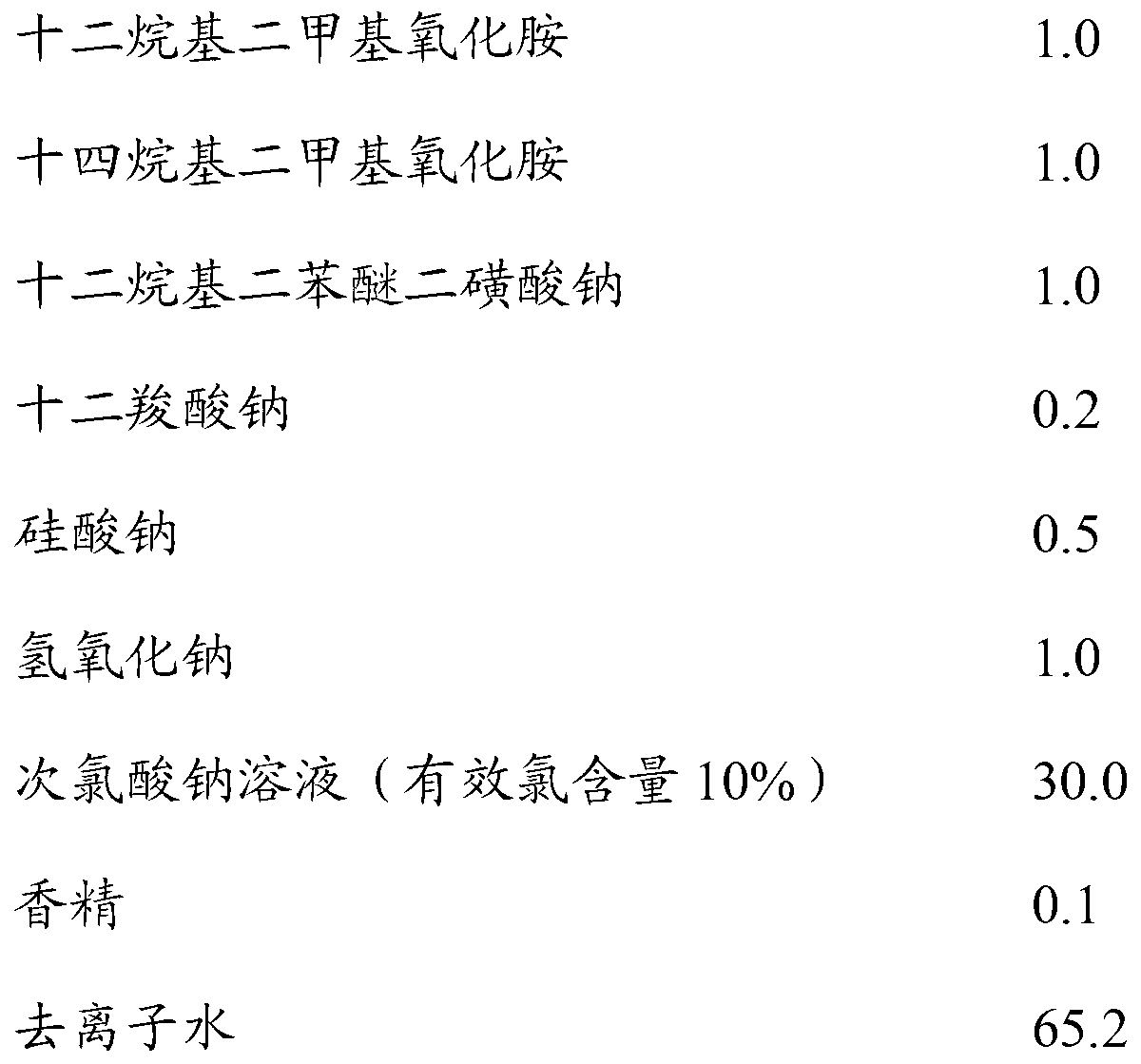

Liquid-state pipeline dredging agent

ActiveCN103289840AWith viscosityImprove wall hanging effectBiocideSurface-active non-soap compounds and soap mixture detergentsChemistrySodium silicate

The invention discloses a liquid-state pipeline dredging agent. The dredging agent comprises the following components in percent by mass: pypocholoride, 0.05-5 percent of alkali metal hydroxides, 0.01-5 percent of sodium silicate, 0.05-10 percent of alkyl amine oxide, 0.05-10 percent of alkyldiphenyloxide disulfonates, 0.05-5 percent of fatty-acid soap, 0.05-0.5 percent of essence and the balance of deionized water, wherein available chlorine in the pypocholoride accounts for 0.1-8 percent. The disclosed liquid-state pipeline dredging agent has a certain viscosity, the wall built-up performance of the dredging agent is improved, and the acting time of the dredging agent and the blocking substances is prolonged for the slightly blocked or incompletely blocked pipeline; the liquid-state pipeline dredging agent does not contain aluminum skimmings, percarbonate, carbonate and other gas production compounds, and the danger caused by heat and gases generated by the sharp reaction is avoided; the liquid-state pipeline dredging agent is simple in preparation process, has no influence on the personnel and environment and is low in cost, convenient to use, safe and high-efficiency; and the liquid-state pipeline dredging agent can serve as a hard surface cleaning agent or bactericide.

Owner:WALCH GUANGZHOU COMMODITY

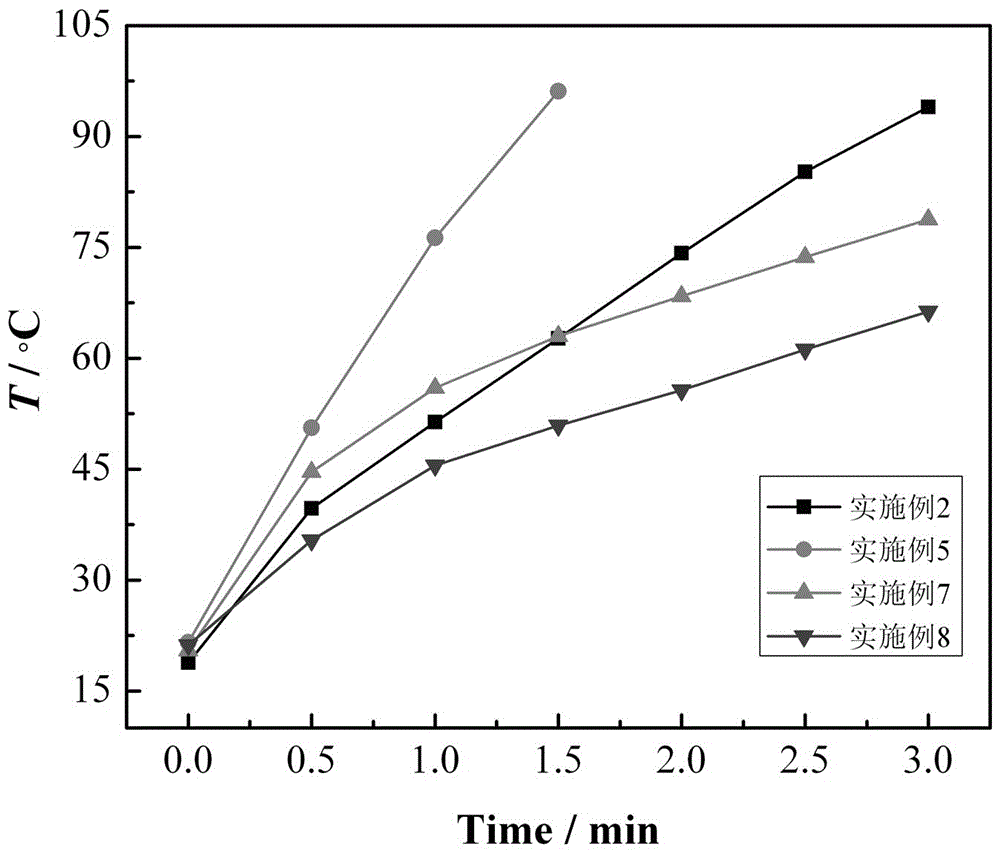

Composite electric heating paint for flexible base material as well as preparation method and use thereof

ActiveCN105754462AExcellent electric heating performanceImprove oxidation resistancePolyurea/polyurethane coatingsEpoxy resin coatingsDaily livingMaterials science

The invention provides composite electric heating paint for a flexible base material as well as a preparation method and a use thereof. Organic or inorganic resin is used as a binder, and the composite material is added into various auxiliaries as conductive filler. The composite electric heating paint consists of the following components in parts by weight: 1-100 parts of composite conductive filler, 1-200 parts of a high molecular resin binder, 1-50 parts of auxiliaries and 100-300 parts of a solvent. The composite electric heating material can be quickly heated within 3-5 minutes, namely the heating rate is higher than the heating rate of the existing similar electric heating paint; the electric heating paint is suitable for being applied in a low-temperature heating field within 0-100 DEG C, is especially suitable for being applied to agricultural, military and industrial production as well as heating, warming and the like in daily life, and can be used for biological breeding, hatching electric-heating insulating chamber and the like in agriculture.

Owner:SHENYANG AEROSPACE XINGUANG GRP

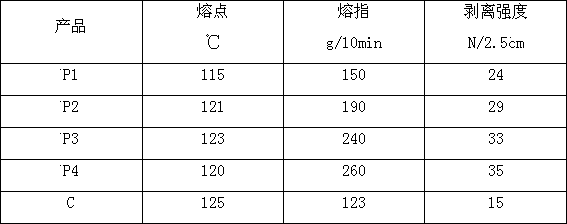

Preparation method of amino inhibited polyamide hot melt adhesive

The invention discloses a preparation method of an amino inhibited polyamide hot melt adhesive. The method is characterized by taking a monoamine as a chain terminator, and preparing copolyamide hot melt adhesive from a diacid, a diamine, a nylon salt and lactam. The obtained product has the characteristics of low viscosity, easy coating, and high bonding strength.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

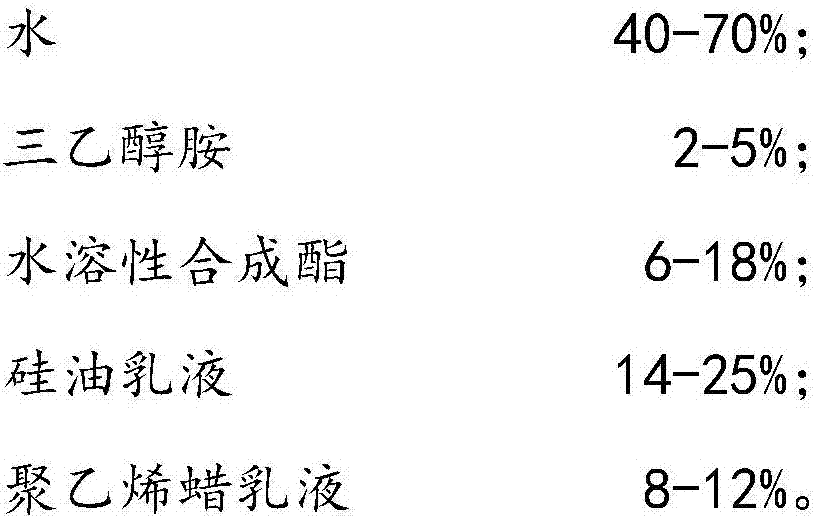

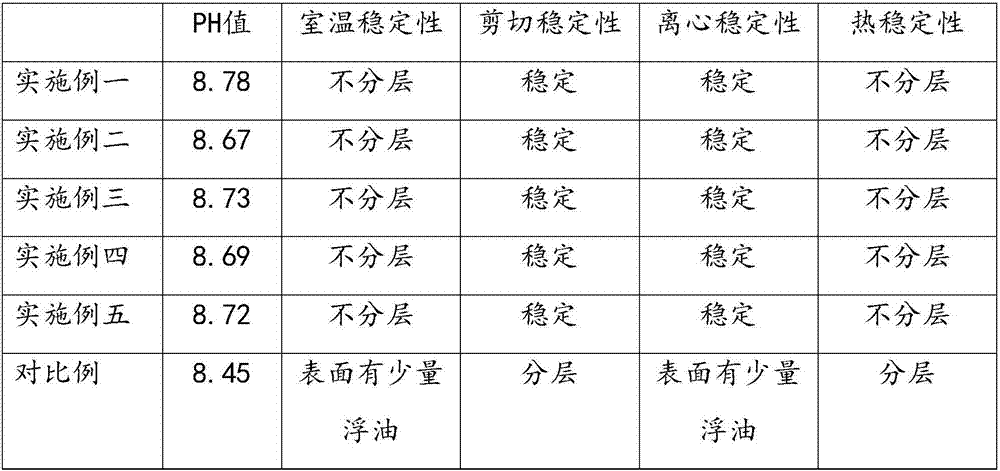

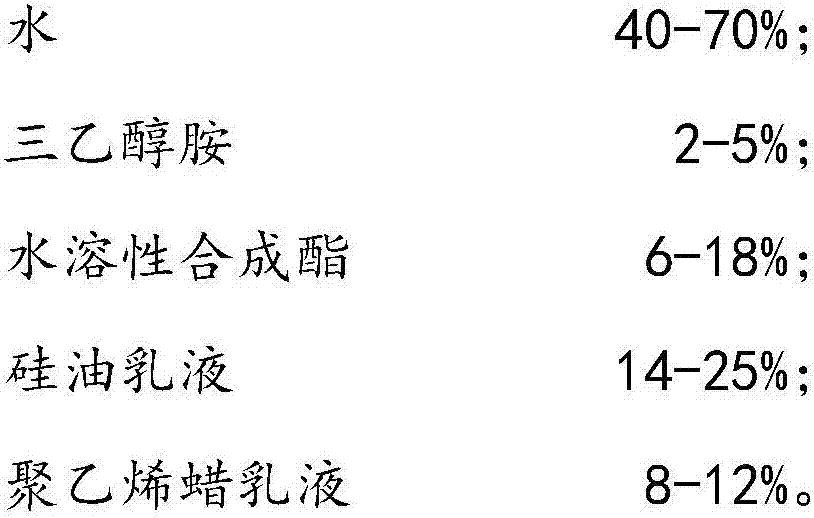

Aluminum alloy water-based die-casting releasing agent and preparation method thereof

ActiveCN107384562AShorten the development cycleDecrease stockFoundry mouldsFoundry coresDispersityWater based

The invention provides an aluminum alloy water-based die-casting releasing agent. The aluminum alloy water-based die-casting releasing agent is prepared from the following components in percentage by weight: 40 to 70 percent of water, 2 to 5 percent of triethanolamine, 6 to 18 percent of water soluble synthetic ester, 14 to 25 percent of silicone emulsion and 8 to 12 percent of polyethylene wax emulsion. The invention also provides a preparation method of the aluminum alloy water-based die-casting releasing agent. The finished emulsion provided by the invention has the advantages of white color, uniformity, delicateness and no layering in centrifuging and standing; meanwhile, the aluminum alloy water-based die-casting releasing agent has good dispersity in water and is mixed with a small amount of ammonia and aqueous solution to rapidly form stable white emulsion; the white emulsion and other components of the releasing agent can form a stable balance system which is easy to blend.

Owner:富兰克润滑科技(太仓)有限公司

Preparation method of potassium gold citrate for gold plating

The invention discloses a preparation method of potassium gold citrate for gold plating, which basically solves the problems that the product prepared by the existing preparation method has poor uniformity and is easy to segregate and agglomerate in the processes of transportation and preservation. The preparation method is technically characterized by comprising the following preparation processes of: adding powdered potassium gold cyanide, water and powdered acidic potassium citrate into mixing equipment and uniformly mixing, wherein the weight ratio of the water to the acidic potassium citrate is (0.01-0.12):1; sieving the mixture with a 10-mesh sieve; drying the sieved mixture; and sieving the dried mixture with a 20-mesh sieve. The optimal weight ratio of the water to the acidic potassium citrate is (0.06-0.08):1. The product prepared by the preparation method disclosed by the invention has good uniformity and can not segregate and agglomerate in the processes of transportation and preservation, and the gold loss is small in the process of preparation.

Owner:张东山

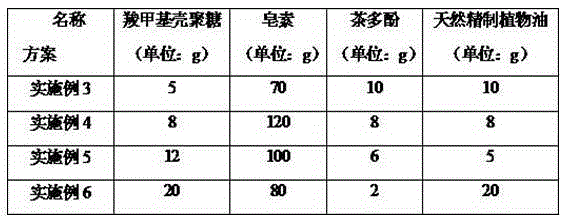

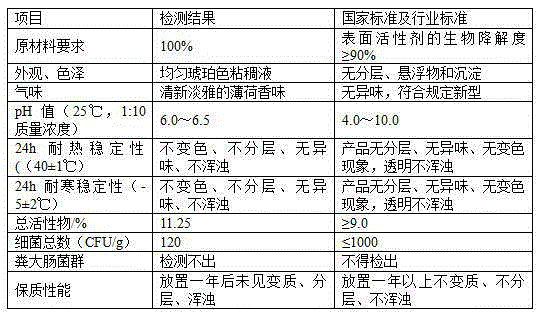

All-natural multifunctional hand sanitizer containing carboxymethyl chitosan and production method thereof

ActiveCN105342932AWith viscosityFull cleaning and decontamination abilityCosmetic preparationsToilet preparationsRoom temperatureHand sanitizer

The invention discloses an all-natural multifunctional hand sanitizer containing carboxymethyl chitosan and a production method thereof and relates to the technical field of washing products. Carboxymethyl chitosan is completely dissolved in deionized water firstly, then saponin and tea polyphenol are added, even stirring is conducted, pH is regulated to be 6.0-6.5 with a lemon juice solution after the mixture system is cooled to room temperature, color modulation is conducted with natural pigment, viscosity regulation is conducted with a sodium chloride solution, and then homogenizing, degassing and subpackaging are conducted. According to the method, technological requirements are low, preparation is easy and environmentally friendly, product stability is high, and the functions of decontamination, sterilization and skin moisturizing and care are realized.

Owner:NANJING WILD PANT COMPREHENSIVE UTILIZATION INST THE ALL CHINA SUPPLY & MARKETING COOPERATIV +1

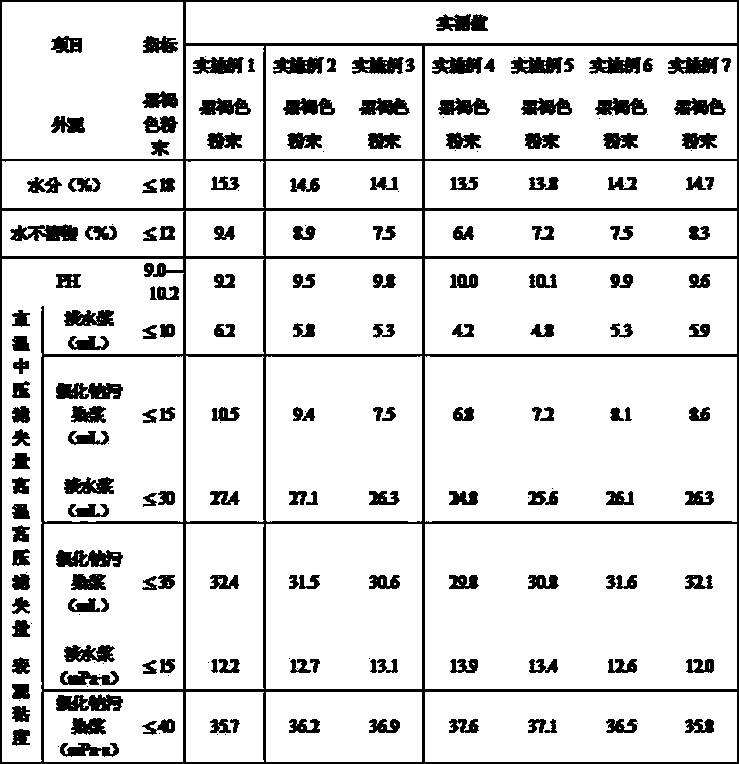

Brown coal resin for drilling fluid and production technology of brown coal resin

InactiveCN108018028AImprove salt resistanceImprove high temperature resistanceDrilling compositionFiltrationSlurry

The invention discloses brown coal resin for a drilling fluid and a production technology of the brown coal resin. Brown coal and sulfonated phenolic resin are used as main materials, sulfonated phenol humic acid with excellent salt resistance and high-temperature resistance is introduced, and the brown coal resin has remarkable high-temperature-resistant, filtration loss reduction and salt-resistant performance after being modified with a basifier and a sulfonating agent and has anti-collapse and viscosity control effects. A small amount of carboxymethyl cellulose is added, and the carboxymethyl cellulose has excellent stability and still has significant performance at 150 DEG C or above; meanwhile, trimethylamine and sulfomethyl sodium humate with excellent temperature resistance, salt resistance and calcium and magnesium ion resistance are introduced, the adsorption capacity of sulfonated phenolic resin and clay is enhanced, the temperature resistance and the salt resistance of theproduct are effectively improved, the value of the product is increased, the addition amount is small, the filtration loss reduction effect is significant, and excellent filtration loss reduction performance can be produced after only 1.0% of base slurry is added.

Owner:YUMEN OIL FIELD KEDA CHEM

Production method of biomass industrial cushion packaging product

The invention discloses a production method of a biomass industrial cushion packaging product. The method is characterized by including the following technological steps: adding straw fiber, starch and auxiliary modifier into the respective processing device; introducing straw fiber and auxiliary modifier into a same device and mixing; introducing starch into a gelatinization container; adding hot water and stirring into a slurry starch paste; introducing the starch paste into the device containing the straw fiber and the auxiliary modifier; and stirring uniformly and conveying to a wet material storage bin for a next production process. The method can greatly reduce the cost of raw materials; and the full biomass synthetic ingredient can be used in production of a magnetic soft iron element transfer pallet packaging product, which has excellent performance, reliable degradation, low cost, and extremely broad industrial promotion value.

Owner:山东九发生物降解工程有限公司

Miao embroidered garment and making method thereof

ActiveCN107385718AEasy to prepareEasy to operateFibre treatmentEmbroidering machines apparatusWaxEthylenediamine tetraacetate

The invention relates to a Miao embroidered garment and a making method thereof, belonging to the field of clothing. The making method comprises the following steps: using an embroidery thread wrapped with a wax layer to embroider patterns on the surface of an embroidery material with patterns so as to obtain a primary embroidery product; coating the primary embroidery product with a color fixative, tidying and ironing to obtain an embroidery product; sewing the embroidery product. The color fixative is prepared from 2-3 parts by weight of acetic acid, 0.4-0.7 part by weight of trimethylamine, 0.05-0.1 part by weight of disodium ethylenediamine tetraacetate, 0.5-1 part by weight of potassium lignosulfonate, 0.4-0.6 part by weight of sodium oleate, 1.5-1.7 parts by weight of polyethylene glycol and 0.06-0.08 part by weight of ethylene propylene diene monomer. The making method is simple and easy to operate. The Miao embroidered garment made by the method is high in wear resistance, does not easily fade, and is better in whole texture.

Owner:贵州凯里经济开发区鑫田民族服饰工艺品发展有限公司

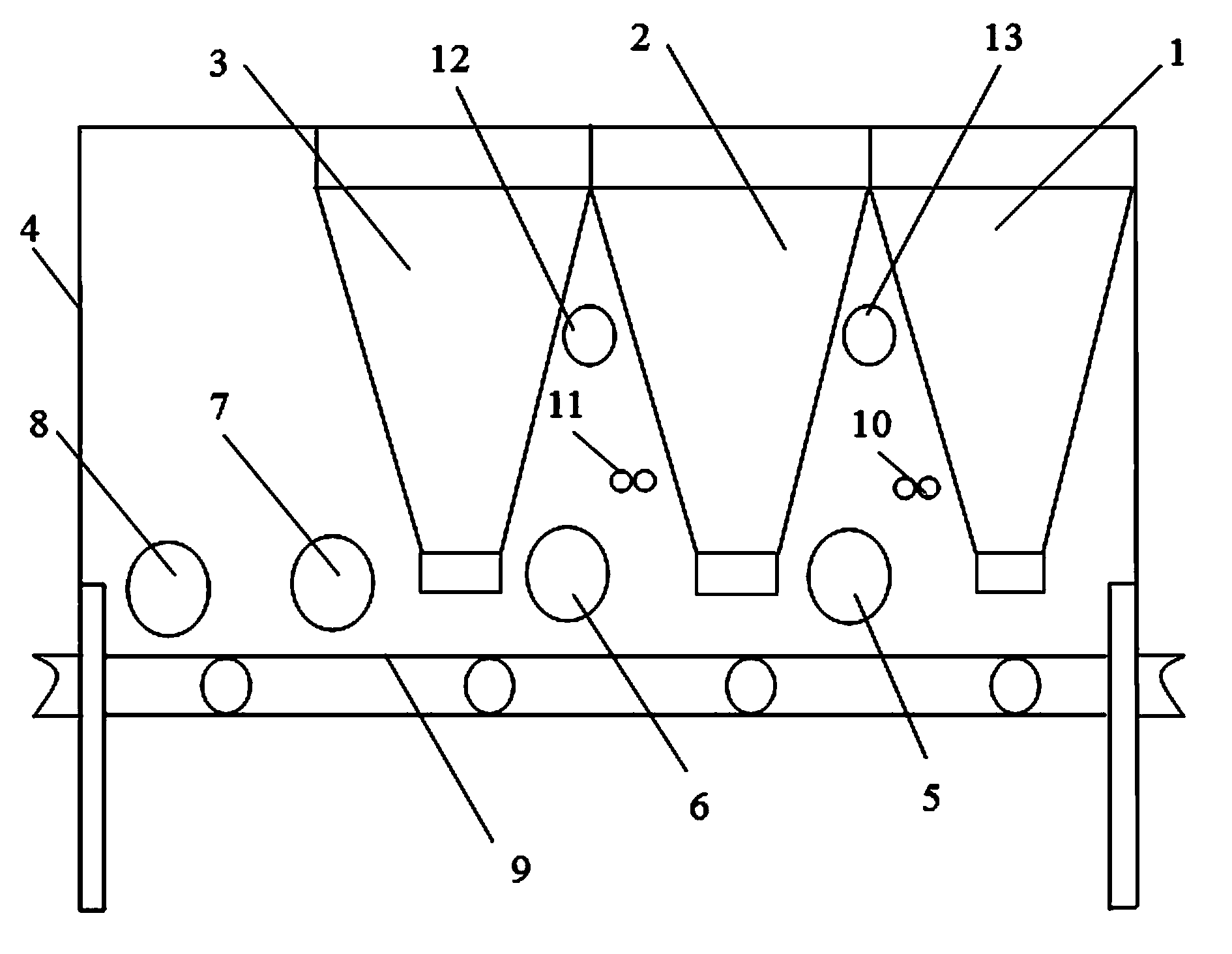

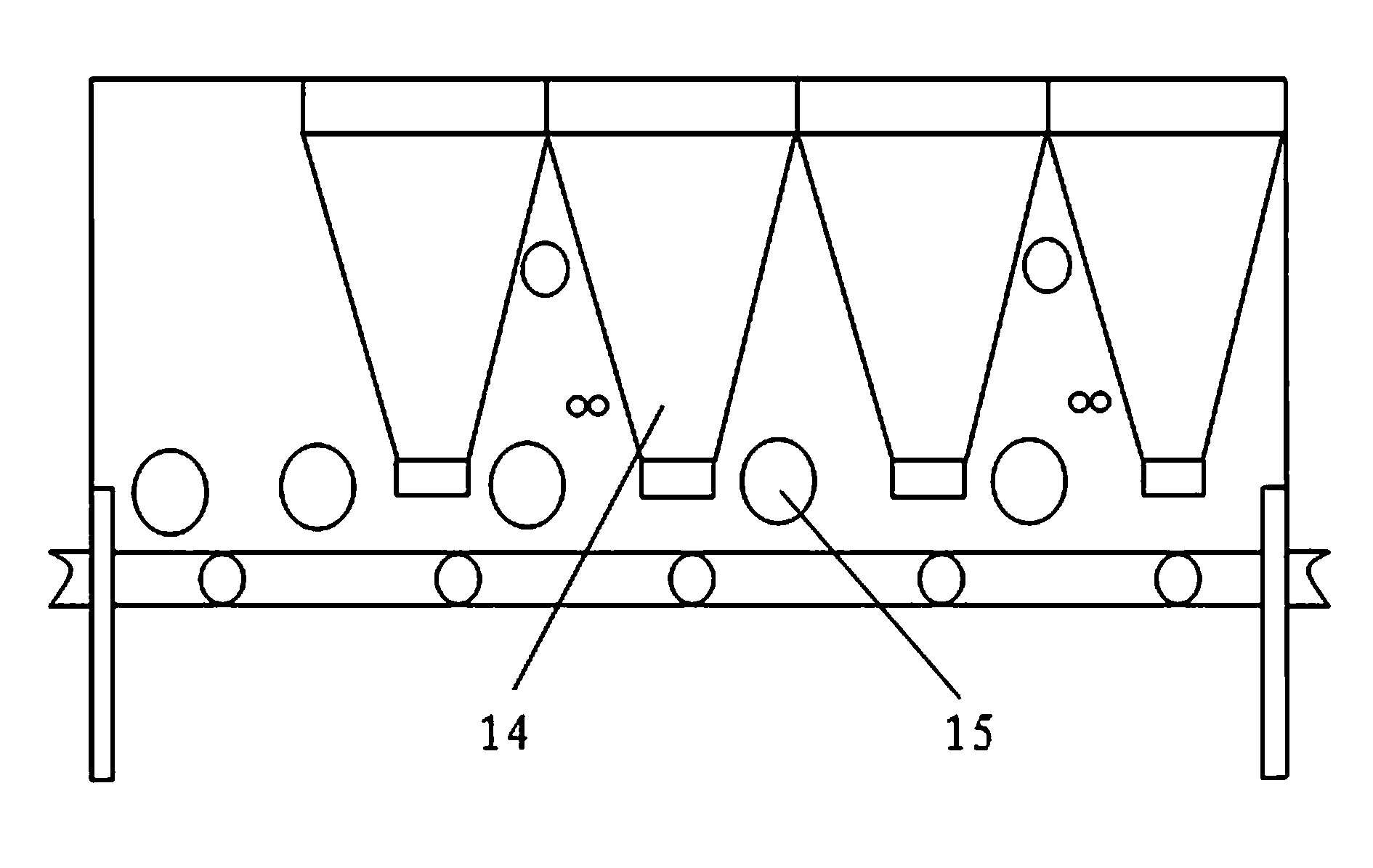

Plate putting machine for fireproof plate production line

InactiveCN104097250ARealize streamlined productionImprove product qualityPress rollersFeeding arrangmentsProduction lineEngineering

The invention relates to a plate putting machine for a fireproof plate production line. Hoppers and compression roller shafts are arranged above a material row conveyer belt, and the hoppers and shaft seats of the compression roller shafts are fixed to a frame. The plate putting machine is characterized in that a first hopper, a second hopper and a third hopper are sequentially arranged from front to back along the running direction of the material row conveyer belt; a first compression roller shaft is arranged between the first hopper and the second hopper; a second compression roller shaft is arranged between the second hopper and the third hopper; a third compression roller shaft is arranged on the rear side of the third hopper; the first compression roller shaft, the second compression roller shaft and the third compression roller shaft correspond to a first layer, a second layer and a third layer of a to-be-processed fireproof plate.

Owner:BEIJING WEIZHONG TECH DEV

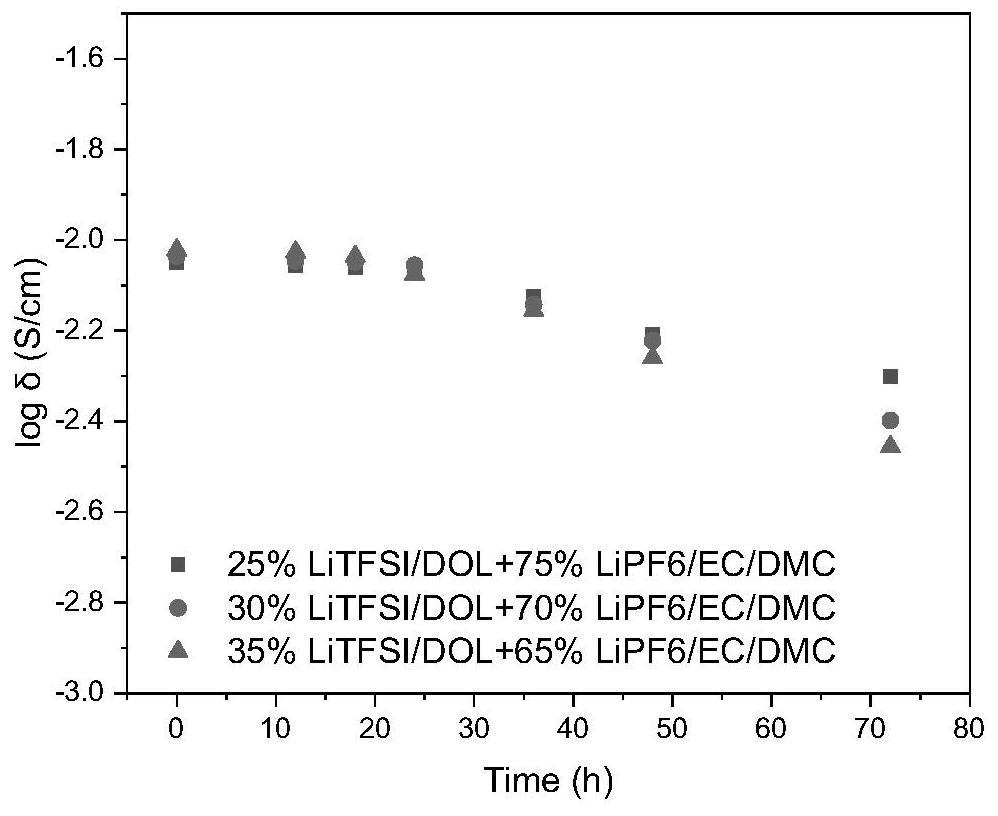

Preparation method of gel polymer electrolyte

ActiveCN111653825AHigh room temperature ionic conductivityWith viscosityFinal product manufactureElectrolyte accumulators manufacturePolymer electrolytesEpoxy

The invention relates to a preparation method of a gel polymer electrolyte. The method comprises the following steps: mixing an electrolyte solvent, a polymerizable solvent monomer and an electrolytelithium salt to obtain an electrolyte composition; and adding cationic ions containing Li<+>, Al<3+>, Ga<3+> and In<3+> and anionic combinations of PF6<->, BF4<->, Cl<->, Br<->, I<-> and CF3SO3<-> orinitiators of BF3 compounds into the electrolyte composition, and polymerizing to generate the gel polymer electrolyte. The preparation method has the following beneficial effects: the epoxy ether monomer is self-polymerized, and the electrolyte is wrapped in the epoxy ether polymer to obtain the gel polymer electrolyte, so that the obtained gel polymer electrolyte has certain viscosity and relatively high room-temperature ionic conductivity.

Owner:武汉瑞科美新能源有限责任公司

Perovskite ink for electrofluid ink-jet printing multi-color light-emitting display and preparation method of perovskite ink

The invention belongs to the technical field of light-emitting display, and discloses perovskite ink for electrofluid ink-jet printing multi-color light-emitting display and a preparation method of perovskite ink. The preparation method comprises the following steps: (1) weighing cesium salt CsX and lead salt PbX2 according to a nominal chemical dose ratio of perovskite CsPbX3, and dissolving thecesium salt CsX and the lead salt PbX2 into a solvent to obtain a perovskite solution, wherein X is one or a mixture of any two of Cl, Br and I, the solvent comprises a high-boiling-point organic solvent of which the boiling point is greater than 180 DEG C; and (2) adding an organic matter into the perovskite solution to adjust the surface tension and viscosity of the solution to obtain the perovskite ink for electrofluid ink-jet printing. By improving the composition of the ink, the composition and proportion of each raw material and reagent adopted by the corresponding preparation method andthe like, the prepared perovskite ink for electrofluid ink-jet printing can meet the requirements of electrofluid ink-jet printing, and can be used for realizing an electrofluid ink-jet printing modeof a perovskite light-emitting display layer.

Owner:HUAZHONG UNIV OF SCI & TECH

Photoluminescent coating material composition

ActiveCN106164192AWith viscosityHas viscosity propertiesSpecial surfacesPolyester coatingsChemical compositionSolid content

This photoluminescent coating material composition is characterized by containing, in terms of solid content ratio based on the total of the resin solid contents of components (A), (B) and (C), said total being taken as 100% by mass, 10-90% by mass of a hydroxyl group-containing resin (A), 5-50% by mass of a curing agent (B), 1-40% by mass of a nonaqueous dispersion resin (C), 1-20% by mass of a basic pigment (D) and 1-30% by mass of a photoluminescent pigment (E). This photoluminescent coating material composition is also characterized in that: the nonaqueous dispersion resin (C) has a structure that has a core portion and a shell portion; and the shell portion of the nonaqueous dispersion resin (C) contains 0.05-5.0% by mass of a sulfonic acid group-containing polymerizable unsaturated monomer based on the total amount of polymerizable unsaturated monomer components that constitute the nonaqueous dispersion resin (C).

Owner:KANSAI PAINT CO LTD

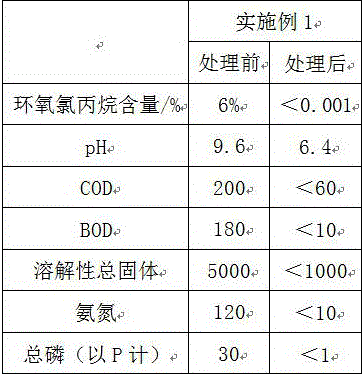

Method for recycling epoxy chloropropane in epoxy chloropropane wastewater and treating wastewater

InactiveCN106007092AReduce solubilityReduce processing costsOrganic chemistryOther chemical processesSolubilityEpoxy

The invention relates to a method for recovering epichlorohydrin from epichlorohydrin wastewater and treating the wastewater. The method includes the following main steps: preparing a pretreatment solution, standing and stratifying the wastewater, adsorbing the wastewater by activated carbon, and treating the wastewater by a membrane module. The pretreatment solution is prepared by reacting sodium chloride and epichlorohydrin wastewater, and the activated carbon is prepared by reacting bamboo charcoal, oxalic acid urea, water, polyurethane resin, ethanol, and N,N-dimethylformamide. The advantage of the present invention is that the solubility of epichlorohydrin in the saturated aqueous sodium chloride solution is small, and separation and purification can be obtained by standing for stratification. It not only solves the problems of high recovery cost and high energy consumption of epichlorohydrin, but also solves the problem of up-to-standard discharge or even zero discharge of waste water. At the same time, the by-product sodium chloride is rationally used, which improves the economic benefits of the enterprise. The method is easy to operate, the activated carbon can be reused, the recovery rate of epichlorohydrin is high, and the waste water can reach the standard of reused water.

Owner:郑巧丹

Novel JQ well killing protection liquid

InactiveCN103173199AGood liquid productionImprove the effect of increasing oilDrilling compositionWell killActive agent

The invention relates to a novel JQ well killing protection liquid for oilfields. The novel JQ well killing protection liquid solves a problem that the measure oil increase effect is reduced because a fractured string is tripped out when a pressure decreases to a certain value (1.5MPa generally) after a ternary composite oil flooding well is fractured. The novel JQ well killing protection liquid is characterized in that the novel JQ well killing protection liquid comprises 10-45% by mass of sodium nitrate, 2% by mass of zinc nitrate, 0.3-0.4% by mass of a polymer, 50.6-86.7% by mass of a surfactant and 1-2% by mass of nitrilotriacetic acid. The well killing protection liquid is a solid-phase-free well killing liquid, can be used for the well killing work under a high pressure, can improve the measure oil increase effect, has the advantages of good compatibleness with a ternary liquid, stable foam, easy preparation, and cheap and easily available raw materials, and has clay expansion prevention and oil reservoir protection effects.

Owner:李瑞清

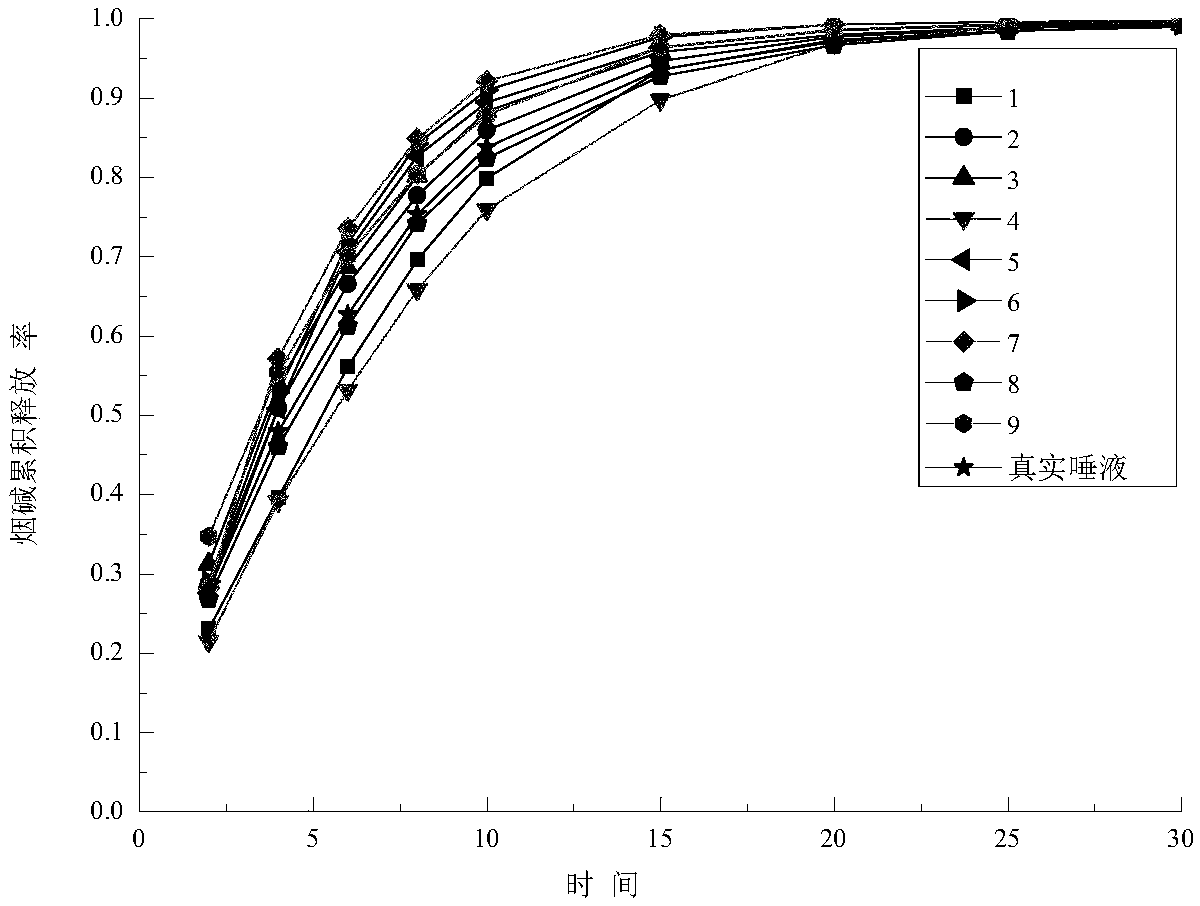

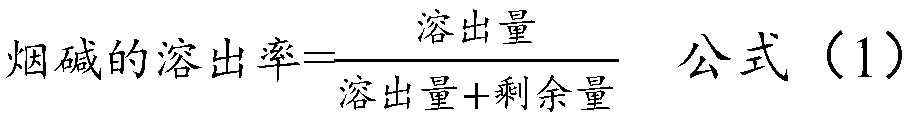

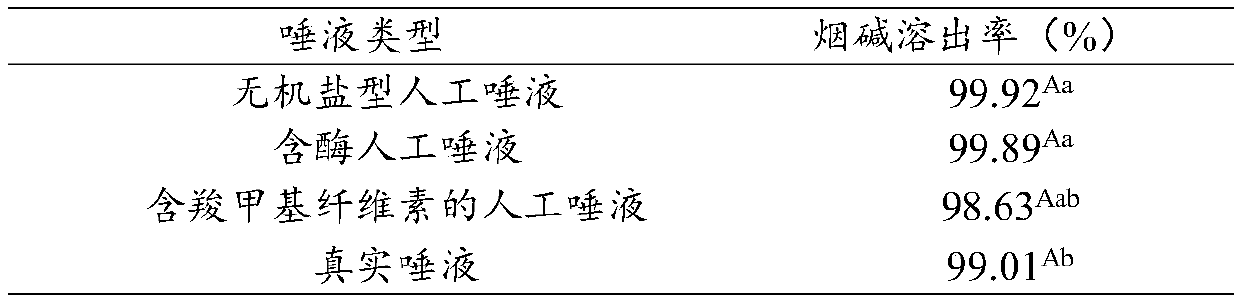

Artificial saliva for oral tobacco research and preparation method and application thereof

InactiveCN109596778AImprove stabilityWith viscosityTobacco treatmentMaterial analysisMedicineArtificial salivas

The invention provides artificial saliva for an oral tobacco research and a preparation method thereof, and belongs to the technical field of artificial saliva preparation. The artificial saliva of the invention is prepared from an aqueous solution comprising the following mass concentration components: NaCl 0.392~0.408g / L, KCl 0.392~0.408g / L, CaCl2.2H2O 0.7791~0.8109g / L, NaH2PO4.2H2O 0.7644~0.7956g / L, Na2S.2H2O 0.0049~0.0051g / L, urea 0.98~1.02g / L, carboxymethylcellulose 2.94~3.06g / L, wherein the artificial saliva has a pH of 7.0. The nicotine detection of the oral tobacco form the artificialsaliva of the invention is similar to the artificial saliva. The artificial saliva has good stability and a certain viscosity. The formula has a small variety of ingredients and is a common compound,and has a low cost.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Tamponade liquid for well completion and cementation and preparation method thereof

ActiveCN105331342AImprove stabilityWith viscosityDrilling compositionCelluloseCarboxymethyl cellulose

The invention relates to the technical field of tamponade liquid for well completion and cementation, in particular to tamponade liquid for well completion and cementation and a preparation method thereof. The tamponade liquid for well completion and cementation is prepared from, by weight, 1.0-3.0 parts of carboxymethylcellulose, 0.5-1.5 parts of sulfonated tannin, 0.5-1.0 part of xanthan gum, 0.2-0.5 part of sodium gluconate, 0.3-0.6 part of tartaric acid and 100 parts of water. The tamponade liquid for well completion and cementation is good in stability at the high temperature of 80 DEG C to 120 DEG C, and has certain viscosity and shearing force, meanwhile, the phenomenon of high-temperature viscosity reduction or high-temperature thickening is avoided in the well cementation coagulating waiting process, an electrical logging cannot meet resistance, and the solid phase suspension need of drilling fluid with barite as main weighting materials on site can be met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Embroidery product and making method thereof

ActiveCN107227615AEasy to prepareEasy to operateLiquid repellent fibresAbrasion resistant fibresPotassiumPolyethylene glycol

The invention relates to an embroidery product and a making method thereof, and belongs to the field of embroidering. The making method comprises the following steps: printing a pattern on the surface of embroidered fabric and embroidering the pattern, so as to obtain a preliminary embroidery product; and coating the preliminary embroidery product with a color retention agent and ironing. The color retention agent comprises the following ingredients in parts by weight: 1-2 parts of potassium lignosulphonate, 0.2-0.4 part of sodium oleate, 1.4-1.7 parts of polyethylene glycol and 0.06-0.08 part of ethylene-propylene-diene-terpolymer rubber. The making method is simple and easy in operation and is especially suitable for making embroidered clothes of the Miao nationality. The embroidery product obtained by the making method is clear in the pattern, soft in color, difficult in color fading and comparatively good in overall texture.

Owner:贵州凯里经济开发区鑫田民族服饰工艺品发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com