Aluminum alloy water-based die-casting releasing agent and preparation method thereof

A release agent, aluminum alloy technology, applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of aluminum-magnesium alloy corrosion, unstable emulsion, easy skinning, etc., to improve production efficiency and shorten research and development. Periodic, easy-to-tune effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

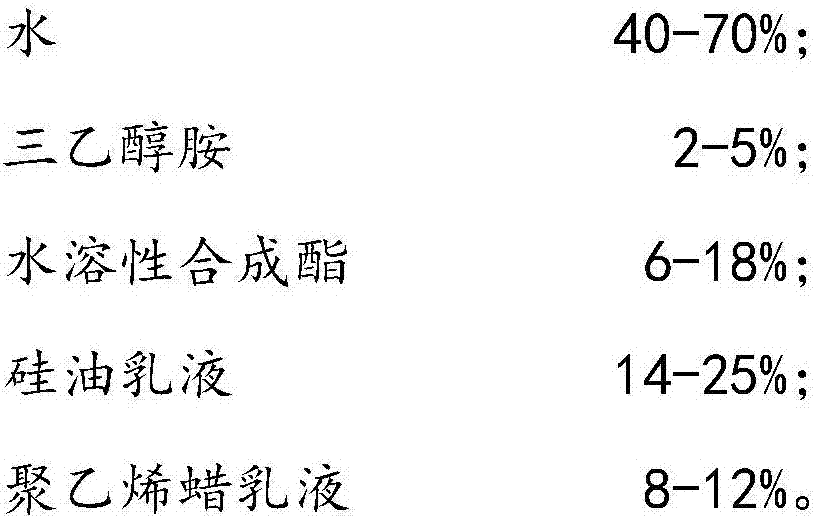

[0025] Add water 40%, triethanolamine 5%, Clariant HOSTAGLISS L4 water-soluble synthetic ester 18%, Momentive silicone oil emulsion 334-50 25%, BASF polyethylene wax emulsion WE-7 12%.

[0026] The preparation method comprises the following steps:

[0027] 1) According to the above ratio, prepare the preparation materials of the aluminum alloy water-based die-casting release agent;

[0028] 2) Add 30% water and triethanolamine into the container, and add water-soluble synthetic ester at a stirring speed of 2000 rpm;

[0029] 3) After continuing to stir for a period of time, add the remaining 70% of water, silicone oil emulsion and polyethylene wax emulsion, and stir evenly at a stirring speed of 750 rpm.

Embodiment 2

[0031] Add water 70%, triethanolamine 2%, Clariant HOSTAGLISS L4 water-soluble synthetic ester 6%, Momentive silicone oil emulsion 334-50 14%, BASF polyethylene wax emulsion WE-7 8%.

[0032] The preparation method comprises the following steps:

[0033] 1) According to the above ratio, prepare the preparation materials of the aluminum alloy water-based die-casting release agent;

[0034] 2) Add 30% water and triethanolamine into the container, and add water-soluble synthetic ester at a stirring speed of 2000 rpm;

[0035] 3) After continuing to stir for a period of time, add the remaining 70% of water, silicone oil emulsion and polyethylene wax emulsion, and stir evenly at a stirring speed of 750 rpm.

Embodiment 3

[0037] Add water 50%, triethanolamine 4%, Clariant HOSTAGLISS L4 water-soluble synthetic ester 15%, Momentive silicone oil emulsion 334-50 22%, BASF polyethylene wax emulsion WE-7 9%.

[0038] The preparation method comprises the following steps:

[0039] 1) According to the above ratio, prepare the preparation materials of the aluminum alloy water-based die-casting release agent;

[0040] 2) Add 30% water and triethanolamine into the container, and add water-soluble synthetic ester at a stirring speed of 2000 rpm;

[0041] 3) After continuing to stir for a period of time, add the remaining 70% of water, silicone oil emulsion and polyethylene wax emulsion, and stir evenly at a stirring speed of 750 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com