Preparation method of gel polymer electrolyte

A gel polymer and electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc. It can solve problems such as electrolyte leakage, low room temperature ionic conductivity, and unsatisfactory practical applications. , to achieve the effect of easy realization, high room temperature ionic conductivity, and simple realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of a gel polymer electrolyte, comprising the steps of:

[0025] S100, mixing a polymerizable solvent monomer with at least one electrolyte solvent and electrolyte lithium salt to obtain an electrolyte composition;

[0026] S200, will contain Li + 、Al 3+ , Ga 3+ 、In 3+ The cation and PF 6- , BF 4- , Cl - 、Br - , I - 、CF 3 SO 3- Anionic combination or BF 3 The initiator of the compound is added to the electrolyte composition to polymerize to form a gel polymer electrolyte.

[0027] As a further optimization of this embodiment, the polymerizable solvent monomer is selected from a monomer containing the following polymerizable functional groups: epoxy group, cyclocarbonate group, unsaturated double bond and other groups.

[0028] The polymerizable solvent monomer is preferably an epoxy ether-containing monomer.

[0029] The polymerizable solvent monomer is further preferably 1,3-dioxolane (DOL) and tetrahydrofuran (THF).

[0030] Wherein t...

Embodiment 1

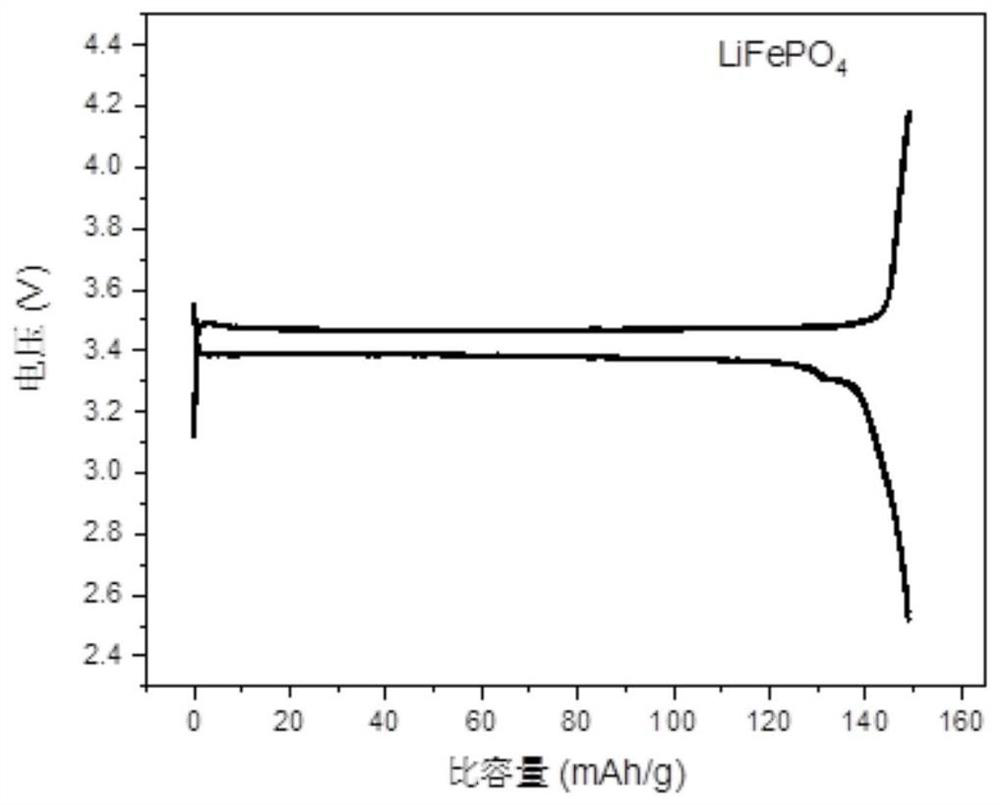

[0039] An embodiment of the present invention provides a method for preparing a gel polymer electrolyte, the method comprising:

[0040] In a glove box filled with argon atmosphere, 8 mmol of lithium trifluoromethanesulfonimide (LiTFSI) was dissolved in 4 mL of 1,3-dioxolane (DOL) to prepare electrolyte A;

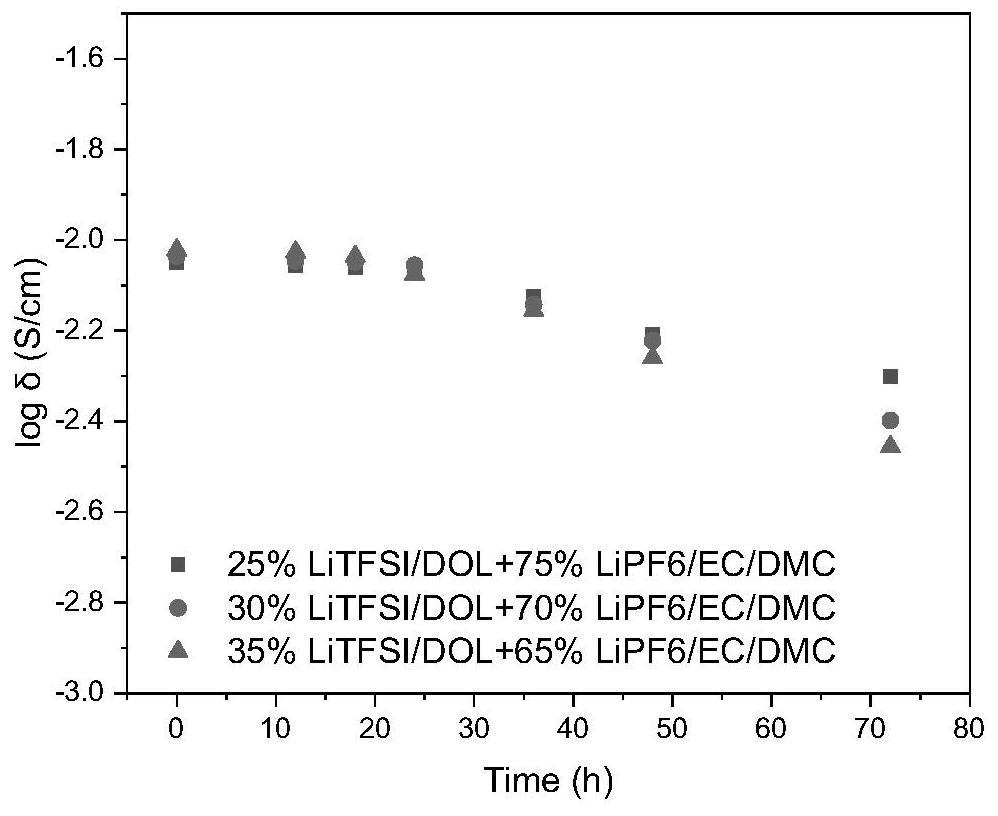

[0041] 4mmol lithium hexafluorophosphate (LiPF 6 ) was dissolved in 4mL of ethylene carbonate (EC): dimethyl carbonate (DMC) = 1:1 (V:V) mixed solvent to prepare electrolyte B, and then electrolyte A and electrolyte B is mixed according to 0.25:0.75 (V:V) to make an electrolyte composition;

[0042] 4mmol of Al(OTf) that can initiate the polymerization reaction 3 Add it into 4mL of electrolyte composition, stir well to make it dissolve evenly, and then start the polymerization reaction. 3 The initiator concentration is 1 mmol / L.

Embodiment 2

[0044]Prepare the gel polymer electrolyte by the same method as in Example 1, except that aluminum trifluoromethanesulfonate (Al(OTf) 3 ) was replaced by boron trifluoride etherate complex (BF 3 ·Et 2 O).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com