Solid-state lithium ion conductor, preparation method and application thereof

A technology of ionic conductors and solid lithium, applied in the direction of non-metallic conductors, oxide conductors, chemical instruments and methods, etc., can solve the problems of low room temperature lithium ion conductivity, metal lithium deposition, large interface contact resistance, etc., to achieve improved cycle Performance, protection of lithium metal, and effect of reducing interface contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of a kind of solid lithium ion conductor of the present invention comprises the following steps:

[0037] (1) dissolving an organolithium salt containing fluorine atoms in an ether organic solvent to obtain an electrolyte;

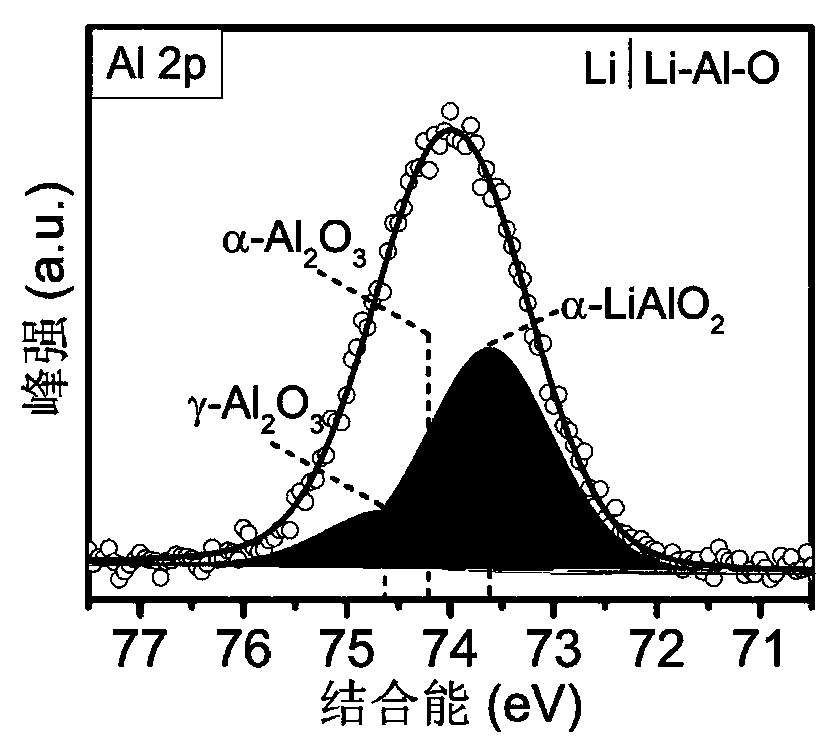

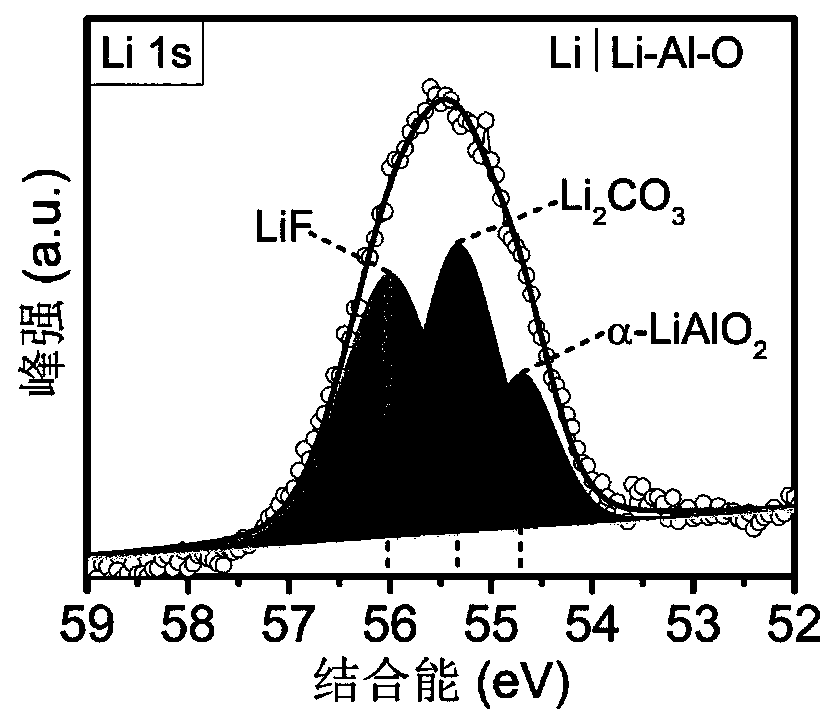

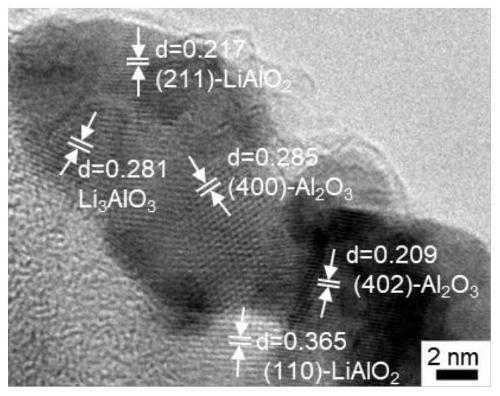

[0038] (2) adding the alkylaluminum solution to the electrolytic solution described in step (1) to obtain a solution; under an inert gas atmosphere, adding LiOH powder to the solution, after sufficient reaction, to obtain a solid lithium ion conductor, The solid lithium ion conductor contains LiAlO 2 and Li 3 AlO 3 polycrystalline composites.

[0039] The organolithium salt containing fluorine atoms described in step (1) is lithium bistrifluoromethanesulfonimide, lithium bisfluorosulfonimide or lithium hexafluorophosphate, and the ether organic solvent is diglyme solution or Tetraethylene glycol dimethyl ether, the concentration of the electrolyte is 0.5mol / L-5mol / L; the aluminum alkyl in step (2) is triethylaluminum or tr...

Embodiment 1

[0054] The preparation method of the solid-state lithium ion conductor is as follows: In this embodiment, a glove box is used as the atmosphere environment, and 2.87 g of bistrifluoromethanesulfonylimide lithium salt is dissolved in 10 mL of diethylene glycol dimethyl ether electrolyte, and stirred at room temperature for 12 h After that, get 1.0molL -1 of electrolyte. Then add 0.05-2 mL of triethylaluminum solution with a concentration of 1 mol / L to the above electrolytic solution and stir for 6 hours to obtain solution A. The concentration of alkylaluminum in solution A is 5-200 mmol / L, and weigh 3.6-144 mg Add LiOH powder into solution A and stir for 1 h to complete the reaction. After the reaction was complete, a white powder was obtained, which was rinsed three times with diethylene glycol dimethyl ether to remove residual triethylaluminum, and then placed in a glove box to dry naturally. Take 5-30 mg of the above powder and apply a pressure of 5-15 MPa to press it into...

Embodiment 2

[0062] Prepare a layer of 40-150um solid lithium ion conductor on the surface of lithium metal obtained in Example 1, and press two lithium sheets containing the solid lithium ion conductor face to face to assemble a lithium-lithium symmetric battery. In close contact with each other, 3 to 5 layers of foamed nickel are tightly pressed on one side of the lithium sheet.

[0063] After the battery is installed, let it stand for 6 hours, and conduct a charge and discharge test on the LAND-CT2001A tester, with a current density of 0.2mAcm -2 , capacity limit 0.4mAh cm -2 . After 70 cycles, the lithium metal surface is smooth without cracks, and no lithium dendrites appear, such as Figure 5 . Even after cycling for 1200h, the battery can still basically remain stable, and the polarization voltage is below 0.04V, such as Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com