Patents

Literature

86results about How to "Reduce interface contact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite solid electrolyte and preparation method thereof

InactiveCN109786816AReduce interface contact resistanceImprove lithium ion conductivityLi-accumulatorsGap fillingPorosity

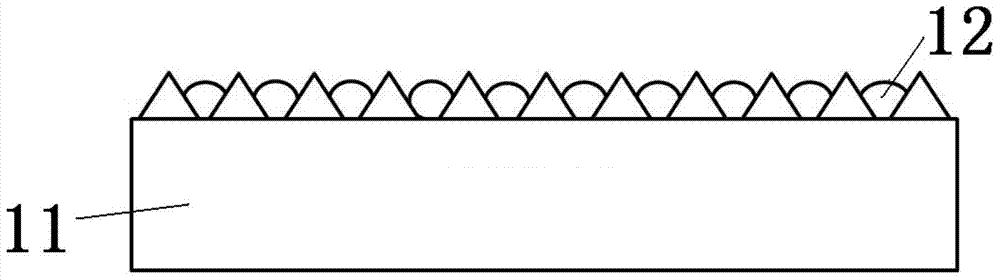

The present invention discloses a composite solid electrolyte and a preparation method thereof. The composite solid electrolyte comprises an inorganic solid electrolyte and a polymer electrolyte. Theinorganic solid electrolyte is of a porous structure; the porosity of the inorganic solid electrolyte is less than 30%; and the inside of the inorganic solid electrolyte is provided with a continuouslithium ion channel composed of particles communicating with each other. The polymer electrolyte is arranged between the inorganic solid electrolytes for filling gaps, and account for less than 30% ofthe composite solid electrolyte. The porous inorganic solid electrolyte of the invention constitutes a main frame structure, which has a porosity below 30% and is the main bearer of lithium ion transportation. The polymer electrolyte is a gap filling material, which is mainly used for improving the overall flexibility of the composite solid electrolyte and reducing the impedance of the solid-solid contact interface between the positive electrode plate and negative electrode plate.

Owner:杭州阳名新能源设备科技有限公司

Environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and preparation method of electrode silver slurry

ActiveCN104934103AGuaranteed normal transmissionReduce interface contact resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurryResistor

The invention discloses an environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and a preparation method of the electrode silver slurry. The silver slurry is composed of 60-80% silver powder, 1-5% of metal oxide, 2-5% of leadless glass powder and 10-37% of organic carriers by weight. The preparation method comprises the steps that the leadless glass powder is prepared by that raw materials are mixed well, placed in a platinum crucible and melt, and the melt material is removed and dried to obtain the leadless glass powder; the organic carriers are prepared by adding an organic solvent into a stainless steel container, adding organic resin, carrying out heating, and carrying out cooling and adding a surfactant after the resin is completely dissolved; and the silver slurry is prepared by mixing the silver powder, the metal oxide, the leadless glass powder and the organic carriers, and stirring and grinding the mixture in a vacuum manner. The preparation method is simple and suitable for both the reflow soldering and immersed soldering technologies, the solderability and the soldering resistance are high, the silver slurry can be used to prepare common type as well as lightning protection type varistor, the adhesion force, the conductivity and the electrical performance are high, and the performance completely reach the using requirements.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

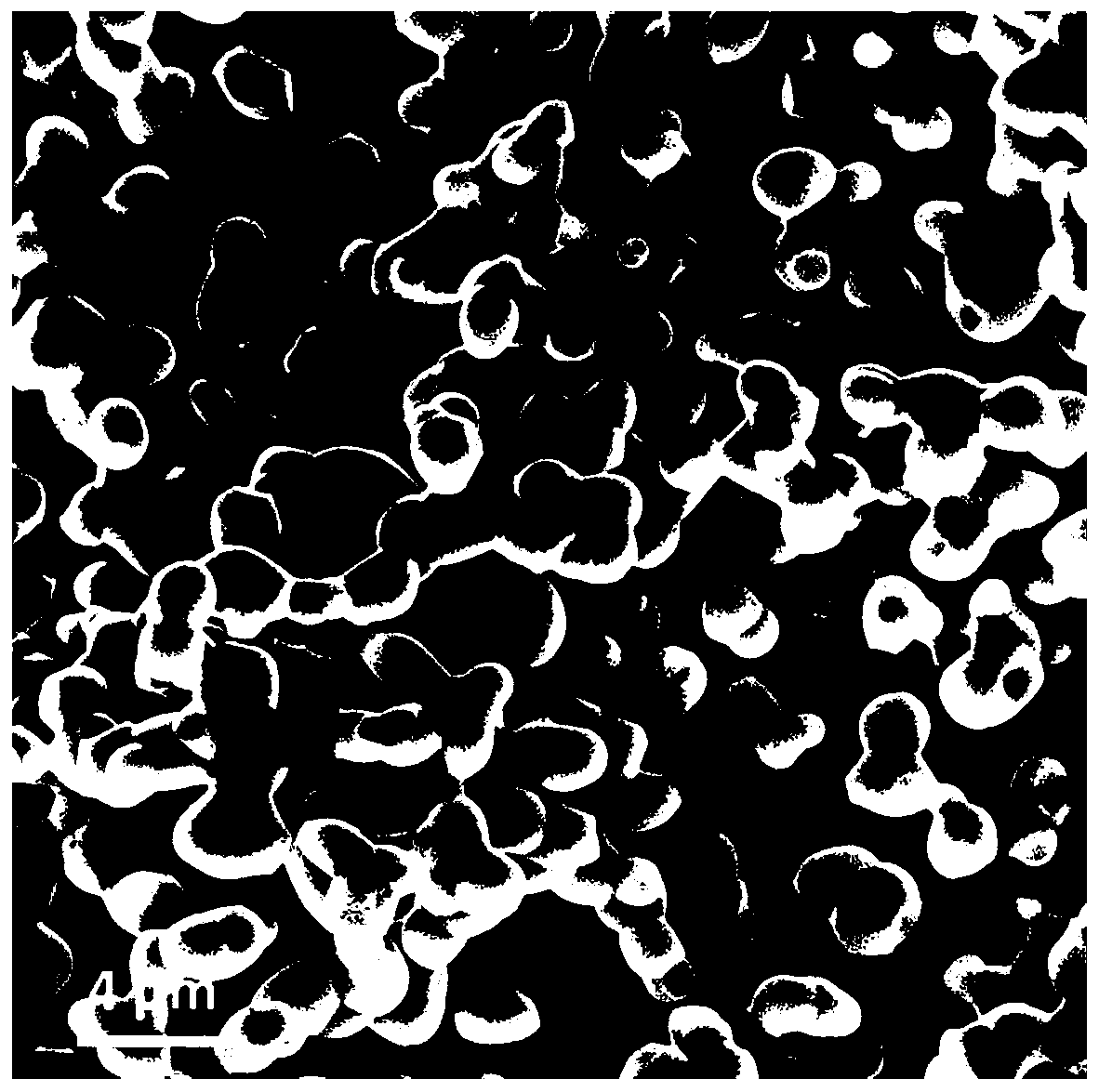

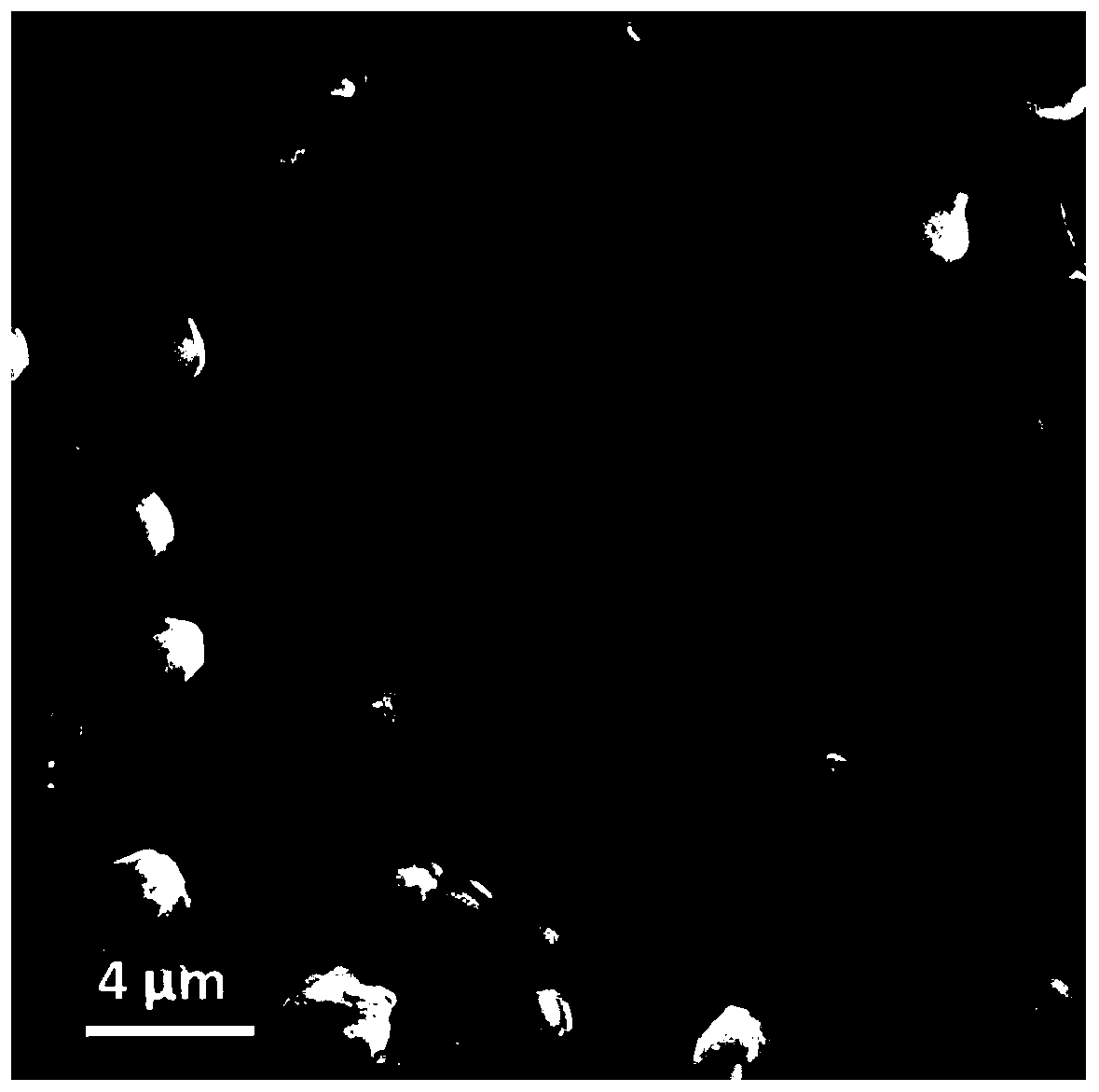

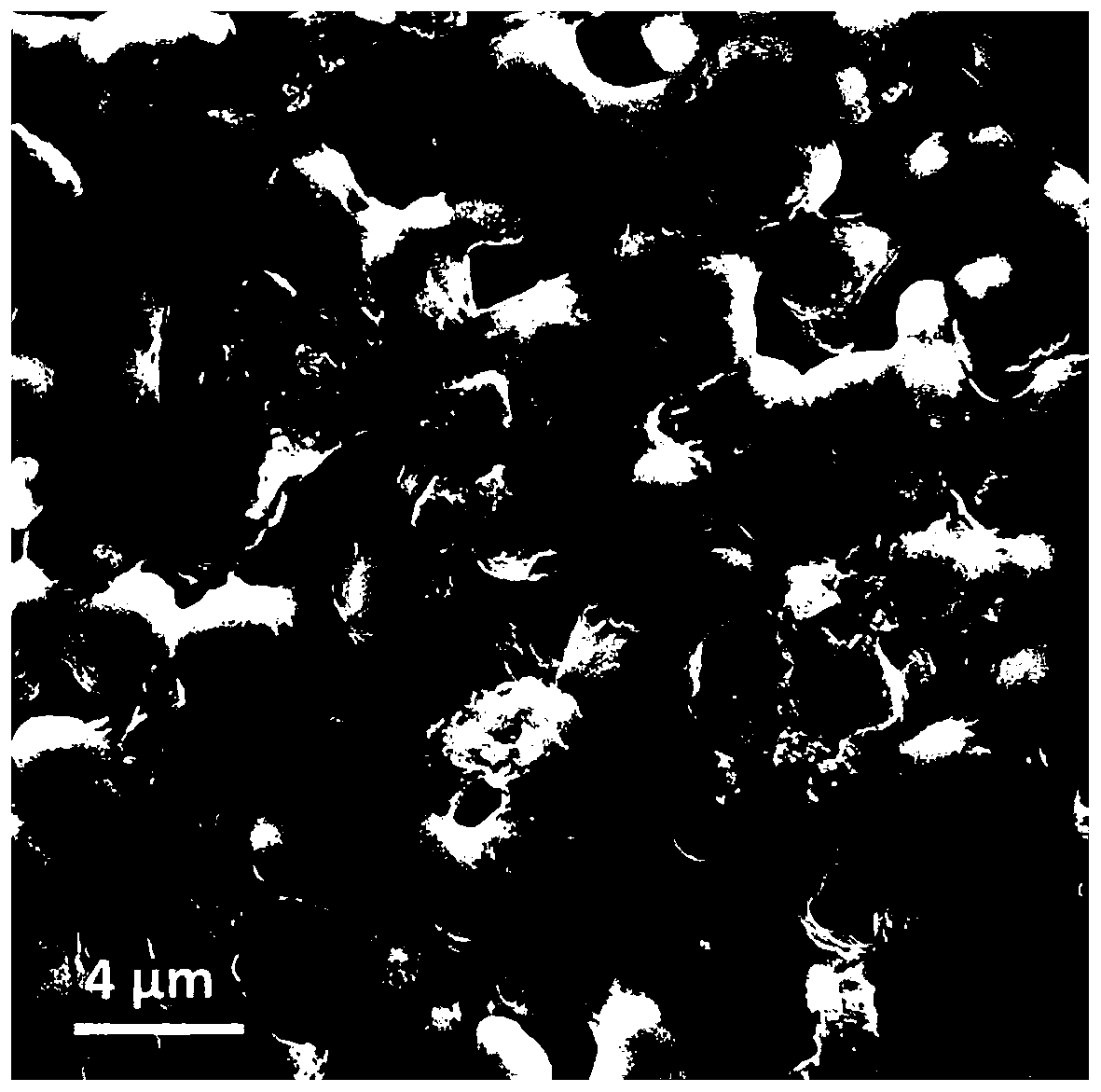

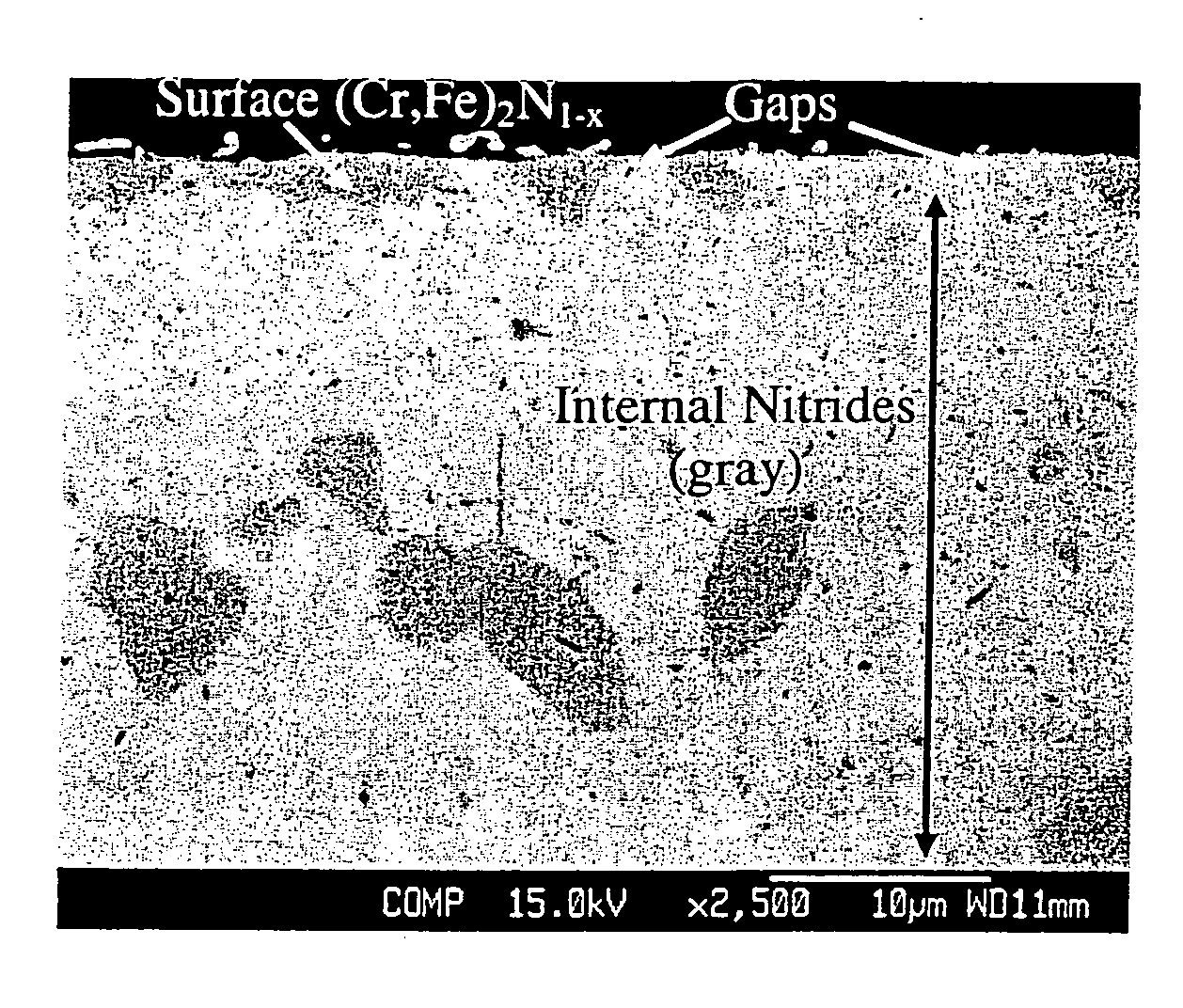

Surface modified stainless steels for PEM fuel cell bipolar plates

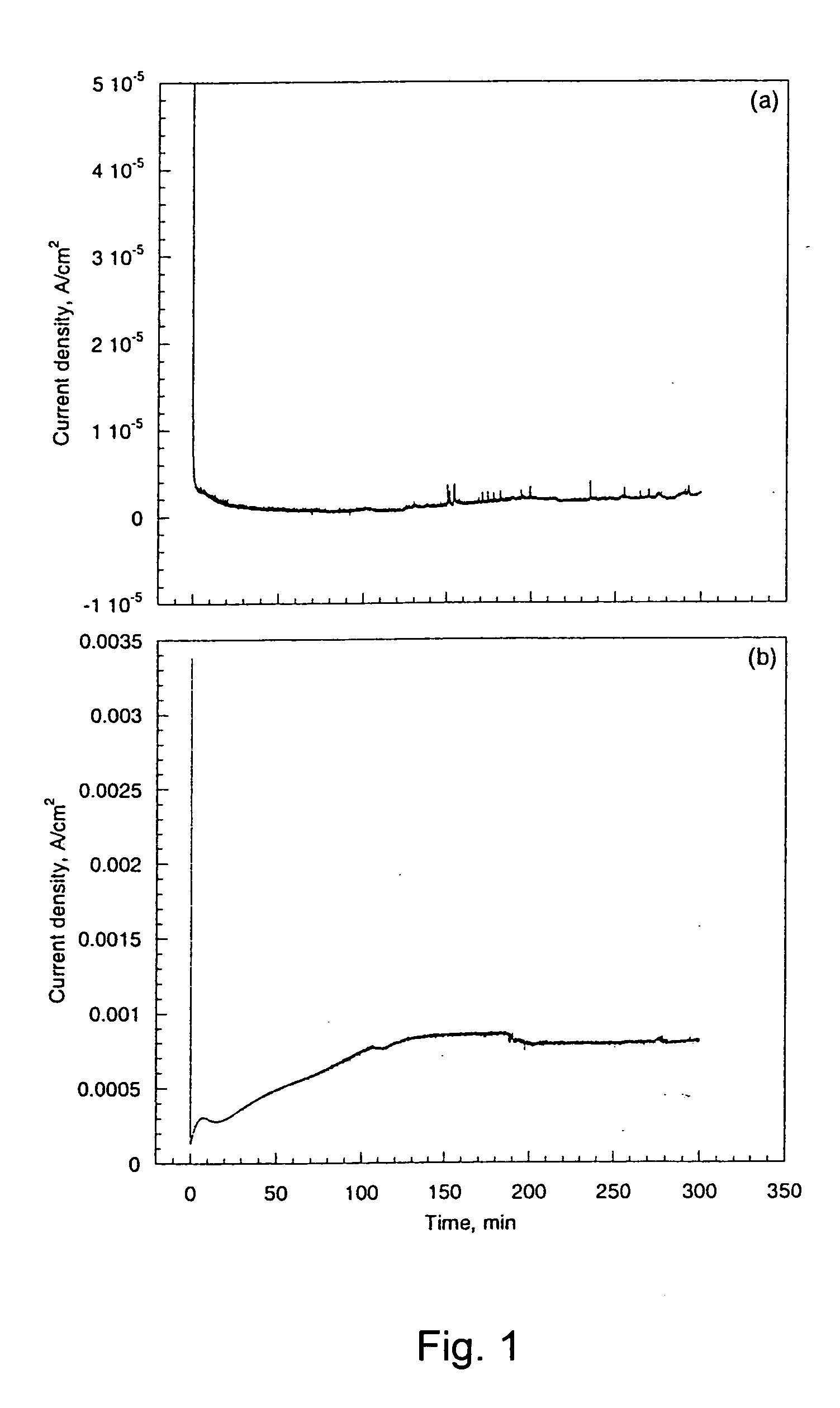

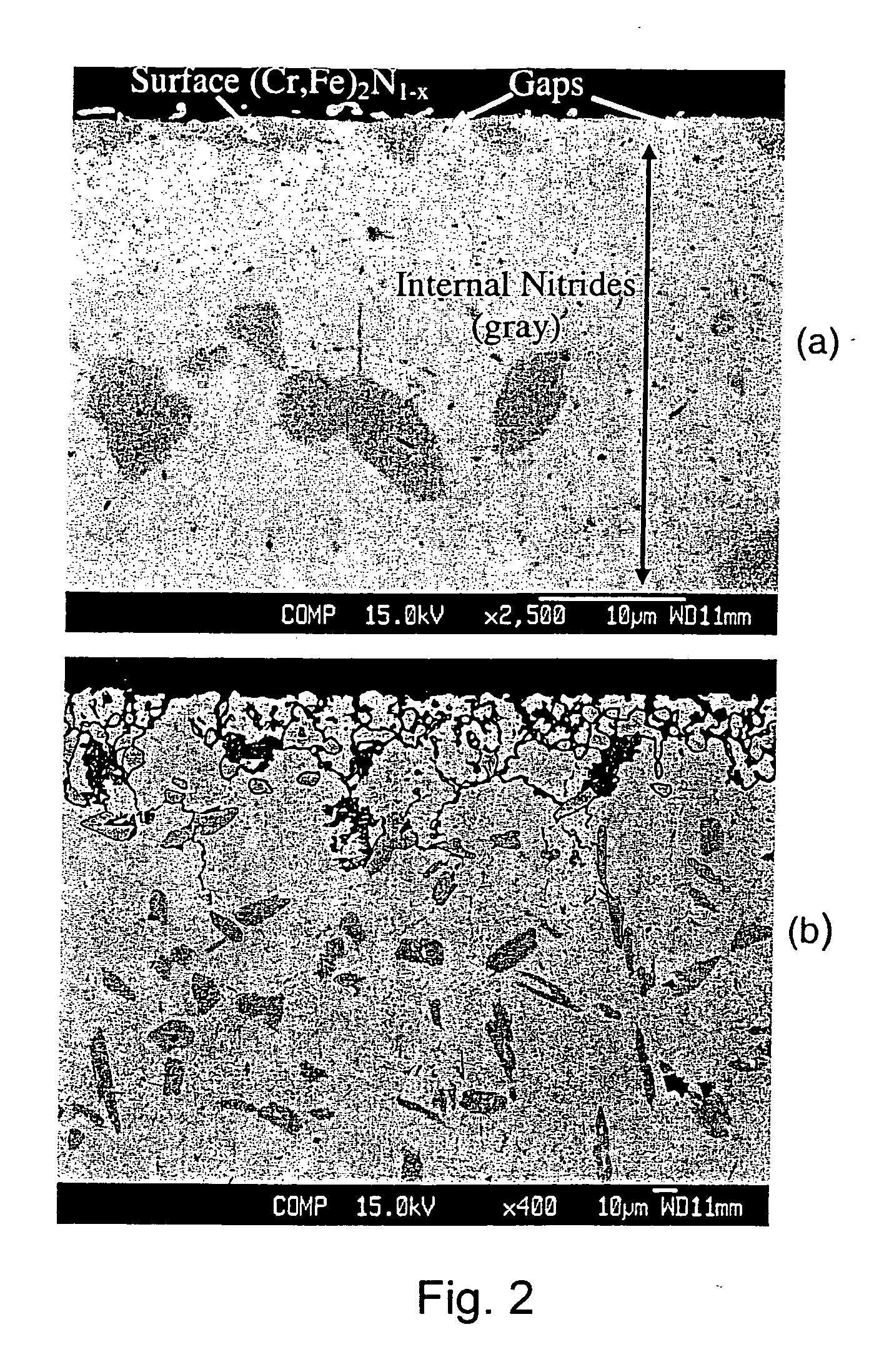

ActiveUS20050238873A1Improve corrosion resistanceReduce interface contact resistanceElectrode carriers/collectorsRecord information storageSurface layerTitanium nitride

A nitridation treated stainless steel article (such as a bipolar plate for a proton exchange membrane fuel cell) having lower interfacial contact electrical resistance and better corrosion resistance than an untreated stainless steel article is disclosed. The treated stainless steel article has a surface layer including nitrogen-modified chromium-base oxide and precipitates of chromium nitride formed during nitridation wherein oxygen is present in the surface layer at a greater concentration than nitrogen. The surface layer may further include precipitates of titanium nitride and / or aluminum oxide. The surface layer in the treated article is chemically heterogeneous surface rather than a uniform or semi-uniform surface layer exclusively rich in chromium, titanium or aluminum. The precipitates of titanium nitride and / or aluminum oxide are formed by the nitriding treatment wherein titanium and / or aluminum in the stainless steel are segregated to the surface layer in forms that exhibit a low contact resistance and good corrosion resistance.

Owner:UT BATTELLE LLC +1

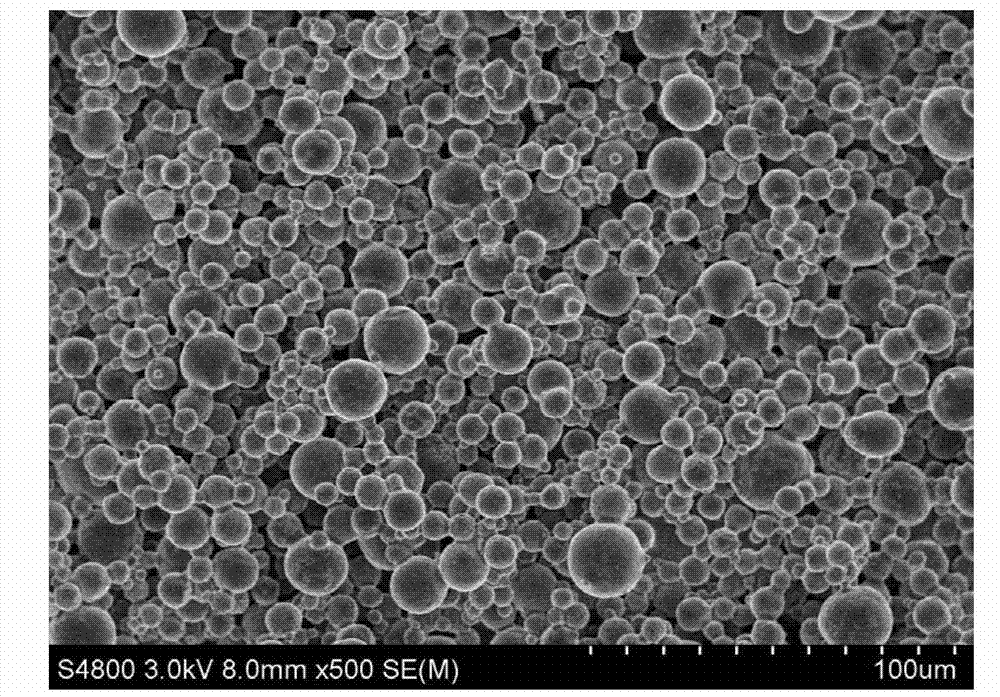

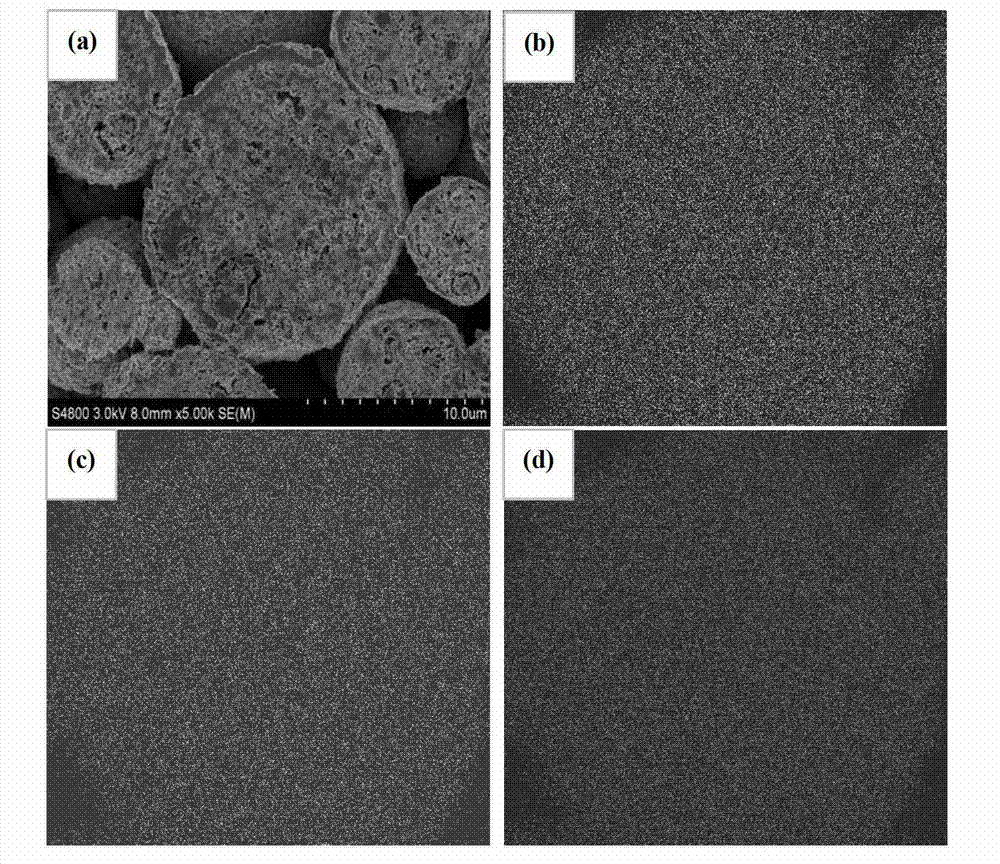

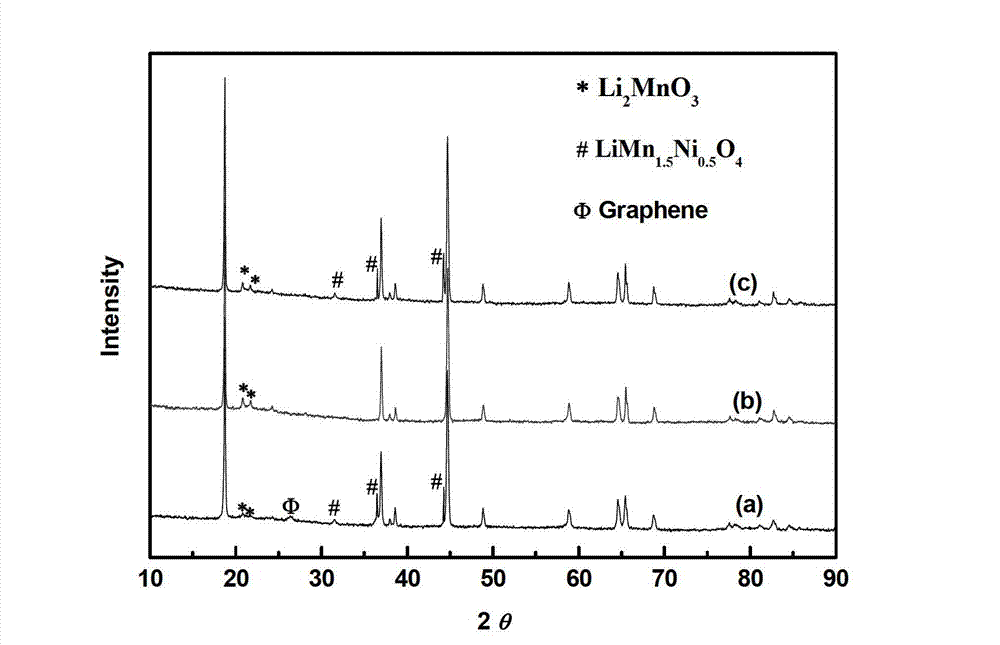

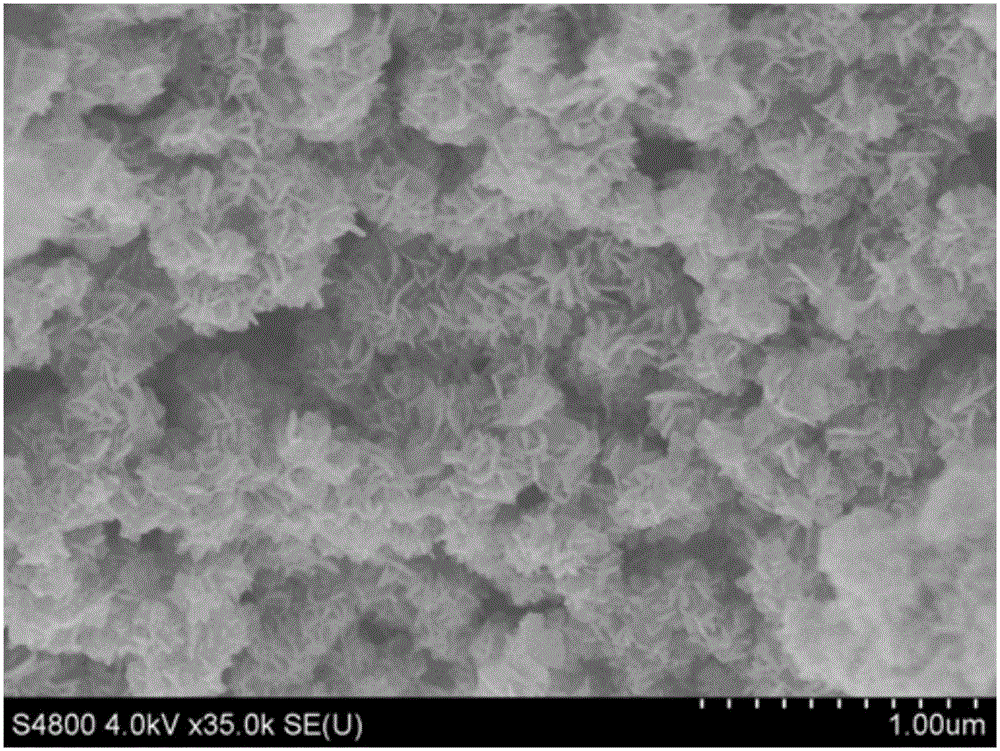

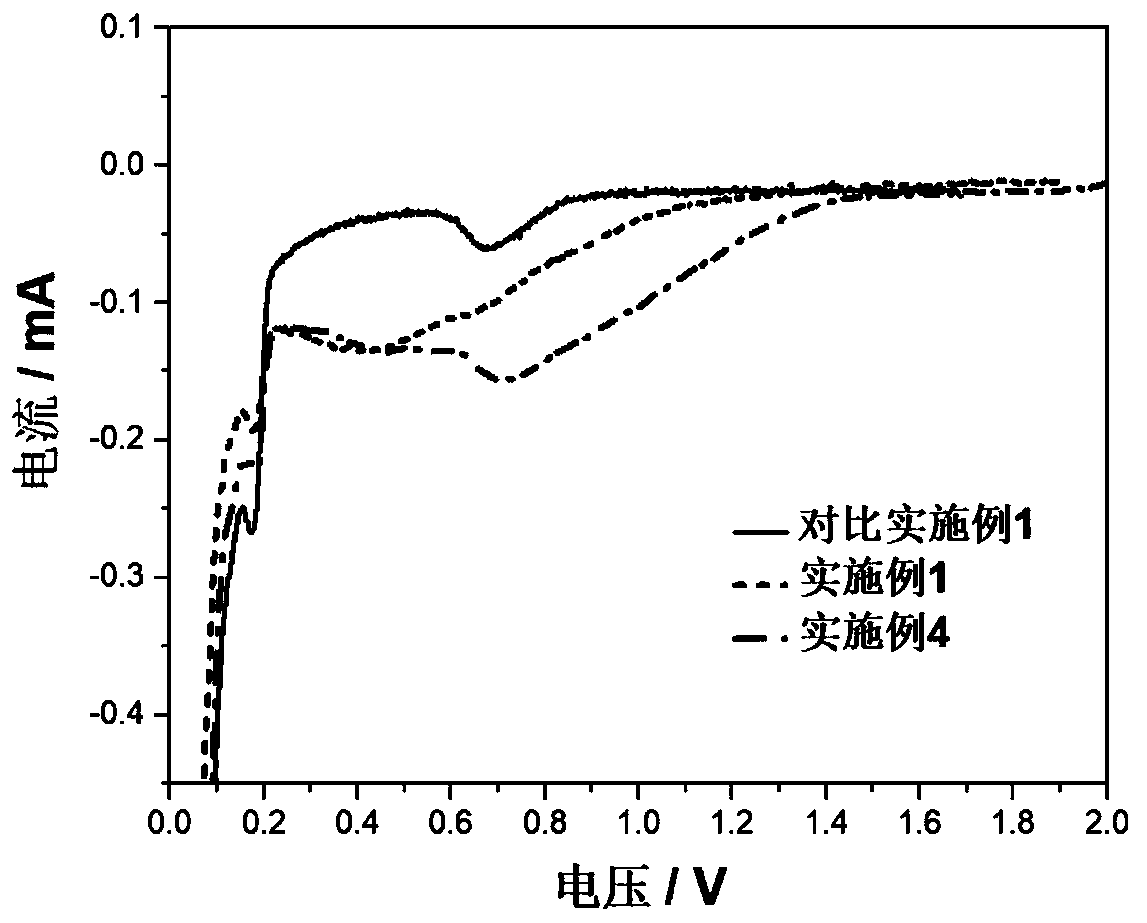

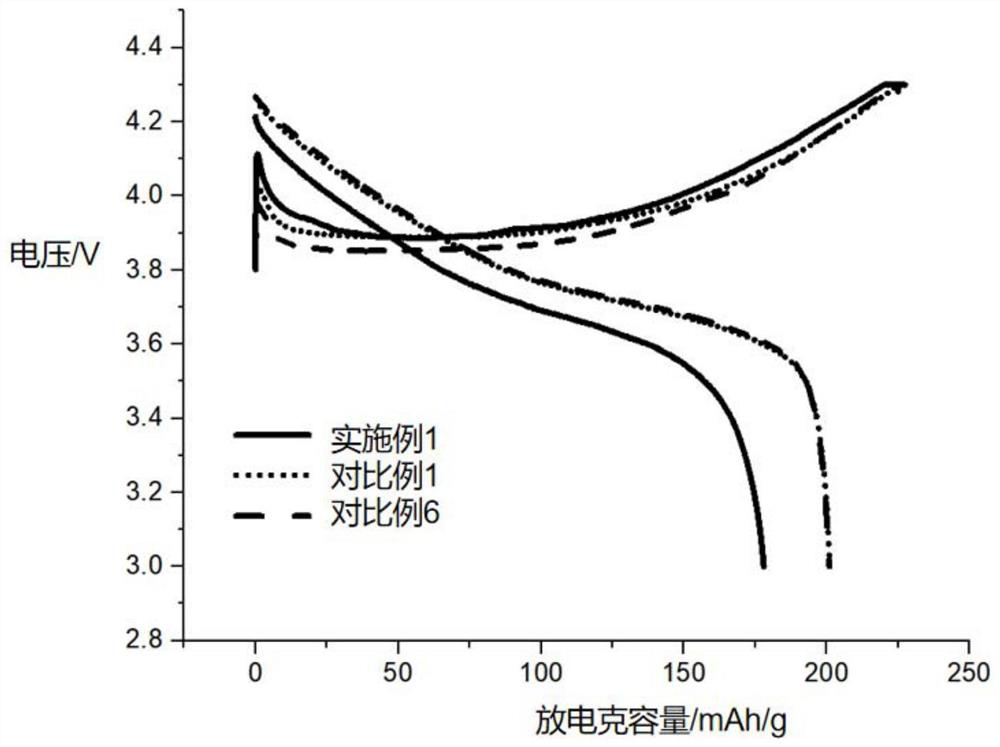

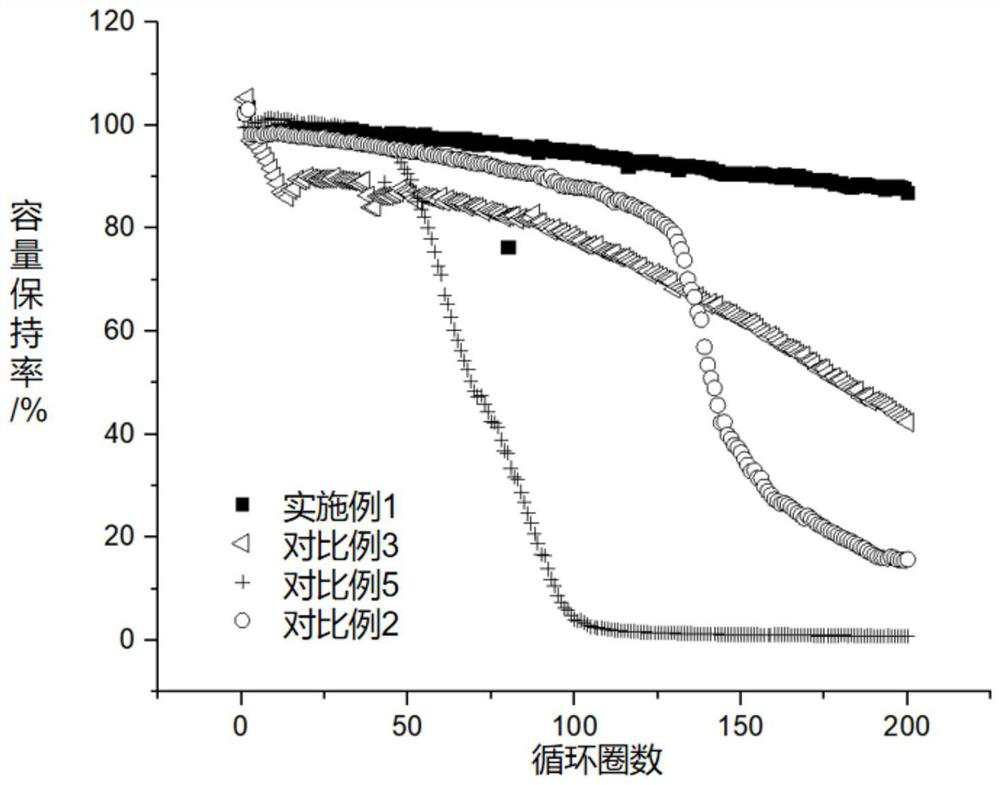

Polyphase manganese base solid solution composite cathode material and preparation method thereof

The invention relates to a preparation method of polyphase manganese base solid solution composite cathode material, which is characterized in that manganese salt, nickel salt, cobalt salt and lithium salt are taken as raw materials, novel polyphase manganese base solid solution is prepared, and then nano highly-conductive graphene is composited on the surface of the novel polyphase manganese base solid solution, so that the polyphase manganese base solid solution composite cathode material is obtained. Compared with the prior art, the polyphase manganese base solid solution composite cathode material comprises three solid solution phases, namely, monoclinal layered Li2MnO3 with space group of C2 / m and rocking chair layered LiMn0.5-xNi0.5-xCo2xO2 with space group of R-3m and three-dimensional network structure high-voltage spinel LiMn1.5-xNi0.5-xCo2xO4 with space group of Fd3m, and through introducing the LiMn1.5-xNi0.5-xCo2xO4 phase and the graphene thin layer, the intrinsic electronic conductivity and ionic conductivity of the solid solution are obviously improved, the first irreversible capacity is reduced, and the low-temperature property and rate capability are obviously improved.

Owner:BTR NEW MATERIAL GRP CO LTD

Electrocondution slurry and preparation method and application of electrocondution slurry

InactiveCN103839605AAvoid affecting charge transportGuaranteed normal transmissionNon-conductive material with dispersed conductive materialCable/conductor manufactureCross-linkMoisture resistance

The invention discloses electrocondution slurry and a preparation method and application of the electrocondution slurry. The slurry comprises, by mass percent, 30-40% of silver-graphene composite materials, 30-48% of organic resin, 5-10% of cross-linking agents and 12-26% of thinning agents. The method that the silver-graphene composite materials are prepared are as follows: graphite oxide and organic silver are added to a mixed system formed by organic solvents and deionized water, and ultrasonic dispersion is carried out on the mixture; hydrazine hydrate is dripped to the mixed system while the mixed system is stirred; after stirring is carried out for 20-30 min at room temperature, the temperature rises to 60-70 DEG C, reaction is conducted for 2-3 h, the mixture is cooled to be at the room temperature, filtered and rinsed by the deionized water, vacuum drying is carried out on the mixture, and the silver-graphene composite materials are obtained. The electrocondution slurry can meet the demands of photovoltaic devices for the electrical property under low silver content conditions and is suitable for flexible substrates, good in temperature and moisture resistance and excellent in filament printing performance, adhesive force of the electrocondution slurry and substrate ITO materials is high, and production cost of the slurry is remarkably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

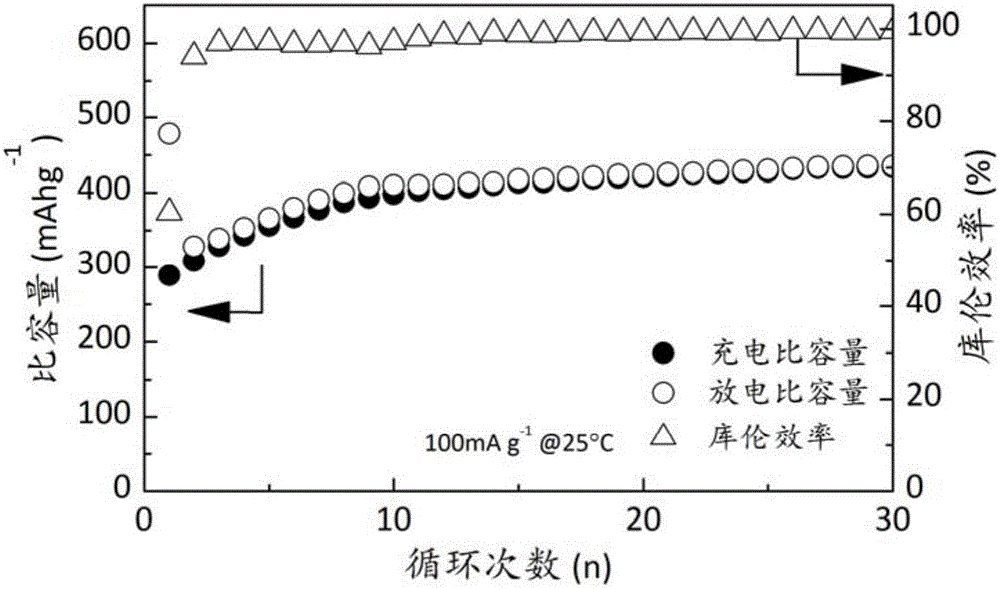

Iron-based sulfide electrode material, preparation method and application in solid state battery

ActiveCN106784815AImprove electrochemical performanceIncrease energy densityMaterial nanotechnologyCell electrodesIron(II,III) sulfideSolid-state battery

The invention provides an iron-based sulfide electrode material, a preparation method and application in a solid state battery, and belongs to the technical field of secondary lithium batteries. The iron-based sulfide electrode material which is based on conversion reaction is selected from one or more of ferrous sulfide, ferriferous sulfide and hepta-ferous octa-sulfide. The preparation method of the iron-based sulfide electrode material has the advantages of being simple and short in time.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Rapidly discharged/charged high power lithium ion battery and manufacturing method thereof

ActiveCN108306013ATake advantage ofHigh tap densityFinal product manufactureElectrode carriers/collectorsManganateCarbon nanotube

The invention discloses a rapidly discharged / charged high power lithium ion battery and a manufacturing method thereof. The positive current collector comprises an aluminum foil and a conductive coating. The negative current collector comprises a copper foil and a conductive coating. The diaphragm is a PE material, which is bidirectionally and synchronously stretched, and ceramic oxide is paintedon the surface of the PE material. The anode paste comprises following components in parts by weight: 10 to 35 parts of lithium cobaltate, lithium nickelate, lithium manganate, lithium iron phosphate,lithium manganese phosphate, lithium iron manganese phosphate, or lithium vanadium phosphate, 62 to 81 parts of nickel cobalt lithium manganate, 1 to 3 parts of Ketjen black or carbon nanotube, and 1to 3 parts of graphene or Super-P and modified 1,3-polyvinylidene fluoride. The cathode paste comprises following components in parts by weight: 55 to 75 parts of artificial graphite or meso-phase carbon micro beads, 20.5 to 36 parts of soft carbon or hard carbon, 1 to 2 parts of CMC, 2 to 4 parts of Super-P, and 1.5 to 3 parts of styrene butadiene rubber SBR or polystyrene-acrylate. The providedlithium ion battery can continuously discharge or charge (30C). The 30C constant current charge capacity can account for 70% or more of 1C capacity, and the 30C discharge capacity can account for 90%or more of 1C capacity.

Owner:FENGFAN

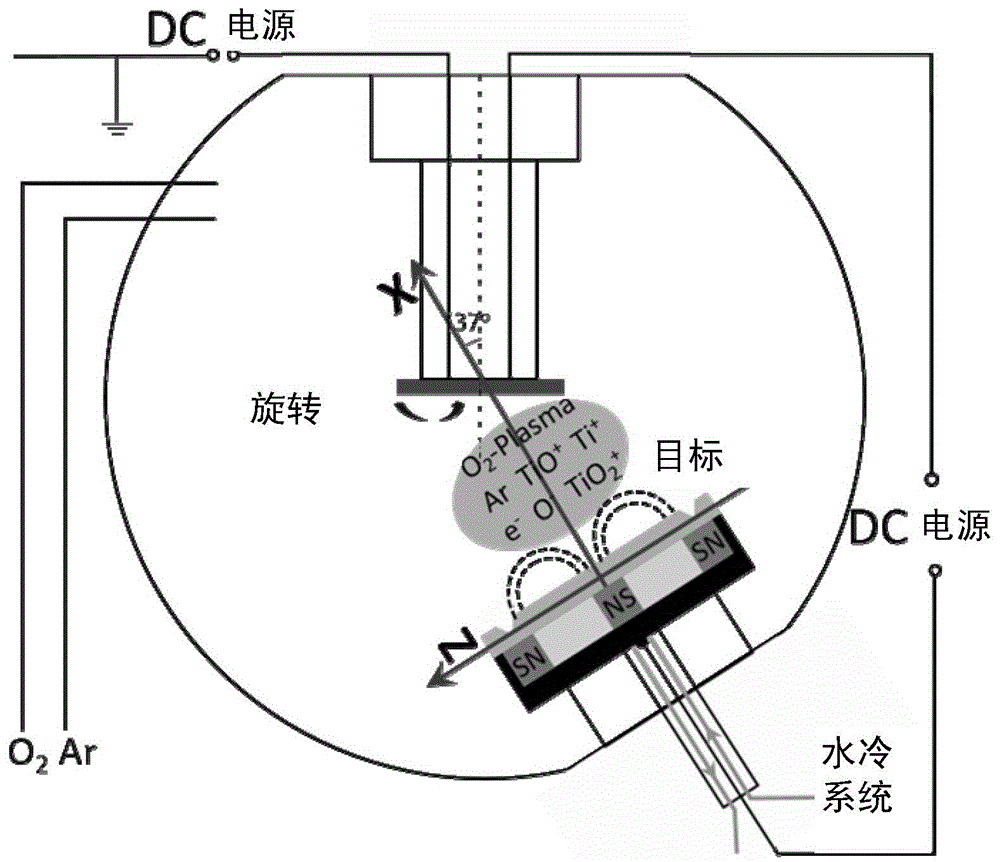

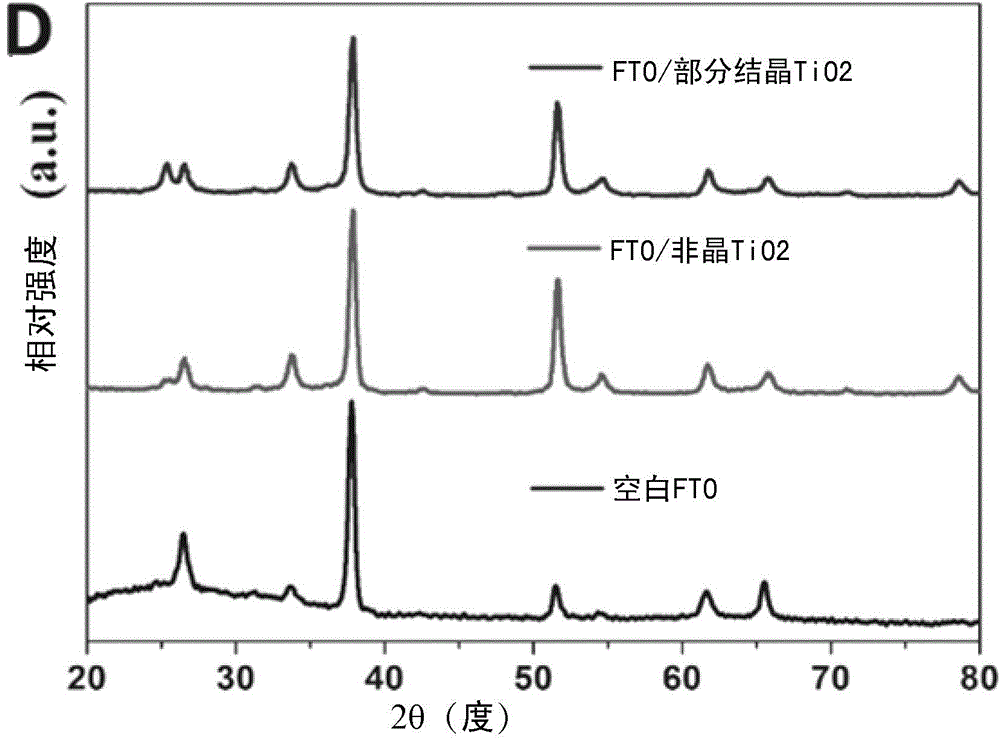

Method for preparing titanium dioxide thin films through room temperature sputtering method

InactiveCN106282926AIncreasing the thicknessImprove propertiesSolid-state devicesVacuum evaporation coatingCrystallinityDirect current magnetron sputtering

The invention relates to a method for preparing titanium dioxide thin films through a room temperature sputtering method. The titanium dioxide thin films with different degrees of crystallinity are prepared through the direct current magnetron sputtering method. A target material is a pure titanium target; the background vacuum degree is 10<-4> Pa or less; sputtering gas is argon and oxygen; the total pressure intensity is 0.5-2.5 Pa; the oxygen partial pressure is 50% or less; the distance between the target material and a base material is 7-20 cm; the initial temperature of the base material is 15-35 DEG C; the power of a direct current power source applied to the target material is 300-900 W; and the depositing time is 5-30 min. The complete amorphous or partial crystallographic titanium dioxide thin films are obtained. According to the method for preparing the titanium dioxide thin films through the room temperature sputtering method, the thin film preparation condition is mild, equipment is simple, and resources and energy sources are saved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Graphene/organic thin film composite current collector, preparation method thereof, electrochemical electrode and electrochemical battery or capacitor

InactiveCN103632845ASimple preparation processLow costElectrode carriers/collectorsCapacitor detailsAdhesiveFiltration

The invention provides a graphene / organic thin film composite current collector and a preparation method thereof. The method comprises the steps that graphite oxide is taken and added into a solvent; after ultrasonic dispersion, graphene oxide suspension liquid is acquired; pH is adjusted to 10 to 11; a hydrazine hydrate solution is added; after reaction, filtration is carried out to acquire graphene; the graphene is added into an organic solvent to acquire graphene suspension liquid; the graphene suspension liquid is coated on an organic thin film; after drying is carried out, roller pressing is repeatedly carried out; and after the soaking of the mixed solution of acetone and isopropyl alcohol, roller pressing is repeatedly carried out, so as to acquire the graphene / organic thin film composite current collector. According to the method, the process is simple; the use of an adhesive is not needed; the prepared graphene / organic thin film composite current collector has the advantages of light quality, strong electrical conductivity, corrosion resistance and small contact resistance with a battery active material; and the power density and the cycle life of the electrochemical battery or capacitor can be improved. The invention further provides an electrochemical electrode and the electrochemical battery or capacitor employing the electrode.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

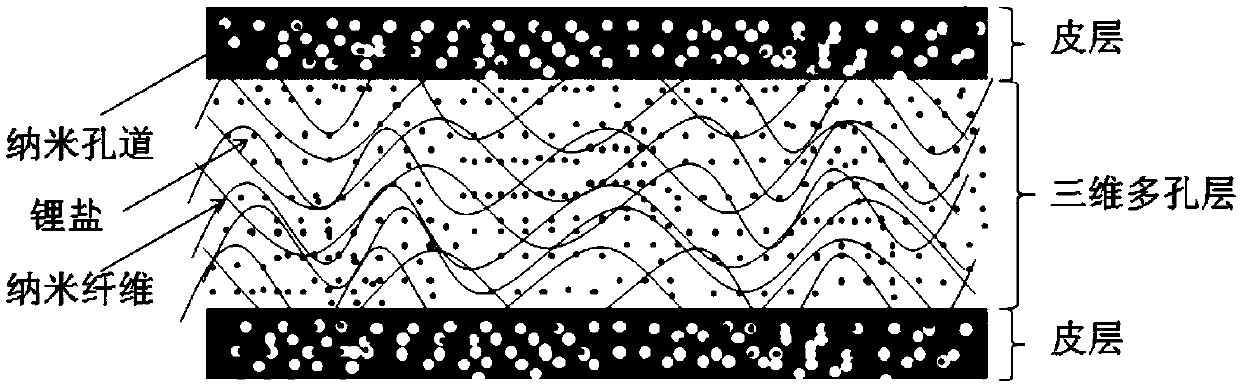

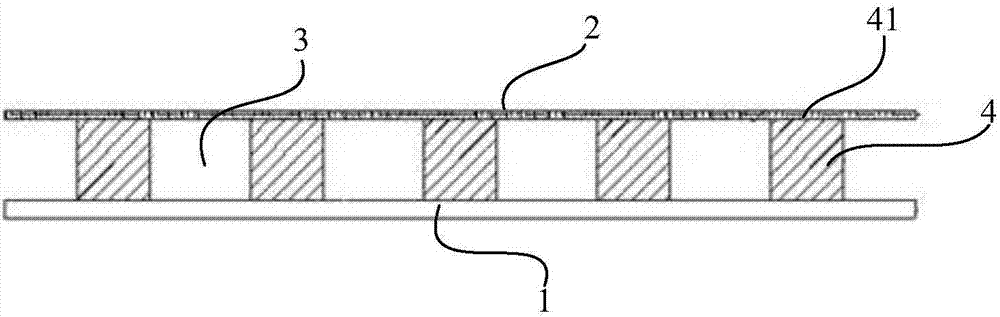

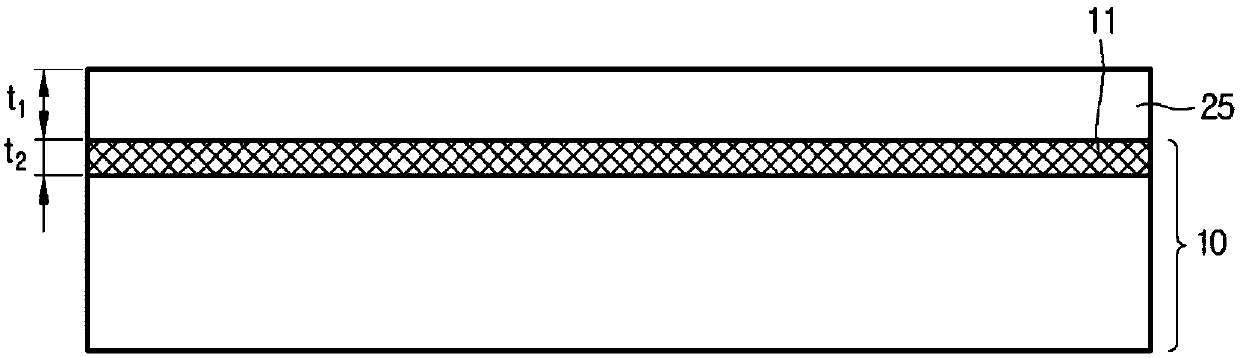

A lithium battery separator in a gel-like structure, a preparation method thereof and an all-solid-state lithium battery

ActiveCN109585759AGood cycle charge and discharge performanceImprove cycle performanceSecondary cellsCell component detailsPorosityAll solid state

The invention provides a lithium battery separator in a gel-like structure, a preparation method thereof and an all-solid-state lithium battery The lithium battery separator includes upper and lower surface layers, an intermediate three-dimensional channel layer and ion conductive functional materials filled in the surface layers and the three-dimensional channel layer, wherein the surface layer has a nano-scale channel structure, and the three-dimensional channel layer has a high porosity and a micron-sized pore structure. The ion conductive functional materials are a mixture of polymer resinand lithium salt. According to the invention, the electrolyte retention capacity of the separator can be improved on the basis of maintaining relatively high ion conductivity through combining the surface layers on the upper and lower surfaces of the high-porosity three-dimensional pore layer, thereby ensuring that the electrolyte does not flow significantly under severe mechanical motion and maintains a gel-like state. The invention is expected to be applied to an all-solid lithium ion battery, and the preparation method has low cost and a simple process, and is convenient for continuous production.

Owner:DONGGUAN UNIV OF TECH +1

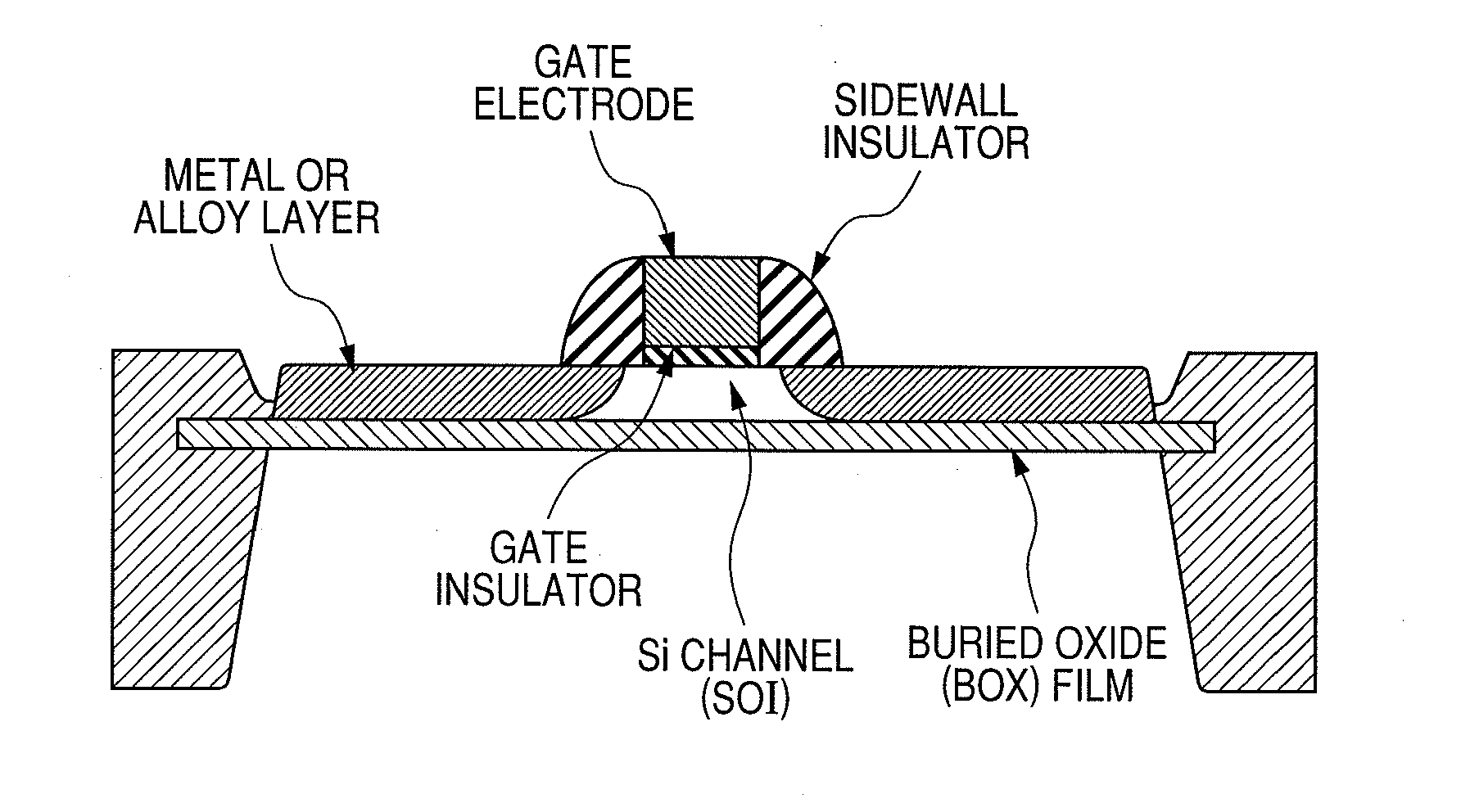

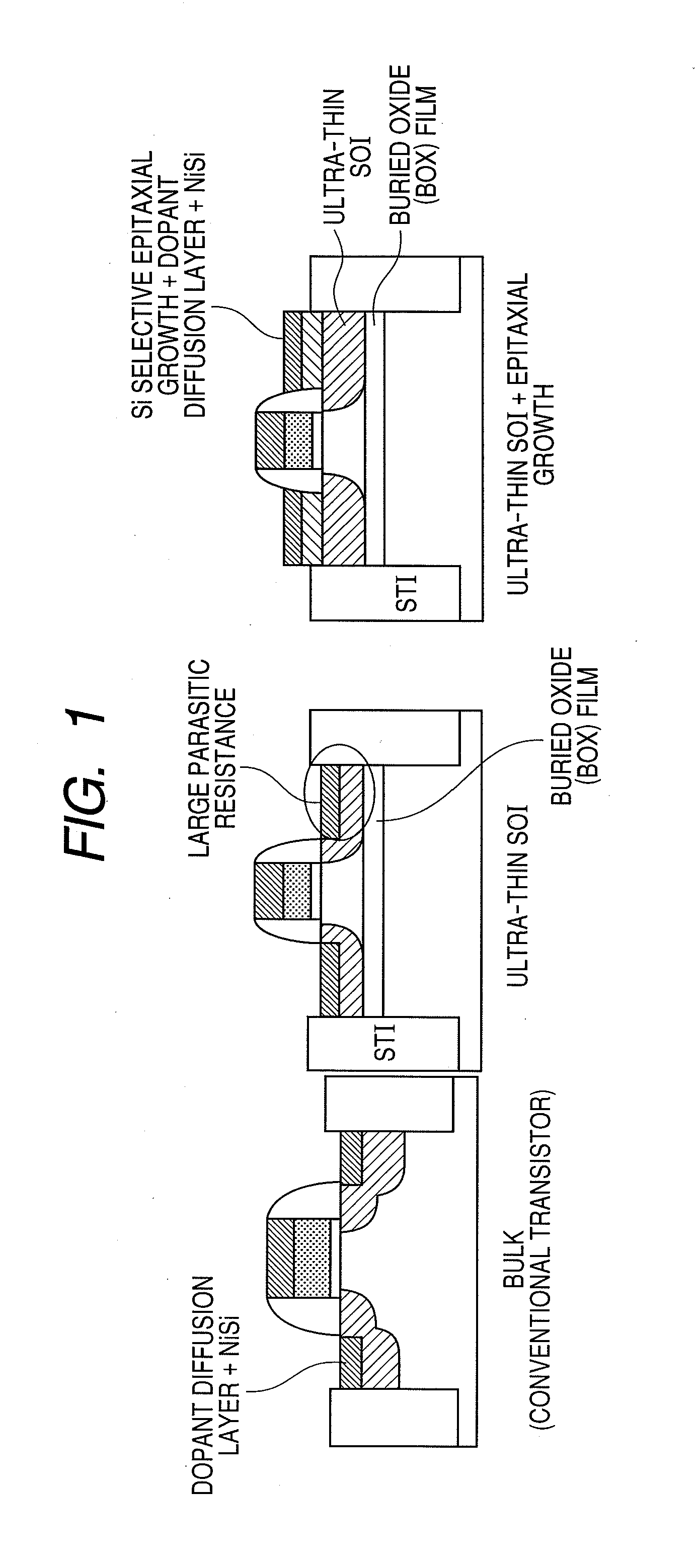

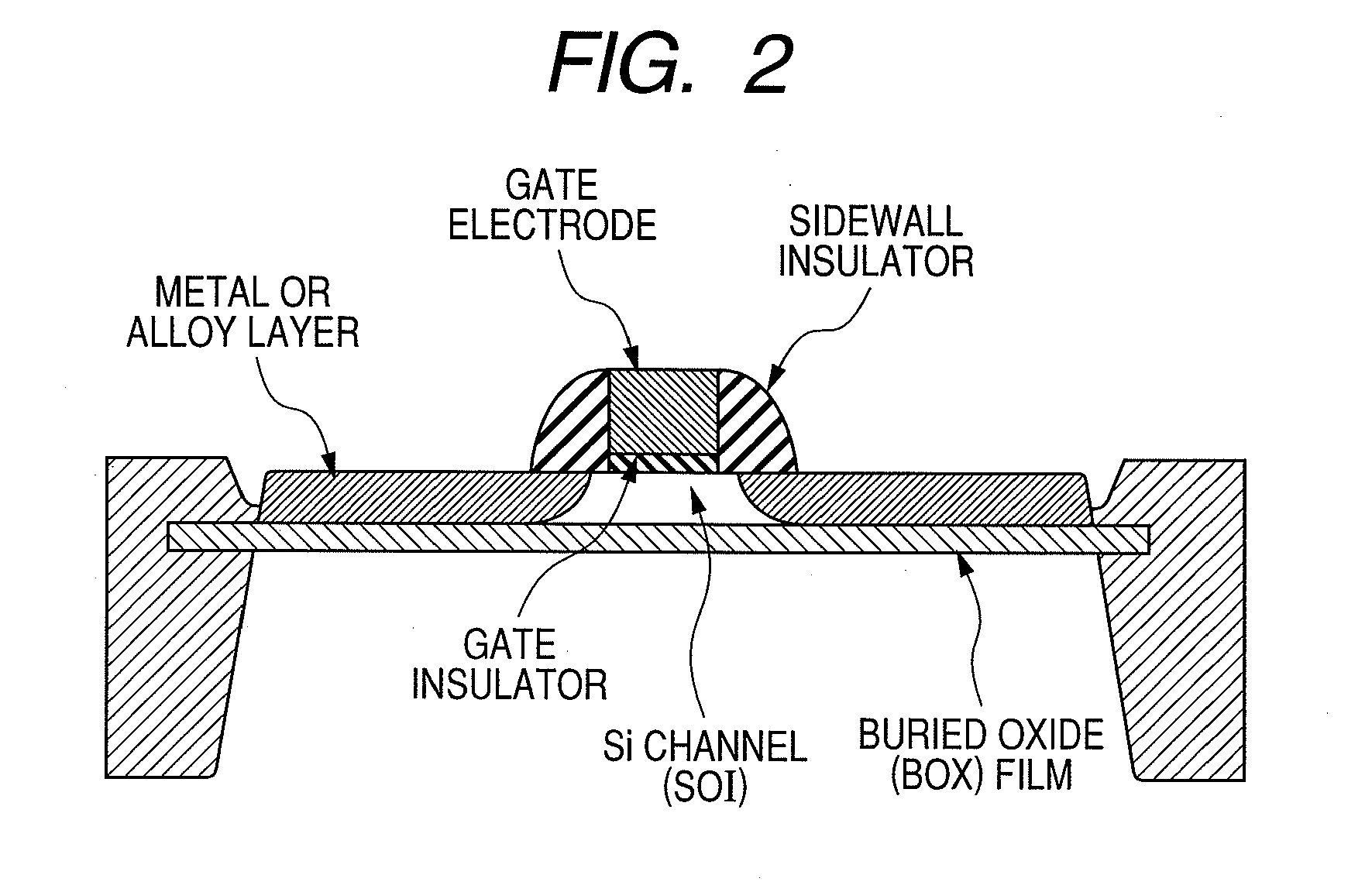

Semiconductor device and method for manufacturing the same

InactiveUS20110001191A1Decreasing source/drain resistanceReduce interface contact resistanceTransistorSolid-state devicesPower semiconductor deviceCrystal orientation

A semiconductor device which includes: a semiconductor layer formed over an insulating layer over a semiconductor substrate; a gate electrode disposed over the semiconductor layer through a gate insulator; a sidewall insulator formed along the gate insulating film and a sidewall of the gate electrode; a source / drain layer including an alloy layer whose bottom surface is in contact with the insulating layer; and an impurity-doped layer which is segregated in a self-aligned manner in an interface between the alloy layer and the semiconductor layer and has a face for junction with a channel region formed along a crystal orientation plane of the semiconductor layer.

Owner:HITACHI LTD

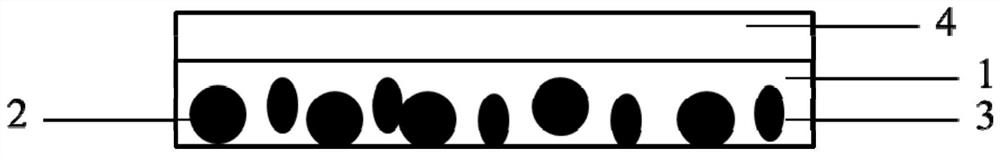

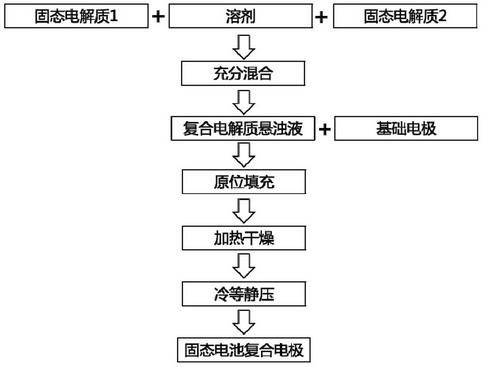

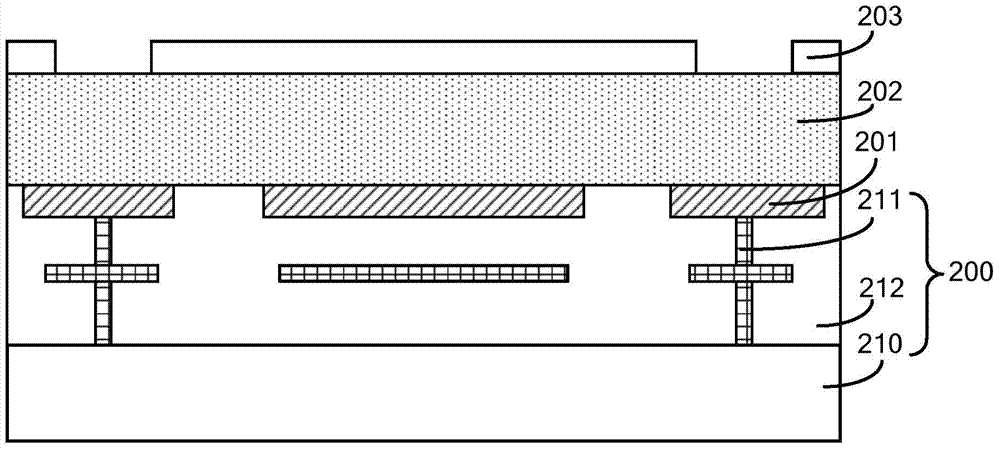

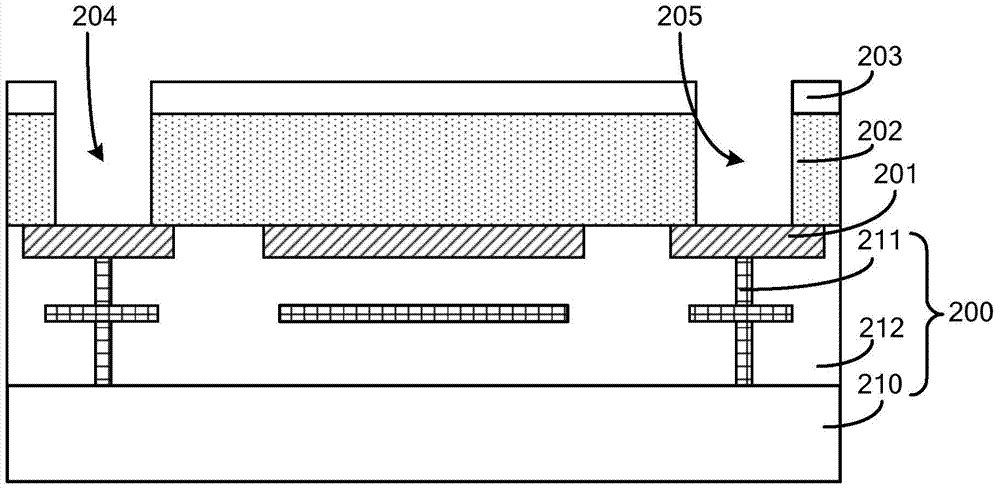

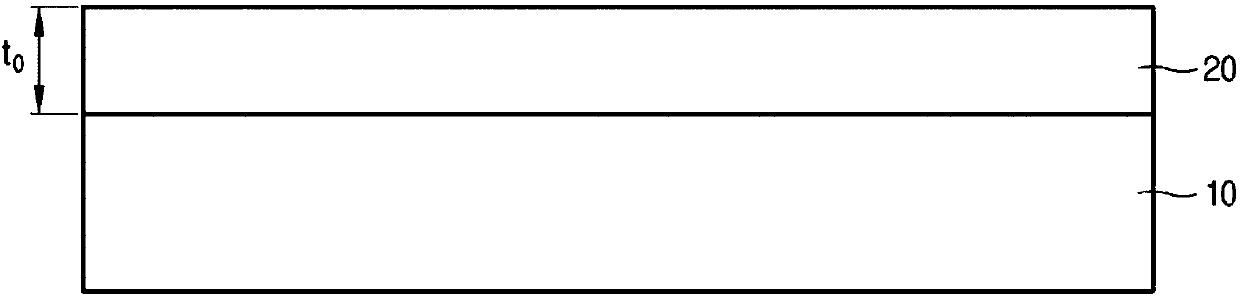

All-solid-state battery electrode and preparation method and application thereof

ActiveCN111628139AIncrease contentIncrease compaction densityElectrode collector coatingLi-accumulatorsSolid state electrolyteComposite electrolyte

The invention relates to an all-solid-state battery electrode and a preparation method and application thereof. The method comprises the following steps: (1) providing a basic electrode, the basic electrode comprising a current collector and an electrode material layer coating the surface of the current collector, and the electrode material layer comprising an active material; (2) mixing a first solid electrolyte, a second solid electrolyte and a solvent to obtain a composite electrolyte turbid liquid, coating the surface of a base electrode with the turbid liquid, and removing the solvent toobtain the electrode; wherein the first solid electrolyte is a sulfide type solid electrolyte and is dissolved in a solvent, and the second solid electrolyte is an inorganic solid electrolyte and is insoluble in the solvent. According to the method, an in-situ filling process is adopted, gaps of the active material are filled with the first solid electrolyte, meanwhile, the solid electrolyte layeris combined with the electrode material layer, interface contact between the active material and the solid electrolyte layer is improved, the production process is simple, and the method is suitablefor large-scale application.

Owner:CHINA FIRST AUTOMOBILE

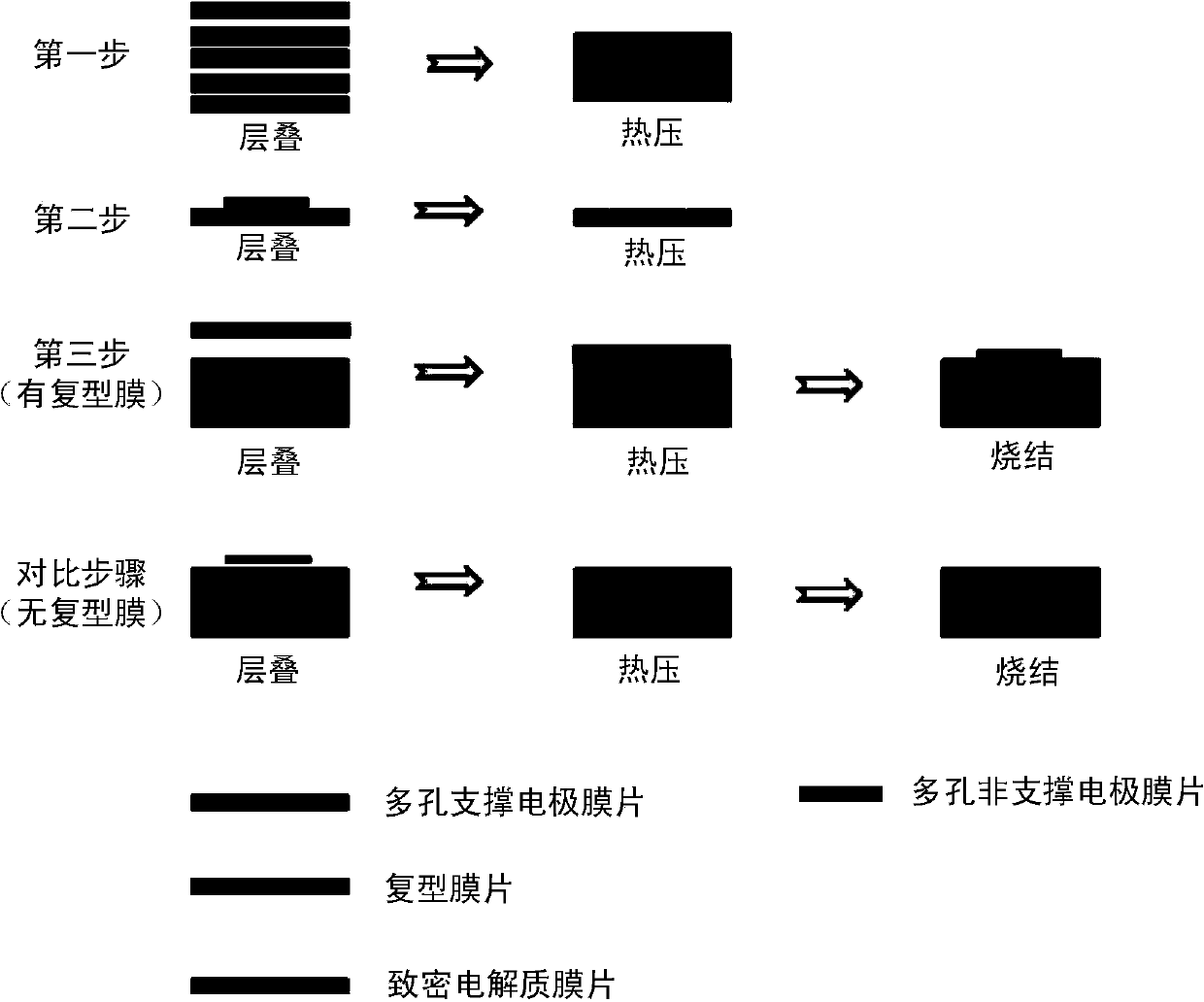

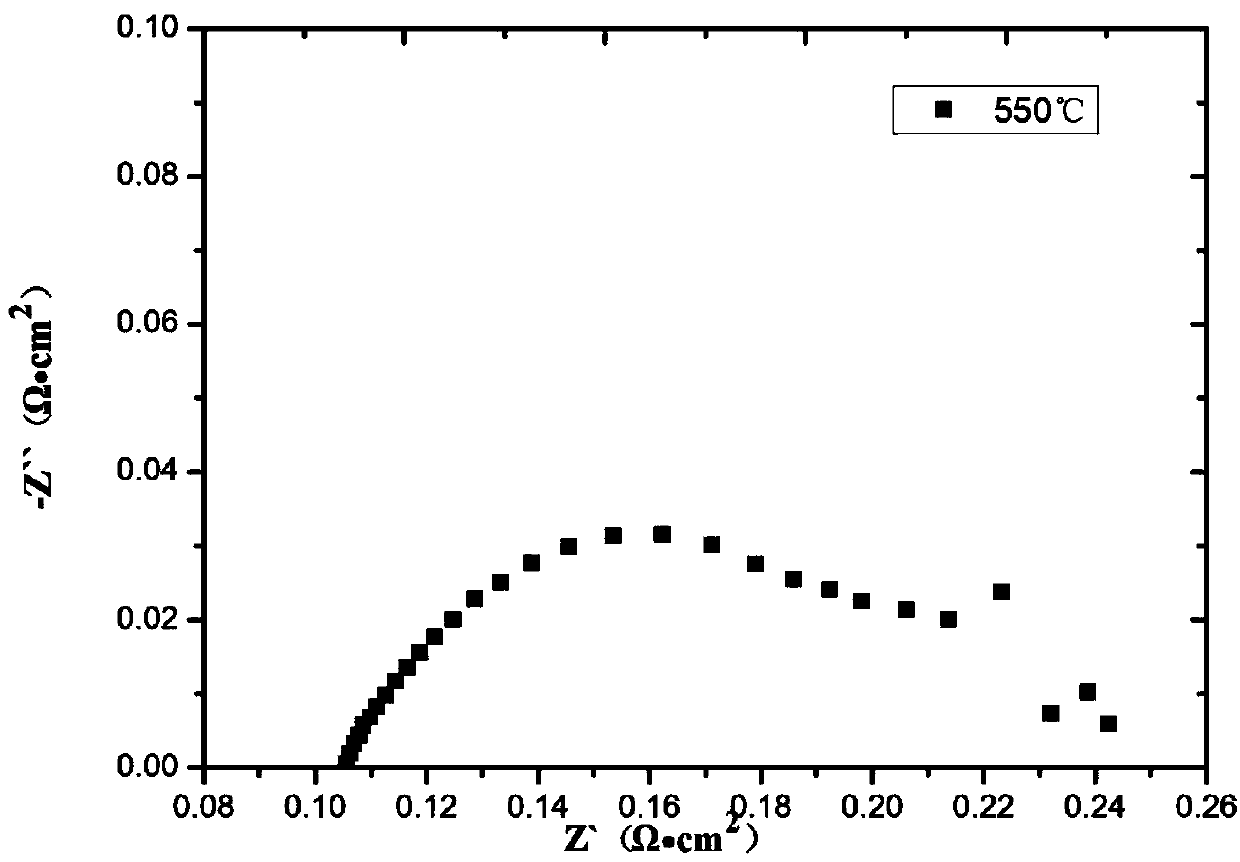

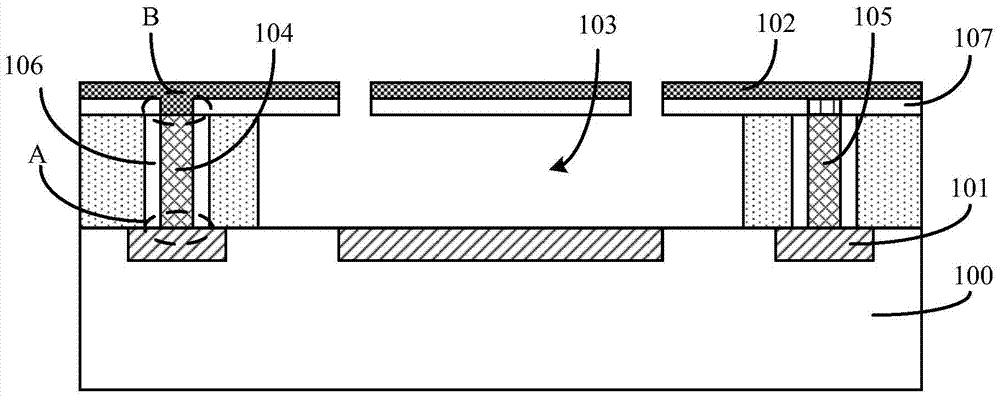

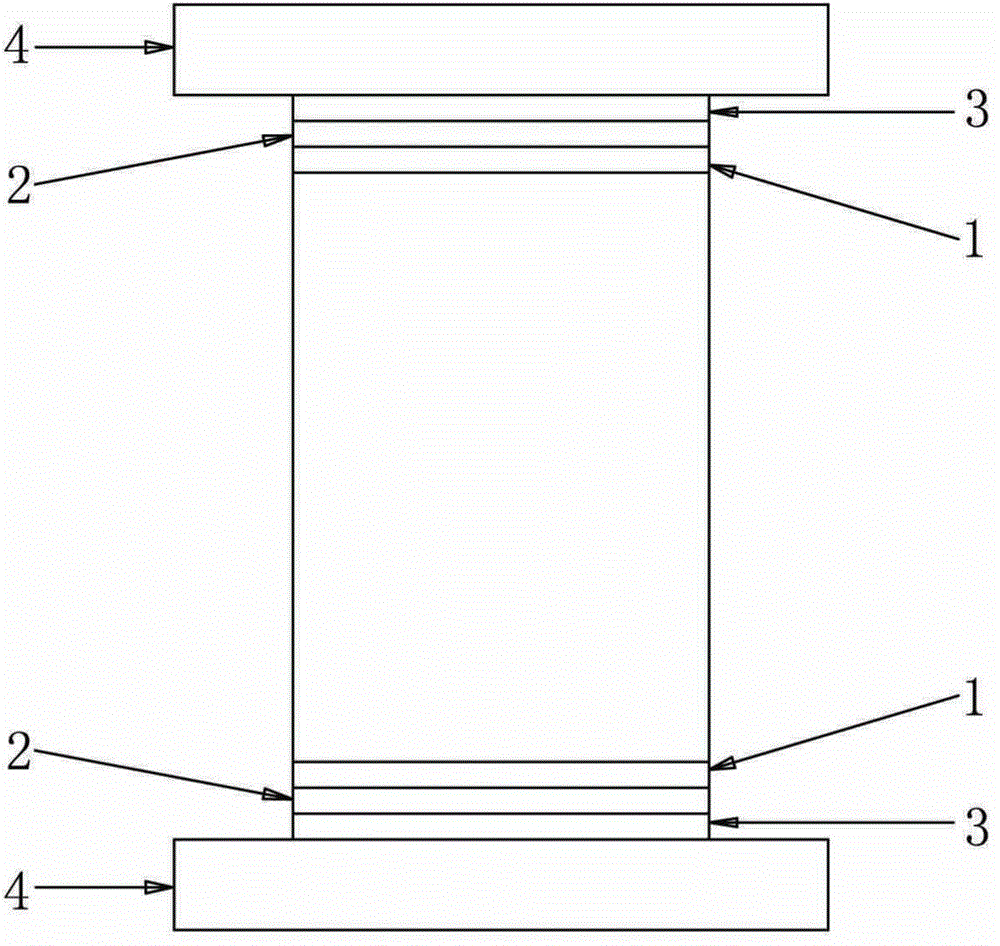

Method for preparing a high-performance slab solid oxide fuel single battery

ActiveCN103474687AEliminate or reduce interface contact resistanceAvoid failureSolid electrolyte fuel cellsFuel cell detailsEngineeringElectrolyte

The invention relates to a method for preparing a high-performance slab solid oxide fuel single battery. The preparation method comprises: a support electrode diaphragm and an electrolyte diaphragm are overlapped and are subjected to hot pressing under a vacuum condition so as to form a first complex diaphragm; a non-support electrode diaphragm and a complex diaphragm are overlapped and then are subjected to hot pressing so as to form a second complex diaphragm; one side of an electrolyte of the first complex diaphragm and one side of the non-support electrode of the second complex diaphragm are overlapped in a contact manner so as to form a single battery blank; the single battery blank is sintered so as to manufacture a single battery, wherein the complex diaphragm is burnt out during the sintering process, a anode diaphragm is formed by the support electrode diaphragm and a cathode diaphragm is formed by the non-support electrode diaphragm, or the cathode diaphragm is formed by the support electrode diaphragm and the anode diaphragm is formed by the non-support electrode diaphragm; the complex diaphragm is prepared from substances which can be burnt out at a temperature of 200-1450 DEG C.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Semiconductor device and forming method thereof

ActiveCN104743504AGood contact interface qualityReduce contact resistanceDecorative surface effectsSolid-state devicesPhysicsSemiconductor

The invention discloses a semiconductor device and a forming method thereof. The forming method of the semiconductor device comprises the following steps: providing a substrate, wherein a first conductive layer is arranged on the surface of the substrate, a sacrificial layer is arranged on the surface of the first conductive layer, a mask layer is arranged on the surface of the sacrificial layer, and the mask layer is exposed on part of the surface of the sacrificial layer; taking the mask layer as a mask, etching the sacrificial layer until the first conductive layer is exposed, and forming a first opening and a second opening in the sacrificial layer; forming conductive films on the surface of the mask layer and on the side walls and bottom surfaces of the first opening and the second opening; forming dielectric layers full of the first opening and the second opening on the surfaces of the conductive films; removing part of conductive films on the surface of the mask layer so as to pattern the conductive films after the dielectric layers are formed, forming a first plug in the first opening, forming a second plug in the second opening, and forming a second conductive layer on the surface of the mask layer, wherein the second plug and the second conductive layer are in electrical open circuit; and electrically connecting the second conductive layer with the first plug. Therefore, the performance of the formed semiconductor device is stable and good.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for preparing lead dioxide electrode with porous matrix

InactiveCN105887131AImprove performanceUnique three-dimensional internal structureElectrolytic inorganic material coatingWater/sewage treatmentElectricityElectrical resistance and conductance

The invention relates to a method for preparing a lead dioxide electrode with a porous matrix. The method includes the following steps that a porous material serves as the matrix, the matrix is subjected to surface treatment, and a mud-crack-free middle coating and a lead dioxide surface layer are prepared on the treated surface of the matrix sequentially. The method has the beneficial effects that the lead dioxide electrode with the porous matrix is of a unique three-dimensional internal structure, and the middle layer can be closely combined with the porous matrix as a solid solution or in other forms, and forms a compact mud-crack-free covering layer, so that the matrix is effectively protected, and the service life of the electrode is greatly prolonged; an active layer and the matrix can be firmly combined, and high bonding force and high anti-stripping capacity are achieved; the special internal meshed communication mechanism of the porous matrix material improves the overall performance of the electrode and plays a significant role in assisting in electrocatalytic oxidation; and the prepared lead dioxide electrode with the porous matrix has the advantages of high oxygen evolution potential, good catalytic activity, large electrode specific surface area, and small interface resistance and internal stress.

Owner:CHANGZHOU UNIV

Fuel cell assembly and preparation method thereof

ActiveCN107978768AImprove binding tightnessImprove conductivityFinal product manufactureCollectors/separatorsFuel cellsEngineering

The invention relates to the technical field of fuel cells, and particularly relates to a fuel cell assembly and a preparation method thereof, which can effectively reduce the interface resistance between a bipolar plate and a gas diffusion layer and improve the overall power density of a stack. The embodiment of the invention provides the fuel cell assembly, comprising the bipolar plate and the gas diffusion layer arranged on one side of the bipolar plate, wherein the gas diffusion layer and an interface of the bipolar plate are combined by forming a compound or a solid solution. The embodiment of the invention is used for the preparation and assembly of fuel cells.

Owner:BEIJING IN POWER NEW ENERGY

Composite-material bipolar storage battery and preparation technology of bipolar plate substrate thereof

InactiveCN103700862AImprove conductivityLower internal resistanceFinal product manufactureElectrode carriers/collectorsSputteringAlloy

The invention discloses a composite-material bipolar storage battery and a preparation technology of a bipolar plate substrate thereof. The bipolar storage battery comprises the substrate, a metal sputtering layer and a composite-material bipolar cell. The substrate comprises thermosetting or thermoplastic polymer, and one or more conductive material distributed evenly in the substrate. The conductive material in the substrate is at least one or more composition. The particle size of the conductive material is at the nanometer level or ranges from the nanometer level to the micron level. The metal sputtering layer is processed by utilization of a metal vacuum magnetron sputtering technology. The substrate the sputtered metal of which is lead or a lead alloy is pasted, dried, cured and assembled to obtain the composite-material bipolar cell. The composite-material bipolar plate prepared by the technology has advantages of good corrosion resistance, firm bonding of the sputtering layer of the polar plate substrate, low contact resistance, light weight, low cost, and the like, and meets requirements of large-scale production.

Owner:CHANGZHOU YOUTEKE NEW ENERGY TECH

Battery electrolyte additive, and electrolyte and lithium ion battery using additive

PendingCN111384443AImprove interfacial wettabilityReduce interface contact resistanceSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentInterface impedance

The invention provides an additive applied to a battery electrolyte, which has a structure as shown in the following (I), and a substituent group is shown in the specification. The invention also provides an electrolyte and a battery using the additive. The additive provided by the invention can effectively reduce the interface impedance and charge transfer impedance between graphite, silicon carbon and other negative electrode materials and an electrolyte, thereby effectively improving the cycle stability and rate capability of the negative electrode materials.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

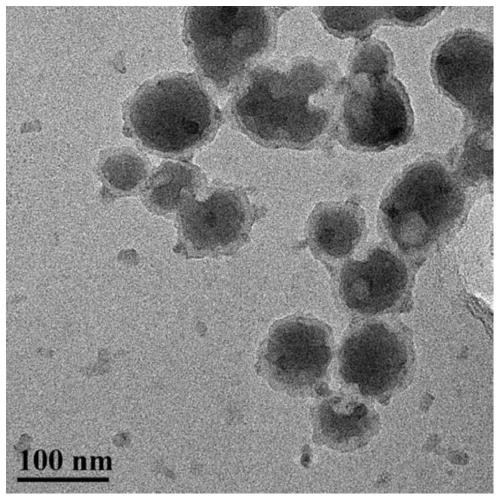

Membrane electrode assembly for solid polymer electrolyte electrolytic cell and preparation method

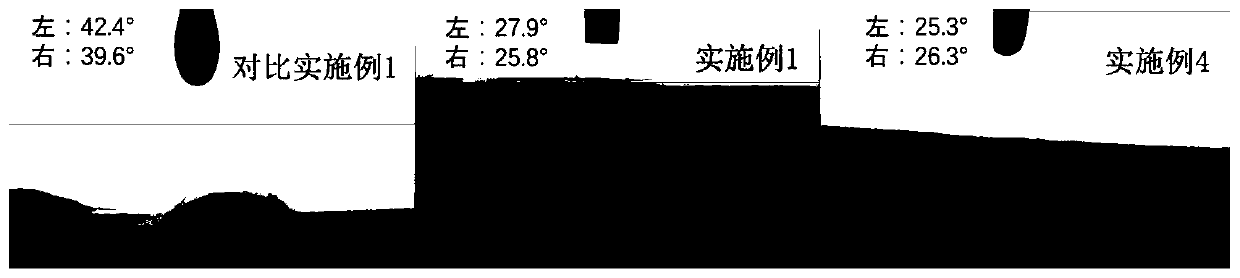

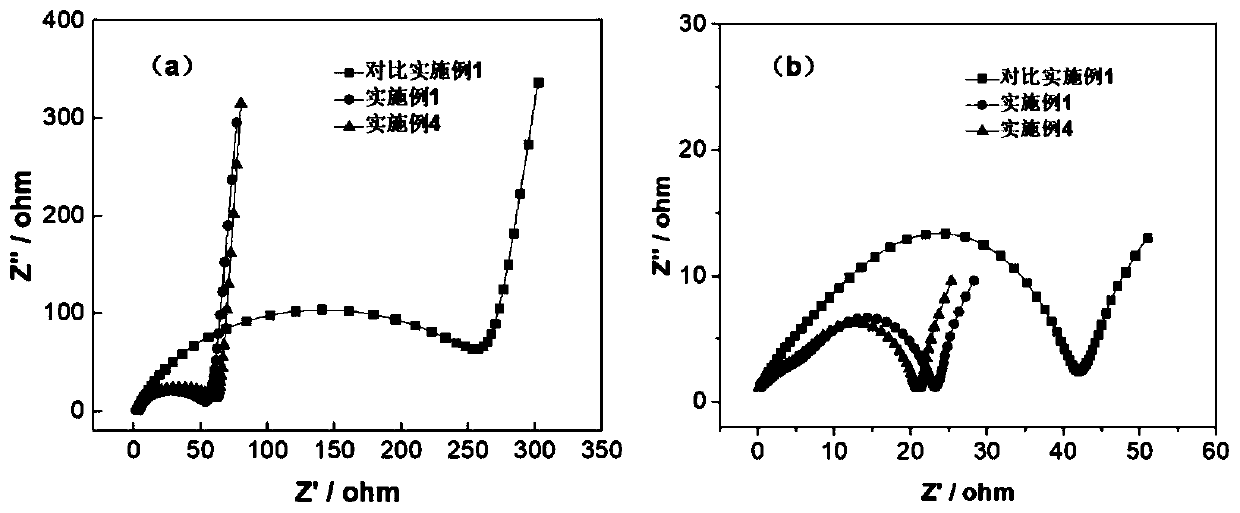

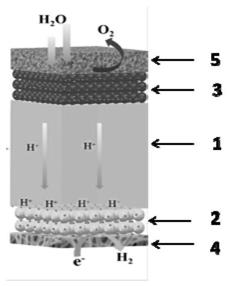

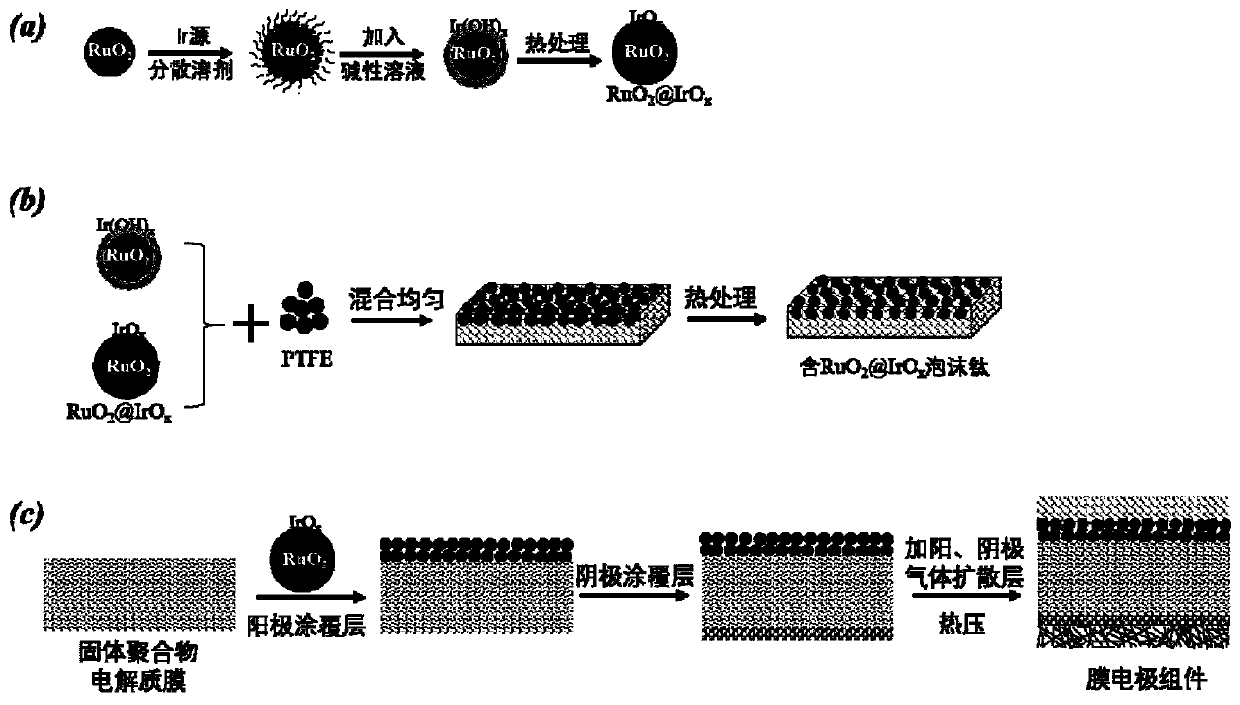

ActiveCN111139497AReduce use costReduce usageCellsElectrode shape/formsPtru catalystMaterials science

The invention provides a membrane electrode assembly for a solid polymer electrolyte electrolytic cell and a preparation method. The membrane electrode assembly comprises a solid polymer electrolyte membrane, a cathode catalyst coating layer and an anode catalyst coating layer which are arranged on the two sides of the solid polymer electrolyte membrane, and a cathode gas diffusion layer and an anode gas diffusion layer which are arranged on the two sides of the cathode catalyst coating layer and the two sides of the anode catalyst coating layer respectively; the above components are combinedtogether through a certain process to form the membrane electrode assembly. The anode catalyst is a core-shell structure catalyst of which the interior is ruthenium oxide and the exterior is iridium oxide; the anode gas diffusion layer is a porous titanium plate or foamed titanium and contains the core-shell structure catalyst; and the certain process combination is a hot-pressing process formingthe assembly. The membrane electrode assembly provided by the invention can realize low-cost, high-activity and long-life SPE electrolytic cell application.

Owner:TONGJI UNIV

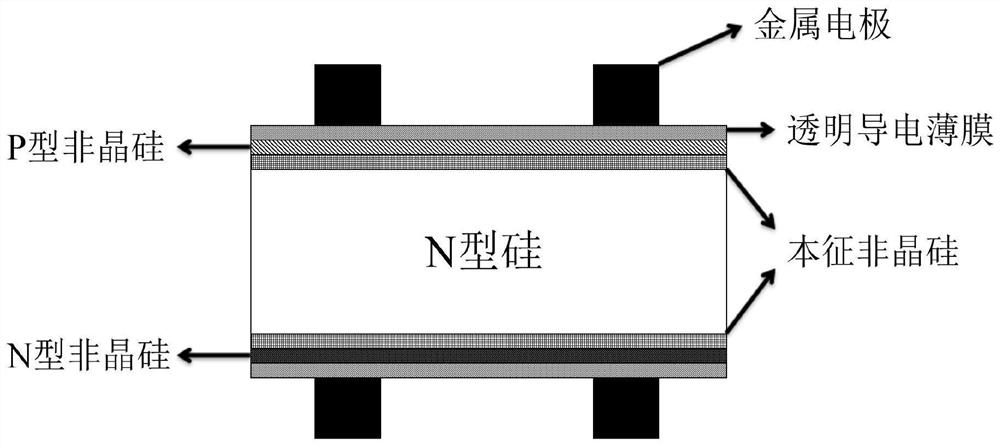

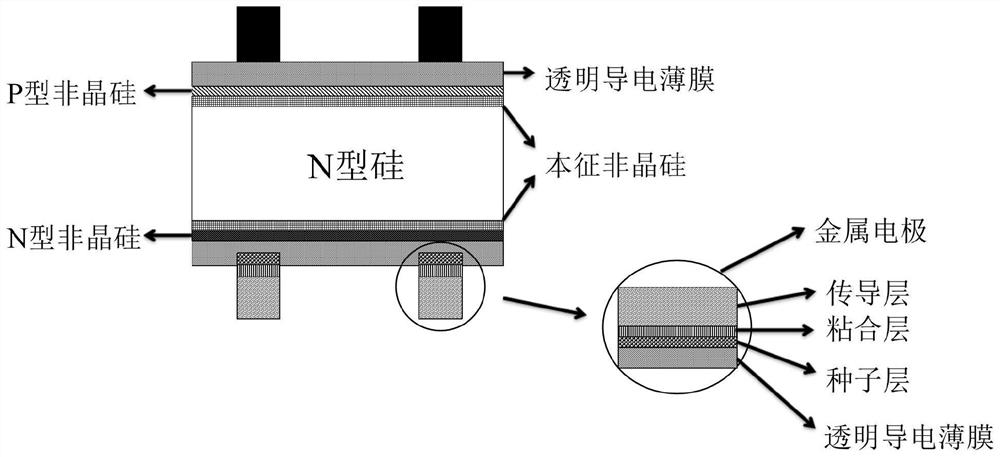

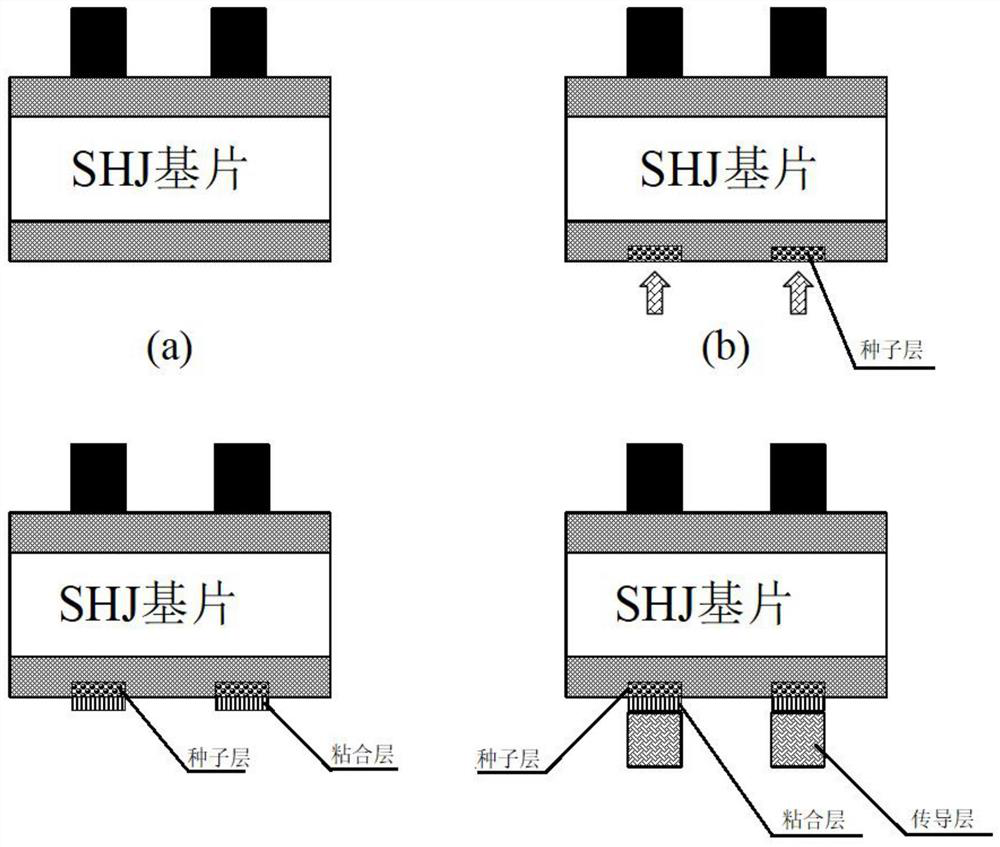

Mask-free preparation method of copper electrode of heterojunction solar cell

ActiveCN113066897AAvoid corrosionAvoids the corrosion processFinal product manufacturePhotovoltaic energy generationHeterojunctionMetallic electrode

The invention discloses a mask-free preparation method of a copper electrode of a heterojunction solar cell, which comprises the following steps of: preparing a heterojunction cell substrate, depositing transparent conductive films on two surfaces of the heterojunction cell substrate, preparing a metal grid line on the P side of the heterojunction cell substrate, immersing the N side into a solution to serve as a negative electrode, and connecting P-side metal grid line with the platinum electrode to serve as a positive electrode; preparing an indium layer metal seed layer through laser assistance; preparing a metal bonding layer on the formed metal seed layer in a chemical plating manner; preparing a metal conducting layer on the formed metal bonding layer in a bipolar pulse electroplating mode. According to the invention, the preparation of the metal electrode can be realized without adopting any mask pattern, the process complexity can be obviously reduced, the seed layer is formed by a laser-assisted method, the mask removal and the corrosion process of the full-area seed layer are avoided, the interface contact resistance can be reduced, the performance of the heterojunction cell is improved, and the purposes of high efficiency and low cost are realized.

Owner:湖州市鹑火光电有限公司

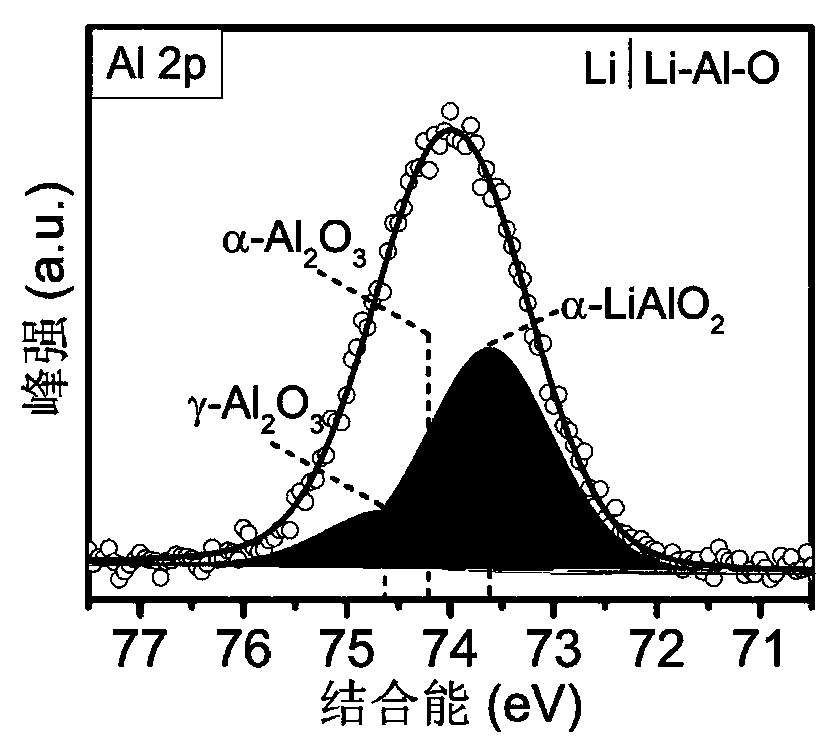

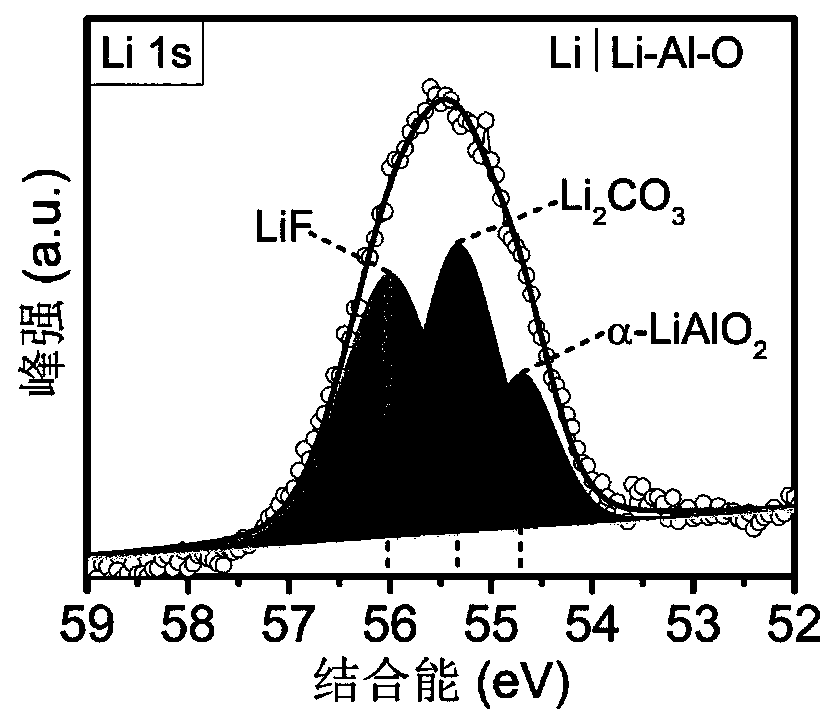

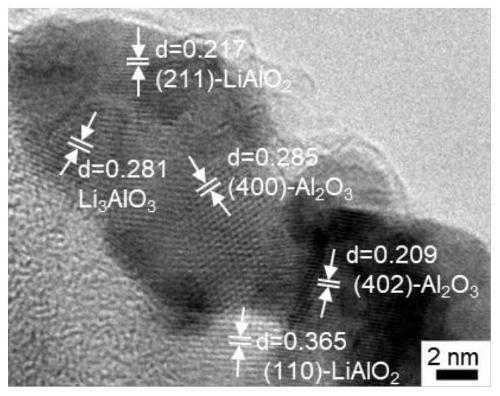

Solid-state lithium ion conductor, preparation method and application thereof

ActiveCN110323489ASimple methodLow costFuel and secondary cellsSecondary cellsElectrical conductorElectron

The invention relates to a solid-state lithium ion conductor, a preparation method and application thereof, and belongs to the field of secondary batteries. LiOH reacts with alkyl aluminum to obtain the solid-state lithium ion conductor of a polycrystal compound containing LiAlO2 and Li3AlO3. Preferably, the reaction is performed in a liquid electrolyte, and the electrolyte is a solution obtainedby dissolving a lithium salt into an organic solvent. Preferably, LiOH is obtained by a lithium on-chip in-situ reaction or powdery LiOH. Electrodes of the solid-state lithium ion conductor prepared in the invention are high in ionic conductivity at room temperature and low in electronic conductivity, and the solid-state lithium ion conductor is tightly combined with lithium metal so that the interface contact resistance can be greatly reduced. The prepared solid-state lithium ion conductor is applied into metal lithium batteries, the problem of lithium dendrites can be improved effectively and obviously, and lithium metal is protected, so that the cycle performance of the metal lithium batteries is promoted comprehensively. The solid-state lithium ion conductor prepared by the method doesnot need heating, the preparation technology is simple, and the cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

Solid-state electrolyte, preparation method thereof and solid-state battery

InactiveCN112086678AImprove ionic conductivityImprove lack of stabilitySolid electrolytesFinal product manufactureSolid state electrolyteElectrolytic agent

The invention discloses a solid electrolyte and a preparation method thereof. The solid electrolyte comprises the following components: a ceramic-based ion conductor, a polymer ion conductor and a lithium salt, wherein the polymer ion conductor includes a base polymer and a dopant. The invention also discloses a solid-state battery. The components of the solid electrolyte are improved and optimized, and the ceramic-based ion conductor, the polymer ion conductor and the lithium salt are combined for use, so the ionic conductivity of the solid electrolyte is improved, and the solid electrolyte has relatively small interface impedance and good mechanical properties; in addition, good stability is achieved. By adding a trace amount of electrolyte into the positive electrode plate, the interface contact impedance can be effectively reduced, and meanwhile, the diffusion rate of lithium ions in a solid phase is increased. The prepared solid-state battery is excellent in performance, the maximum working voltage is greater than 4V, the safety performance is good, and the solid-state battery has a very good application prospect.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

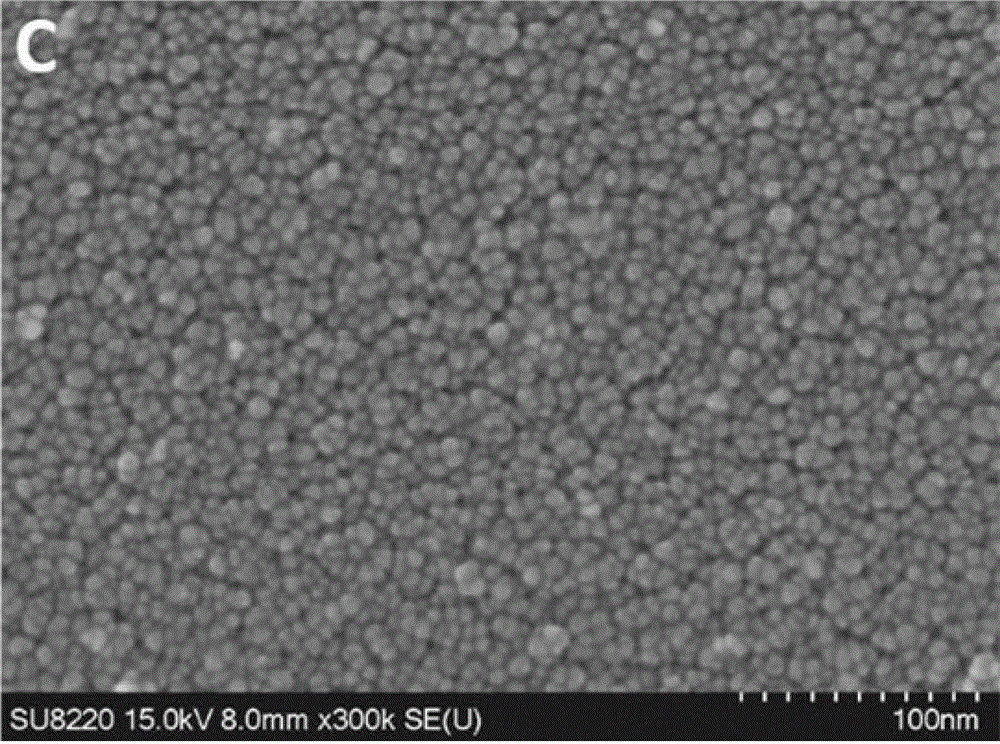

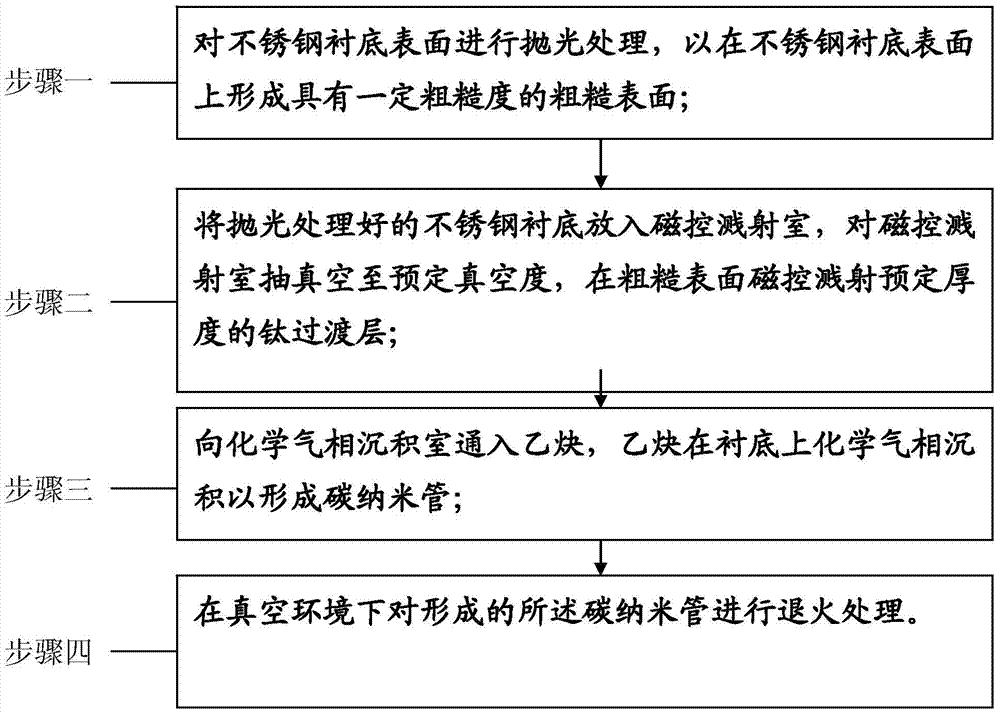

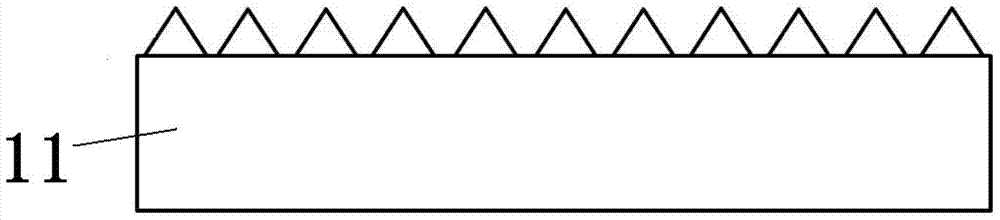

Carbon nano-tube cathode preparation method

InactiveCN103811240ASimple processLow impurity contentDischarge tube main electrodesCold cathode manufactureRough surfaceCarbon nanotube

The invention relates to a carbon nano-tube cathode preparation method. The method includes the steps: polishing the surface of a stainless steel substrate, and forming a rough surface with a certain roughness on the surface of the stainless steel substrate; placing the stainless steel substrate into a magnetron sputtering chamber, evacuating the magnetron sputtering chamber to reach a preset vacuum degree, sputtering a titanium transition layer with a preset thickness on the rough surface by magnetron, placing the stainless steel substrate sputtered with the titanium transition layer into a chemical vapor deposition chamber, leading acetylene into the chemical vapor deposition chamber, and performing chemical vapor deposition of the acetylene on the substrate to form a carbon nano-tube; annealing the formed carbon nano-tube in a vacuum environment. When the formed carbon nano-tube is annealed, titanium, the carbon nano-tube and the substrate react, so that the carbon nano-tube and the substrate are organically combined, the combined strength of the carbon nano-tube and the substrate is enhanced, interface contact resistance is decreased, electron transfer capacity is enhanced, the carbon nano-tube in a carbon nano-tube cathode is prepared by the method, and performances of the carbon nano-tube cathode can be improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

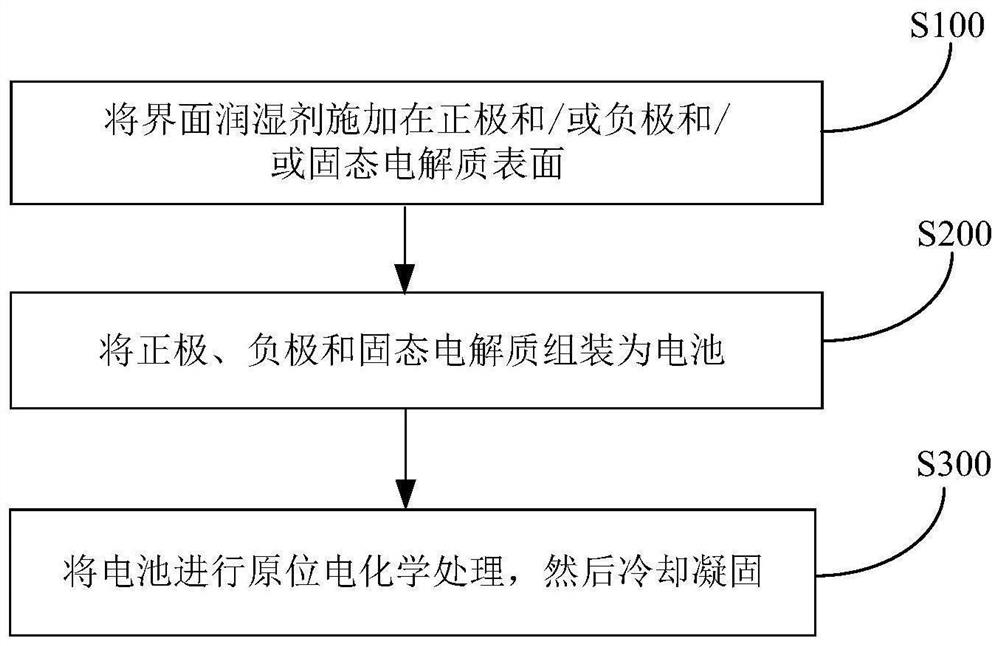

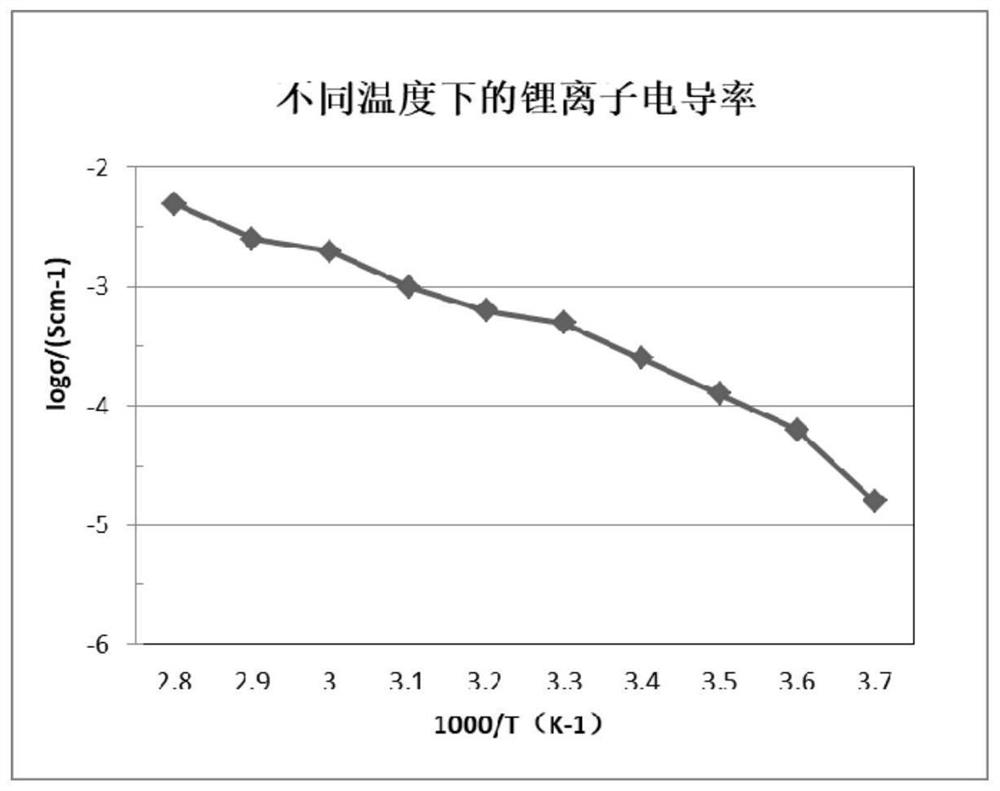

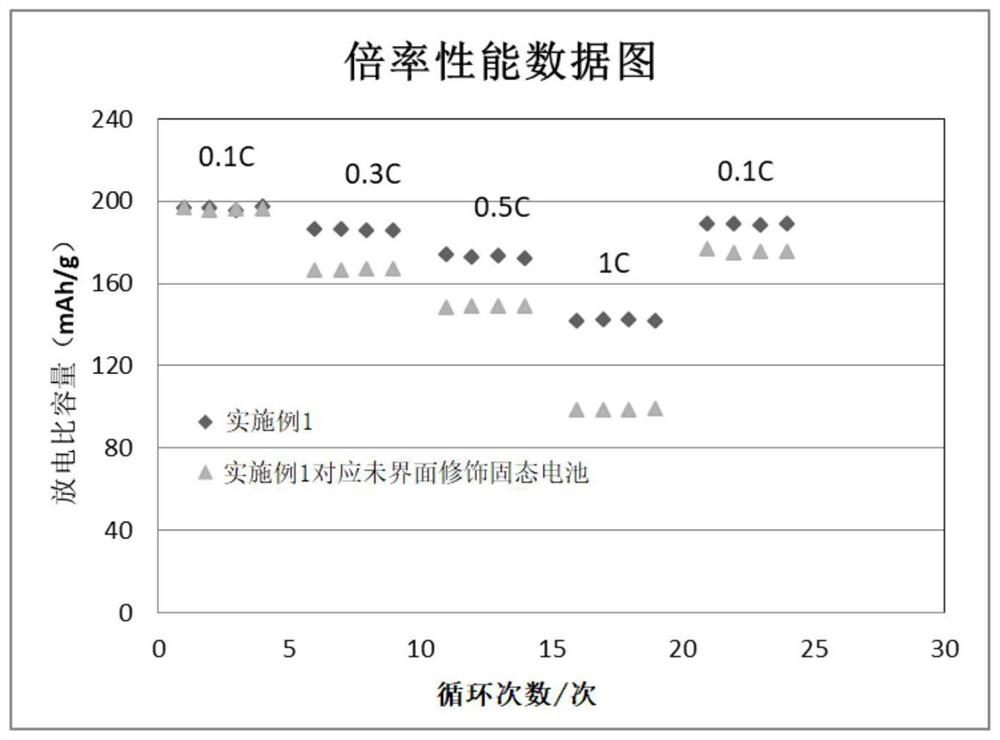

Interface wetting agent and preparation method and application thereof

InactiveCN112002951AHigh lithium ion conductivityGuaranteed uniformityFinal product manufacturePropulsion by batteries/cellsPhosphorous acidMethyl carbonate

The invention discloses an interface wetting agent and a preparation method and application thereof. The interface wetting agent comprises a plastic crystal compound, inorganic lithium salt, a first additive and a second additive, wherein the first additive comprises at least one of ethyl carbonate / propylene ester, dimethyl carbonate / ethyl carbonate, ethyl methyl carbonate, trifluoropropenyl esterand lithium difluorophosphate; the second additive comprises at least one from lithium carbonate, trifluoromethyl phosphorous acid, methyl chloroformate, bromo-butyrolactone, fluoroacetate ethane, fluoroethylene carbonate, vinylene carbonate, vinylethylene carbonate, vinyl acetate, styrene carbonate, ethyl aminocarbonate, methyl aminocarbonate, 1, 3-dioxolane, 1, 4-dioxane, 1, 2-bis (cyanoethoxy)ethane, ethylene sulfate and dimethyl sulfite. The interface wetting agent has the advantages of high lithium ion conductivity and better electrochemical stability, the interface resistance of the solid-state battery can be effectively reduced, and the multiplying power and the cycle performance of the solid-state battery are improved.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

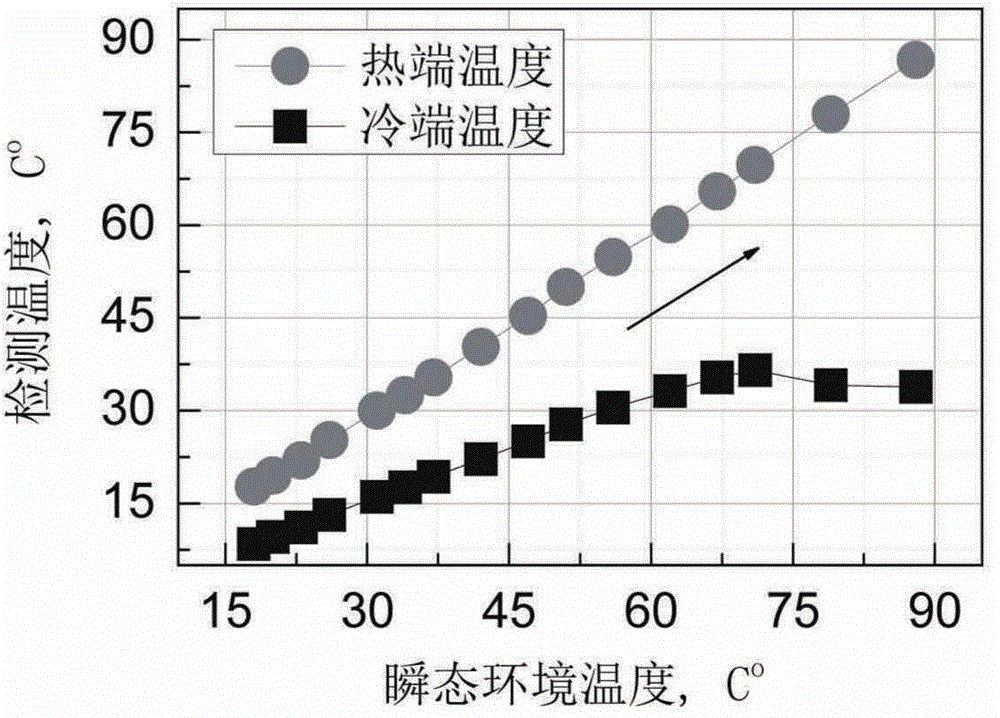

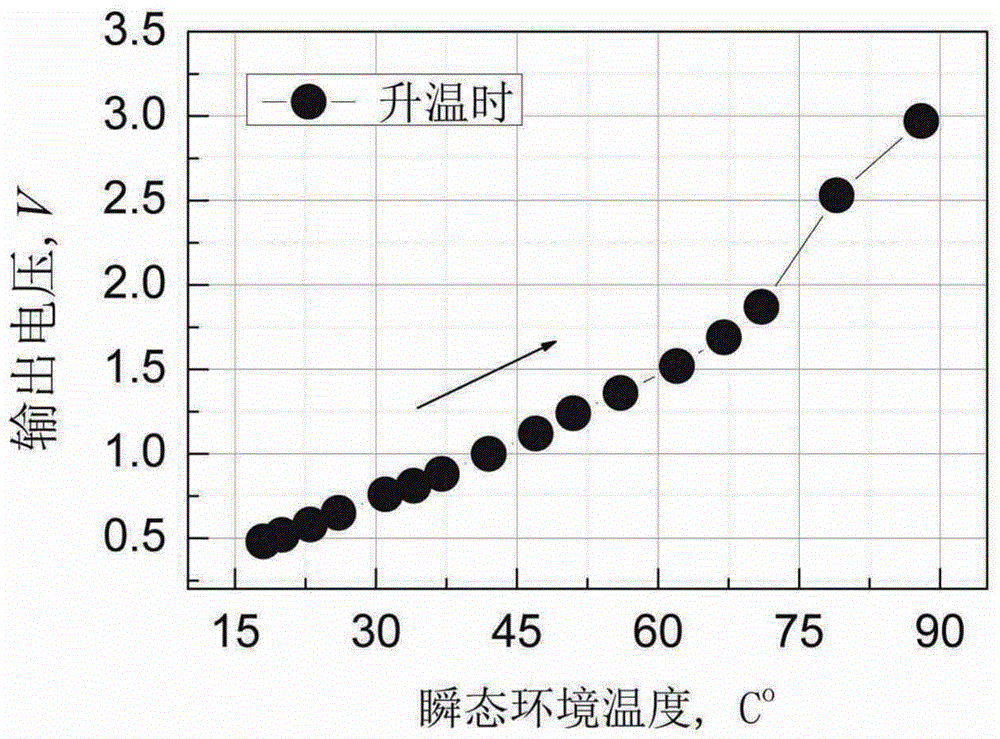

Preparation process of single-arm structure of thermoelectric semiconductor temperature sensor chip

InactiveCN103698035BImprove performanceSolution to short lifeThermometers using electric/magnetic elementsUsing electrical meansSemiconductor chipEngineering

The invention relates to a single arm structure for a thermoelectric semiconductor temperature sensing sheet and a preparation process, and aims to solve the technical problem of thermal cracks caused by large thermal stress in a like product. The single arm structure for the thermoelectric semiconductor temperature sensing sheet comprises a thermoelectric semiconductor and Cu guide vanes positioned at the two ends of the thermoelectric semiconductor, wherein three transition layers, i.e. an Ni-coated layer, an Ni-plated layer and an Sn95Ag5-plated layer, are arranged between each of the two ends of the thermoelectric semiconductor and the corresponding Cu guide vane; the Ni-coated layers, the Ni-plated layers and the Sn95Ag5-plated layers are sequentially arranged from the end parts of the thermoelectric semiconductor to the surfaces of the Cu guide vanes. According to the single arm structure and the preparation process, the transition layers are arranged, so that a buffering function is realized, and the thermal stress which is generated between the thermoelectric conductor and the Cu guide vanes caused by the great thermal expansion coefficient difference is reduced; the single arm structure is high in thermal stability and suitable for various thermoelectric semiconductor temperature sensing sheets, the problem of thermal cracks in a thermoelectric semiconductor temperature sensor is solved, and the service life of the temperature sensor is prolonged.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Stainless steel for fuel cell separator plate and manufacturing method therefor

ActiveCN107925040AReduce interface contact resistanceImprove corrosion resistanceFinal product manufactureCell component detailsFuel cellsSS - Stainless steel

Stainless steel for a fuel cell separator plate and a manufacturing method therefor are disclosed. The stainless steel for a fuel cell separator plate, according to one embodiment of the present invention, comprises: a stainless base material; and a passive film formed on the stainless base material, wherein a Cr / Fe atomic weight ratio in a 1 nm or less thickness region of the stainless base material, which is adjacent to an interface between the stainless base material and the passive film, is 0.45 or more. Therefore, by modifying the surface of the stainless steel for a fuel cell separator plate, a low interface contact resistance and a good corrosion resistance can be obtained, and a separate additional process such as precious metal coating can be removed, such that manufacturing costsare reduced and productivity can be improved.

Owner:浦项股份有限公司

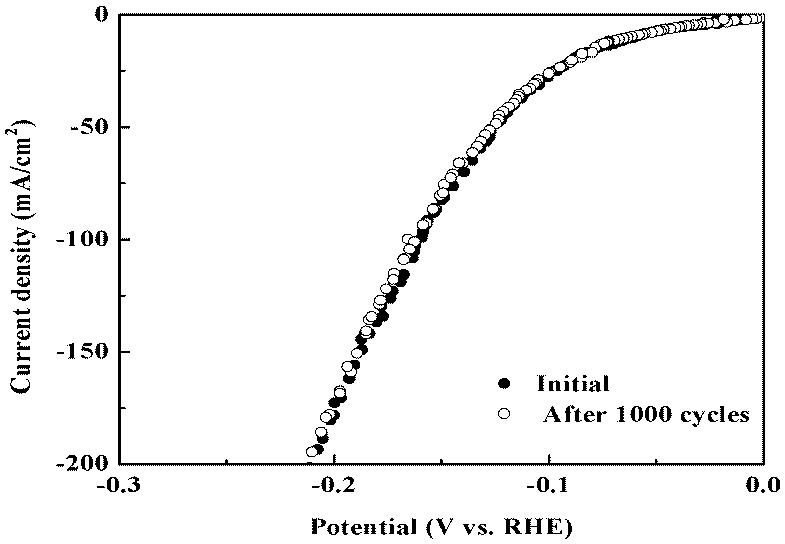

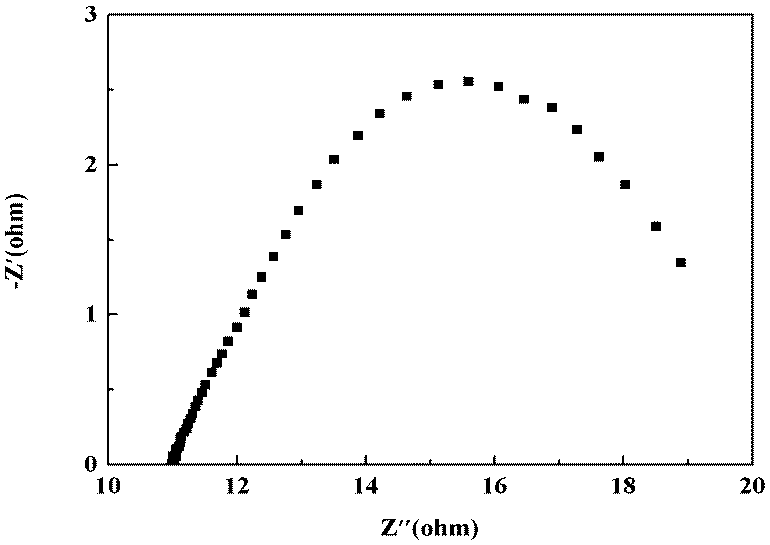

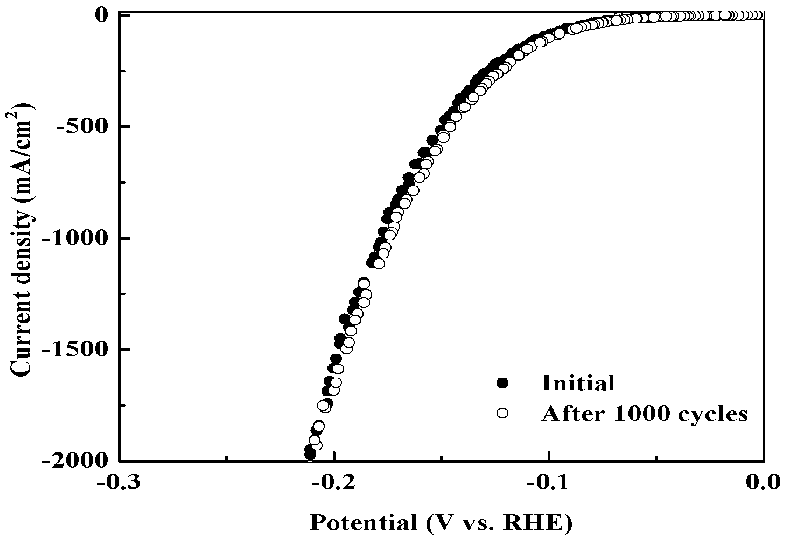

Design synthesis and water electrolysis hydrogen evolution research of efficient nickel-cobalt phosphide heterojunction catalyst

PendingCN113856711AWide variety of sourcesGood bondingPhysical/chemical process catalystsElectrodesPtru catalystHydrogen fuel cell

The invention discloses a preparation method of a high-performance nickel-cobalt phosphide hydrogen evolution catalyst and an efficient water electrolysis hydrogen evolution research, and belongs to the technical field of water electrolysis hydrogen production and new energy. The preparation method is characterized by comprising the steps of: phosphorizing foam metal substrates such as foam cobalt and foam nickel through a chemical vapor deposition method to prepare a non-noble metal phosphide Co2P / Ni2P porous conductive skeleton; and soaking the conductive skeleton in a solution of cobalt, nickel and other metal salts, and drying and phosphorizing the conductive skeleton again to obtain the non-noble metal phosphide hydrogen evolution catalyst with a nano-porous structure which shows excellent catalytic hydrogen evolution activity and stability in neutral and alkaline environments. The unique structural design greatly exposes the active sites of the metal phosphide, reduces the contact resistance among the components of the material, contributes to hydrogen adsorption and release and accelerates charge transfer among different component interfaces, thereby greatly reducing the overpotential of hydrogen reaction and assisting the development of the hydrogen energy industry and hydrogen fuel cells in China.

Owner:HUNAN NORMAL UNIVERSITY

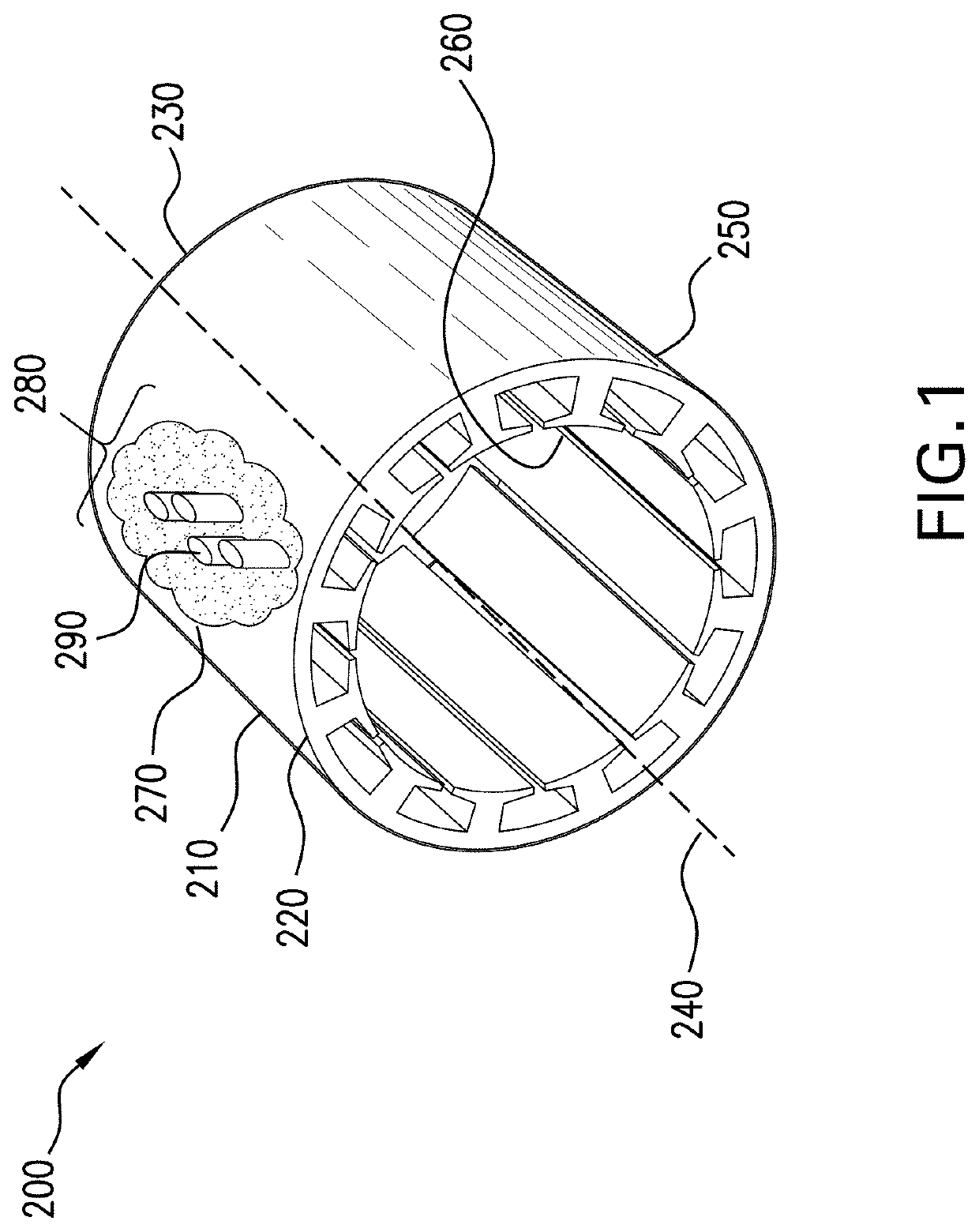

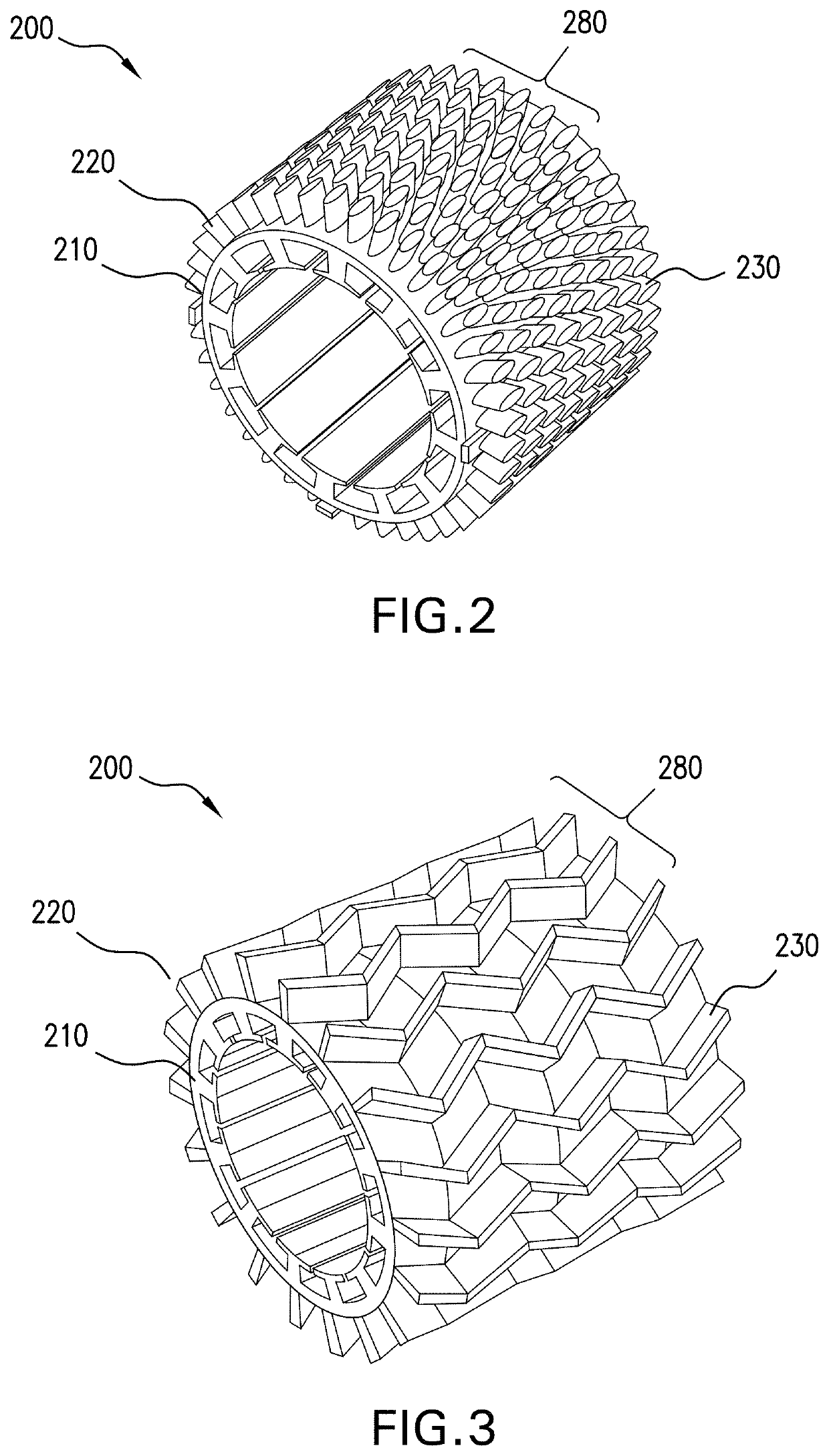

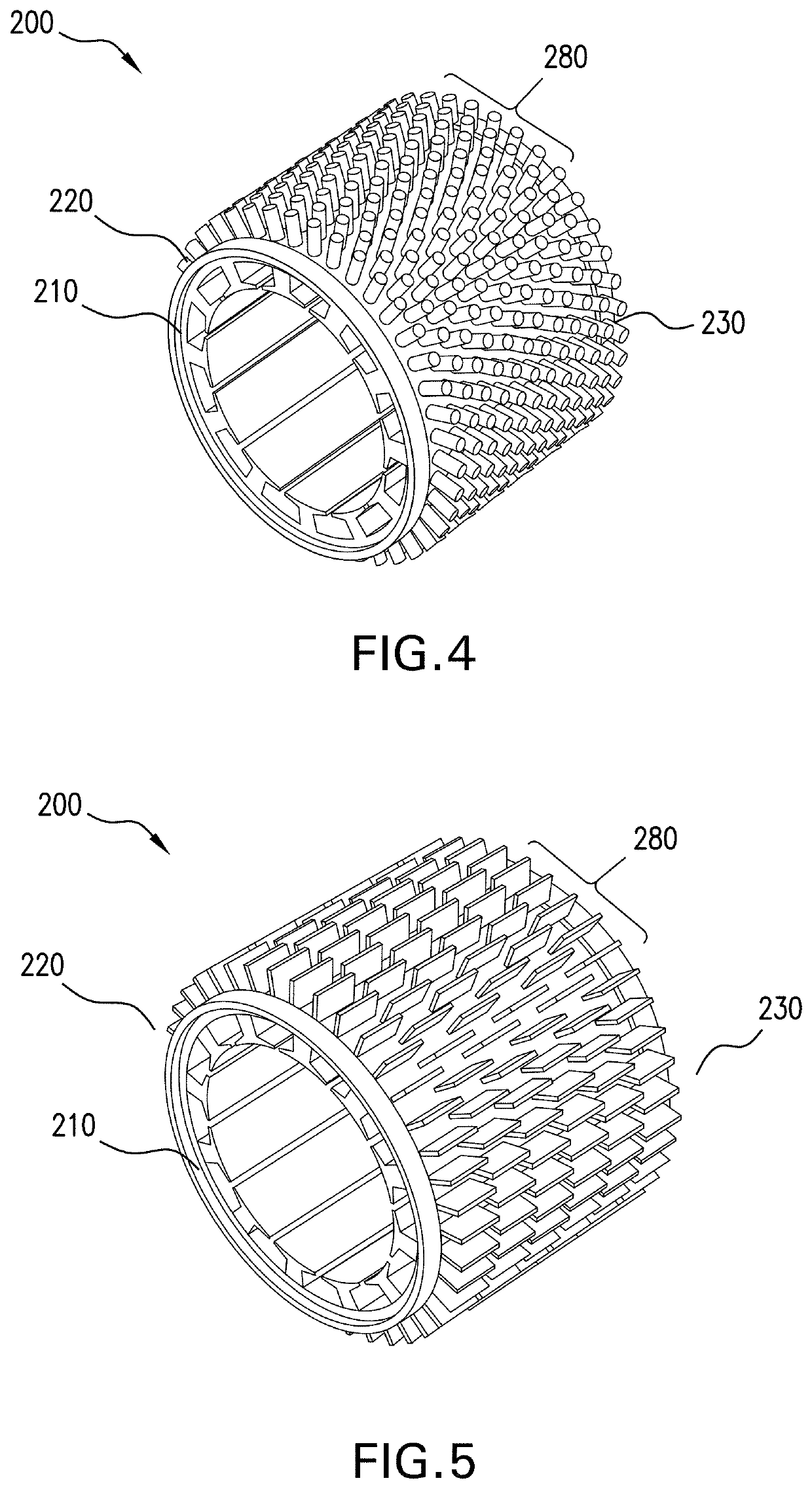

Electric machine cooling features

ActiveUS20200083783A1Reduce interface contact resistanceMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectrical resistance and conductanceElectric machine

Disclosed is a stator having: a first member having a first plurality of axially opposing ends including a first front end and a first back end mutually spaced along a first stator center axis, a first outer diameter (OD) side and a first inner diameter (ID) side, wherein first member comprises laminated steel; a plurality of cooling features disposed directly against the first member, wherein the plurality of fins spans between the first plurality of axially opposing ends of the first member, and wherein: the stator comprises a base layer disposed directly against the first member, between the first member and the cooling features, thereby reducing an interface contact resistance between the first member and the plurality of cooling features.

Owner:HAMILTON SUNDSTRAND CORP

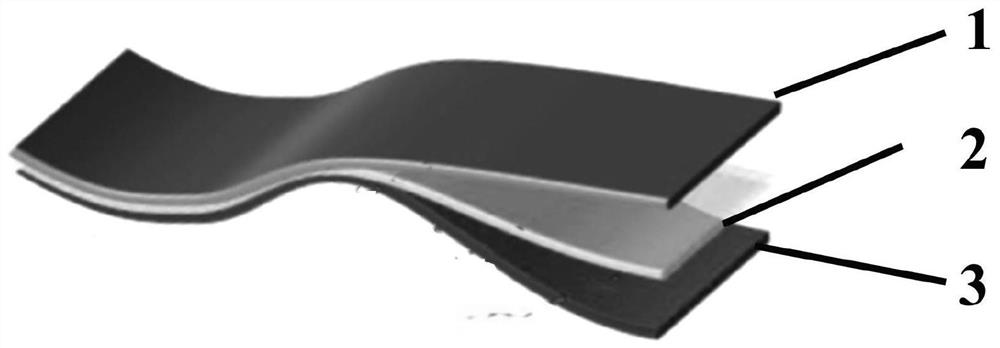

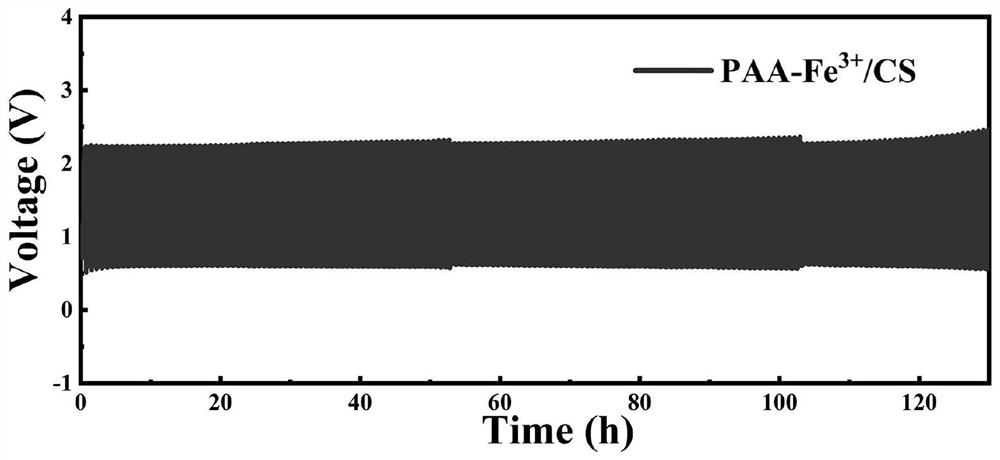

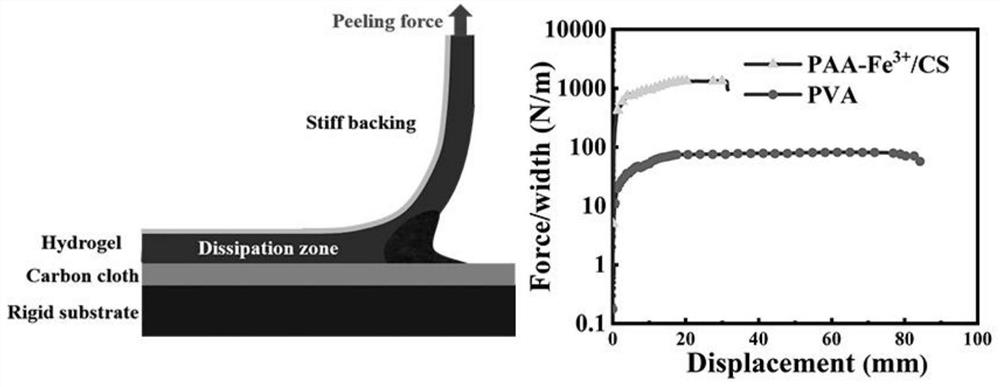

Preparation method of high-toughness gel electrolyte and all-solid-state zinc-air battery with firm interface

ActiveCN112886100AReduce interface contact resistanceReduce battery polarizationFuel and primary cellsElectrolyte immobilisation/gelificationIron chlorideSalt solution

The invention discloses a high-toughness gel electrolyte. Specifically, an original weak PAA-Fe<3+> / CS hydrogel is soaked in a salt solution by utilizing a Hofmeister effect, and the toughness-enhanced PAA-Fe<3+> / CS hydrogel electrolyte with excellent mechanical properties is prepared. Ammonium chloride and zinc chloride are used as ionic conductors in an electrolyte, polyacrylic acid is used as a polymer skeleton, ammonium persulfate is used as an initiator, in the presence of chitosan and ferric chloride, PAA-Fe<3+> / CS hydrogel is prepared through one-pot free radical polymerization, after a PAA-Fe<3+> network is constructed, chain entanglement of chitosan is induced by adopting a soaking strategy, and the high-toughness electrolyte for an zinc-air battery is obtained. The electrolyte has high toughness, can be assembled into a battery to avoid relative displacement or separation caused by bending strain, enhances interface contact to promote electrochemical kinetics, and shows good working time and durability.

Owner:ANHUI UNIVERSITY

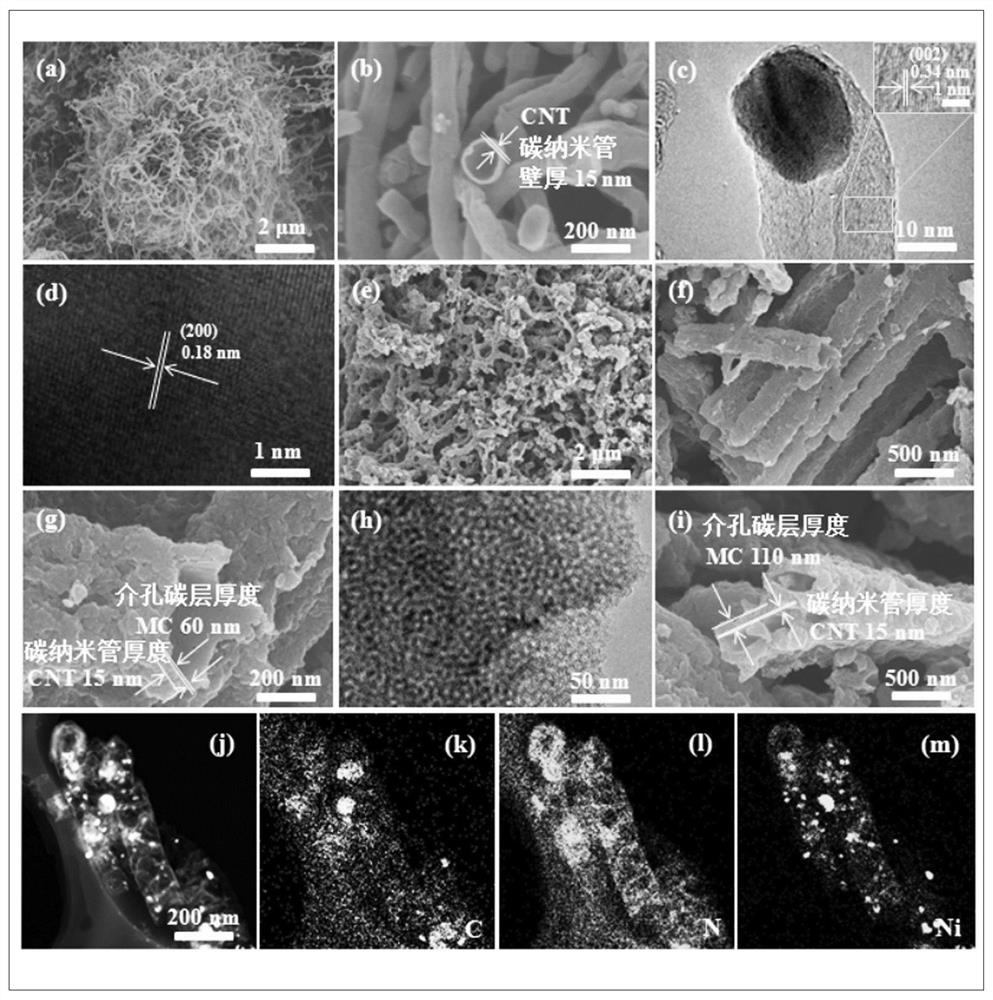

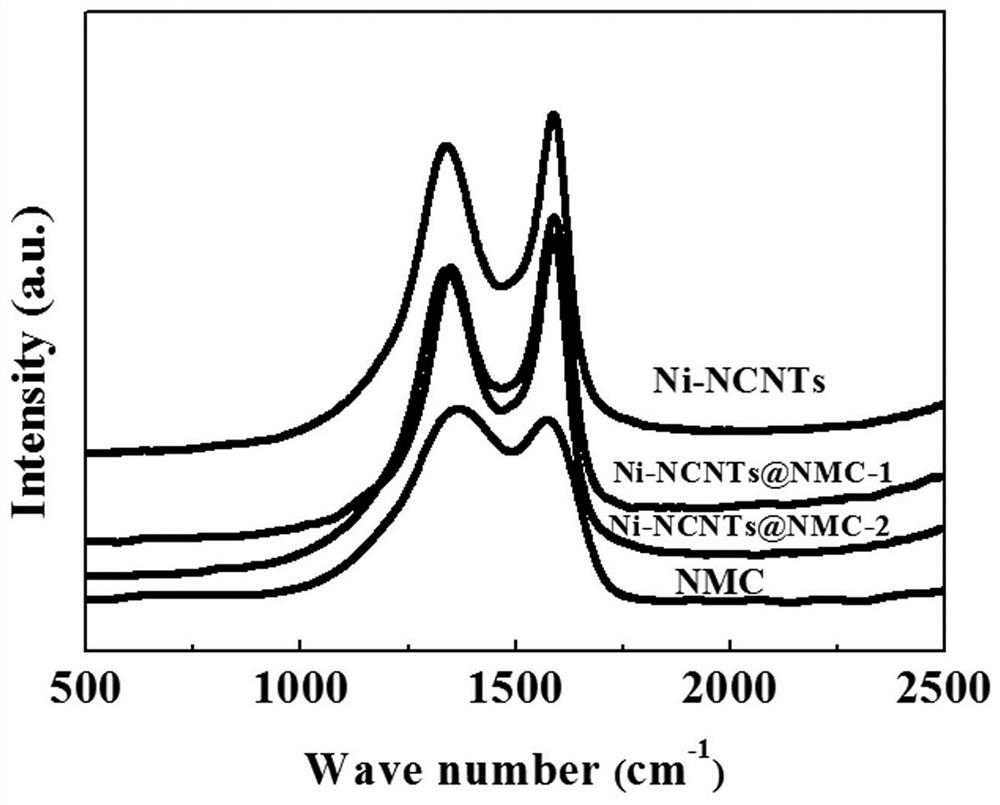

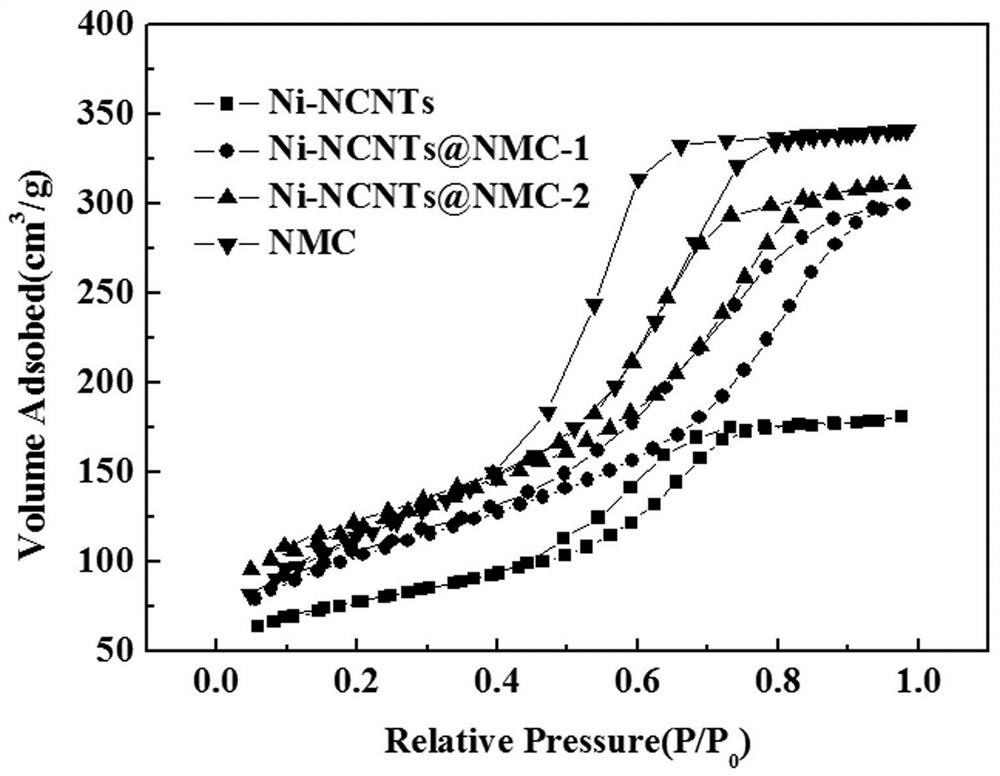

Transition metal-nitrogen co-doped carbon nanotube-mesoporous carbon composite counter electrode material for dye-sensitized solar cell

PendingCN114496579AReduce interface contact resistanceIncrease the interfacial electron transfer rateLight-sensitive devicesDye-sensitized solar cellDoped carbon

The invention discloses a transition metal / nitrogen co-doped carbon nanotube and mesoporous carbon shell composite counter electrode material for a dye-sensitized solar cell. The transition metal / nitrogen co-doped carbon nanotube and mesoporous carbon shell composite counter electrode material is composed of a transition metal / nitrogen co-doped carbon nanotube and a mesoporous carbon shell layer, the outer layer of the metal / nitrogen co-doped carbon nanotube is coated with the mesoporous carbon shell layer to form a tube-in-tube carbon special-shaped interface structure, the thickness of the mesoporous carbon shell layer in the composite counter electrode material is 50-200 nanometers, and the size of a mesoporous channel is 3-6 nanometers. The transition metal / nitrogen co-doped carbon nanotube-mesoporous carbon shell composite counter electrode material with specific chemical components and morphological structure provided by the invention shows the application advantages of lower charge transfer impedance, higher photoelectric conversion efficiency, better electrochemical stability and the like compared with a traditional Pt counter electrode in the application of a dye-sensitized solar cell; and the preparation process is simple, the cost is low, large-scale production is easy, and commercial application of the dye-sensitized solar cell is promoted.

Owner:XINYANG NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com