Stainless steel for fuel cell separator plate and manufacturing method therefor

A fuel cell and stainless steel technology, used in fuel cell parts, fuel cells, battery pack parts, etc., can solve the problems of spending a lot of time, low pickling efficiency, etc., to improve productivity, low interface contact resistance, reduce The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

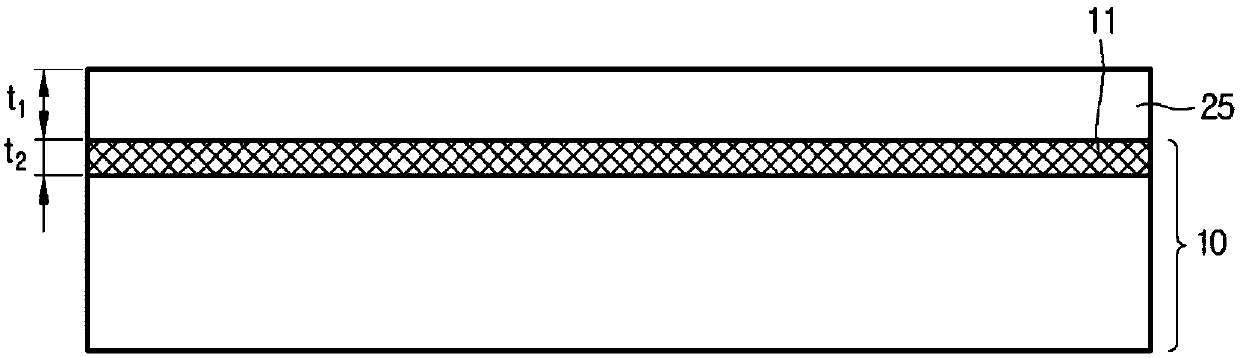

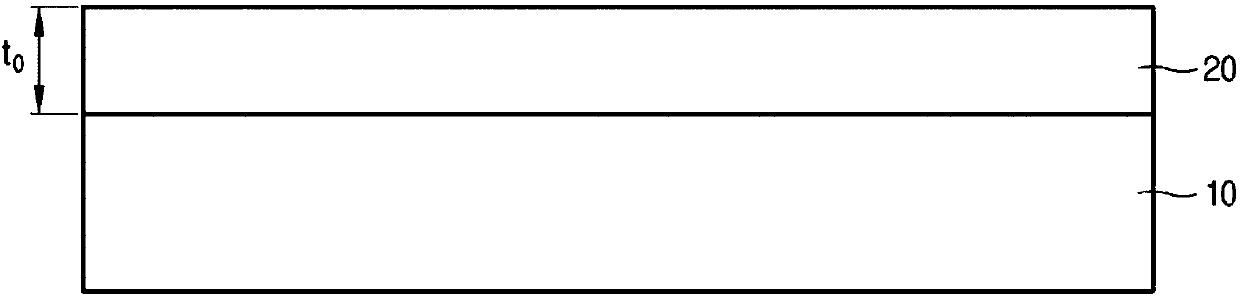

[0119] Under the conditions of Example 1 of the present invention listed in the following table 1, in a sulfuric acid solution, a cold-rolled sheet with a thickness of 0.1 mm (using a cold rolling mill (i.e. a Z-rolling mill) to contain 30% by weight (weight %) Cr After cold rolling, the ferritic-based stainless steel was subjected to a bright annealing heat treatment in a reducing atmosphere containing hydrogen (75% by volume) and nitrogen (25% by volume) to undergo first and second film denaturations, and then subjected to the second A three-membrane denaturation process in which the board is immersed in a mixed acid solution containing nitric and hydrofluoric acids. Thereafter, the physical properties of the cold-rolled sheets were evaluated.

Embodiment 2

[0121] A cold-rolled sheet having a thickness of 0.1 mm was produced under the same conditions as in Example 1, except that the cold-rolled sheet was made in a sulfuric acid solution under the conditions of Example 2 of the present invention listed in Table 1 below. Subjected to first and second membrane denaturations and then to a third membrane denaturation process in which the plates were immersed in a mixed acid solution comprising nitric acid and hydrofluoric acid. Thereafter, the physical properties of the cold-rolled sheets were evaluated.

Embodiment 3

[0123] A cold-rolled sheet having a thickness of 0.1 mm was produced under the same conditions as in Example 1, except that the cold-rolled sheet was made in a sulfuric acid solution under the conditions of Example 3 of the present invention listed in Table 1 below. Subjected to first and second membrane denaturations and then to a third membrane denaturation process in which the panels are immersed in a mixed acid solution comprising nitric and hydrofluoric acids. Thereafter, the physical properties of the cold-rolled sheets were evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com