Design synthesis and water electrolysis hydrogen evolution research of efficient nickel-cobalt phosphide heterojunction catalyst

A phosphide and catalyst technology, which is applied in the design and synthesis of high-efficiency nickel-cobalt phosphide heterojunction catalysts and the research field of electrolysis of water for hydrogen evolution, can solve the problems of limited activity of non-precious metal catalysts, increased hydrogen production cost, low energy conversion efficiency, etc. Achieve the effect of accelerating interface charge transfer, realizing industrial application, accelerating hydrogen ion adsorption and hydrogen molecule desorption process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

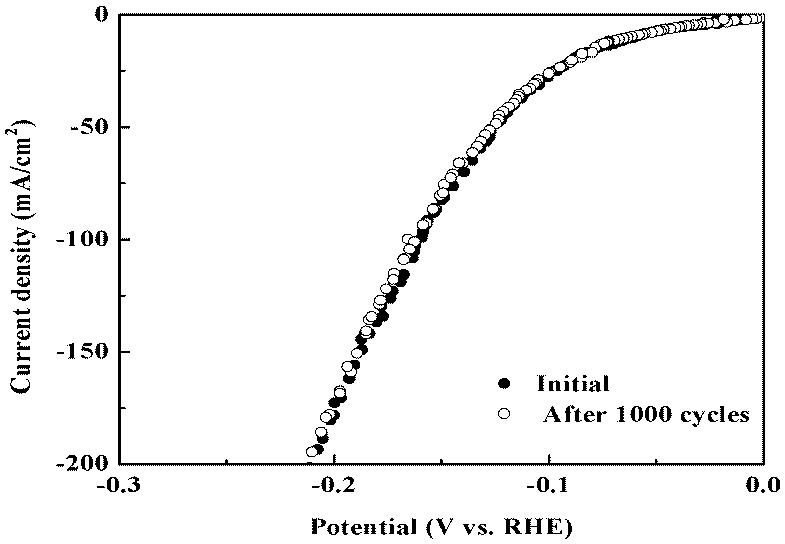

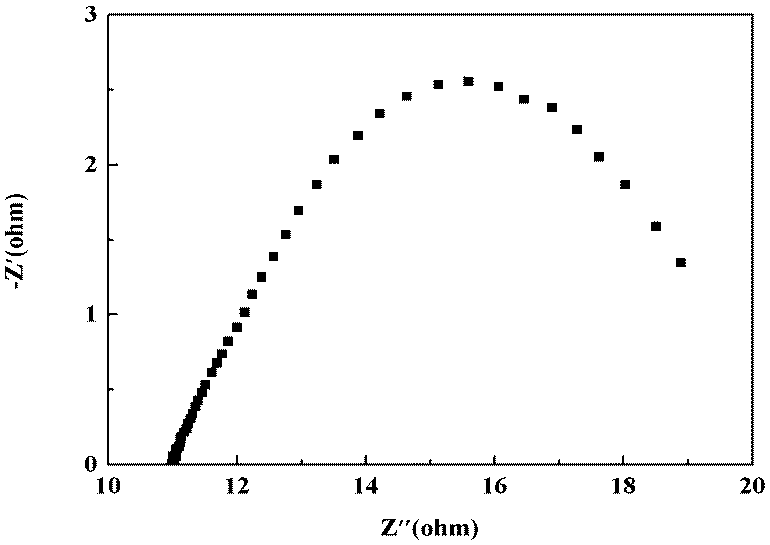

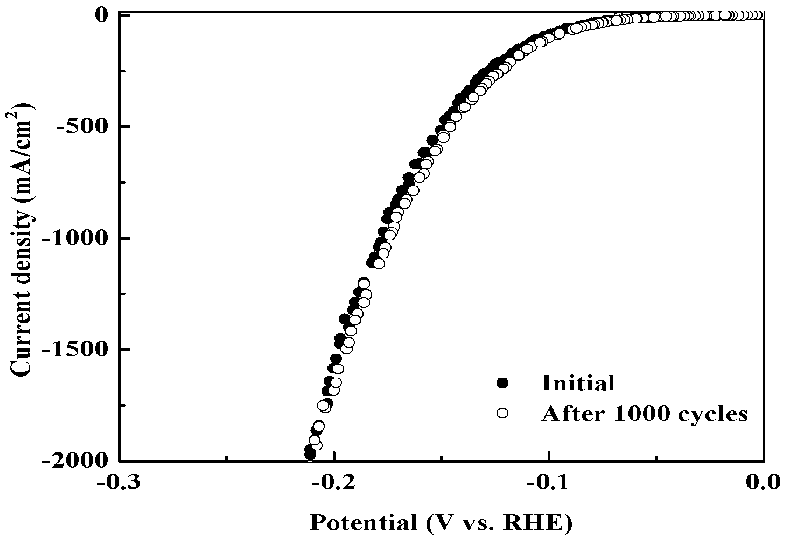

[0022] Example 1: Co 2 Preparation of P / CoNiP nanoporous catalyst and its electrocatalytic hydrogen evolution test in the environment of 1M PBS, 1 M KOH and 30% KOH.

[0023] Step 1: Cut the foamed cobalt-nickel base substrate, and the cutting area is 15 mm long * 5 mm wide.

[0024] Step 2: Prepare the CoNiP foam substrate. The method is as follows: push the cut foamed cobalt nickel and 50 mg of phosphorus powder into a double-temperature zone high-temperature tube furnace for phosphating reaction, and the phosphorus powder is placed in the center of the temperature zone upstream of the gas. A CoNiP foam substrate is placed in the center of the temperature zone downstream of the gas. Phosphorus powder and CoNiP foam substrate were heated from room temperature to 400 °C and 450 °C at a heating rate of 15 °C / min, respectively, and maintained at this temperature for 1 hour, then lowered to room temperature and taken out to obtain a CoNiP foam substrate.

[0025] Step 3: grow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com