Patents

Literature

199 results about "Hydrogen adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

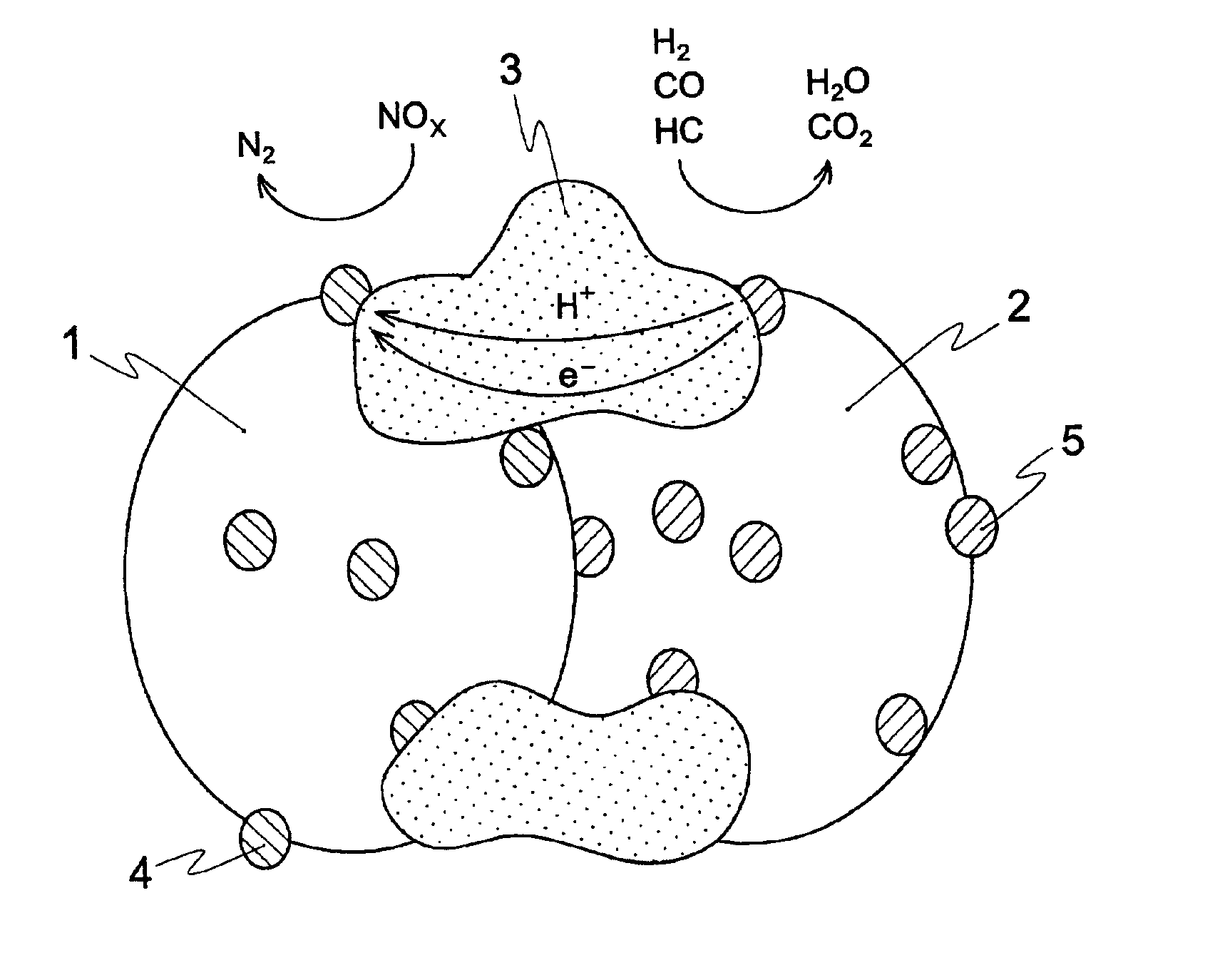

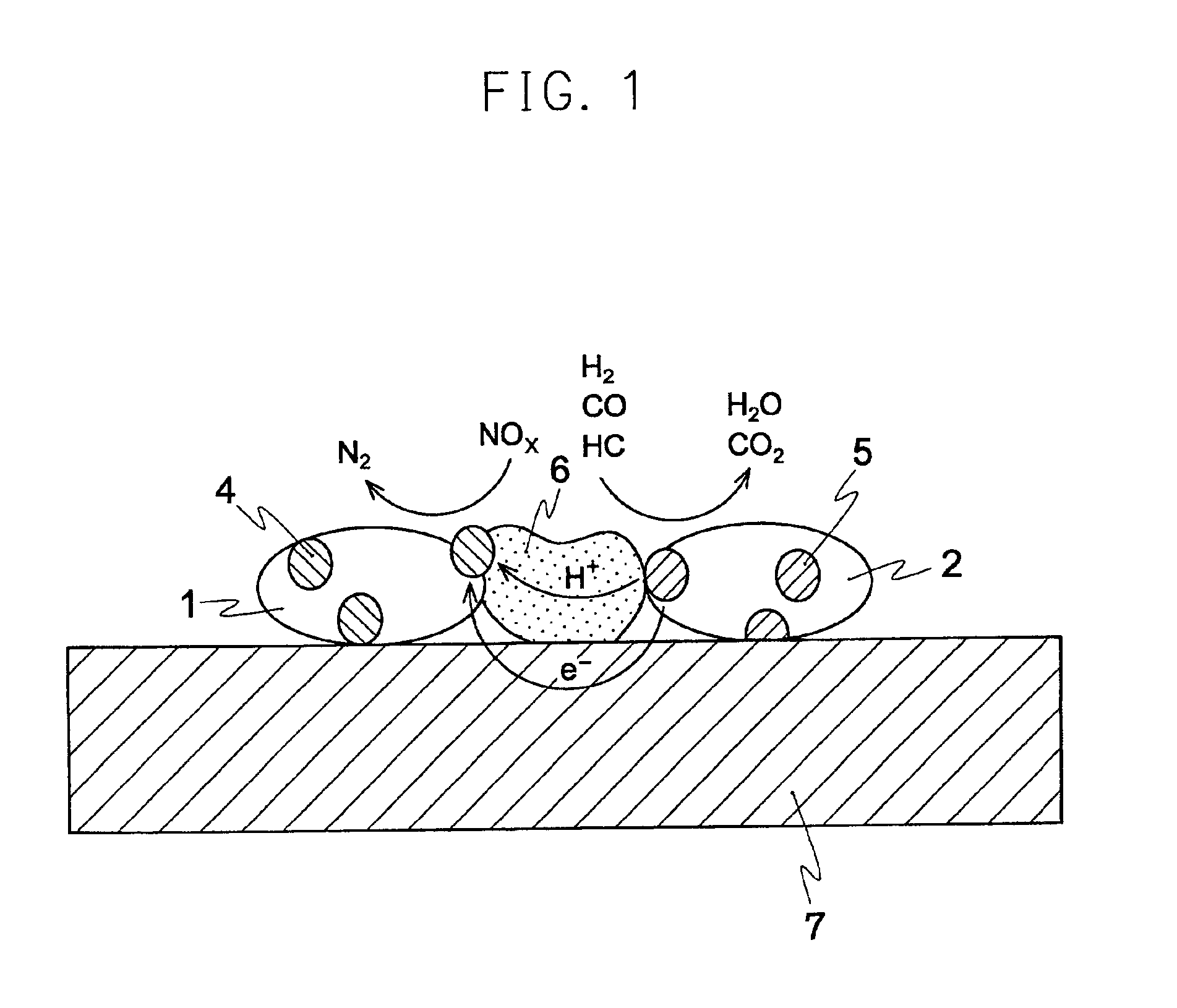

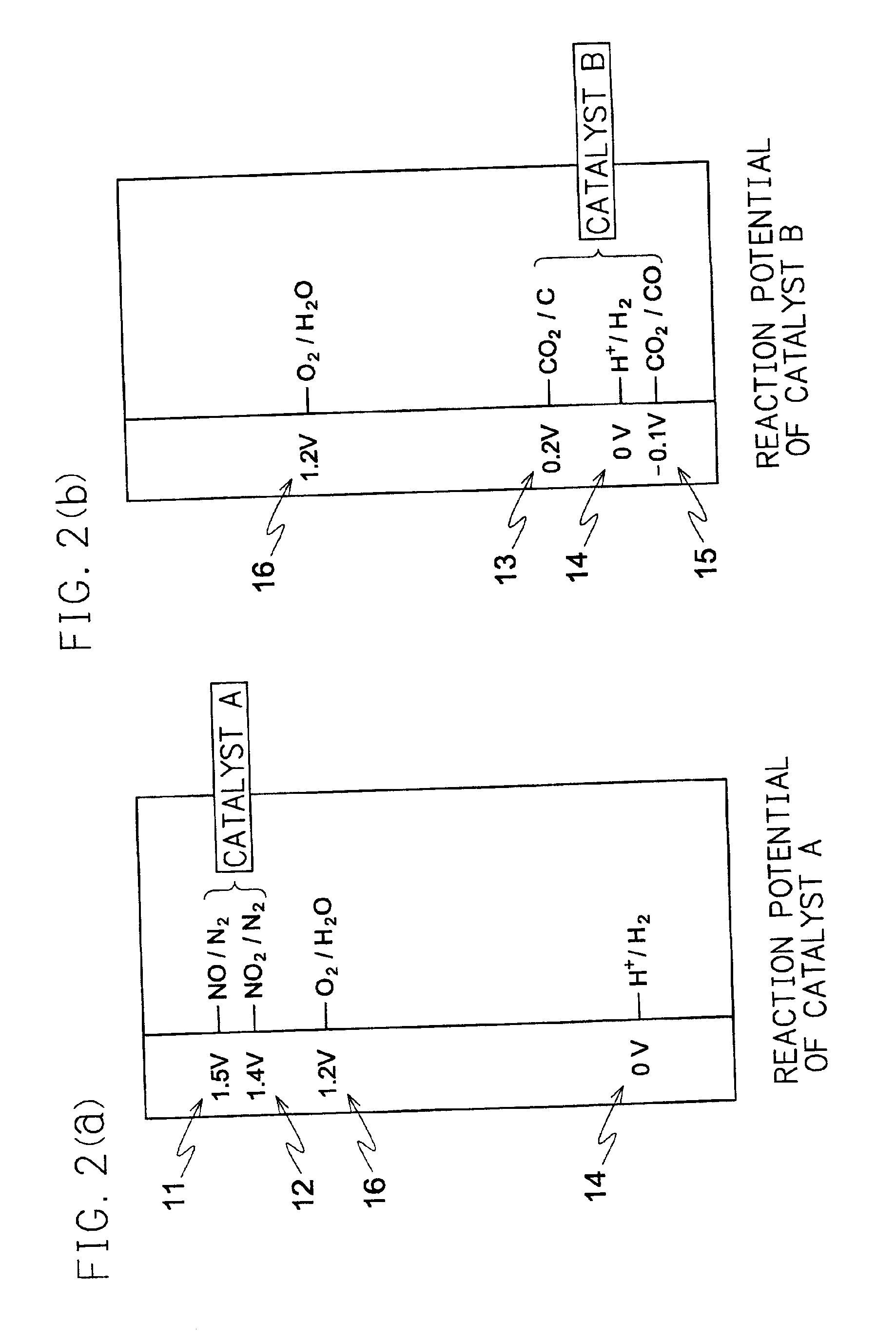

Catalyst and process for exhaust purification

A catalyst for internal combustion engine exhaust purification without frequently switching to a rich burn mode. The catalyst includes a catalyst A containing an NOx absorbing substance and an NOx reducing catalyst, a catalyst B containing a hydrogen adsorption substance and a hydrogen oxidizing catalyst, an electron conductive substance C, and an ion conductive substance D. Electrons move between the catalyst A and the catalyst B through the electron conductive substance C, ions move through the ion conductive substance D, and an electrochemical reducing reaction and an electrochemical oxidizing reaction respectively occur on the catalyst A and on the catalyst B. Therefore, it is possible to quickly reduce the adsorbed NOx using the adsorbed hydrogen without depending on the atmosphere.

Owner:MITSUBISHI ELECTRIC CORP

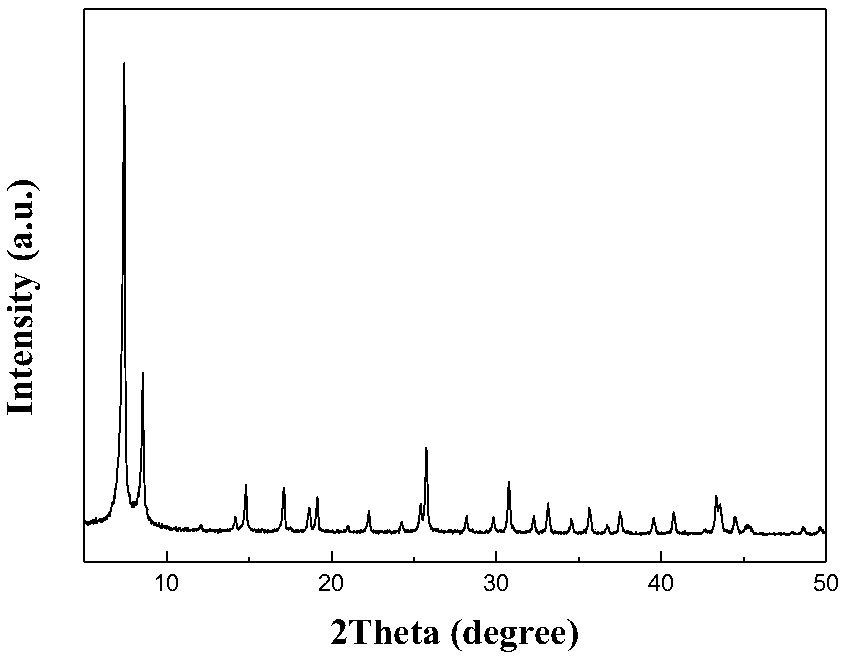

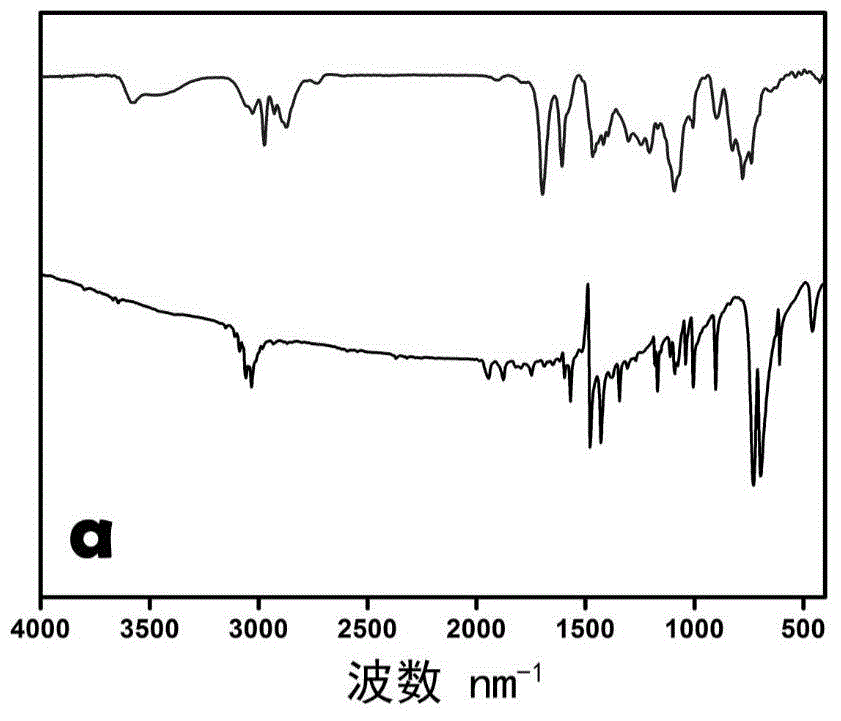

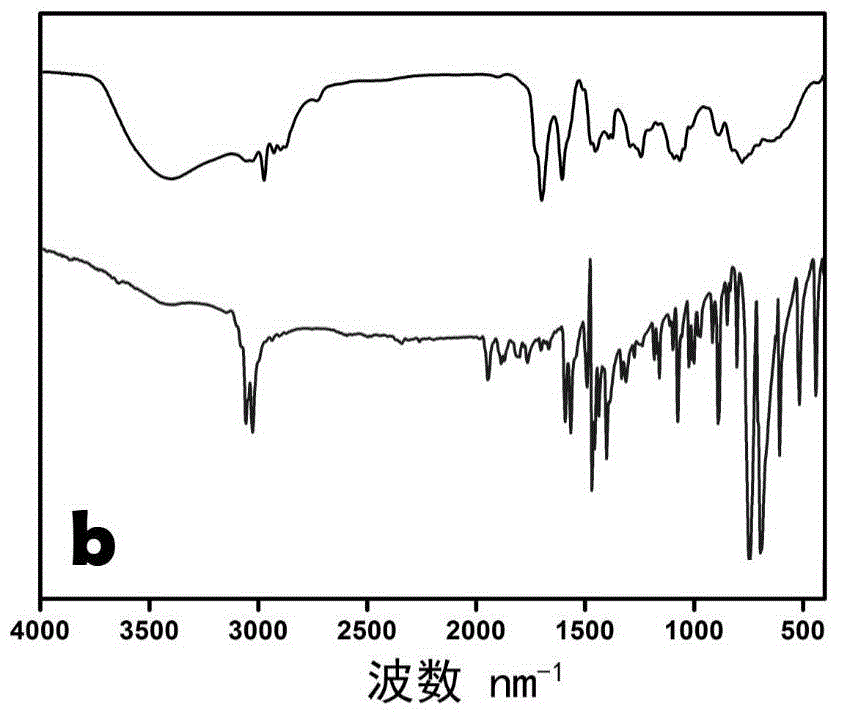

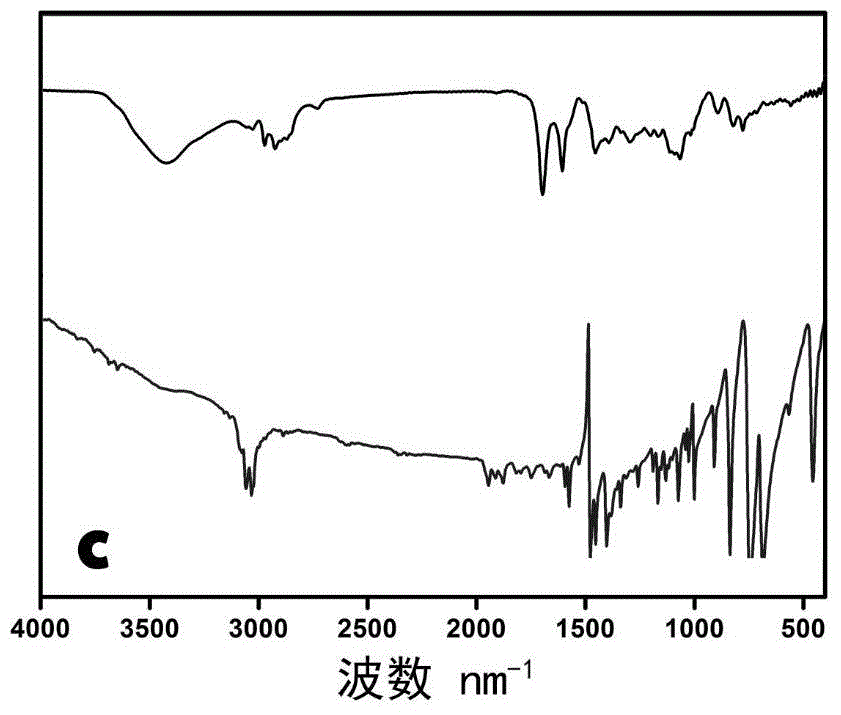

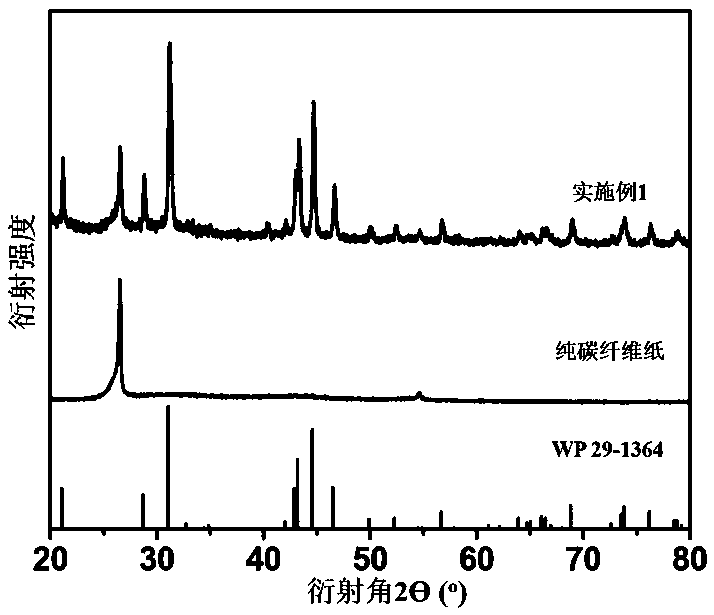

Preparation method for synthesizing metal organic framework UiO-66 adsorbents by aid of mixed ligands

InactiveCN109395698AFacilitated DiffusionImprove adsorption capacityOther chemical processesSorbentMetal-organic framework

The invention provides a preparation method for synthesizing metal organic framework UiO-66 adsorbents by the aid of mixed ligands. The preparation method includes mixing zirconium sources and regulators with one another and then dissolving the zirconium sources and the regulators in solvents to obtain solution A; uniformly dissolving 2-aminoterephthalic acid, terephthalic acid and solvents to obtain mixed ligand solution B; dropwise adding the solution A into the solution B at the constant speed to obtain solution C; injecting the solution C into reaction kettles with polytetrafluoroethylenelinings and carrying out crystallization at the temperatures of 100-160 DEG C for 18-24 h; carrying out reaction, and then carrying out treatment to obtain target products. As proved by XRD (X-ray diffraction) analysis, the obtained products are UiO-66 adsorbent materials. The preparation method for synthesizing the adsorbent materials has the advantages that the preparation method is simple; theUiO-66 adsorbents synthesized by the aid of the mixed ligands are excellent in chemical and thermal stability; the hydrogen adsorption capacity of the metal organic framework UiO-66 adsorbents can beimproved to a great extent, and effective treatment methods and research directions can be provided to hydrogen adsorption separation and storage.

Owner:DALIAN UNIV OF TECH

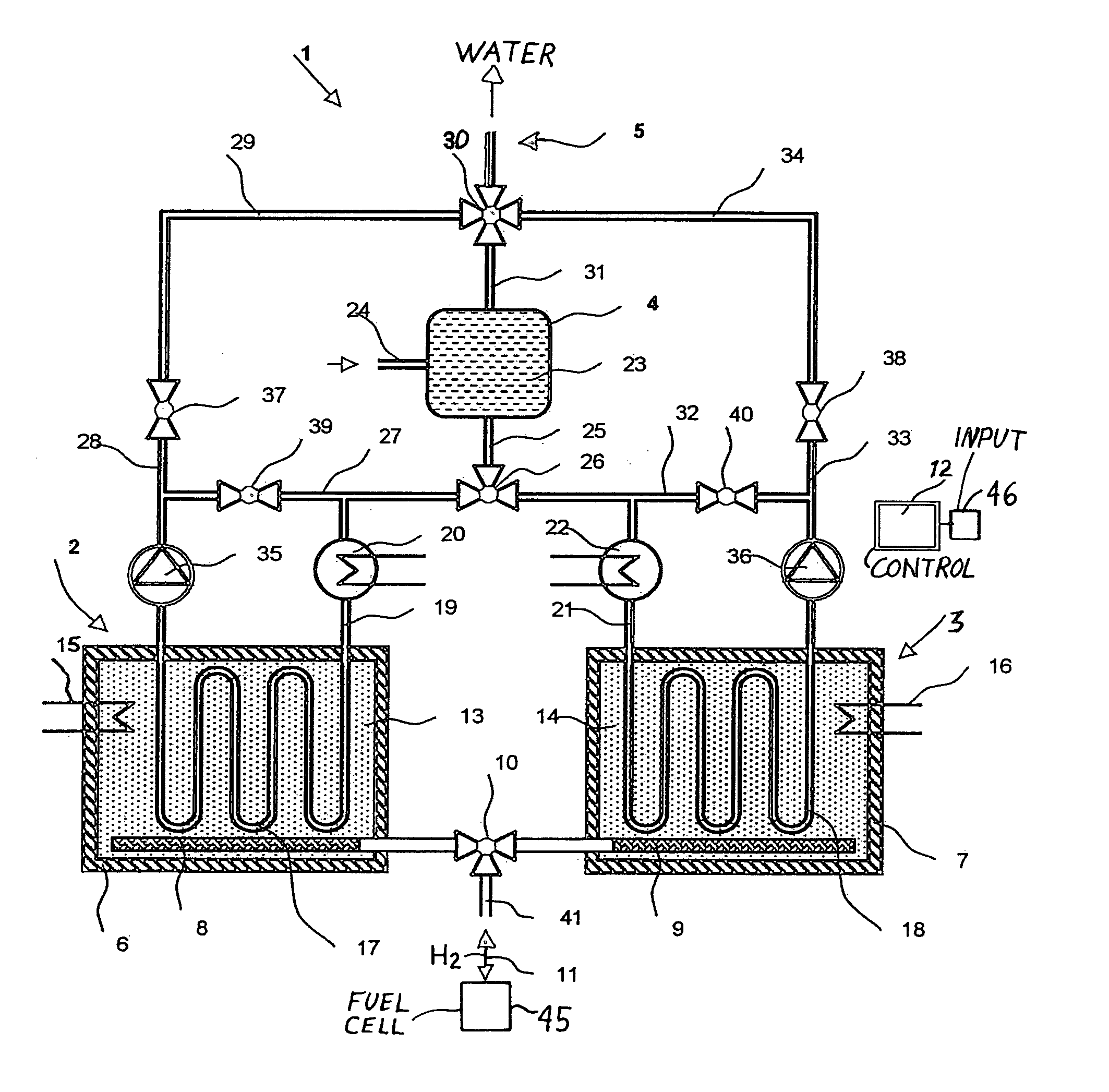

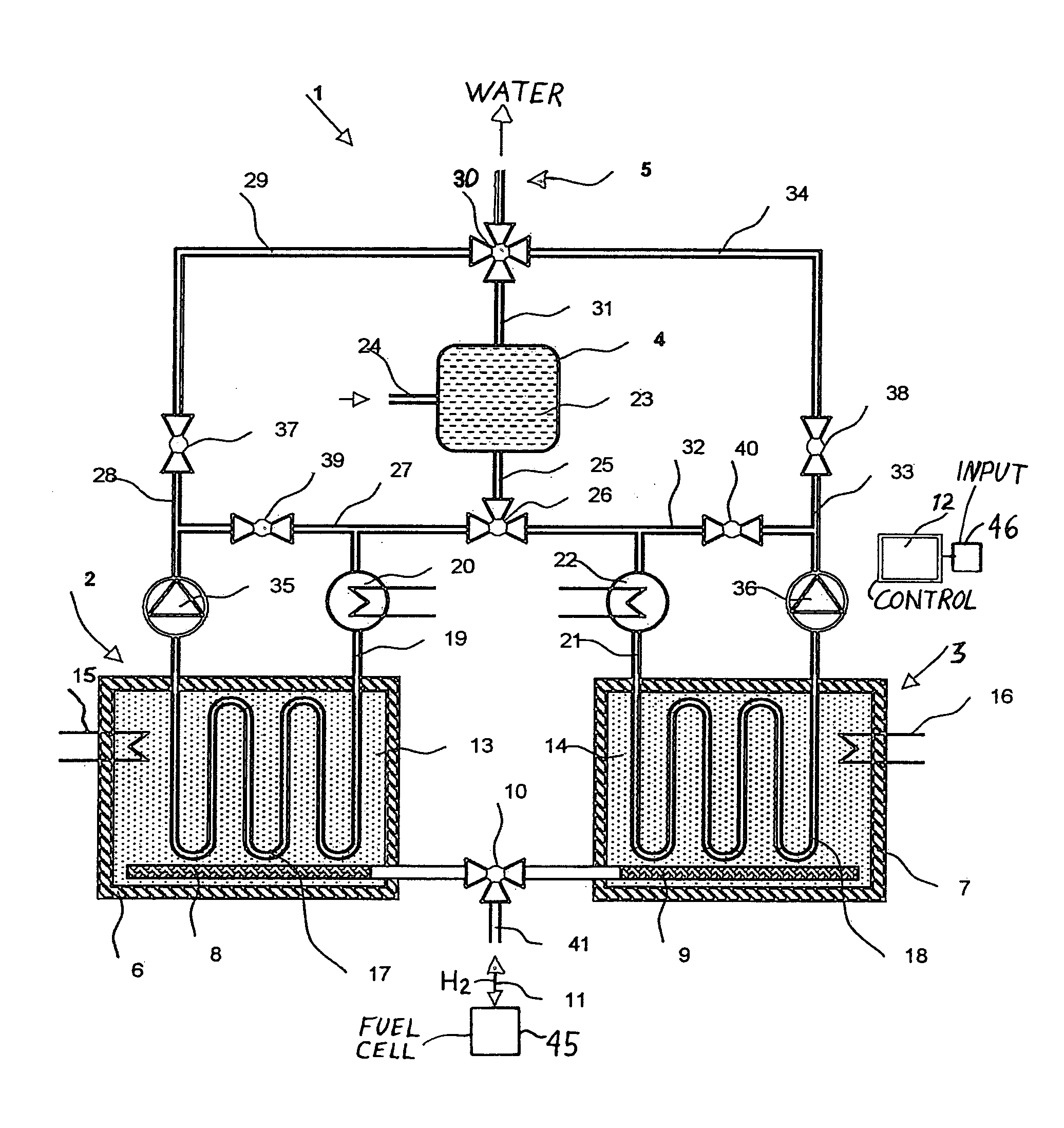

Method and apparatus for tempering gaseous and/or liquid media in transportation vehicles, particularly in aircraft

InactiveUS20050253019A1Heating up fastSupply will become excessiveHeat storage plantsAir-treatment apparatus arrangementsAirplaneHydrogen sorption

For example an aircraft includes a fluid tempering arrangement to supply a gaseous and / or liquid, heated and / or cooled, fluid such as water. At least one thermochemical reservoir is in heat exchange relation with a conduit system, having at least one valve and a controller that controls the transfer of heat between the fluid and the thermochemical reservoir to adjust the temperature of the fluid provided to an outlet. Preferably two interconnected thermochemical reservoirs respectively contain hydride-forming metals having different hydrogen sorption-desorption temperatures. A method involves supplying and chemically storing heat energy in at least one thermochemical reservoir, then performing a reverse reaction to release and transfer heat from at least one thermochemical reservoir to the fluid, preferably involving the sorption and desorption of hydrogen in respective hydride-forming metals in two reservoirs exhibiting different hydrogen reaction temperatures. Heat energy produced electrically during low electrical demand can be chemically stored and later released for heating the fluid during high electrical demand.

Owner:AIRBUS OPERATIONS GMBH

Method for preparing composite perovskite oxide loaded palladium catalyst

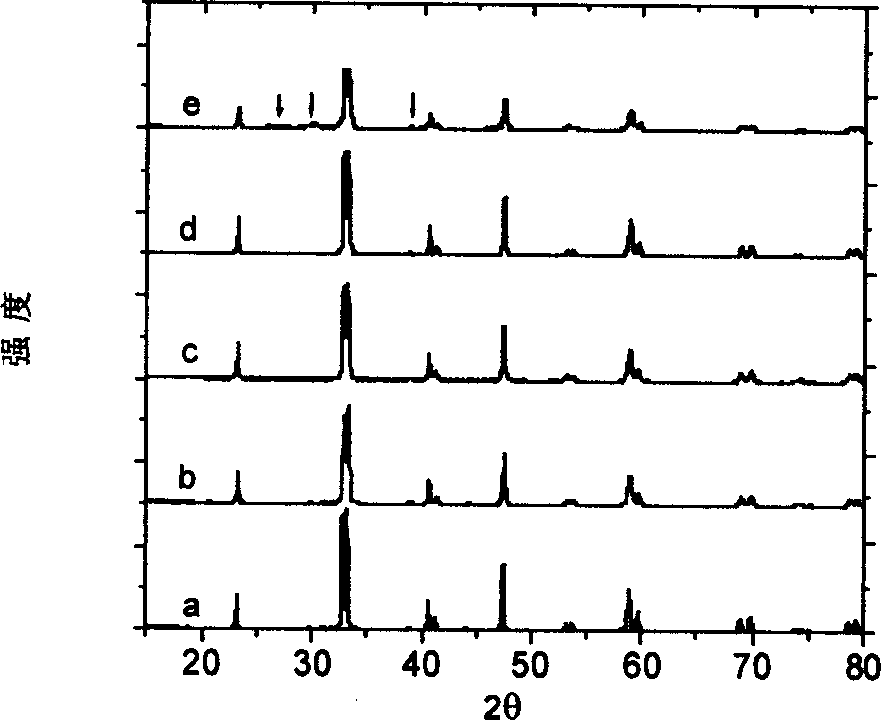

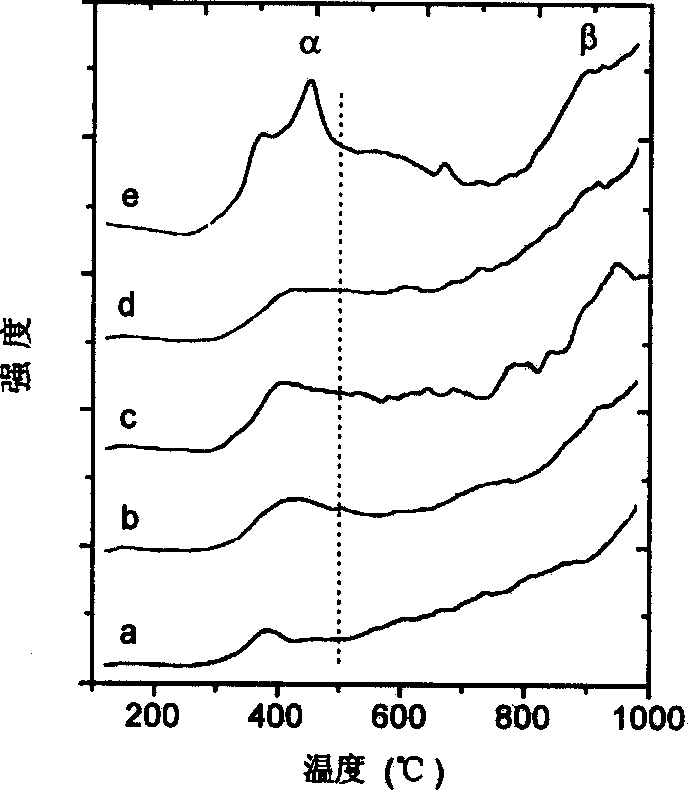

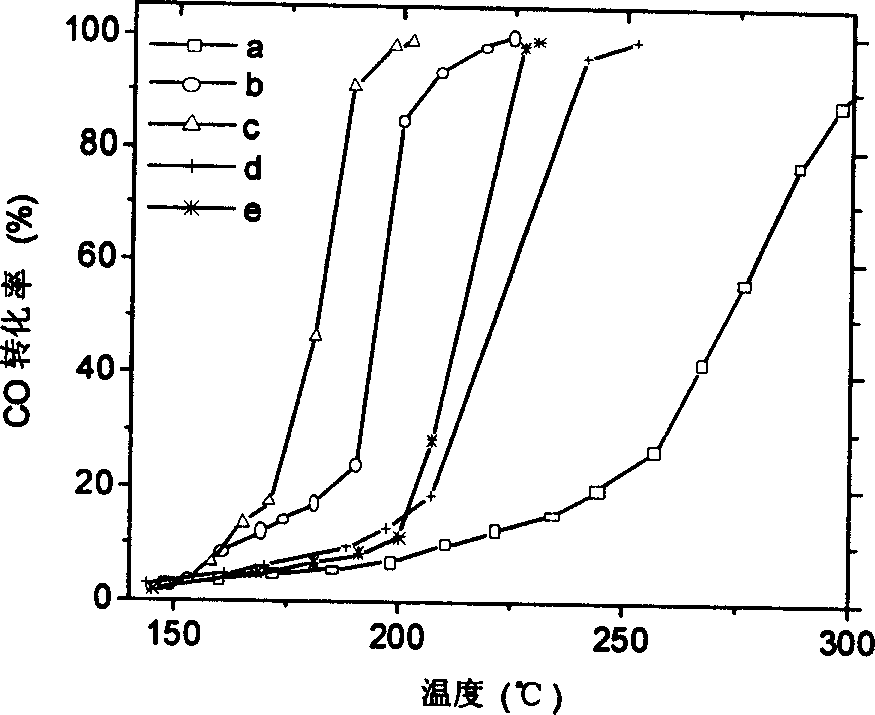

InactiveCN1531997AEvenly dispersedHigh catalytic activityDispersed particle separationCatalyst activation/preparationDesorptionX-ray

The preparation process of composite perovskite oxide loaded palladium catalyst includes the main steps of: compounding soluble metal salt solution with soluble salt of La, Co and Pd as material; dropping metal salt solution into citric acid as complexing agent to form sol; heating sol at 50-95 deg.c while stirring to obtain gel; drying at 110-160 deg.c for 10-24 hr and roasting at 600-1000 deg.c for 3-24 hr; and reduction processing of the obtained perovskite oxide. The catalyst is determined via X-ray powder diffraction process, hydrogen adsorption process and programmed heating-up desorption process to obtain its crystal phase, surface Pd density and oxygen adsorbing performance. The prepared catalyst is perovskite oxide loaded palladium catalyst with oxygen fault, and this structure has synergist effect of perovskite and Pd and excellent catalytic activity.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Modified activated carbon hydrogen sulfide adsorbent and preparation method thereof

InactiveCN103521176AHigh reactivityThe efficiency of hydrogen sulfide removal is improvedOther chemical processesDispersed particle separationActivated carbonSulfide

The invention relates to a modified activated carbon hydrogen sulfide adsorbent which is prepared from the following raw materials in parts by weight: 100-120 parts of activated carbon, 12-14 parts of copper sulfate, 20-23 parts of high-alumina bauxite, 4-5 parts of magnesium oxide, 5-6 parts of calcium oxide, 6-8 parts of sodium carbonate, 8-10 parts of modified attapulgite and a right amount of water. According to the invention, the activated carbon is modified by using copper sulfate, high-alumina bauxite, magnesium oxide, calcium oxide and sodium carbonate, so that the removal efficiency of hydrogen sulfide is increased; the reaction activity of the activated carbon is improved by processes such as calcination and spray drying, thereby being favorable to the removal of sulfides contained in low-concentration fume. The modified activated carbon hydrogen sulfide adsorbent is simple in process and easily available in raw materials, and can realize industrial production.

Owner:BENGBU DEMO FILTRATION TECH

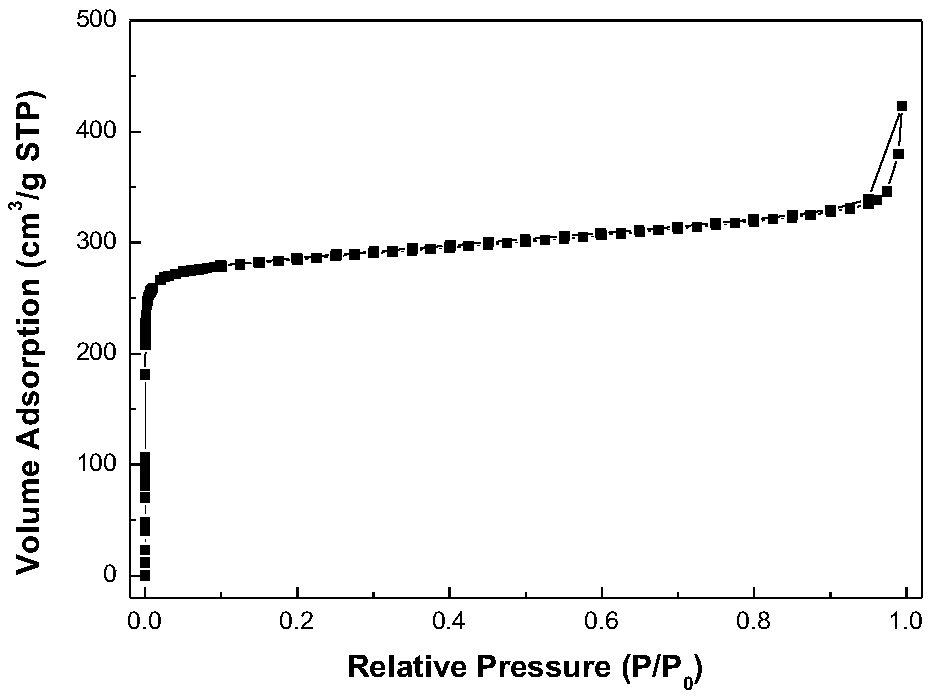

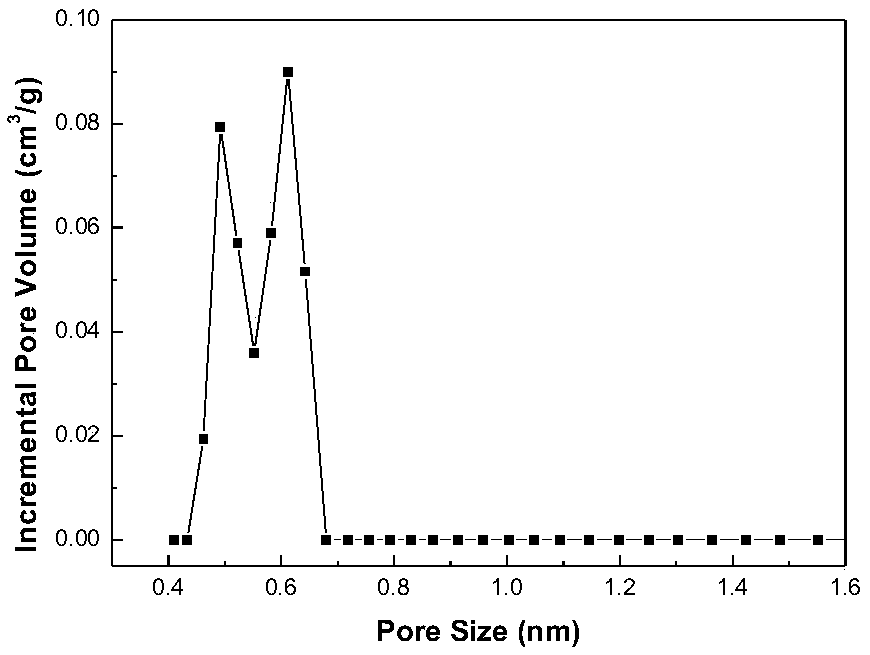

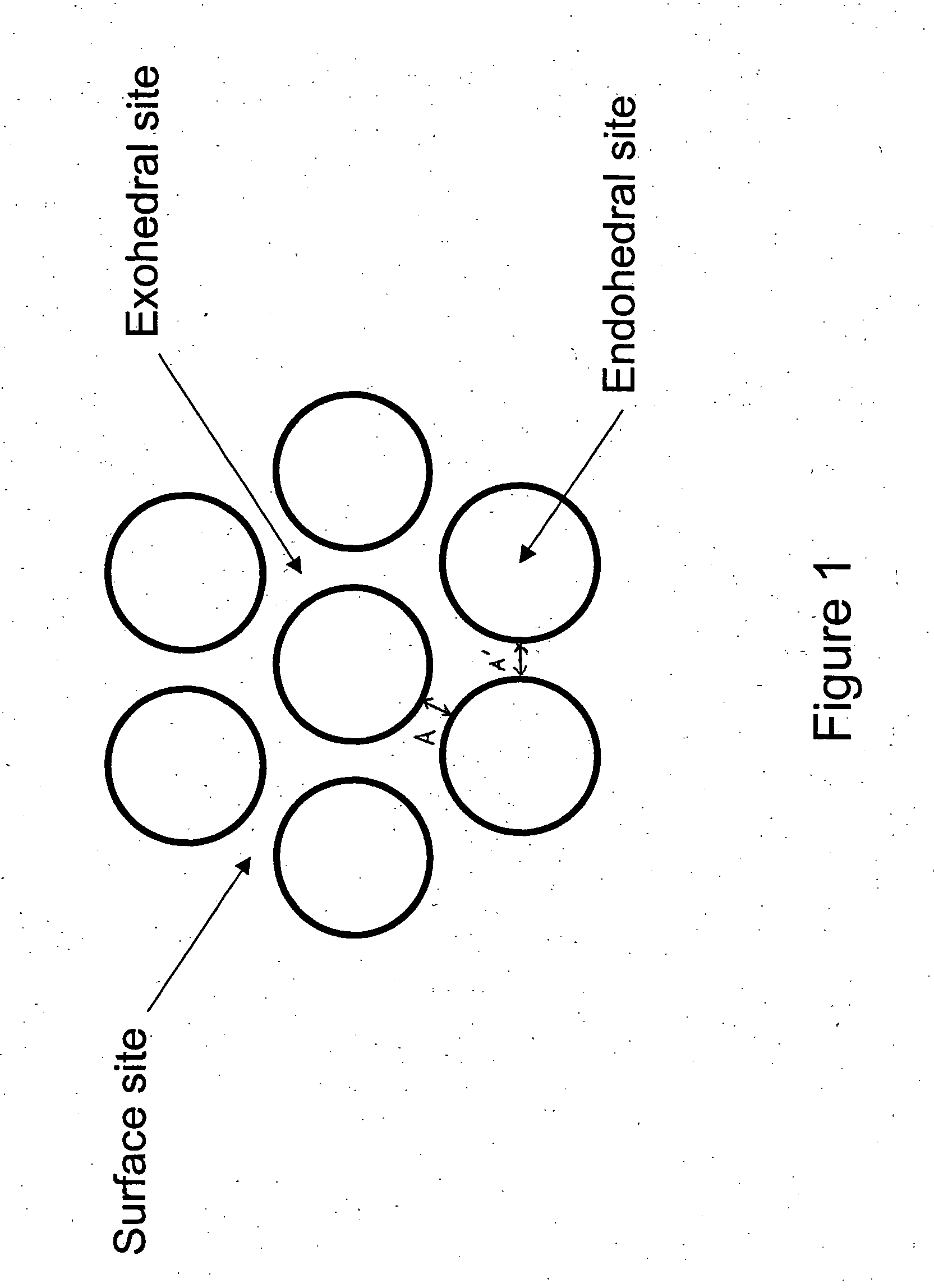

Hydrogen storage utilizing carbon nanotube materials

A material for the storage of hydrogen is provided comprising single wall carbon nanotubes (SWNT), wherein the majority of the diameters of the single wall carbon nanotubes of the assembly range from 0.4 to 1.0 nanometers (nm), and the average length is less than or equal to 1000 nm, or the diameters of the single wall carbon nanotubes of the assembly range from 0.4 to 1.0 nanometers (nm), and the heat (−ΔH) of hydrogen adsorption of the material is within the range from 4 kcal / mole H2 to 8 kcal / mole H2. Processes for the storage and release of hydrogen using the materials are disclosed.

Owner:AIR PROD & CHEM INC

Desulfurizing agent for hydrocarbon derived from petroleum, method for producing hydrogen for use in fuel cell and method for producing nickel-based desulfurizing agent

InactiveUS7268097B2Efficient removalEasy to useOther chemical processesSulfur compoundsSteam reformingSilicon dioxide

A desulfurizing agent comprising a silica-alumina carrier having an Si / Al mole ratio of 10 or less and nickel carried thereon; a desulfurizing agent for hydrocarbons derived from petroleum which comprises a carrier and a metal component carried thereon and has a specific surface area of pores having a pore diameter of 3 nm or less of 100 m2 / g or more; an Ni-Cu based desulfurizing agent comprising a carrier and, carried thereon, (A) nickel, (B) copper, and (C) an alkali metal or another metal; a desulfurizing agent for hydrocarbons derived from petroleum which comprises a carrier and a metal component carried thereon and has a hydrogen adsorption capacity of 0.4 mmol / g or more; and methods for producing these nickel-based and nickel-copper-based desulfurizing agents. The above desulfurizing agents are capable of adsorbing and removing with good efficiency the sulfur contained in hydrocarbons derived from petroleum to a content of 0.2 wt. ppm or less and have a long service life. The steam reforming of hydrocarbons derived from petroleum having been desulfurized by use of any one of the above desulfurizing agents allows the production of hydrogen for use in a fuel cell with good efficiency.

Owner:IDEMITSU KOSAN CO LTD

Hydrogen storage and supply system

Owner:NANOMIX INC

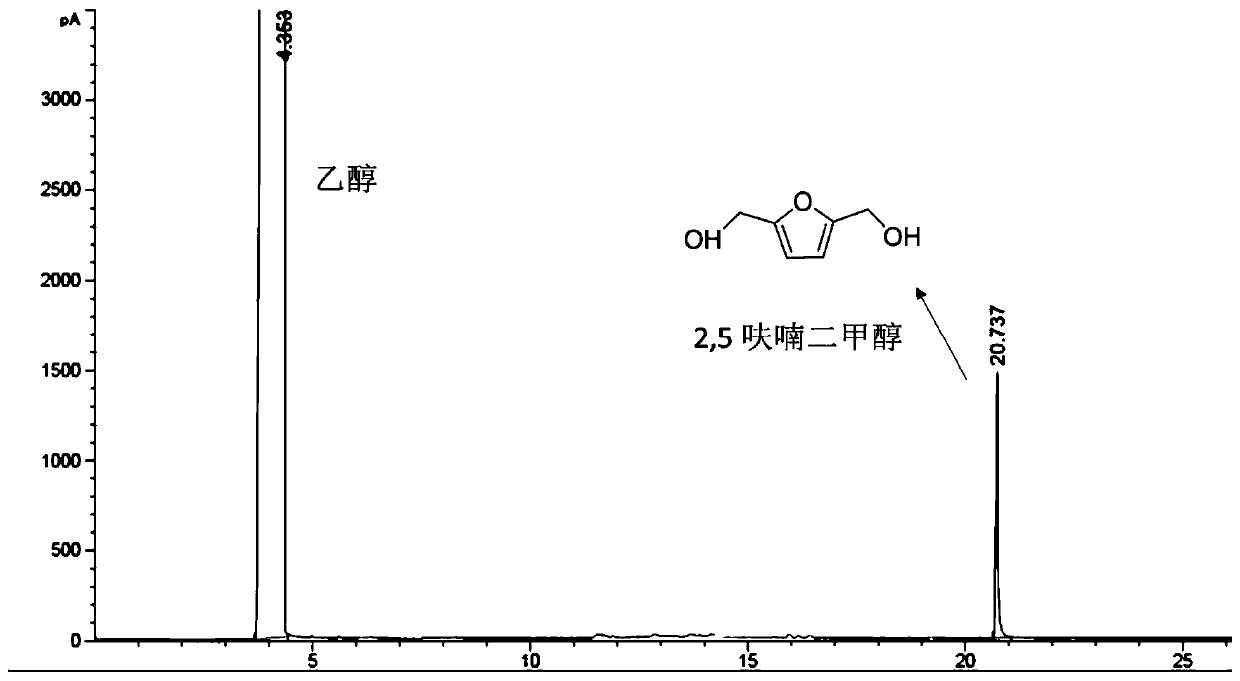

Method for preparing 2,5-furandimethanol by selective hydrogenation of 5-hydroxymethylfurfural

ActiveCN110128378ALarge specific surface areaLow priceOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsReusabilityNano copper

The invention discloses a method for preparing 2,5-furandimethanol by selective hydrogenation of 5-hydroxymethylfurfural, and the method comprises the following steps: adding the 5-hydroxymethylfurfural, catalyst CuNPs@ZIF-8 and ethanol to a stainless steel closed reactor, charging with H2, and reacting at thetemperature of 120-150DEG C and the pressure of 1-4 MPa for 0.1-5 h. The method adopts the CuNPs@ZIF-8 as the catalyst, and the catalyst not only has large specific surface area, high dispersion of nano copper and good hydrogen adsorption performance, but also has simple preparation, lowprice and reusability. The method overcomes the problem of expensive use of precious metals as catalysts and low efficiency of non-precious metals as catalysts in prior studies.

Owner:XIAMEN UNIV

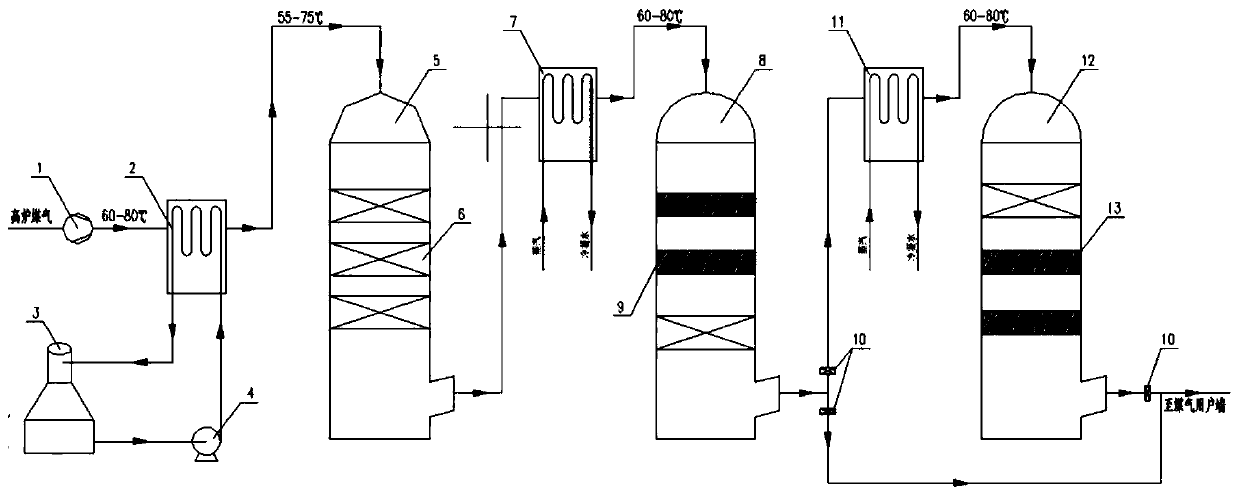

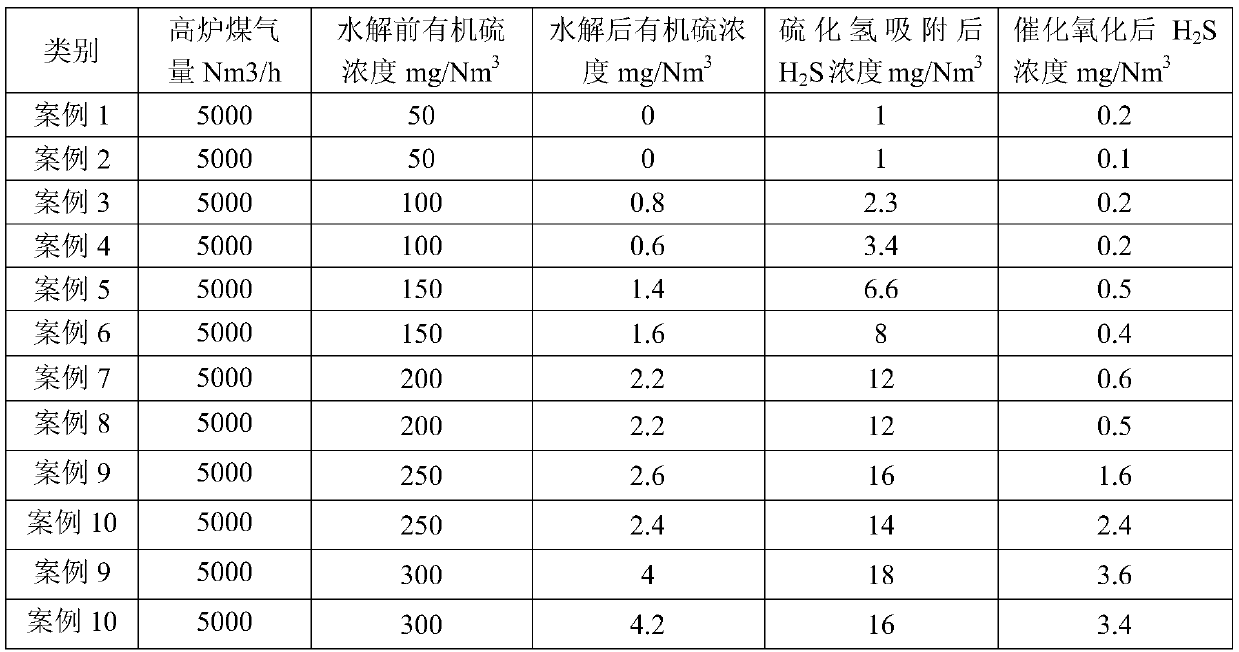

Blast furnace gas hydrolysis and dry-process fine desulfurization treatment system and method

PendingCN111534335ASolve the problem of desulfurization process wastewaterGas contaminants removalGas dust removalPtru catalystCatalytic oxidation

The invention provides a blast furnace gas hydrolysis and dry fine desulfurization treatment system and method. The system comprises a gas cooling heat exchanger, a catalytic hydrolysis tower, a hydrogen sulfide adsorption tower and a catalytic oxidation tower. Blast furnace gas firstly enters the gas cooling heat exchanger to be cooled, the gas temperature is reduced by 5 DEG C through the cooling heat exchanger, and part of moisture is separated out. Then the blast furnace gas enters a catalytic hydrolysis tower, organic sulfur contained in the gas is converted into inorganic sulfur after passing through a hydrolysis catalyst, the hydrolyzed blast furnace gas is heated by a reheater at the front end of an adsorption tower and enters a hydrogen sulfide adsorption tower, and the inorganicsulfur in the gas is removed through a catalyst in the tower. The blast furnace gas without the inorganic sulfur can be directly conveyed to a downstream client side, and a catalytic oxidation step can also be added after hydrogen sulfide is adsorbed to remove COS, H2S and other sulfur-containing substances. The blast furnace gas hydrolysis reaction time only needs 1-3 seconds, the conversion ratecan reach 98% or above, the removal efficiency of the hydrogen sulfide adsorption catalyst is 90% or above, and the removal efficiency in the catalytic oxidation tower reaches up to 70% or above.

Owner:NANJING CEEP TECH

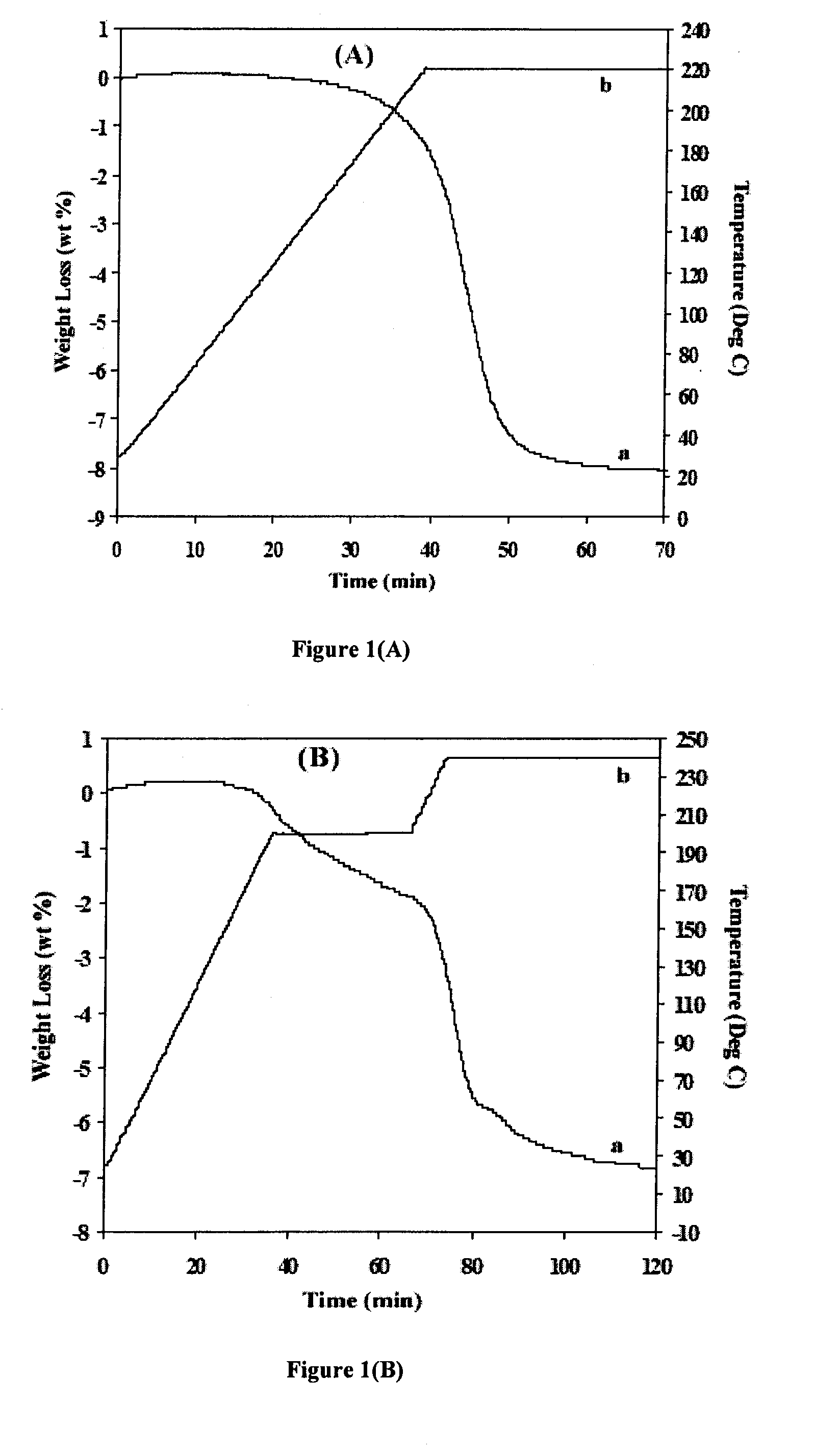

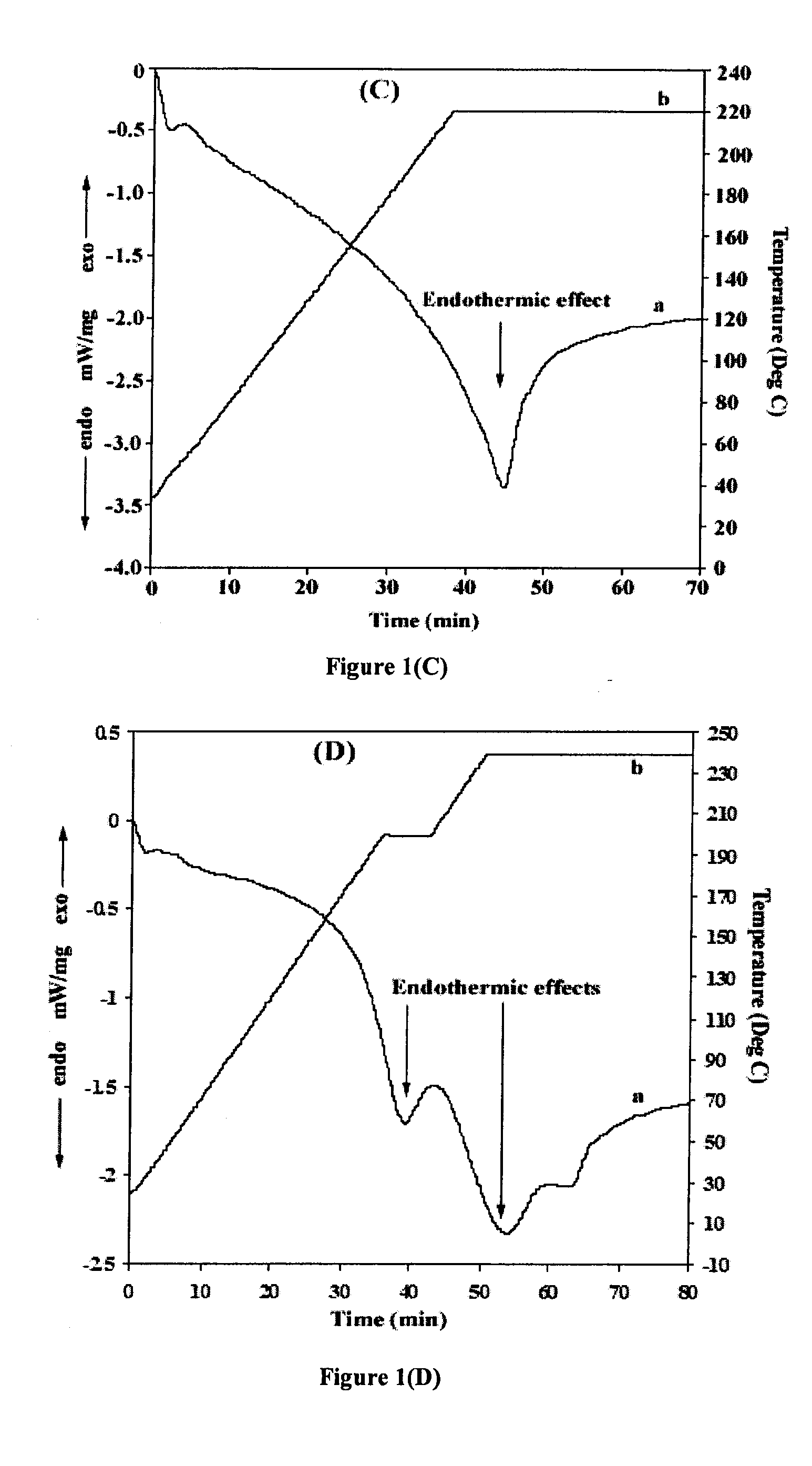

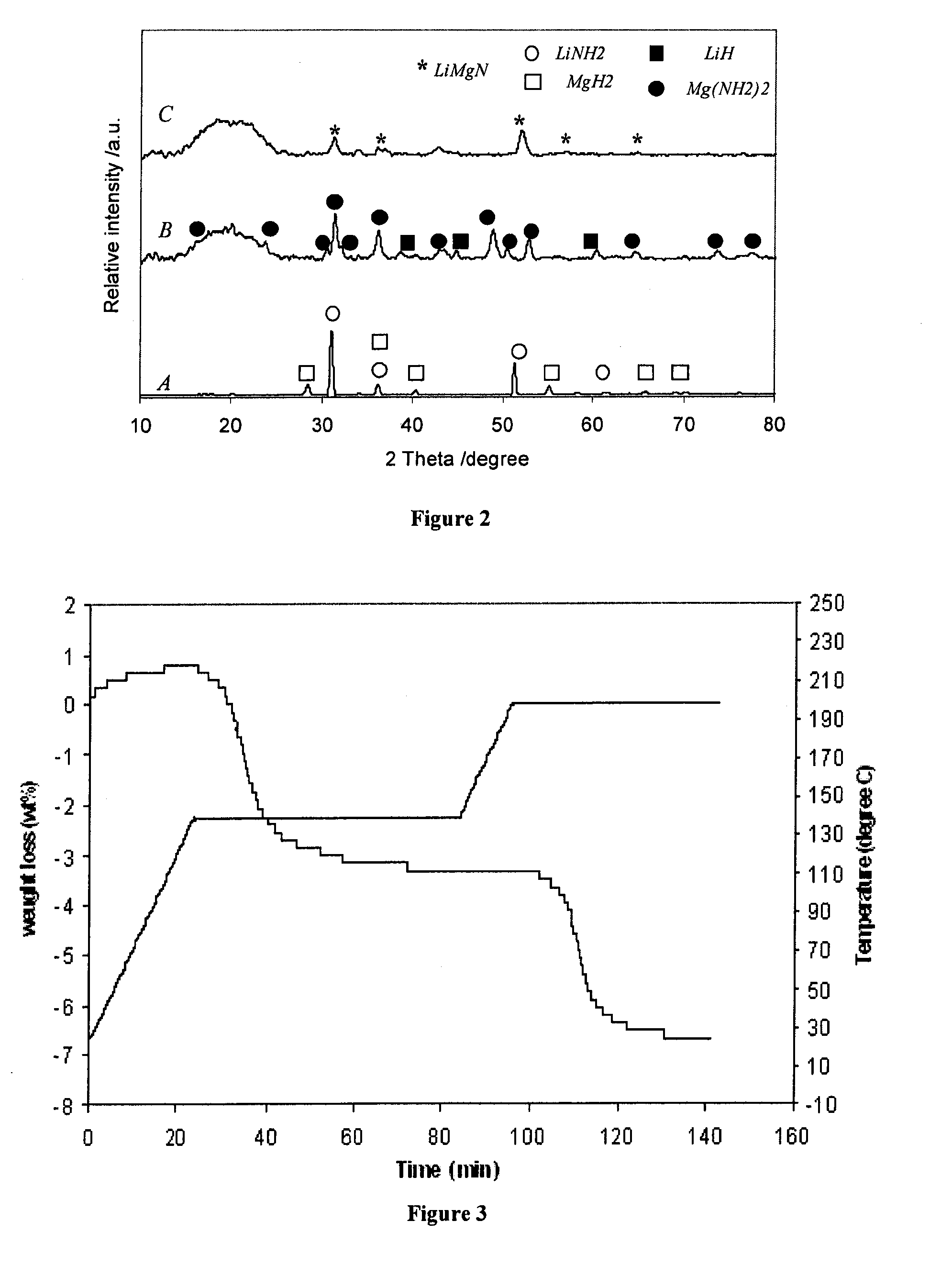

Light metal based material system for hydrogen storage

The invention provides methods, compositions, and systems for a reversible hydrogen storage material. The hydrogen storage material contains a lithium-magnesium compound, having LiMgN in a dehydrogenated state and a hydrogenated lithium magnesium product in a hydrogenated state, where the hydrogenated and dehydrogenated states are reversible. The lithium-magnesium compound is formed by reacting MgH2 and LiNH2 in a substantially inert atmosphere in amounts sufficient to obtain a hydrogen adsorption of at least 3 wt %, and in many cases up to about 8.1 wt %.

Owner:UNIV OF UTAH RES FOUND

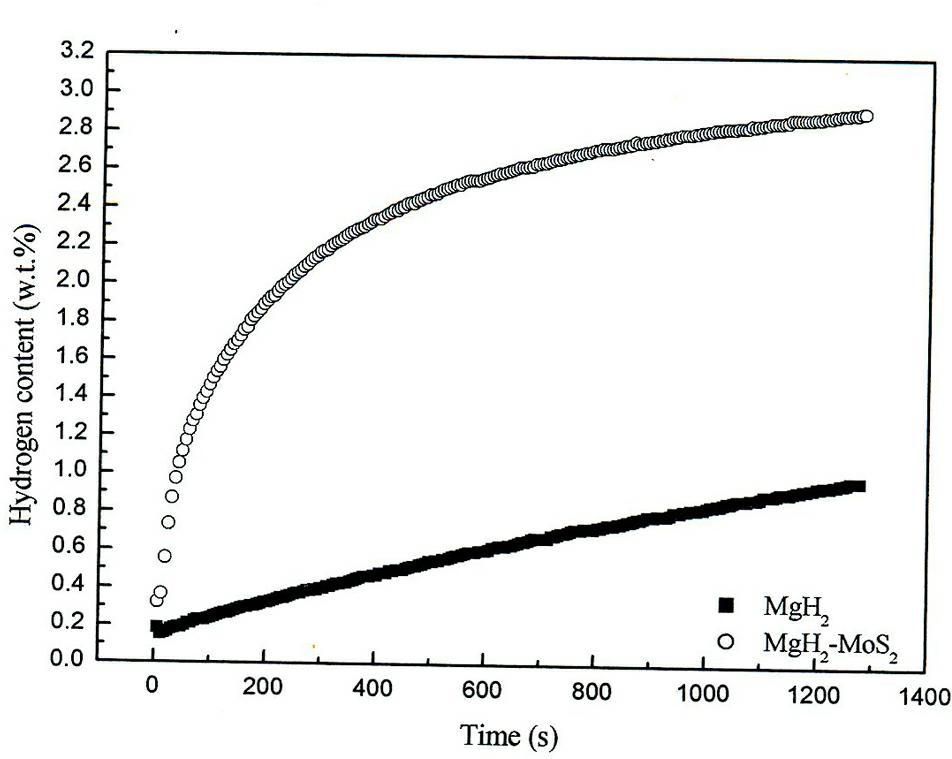

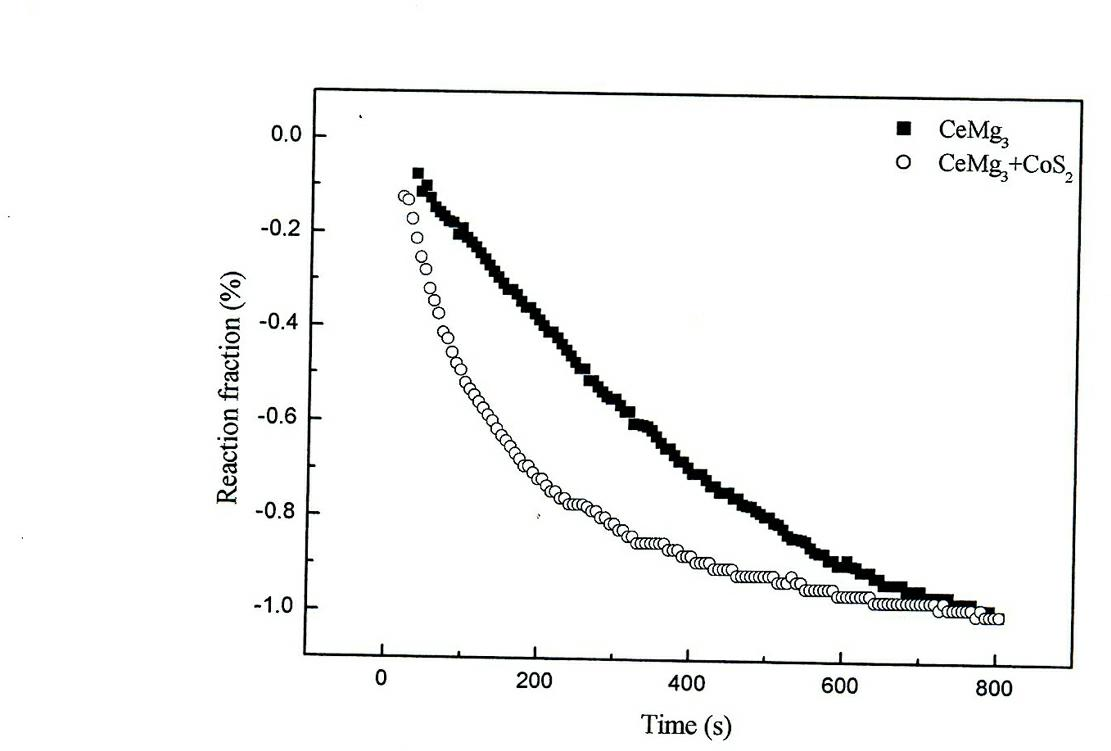

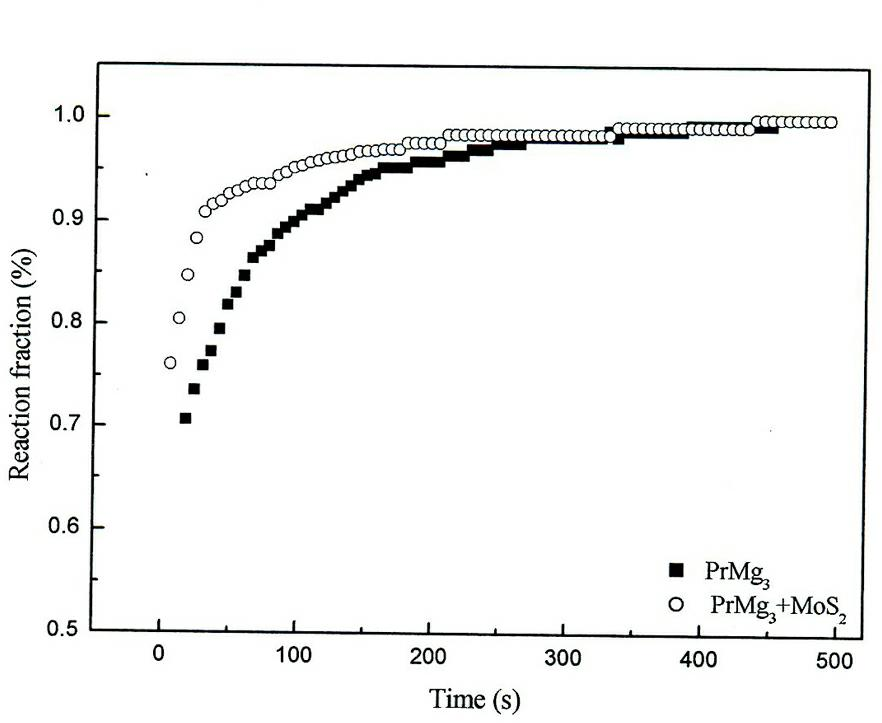

Magnesium-based hydrogen storage alloy composite material with metal sulfide added

InactiveCN102586660AIncreased hydrogen absorption/desorption rateLower initial dehydrogenation temperatureFuel cellsHydrogen atmosphere

The invention relates to a magnesium-based hydrogen storage alloy composite material with metal sulfide added, which consists of a magnesium-based hydrogen storage alloy and the metal sulfide of which the mass is 10-30 percent of that of the magnesium-based hydrogen storage alloy, wherein the magnesium-based hydrogen storage alloy is Mg and REMg3 or RE2Mg17 (RE=La, Ce, Pr and Nd), the metal sulfide can be one of MoS2, CoS2 and CoS. A preparation method of the magnesium-based hydrogen storage alloy composite material with the metal sulfide added mainly comprises the following steps of: (1) enabling the magnesium-based hydrogen storage alloy to fully adsorb hydrogen in a hydrogenation reactor, and (2) performing ball milling under protection of hydrogen atmosphere. The hydrogen adsorption / releasing rate of the composite material prepared by the method is improved by over 1.5 times than that of the magnesium-based hydrogen storage alloy without adding the metal sulfide, and the initial dehydrogenation temperature of the composite material is reduced by 15-100K. The composite material is simple in preparation process and stable in performance, and can be applied to hydrogen storage and supplying in fields such as electromobiles and fuel cells.

Owner:YANSHAN UNIV

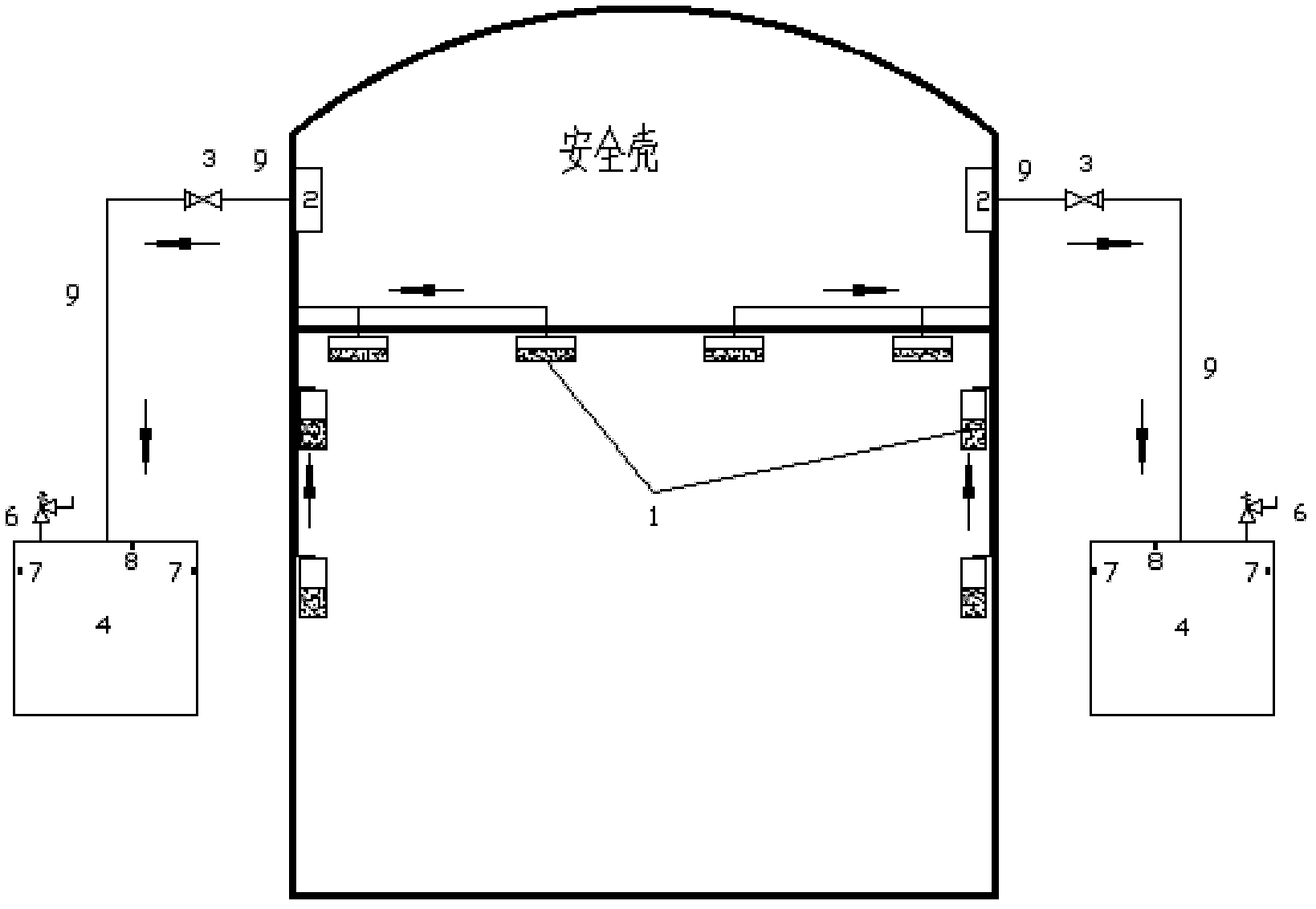

Hydrogen-explosion-preventing serious nuclear accident relieving device and method

InactiveCN102208216AReliable Hydrogen Storage CapacityHigh hydrogen storage capacityNuclear energy generationEmergency protection arrangementsHydrogenNuclear engineering

The invention discloses a hydrogen-explosion-preventing serious nuclear accident relieving device and a hydrogen-explosion-preventing serious nuclear accident relieving method, and belongs to the fields of safety equipment and technology of a nuclear power station. A hydrogen adsorption device is installed on the inner wall and in an upper space of a safety shell; by using the physical adsorptionproperty of a carbon nanofiber material, the hydrogen adsorption device is used for adsorbing and storing hydrogen without the help of external power; when a large amount of hydrogen is generated in the safety shell, the hydrogen adsorption device reduces the concentration of the hydrogen in the safety shell by adsorbing the hydrogen continuously and igniting the hydrogen, so that the explosion of the hydrogen is avoided; and the pressure in the safety shell is reduced, so that the aim of relieving a serious accident of a reactor is fulfilled. In the running process of the hydrogen-explosion-preventing serious nuclear accident relieving device, the external power is not required; the device can work stably for a long time, is reliable in performance, good in spare safety, convenient to implement and easy to control and meets the design requirements of a current novel nuclear power reactor.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

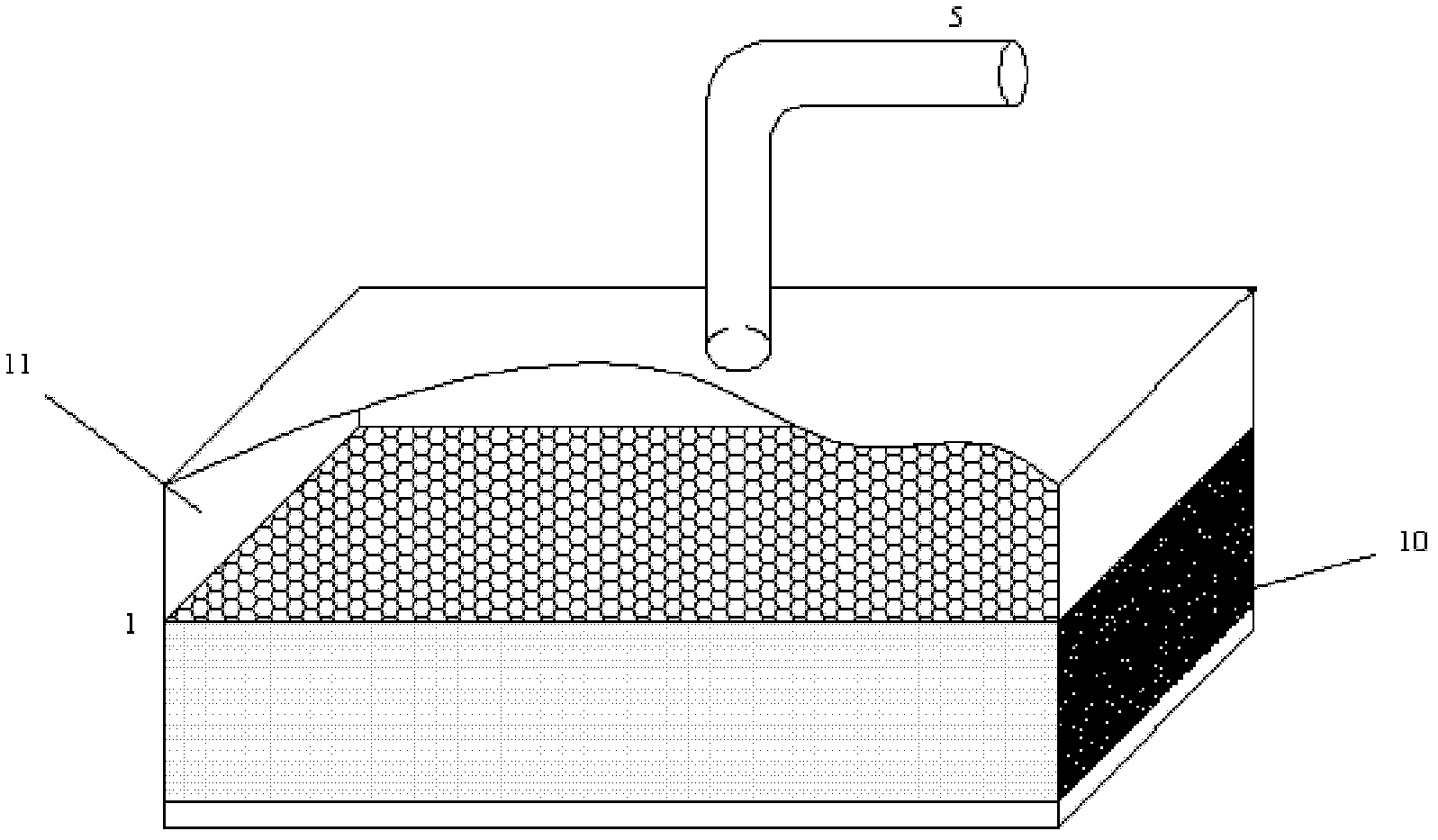

Refining apparatus and technology of pressure casting aluminium product

ActiveCN103397196AAvoid secondary hydrogen absorptionImprove product qualityHydrogenPressure casting

The invention provides a refining apparatus of a pressure casting aluminium product. The refining apparatus comprises a melting furnace and a closed holding furnace; a height adjustable stirring shaft and stirring blades arranged on the stirring shaft are arranged above the melting furnace; a through hole used for delivering inert gas is arranged in the stirring shaft; the melting furnace is connected to the closed holding furnace by a feed delivery pipe; the closed holding furnace is provided with bleeder pipe; the refining apparatus also comprises a vacuum pump; and the closed holding furnace is connected to the vacuum pump by a vacuum pipeline. The invention also provides a refining technology of the pressure casting aluminium product. The refining technology is capable of avoiding secondary hydrogen adsorption and oxidation of refined molten aluminum in delivery process, reducing pores and impurities of the pressure casting aluminium product, and improving the quality of the pressure casting aluminium product greatly in the whole delivery process comprising melting of aluminum ingots, hydrogen removing treatment and heat preservation process. Application prospect of the technology is promising.

Owner:FUAN GUANGYUAN ELECTROMECHANICAL

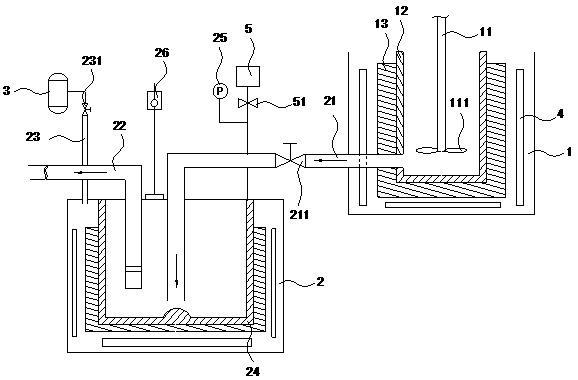

Helium circulation, purification and storage system

The invention discloses a helium circulation, purification and storage system. The helium circulation, purification and storage system comprises a pressure gas bottle, a gas extraction pump, an oil filtration filter, a low temperature filter and a hydrogen adsorption device; the pressure gas bottle is used for injecting helium gas into the system; the gas extraction pump is in series connection with an output end of the pressure gas bottle; the oil filtration filter is in series connection with an output end of the gas extraction pump; the low temperature filter is in series connection with an output end of the oil filtration filter; the hydrogen adsorption device is in series connection with an output end of the low temperature filter; an output end of the hydrogen adsorption device is input into a cryostat through a gas conveying pipeline, wherein the helium gas is to be supplied by the cryostat; the helium circulation, purification and storage system also comprises a gas storage tank which is used for recycling the helium gas in the system when the cryostat stops working; a gas outlet of the gas storage tank is connected with an input end of the gas extraction pump; a gas inlet of the gas storage tank is connected between the oil filtration filter and the low temperature filter. According to the helium circulation, purification and storage system, the structure is simple; the helium gas conveyed into the cryostat is high in purity and good in cooling effect; the helium gas can be recycled through the gas storage tank and accordingly the utilization rate of the helium gas is improved.

Owner:苏州衡微仪器科技有限公司

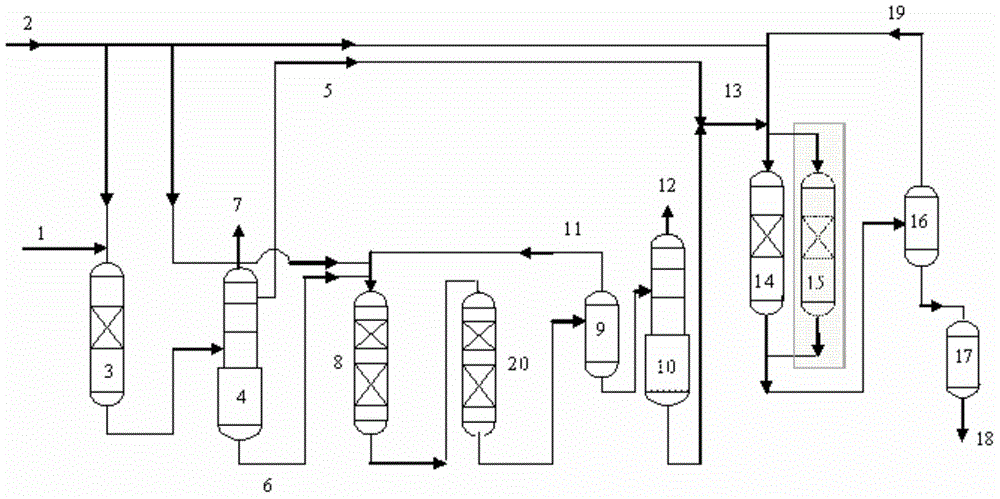

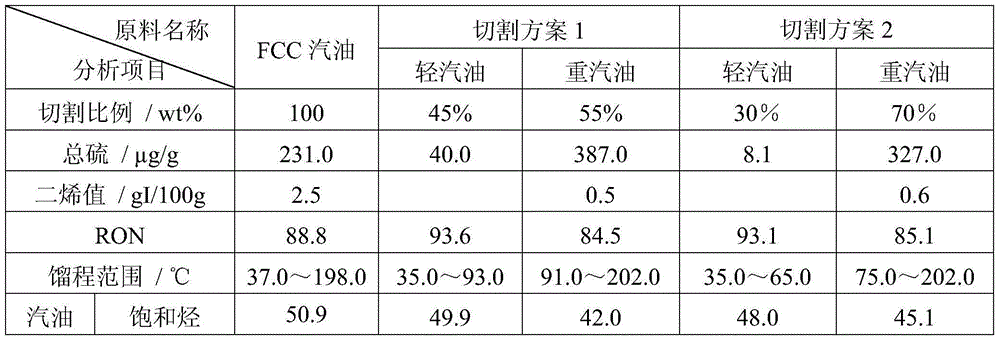

Ultra low sulfur gasoline combination production method

InactiveCN105733672AAvoid the shortcoming of short running cycleReduce lossesTreatment with hydrotreatment processesIsomerizationHydrodesulfurization

The invention discloses a combined production method of ultra-low-sulfur gasoline, which comprises the following steps: pre-hydrogenating full-distillate catalytically cracked gasoline and hydrogen after preheating, removing part of dienes in FCC gasoline raw materials, and part of light sulfurized gasoline. The reaction effluent is introduced into the fractionation tower, and it is fractionated into light gasoline and heavy gasoline at 65-100 ℃, and the sulfur content of the light gasoline is controlled at 20-50 μg / g; the heavy gasoline and hydrogen flowing out from the bottom of the fractionation tower are mixed into Aromatization / isomerization is carried out in the hydro-upgrading reactor to increase the octane number, and the reaction effluent enters the hydro-desulfurization reactor for selective hydro-desulfurization, and the sulfur content of heavy gasoline is controlled at 40-70 μg / g; The heavy gasoline after hydrogen desulfurization is subjected to gas-liquid separation, and the hydrogen sulfide is removed by stripping, and then mixed with light gasoline into the fixed bed hydrogen adsorption desulfurization reactor, and mixed with hydrogen for fixed bed hydrogen adsorption desulfurization reaction, so as to ensure the mixed gasoline The sulfur content is controlled within 10μg / g to achieve ultra-deep desulfurization without loss of octane number.

Owner:PETROCHINA CO LTD

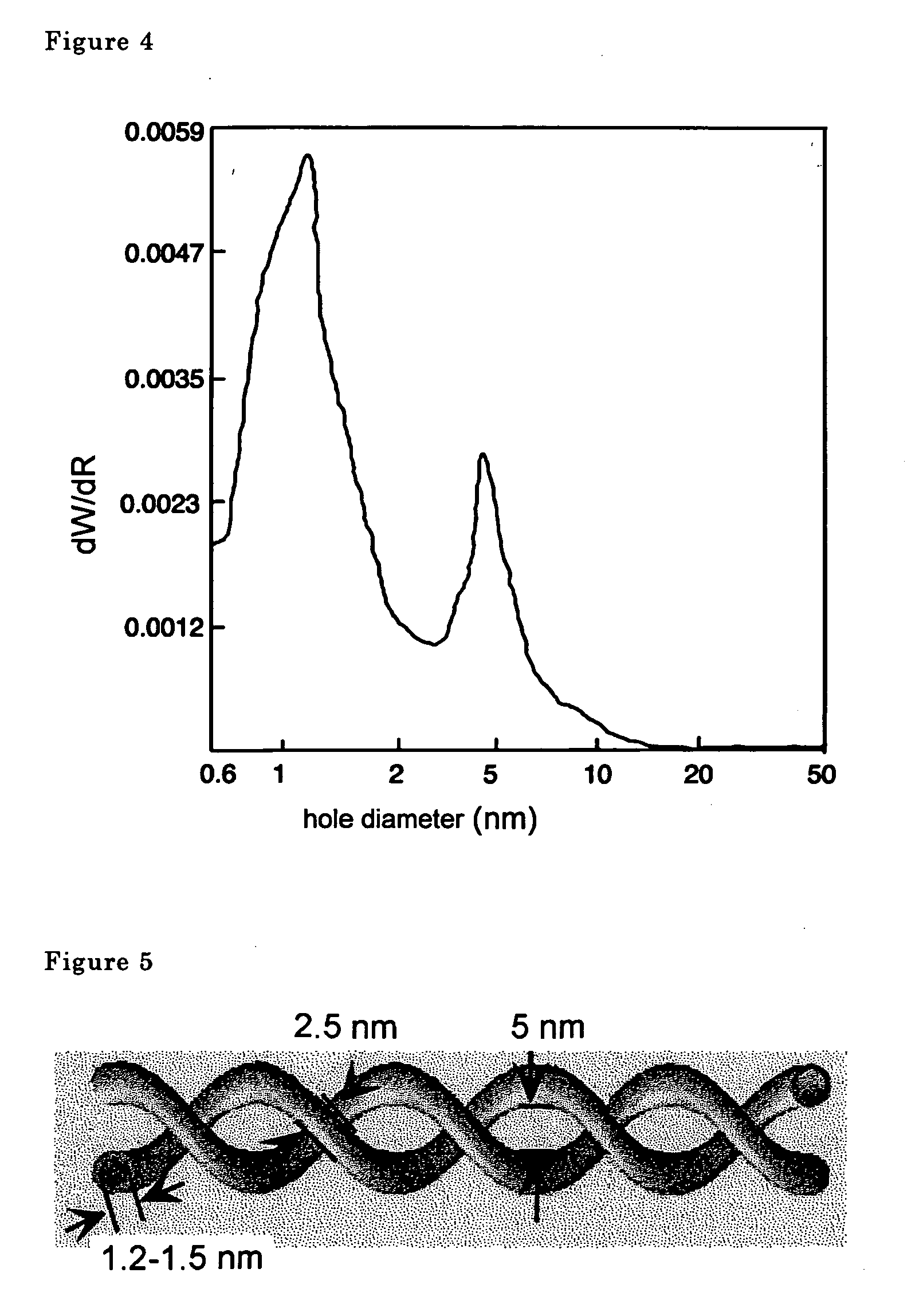

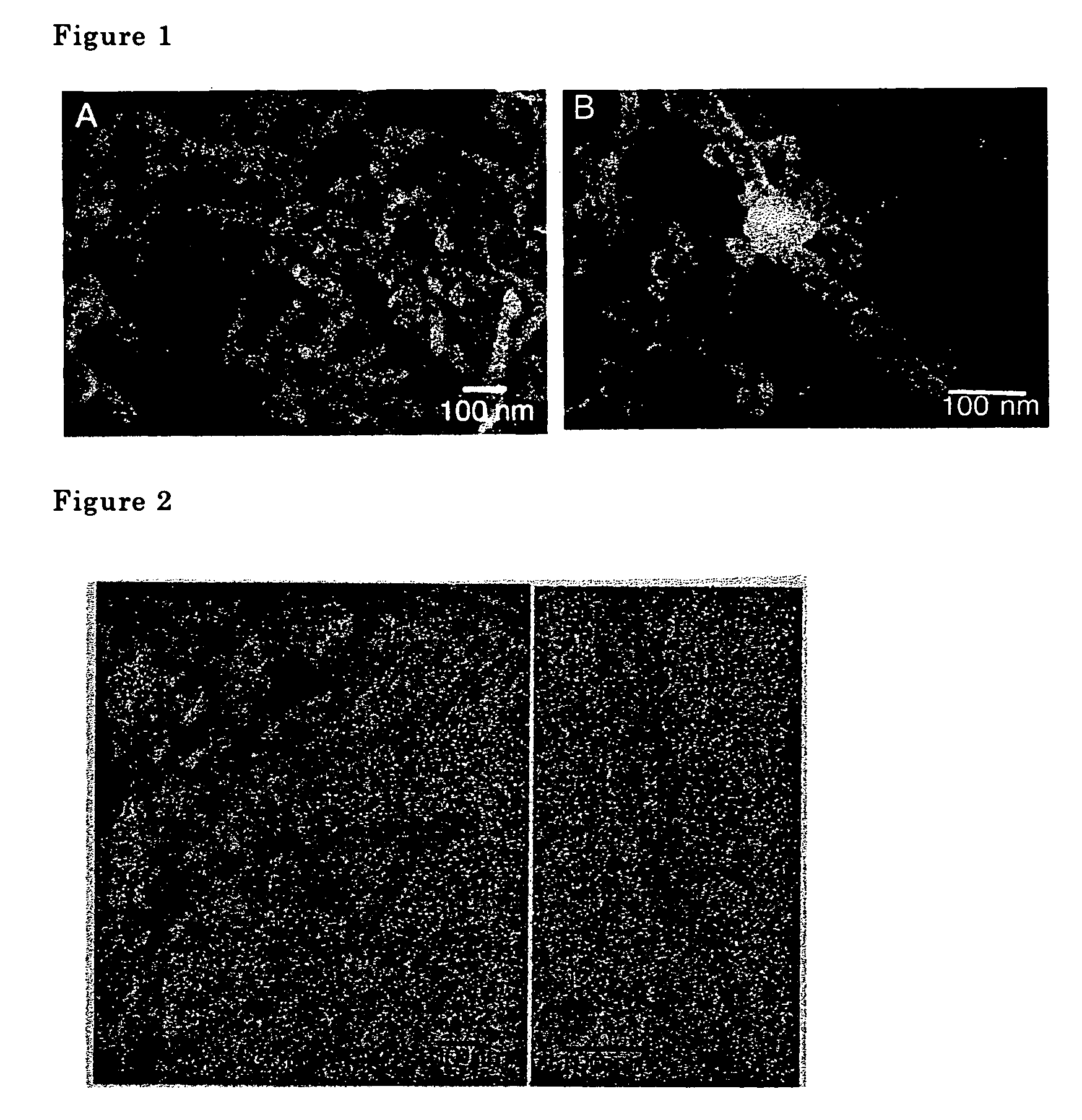

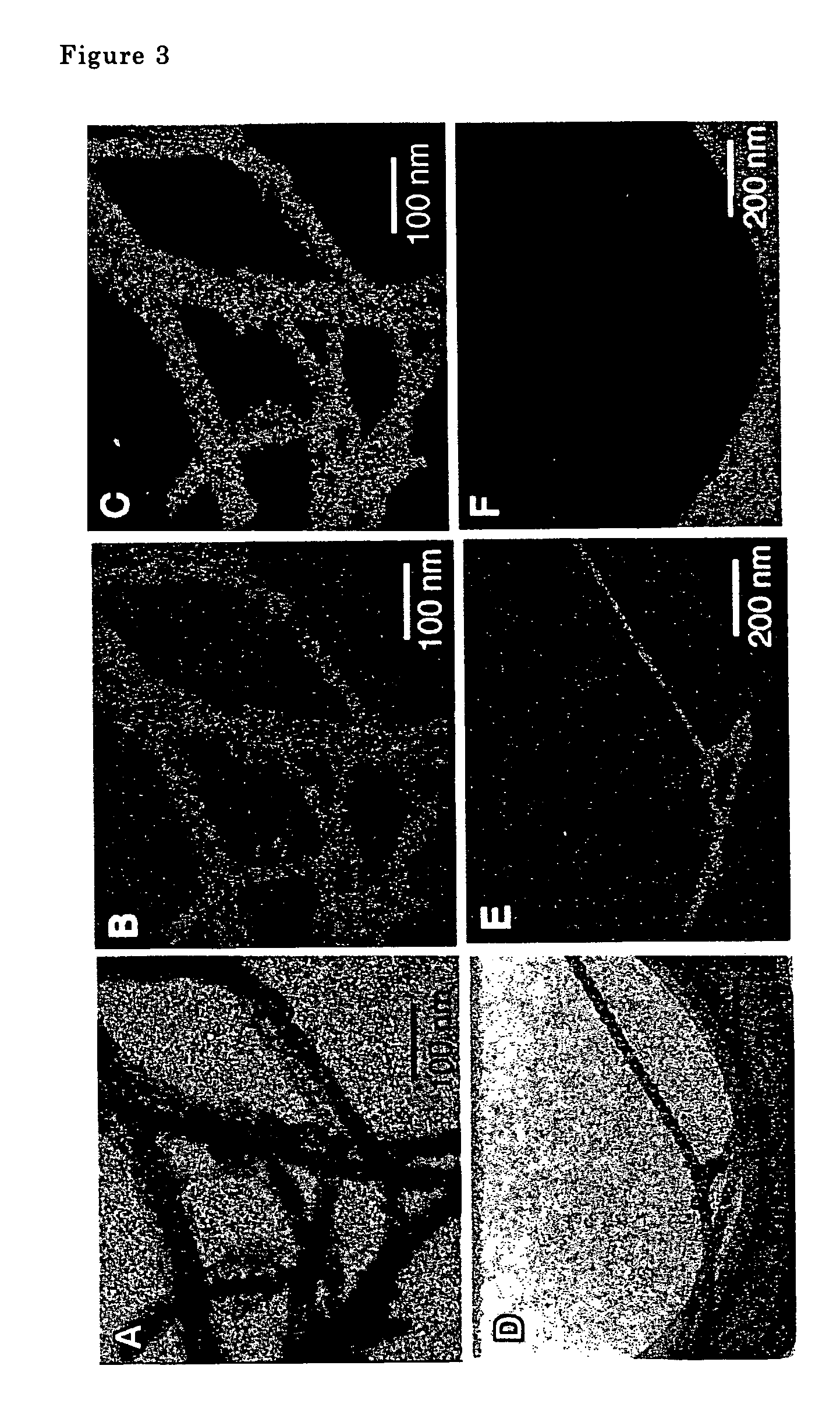

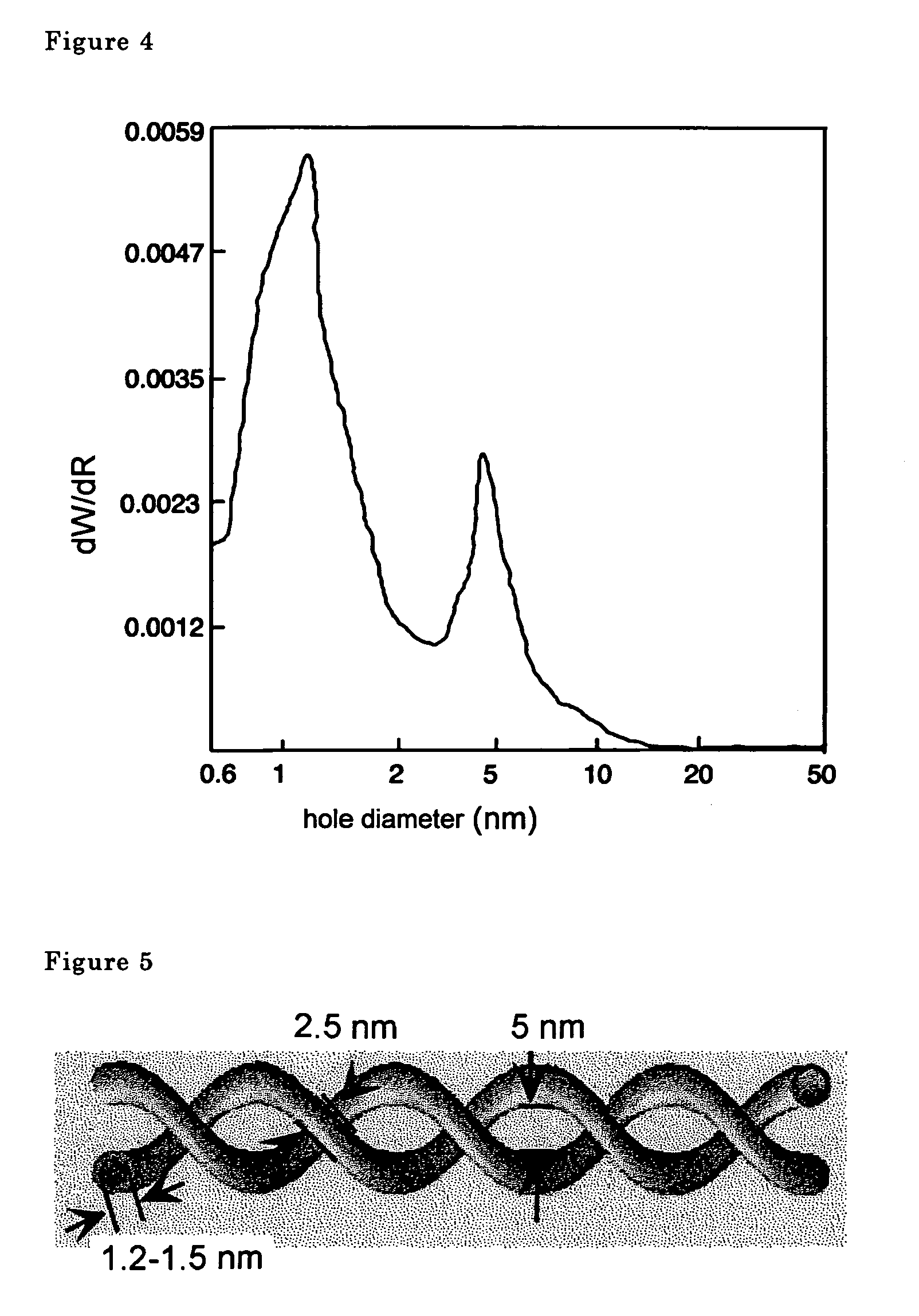

Metal oxide nanotube and process for production thereof

InactiveUS20050077496A1High utility valueLarge capacityMaterial nanotechnologySilicaFiberHydrogen adsorption

Spiral shaped fibers were utilized to prepare completely novel metal oxide nanotubes comprising solely metal oxides. The metal oxide nanotubes comprise solely a hollow cylinder shaped metal oxide which may contain hydroxyl groups constituting a double helix and having hole diameter distributions containing two peak hole diameters ranging from 1 to 2 nm and from 3 to 7 nm. The tubes may be obtained by forming spiral shaped fibers from a solution of compound 1 and compound 2 and using the fibers as a template for making the nanotubes. The hydrogen adsorption and storage capacity of the metal oxide nanotubes are extremely good.

Owner:JAPAN SCI & TECH CORP

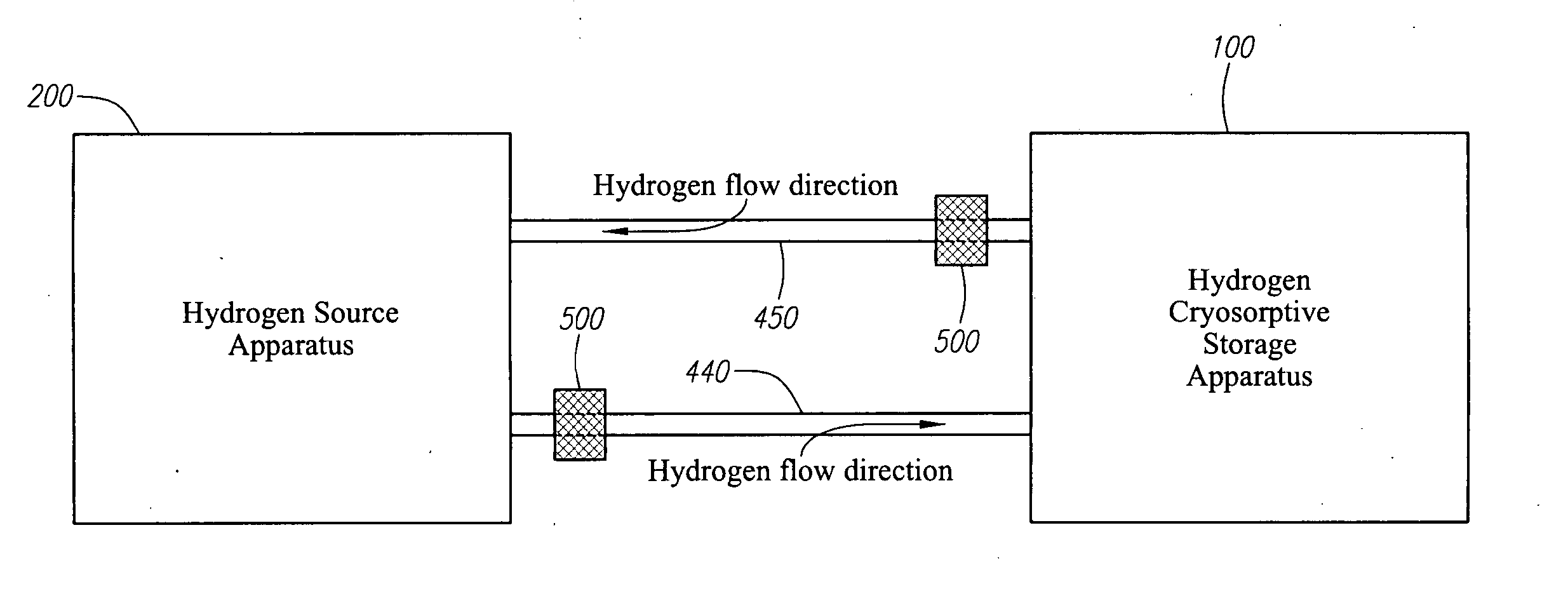

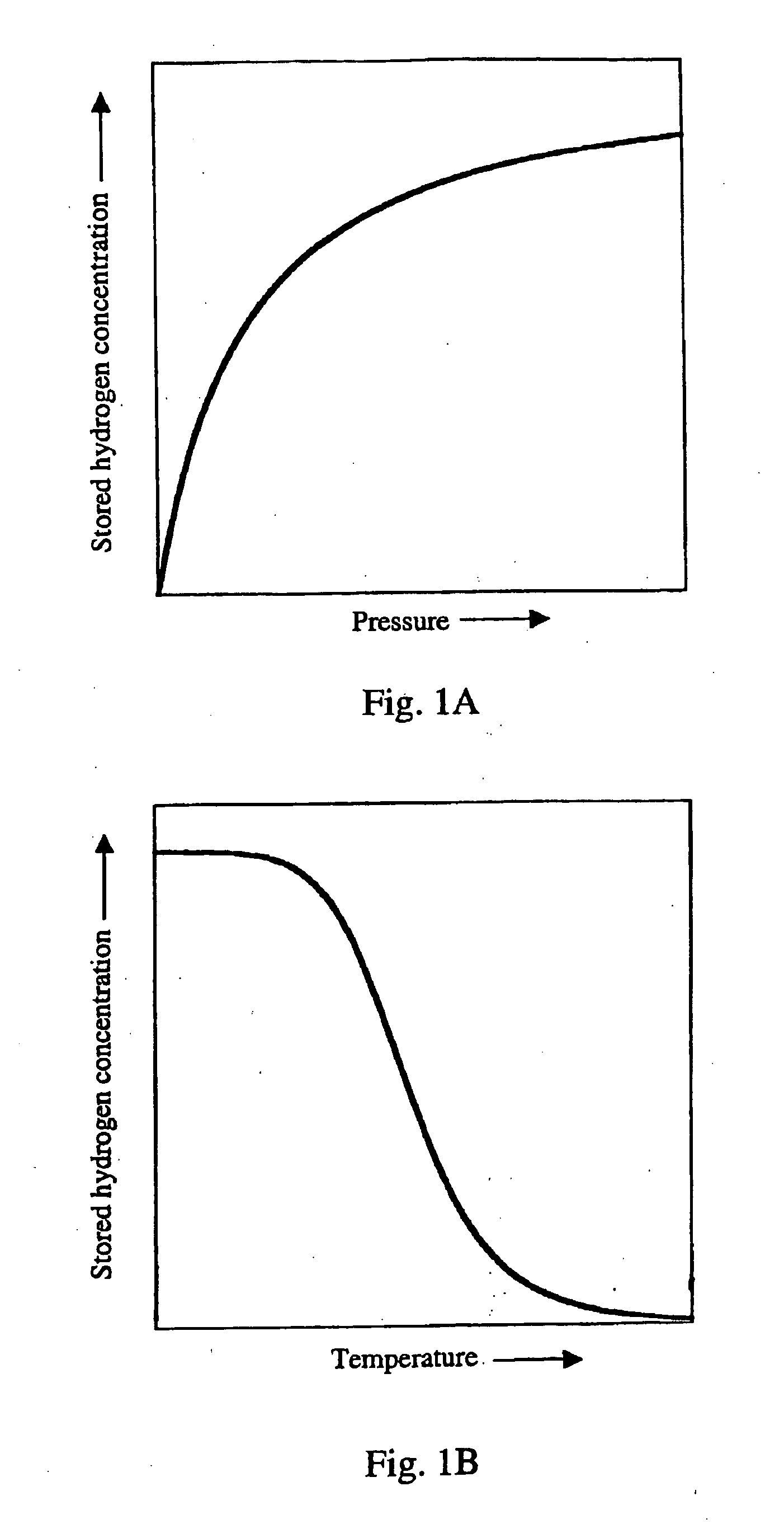

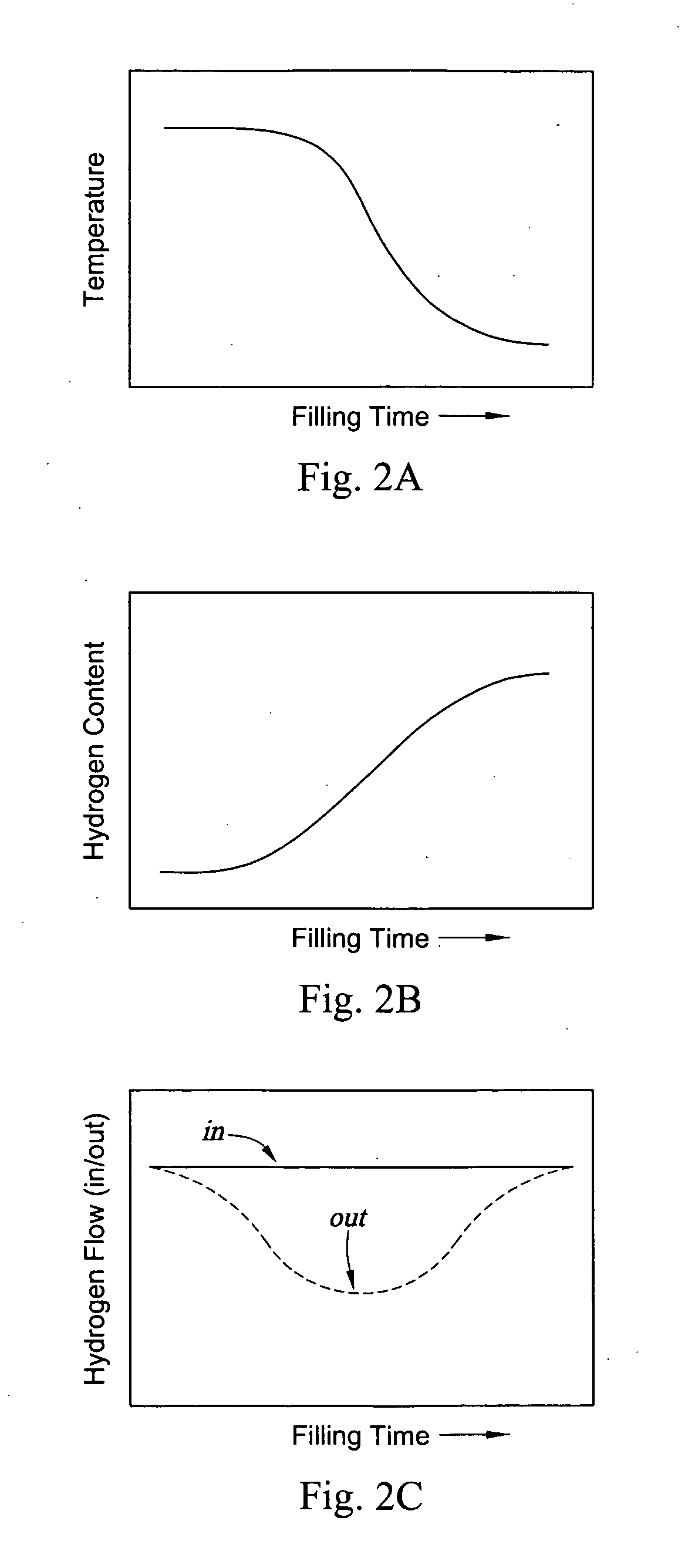

Hydrogen storage and supply system

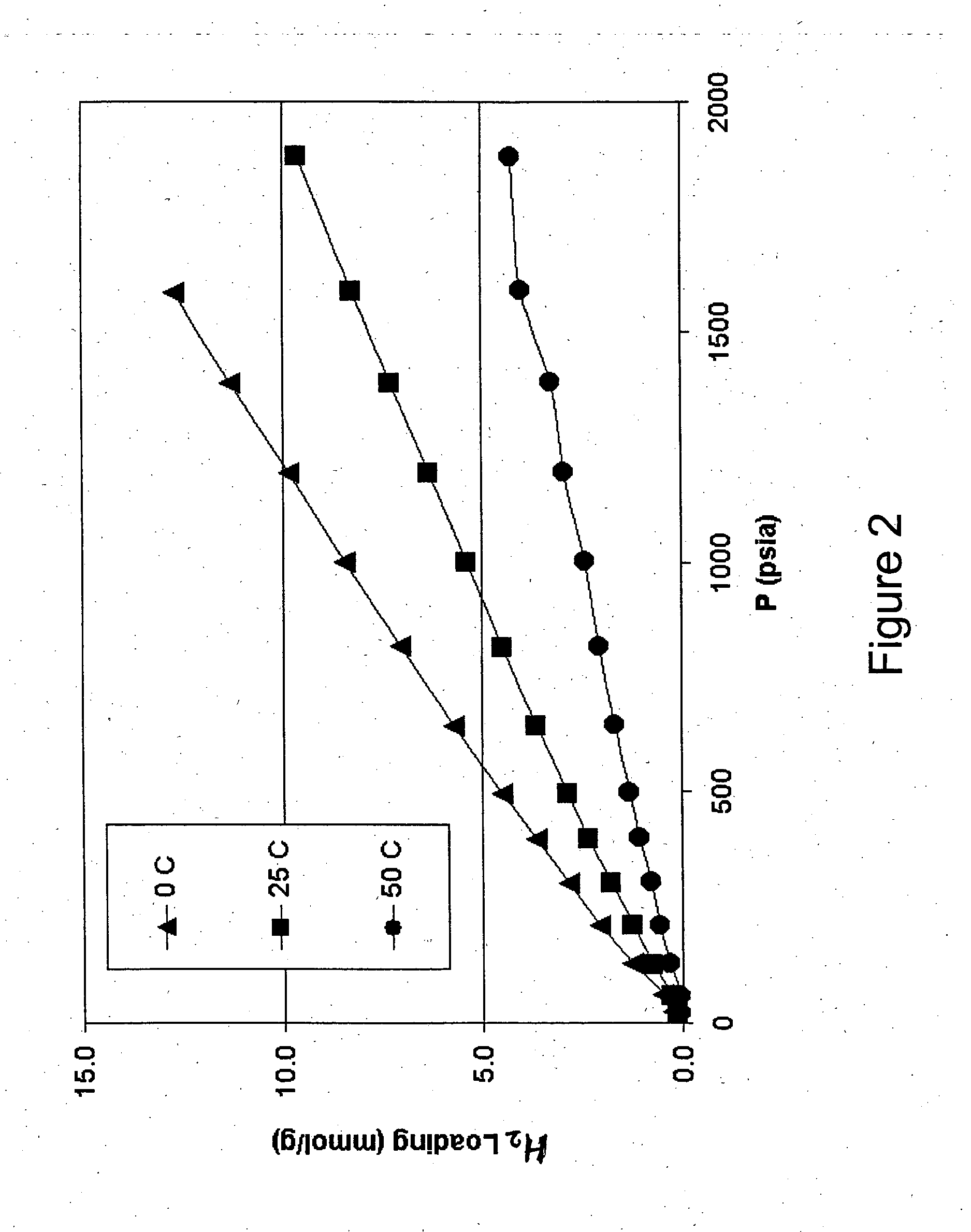

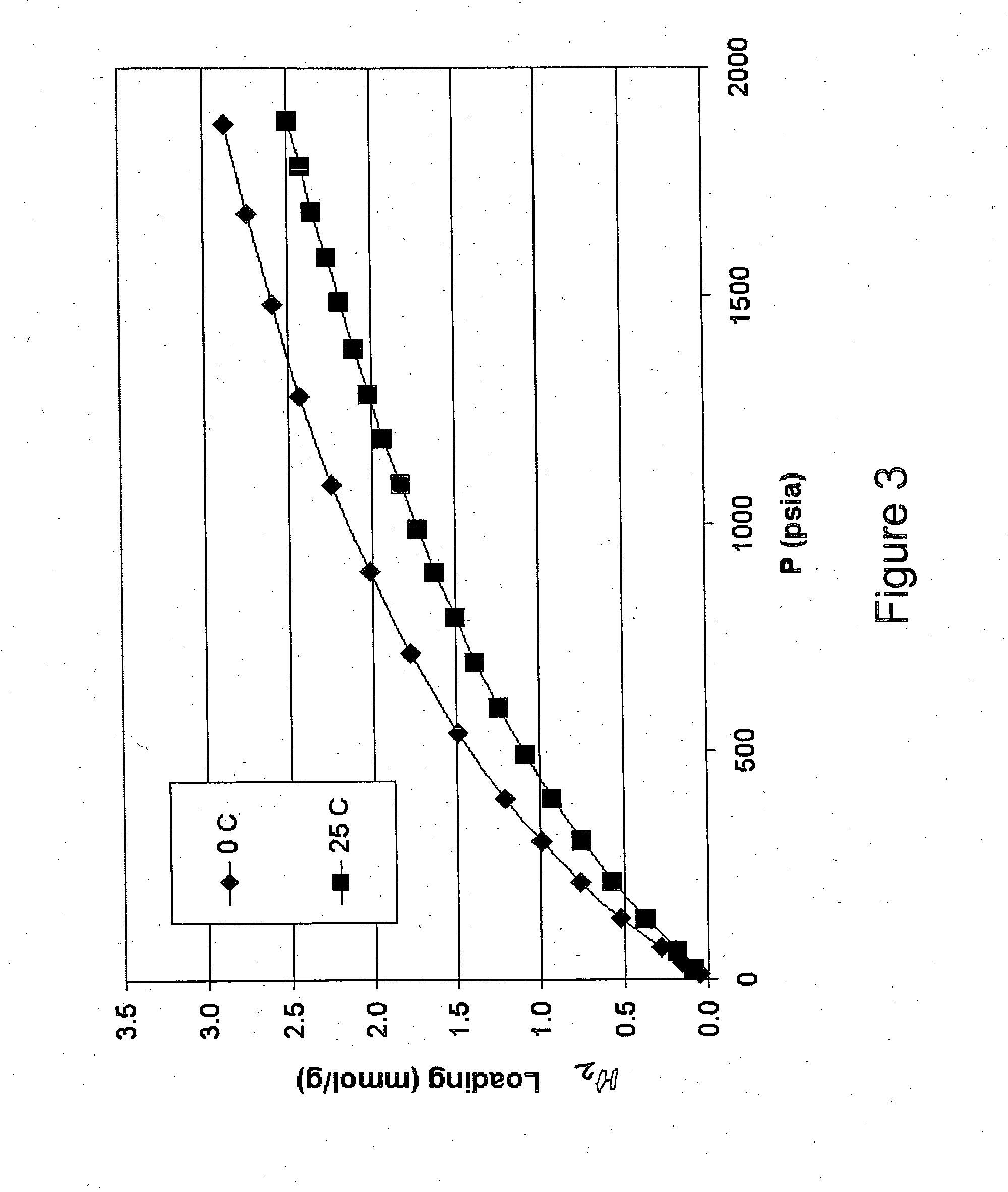

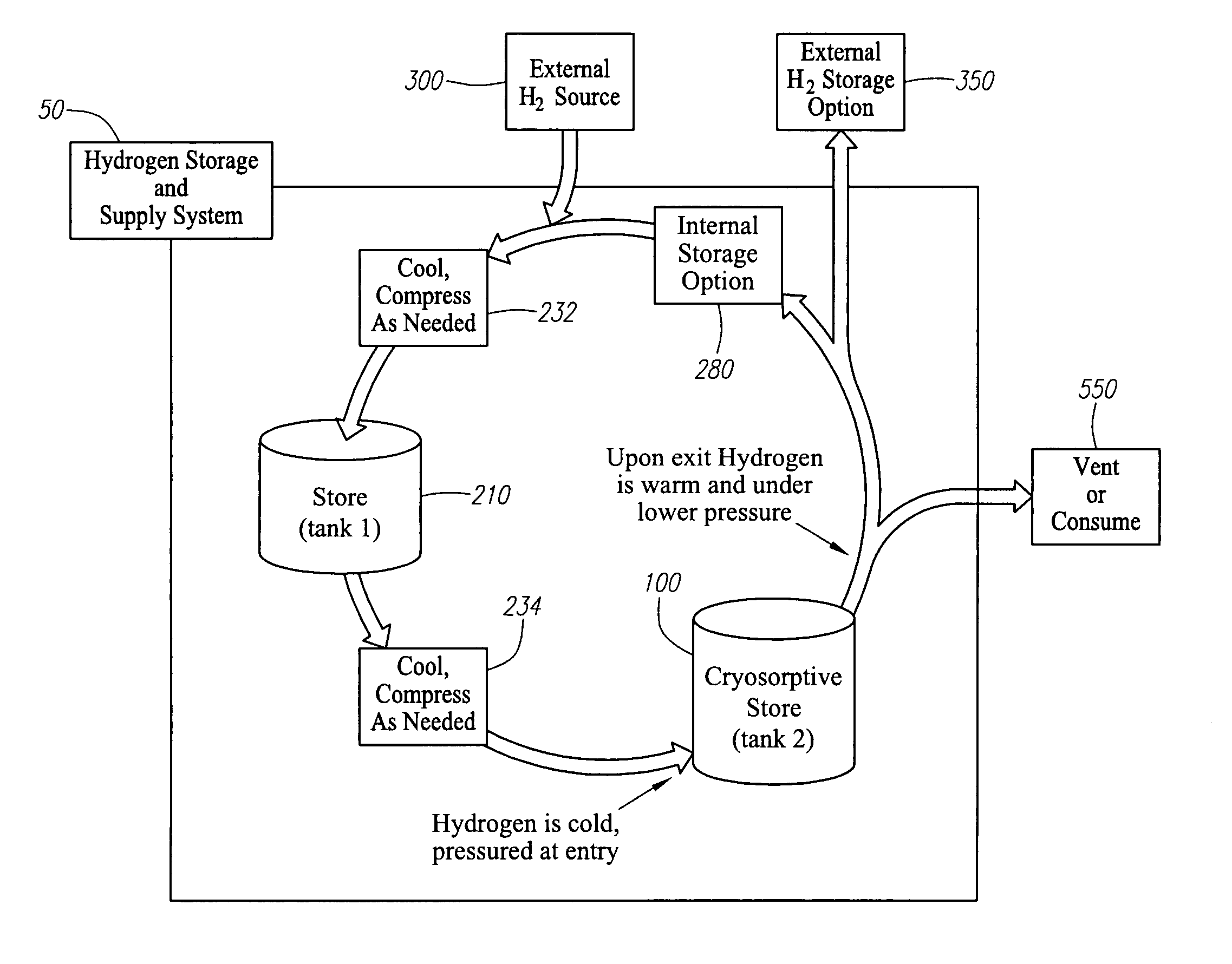

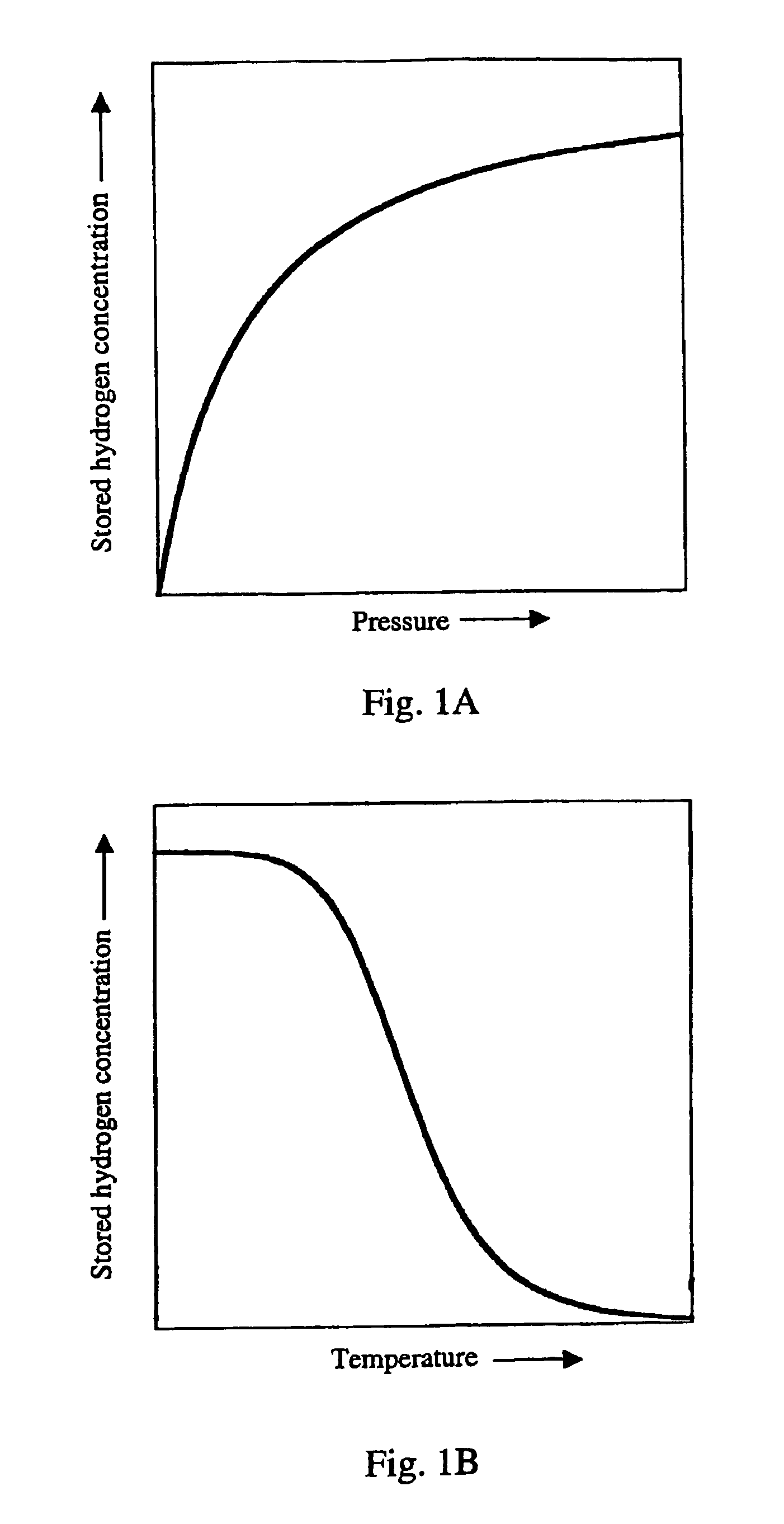

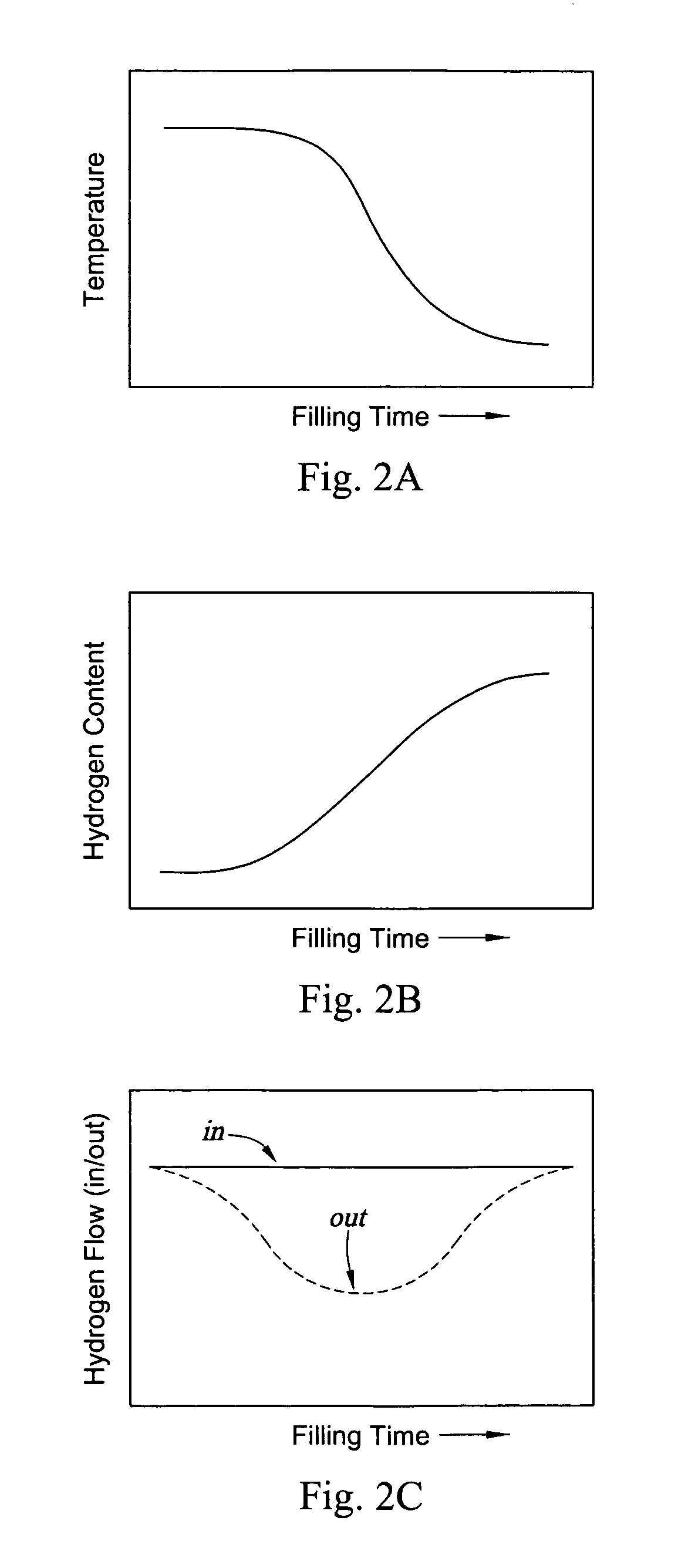

InactiveUS20050183424A1Large specific surface areaData processing applicationsLiquid fillingPorous mediumProcess engineering

This invention provides for an apparatus and a method for operation of a cryogenic hydrogen storage system that contains a porous medium configured to adsorb hydrogen. The hydrogen storage and supply system includes a hydrogen source apparatus and a cryosorptive storage apparatus. Methods and devices that allow for an energy efficient filling of the cryosorptive apparatus from the hydrogen source apparatus are described. The cryosorptive hydrogen storage apparatus is filled with cold, pressurized hydrogen. During the course of filling, heat is generated in the cryosorptive storage device by the process of hydrogen adsorption on to the host medium. Methods and devices are provided for the removal the generated heat and the warm hydrogen. Further provided are devices and methods for the capture and recycle of escaped hydrogen within the hydrogen source apparatus.

Owner:NANOMIX

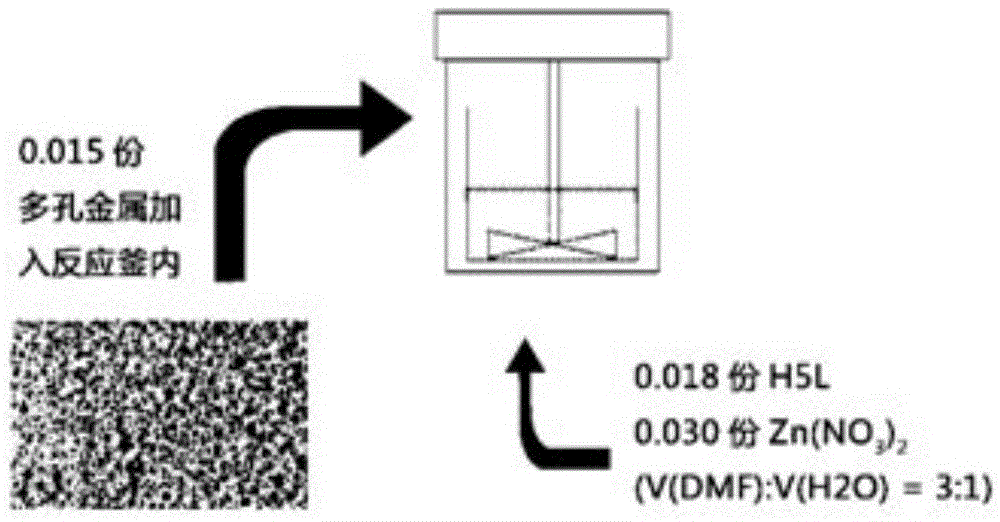

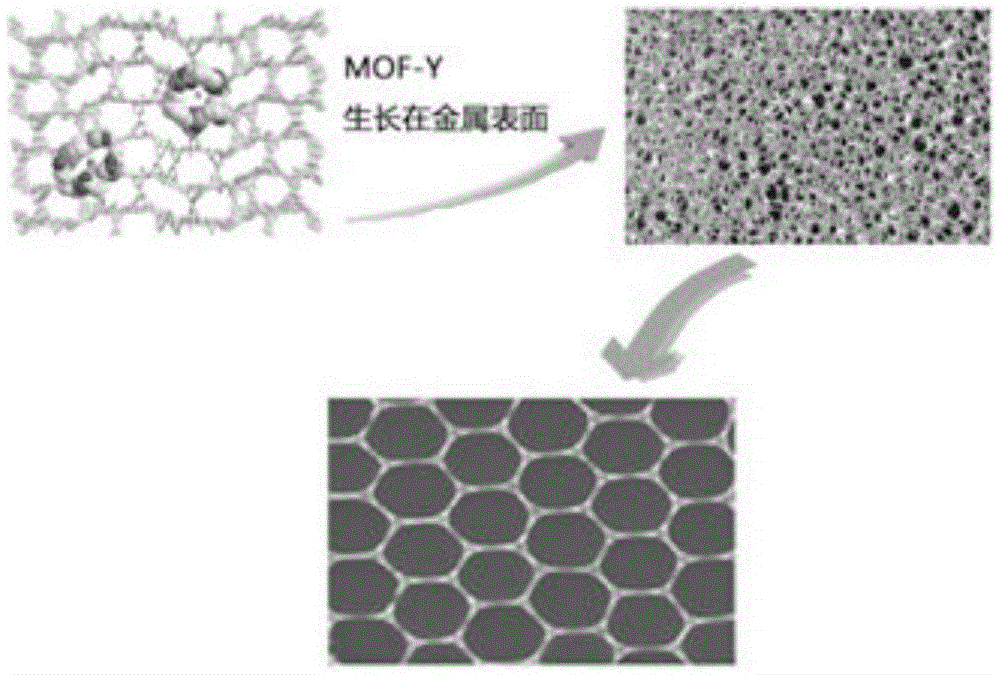

Compounding method and application of porous MOFs (metal-organic frameworks)

InactiveCN105478083AImprove push effectGas treatmentOther chemical processesMetal-organic frameworkAlloy composite

The invention relates to a compounding method of porous MOFs (metal-organic frameworks). The method comprises the following steps: S1, a porous metal interface is activated; S2, MOF-Y is prepared; S3, porous metal Ti and a Ni-Co-Mn ternary alloy which are activated in the step S1 are chemically compounded with MOF-Y, and compounding is realized; S4, the composite is represented. The invention further provides an application of the material prepared with the compounding method of the porous MOFs in hydrogen adsorption. The compounding method and the application have the following advantages: a novel technology and a novel thought are provided for preparation of the MOFs, porous metal Ti and Ni-Co-Mn ternary alloy composite, the novel composite which has wide application prospect in hydrogen adsorption is obtained, a good boost function is realized for acceleration of further practical application of MOFs, and important material support is provided for a hydrogen storage technology, so that the method and the application have very important practical values.

Owner:NORTHWEST UNIV(CN)

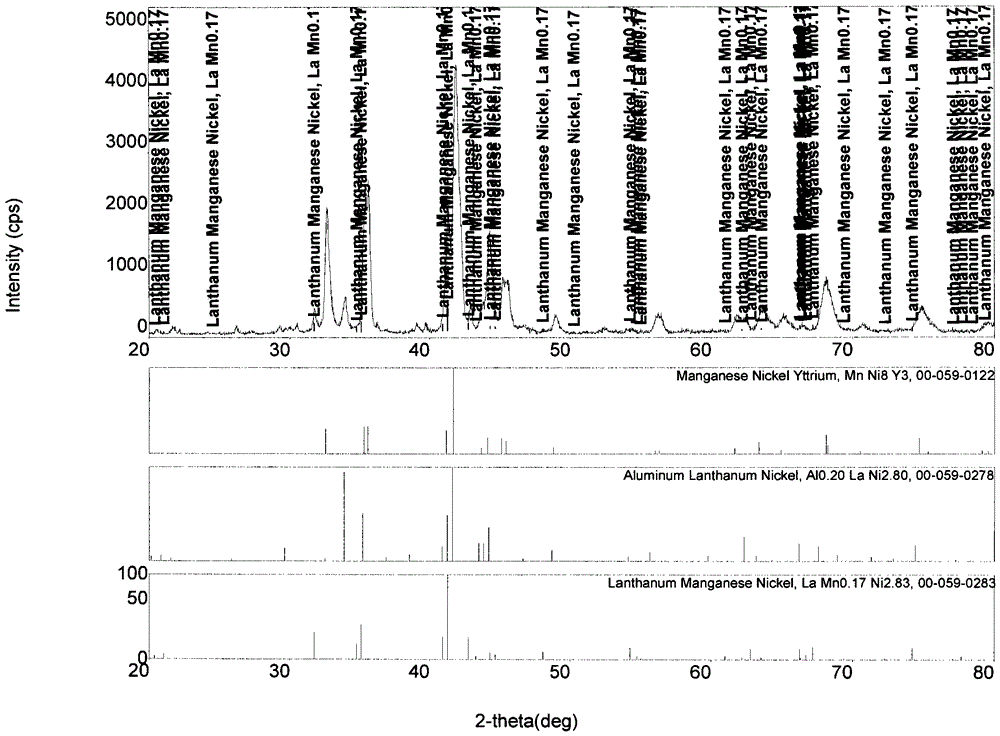

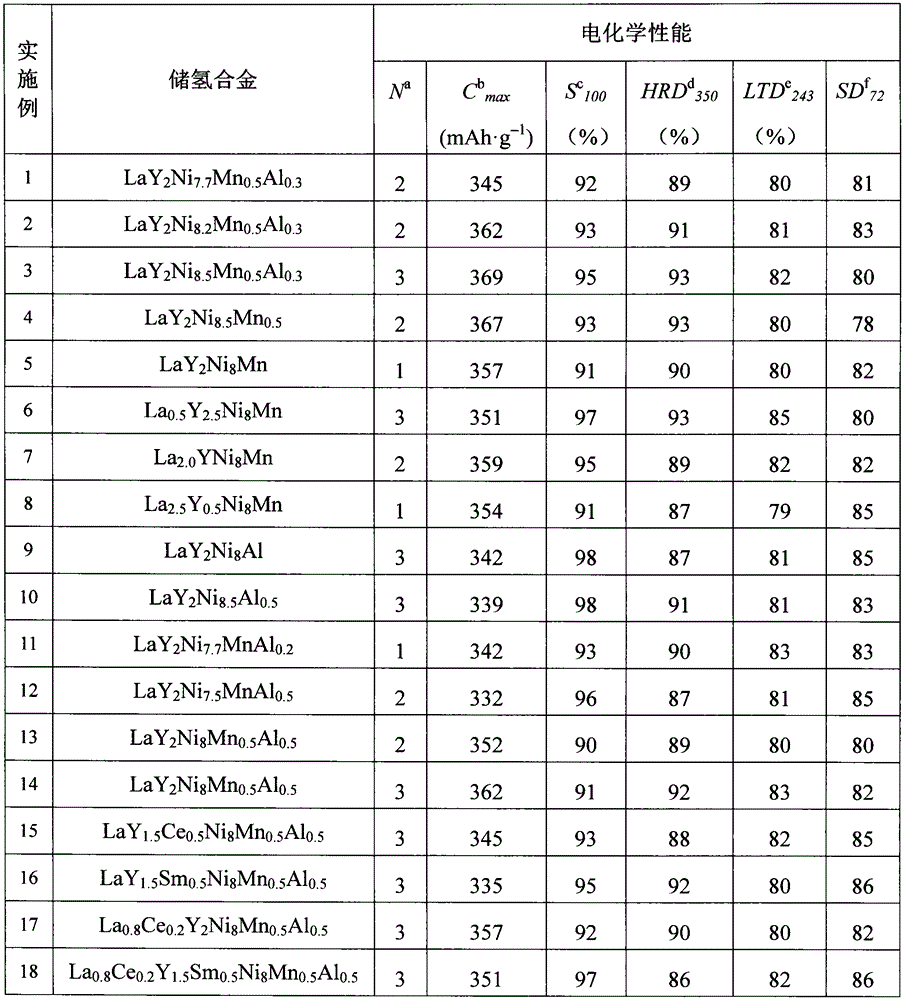

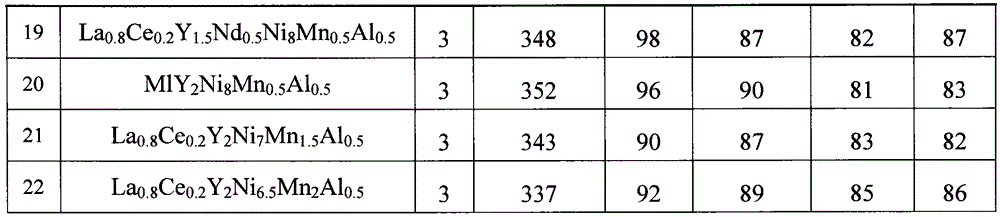

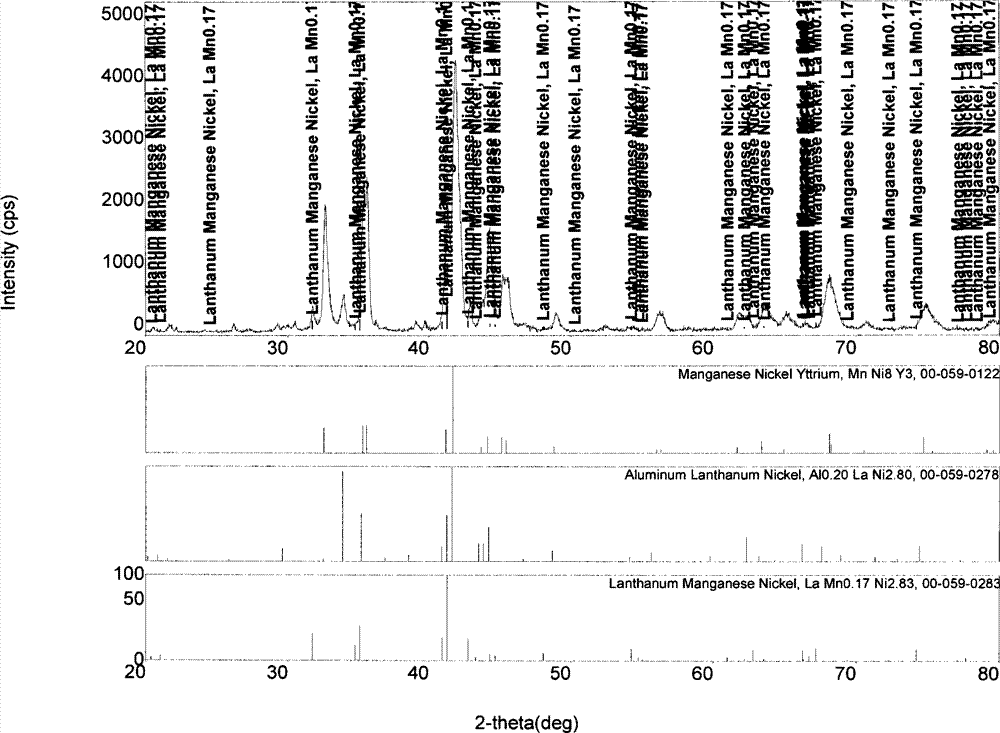

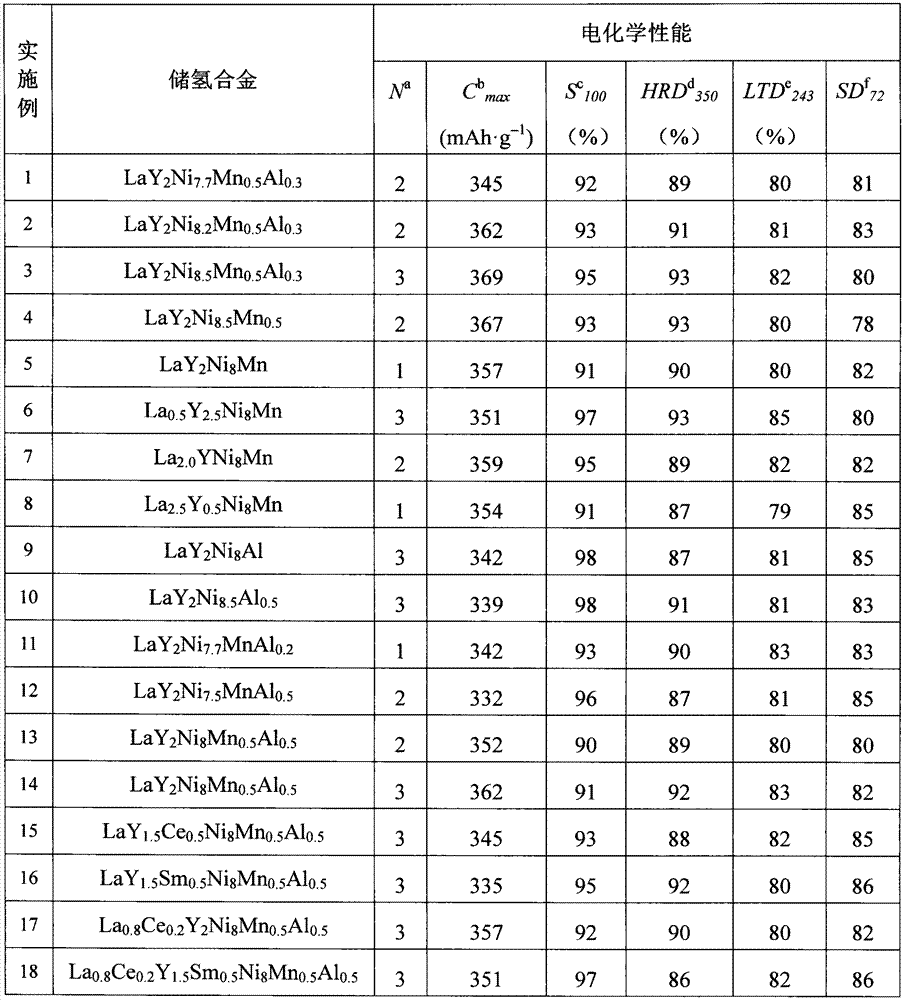

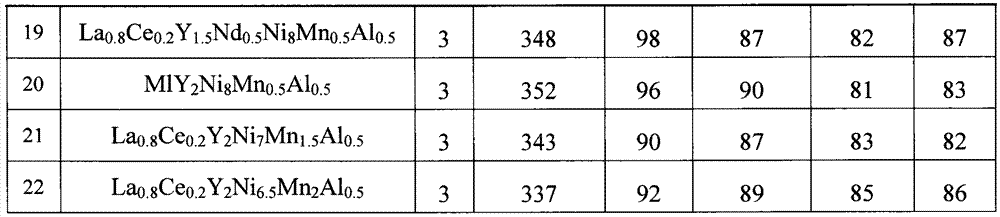

A yttrium-nickel rare earth hydrogen storage alloy and a secondary battery containing the hydrogen storage alloy

ActiveCN104513925BStructural stress reliefImprove mechanical propertiesAlkaline accumulator electrodesDesorptionGas phase

A yttrium-nickel rare earth hydrogen storage alloy and a secondary battery containing the hydrogen storage alloy of the present invention relate to an AB3 type RExYyNiz-a-bMnaAlb hydrogen storage electrode alloy. The alloy has good activation performance, rate discharge capability, cycle stability of charging and discharging or hydrogen absorption and desorption, can be used in a wide temperature range, has small self-discharge, and its maximum electrochemical capacity can reach more than 360mAh·g-1 . The electrochemical performance of the alloy as a hydrogen storage electrode and the gas-phase hydrogen absorption and desorption performance as a hydrogen storage material are superior to those of the traditional LaNi5 type hydrogen storage alloy. In comparison, the fabrication method is simple and safe.

Owner:BAOTOU RES INST OF RARE EARTHS +2

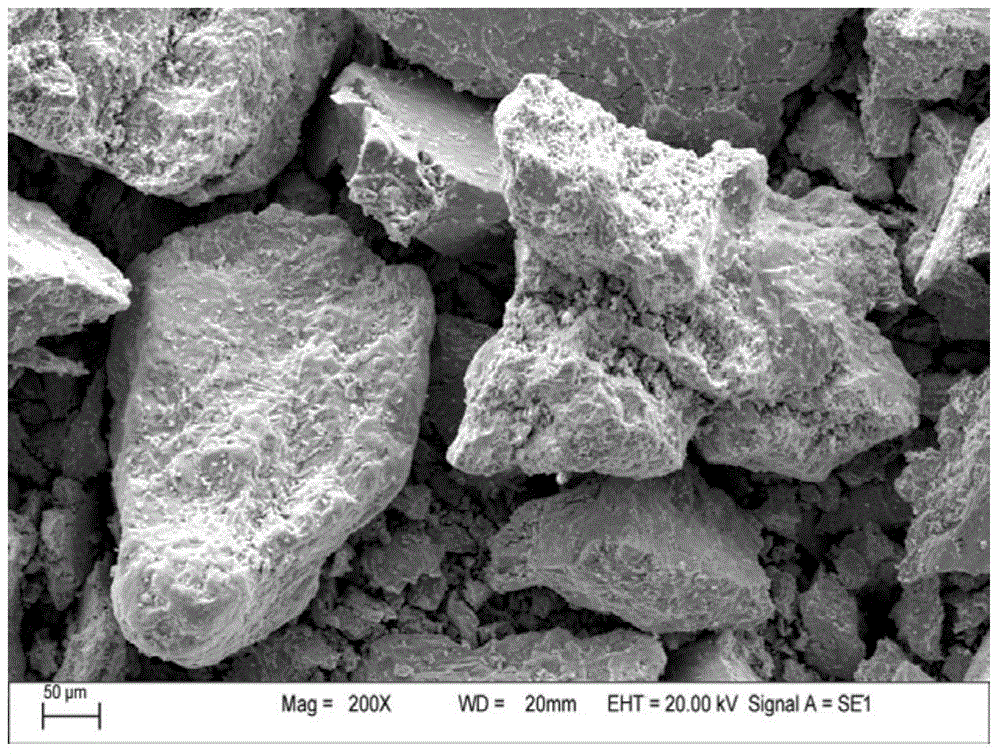

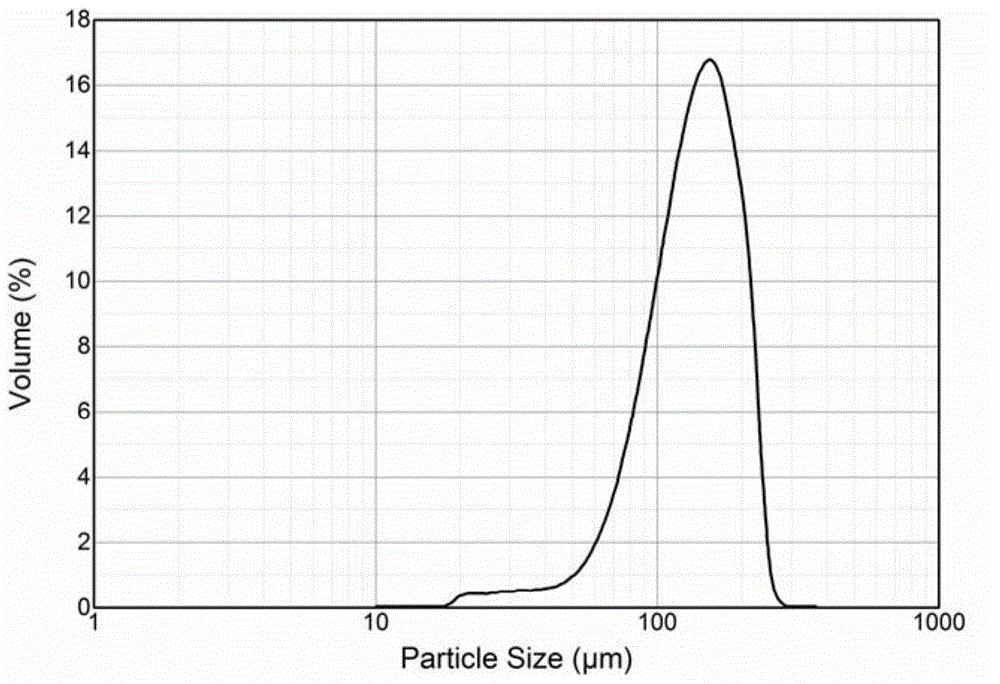

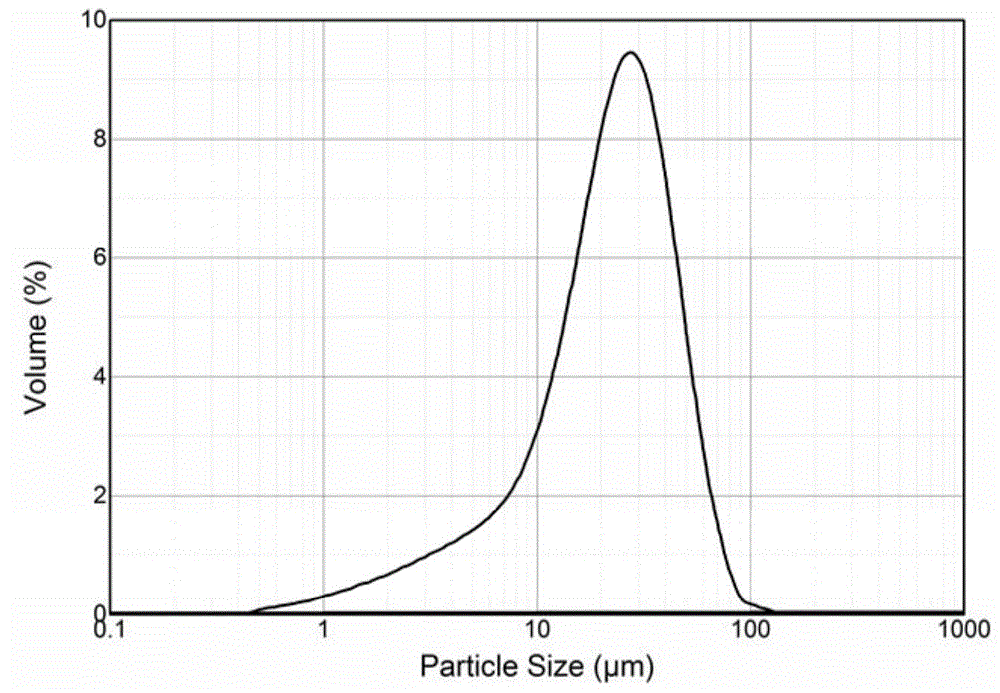

Metal oxide and porous material composite hydrogen storage material and preparation method thereof

PendingCN110963461AAccelerate the rate of hydrogenationSmall particle sizeHydrogenHydrogen adsorptionHigh surface area

The invention belongs to the technical field of hydrogen storage materials and particularly relates to a metal oxide and porous material composite hydrogen storage material and a preparation method thereof. The metal oxide and porous material composite hydrogen storage material is formed by compounding magnesium hydride, a porous material and a metal oxide, and the weight ratio of the magnesium hydride to the porous material to the metal oxide is (100-10): (5-0.1): (1-0.05). The magnesium hydride is taken as a base material, and metal oxide particles are mixed and grinded to obtain an activated magnesium hydride material; and the obtained activated magnesium hydride material is mixed with the porous material, and ball milling or compression is carried out to obtain the composite hydrogen storage material. According to the material and the preparation method, nanoscale metal oxide particles are added and compounded with the porous material, so that the hydrogenation speed of magnesium-based composite powder in the hydrogen charging ball milling process can be increased, and meanwhile, the hydrogen storage material has good characteristics in the aspects of hydrogen adsorption and desorption kinetics in combination with the properties such as excellent pore channels and high surface area of the porous material.

Owner:世能氢电科技有限公司 +1

Yttrium-nickel rare earth family hydrogen storage alloy, and secondary battery containing hydrogen storage alloy

ActiveCN104513925AStructural stress reliefEliminate component segregationAlkaline accumulator electrodesDesorptionGas phase

The invention relates to a yttrium-nickel rare earth family hydrogen storage alloy, and a secondary battery containing the hydrogen storage alloy, and concretely relates to an AB3 type RExYyNiz-a-bMnaAlb hydrogen storage electrode alloy. The alloy has good activation performances, rate discharge ability, and charge and discharge or hydrogen adsorption desorption cycle stability, can be used in a wide temperature range, has small self discharge, and has a highest electrochemical capacity reaching above 360mAh.g<-1>. The alloy has better electrochemical performances and gas phase hydrogen adsorption and desorption performances than traditional LaNi5 type hydrogen storage alloy as a hydrogen storage electrode and a hydrogen storage material respectively, and contains no magnesium element; and the preparation method of the hydrogen storage electrode alloy is simpler and safer than the preparation method of rare earth-magnesium-nickel family AB3 hydrogen storage alloy.

Owner:BAOTOU RES INST OF RARE EARTHS +2

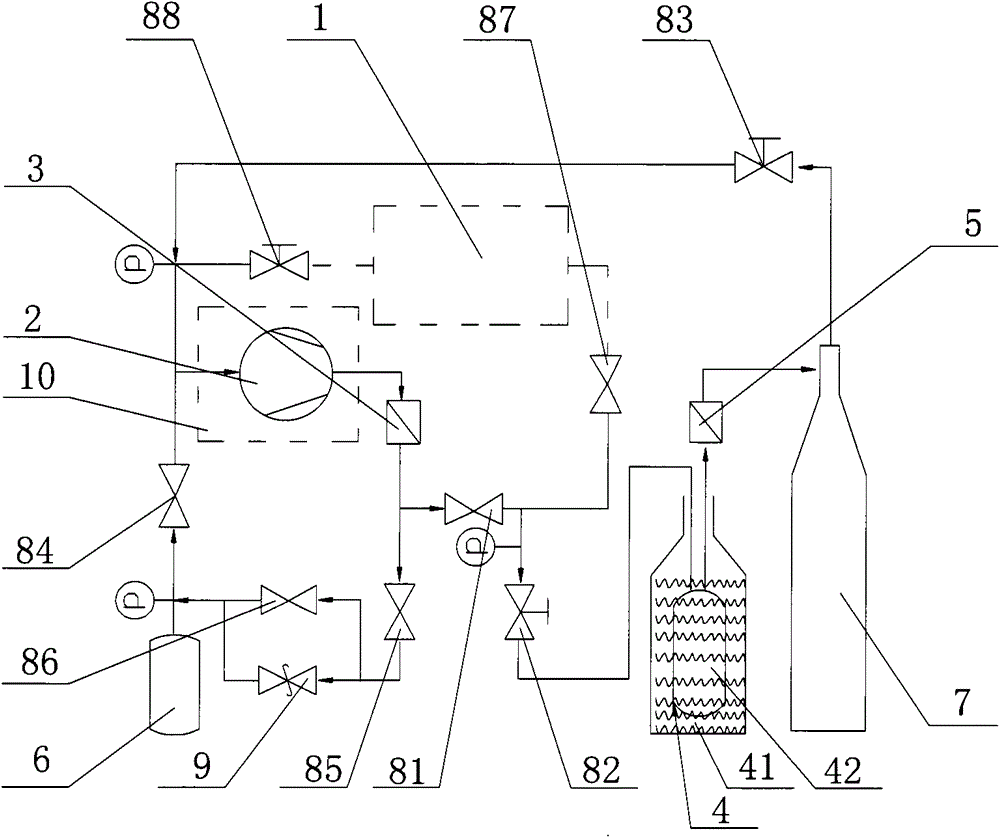

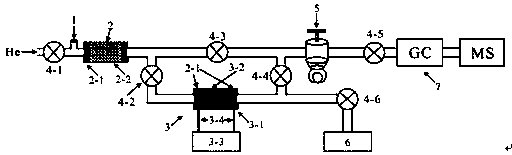

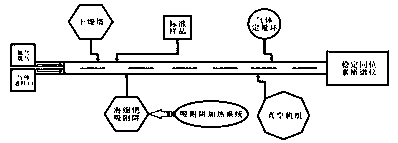

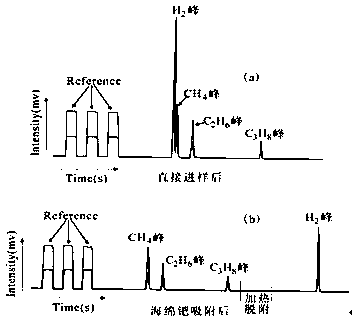

Device and method capable of separating hydrogen and methane in mixed gas and measuring hydrogen isotope

ActiveCN109603413ASmall distortionHigh precisionGas treatmentComponent separationProduct gasHydrogen adsorption

The invention belongs to the field of oil gas geochemistry, and in particular to a device and method capable of separating hydrogen and methane in a mixed gas and measuring a hydrogen isotope. The device comprises a gas sample inlet, a drying unit, a hydrogen adsorption separation unit, a quantifying loop, a vacuum unit and an isotope measuring unit; and the gas sample inlet, the drying unit, thehydrogen adsorption separation unit, the quantifying loop and the isotope measuring unit are sequentially connected in series; the hydrogen adsorption separation unit can release adsorbed hydrogen tomeasure the hydrogen isotope, so that the methane and hydrogen in the mixed gas are separated, the separated hydrogen and methane are used for measure of the hydrogen isotopes respectively, and measure of the hydrogen isotope of the hydrogen and the hydrogen isotope of the methane in the hydrogen-methane mixed gas is realized; and the vacuum degree of the whole system is high, deviation caused bymutual interference between a hydrogen peak and a methane peak in the prior art is overcome, and accuracy of an analytical test is improved.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

Reversible hydrogen adsorption and desorption method using piperidine as media and device

The invention relates to a novel hydrogen adsorption and desorption method, which aims at providing a reversible hydrogen adsorption and desorption method using piperidine as a media and a device. The method uses hydrogen storage alloy as a catalyst, and the reversible hydrogen adsorption and desorption process comprises the hydrogen desorption process and the hydrogen adsorption process, wherein in the hydrogen desorption process, under the temperature condition of 120 to 350 DEG C, the piperidine is converted into pyridine under the effect of the hydrogen storage alloy, and at the same time, the hydrogen gas is released out; and in the hydrogen adsorption process, under the temperature condition of 95 to 115 DEG C, the hydrogen gas is introduced into the pyridine, and the pyridine and the hydrogen gas generate the piperidine under the effect of the hydrogen storage alloys. The piperidine is used as the hydrogen storage media, so the hydrogen storage quantity which is much higher than that of the metal hydrogen storage alloy can be provided, and the invention is hopeful to become a hydrogen source of a fuel battery for generating electricity and to be used as motive power of a fuel battery vehicle. The hydrogen gas through the decomposition of the piperidine is pure, does not contain CO, can be directly used for the fuel battery, and does not need the purification like the hydrogen gas obtained through the methanol modification, so the system is simple, and the operation is convenient.

Owner:ZHEJIANG UNIV

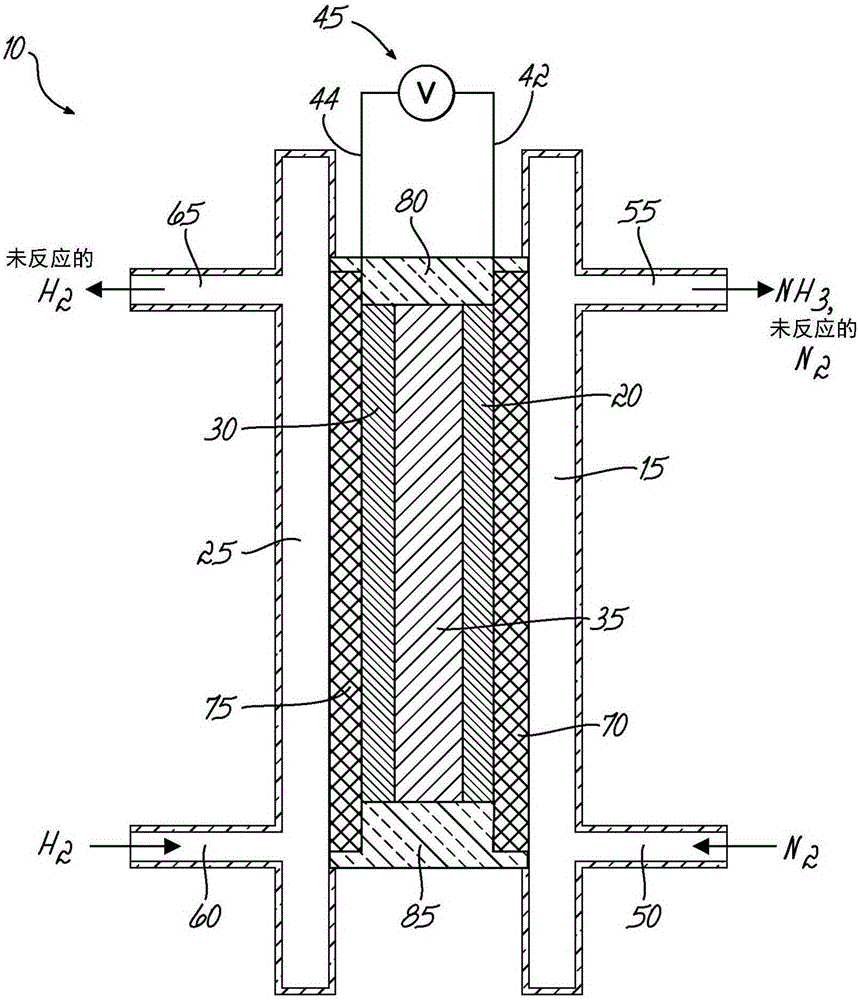

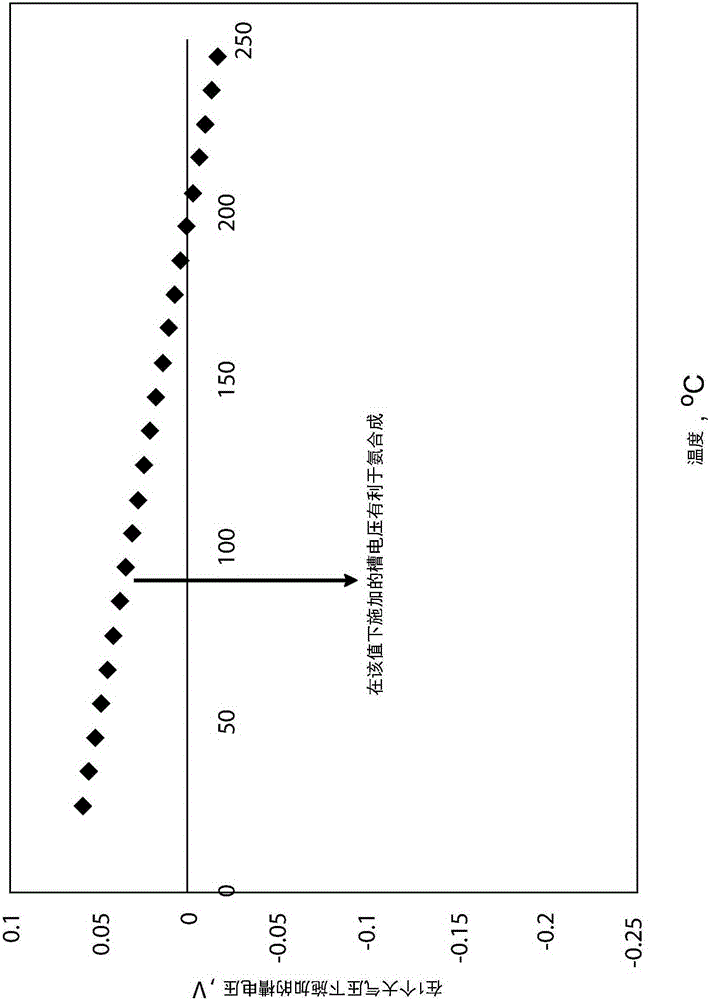

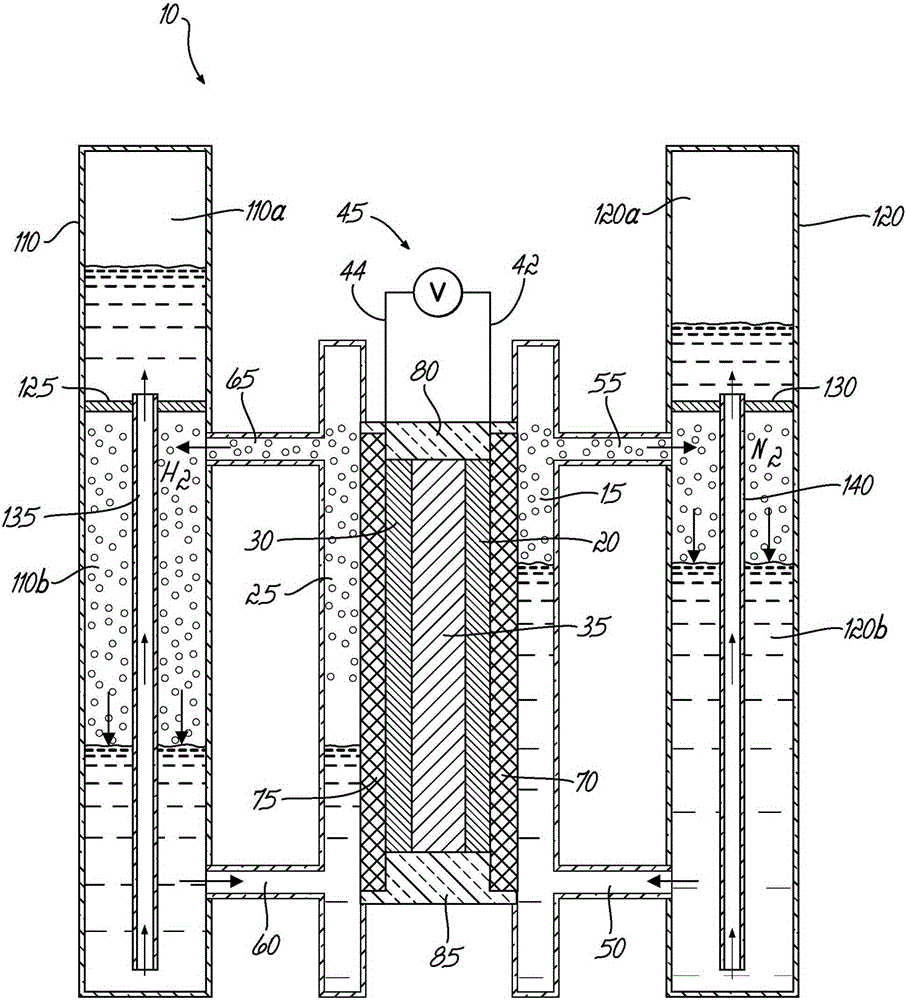

Electrochemical synthesis of ammonia in alkaline media

A method is provided for an electrochemical synthesis of ammonia in alkaline media. The method electrolytically converts N2 and H2 to NH3 in an electrochemical cell 10 comprising an anode 30, a cathode 20, and an alkaline electrolyte. The method includes exposing an anode to a H2-containing fluid, wherein the anode 30 is active toward adsorption and oxidation of H2; exposing a cathode to a N2-containing fluid, wherein the cathode 20 is active toward adsorption and reduction of N2 to form NH3; and applying a voltage between the anode 30 and the cathode 20 so as to facilitate adsorption of hydrogen onto the anode 30 and adsorption of nitrogen onto the cathode 20; wherein the voltage is sufficient to simultaneously oxidize the H2 and reduce the N2. The electrolytic method is performed with the H2 and N2 pressures from about 10 atmospheres (atm) to about 1 atm; and at temperatures from about 25DEG C to about 205 DEG C.

Owner:THE OHIO STATES UNIV

Preparation method of porous aromatic framework compound constructed with benzene ring base blocks

The invention discloses a preparation method of a porous aromatic framework compound constructed with benzene ring base blocks. According to the preparation method, an aromatic rigid monomer with no substituent group and composed of and only of a plurality of benzene rings is adopted as a reactant; and Lewis acid is adopted as a catalyst. Especially, biphenyl, m-terphenyl, p-terphenyl, o-terphenyl or 1,3,5-triphenylbenzene are adopted as the reactant; aluminum trichloride is adopted as the catalyst, and the porous aromatic framework compound is prepared. The reaction raw materials and the catalyst used in the method are cheap and easy to obtain, such that cost is low. The yield of the reaction is extremely high; the reaction method is simple and feasible; and the reaction conditions are substantially easy to obtain. An obtained product has extremely high hydrogen adsorption property, such that the product has high application and market values. With the method, the application prospect of the type of aromatic framework compound is expanded.

Owner:苏州纳埃净化科技有限公司

Preparation method of hydrogen absorption component

ActiveCN104651652ALarge specific surface areaLow activation temperatureHydrogen separation using solid contactElectric discharge tubesDehydrogenationBiological activation

The invention relates to a preparation method of a hydrogen absorption component. The preparation method comprises the following steps: suspension induction melting or medium-frequency induction melting is carried out on a raw material metal and / or an intermediate alloy to obtain a target ingredient alloy ingot; after vacuum activation of the hydrogen absorption alloy ingot, hydrogenation treatment is carried out to obtain hydrogen-containing alloy particles; the alloy particles undergo ball-milling and screening to make all materials meet jet-milling feeding requirements; the alloy particles are ground into a powder by jet-milling; hydrogenated alloy particles undergo spheroidizing and dehydrogenation by radio frequency plasma discharge spheroidizing; and the obtained powder is pressed or sintered to prepare the hydrogen absorption component. Hydrogen adsorption properties of the hydrogen absorption component prepared by the above method are obviously better than those of a hydrogen absorption component prepared by traditional preparation methods such as a direct crushing method and a hydrogenation crushing method. The prepared hydrogen absorption component has excellent hydrogen absorption properties at high temperature and can replace existing hydrogen absorption components for solar vacuum tubes.

Owner:GRIMAT ENG INST CO LTD

Metal oxide nanotube and process for production thereof

InactiveUS7172747B2High utility valueLarge capacityMaterial nanotechnologyOxide/hydroxide preparationFiberHydrogen

Spiral shaped fibers were utilized to prepare completely novel metal oxide nanotubes comprising solely metal oxides. The metal oxide nanotubes comprise solely a hollow cylinder shaped metal oxide which may contain hydroxyl groups constituting a double helix and having hole diameter distributions containing two peak hole diameters ranging from 1 to 2 nm and from 3 to 7 nm. The tubes may be obtained by forming spiral shaped fibers from a solution of compound 1and compound 2and using the fibers as a template for making the nanotubes. The hydrogen adsorption and storage capacity of the metal oxide nanotubes are extremely good.

Owner:JAPAN SCI & TECH CORP

Preparation method and application of spherical adsorbent for efficiently removing low-concentration hydrogen sulfide

InactiveCN108568290AEfficient adsorption capacityReduce adsorptionGas treatmentOther chemical processesSpherisorb ODSSorbent

The invention discloses a preparation method and application of a spherical adsorbent for efficiently removing low-concentration hydrogen sulfide. The preparation method comprises the following steps:taking pretreated industrialized spherical pseudo-boehmite as a carrier, then soaking the carrier in a certain amount of soluble alkali metal salt solution to obtain an adsorbent precursor, and drying and roasting the adsorbent precursor to obtain a load type adsorbent with high adsorption capacity. The adsorbent disclosed by the invention belongs to a dry desulfurization agent; firstly the adsorbent overcomes the defects caused by using a wet desulfurization agent that a liquid absorbent is used for removing sulfide, the treatment capacity of the equipment is large, the operation of the adsorbent is complicated, the adsorption capacity is low, the requirement of high adsorption capacity is difficult to meet, and especially, the wet process is difficult in meeting the high requirement ofremoving low-concentration hydrogen sulfide; secondly, the spherical adsorbent has the advantages of high adsorption capacity of adsorbing low-concentration hydrogen sulfide, large strength, low costand the like; and the spherical adsorbent is simple in preparation process and easy to produce widely and has good industrialized potential.

Owner:FUZHOU UNIV

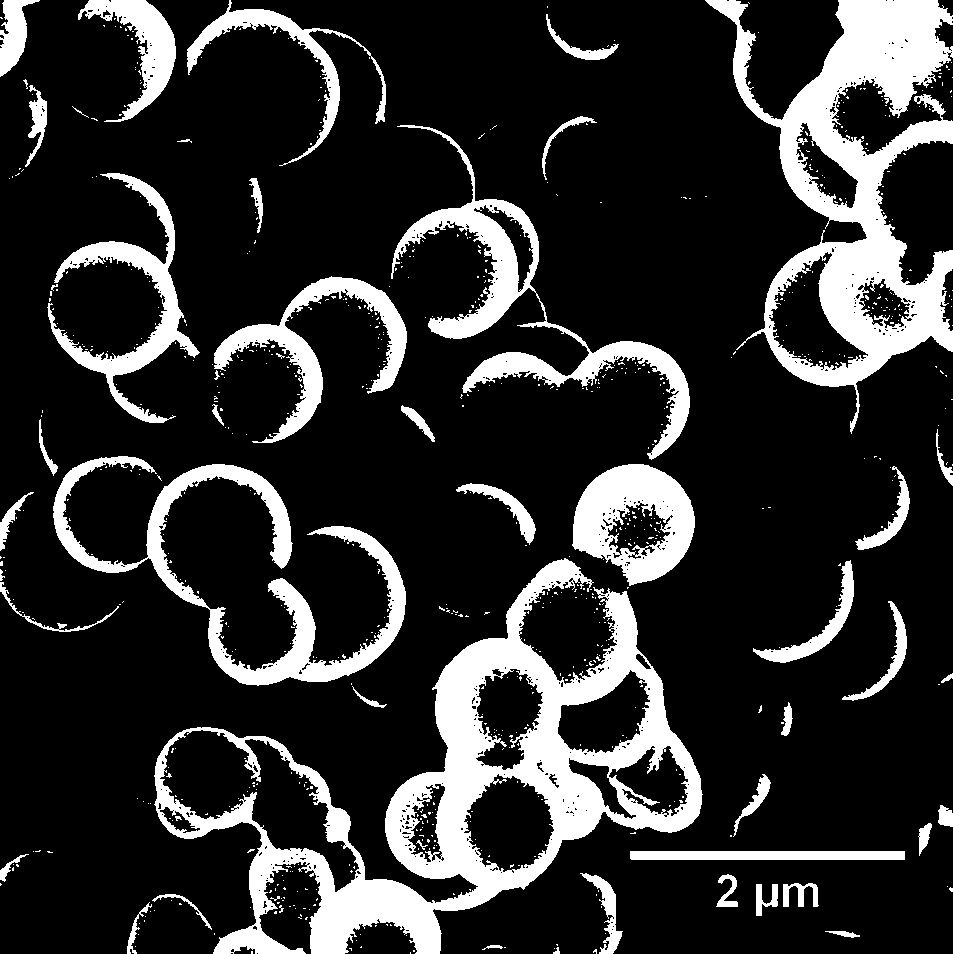

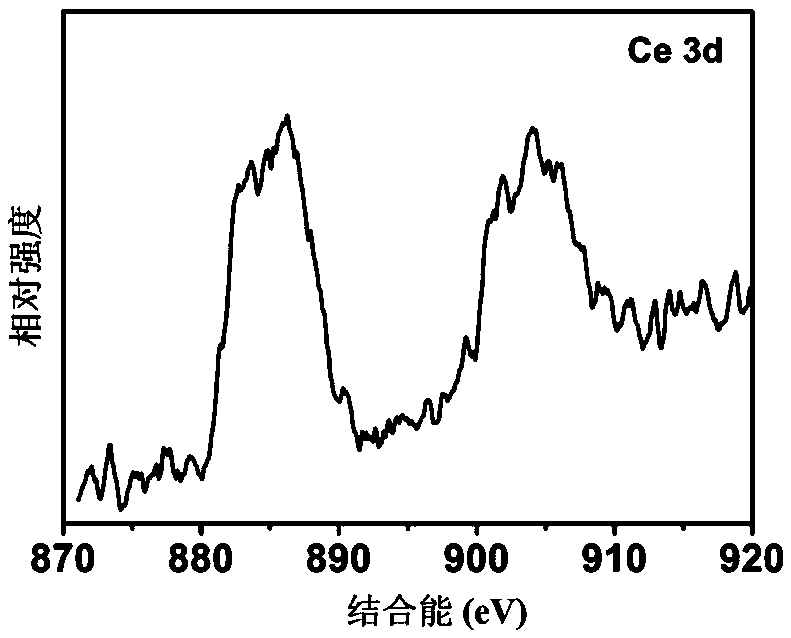

Cerium-doped tungsten phosphide submicron sphere composite material, preparation method and application thereof

ActiveCN110904468AUniform particlesFast transmissionCatalyst activation/preparationElectrodesPtru catalystElectrolysis

The invention provides a cerium-doped tungsten phosphide submicron sphere composite material, a preparation method and application thereof. Cerium in the cerium-doped tungsten phosphide submicron sphere composite material is uniformly doped in tungsten phosphide submicron spheres, and the cerium-doped tungsten phosphide submicron sphere composite material is prepared by loading cerium-doped tungsten oxide submicron spheres on a substrate through a solvothermal synthesis method and then phosphating the cerium-doped tungsten oxide submicron spheres. The preparation process adopted by the invention is simple, the obtained composite material has uniform particles, and when used as an industrial water electrolysis catalyst, the composite material has high charge transmission speed, enhanced hydrogen adsorption capacity and desorption capacity, improved electro-catalytic hydrogen evolution activity, excellent catalytic performance, and strong stability.

Owner:陕西帅能能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com