Helium circulation, purification and storage system

A storage system and helium technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of reduced cooling effect and high cooling cost, and achieve reduced cooling cost, improved cooling effect, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

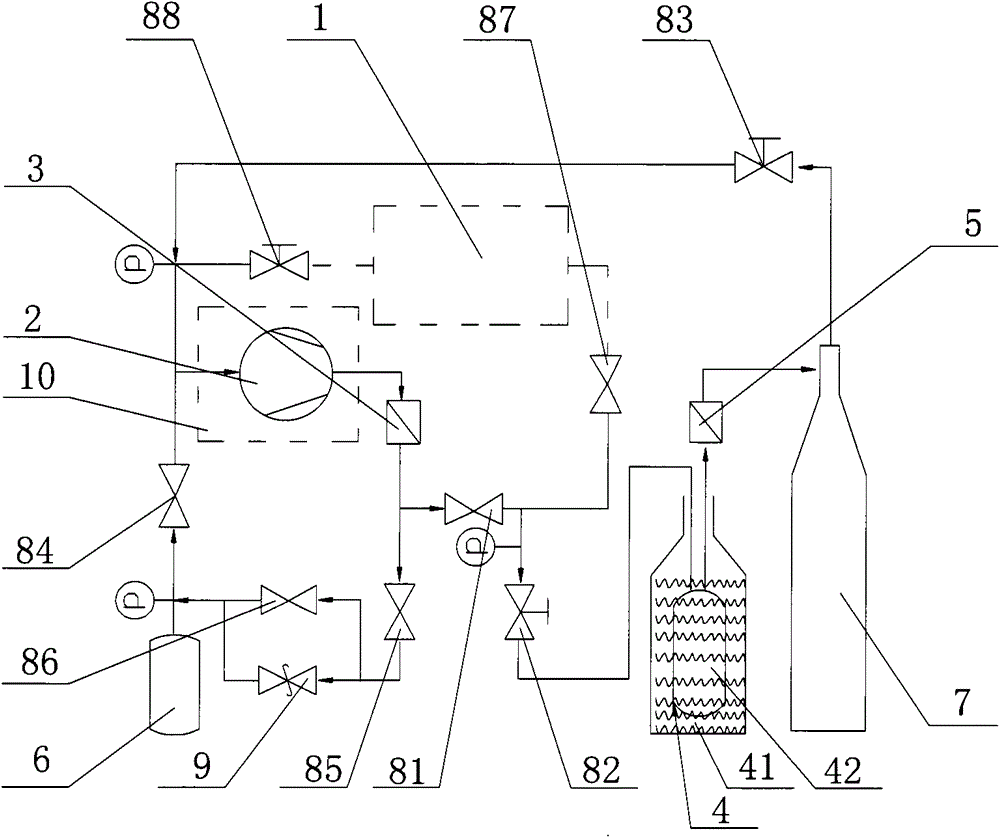

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] see figure 1 As shown, a helium circulation, purification and storage system, the system includes a pressure cylinder 1, an air pump 2, an oil filter 3, a cryogenic filter 4, and a hydrogen adsorber 5 connected in sequence, after passing through the hydrogen adsorber 5 The helium gas is input into the cryostat 7 to be supplied with helium through the gas delivery pipeline. Among them, the pressure gas cylinder 1 is mainly used to provide helium gas to the system; the oil filter filter 3 is mainly used to remove the oily substances in the helium gas after passing through the pump 2; the low temperature filter 4 is mainly used to remove the Impurities and organic substances that may exist in the helium therein; the hydrogen adsorber 5 is mainly used to adsorb hydrogen that may exist in the helium.

[0024] see figure 1 As shown, the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com