Method for preparing 2,5-furandimethanol by selective hydrogenation of 5-hydroxymethylfurfural

A technology of hydroxymethylfurfural and furan dimethanol, which is applied in two fields, can solve the problems of long reaction time and high hydrogen pressure, and achieve the effect of low price, large specific surface area and reusable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

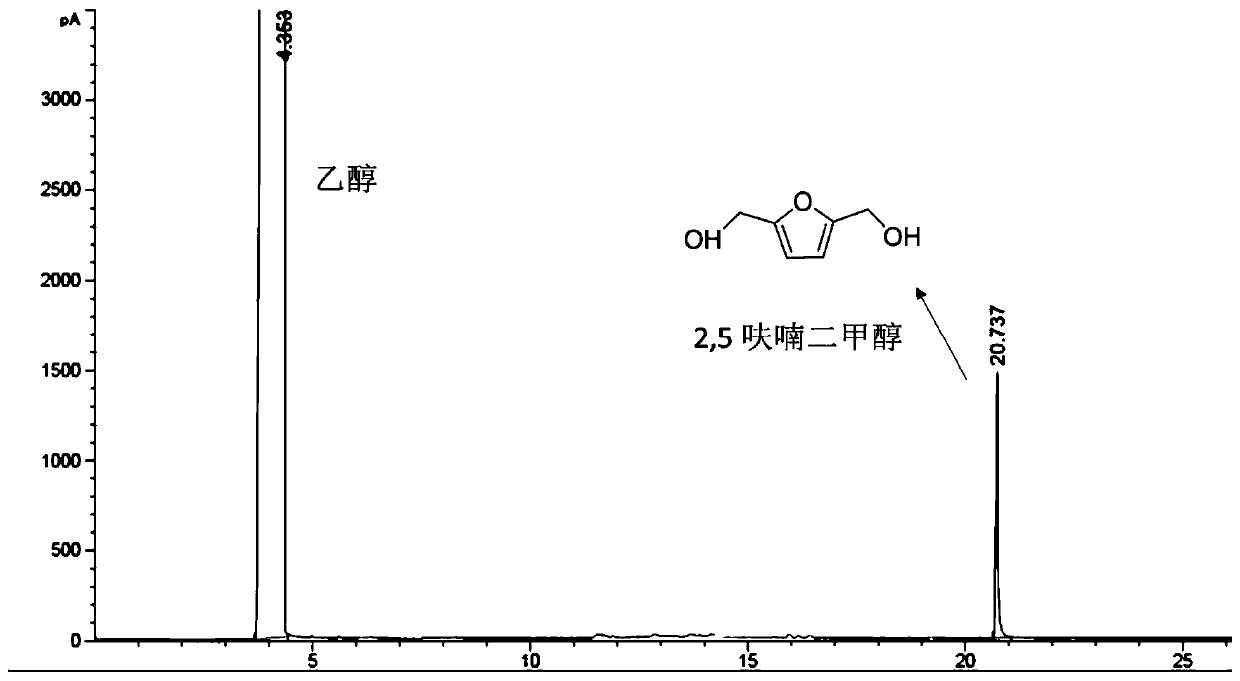

[0031] 5-Hydroxymethylfurfural (0.5 mmol), catalyst CuNPs@ZIF-8 (7.2% mol Cu, relative to 5-Hydroxymethylfurfural) and 5 mL of ethanol were added into a stainless steel closed reactor, filled with 2Mpa H 2 , heated to 140° C. for 3 h at a stirring speed of 600 rpm, and cooled to room temperature after the reaction was completed. The catalyst is centrifuged and the reaction solution is tested. Through gas chromatography analysis, the calculated selectivity of 2,5-furandimethanol is greater than 99%, and the molar yield is 99%.

[0032] The GC-MS collection of illustrative plates of the 2,5-furandimethanol that the present embodiment makes is as follows figure 1 shown.

Embodiment 2

[0034] Add 5-hydroxymethylfurfural (0.5 mmol), catalyst CuNPs@ZIF-8 (7.2% mol Cu, relative to 5-hydroxymethylfurfural) and 5 mL ethanol into a stainless steel closed reactor, filled with 3Mpa H 2 , heated to 140° C. for 1 h at a stirring speed of 600 rpm, and cooled to room temperature after the reaction was completed. The catalyst is centrifuged and the reaction solution is tested. Through gas chromatography analysis, the calculated selectivity of 2,5-furandimethanol is greater than 99%, and the molar yield is 96%.

Embodiment 3

[0036] Add 5-hydroxymethylfurfural (0.5 mmol), catalyst CuNPs@ZIF-8 (7.2% mol Cu, relative to 5-hydroxymethylfurfural) and 5 mL ethanol into a stainless steel closed reactor, filled with 4Mpa H 2, heated to 140° C. for 0.5 h at a stirring speed of 600 rpm and reacted for 0.5 h. After the reaction was completed, it was cooled to room temperature. The catalyst is centrifuged and the reaction solution is tested. Through gas chromatography analysis, the calculated selectivity of 2,5-furandimethanol is greater than 99%, and the molar yield is 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com