Compounding method and application of porous MOFs (metal-organic frameworks)

A porous metal and organic framework technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of lack of application, lack of composite methods of porous metal and organic framework compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

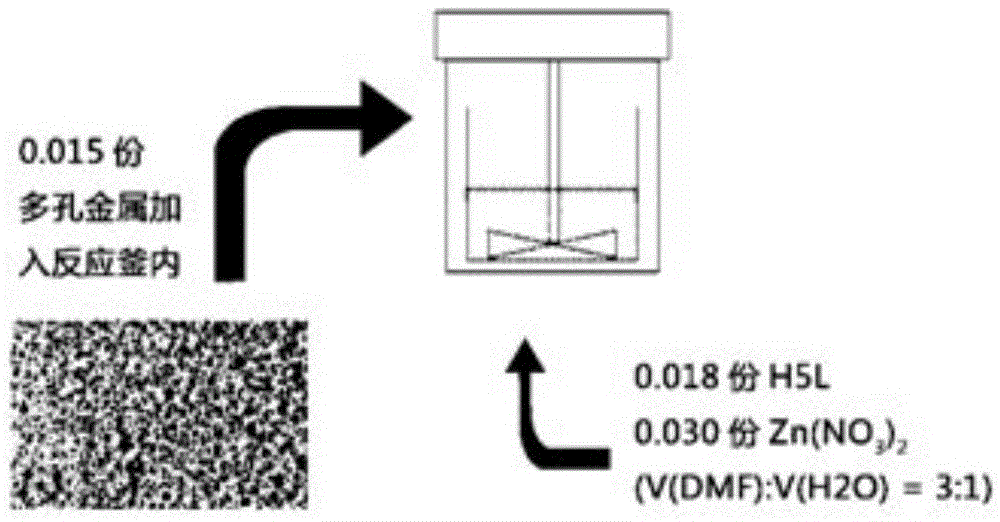

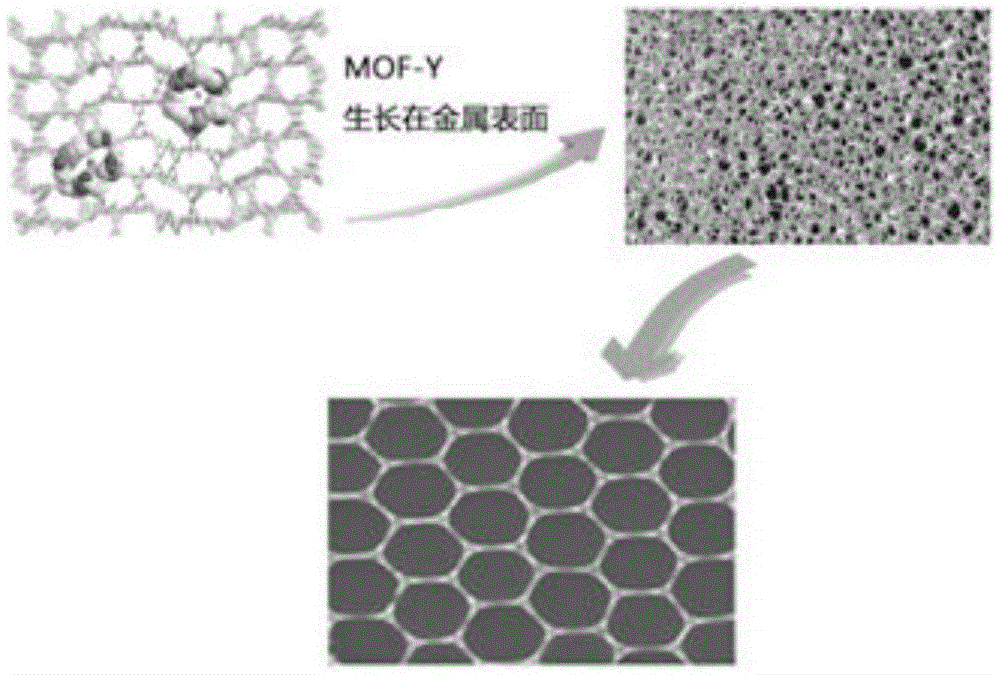

[0036] In this example, a composite material of MOF, porous metal titanium, and Ni-Co-Mn ternary alloy is prepared by chemical compounding. The specific preparation method is as follows:

[0037](1) Activate the porous metal titanium and the Ni-Co-Mn ternary alloy, wherein the porous titanium is treated with 0.1mol / L hydrofluoric acid for 15 minutes, and the Ni-Co-Mn ternary alloy is treated with 0.2mol / L hydrochloric acid Treat for 20 minutes to remove the oxide film on the surface and expose the metal.

[0038] (2) Preparation of MOF-Y: Accurately weigh H 5 L (0.018g, 0.04mmol) and Zn (NO 3 ) 2 6H2O (0.1mmol, 0.030g), dissolved in 2mL of N,N-dimethylformamide (DMF) and water mixed solvent (V(DMF):V(H2O)=3:1), stirred evenly, packaged in In a reaction kettle lined with polytetrafluoroethylene, heated to 105°C for 72 hours, then cooled to room temperature at a cooling rate of 5°C, washed with DMF solvent, and dried at room temperature to obtain colorless blocky crystals. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com