Method for hydrolyzing biomasses in two steps by utilizing carbon-based solid acid catalyst

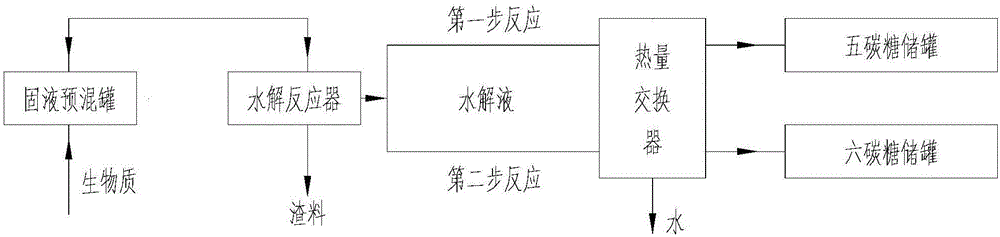

A carbon-based solid acid and biomass technology, applied in the fields of application, sugar production, xylose production, etc., can solve the problems of limited development, low reaction efficiency, cumbersome operation procedures, etc., and achieve the goal of reducing operation steps and increasing reaction intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

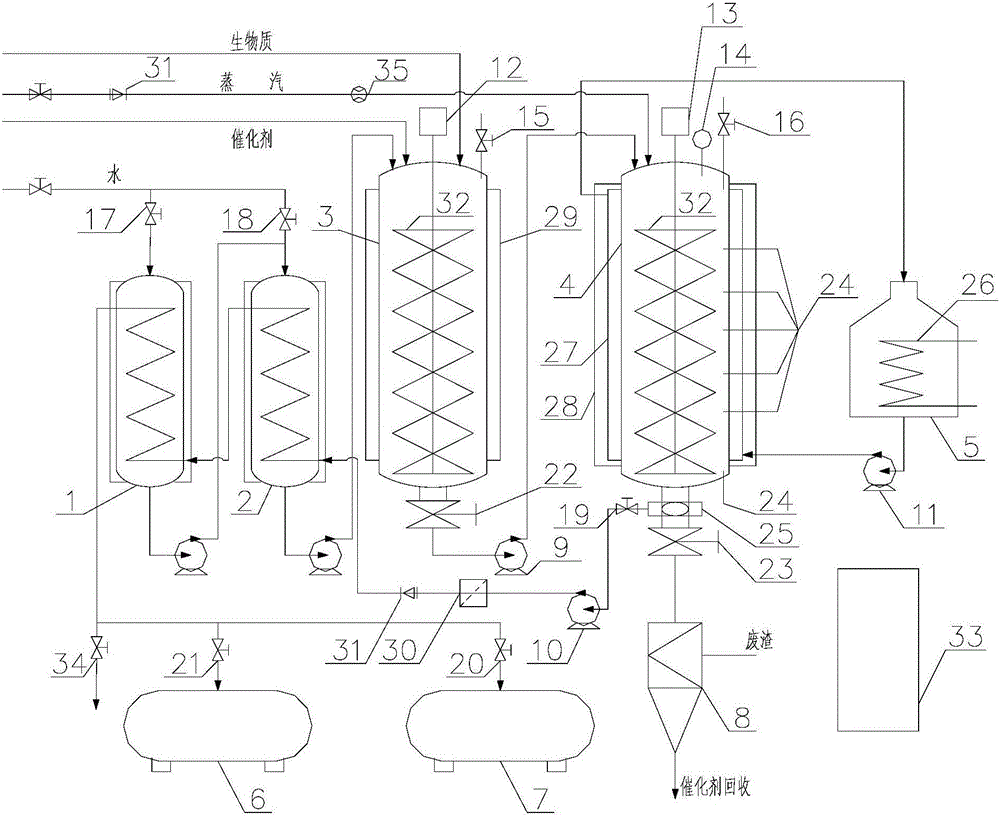

[0056] The steps of the reaction of utilizing carbon-based solid acid catalyst for two-step hydrolysis of biomass are:

[0057] (1) Open the second pipeline valve 17 and the third pipeline valve 18 in the water pipeline, add water to the second water storage tank 1 and the first water storage tank 2 respectively, and check the airtightness and valves of the entire system;

[0058] (2) In the solid-liquid premixing tank 3, add carbon-based solid acid catalyst and biomass material (biomass material is a corn cob with a particle size of 0.2-5mm) and water with a mass ratio of 2:1, and open the premixing tank Stir the motor 12 and set the speed in the control system 33, and open the first pipeline valve 15, so that the solid-liquid materials in the solid-liquid premix tank 3 are evenly mixed;

[0059] (3) Turn on the electric heater 26 in the heat transfer oil tank 5, and set the heating temperature to 120° C. through the control system 33;

[0060] (4) Open the vent valve 16 in ...

Embodiment 2

[0073] Reaction steps are identical with embodiment 1, difference is:

[0074] Select corncobs with a particle size of 0.2-5mm as the biomass material, put the carbon-based solid acid catalyst and corncobs into the reactor according to the mass ratio of 5:1, and put the corncobs and water into the reactor according to the mass ratio of 1:40 Add water to the hydrolysis reactor; turn on the heating device of the hydrolysis reactor, start timing when the temperature in the hydrolysis reactor reaches 140°C, and discharge the hydrolyzate after 2 hours of reaction; reset the temperature of the hydrolysis reactor heating device , based on the initial corncob mass, and add water to the hydrolysis reactor according to the ratio of the initial corncob to water mass ratio of 1:40, start timing after the temperature in the hydrolysis reactor reaches 170 ° C, and react for 3 hours. The liquid is drained and retained.

[0075] The hydrolyzate obtained in the two steps was analyzed, and the...

Embodiment 3

[0077] Reaction steps are identical with embodiment 1, difference is:

[0078] Select the corn cob with a particle size of 0.2-5mm as the biomass material, put the carbon-based solid acid catalyst and the corn cob into the hydrolysis reactor according to the mass ratio of 5:1, and the corn cob and water according to the mass ratio of 1: Add water to the hydrolysis reactor at a ratio of 40; turn on the heating device of the hydrolysis reactor, start timing when the temperature in the hydrolysis reactor reaches 140°C, and discharge the hydrolyzate after 2 hours of reaction; reset the heating device of the hydrolysis reactor Temperature, based on the initial corn cob mass, and add water to the hydrolysis reactor according to the mass ratio of the initial corn cob and water in the ratio of 1:40, start timing after the temperature in the hydrolysis reactor reaches 180 °C, after 3 hours of reaction Drain the hydrolyzate and keep it.

[0079] The hydrolyzate obtained in the two step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com