Preparation process of single-arm structure of thermoelectric semiconductor temperature sensor chip

A thermoelectric semiconductor and preparation process technology, applied in the field of temperature sensor sheets, can solve problems such as thermal cracking and large thermal stress, and achieve the effect of prolonging the service life and solving the problem of thermal cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

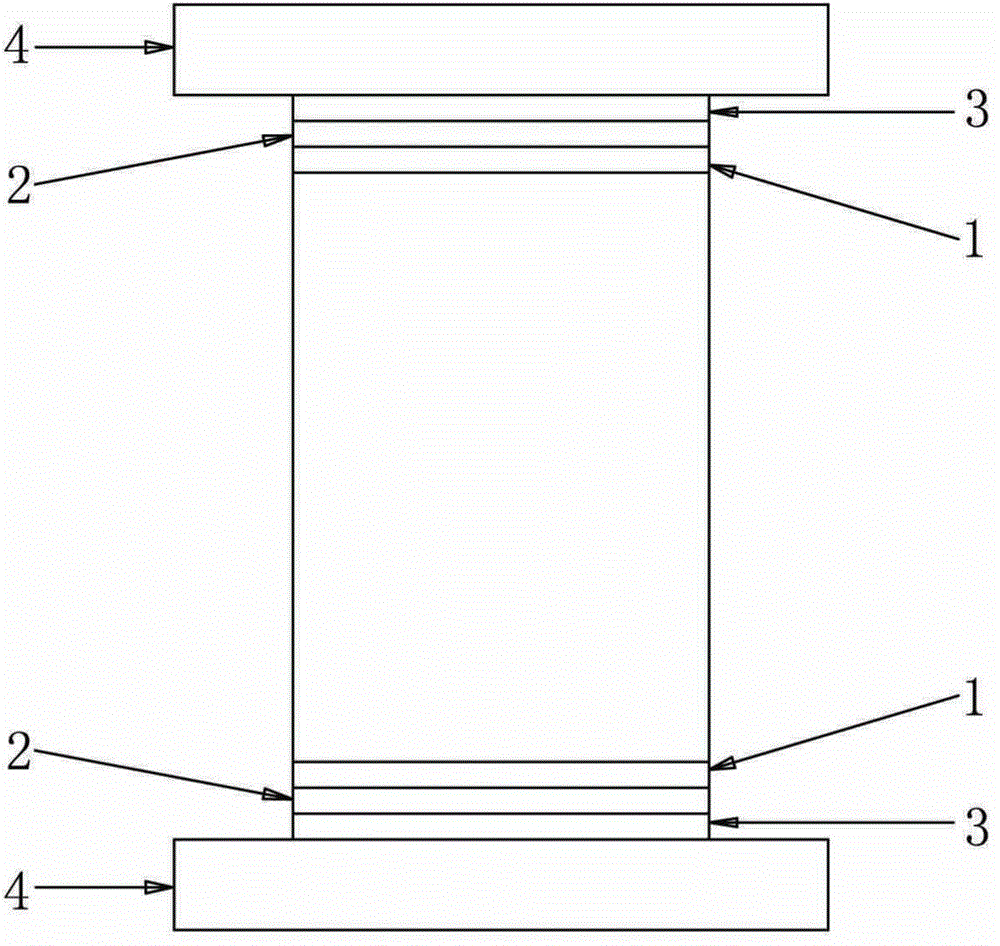

[0021] now attached Figure 1~5 , taking the specific preparation process of the single-arm structure of the thermoelectric semiconductor temperature sensing chip as an example to further describe the present invention.

[0022] Step 1: The thermoelectric semiconductor p-type material of the temperature sensing sheet is used (Cu 4 Te 3 ) 0.025 -(Bi 0.5 Sb 1.5 Te 3 ) 0.975 Pseudo-binary alloy, the alloy can obtain the best thermoelectric performance (ZT=1.2) when the alloy is around 170°C; 2 Te 3 ) 0.9 -(Bi 1.9 Cu 0.1 Se 3 ) 0.1 Pseudo-binary alloy, the alloy obtains the best thermoelectric performance (ZT=0.98) at about 144°C. Cut according to the size of the thermoelectric pair, the size of p-type and n-type single arm material is 2.2×1.4×1.4mm 3 , where 2.2mm is the height.

[0023] Step 2: A total of 127 pairs of thermoelectric semiconductor temperature sensor chips are designed. The two ends of the single arm of each pair of thermoelectric semiconductor sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com