Patents

Literature

32results about How to "Solve the problem of thermal cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

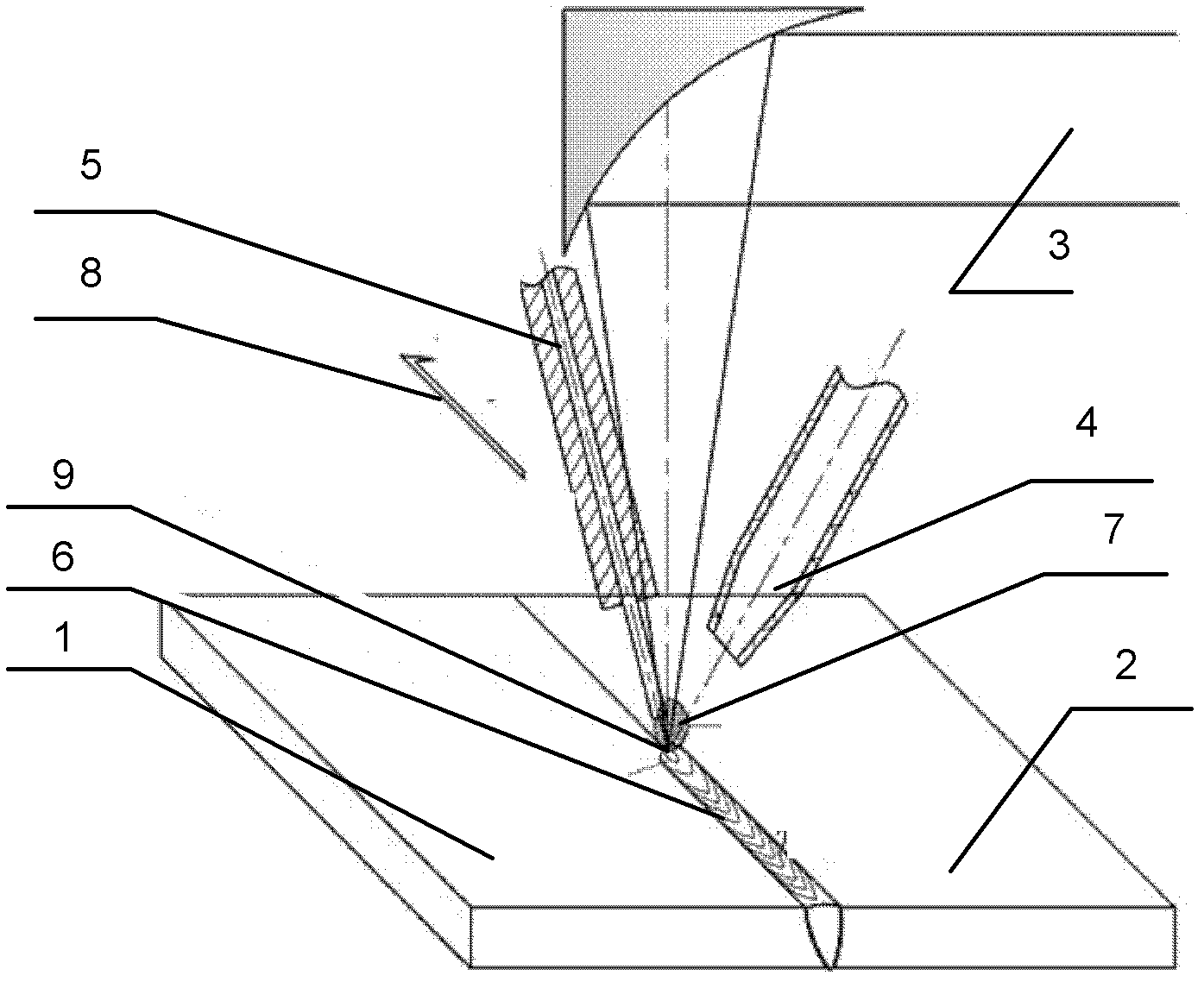

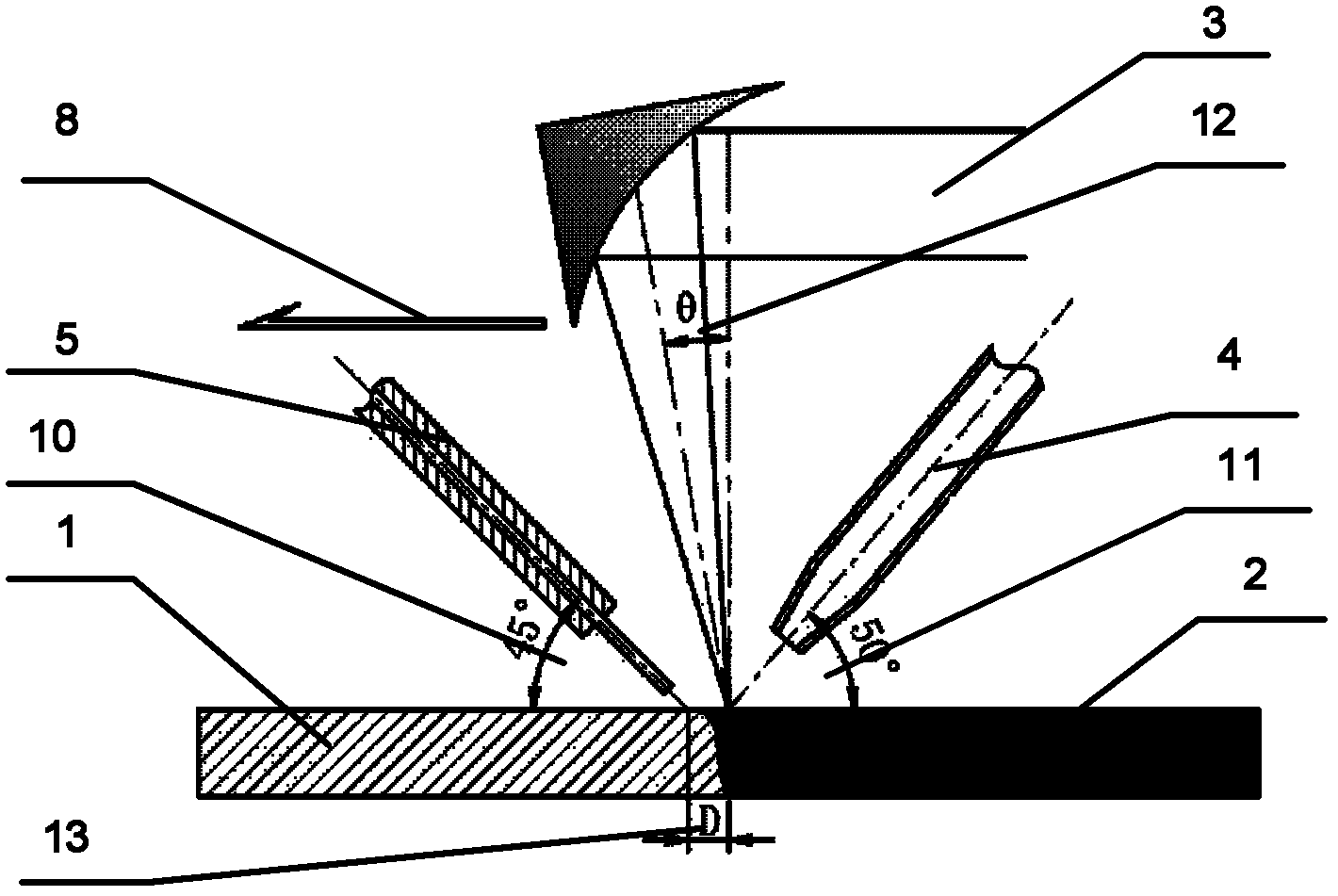

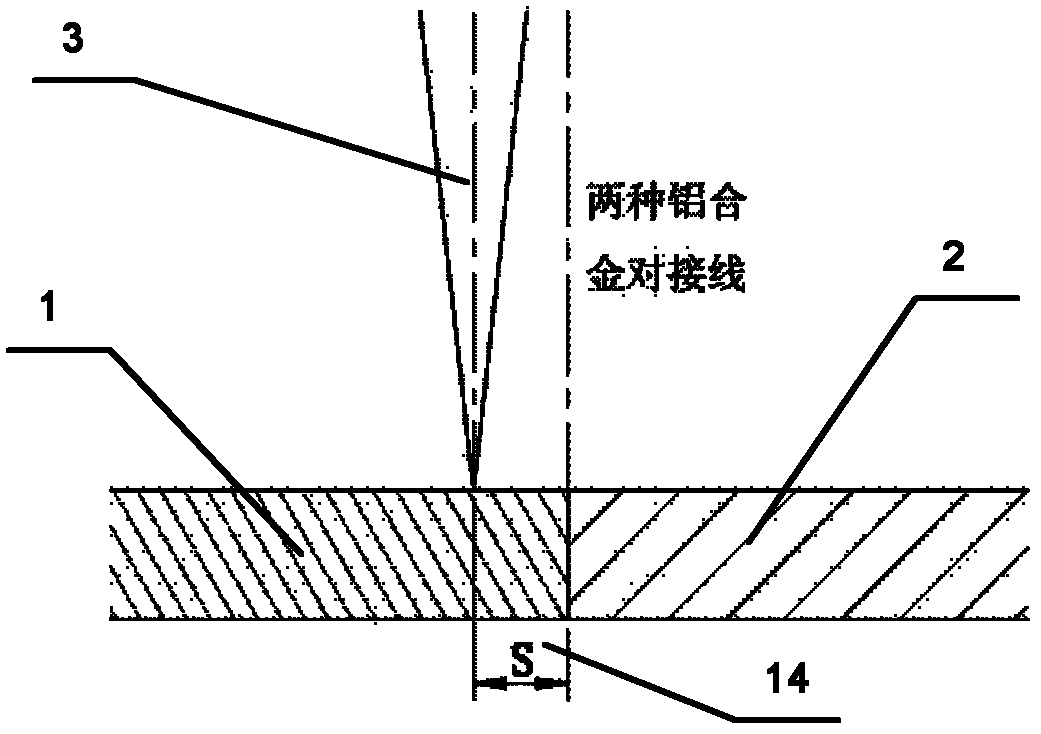

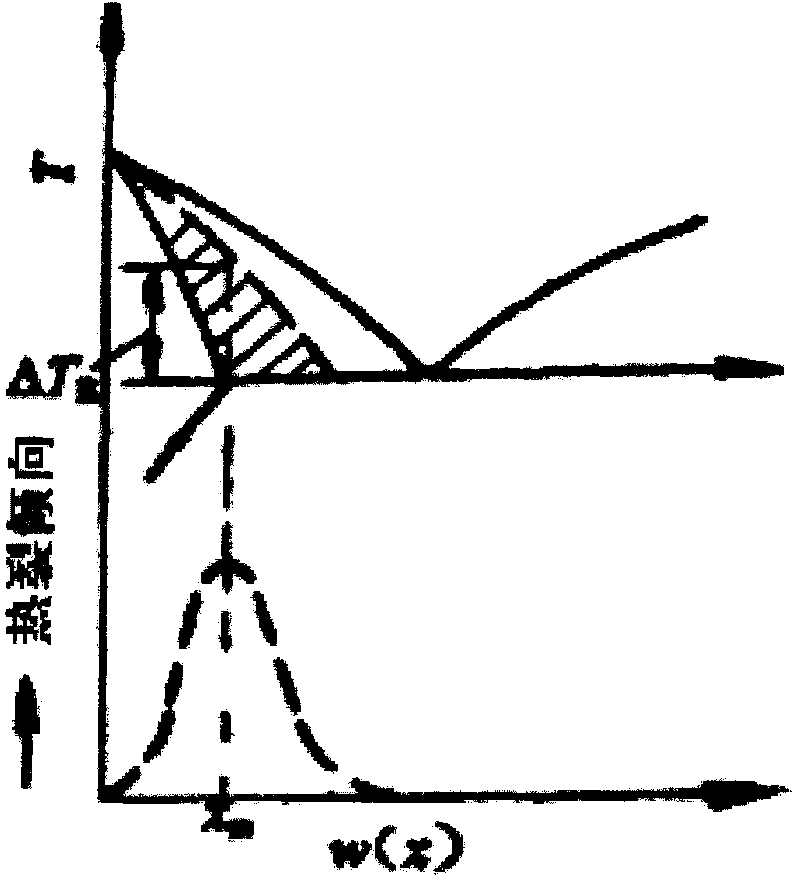

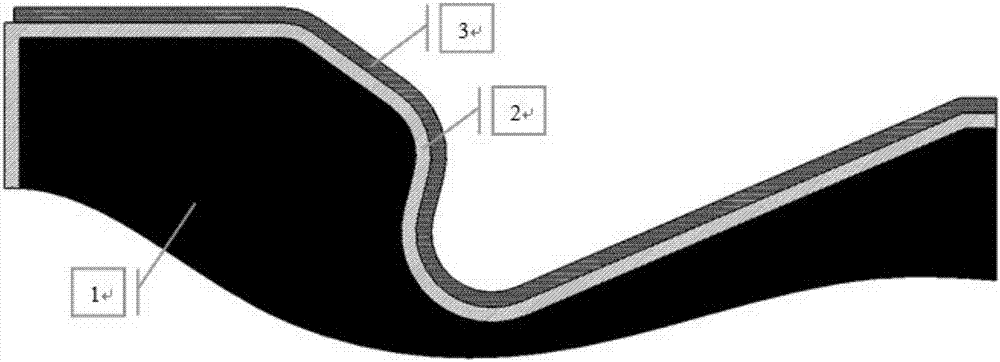

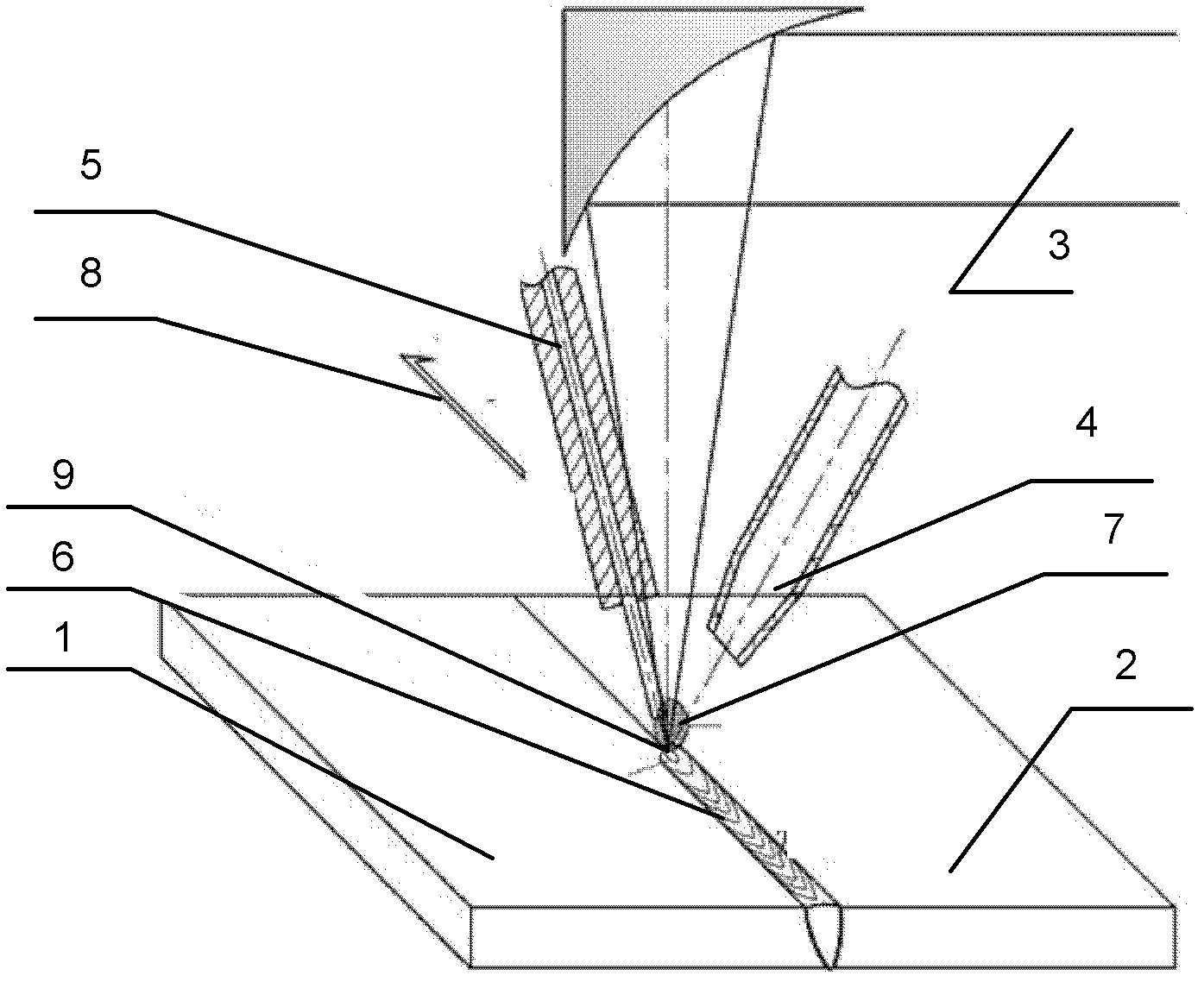

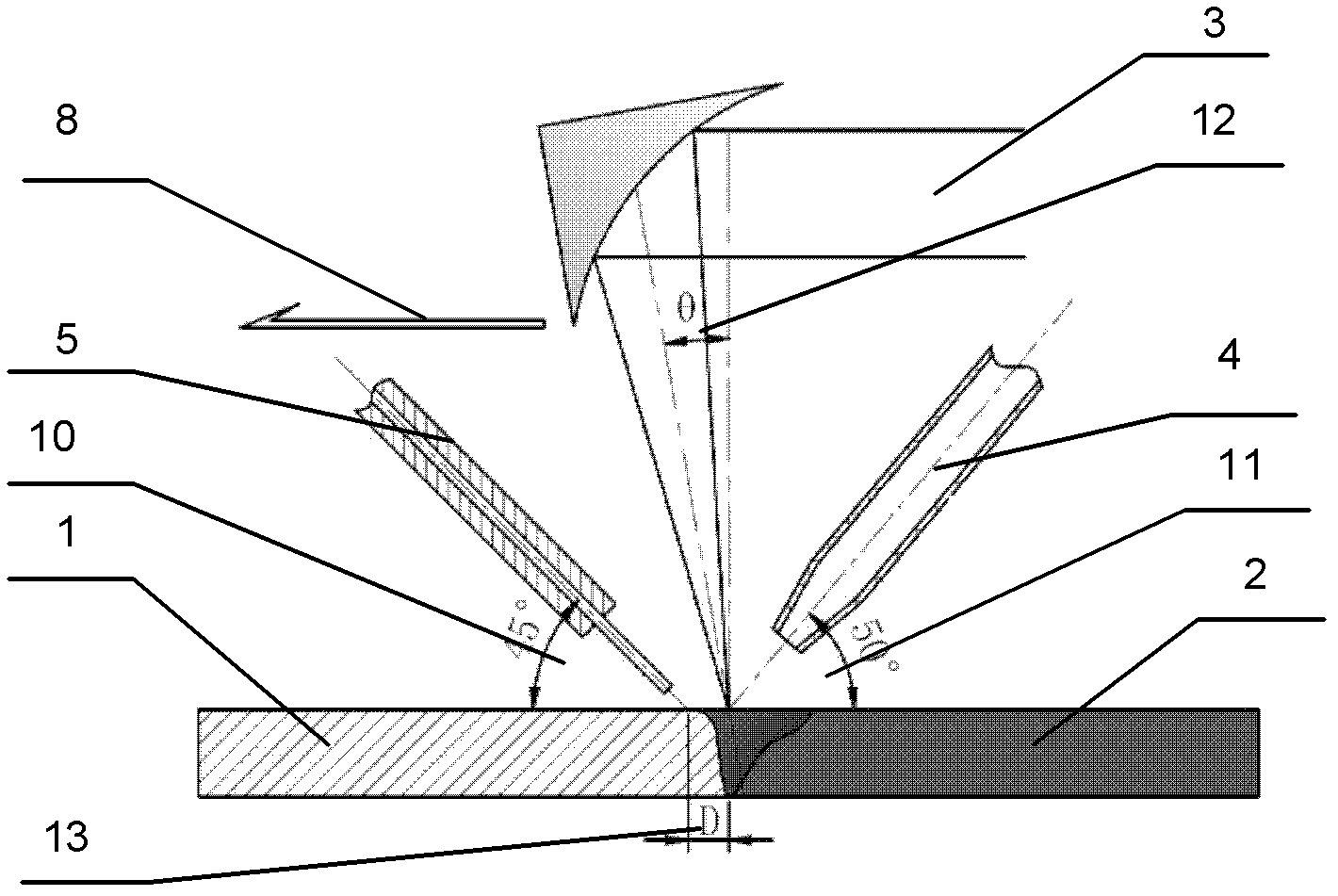

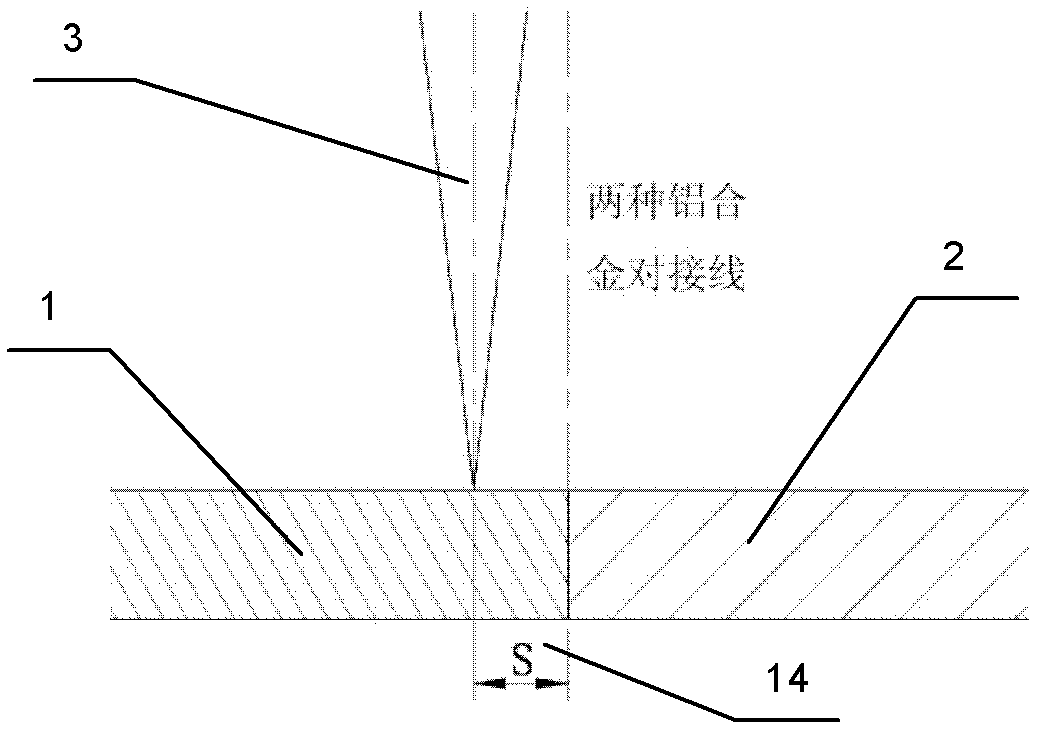

Method for connecting 2XXX and 7XXX heterogeneous aluminum alloy by laser filler wire

InactiveCN102357734AWeld firmlyReduce the temperatureLaser beam welding apparatusAdditive ingredientButt joint

The invention discloses a method for connecting 2XXX and 7XXX heterogeneous aluminum alloy by the laser filler wire, which is suitable for the connection field of 2XXX and 7XXX-series of heterogeneous aluminum alloy. The method comprises the following steps of: firstly, assembling two aluminum alloy plates to be welded into a butt joint mode; regulating position relationship among a laser focal point, the wire falling point of an aluminum alloy welding wire and a butt joint gap between two aluminum alloy plates to ensure that the laser beam, the welding wire and the welded aluminum alloy plates are positioned on the reasonable opposite positions; and adopting reasonable welding parameters, laser power, welding speed, wire conveying speed and the like, utilizing AlCu or Alsi welding wires as filler material in the welding process to regulate the ingredient of the welding line and improve the performance of the joint. According to the method, the problems that the 2XXX and 7XXX heterogeneous aluminum alloy is difficult to connect, the welding line is softened during melting, and heat checking tendency exists can be solved.

Owner:BEIJING UNIV OF TECH

Non-cadmium lead stibium slab lattice alloy for traction type accumulator

InactiveCN101295789ASolve the problem of thermal crackingSmall and uniform crystal grainsElectrode carriers/collectorsRare-earth elementAlloy

The invention discloses a cadmium free lead-antimony grid alloy for traction batteries. The lead-antimony alloy contains antimony, mischmetal and lead and the weight percentage of the antimony in the lead-antimony alloy is 0.5 to 4.5 percent, that of the mischmetal is 0.05 to 2 percent and the rest is the lead. The grid alloy adds rare earth elements into the lead-antimony alloy and causes the grains of the alloy to become small and even, thereby solving the problem of the hot cracking of the lead-antimony alloy and obviously improving and increasing the toughness, aging strength and corrosion resistance of the alloy. Meanwhile, the adding of the rare earth obviously inhibits the growth of the Pb(II) oxide film and reduces the impedance thereof, thus improving the charging and discharging performance and the deep circulation of the battery. Batteries for electric vehicles combined by lead-acid battery grids produced by the alloy have the advantages of corrosion resistance, deep circulation, high-current discharge and long service life.

Owner:上海飞轮有色冶炼厂

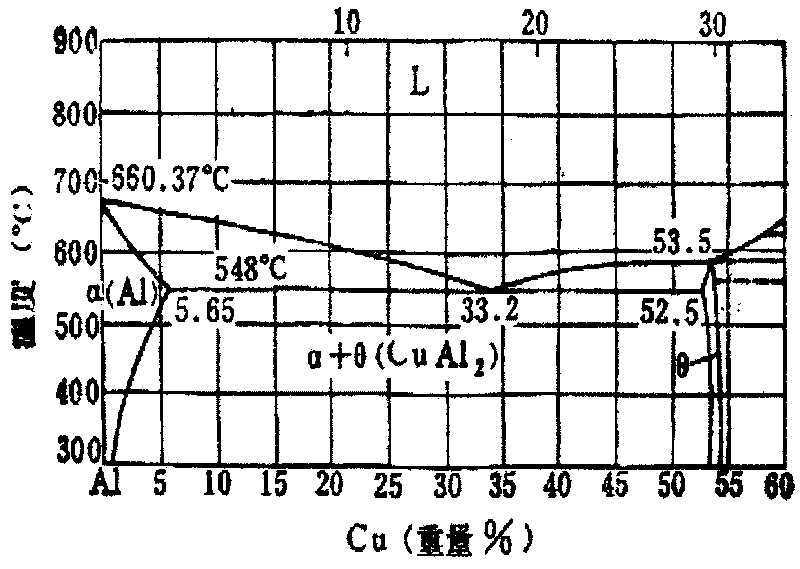

Low heat track sensitive high-toughness casting aluminium copper alloy

InactiveCN101760672APrevent hot crack defectsSolve the problem of thermal crackingRare-earth elementUltimate tensile strength

The invention relates to a low heat track sensitive high-toughness casting aluminium copper alloy which is characterized in that: on the basis of the body material, 0.001-1 percent of M is added by mass percent, and M is one of Ce, La and Y or arbitrary combination thereof; aiming at heat cracks of the aluminium copper alloy, the heat cracking inclination of the high-toughness aluminium copper alloy can be effectively reduced by microalloying and adding trace rare-earth elements, so as to develop the high-toughness casting aluminium copper alloy with low heat-cracking inclination successfully; under the same intensity, the defect of heat crack generation can be effectively reduced.

Owner:SHENYANG RES INST OF FOUNDRY

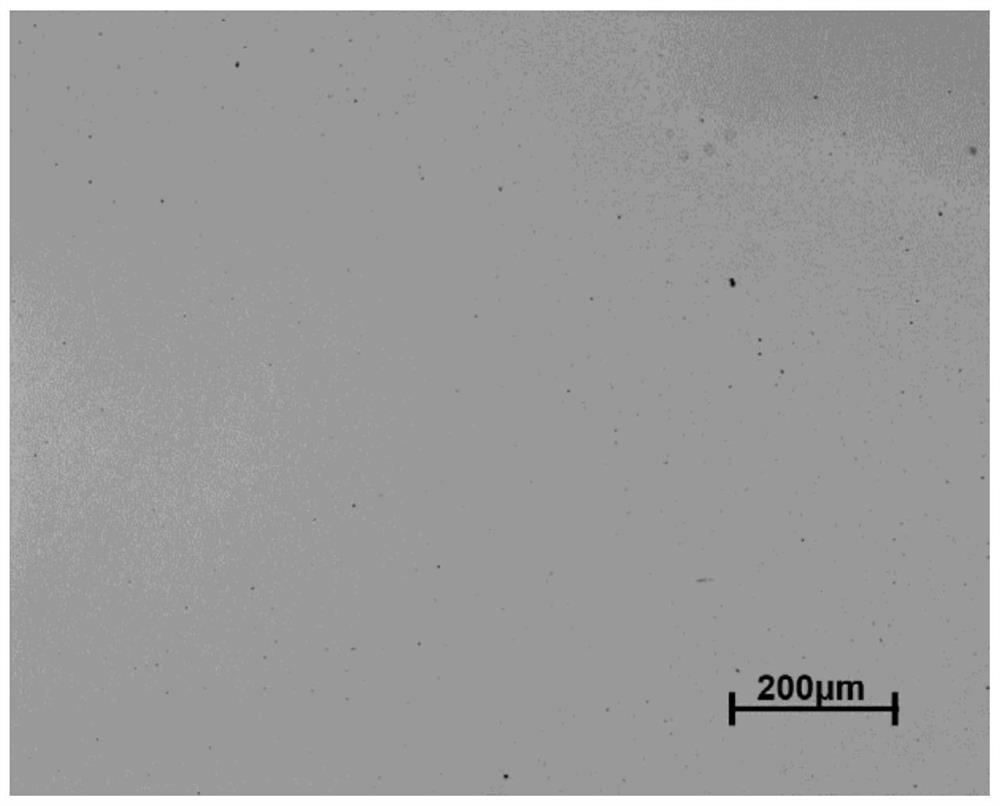

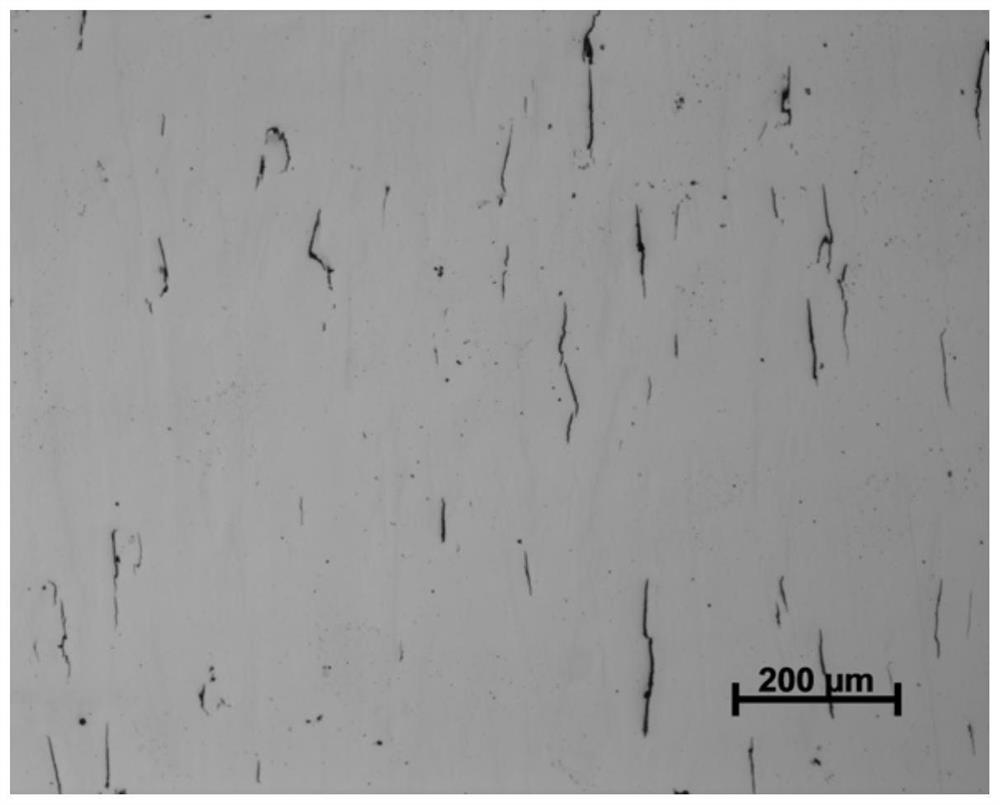

Graphite mould casting method for precise forming of low expansion alloy

ActiveCN102527936ASolve the problem of prone to thermal cracksSolve the problem of thermal crackingFoundry mouldsFoundry coresGraphite electrodeIngot

The invention provides a graphite mould casting method for precise forming of low expansion alloy. The method comprises the following steps: firstly preparing a part casting mould by using a graphite electrode, and adding 1-3% of shrinkage amount in a mould cavity of the casting mould; preparing a paint by using 325-mesh electric melting aluminum oxide powder, electric melting yttrium oxide powder and zirconium acetate at a mass ratio of (1-2.5):(1-2.5):1; then spraying the prepared paint on the surface of the mould cavity of the casting mould to form a coating with the thickness of 0.2-0.5mm, and shaping and pouring, wherein a 4J36 or 4J32 alloy ingot can be used as a consumable electrode for pouring; and finishing the pouring, thus obtaining the cast product. The method provided by the invention can be used for solving the problems that the 4J36 or 4J32 alloy has high melting point, the graphite chilling action is strong, the grains are coarse and the casting can generate hot crackseasily, and improving the quality and production efficiency of the 4J36 or 4J32 low expansion alloy casting.

Owner:SHENYANG RES INST OF FOUNDRY

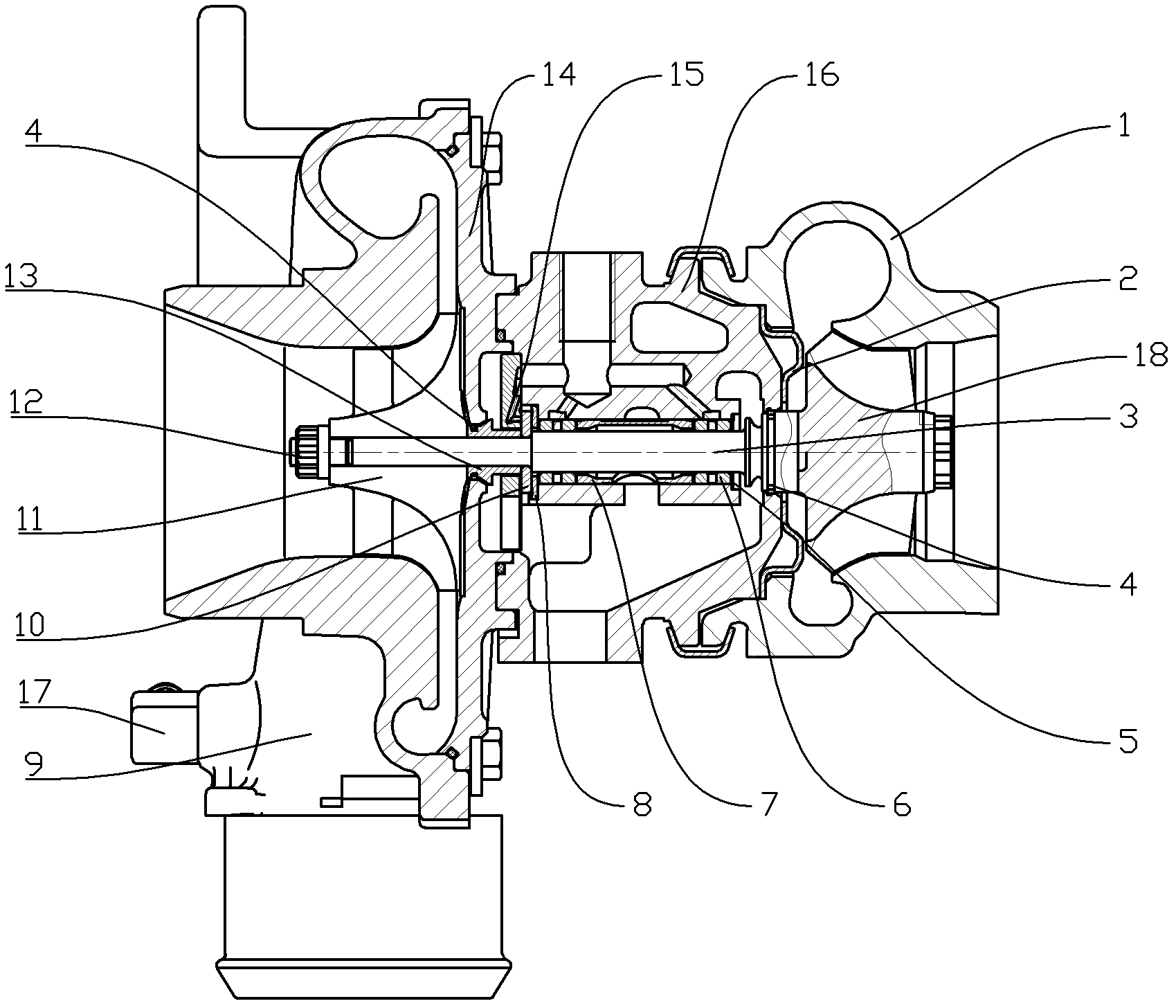

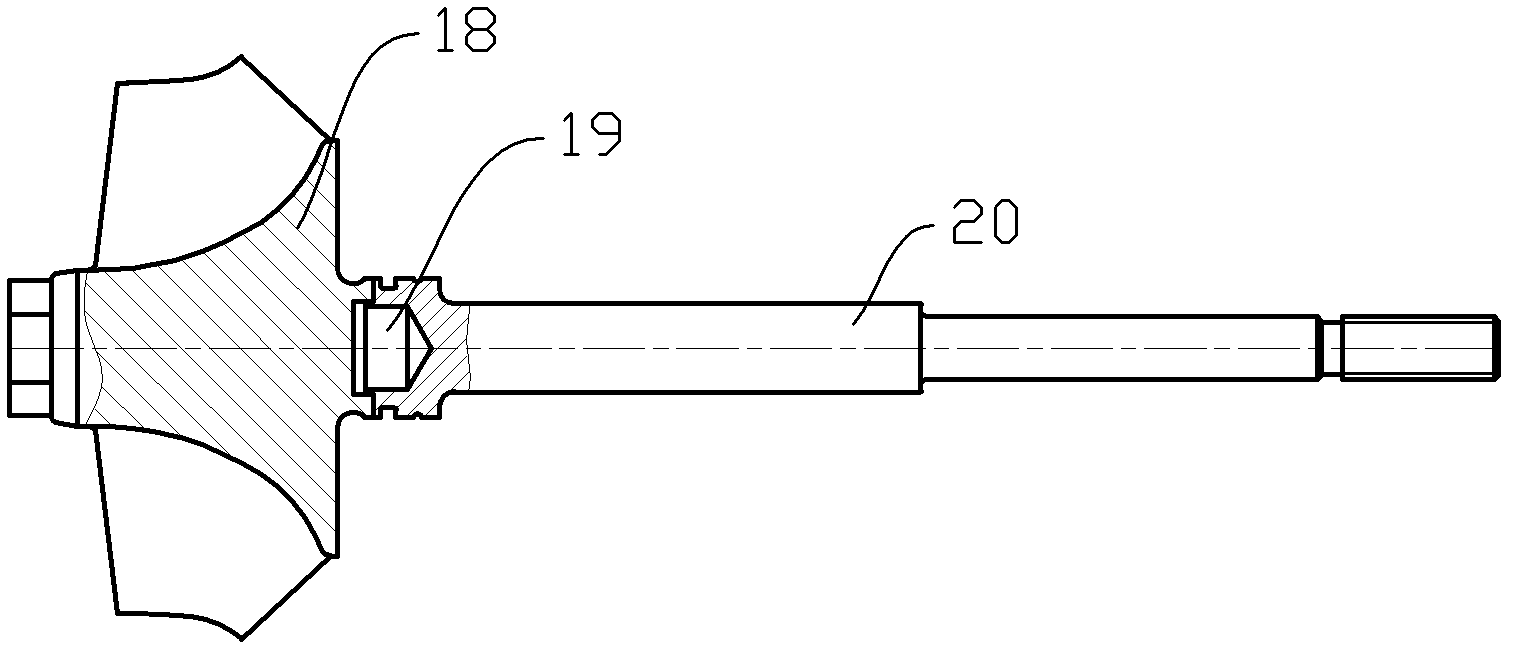

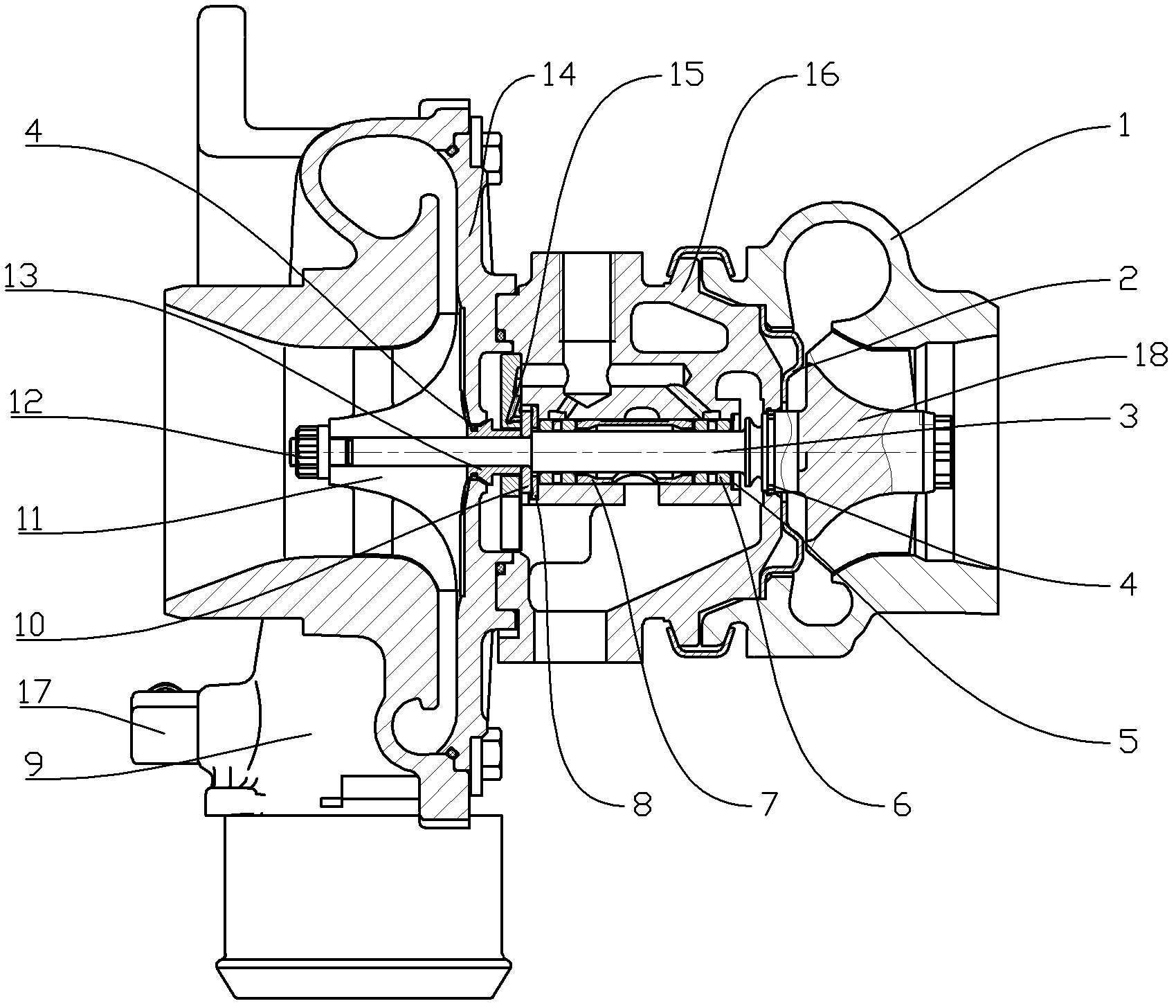

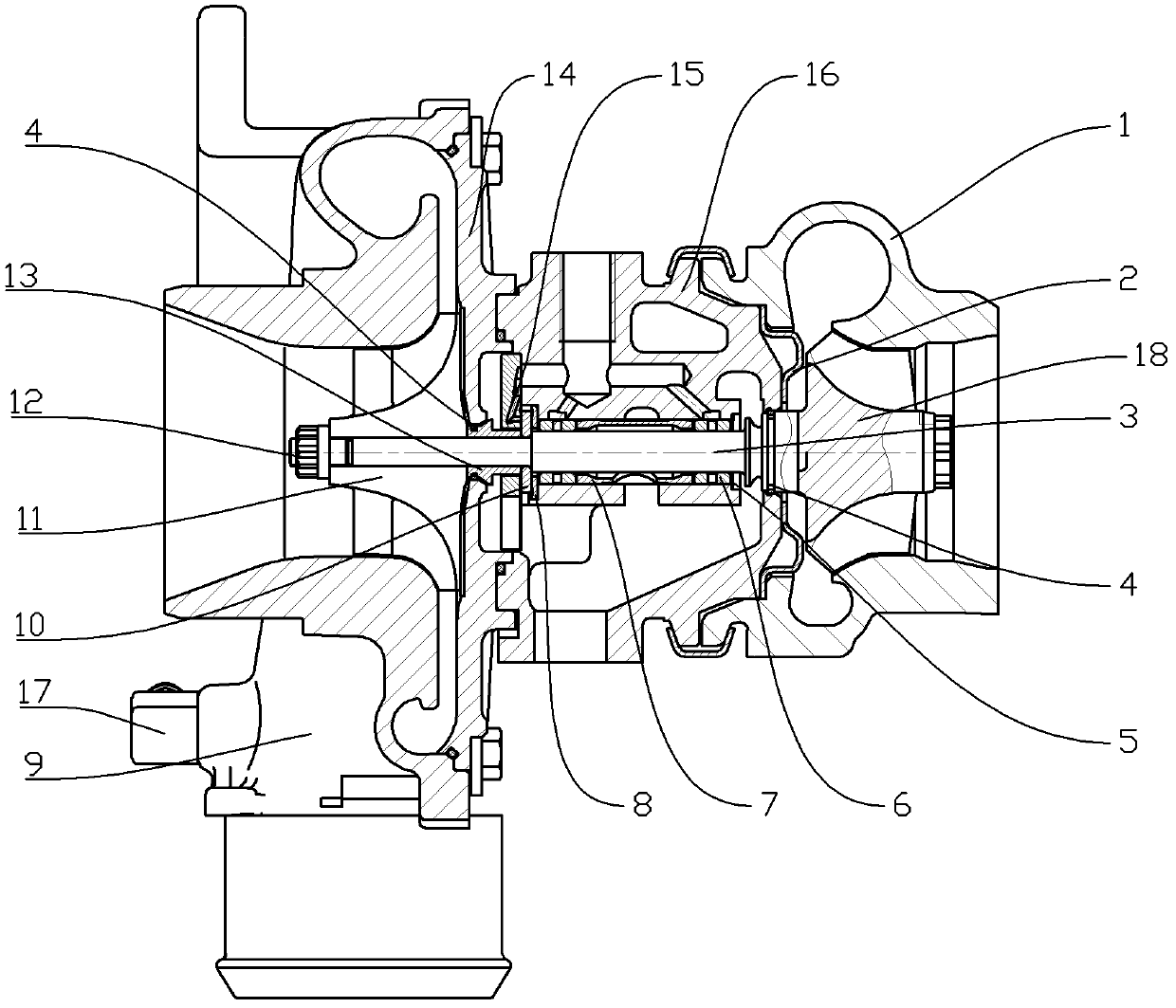

Gasoline engine turbocharger

ActiveCN102536431ALow failure rateSolve the deformationInternal combustion piston enginesEngine componentsTurbochargerThrust bearing

The invention discloses a gasoline engine turbocharger, which comprises a worm wheel casing, a middle body and a compressor casing, wherein the worm wheel casing, the middle body and the compressor casing are connected together. A worm in the turbocharger is provided with a hollow portion, a worm wheel and the worm are fixedly installed together by adopting an electron beam welding process, a heat shield is arranged between the middle body and the worm wheel casing, and a lubricating oil cavity and a cooling water cavity are arranged in the middle body. The worm wheel casing is formed by casting nodular cast iron, an inner thrust bearing is arranged between the middle body and a worm wheel shaft, an outer thrust bearing is arranged between the compressor casing and the worm wheel shaft, and a thrust piece is arranged between the inner thrust bearing and the outer thrust bearing. A sealing sleeve is sleeved on the worm wheel shaft, the outer thrust bearing is installed on the sealing sleeve, and an actuator comprises an air-release valve and an air valve connecting rod. The gasoline engine turbocharger effectively block heat transfer from the worm wheel end to the middle body, ensures lubrication quality of lubricating oil at the worm wheel end, solves the problems including worm wheel shaft getting-stuck, shaft grinding and the like caused by lubrication failure of a floating bearing, and solves the problem that the side of an air compressor of the gasoline engine turbocharger leaks oil.

Owner:潍坊富源增压器有限公司

HIGH-PERFORMANCE Al-Zn-Mg-Zr BASE ALUMINUM ALLOYS FOR WELDING AND ADDITIVE MANUFACTURING

PendingCN112601830ASolve the problem of thermal crackingHigh strengthAdditive manufacturing apparatusMolten spray coatingAdditive layer manufacturingZirconium

Owner:NANOAL

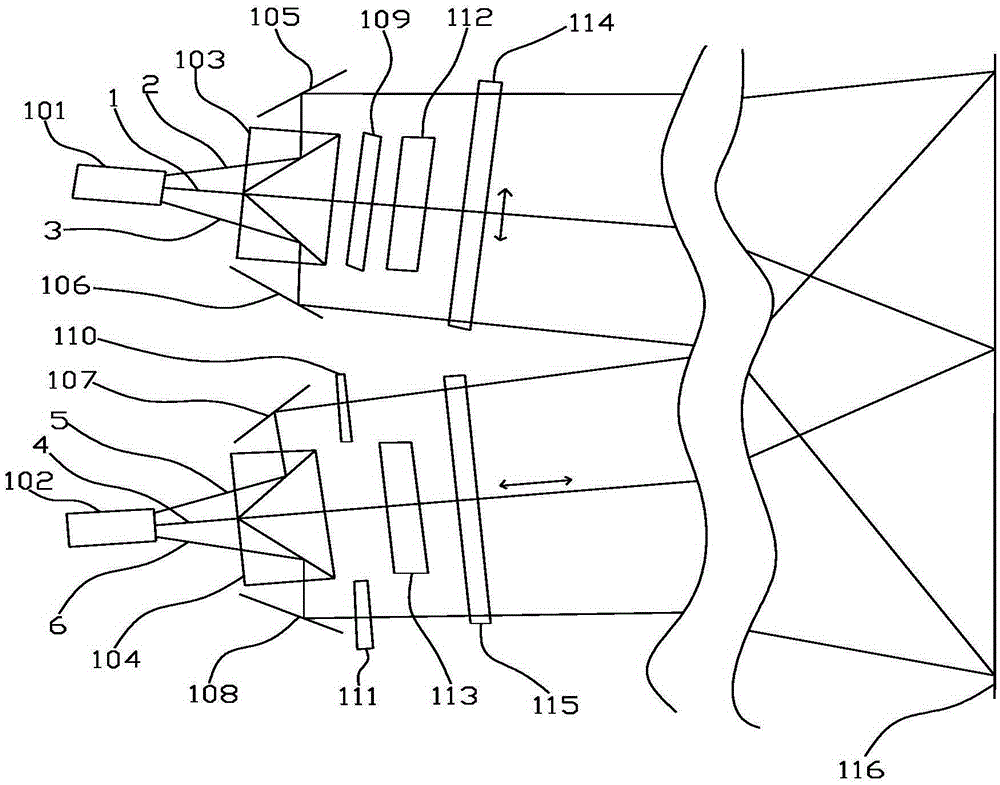

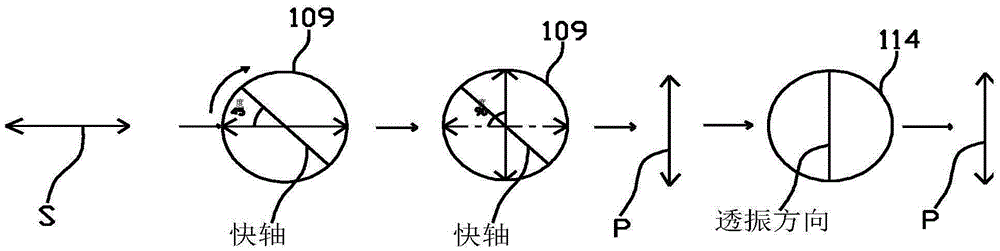

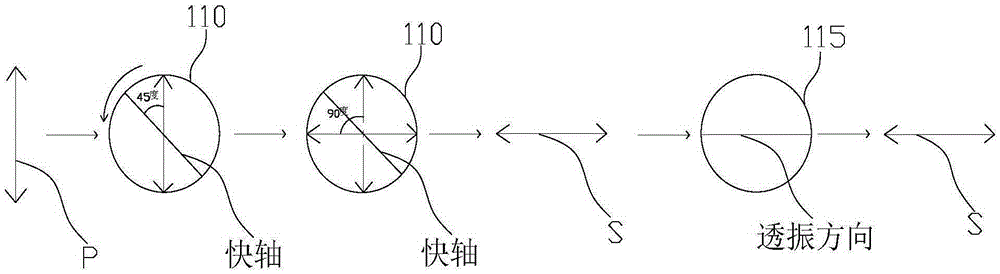

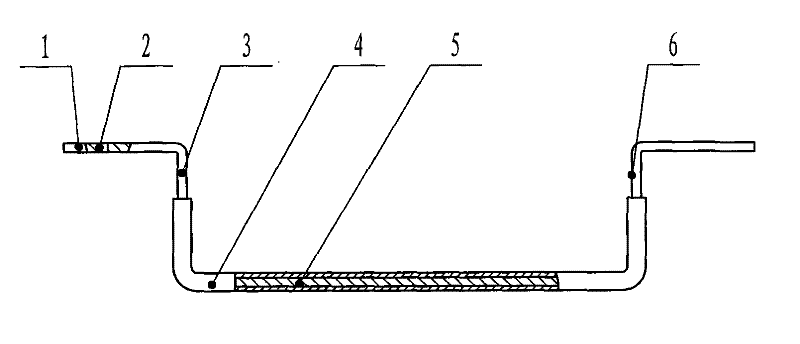

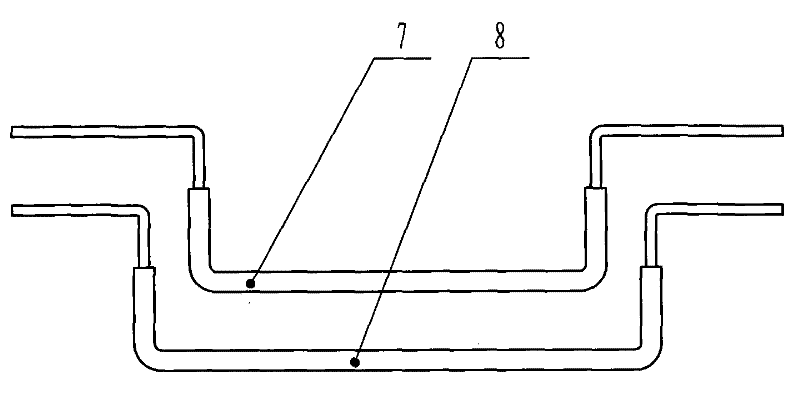

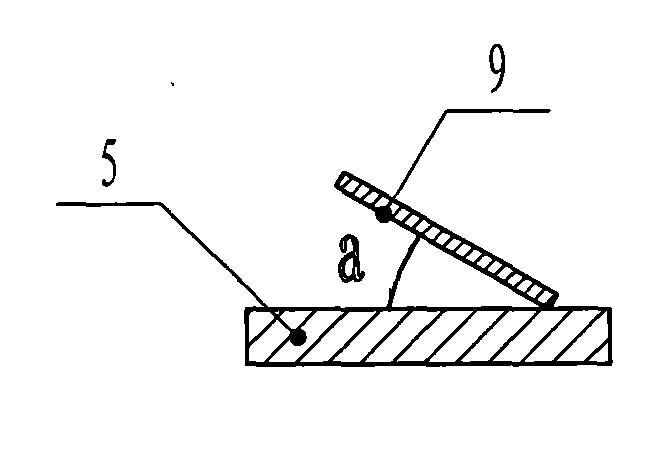

Double-machine high-luminous efficiency stereo projection system

InactiveCN105404012ASolve the problem of thermal crackingProjectorsOptical elementsLight beamProjection system

The invention provides a double-machine high-luminous efficiency stereo projection system. The projection system comprises a first projector, a first projector accessory polarization subsystem, a second projector and a second projector accessory polarization subsystem. The first projector accessory polarization subsystem is arranged between the first projector and a screen. The second projector accessory polarization subsystem is arranged between the second projector and the screen. An angle is formed between the first projector and the first projector accessory polarization subsystem, and the second projector and the second projector accessory polarization subsystem, thereby projecting images on the screen. Thus, left eye image light beams projected to the screen by the first projector through the first projector accessory polarization subsystem are P linearly polarized light. Right eye image light beams projected to the screen by the second projector through the second projector accessory polarization subsystem are S linearly polarized light, so audiences can see stereo images after wearing linear polarization glasses.

Owner:刘飞

Pb-Sb grid material for storage battery

InactiveCN101604754ASolve the problem of thermal crackingSmall and uniform crystal grainsElectrode carriers/collectorsRare-earth elementAlloy

The invention provides a Pb-Sb grid material for a storage battery, which comprises the following components in percentage by weight: 0.5-3.5 percent of Sb, 0.01-2 percent of La as a rare earth element and the balance of Pb. The rare earth element is added into Pb-Sb alloy, thereby leading a crystal grain of the alloy to become small and even, solving the problem of the thermal cracking of the Pb-Sb alloy and obviously improving the toughness, the aging strength and the erosion resistance of the alloy. The added rare earth element obviously restrains the growth of a Pb (II) oxide film and reduces the resistance of the Pb (II) oxide film, thereby improving the charge-discharge performance and the deep-cycle performance of the storage battery. A Pb-acid battery grid assembled electrocar battery produced by the alloy has the advantages of erosion resistance, deep cycle, large current discharge and long service life.

Owner:上海飞轮有色冶炼厂

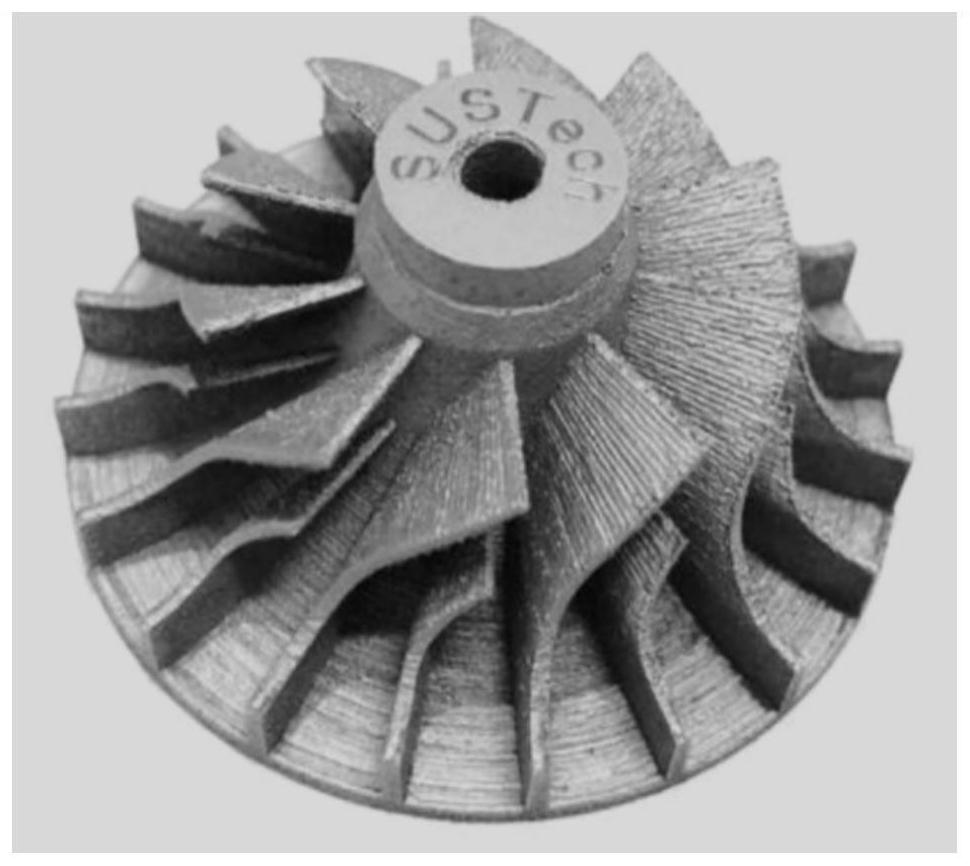

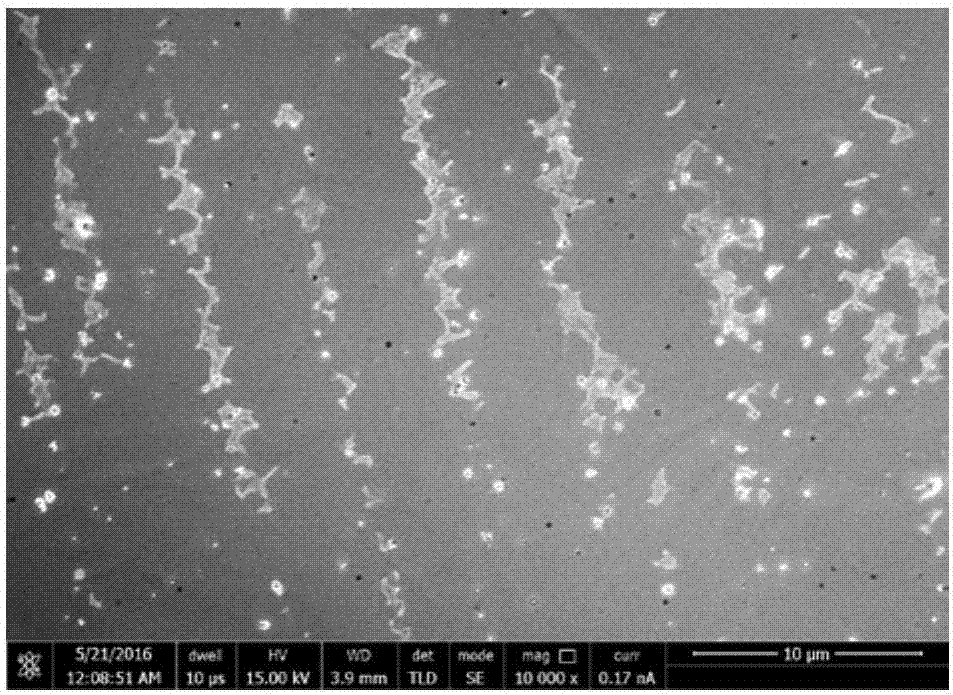

Selective laser melting forming method of hot-crack-free precipitation strengthened high-temperature alloy

ActiveCN111957960AImprove mechanical propertiesSolve the problem of thermal crackingAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSuperalloy

The invention provides a selective laser melting forming method of a hot-crack-free precipitation strengthened high-temperature alloy. The method comprises the step of mixing precipitation strengthened high-temperature alloy powder with melt-reducing element particles before laser melting. The method can remarkably solve the problem of thermal cracking of the selective laser melting forming precipitation strengthened high-temperature alloy, and the mechanical property of the alloy is improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

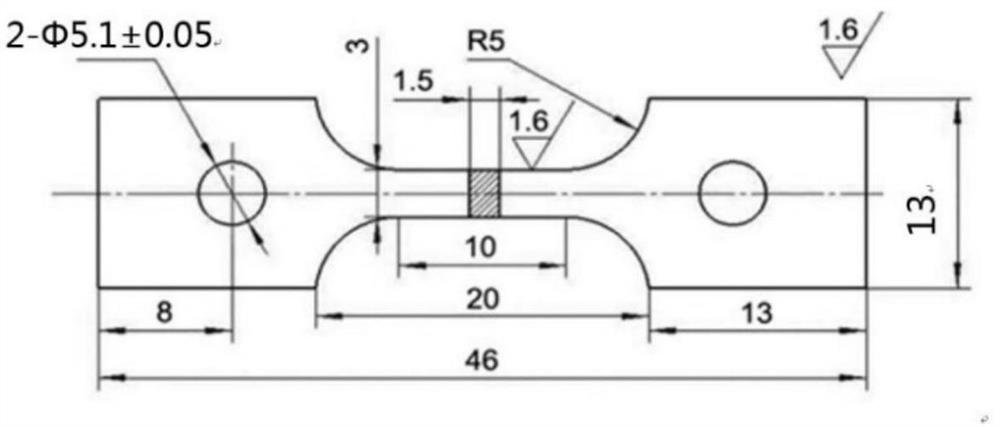

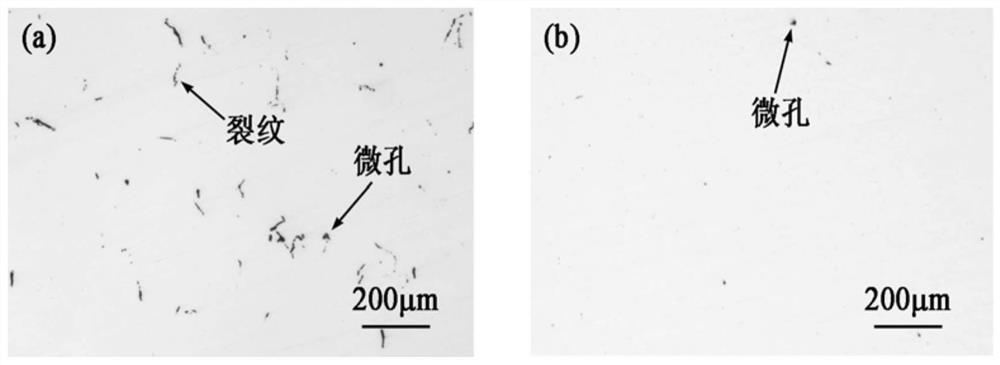

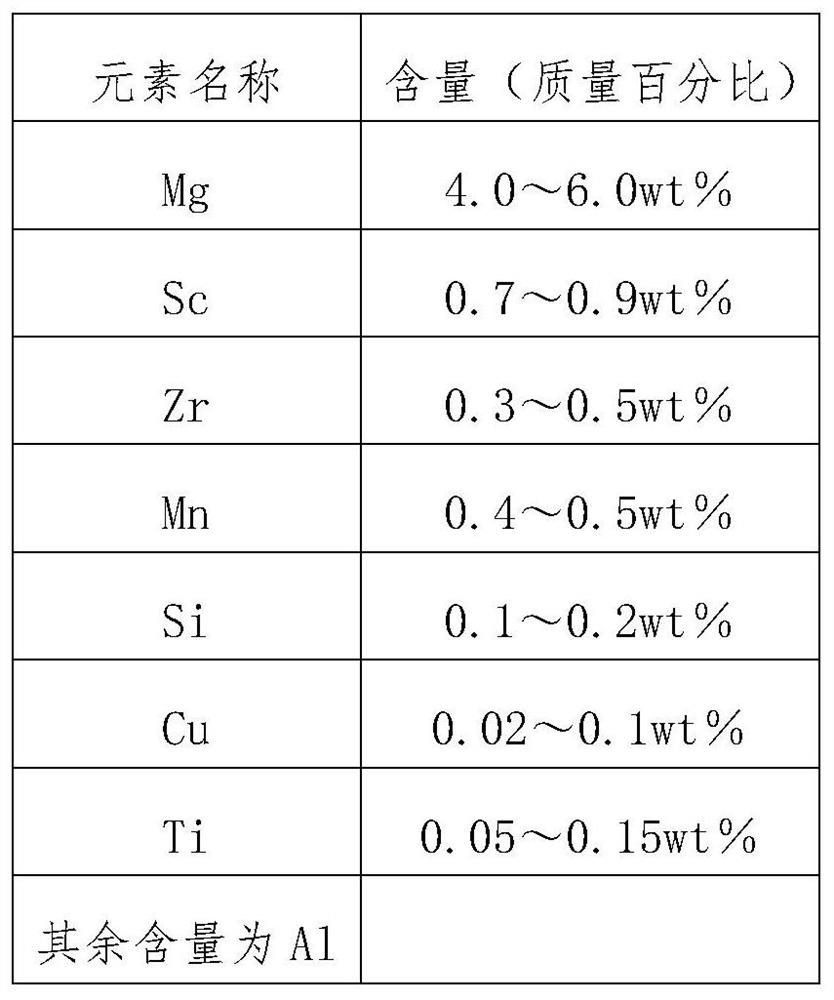

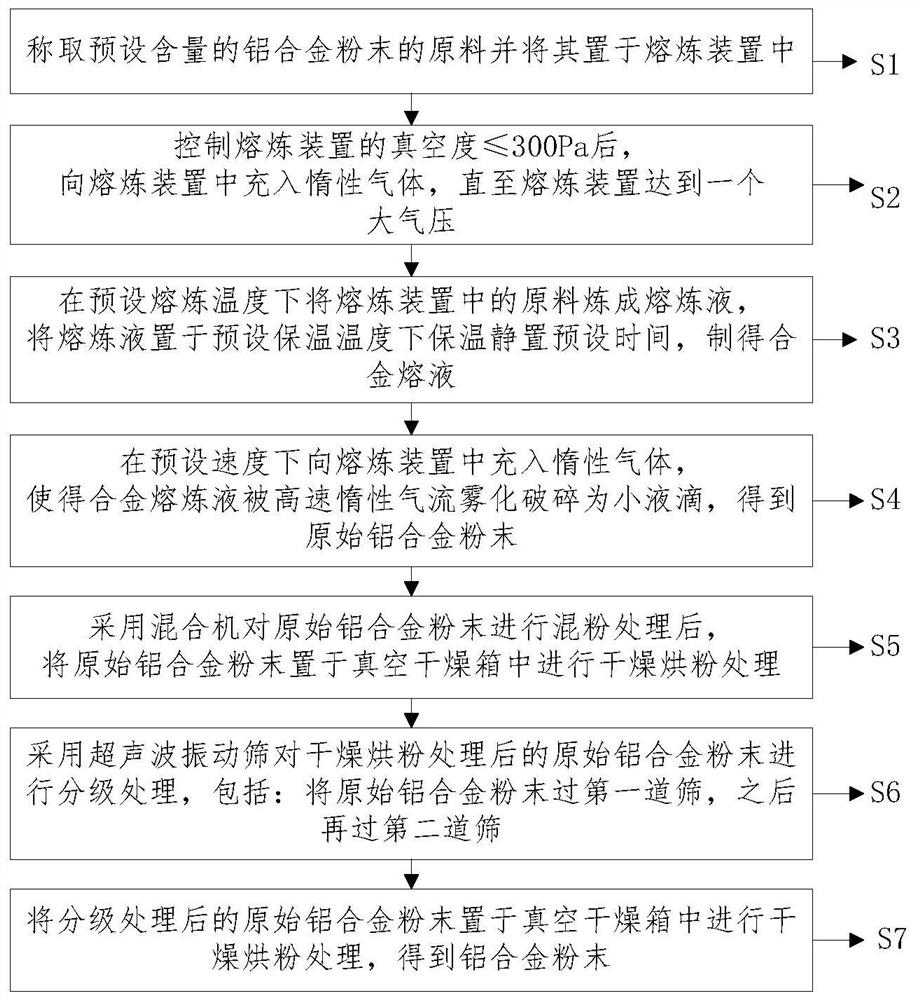

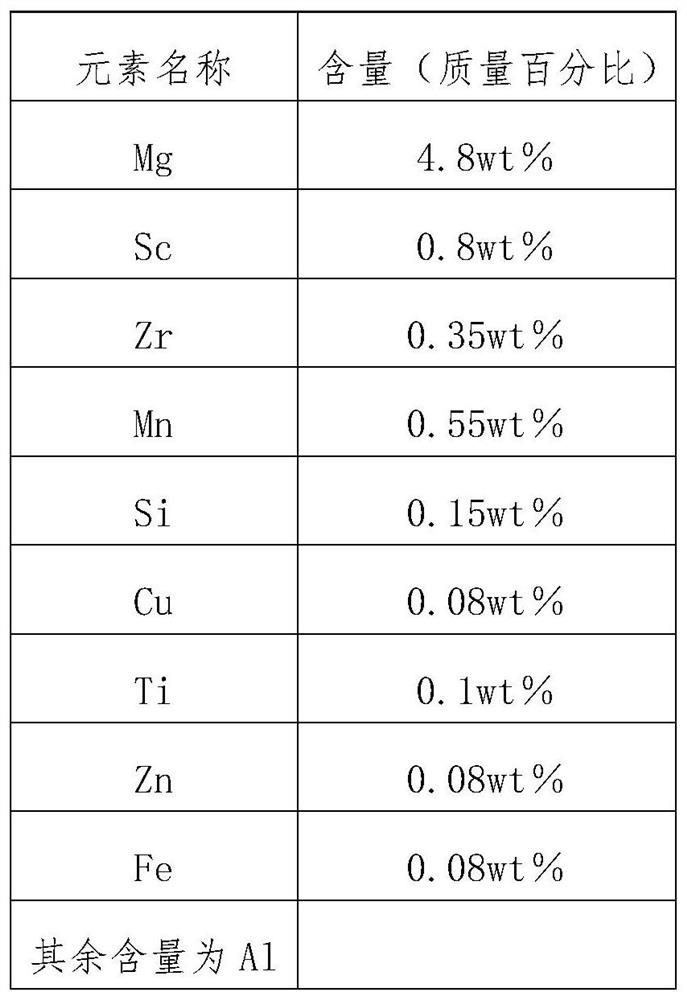

Aluminum alloy powder material for aviation additive manufacturing, preparation method and 3D printing method

ActiveCN113020606AReduce laser reflectivitySolving Hot Crack PropensityAdditive manufacturing apparatusTransportation and packagingHigh reflectivityUltimate tensile strength

The invention provides aluminum alloy powder for aviation additive manufacturing, a preparing method and a 3D printing method. The aluminum alloy powder comprises 4.0 wt%-6.0 wt% of Mg, 0.7 wt%-0.9 wt% of Sc, 0.3 wt%-0.5 wt% of Zr, 0.4 wt%-0.5 wt% of Mn, 0.1 wt%-0.2 wt% of Si, 0.02 wt%-0.1 wt% of Cu, 0.05 wt%-0.15 wt% of Ti, smaller than 0.1 wt% of Zn or smaller than 0.1 wt% of Fe and the balance Al. By doping elements with different components, the material has very high strength and toughness, the material characteristics of the aluminum alloy can be compensated, the high reflectivity of the aluminum alloy powder material to laser during laser forming is reduced, meanwhile, the problem of hot cracking of the aluminum alloy powder material is solved, and he aluminum alloy powder can be used for an additive manufacturing method in the aviation field.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

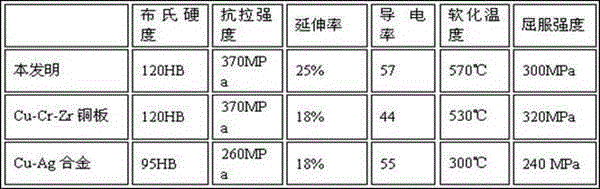

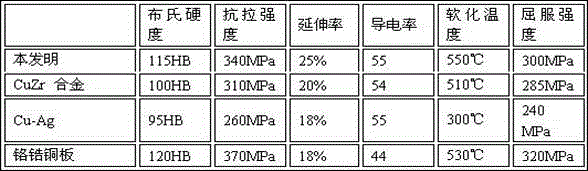

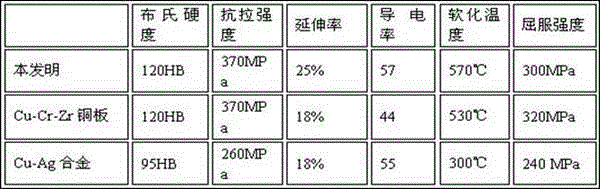

Cu-Cr-Ag alloy crystallizer copper plate and preparation process thereof

The invention discloses a Cu-Cr-Ag alloy crystallizer copper plate comprising the following components in percentage by mass: 0.1-0.3% of metal chromium, 0.03-0.05% of a deoxidizing agent namely metal magnesium, 0.08-0.2% of metal silver and 99.56-99.79% of metal copper. The invention also discloses a preparation process of the Cu-Cr-Ag alloy crystallizer copper plate. The Cu-Cr-Ag alloy crystallizer copper plate disclosed by the invention has very good heat-conducting property and relatively high tensile strength, and simultaneously has very high softening temperature, high thermal cracking resistance and good creep resistance, so that the service life of the crystallizer copper plate is prolonged, the pulling rate of a plate blank casting machine is improved, the production efficiency of plate blanks is greatly improved, and thus the Cu-Cr-Ag alloy crystallizer copper plate is a novel high-thermal-cracking-resistance crystallizer copper plate which is suitable for multi-steel-type continuous casting operation for high-pulling-rate high-efficiency production of ultra-low-carbon steel, silicon steel, SPHC and the like.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

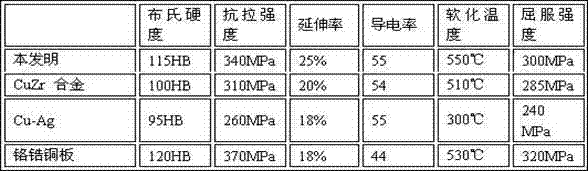

Cu-Zr-Ag alloy crystallizer copper plate and preparation process thereof

The invention discloses a Cu-Zr-Ag alloy crystallizer copper plate, containing metal Zr of 0.05 to 0.25wt%, deoxidizing agent metal Mg of 0.05wt%, metal Ag of 0.06 to 0.15wt% and metal Cu of 99.65 to 99.77wt%. The invention also discloses a preparation process of the Cu-Zr-Ag alloy crystallizer copper plate, which has better heat conductivity and high pulling resistance and higher softening temperature, the service life of the crystallizer copper plate is prolonged, pull speed of a slab casting machine is improved, production efficiency of slabs is greatly improved, and the copper plate is a novel long-service life crystallizer copper plate suitable for high-pull speed, high-efficiency, high-pace and high-yield continuous casting operation.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

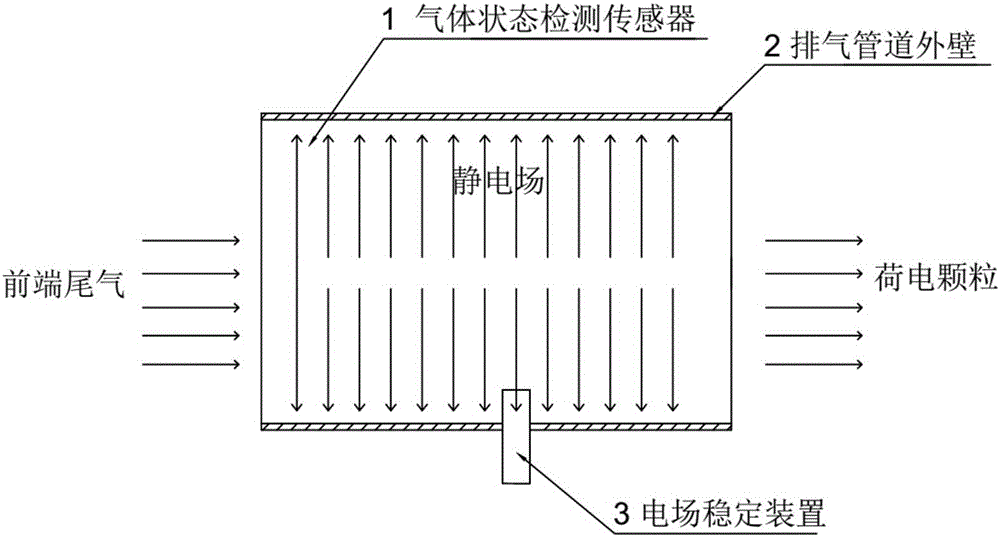

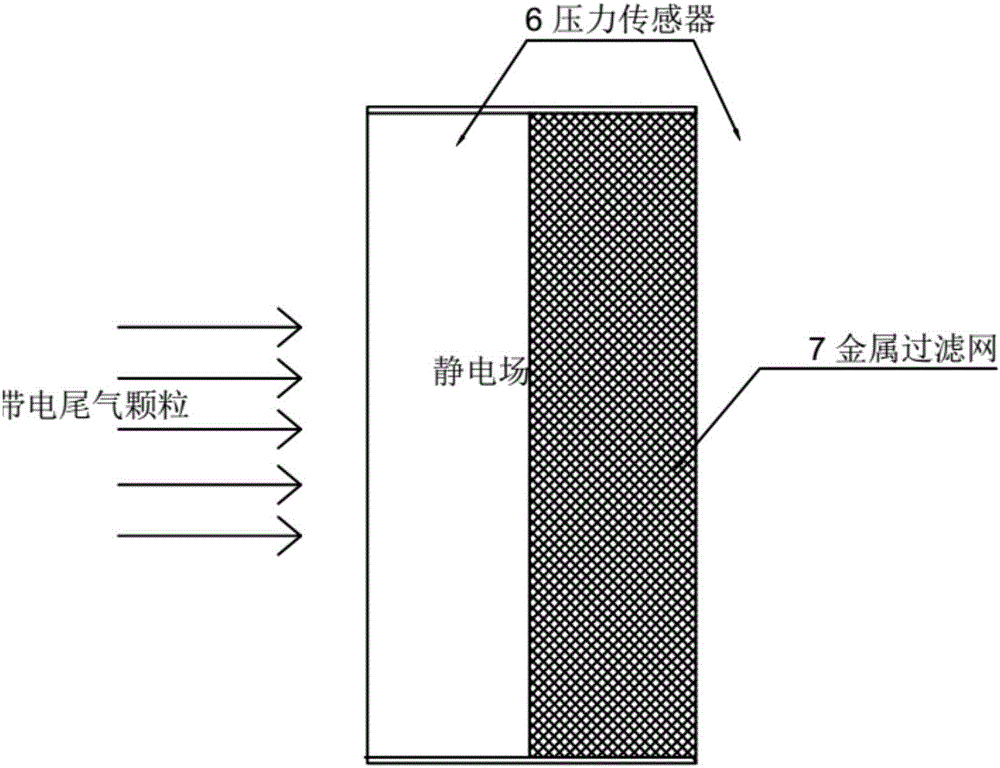

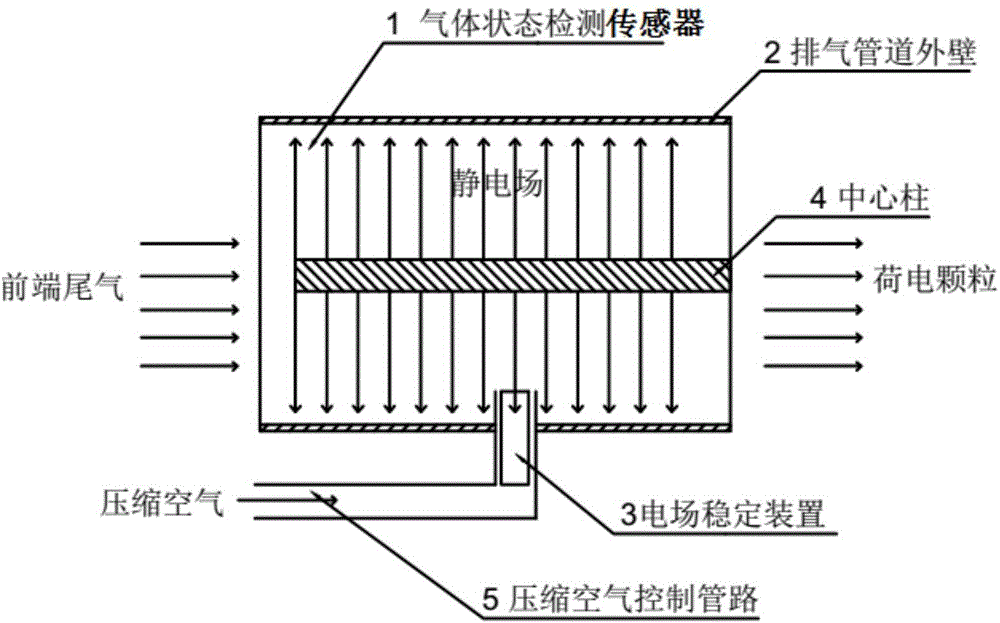

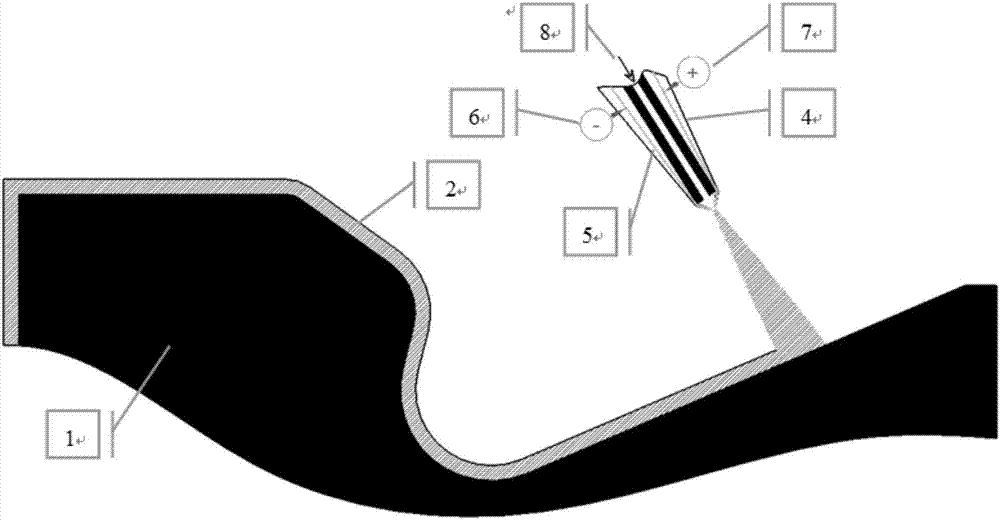

Composite automobile exhaust particle filtering device

InactiveCN106567761AReduce intensityHigh strengthInternal combustion piston enginesExhaust apparatusHigh pressureHeavy load

The invention belongs to the field of electrostatic-type exhaust treatment systems and discloses a composite automobile exhaust particle filtering device. The device is characterized in that an electric charging device is disposed in an exhaust pipeline; the electric charging device is connected to a high-voltage positive electrode; the outer wall of the exhaust pipeline is connected to a grounding electrode; an electrostatic field is formed in the exhaust pipeline to conduct pre-charging of exhaust particles; a metal filtering screen is disposed at a discharge hole of the exhaust pipeline to collect the exhaust particles; the electric charging device is a center pillar, multiple parallel electrode pillars or an electrode board; and devices such as an electric field stabilization device, a compressed air control pipeline, a gas state detection sensor and a pressure sensor are also disposed on the exhaust pipeline to promote electric field stabilization and collect the exhaust particles. The filtering device disclosed by the invention has the advantages that a demand for exhaust filtering under different loads, especially heavy loads, can be satisfied; the electric charging capability of a filtering system can be enhanced effectively, and particle collection can be perfected; filtering performance can be improved; the efficiency is high; and the filtering performance is stable.

Owner:HUAZHONG UNIV OF SCI & TECH

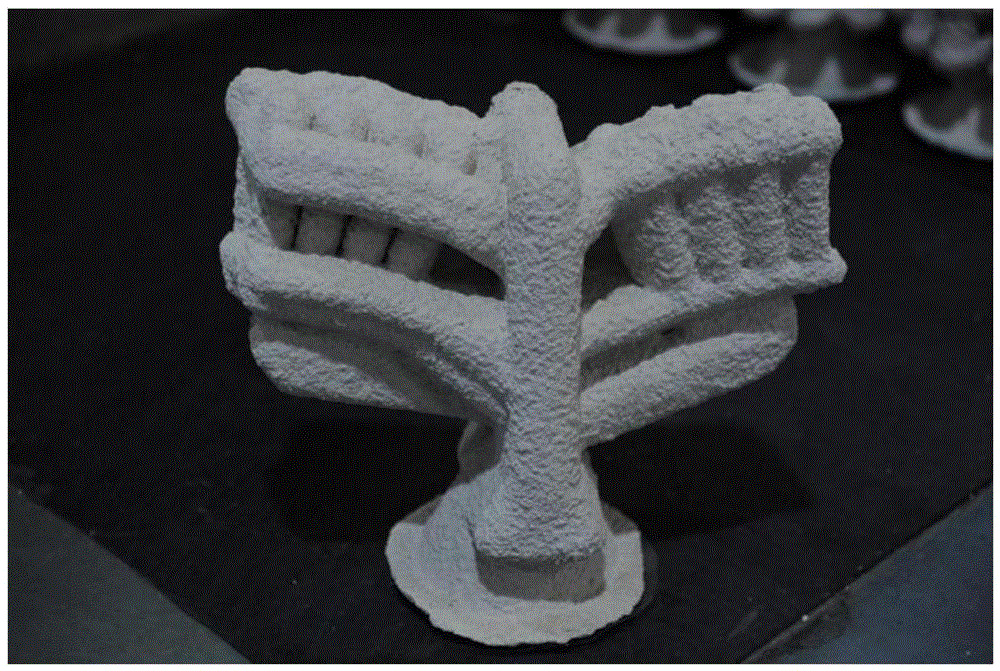

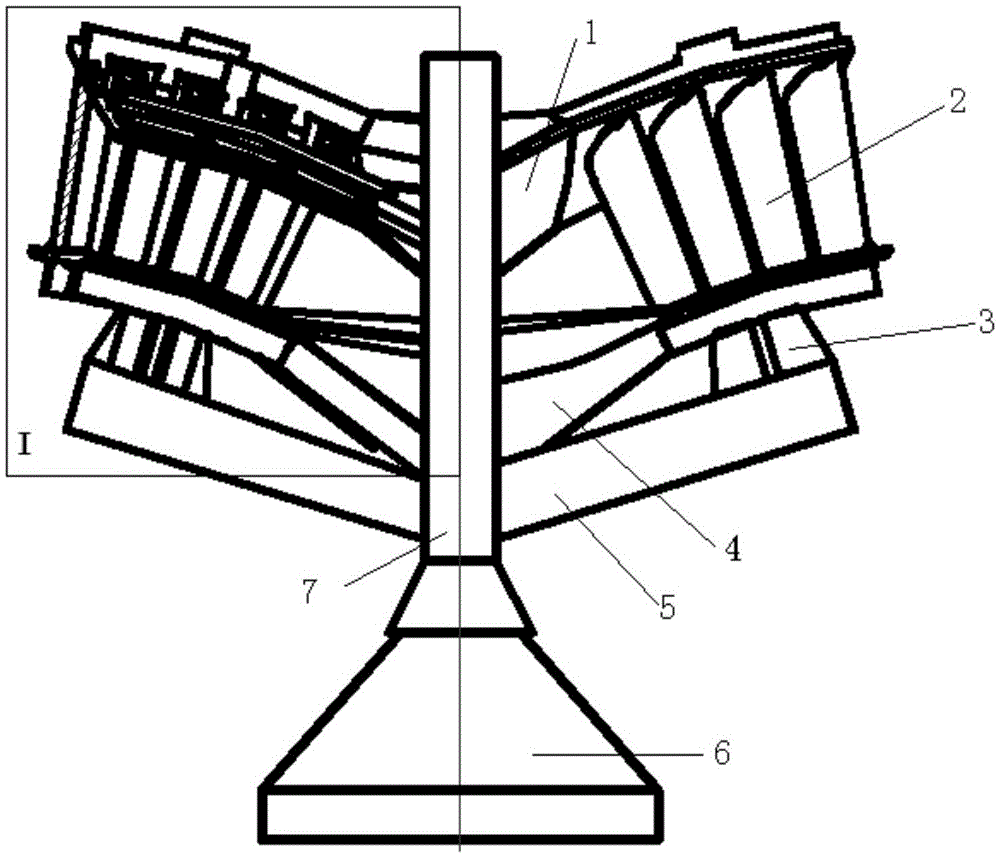

A casting method for hollow turbine guide vanes

The invention provides a pouring method of a hollow turbine guide vane. The pouring method comprises the following steps: (1) manufacturing a wax mold combination; (2) carrying out shell making on the wax mold combination to obtain a hollow turbine guide vane shell; (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part; covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace and carrying out casting, wherein in a casting process, the temperature of casting the shell is 1065-1085 DEG C and the pouring temperature is 1460-1480 DEG C. According to the pouring method of the hollow turbine guide vane, a pouring system of the hollow turbine guide vane is not changed and the shell temperature and the pouring temperature are adjusted so that the casting temperature field is changed; the two layers of ceramic cotton on the whole body and one layer of the ceramic heat-preservation cotton on the vane body part are matched so that after the temperature of the whole shell is improved, the temperature field is uniform, the casting stress is eliminated and the casting temperature is reduced; and furthermore, the temperature field on a casting vane body and an edge plate keeps uniform, the shell is effectively insulated and the casting stress is eliminated.

Owner:AECC AVIATION POWER CO LTD

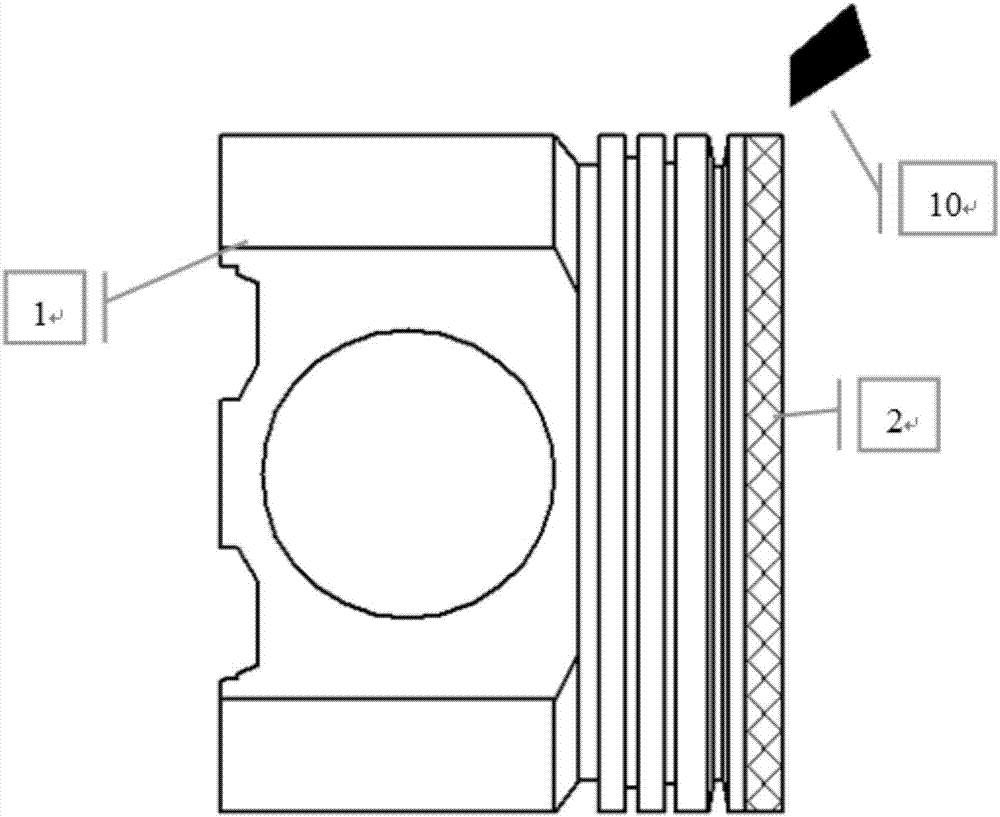

Metal-ceramic composite coating layer for steel piston

ActiveCN107338408AHigh dimensional accuracyIncrease roughnessMolten spray coatingMicro arc oxidationPlasma electrolytic oxidation

The invention provides a metal-ceramic composite coating layer for a steel piston. A mature arc spraying technology is introduced; a layer of such compact materials easy to perform electrochemical oxidation as aluminum, magnesium and titanium is firstly prepared on the top surface of the steel piston; and then, on this basis, such electrochemical methods as hard anodic oxidation and microarc oxidation are used for preparing a thermal insulation layer. An area to be treated of the steel piston is machined; the arc spraying is adopted to form a metal transition layer on the surface of the machined steel piston; the steel piston covered with the metal transition layer is secondarily machined; and a ceramic thermal insulation layer is prepared on the surface of the secondarily machined steel piston by adopting the electrochemical method. As the metal spraying difficulty is far lower than the spraying of such ceramic materials as zirconium oxide and aluminum oxide, the arc spraying is particularly adopted, and the manufacturing cost is greatly reduced.

Owner:BINZHOU BOHAI PISTON CO LTD

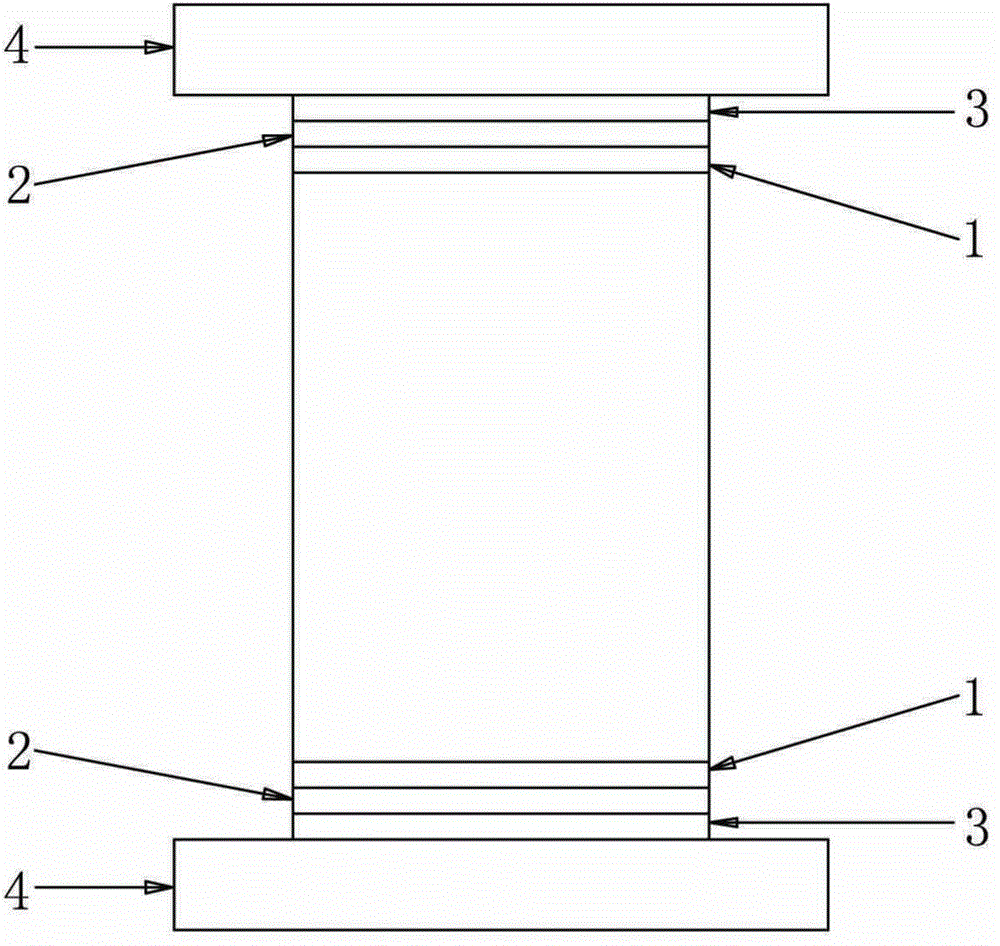

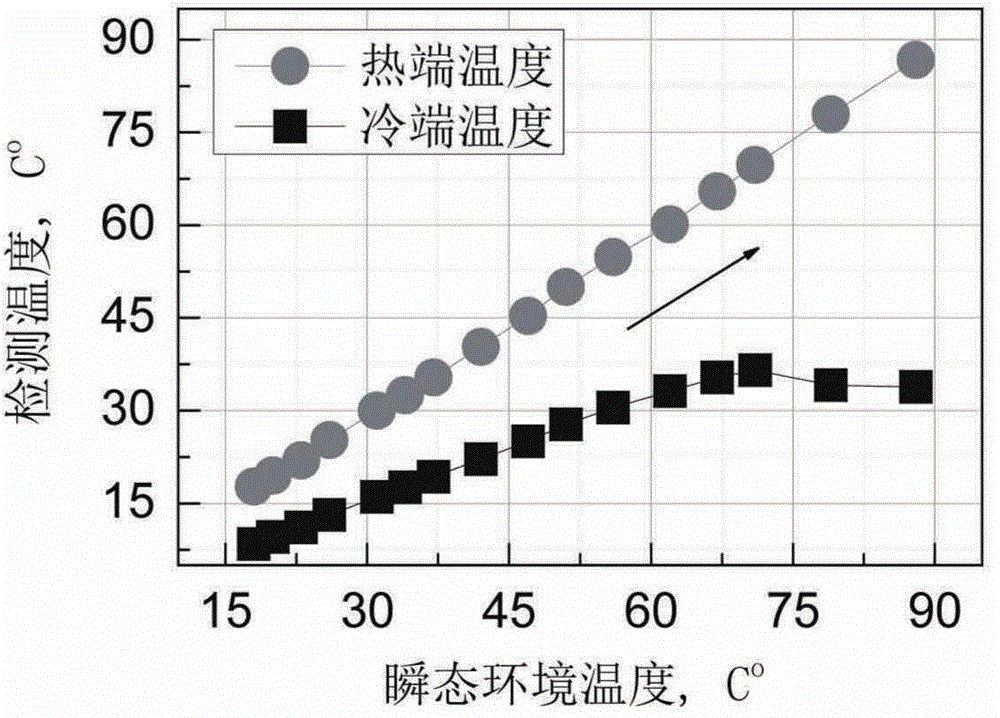

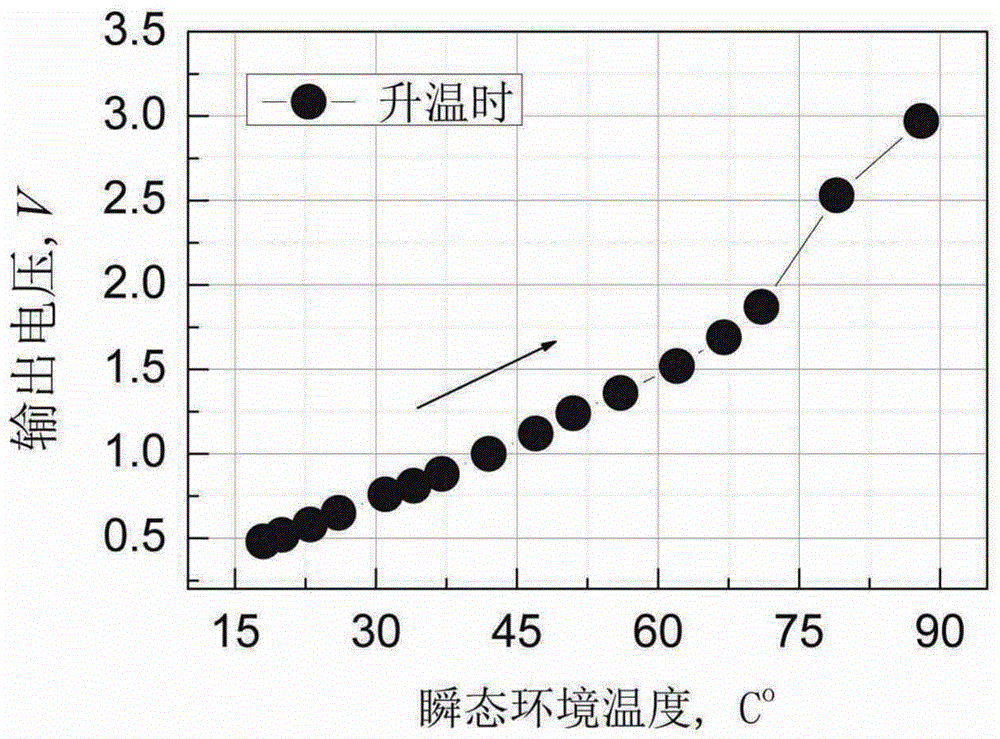

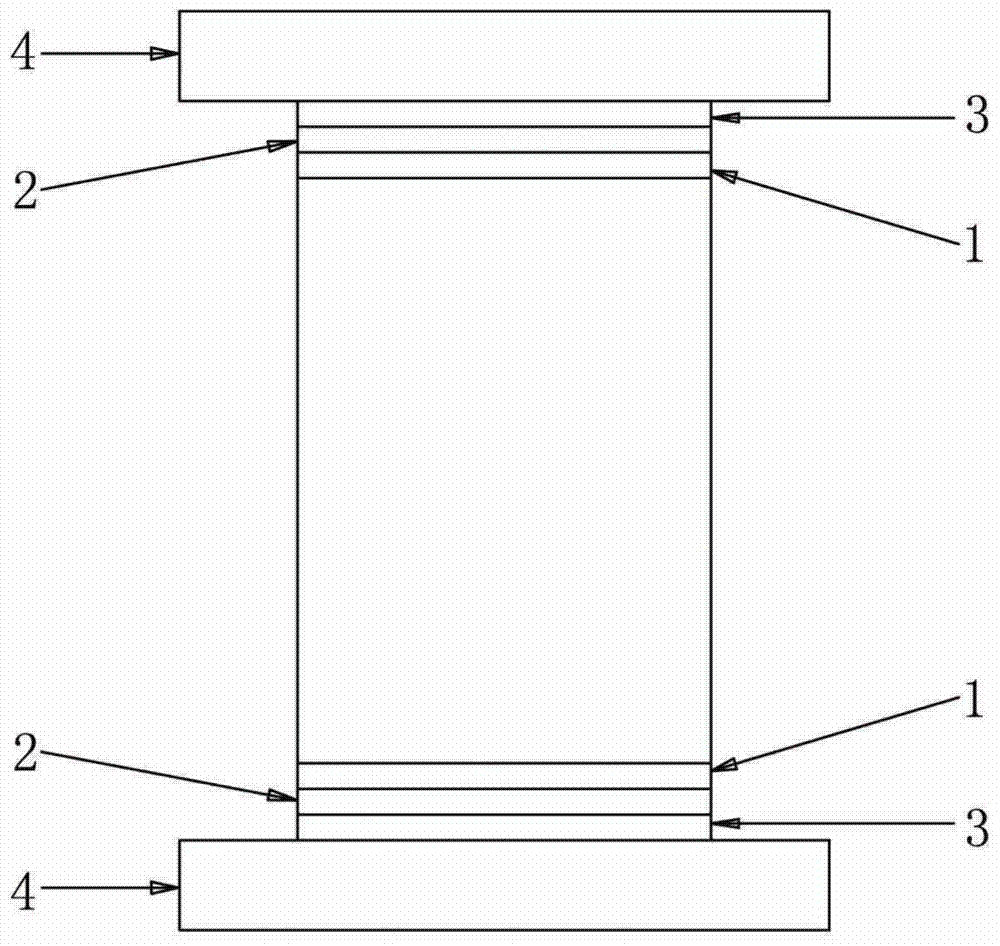

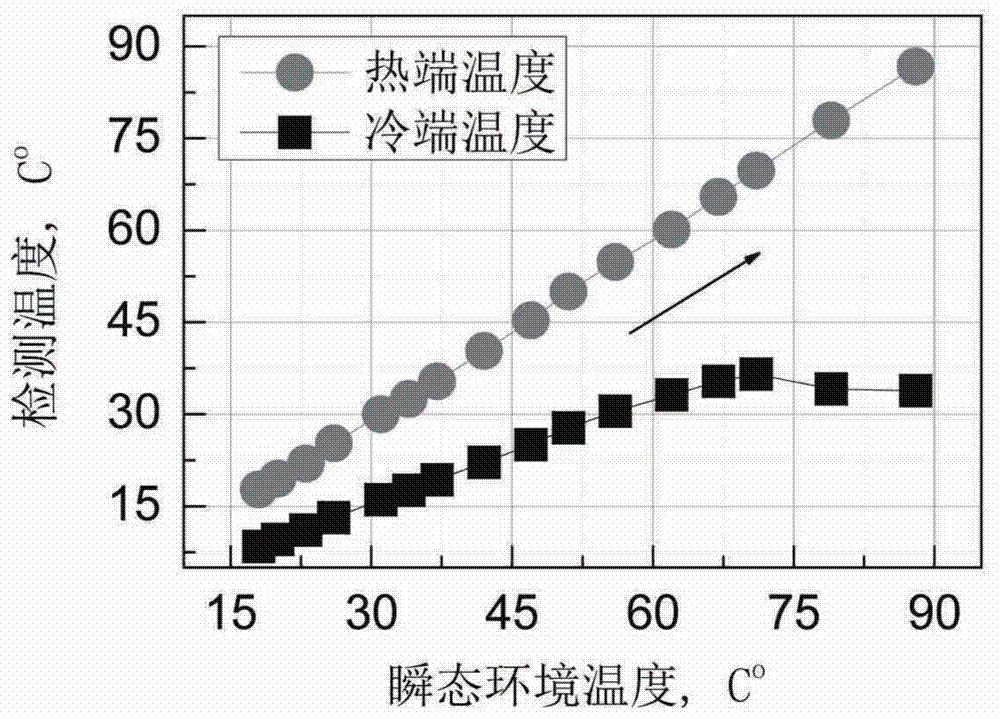

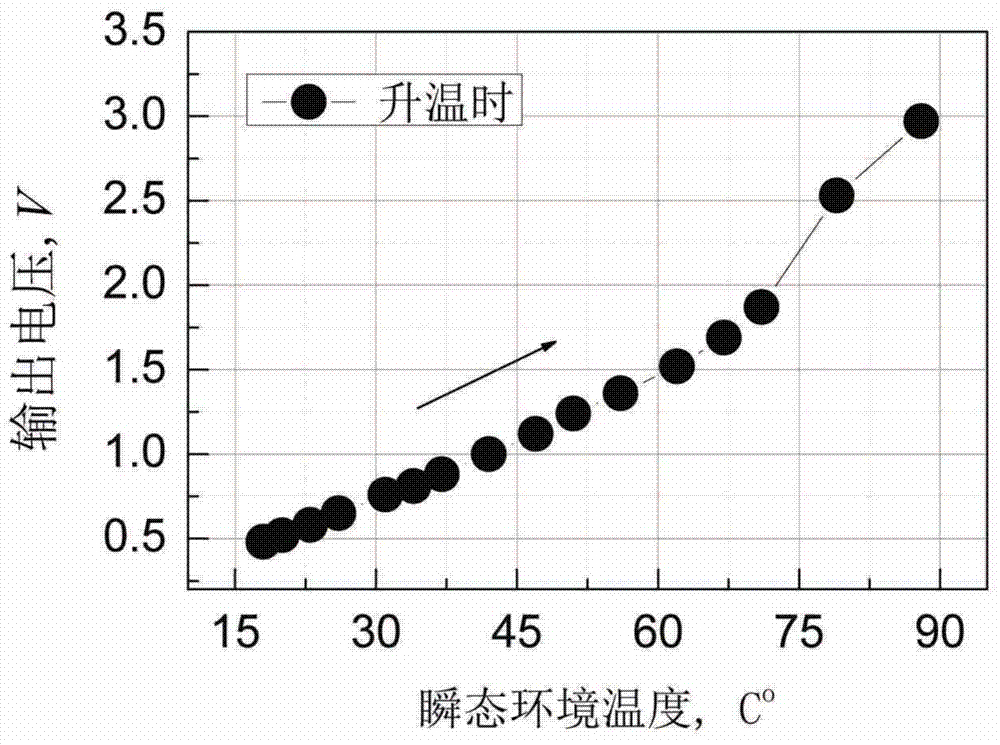

Preparation process of single-arm structure of thermoelectric semiconductor temperature sensor chip

InactiveCN103698035BImprove performanceSolution to short lifeThermometers using electric/magnetic elementsUsing electrical meansSemiconductor chipEngineering

The invention relates to a single arm structure for a thermoelectric semiconductor temperature sensing sheet and a preparation process, and aims to solve the technical problem of thermal cracks caused by large thermal stress in a like product. The single arm structure for the thermoelectric semiconductor temperature sensing sheet comprises a thermoelectric semiconductor and Cu guide vanes positioned at the two ends of the thermoelectric semiconductor, wherein three transition layers, i.e. an Ni-coated layer, an Ni-plated layer and an Sn95Ag5-plated layer, are arranged between each of the two ends of the thermoelectric semiconductor and the corresponding Cu guide vane; the Ni-coated layers, the Ni-plated layers and the Sn95Ag5-plated layers are sequentially arranged from the end parts of the thermoelectric semiconductor to the surfaces of the Cu guide vanes. According to the single arm structure and the preparation process, the transition layers are arranged, so that a buffering function is realized, and the thermal stress which is generated between the thermoelectric conductor and the Cu guide vanes caused by the great thermal expansion coefficient difference is reduced; the single arm structure is high in thermal stability and suitable for various thermoelectric semiconductor temperature sensing sheets, the problem of thermal cracks in a thermoelectric semiconductor temperature sensor is solved, and the service life of the temperature sensor is prolonged.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

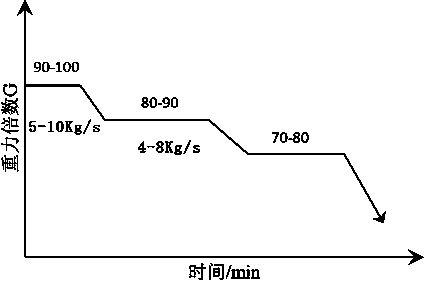

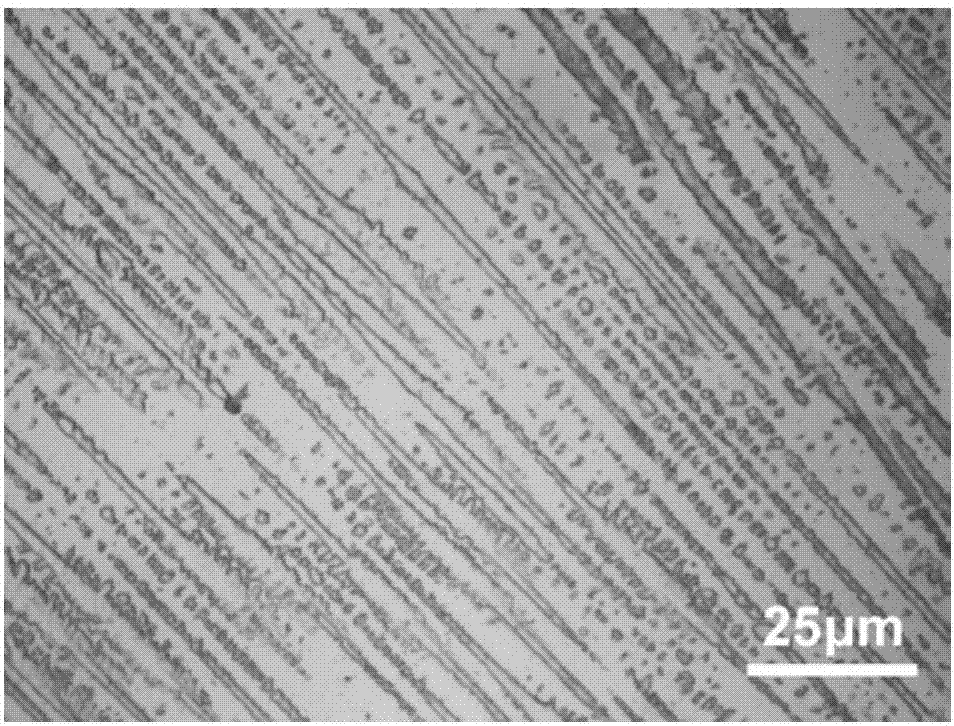

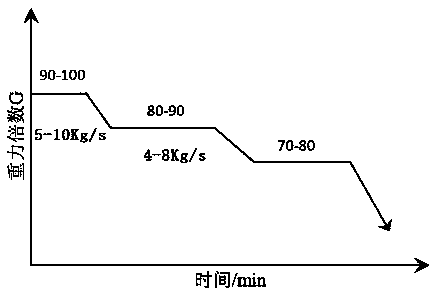

Method for avoiding hot crack on outer layer of high speed steel roll for rods and wires

The invention discloses a method for avoiding a hot crack on the outer layer of a high speed steel roll for rods and wires. The method includes the following steps: a centrifugal pattern is adopted to forge the outer layer of the high speed steel roll; during centrifugal casting of the outer layer, the rotating speed of a centrifuge is changed by phase, and the molten steel casting speed and the rotating speed of the centrifuge are changed accordingly; at the starting phase of the centrifugal casting, a high rotating speed and high-speed casting are adopted; at the medium phase of the centrifugal casting, a medium rotating speed and low-speed casting are adopted; after casting is finished, a low rotating speed is adopted. Through the variable-speed centrifugal casting of molten steel for the outer layer of the high speed steel roll, the molten steel mold filling is facilitated at the starting phase of casting; molten steel is guaranteed to quickly and evenly cover the entire inner chamber of a casting mold; cold-lap, cold shut and other defects are avoided; the stress on the centrifugal outer layer is also improved; element segregation on the outer layer is reduced; stress cracking tendency is reduced; finally, the purpose of preventing the outer layer from the hot crack is achieved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Precipitation strengthening nickel-based high-temperature alloy laser powder bed melting forming method capable of reducing hot cracks

PendingCN112828289ASolve the problem of thermal crackingImprove versatilityAdditive manufacturing apparatusRare-earth elementNickel

The invention provides a precipitation strengthening nickel-based high-temperature alloy laser powder bed melting forming method capable of reducing hot cracks. According to the method, rare earth element oxide particles and precipitation strengthening nickel-based high-temperature alloy powder are mixed and then subjected to laser powder bed melting forming, the rare earth element oxide particles and the precipitation strengthening nickel-based high-temperature alloy powder interact under the action of continuous laser, and therefore harmful elements in the original precipitation strengthening nickel-based high-temperature alloy powder can be enriched, segregation of the harmful elements along the crystal boundary is reduced, forming of a liquid film of melt at the final stage of solidification is correspondingly hindered, and the hot cracks are greatly reduced.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Method for manufacturing high-strength light alloy products with hot tearing tendency

PendingCN107755632ASolve the problem of thermal crackingGuaranteed alloying effectFoundry mouldsFoundry coresAlloyUltimate tensile strength

The invention discloses a method for manufacturing high-strength light alloy products with hot tearing tendency. The method comprises the following steps: firstly, template component pieces are analyzed according to casting structures and technology condition requirements; molding cavities of molds are designed and manufactured; a pouring process is analyzed; shapes of mold bundles are designed; the mold bundles are manufactured; and then, finished products are finished through sand filling compaction, smelting and refining of alloy liquid, pouring, casting obtaining and primary machining of castings. The method effectively solves the hot tearing problems of the castings, and meanwhile, guarantees the alloying effects of the castings; and the manufactured casting products are low in deformation, excellent in quality and high in strength.

Owner:荣泽发动机零部件(常熟)有限公司

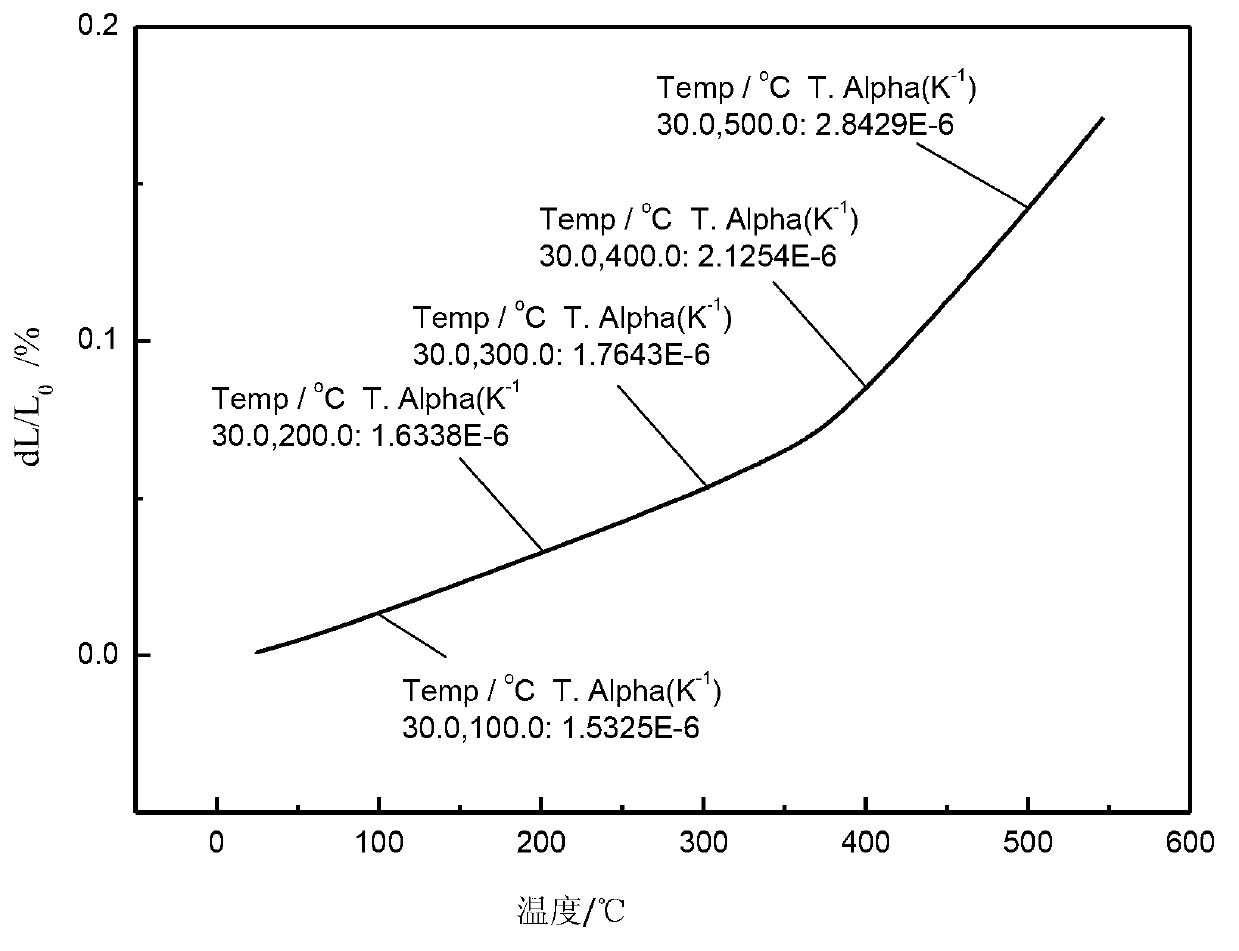

Welding materials for connection of low thermal expansion coefficient alloys

InactiveCN103273220AHot tear tendency controlAchieve preparationWelding/cutting media/materialsSoldering mediaThermal dilatationManganese

The invention discloses welding materials. The thermal expansion coefficient is from 1.53 *10-6 to 2.84 * 10 - 6k -1. The welding materials are mainly formed by, by weight percent, nickel of 35% to 36.5%, carbon of 1.15 % to 0.12 %, manganese of 1.0% to 3.0 %, silicon of 0.01 % to 0.1 %, titanium of 0.8 % to 1.5 %, cobalt of 0.4 % to 0.7 %, scandium oxide of 0.5 % to 8.0 %; the balance to be ferrum; and the impurity S is no more than 0.01 % and the P is no more than 0.01 %. The production technology comprises compounding materials; performing vacuum induction melting; naturally cooling after a mold casing is achieved pouring; performing ingot pressing and forming; and performing an annealing process. The welding materials can be used for welding of low thermal expansion coefficient alloys and also can be served as buffering materials to achieve heterojunction of materials such as the low thermal expansion coefficient alloys and higher thermal expansion coefficient carbon steel.

Owner:SHANGHAI UNIV OF ENG SCI

A cu‑zr‑ag alloy crystallizer copper plate and preparation process thereof

The invention discloses a Cu-Zr-Ag alloy crystallizer copper plate, containing metal Zr of 0.05 to 0.25wt%, deoxidizing agent metal Mg of 0.05wt%, metal Ag of 0.06 to 0.15wt% and metal Cu of 99.65 to 99.77wt%. The invention also discloses a preparation process of the Cu-Zr-Ag alloy crystallizer copper plate, which has better heat conductivity and high pulling resistance and higher softening temperature, the service life of the crystallizer copper plate is prolonged, pull speed of a slab casting machine is improved, production efficiency of slabs is greatly improved, and the copper plate is a novel long-service life crystallizer copper plate suitable for high-pull speed, high-efficiency, high-pace and high-yield continuous casting operation.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

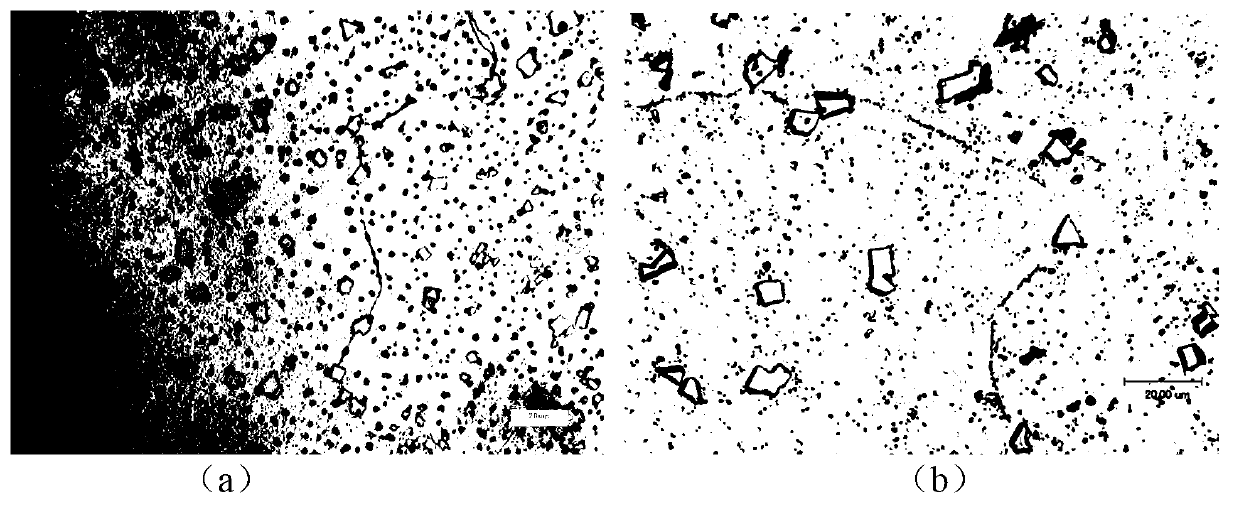

Anode plate of stainless-steel cold-rolling pickling line and manufacture method thereof

InactiveCN101717988BFine and uniform grainSolve the problem of thermal crackingElectrolysis componentsCorrosion resistant alloyCopper

The present invention relates to an anode plate of a stainless-steel cold-rolling pickling line and a manufacture method thereof. The anode plate is characterized in that one part of a core plate soaking in acid when the core plate is in acid cleaning is coated by a corrosion-resistant alloy layer which comprises 5-12% of Sb, 0.2-1.0% of Cu, 0.2-1.0% of Bi, 0.1-0.5% of Ce and the balance of Pb and unavoidable impurities. The manufacture method comprises the following steps of: (1) preparing an alloy layer soldering sheet: firstly, preparing a Cu-Sb interalloy: a, using CuSb50 as a Cu-Sb alloy; b, casting the Cu-Sb alloy in a die into a furnace burden; secondly, smelting the alloy: a, preheating a smelting furnace; adding the Cu-Sb interalloy to smelt; b, adding Bi, Sb and Ce; c, adding the rest Pb; d, discharging from the furnace and casting; thirdly, preparing a soldering sheet: casting alloy liquid into a soldering sheet; and (2) welding the soldering sheet: a, polishing the core plate and removing gas; b, firmly clamping the core plate; and c, welding the soldering sheet and the core plate. The anode plate of the stainless-steel cold-rolling pickling line resists corrosion and has low cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD +2

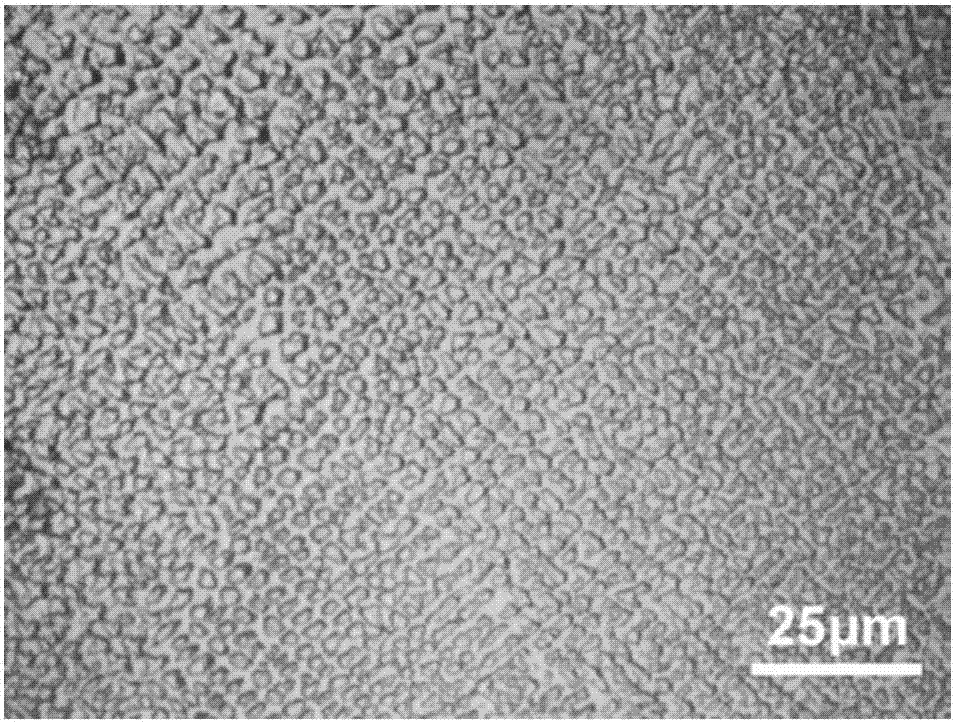

A method for controlling the brittle laves phase in the process of laser additive manufacturing of nickel-based superalloy

InactiveCN106077647BIncrease cooling rateIncrease subcoolingAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsLaser source

The invention discloses a method for controlling the brittle Laves phase in the process of laser additive manufacturing of nickel-base superalloy. Preliminary optimization of laser additive manufacturing process parameters, using cooling medium to cool the bottom of the substrate; then using laser modulation technology to modulate the light source to obtain better laser modulation parameters, square wave: peak power: 600 ~ 1000W, pulse frequency : 10HZ~100HZ, duty cycle: 0.3~0.6; sawtooth wave: peak 600~1200W, valley 0W, pulse frequency: 10HZ~100HZ; parameters of sine wave: peak 600~1000W, valley 0W, pulse frequency: 10HZ~ 100HZ; Finally, laser additive manufacturing of nickel-based superalloys is carried out according to the above parameters to obtain formed parts with all fine equiaxed dendrite structures and fine discrete Laves phases. Through the laser modulation method, the invention can effectively control the precipitation behavior of Laves phase in the process of laser additive manufacturing of nickel-based superalloy, reduce the cracking sensitivity of laser additive manufacturing parts, and improve the microstructure.

Owner:HUNAN UNIV

Method to Solve Hot Cracks in Outer Layer of High Speed Steel Roll for Rod and Wire Rod

Owner:邢台轧辊线棒辊有限责任公司

High-temperature wear-resistant self-lubricating side guide plate lining plate and machining method thereof

PendingCN113737177AExtend your lifeSolve the problem of low lifespanMetallic material coating processesHigh entropy alloysHexagonal boron nitride

The invention discloses a high-temperature wear-resistant self-lubricating side guide plate lining plate and a machining method thereof. The side guide plate lining plate is of a sandwich structure, a middle base plate is made of 45 steel, high-temperature wear-resistant self-lubricating layers obtained through laser cladding are arranged on the two sides of the middle base plate, each high-temperature wear-resistant self-lubricating layer is composed of 85-97 wt% of high-entropy alloy, 1-5 wt% of hexagonal boron nitride and 2-10 wt% of eutectic BaF2 / CaF2, the high-entropy alloy is NiFeAlCoCrB<x> and is composed of Ni, Fe, Al, Co and Cr which are equal in mole and B with the mole content of x, x ranges from 0.02 to 0.1, and the high-temperature wear-resistant self-lubricating layers are formed on the surface of the middle base plate through two paths of laser cladding. The hardness of the lining plate is improved by adopting the high-entropy alloy, the high-temperature lubricity of the lining plate is improved by adopting boron nitride and eutectic BaF2 / CaF2 together, and the problems that a side guide plate lining plate is fast in abrasion and short in service life and the end face of strip steel is strained during hot rolling of the strip steel are effectively solved.

Owner:SHANGHAI DIANJI UNIV

Single arm structure for thermoelectric semiconductor temperature sensing sheet and preparation process

InactiveCN103698035AImprove thermal stressSolve the problem of thermal crackingThermometers using electric/magnetic elementsUsing electrical meansThermal expansionEngineering

The invention relates to a single arm structure for a thermoelectric semiconductor temperature sensing sheet and a preparation process, and aims to solve the technical problem of thermal cracks caused by large thermal stress in a like product. The single arm structure for the thermoelectric semiconductor temperature sensing sheet comprises a thermoelectric semiconductor and Cu guide vanes positioned at the two ends of the thermoelectric semiconductor, wherein three transition layers, i.e. an Ni-coated layer, an Ni-plated layer and an Sn95Ag5-plated layer, are arranged between each of the two ends of the thermoelectric semiconductor and the corresponding Cu guide vane; the Ni-coated layers, the Ni-plated layers and the Sn95Ag5-plated layers are sequentially arranged from the end parts of the thermoelectric semiconductor to the surfaces of the Cu guide vanes. According to the single arm structure and the preparation process, the transition layers are arranged, so that a buffering function is realized, and the thermal stress which is generated between the thermoelectric conductor and the Cu guide vanes caused by the great thermal expansion coefficient difference is reduced; the single arm structure is high in thermal stability and suitable for various thermoelectric semiconductor temperature sensing sheets, the problem of thermal cracks in a thermoelectric semiconductor temperature sensor is solved, and the service life of the temperature sensor is prolonged.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

A kind of cu-cr-ag alloy crystallizer copper plate and its preparation process

The invention discloses a Cu-Cr-Ag alloy crystallizer copper plate comprising the following components in percentage by mass: 0.1-0.3% of metal chromium, 0.03-0.05% of a deoxidizing agent namely metal magnesium, 0.08-0.2% of metal silver and 99.56-99.79% of metal copper. The invention also discloses a preparation process of the Cu-Cr-Ag alloy crystallizer copper plate. The Cu-Cr-Ag alloy crystallizer copper plate disclosed by the invention has very good heat-conducting property and relatively high tensile strength, and simultaneously has very high softening temperature, high thermal cracking resistance and good creep resistance, so that the service life of the crystallizer copper plate is prolonged, the pulling rate of a plate blank casting machine is improved, the production efficiency of plate blanks is greatly improved, and thus the Cu-Cr-Ag alloy crystallizer copper plate is a novel high-thermal-cracking-resistance crystallizer copper plate which is suitable for multi-steel-type continuous casting operation for high-pulling-rate high-efficiency production of ultra-low-carbon steel, silicon steel, SPHC and the like.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Method for connecting 2XXX and 7XXX heterogeneous aluminum alloy by laser filler wire

Owner:BEIJING UNIV OF TECH

Gasoline engine turbocharger

ActiveCN102536431BLow failure rateSolve the deformationInternal combustion piston enginesEngine componentsTurbochargerThrust bearing

Owner:潍坊富源增压器有限公司

Method for controlling precipitation of delta phase in Nb-containing nickel-based superalloy

ActiveCN112941370APlay a role in precipitation strengtheningHigh strengthIncreasing energy efficiencyChemical compositionPhysical chemistry

The invention discloses a method for controlling precipitation of a delta phase in a Nb-containing nickel-based superalloy, and belongs to the technical field of superalloy materials. The method comprises the steps of burdening, casting and heat treatment, Al, Ti and microelements B and Hf are added on the basis of original material chemical components, and according to experimental verification, when the addition amount of Al is 0.5-1.5 wt%, the addition amount of Ti is 0.2-1.0 wt%, the addition amount of B is 0.0010-0.0075 wt% and the addition amount of Hf is 0.1-1.00 wt%, the effects of controlling precipitation of the delta phase in a grain boundary area, reducing a gamma" metastable phase, inhibiting conversion from gamma" to the delta phase, and promoting the precipitation of a stable precipitation strengthening phase are achieved. Therefore, the endurance life, the strength and the structure stability of the materials are remarkably improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com