Composite automobile exhaust particle filtering device

A technology for automobile exhaust and particle filtration, which is applied to exhaust devices, electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, etc., can solve the problems of large filtering resistance, insufficient filtering capacity, and fast exhaust gas flow rate, Achieve the effect of improving filtration efficiency, facilitating filtration and collection, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

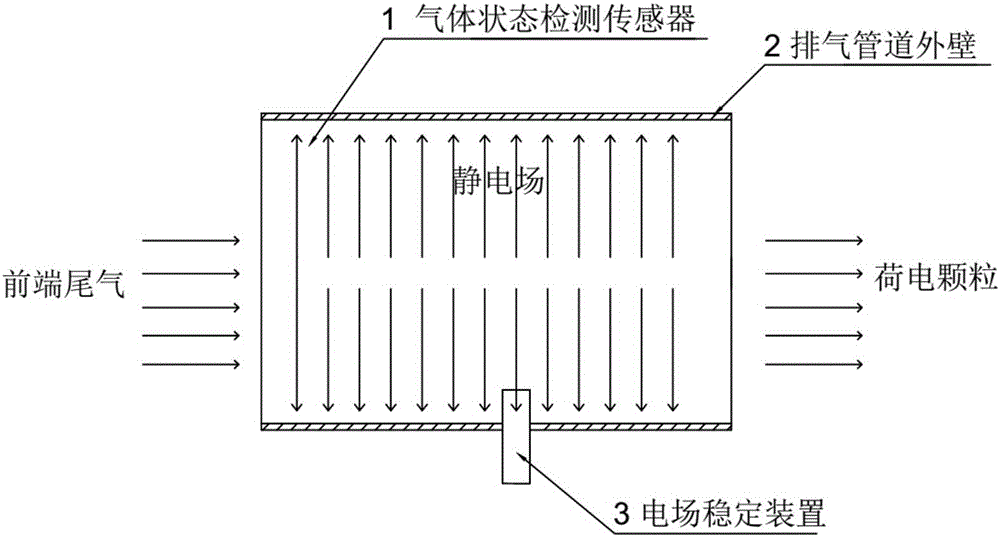

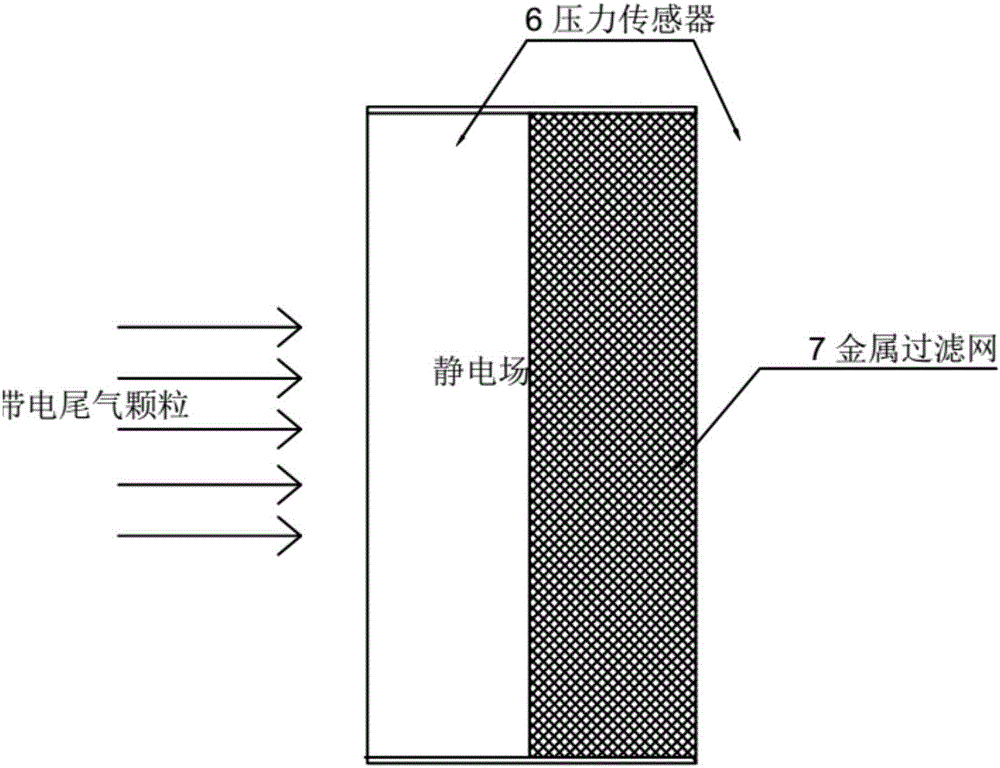

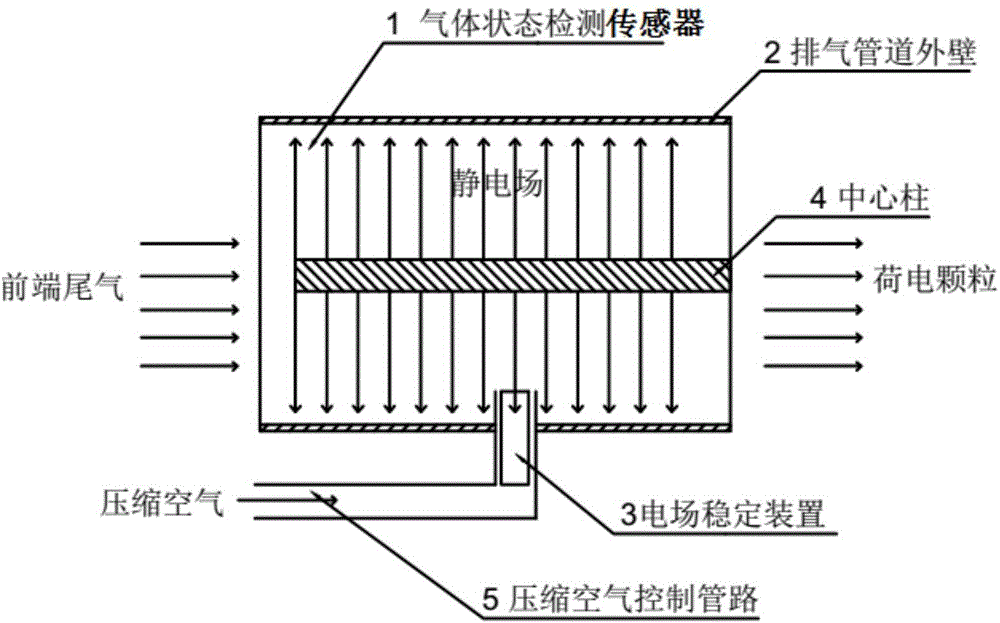

[0040] Such as image 3 As shown, a composite vehicle exhaust particle filter device, the device includes a gas state detection sensor 1 arranged at the intake end of the exhaust pipe, an outer wall of the exhaust pipe 2 and an electric field stabilization device 3, along the exhaust pipe in the exhaust pipe There is a central column 4 in the direction of the pipeline axis, the central column 4 is connected to the high-voltage positive electrode, and the outer wall of the exhaust pipe 2 is grounded, so that an electrostatic field is formed in the exhaust pipe to pre-charge the exhaust particles. There is a metal filter screen 7 to collect exhaust gas particles, and the exhaust gas enters the metal filter screen after being pre-charged;

[0041] The electric field stabilizing device 3 made of ceramic body is arranged at the bottom of the exhaust pipe, and the electric field stabilizing device 3 is in the compressed air control pipeline 5, and compressed air is passed into the c...

Embodiment 2

[0043] Such as Figure 4 As shown, a composite vehicle exhaust particle filter device, the device includes a gas state detection sensor 1 arranged at the intake end of the exhaust pipe, an outer wall of the exhaust pipe 2 and an electric field stabilization device 3, and is parallel to the exhaust pipe in the exhaust pipe. There are multiple poles 8 arranged on the axis of the gas pipeline, and one end of the poles 8 passes through the metal filter 7. The poles 8 are connected to the high-voltage positive pole, and the outer wall 2 of the exhaust pipe is grounded, thereby forming static electricity in the exhaust pipe. Pre-charge the exhaust particles in the field, and a metal filter 7 is installed at the outlet of the exhaust pipe to collect the exhaust particles. After the exhaust gas is pre-charged, it enters the metal filter;

[0044] The electric field stabilizing device 3 made of ceramic body is arranged at the bottom of the exhaust pipe, and the electric field stabilizi...

Embodiment 3

[0046] Such as Figure 5 As shown, a composite vehicle exhaust particle filtering device, the device includes a gas state detection sensor 1 arranged at the intake end of the exhaust pipe, an outer wall of the exhaust pipe 2 and an electric field stabilization device 3, parallel to the metal in the exhaust pipe The polar plate 9 provided by the filter screen 7 is connected to the high-voltage positive electrode, and the outer wall 2 of the exhaust pipe is grounded, so that an electrostatic field is formed in the exhaust pipe to pre-charge the exhaust particles. A metal filter screen 7 is provided to form an electrostatic field in the metal filter screen 7, and then the particles are collected under the joint action of the metal filter screen and the static electricity;

[0047] The electric field stabilizing device 3 made of ceramic body is arranged at the bottom of the exhaust pipe, and the electric field stabilizing device 3 is in the compressed air control pipeline 5, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com