HIGH-PERFORMANCE Al-Zn-Mg-Zr BASE ALUMINUM ALLOYS FOR WELDING AND ADDITIVE MANUFACTURING

An aluminum alloy, alloy technology, applied in welding/cutting medium/material, welding medium, additive processing, etc., can solve problems such as restricted use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153]The chemical composition and physical properties of the example alloy 1 (excluding ZR) and a new alloy containing Zr were compared in Table 2. Both alloys are fushed, followed by hot pressing into a blank, and then extruded into profiles. Although the two compositions have similar hardness after fusion, the alloy exhibits a time-effect hardening reaction during the heat treatment, and the example alloy is not (Figure 5 ). Not subject to the constraints of any particular theory, I believe this is the role of forming Al-X precursor during the heat treatment. Both alloys respond to the second thermal efficiency, forming a conventional Zn during the second time.2Mg precipitates and the alloy maintains the same incremental growth in hardness compared to the example alloy.

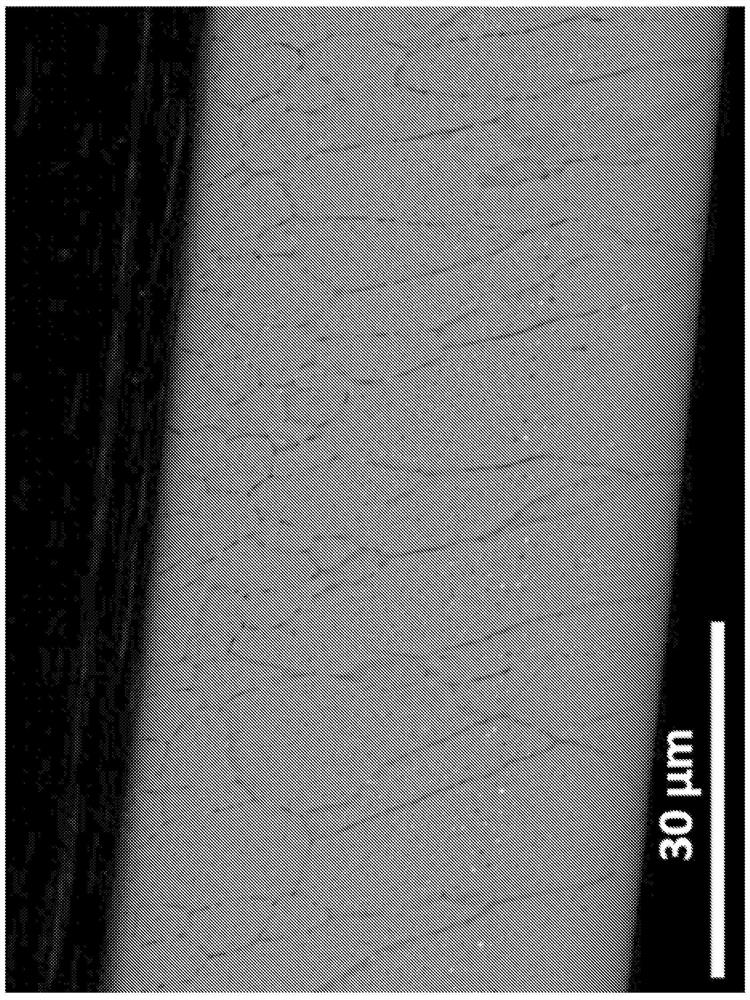

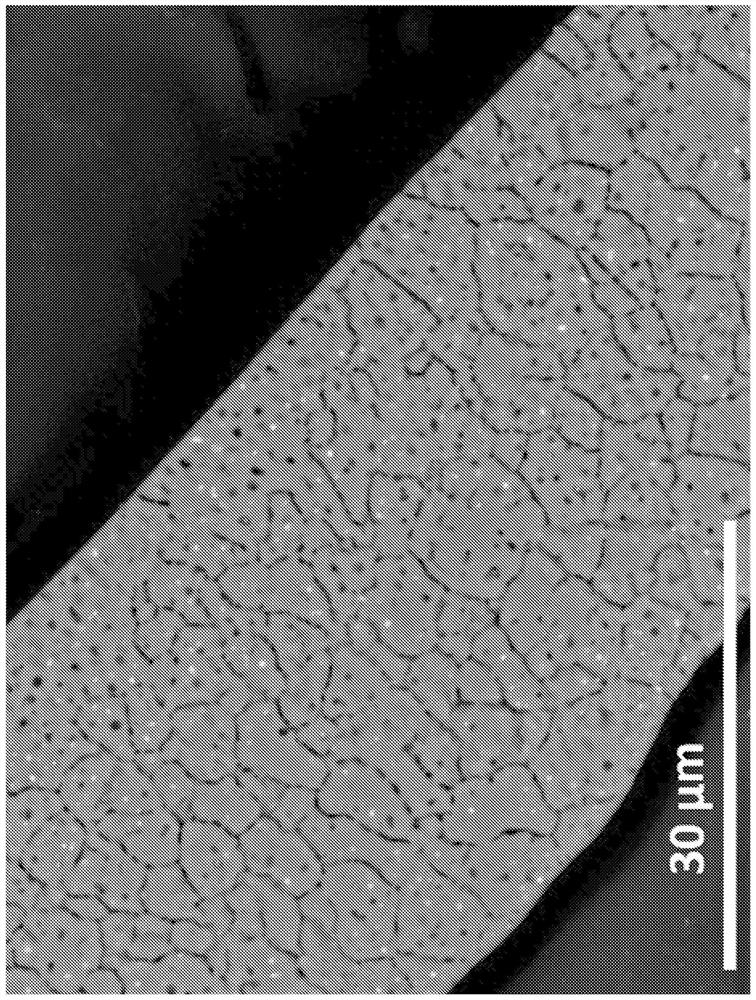

[0154]The addition of Zr allows the alloy to achieve a higher maximum strength, and the thermal stability is improved by maintaining fine grains during high temperature heat treatment, such asimage 3 (Example alloy...

Embodiment 2

[0159]A conventional 7000 series aluminum alloy has been prepared by a reducing manufacturing process, i.e., selective laser melting (SLM). Due to heat pulling problems, these attempts have no success (install alloy 1) [see Sistiaga publication HRL]. To this end, some researchers are committed to developing custom 7000 series alloys customized for AM process. An example is an Al-Zn-mg alloy (instant alloy 3) [ZHOU] added with a large amount of SC added.

[0160]Another solution is to blend the second powder of the aluminum alloy powder, which is used as a pregnancy agent (instance alloy 2) [HRL] of the fine crystal granuli nucleation during the solidification process. Although it is feasible, this method increases complexity and cost.

[0161]The alloy solves the heat pulling problem during the printing process without using expensive elements (such as 钪), and improves strength than other examples of 3D printing 7000 series aluminum.

[0162]Table 3 lists the performance of 7000 series alumi...

Embodiment 3

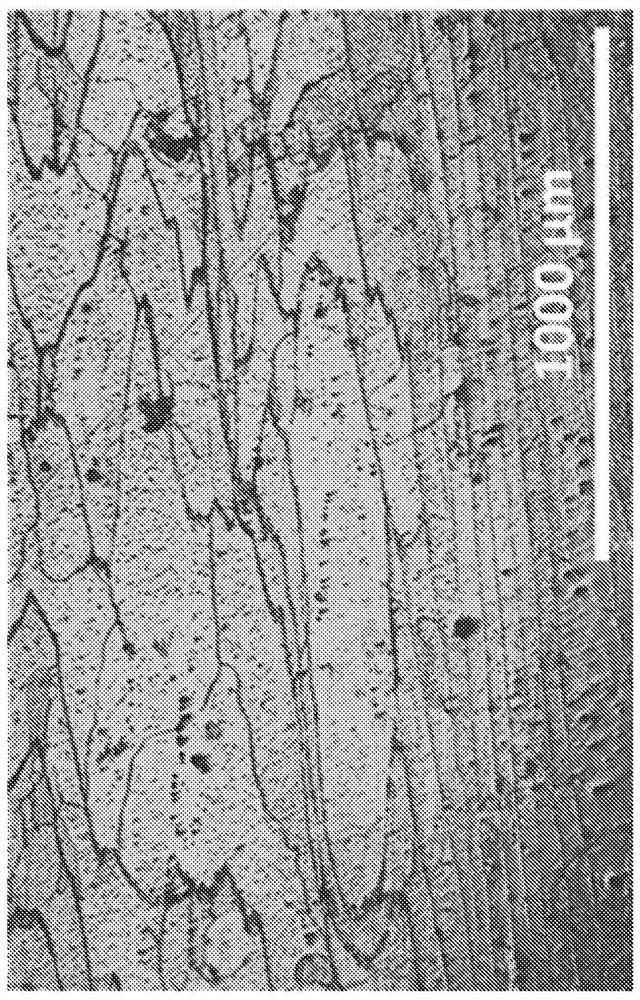

[0170]The 7000 series alloy can be prepared by a rapid solidification process and can be constructed by a conventional powder process. One such an alloy is a commercial production AA7034, which cuts the melt spinning with a fragment, and is formed into a blank by hot pressing, and extruded into a profile. In this example, a copper-free 7000 series alloy is made of a powder by a gas atomization (fast solidification process), and is formed into a blank by hot pressing, and is extruded into a profile (process 1). Also in this example, it is also a copper-free 7000 series alloy which is made of powder through gas atomization, and is directly squeezed into a molded material without the intermediate consolidation step (process 2).

[0171]Although mechanical properties are similar to commercially produced alloys, it is advantageous to eliminate copper in alloy chemistry, which improves weldability and corrosion resistance. The addition of zirconia is also advantageous for improved weldabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com