A kind of cu-cr-ag alloy crystallizer copper plate and its preparation process

A crystallizer copper plate, cu-cr-ag technology, applied in the field of continuous casting equipment components, can solve problems such as difficult to meet the high casting speed mold, high temperature creep of copper plate, low recrystallization temperature, etc., to solve the problem of thermal cracking, The effect of enhancing the material's high temperature creep resistance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation technology of Cu-Cr-Ag alloy crystallizer copper plate, it comprises the steps:

[0043] a. Obtain the cast slab of Cu-Cr-Ag alloy through vacuum smelting and vacuum casting, and its alloy formula and process are as follows:

[0044] Metal chromium mass percent: 0.2%, metallic silver mass percent: 0.14%, deoxidizer metallic magnesium mass percent: 0.04%, metallic copper mass percent: 99.62%,

[0045] Refining vacuum degree: ≤30Pa, refractory funnel aperture: 36mm, refining temperature: 1380°C, vacuum degree after filling with argon: -0.08MPa, pouring temperature: 1260°C;

[0046] b. After determining the forging deformation direction, the Cu-Cr-Ag alloy billet is hot forged, and the process is as follows:

[0047] Hot forging heating time: 3h, initial forging temperature: 910°C, forging deformation: 28mm, final forging temperature: 630°C;

[0048] c. The Cu-Cr-Ag alloy plate after hot forging is subjected to solid solution treatment, and the pr...

Embodiment 2

[0056] A kind of preparation technology of Cu-Cr-Ag alloy crystallizer copper plate, it comprises the steps:

[0057] a. Obtain the cast slab of Cu-Cr-Ag alloy through vacuum smelting and vacuum casting, and its alloy formula and process are as follows:

[0058] Metal chromium mass percent: 0.1%, metallic silver mass percent: 0.14%, deoxidizer metallic magnesium mass percent: 0.04%, metallic copper mass percent: 99.72%,

[0059] Refining vacuum degree: ≤30Pa, refractory funnel aperture: 36mm, refining temperature: 1380°C, vacuum degree after filling with argon: -0.08MPa, pouring temperature: 1260°C;

[0060] b. After determining the forging deformation direction, the Cu-Cr-Ag alloy billet is hot forged, and the process is as follows:

[0061] Hot forging heating time: 3h, initial forging temperature: 910°C, forging deformation: 28mm, final forging temperature: 630°C;

[0062] c. The Cu-Cr-Ag alloy plate after hot forging is subjected to solid solution treatment, and the pr...

Embodiment 3

[0070] A kind of preparation technology of Cu-Cr-Ag alloy crystallizer copper plate, it comprises the steps:

[0071] a. Obtain the cast slab of Cu-Cr-Ag alloy through vacuum smelting and vacuum casting, and its alloy formula and process are as follows:

[0072] Metal chromium mass percent: 0.2%, metallic silver mass percent: 0.8%, deoxidizer metallic magnesium mass percent: 0.04%, metallic copper mass percent: 99.68%,

[0073] Refining vacuum degree: ≤30Pa, refractory funnel aperture: 36mm, refining temperature: 1380°C, vacuum degree after filling with argon: -0.08MPa, pouring temperature: 1260°C;

[0074] b. After determining the forging deformation direction, the Cu-Cr-Ag alloy billet is hot forged, and the process is as follows:

[0075] Hot forging heating time: 3h, initial forging temperature: 910°C, forging deformation: 28mm, final forging temperature: 630°C;

[0076] c. The Cu-Cr-Ag alloy plate after hot forging is subjected to solid solution treatment, and the pro...

PUM

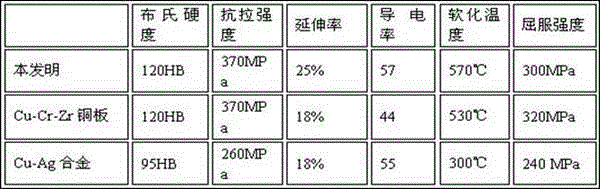

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com