Heat accumulation-exchange type heating stove and heating method thereof

A heating method and heating furnace technology, which are applied to lighting and heating equipment, furnaces, preheating costs, etc., can solve the problems of easy burning of the furnace door, rising smoke temperature of the heating furnace, short service life of the heating furnace, etc. Reduced maintenance costs, improved utilization of flue gas waste heat, and improved furnace environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is specifically described below by accompanying drawing:

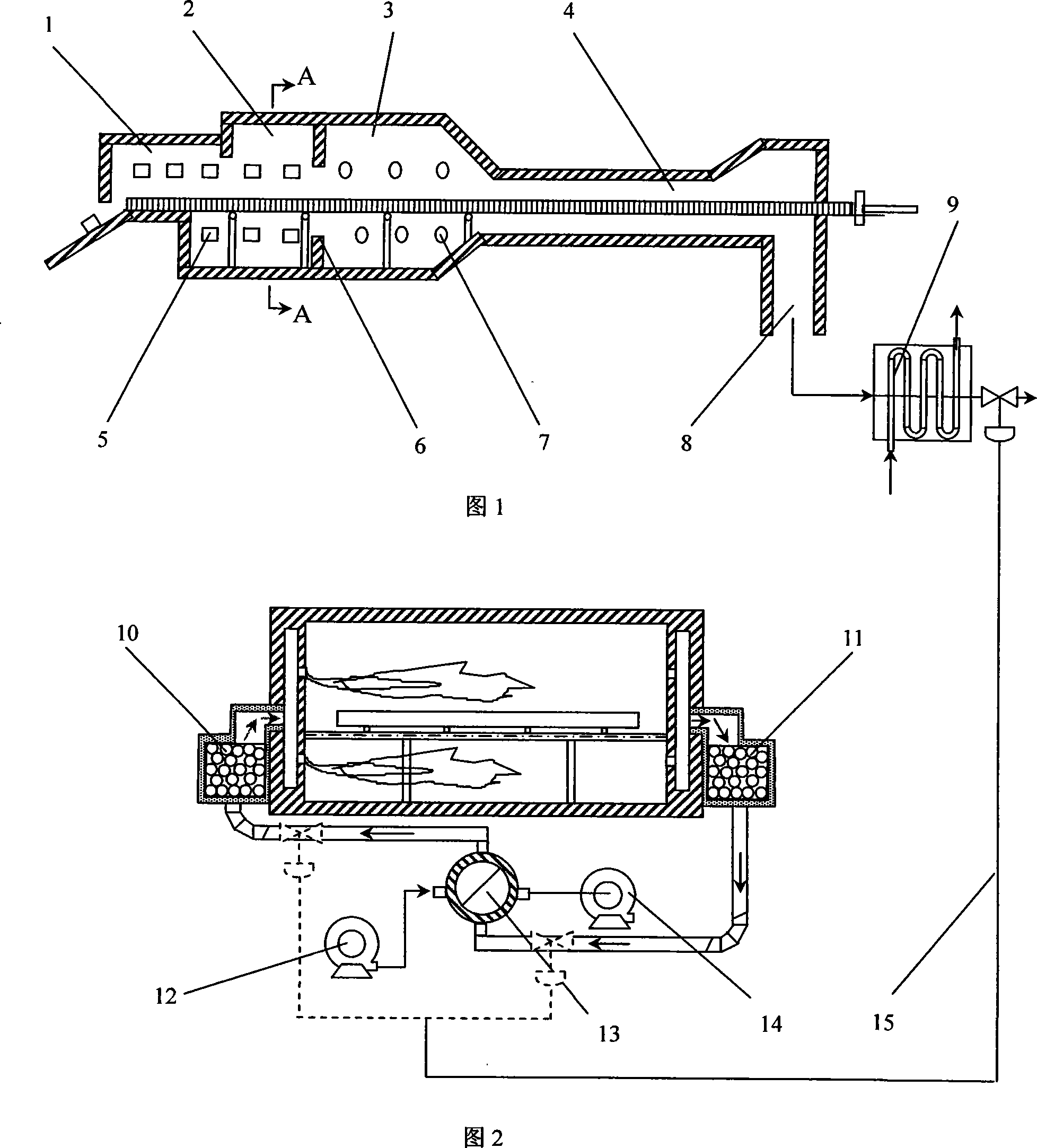

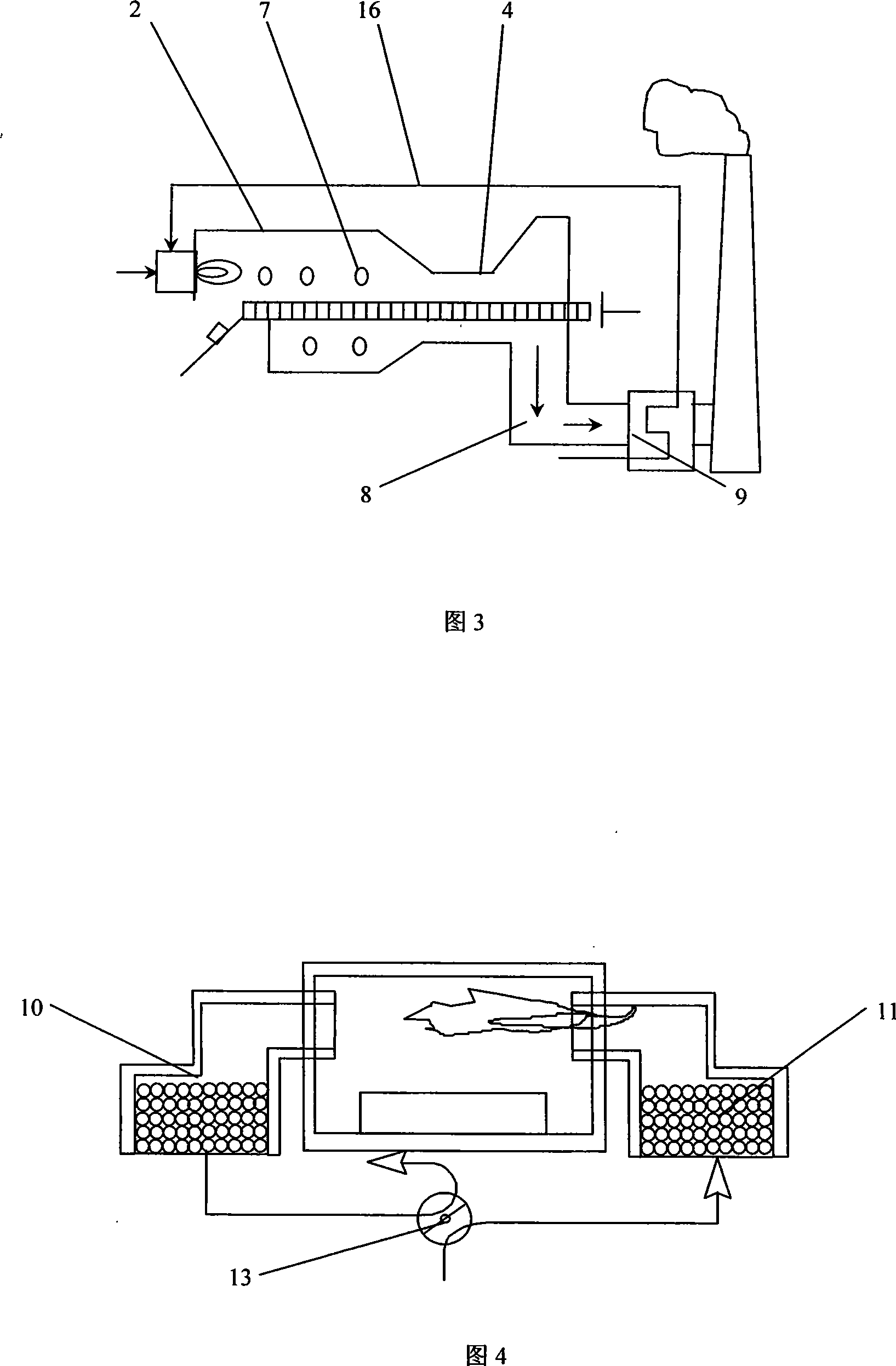

[0020] The technical solution adopted in the present invention is: to provide a heat storage-heat exchange combined heating furnace and its technology for recovering the waste heat of flue gas, using multiple points such as soaking section 1, heating section 2, 3 and preheating section 4 heating system. It can not only maintain high thermal efficiency and heating capacity, but also ensure the smooth operation of the heating furnace. The furnace takes into account the characteristics of both the regenerative heating furnace and the heat exchange heating furnace. It has both heat exchange burners and regenerative burners; it has both natural smoke exhaust from the chimney and forced smoke exhaust from the induced draft fan; both auxiliary Flue and heat exchanger, also has regenerator.

[0021] On the structure diagram of the heat storage-heat exchange combined heating furnace, there are hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com