Patents

Literature

436results about How to "Improve waste heat utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

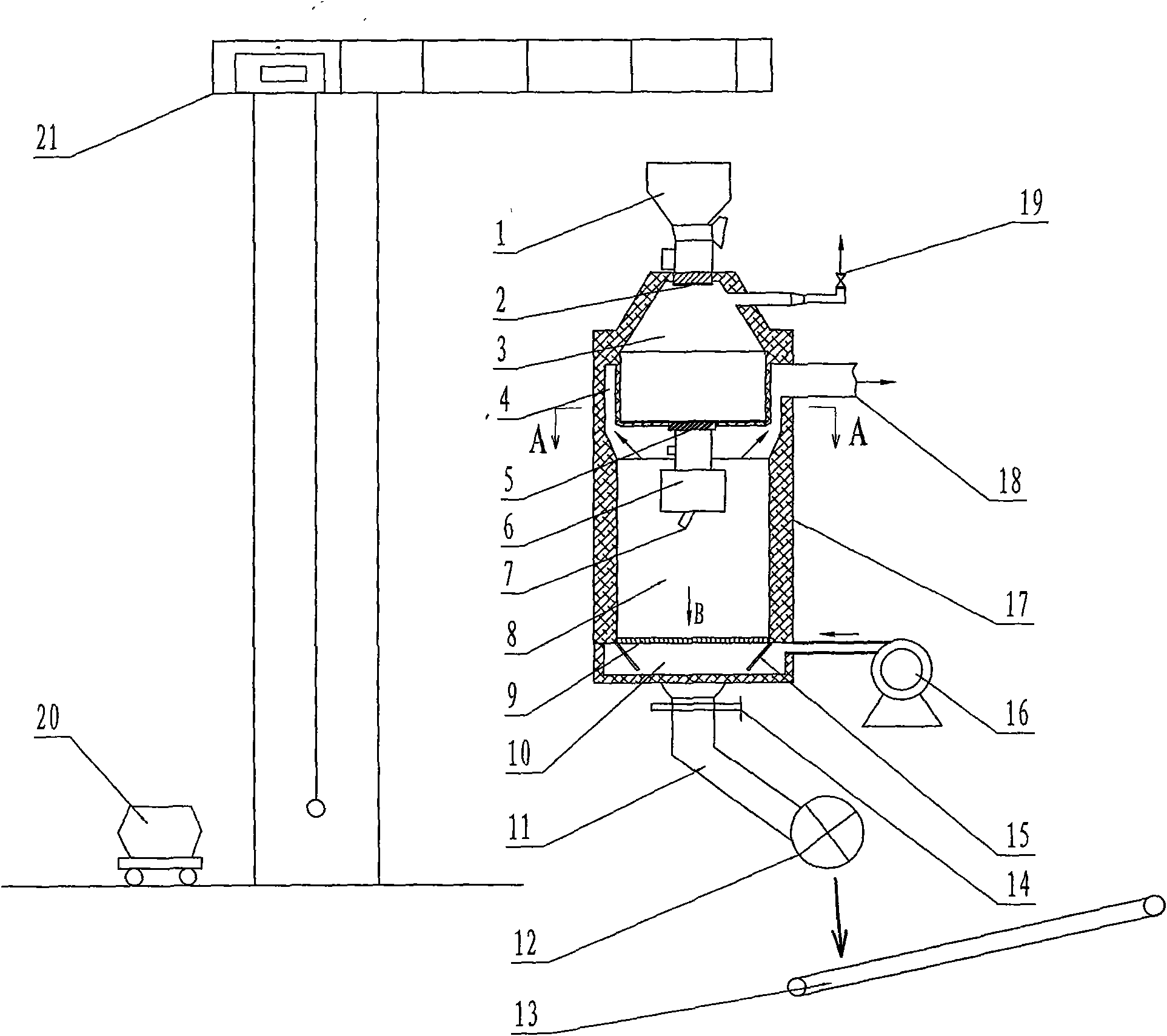

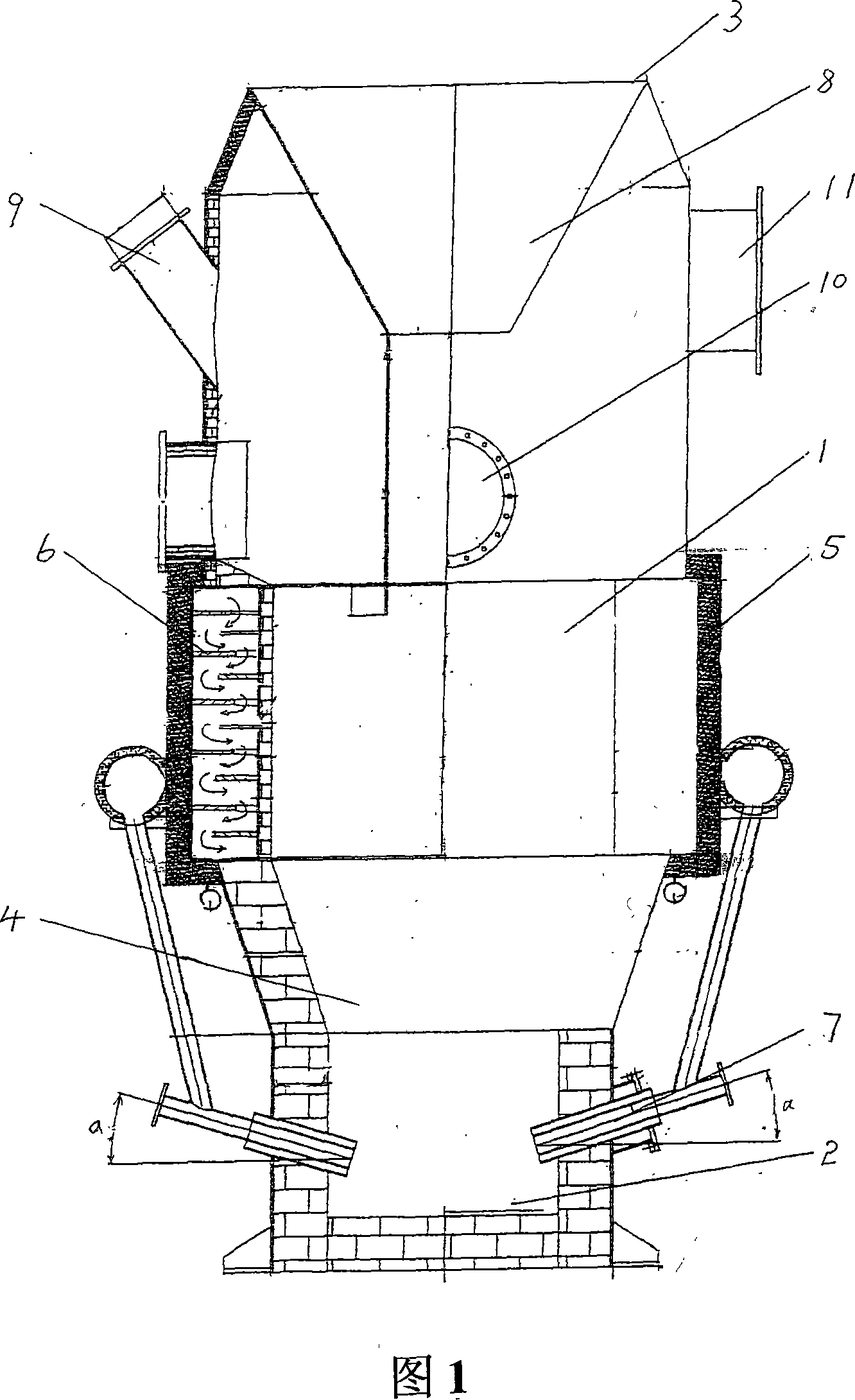

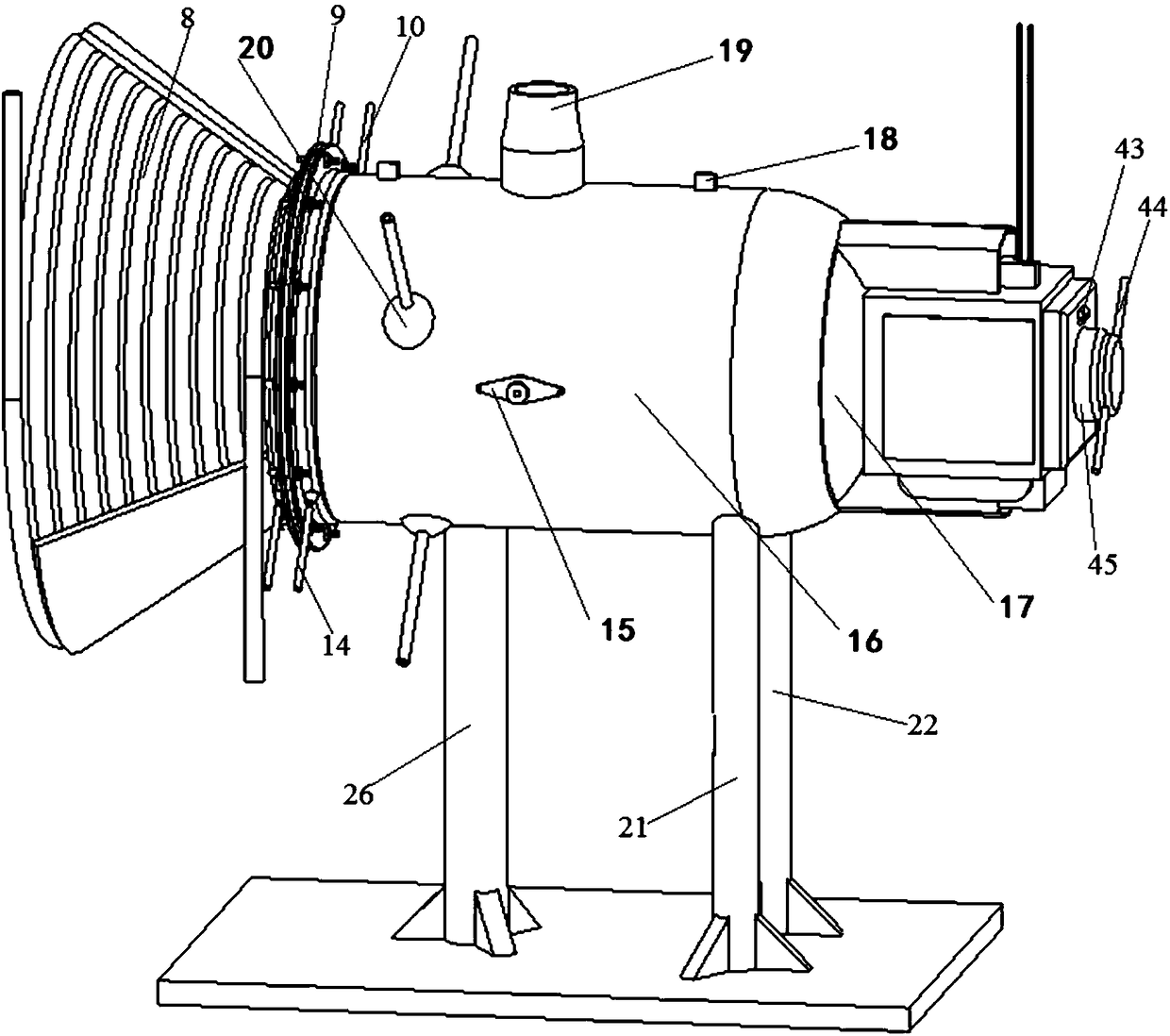

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Ammonia absorption type refrigerating apparatus utilizing waste heat of exhaust

InactiveCN1766462AEfficient use ofImprove waste heat utilizationBoilers/analysersEnergy efficient heating/coolingAmmonium hydroxideProcess engineering

The invention discloses an ammonia absorption refrigerating device of tail gas residual heat, which consists of ammonia solution circulation loop and ammonia circulation loop, wherein the pumped cooling high concentrated ammonia solution is given back to the residual heat generator to heat, which utilizes the heat of heat regenerator, finestiller coiler, generation-absorption heat exchanger and the combination body of exhausting device and heat regenerator; the cooling quantity of low-temperature ammonia steam from evaporator and liquid ammonia from condenser is withdrawn to improve the refrigeration coefficient. The invention adapts the tail gas to heat directly, which can be used in other non residual heat occasions.

Owner:ほう啓東

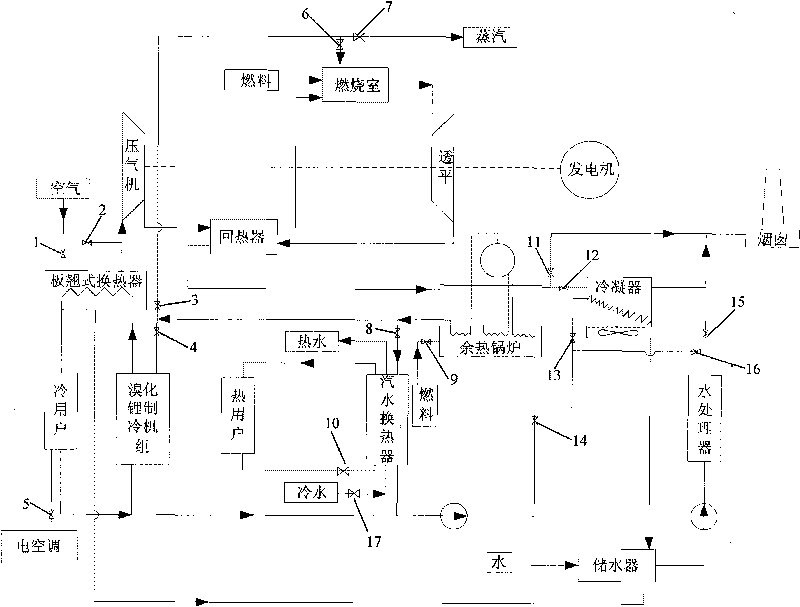

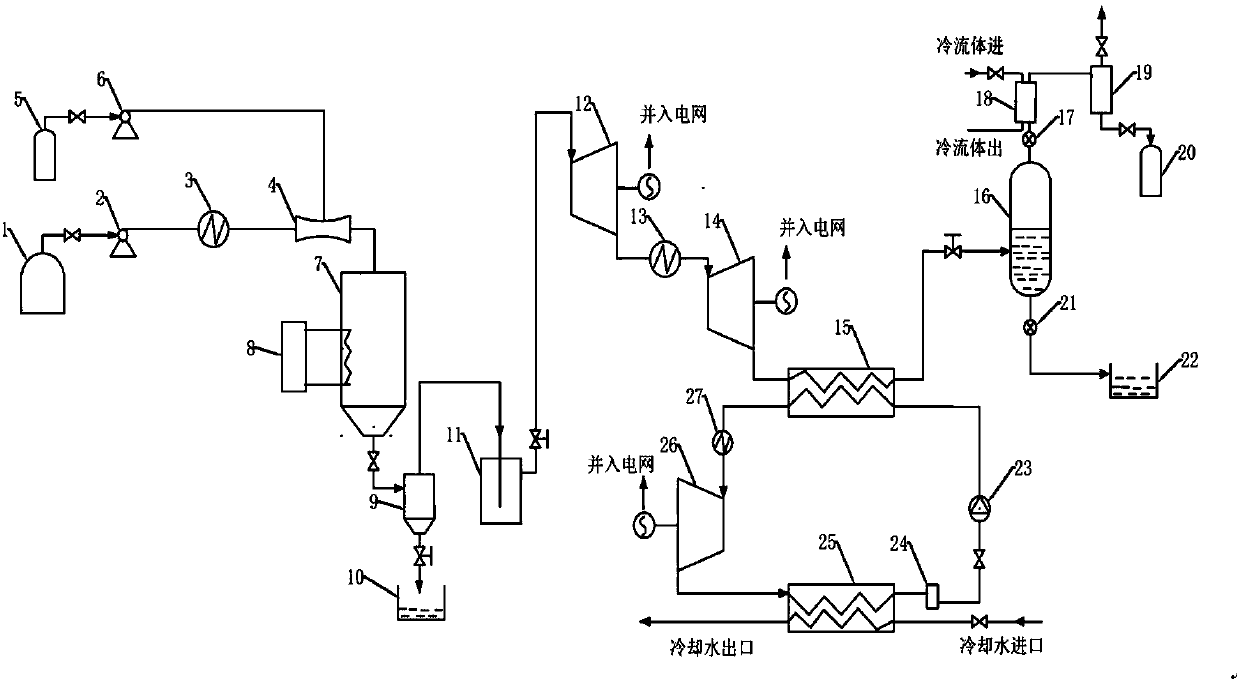

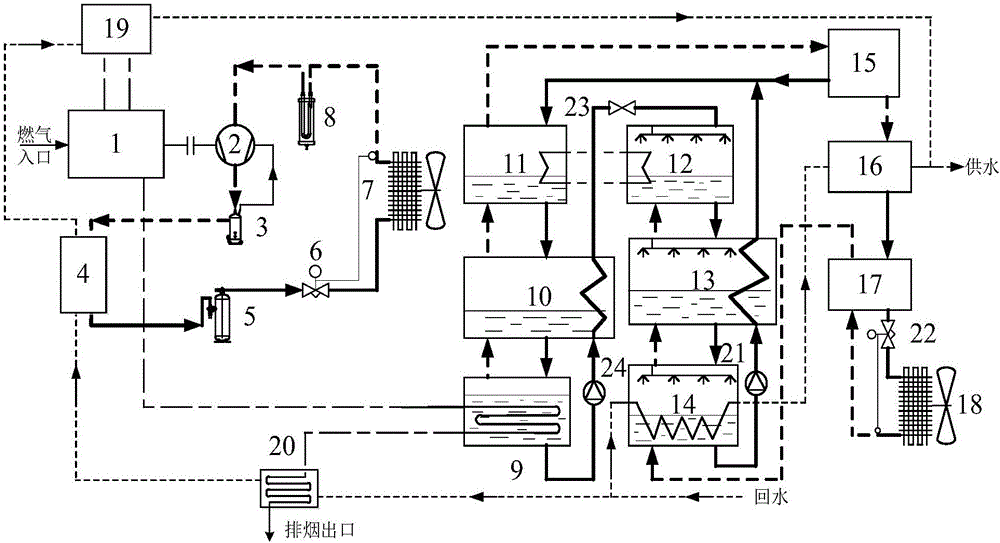

Heat and cool power cogeneration system of integrated multi-functional efficient mini-type gas turbine

InactiveCN101761392AIncrease power generationImprove power generation efficiencyClimate change adaptationGas turbine plantsElectricityCogeneration

The invention proposes a heat and cool power cogeneration system of an integrated multi-functional efficient mini-type gas turbine, which belongs to the novel heat and cool power cogeneration system device. To solve the frequent mismatching of cold and heat load and low efficiency operation of the conventional cogeneration system, measures such as steam reinjection, inlet gas cooling, gas fume and condensate water recovery are introduced on the basis of the heat and cool power cogeneration system of the mini-type gas turbine; in addition, the number of steam outlets and hot-water outlets is increased, thus forming the heat and cool power cogeneration system of the integrated multi-functional efficient mini-type gas turbine. The system is provided with various operation modes suitable for different occasions, can effectively solve the problem of mismatching of cold and heat load of the cogeneration system, so that the system can keep working in highly efficient mode.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement

ActiveCN105129744AImprove decomposition efficiencyIncrease concentrationSulfur compoundsClinker productionDecompositionPhosphogypsum

The invention relates to the technical field of industrial production of sulfuric acid and cement, the field of industrial solid waste comprehensive utilization, and the field of environment protection and treatment, and particularly relates to a pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement. The method includes the steps of powder grinding of raw materials, multi-stage cyclic pre-heating, high-effective decomposition and kiln gas separation and purification. The method is used for preparing a cement raw material from the phosphogypsum subjected to pre-heating decomposition with clay, sand rock, coke and such auxiliary materials in the process of producing the sulfuric acid from the phosphogypsum with co-production of the cement. The method solves the problems that a pre-heating decomposition technology in the prior art is low in decomposition ratio of phosphogypsum, is low in productivity of sulfuric acid and clinker, is liable to cause crusting and blocking in a kiln and is high in production energy consumption, can reduce the decomposition efficiency of the phosphogypsum and accelerate escape of SO2, and further increase the productivity of the sulfuric acid and cement clinker. The pre-heating decomposition method of producing the sulfuric acid from the phosphogypsum with co-production of the cement can significantly reduce sintering temperature and energy consumption of the clinker, can reduce production cost of sulfuric and cement clinker, and can further increase comprehensive utilization rate of the phosphogypsum.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

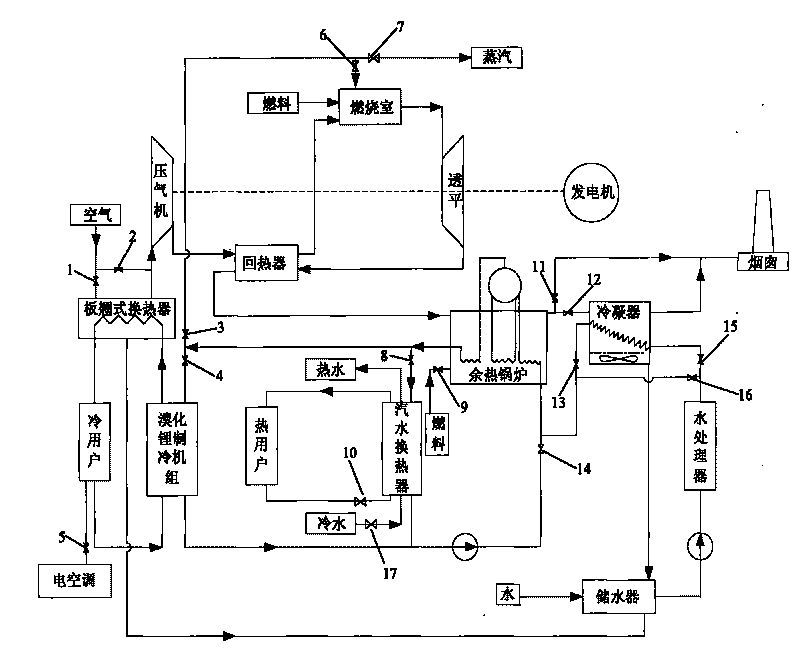

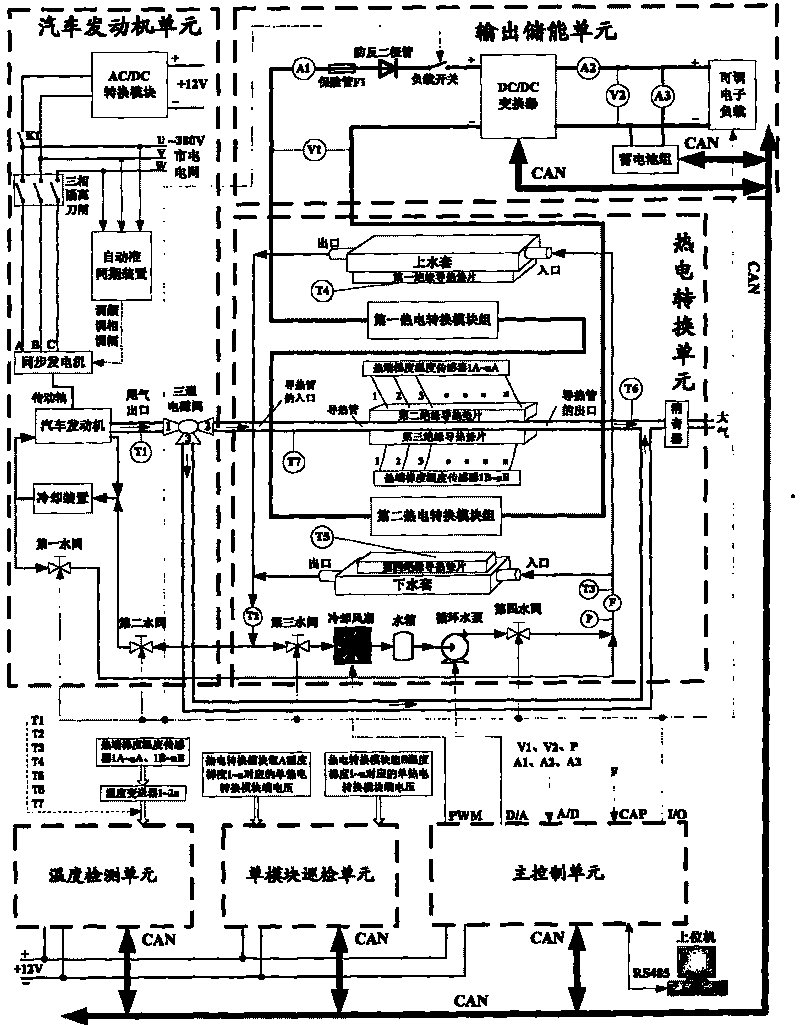

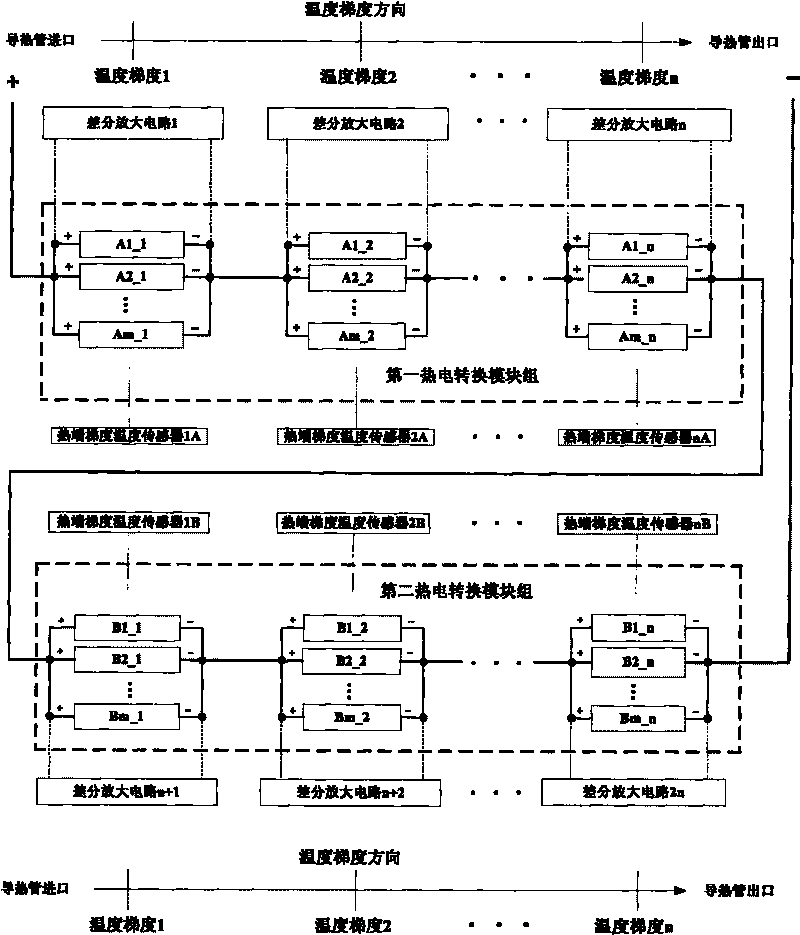

Automobile engine tail gas waste-heat and electricity converting stand test device and method for controlling same

InactiveCN101701873ALower internal resistanceAvoid wasteful deficienciesInternal-combustion engine testingElectricityTerminal voltage

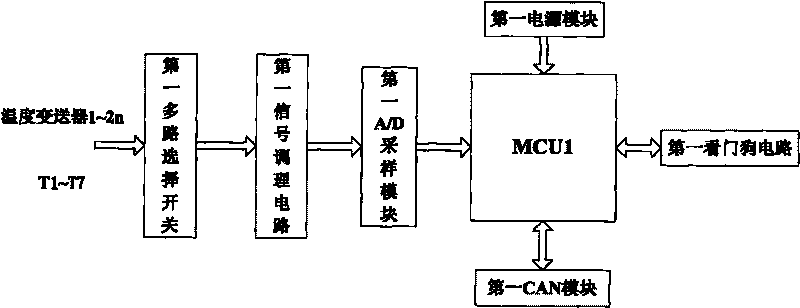

The invention relates to an automobile engine tail gas waste-heat and electricity converting stand test device and method for controlling the same. The automobile engine tail gas waste-heat and electricity converting stand test device comprises an automobile engine unit, a waste-heat and electricity converting unit, an outputting and energy storing unit, a temperature detecting unit, a single-module patrolling unit and a main control unit and is characterize in that the automobile engine unit uses an automobile engine to drive a power generator to generate power to be combined to the three-phase commercial power and exhaust the high-temperature tail gas; the waste-heat and electricity converting unit absorbs the waste-heat from the tail gas and converts the waste-heat into the DC electricity; the outputting and energy storing unit changes the voltage of the generated DC electricity so as to supply the DC electricity to the load or store the DC electricity; the temperature detecting unit detects the temperature information of all the units; the single-module patrolling unit patrols the terminal voltages of waste-heat and electricity converting modules which are connected in parallel under each temperature gradient; and the main control unit detects the outputted voltage, the outputted current and other parameters, sends the control information and comprehensively manages the energy. The automobile engine tail gas waste-heat and electricity converting stand test device can simulate the automobile-mounted running environment and is suitable for the test and the research of the automobile engine tail gas waste-heat and electricity conversion.

Owner:WUHAN UNIV OF TECH

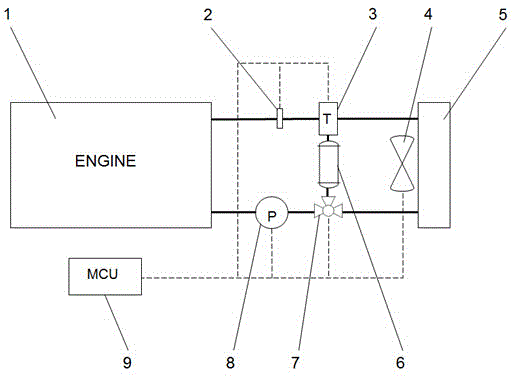

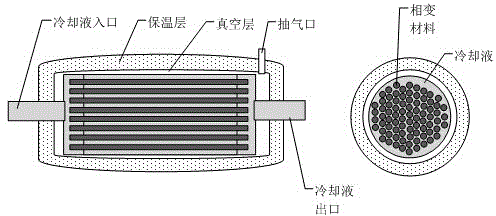

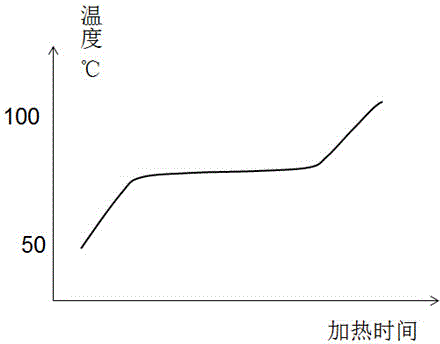

Engine coolant waste heat utilization engine warming system adopting solid-liquid phase change heat reservoir and method of engine coolant waste heat utilization engine warming system

ActiveCN104989548AImprove waste heat utilizationSolve the problem of waste heat utilizationCoolant flow controlInternal combustion piston enginesEnergy preservationCoolant flow

The invention discloses an engine coolant waste heat utilization engine warming system adopting a solid-liquid phase change heat reservoir and a method of the engine coolant waste heat utilization engine warming system. The system comprises a temperature sensor, an electronic thermostat, an electronic fan, a radiator, the solid-liquid phase change heat reservoir, an electronic three-way valve and an MCU. Coolant flows through the phase change heat reservoir to heat phase change materials. The phase change happens to the phase change materials, the phase change materials absorb a large amount of latent heat, and residual heat of an engine is transferred into the phase change heat reservoir to be stored and used for starting engine warming. The electronic thermostat and the electronic three-way valve are controlled by the MCU and kept running synchronously all the time. The premise that normal work of an engine cooling system is not influenced is ensured. After the engine stops, large circulation is closed through the electronic thermostat and the electronic three-way valve. The phase change heat reservoir is sealed and enters the energy preservation state. Thus, under the condition that the existing engine power consumption is hardly increased, waste heat recycle is achieved. The engine warming starting process is achieved under the condition that the engine power consumption is not increased.

Owner:ZHEJIANG UNIV +1

Supercritical-water-oxidation energy recovery system

PendingCN107935287AEmission reductionReduce energy inputWater/sewage treatment by centrifugal separationWater treatment parameter controlInorganic saltsSewage outfall

The invention discloses a supercritical-water-oxidation energy recovery system. The supercritical-water-oxidation energy recovery system disclosed by the invention has the beneficial effects that theoutlet end of a supercritical water oxidation reactor is connected with a high-pressure hydrocyclone, inorganic salts in reaction products in the supercritical water oxidation reactor are discharged from a sewage discharging port, high-pressure and high-pressure gas generated is exhausted into a buffering tank to carry out flat-pressing treatment, then the flatly-pressed gas passes through a high-pressure turboexpander and a low-pressure turboexpander in sequence to carry out residual-heat utilization for generating power, an outlet of the low-pressure turboexpander is connected with an evaporator, a Rankine circulation system is connected on the evaporator and is utilized for further utilizing residual heat of fluid passing through the evaporator, so that the energy input of the Rankine circulation system is reduced; the supercritical water oxidation system and a residual-heat and residual-pressure recovery system are fully combined, and heat energy and pressure energy of supercritical water oxidation products are fully utilized, so that the energy recovery and utilization rate of the supercritical water oxidation system is increased; carbon dioxide in the products is separated and recovered by utilizing a gas-liquid separator and a rectifying tower, so that the emission of greenhouse gas is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

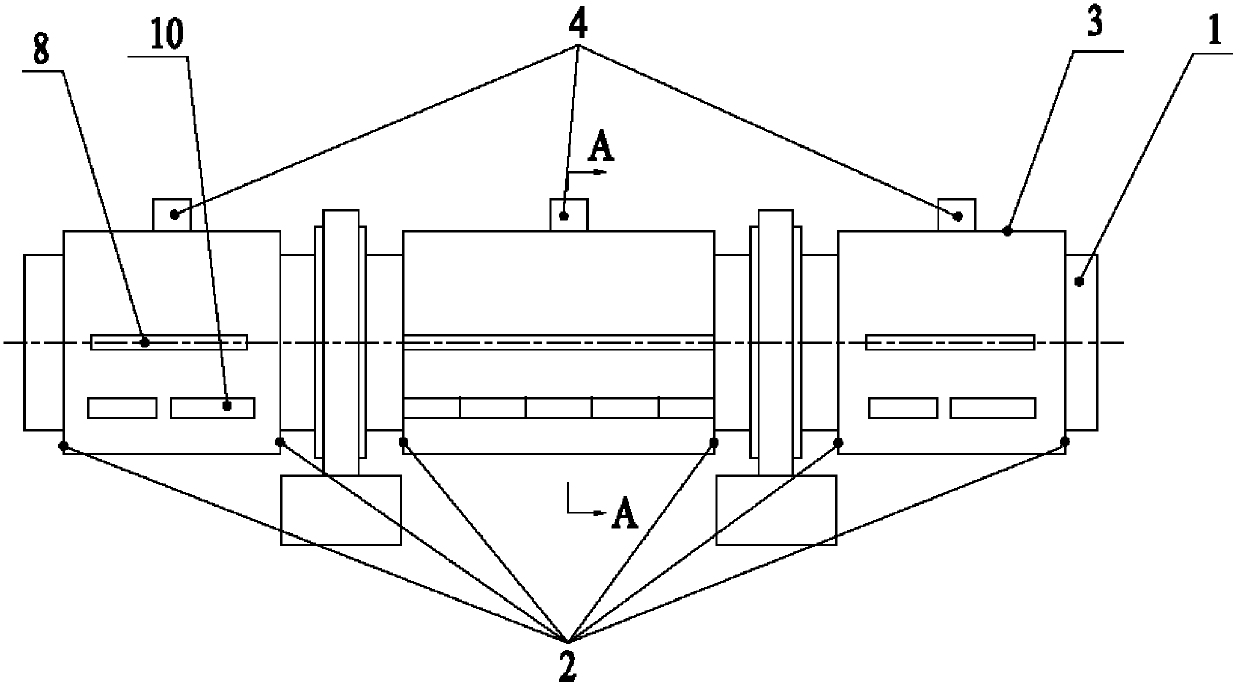

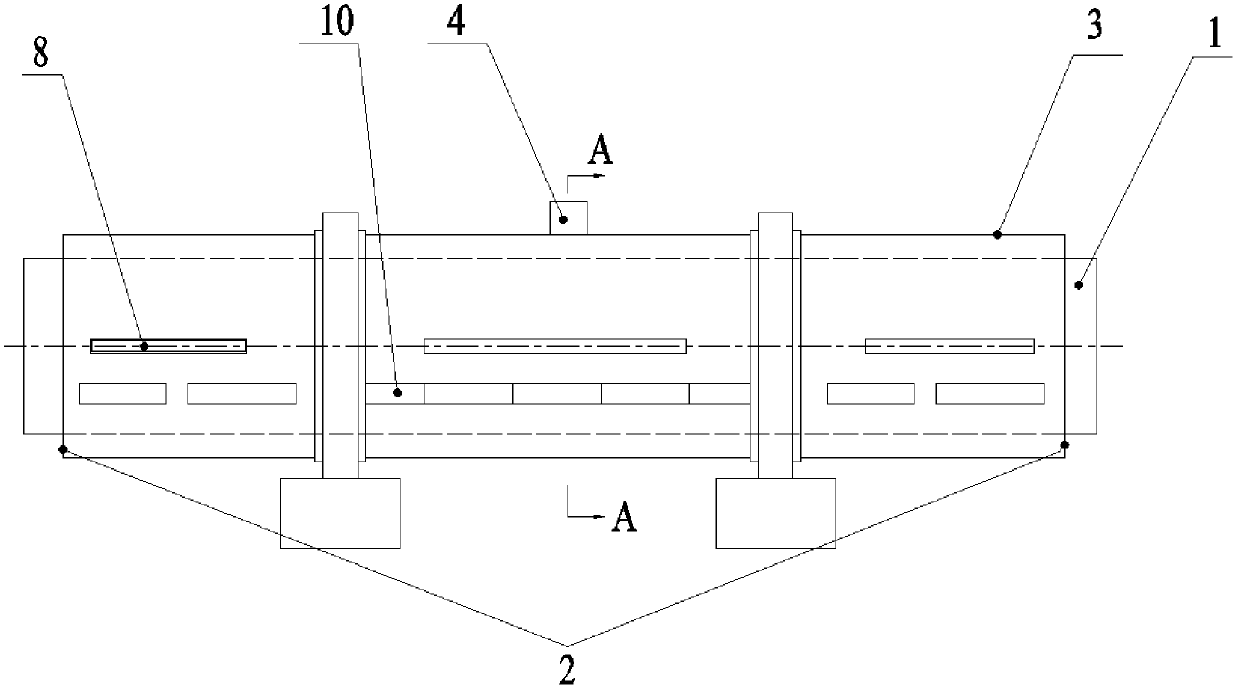

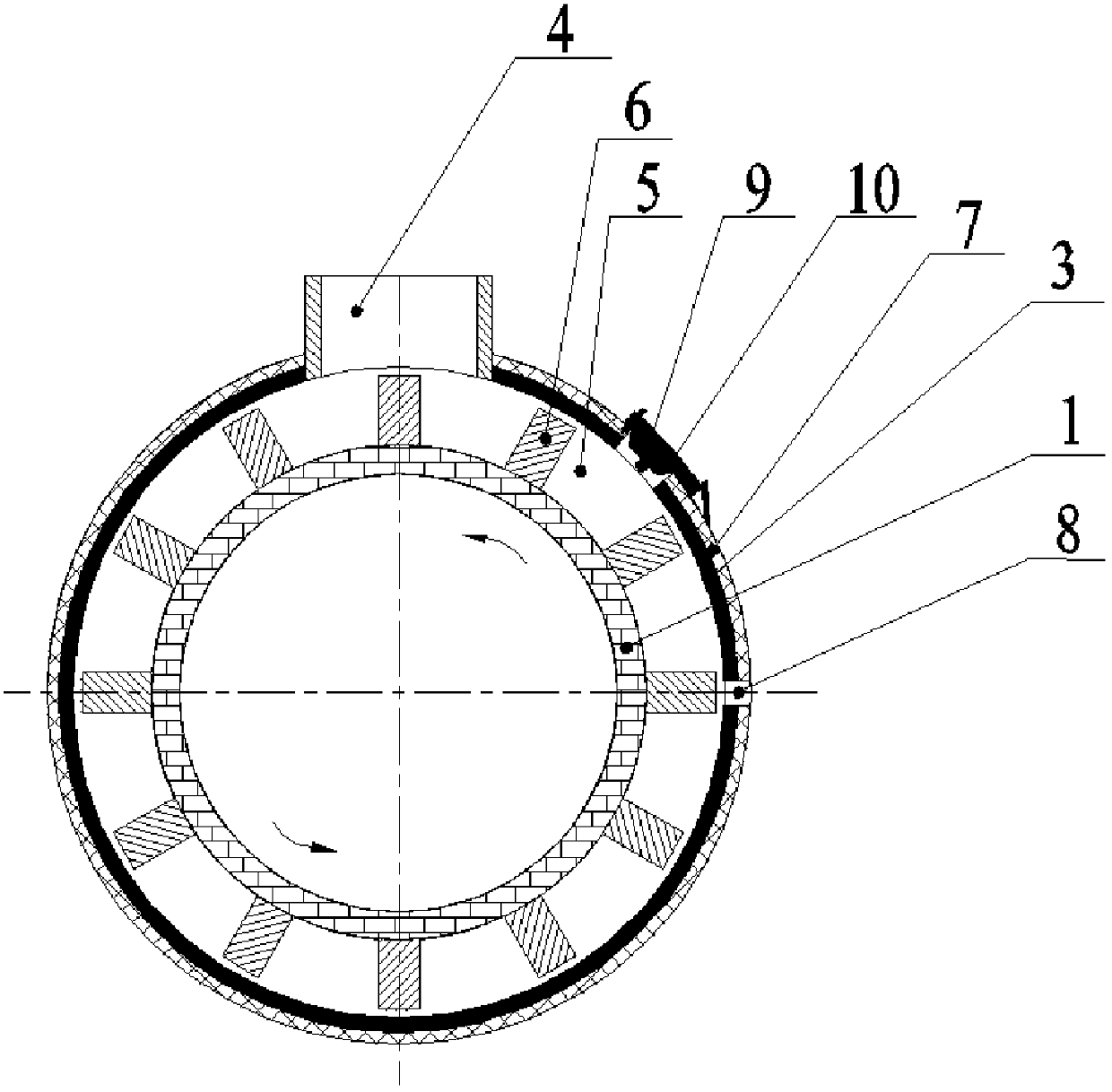

Cylinder wall residual heat recovery and heat transfer device of dry method cement rotary kiln

InactiveCN102636022AIncrease power generationHigh utilization rate of waste heat and high reliabilityRotary drum furnacesIncreasing energy efficiencyCement kilnSurface heat

The invention discloses a cylinder wall residual heat recovery method and heat transfer device of a dry method cement rotary kiln. A section or multiple sections of fixed outer cylinder walls are sleeved on the outer side of a kiln body of a cement rotary kiln; working medium inlets are arranged at two ends of the outer cylinder wall; an interval is maintained between the kiln body of the cement rotary kiln and the outer cylinder wall and a working medium flow channel and a heat transfer space are formed; the middle part of the outer cylinder wall is provided with a working medium outlet; a cold heat transfer working medium can enter the interval between two cylinder bodies from two ends of each section of outer cylinder wall; the heated working medium is discharged from the fixed outlet at the middle part of the section so as to be supplied to an external heat utilization system and the surface residual heat recovery of the cement rotary kiln is finished. According to the invention, on the basis that the structure of the existing cement rotary kiln body is not changed and the operation of the existing cement rotary kiln body is not influenced, the wasted surface heat of the cement rotary kiln is recovered, not only can the cement production comprehensive energy consumption be reduced, but also the cement kiln body can be protected from exceeding the temperature, and the service life of the cement rotary kiln body is prolonged.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

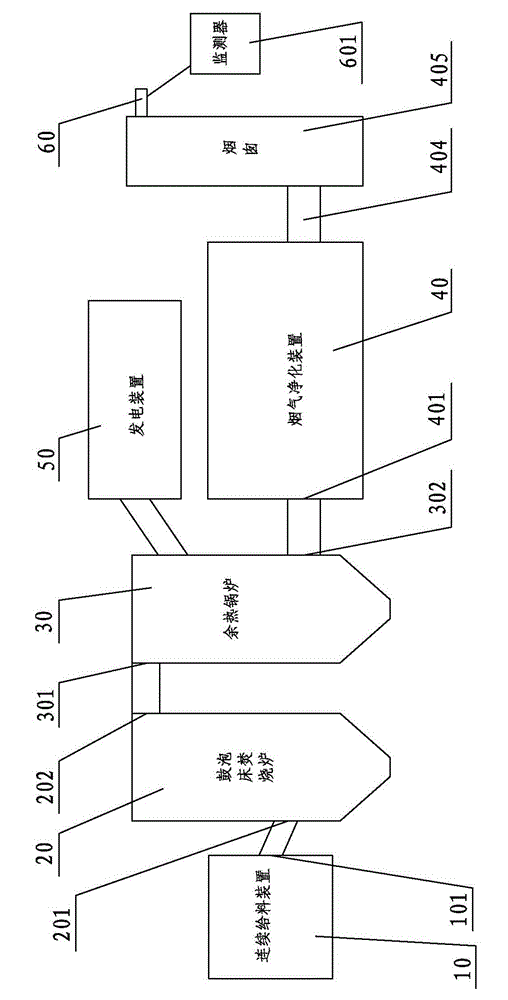

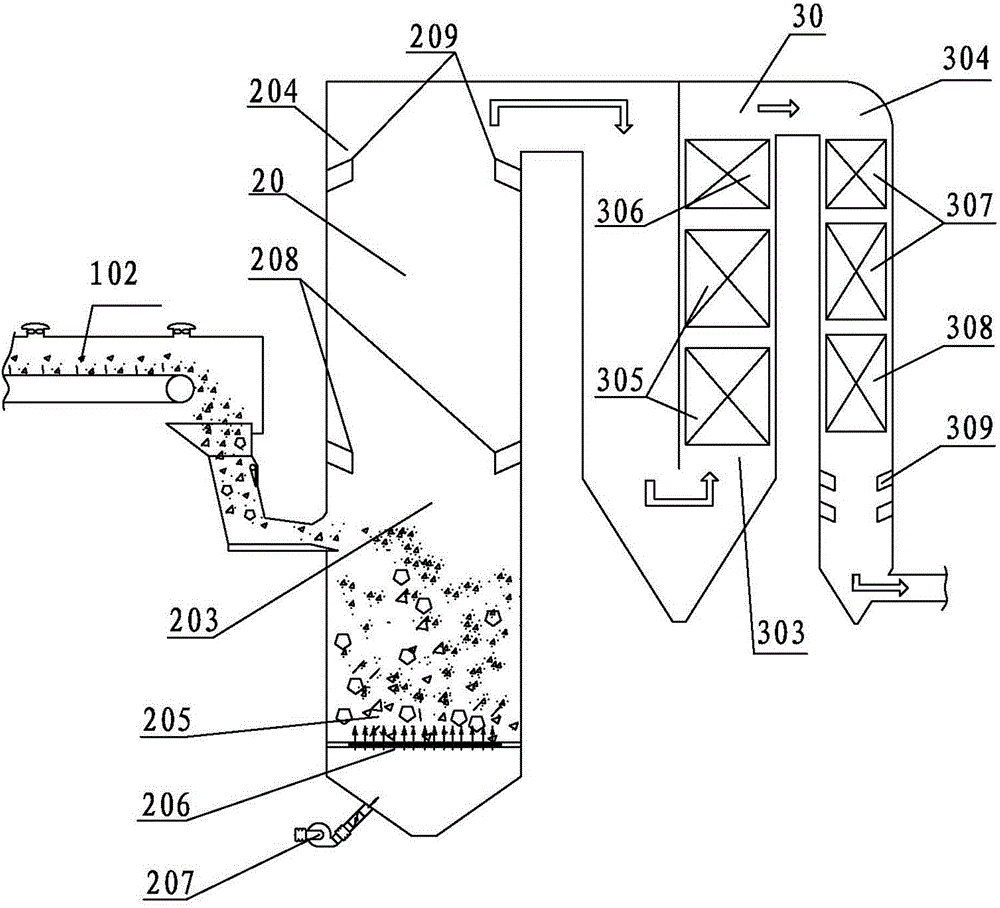

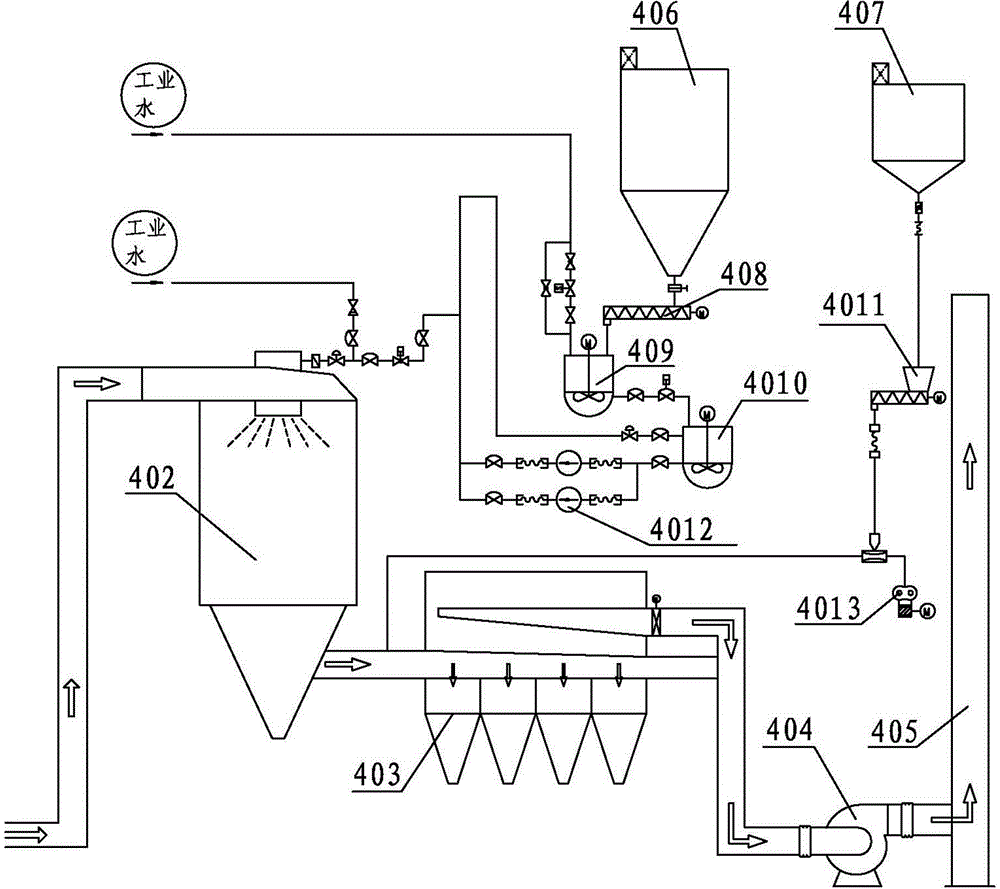

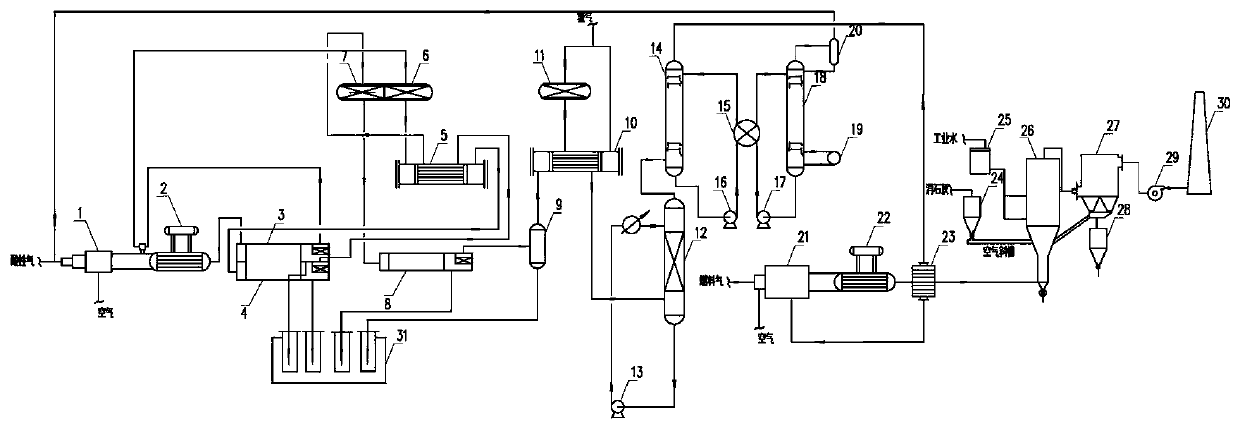

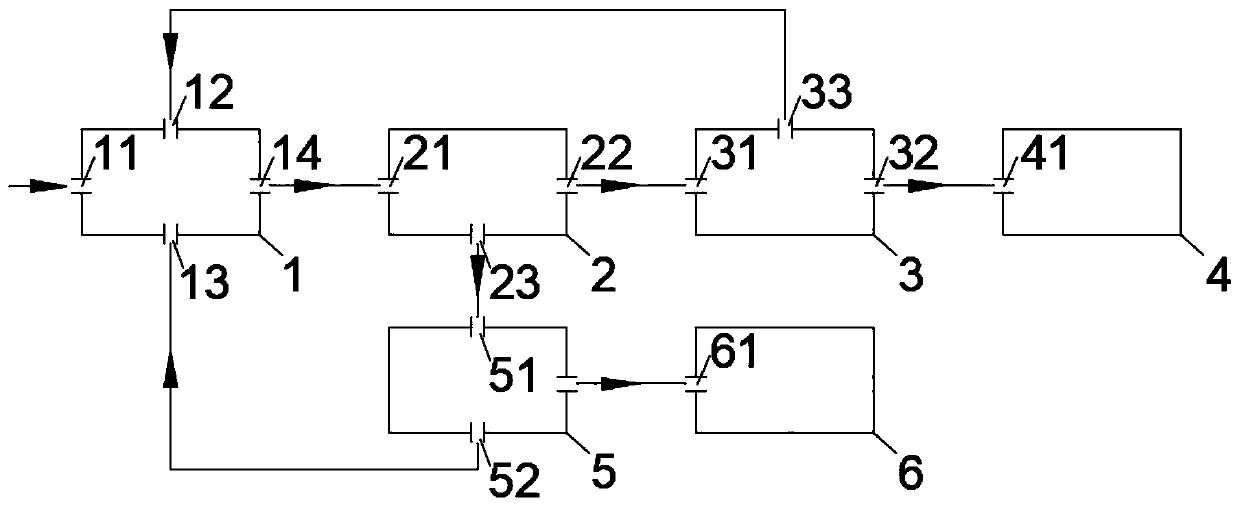

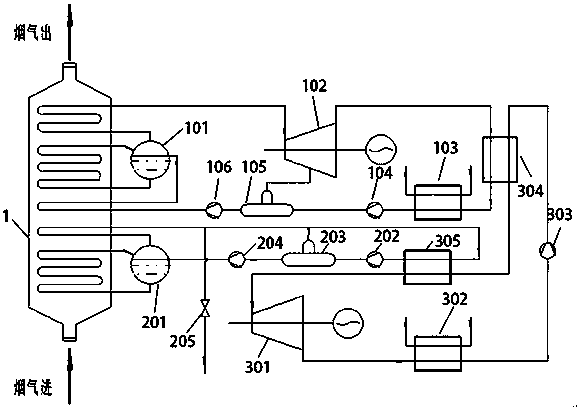

Burning and waste heat power generation system for hazardous wastes

ActiveCN102944018AImprove waste heat utilizationReduce pollutionSteam engine plantsIncinerator apparatusFlue gasProcess engineering

Disclosed is a burning and waste heat power generation system for hazardous wastes. The burning and waste heat power generation system comprises a continuous feeding device, a flue gas purifying device, a power generation device, an online monitoring device, a bubbling bed incinerator and a waste heat boiler. The continuous feeding device is provided with a discharge port, the bubbling bed incinerator is provided with a feed port and an A flue gas outlet. The feed port of the bubbling bed incinerator is connected with the discharge port of the continuous feeding device; the waste heat boiler is provided with an A flue gas inlet and a B flue gas outlet, and the A flue gas outlet is connected with the A flue gas inlet of the waste heat boiler through a pipeline; the flue gas purifying device is provided with a B flue gas inlet, and the B flue gas outlet of the waste heat boiler is connected with the B flue gas inlet of the gas purifying device through a pipeline; and the power generation device is connected with the waste heat boiler through a main steam pipeline. According to the burning and waste heat power generation system for hazardous wastes, high-temperature flue gas produced by burning of deinking residues enters the waste heat boiler to absorb heat and produce superheated steam which is used for generating power, and accordingly, electric energy is added, and purposes of using flue gas waste heat for generating power and reducing environmental pollution are achieved.

Owner:广东新开能工程技术有限公司

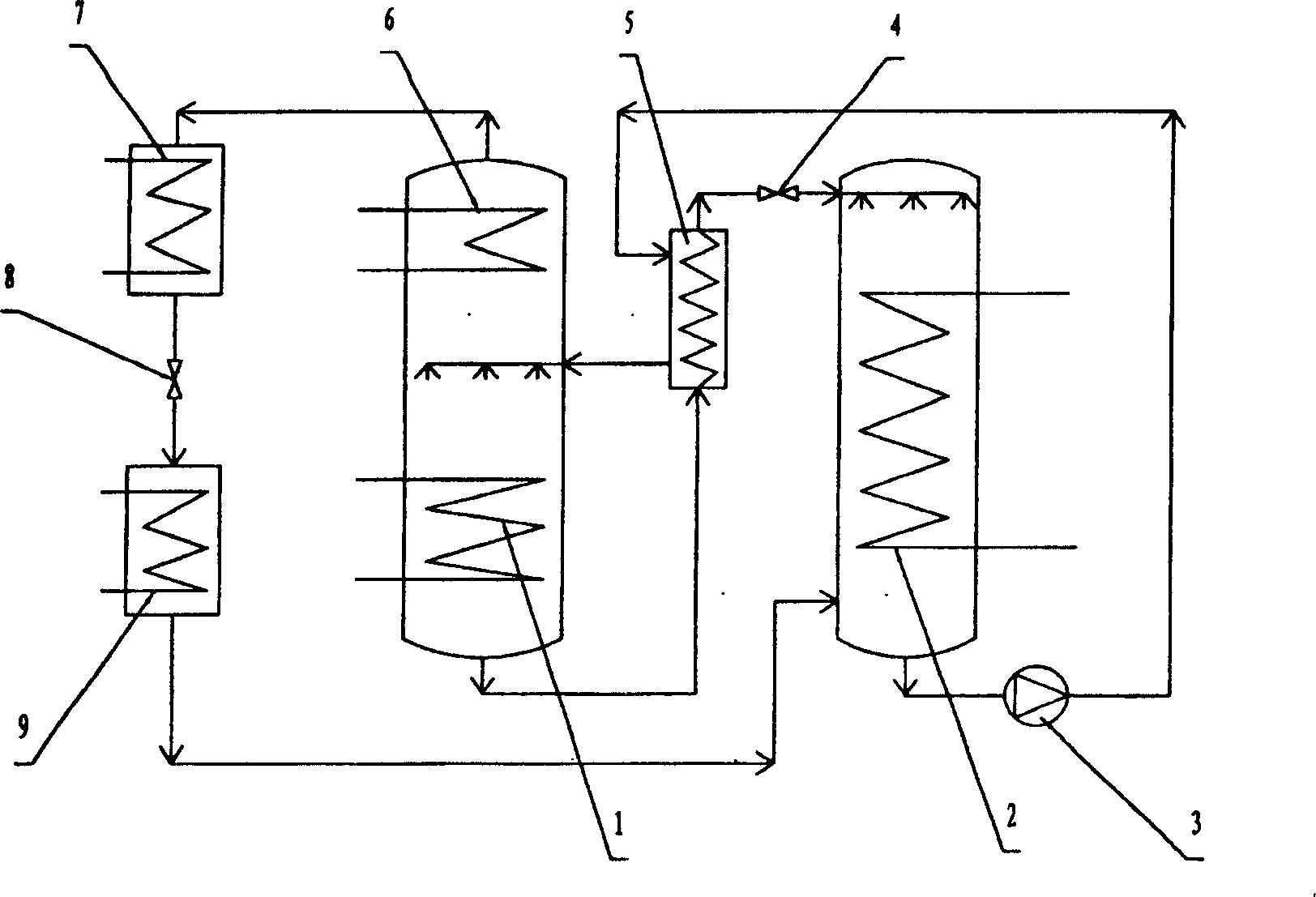

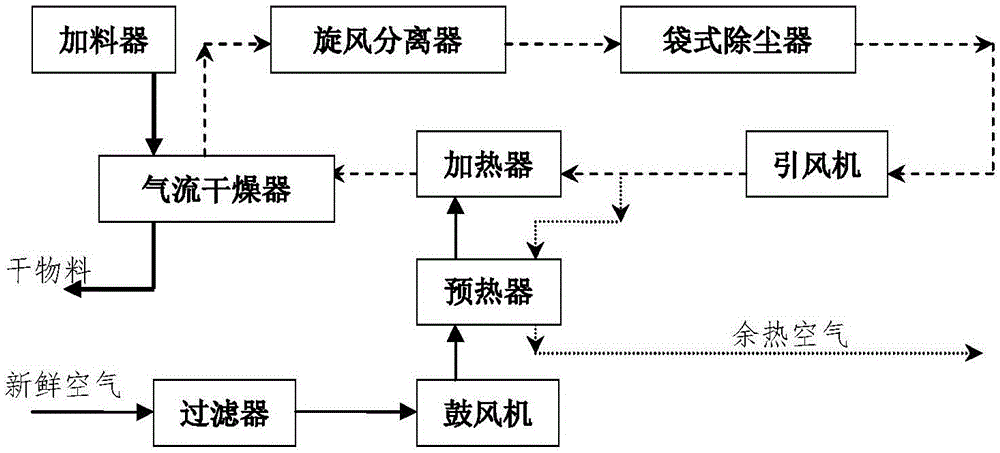

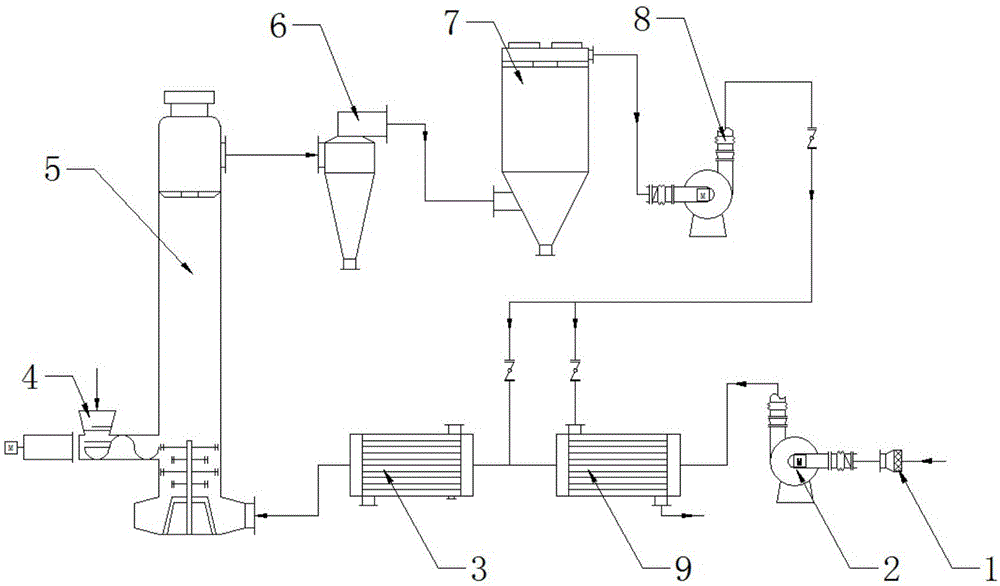

Airflow energy-saving drying device and airflow energy-saving drying method

ActiveCN105115283AReduce consumptionNo oxidationSludge treatment by de-watering/drying/thickeningDrying gas arrangementsBaghouseWaste management

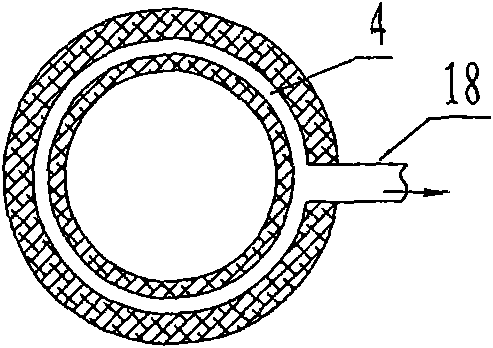

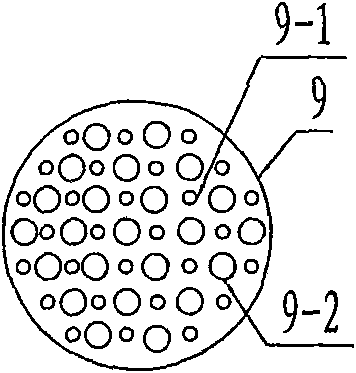

The invention discloses an airflow energy-saving drying device and an airflow energy-saving drying method and belongs to the field of drying and energy saving. The device comprises a filter (1), an air blower (2), a heater (3), a feeder (4), an airflow dryer (5), a cyclone separator (6), a bag dust remover (7), an induced draft fan (8) and a pre-heater (9), wherein the filter (1) is connected to an inlet of the air blower (2); the air blower (2) is connected to an inlet of the pre-heater (9); an outlet of the pre-heater (9) is connected to an inlet of the heater (3); an outlet of the heater (3) is connected to an inlet of the airflow dryer (5); the airflow dryer (5), the cyclone separator (6), the bag dust remover (7) and the induced draft fan (8) are connected with one another in sequence; an outlet of the induced draft fan (8) is simultaneously connected with the pre-heater (9) and the heater (3). The airflow energy-saving drying device and the airflow energy-saving drying method are capable of recycling the waste heat of the airflow drying tail gas to the maximum extent; the problem of accumulation of moisture in circulating air is solved; the operation load of the device is effectively reduced.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

Gas engine driven heat pump defrosting device

InactiveCN101012989ASolve the phenomenon of indoor temperature fluctuating hot and coldIndoor side heating is not affectedInternal combustion piston enginesEnergy industryFour-way valveControl system

The invention relates to a heat pump defrost device driven by the gas turbine, which can combine the abundant heat utilization and the heat pump defrost techniques. The invention comprises a heating defrost circulator, a cooling water circulator and a control system, wherein, the defrost circulator via the thermal-insulated water box is connected with the cooling water circulator; and the defrost circulator and the cooling water circulator are connected with the control system electrically. In the defrost process, the invention recycles the heat of engine and discharge smoke, via the water circulator to be stored in the thermal-insulated water box, to utilize the energy of stored hot water of water box to defrost. And in the defrost process, the four-way valve is not steered, to avoid affecting the indoor heat supply. The invention can supply hot water at 70Deg. C without defrosting.

Owner:SOUTHEAST UNIV

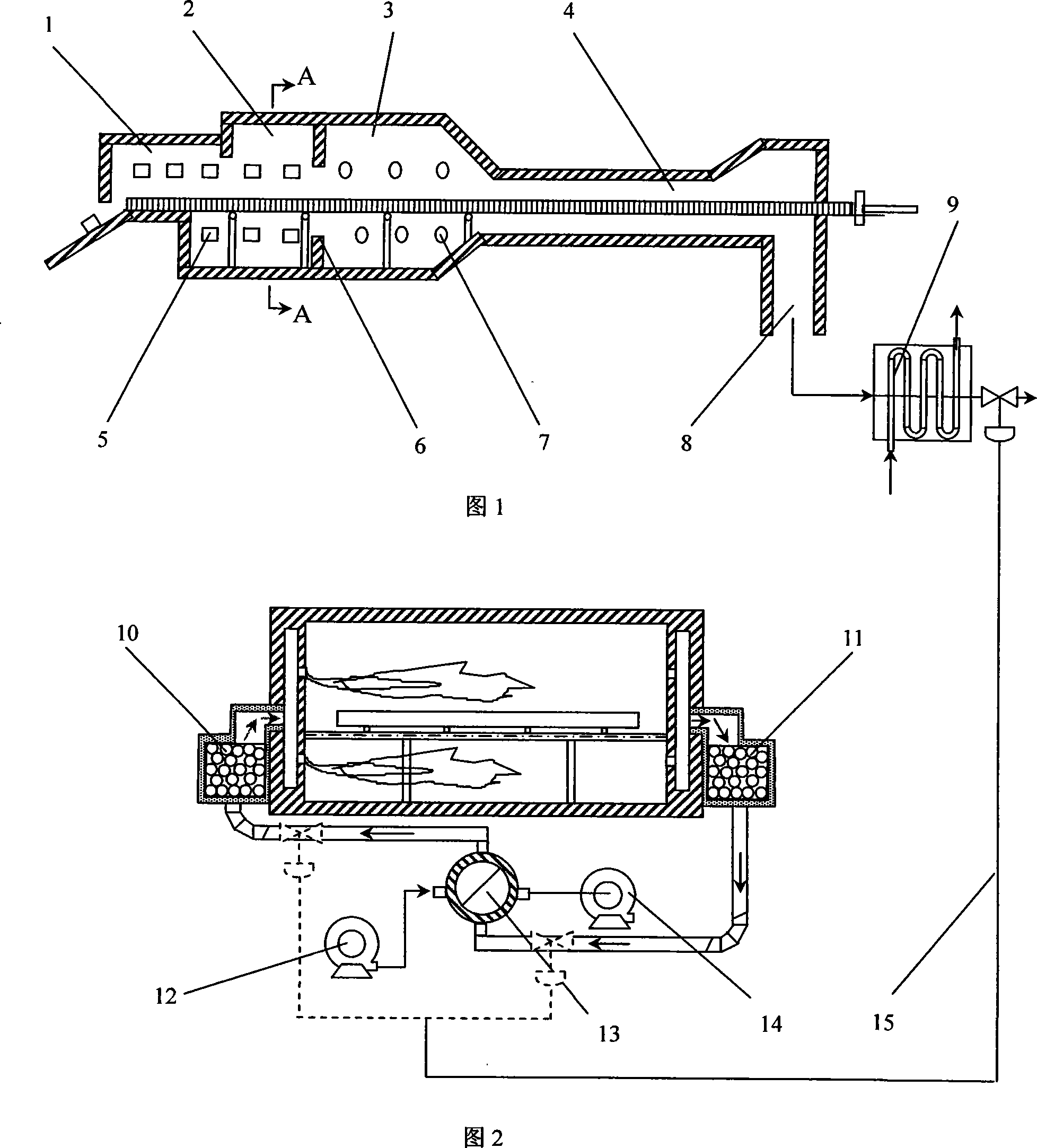

Heat accumulation-exchange type heating stove and heating method thereof

InactiveCN101196369AExtend your lifeImprove work rateFurnace typesIncreasing energy efficiencyCombustionFlue gas

The invention provides a regenerative-recuperative combined heating furnace and the heating means, which relate to the technology field of industrial heating and recovery of waste heat. The invention is characterized in that: a regenerator and a heat exchanger are provided at the same time in the system; a soaking zone and a heating zone are arranged in front of the heating furnace; a preheating zone is provided on the tail of the heating furnace; multi-zone (point) heating system of the soaking zone, heating zone and preheating zone is adopted, the front of the heating furnace adopts regenerative combustion method and the back adopts recuperative combustion method; the preheating zone directly adopts flue gas waste heat to heat the materials. The objectives of the invention are to realize maximization of the heating furnace and smooth control of the furnace pressure, overcome the defects of the regenerative-recuperative heating furnaces and flue gas waste heat recovery technology and facilitate the low heat value fuels like pure blast furnace gas being applied in the heating furnace. The heating furnace has smooth pressure and long service life. The implementation of the invention realizes the maximization of the heating furnace, improves the flue gas waste heat utilization rate and reaches the aims of improving the pressure condition in the furnace, reducing air draft and sparking and energy conservation and emission reduction, etc.

Owner:蔡九菊

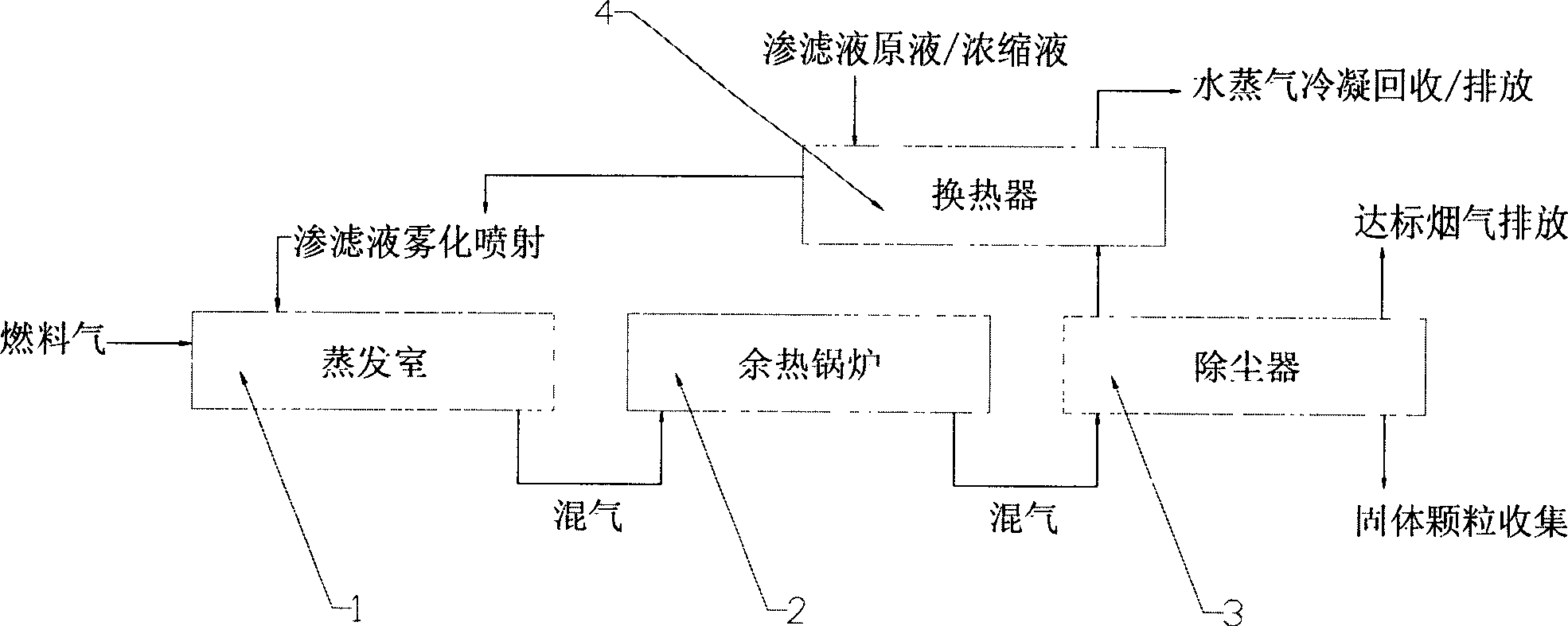

Percolate atomization evaporation technology

ActiveCN1785825AImprove waste heat utilizationSave energyWater/sewage treatment by heatingWater qualityEvaporation

The present invention relates to an economic, high-effective and energy-saving landfill yard percolation liquor atomization, combustion and evaporation process. It is characterized by that it uses the landfill gas as energy source, and utilizes the flame produced after the landfill gas is combusted by means of combustor and high-temperature smoke to directly and simultaneously incinerate the combustible substances in the atomized percolation liquor and evaporate water content in the atomized percolation liquor, then introduces the hot mixed tail gas into a waste-heat boiler to implement waste-heat reutilization, finally can condense and recover the aqueous vapour in the mixed gas.

Owner:北京时代桃源环境科技股份有限公司

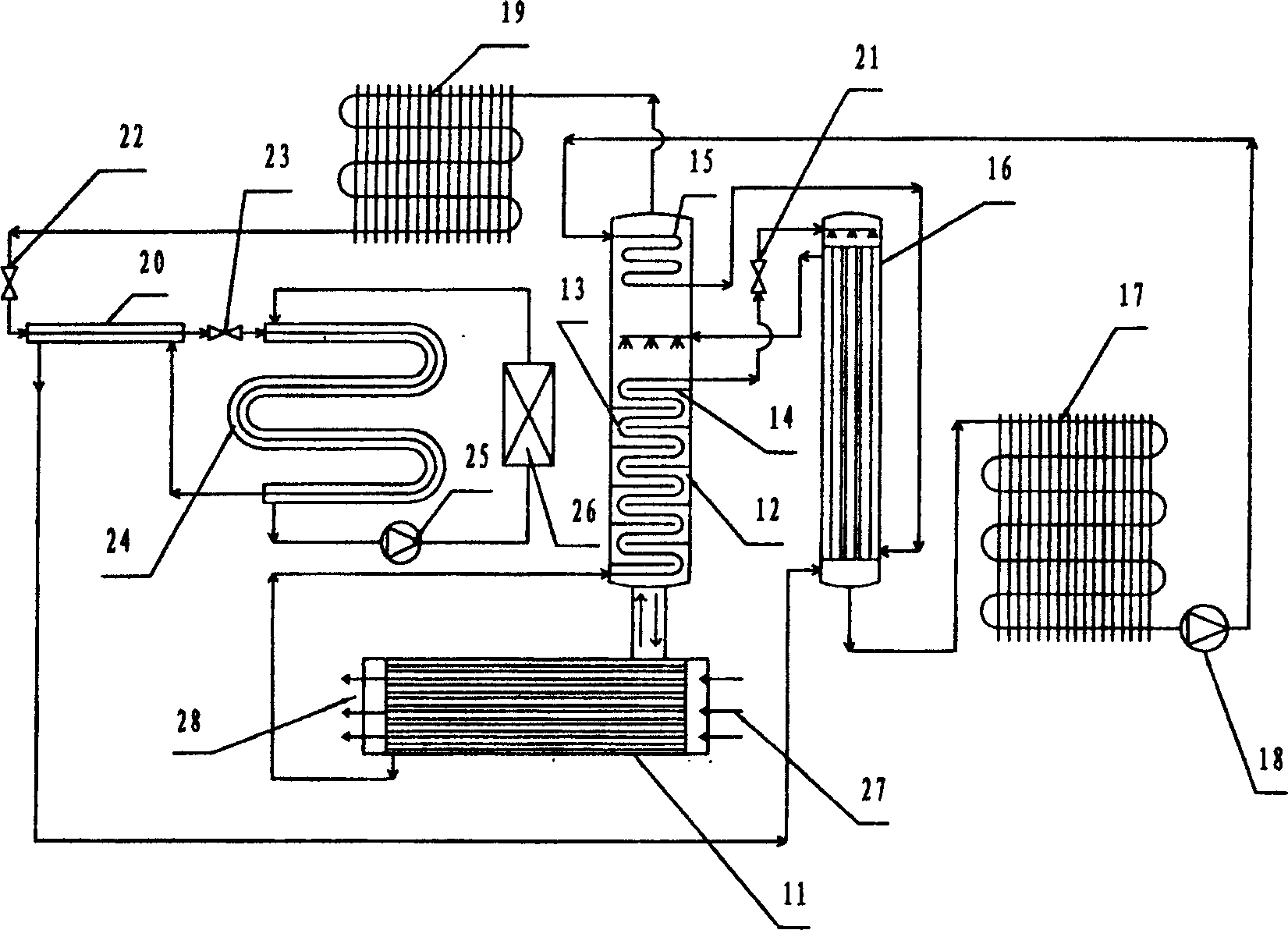

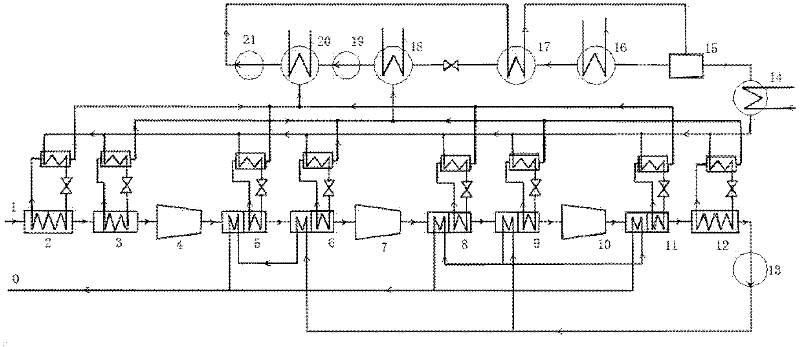

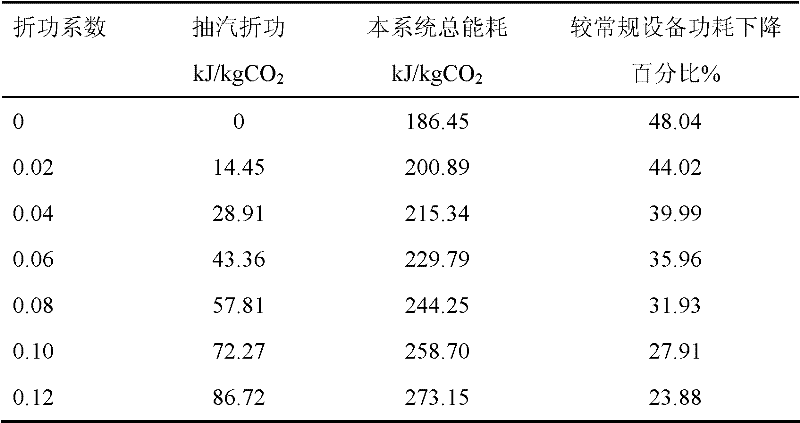

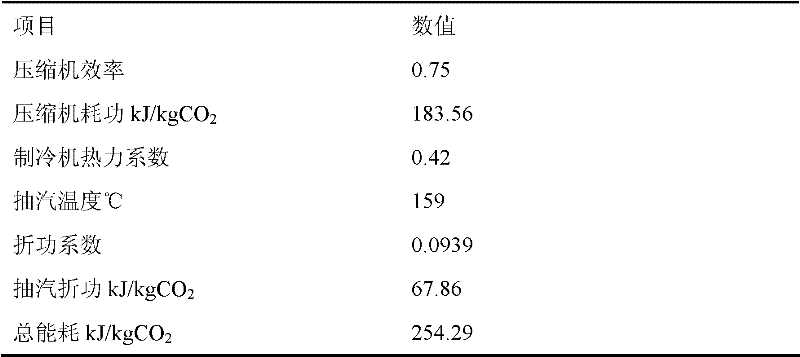

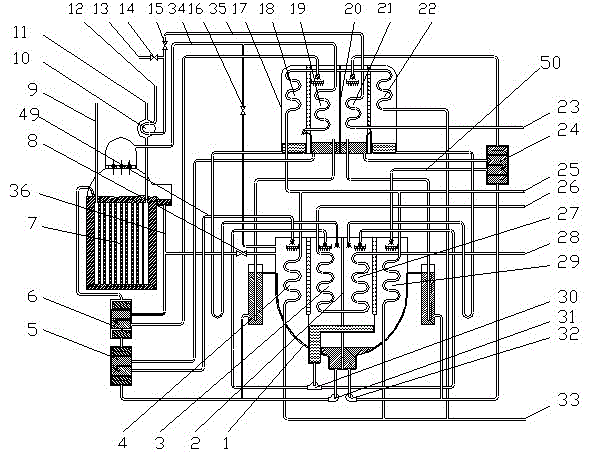

Co2 compression liquefaction system combined with waste heat driven refrigeration

InactiveCN102269509AReduce power consumptionImprove waste heat utilizationSolidificationLiquefactionPre coolingPost treatment

The invention belongs to the technical field of CO2 post treatment, and in particular relates to a CO2 compression and liquefaction system combined with waste heat driven refrigeration. Based on the CO2 compression and liquefaction system consisting of a multistage compressor, a cooler and a circulating water system, a CO2 gas pre-cooling system, an ammonia absorption type refrigerating system, astaged cooling system, a waste heat steam extraction system, a liquid oxygen pump supercharging system and a liquid CO2 cold reclaiming system are additionally provided; and through the measures of combining the rich waste heat environment of a power plant, making cold by using a waste heat driven refrigerating machine, reducing the liquefaction pressure of CO2 with low temperature and raising the pressure by using the pump after the CO2 is liquefied and the like, the total CO2 compression power consumption is reduced, the electrical energy is saved, and the heat efficiency of the whole plantis improved. The system is suitable for multiple occasions supplied with waste heat and required for compressing and liquefying CO2, and particularly can effectively utilize the waste heat of the power plant and reduce the energy consumption level of CO2 compression and liquefaction in the thermal power plant required for reclaiming the CO2.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Sulfur recovery tail gas processing technology and system

InactiveCN107684808AReduce secondary pollutionImprove liquidityGas treatmentDispersed particle separationOperating costCorrosion

The invention relates to a sulfur recovery tail gas processing technology and system. After sulfur is recovered from an acid gas containing hydrogen sulfide through a Klaus+SCOT technology, the tail gas of sulfur production performs the heat exchange with intermediate temperature smoke of the outlet of a tail gas heat recovery boiler, so the fuel consumption of the tail gas boiler is saved, the waste-heat utilization efficiency is improved, the smoke temperature is further reduced, and the effective combination with a semi-drying desulfurization technology is realized. The smoke containing SO2is fed into a circulating fluidized bed desulfurizing tower, the SO2 and an absorbent perform the neutral reaction under the action of atomized water, and the SO2 content in the discharged smoke is less than 50 mg / Nm3. The desulfuration process of the technology and system has no wastewater discharge, no corrosion and no rime fog phenomenon, and the investment and operating cost is low.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

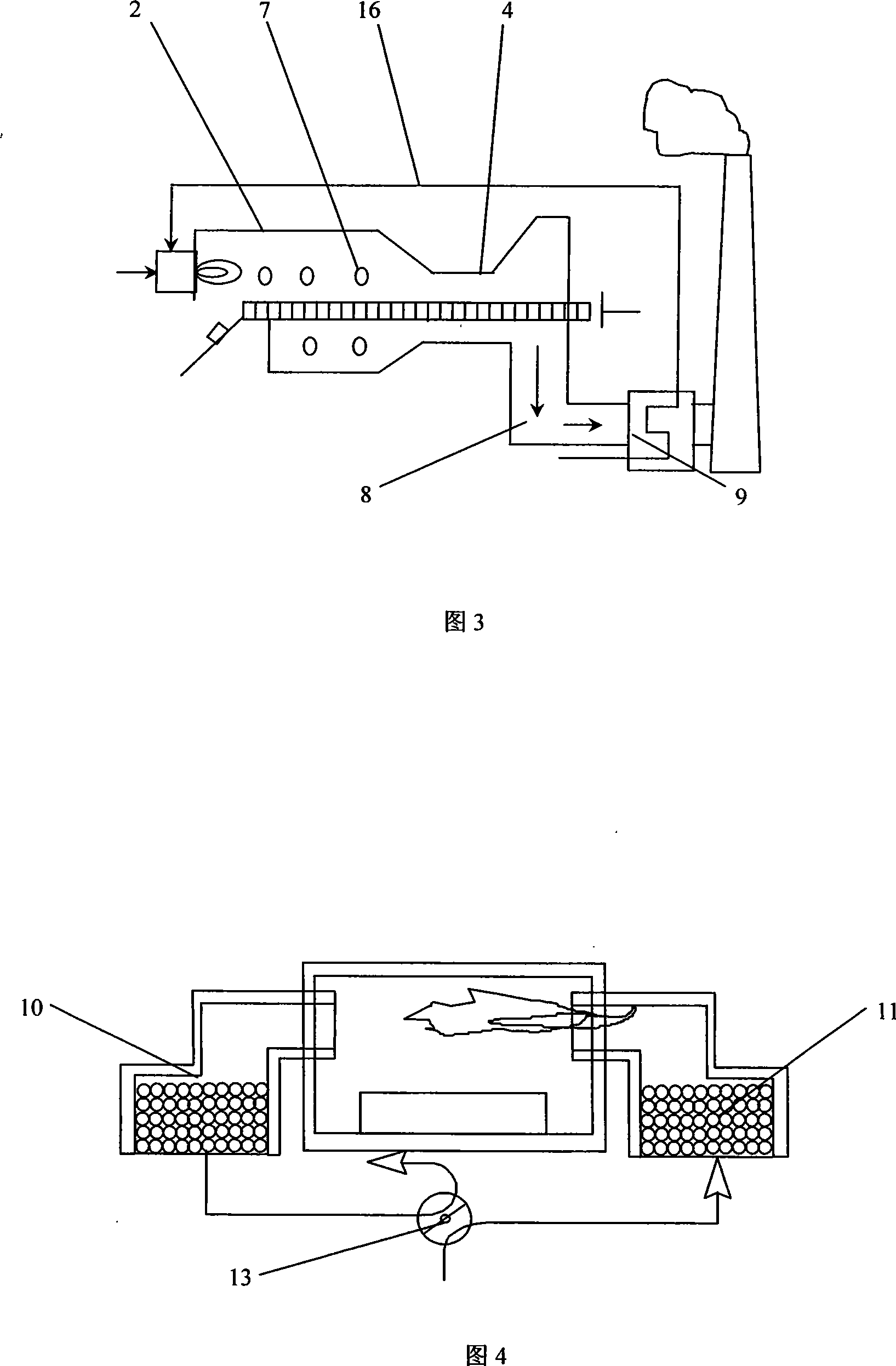

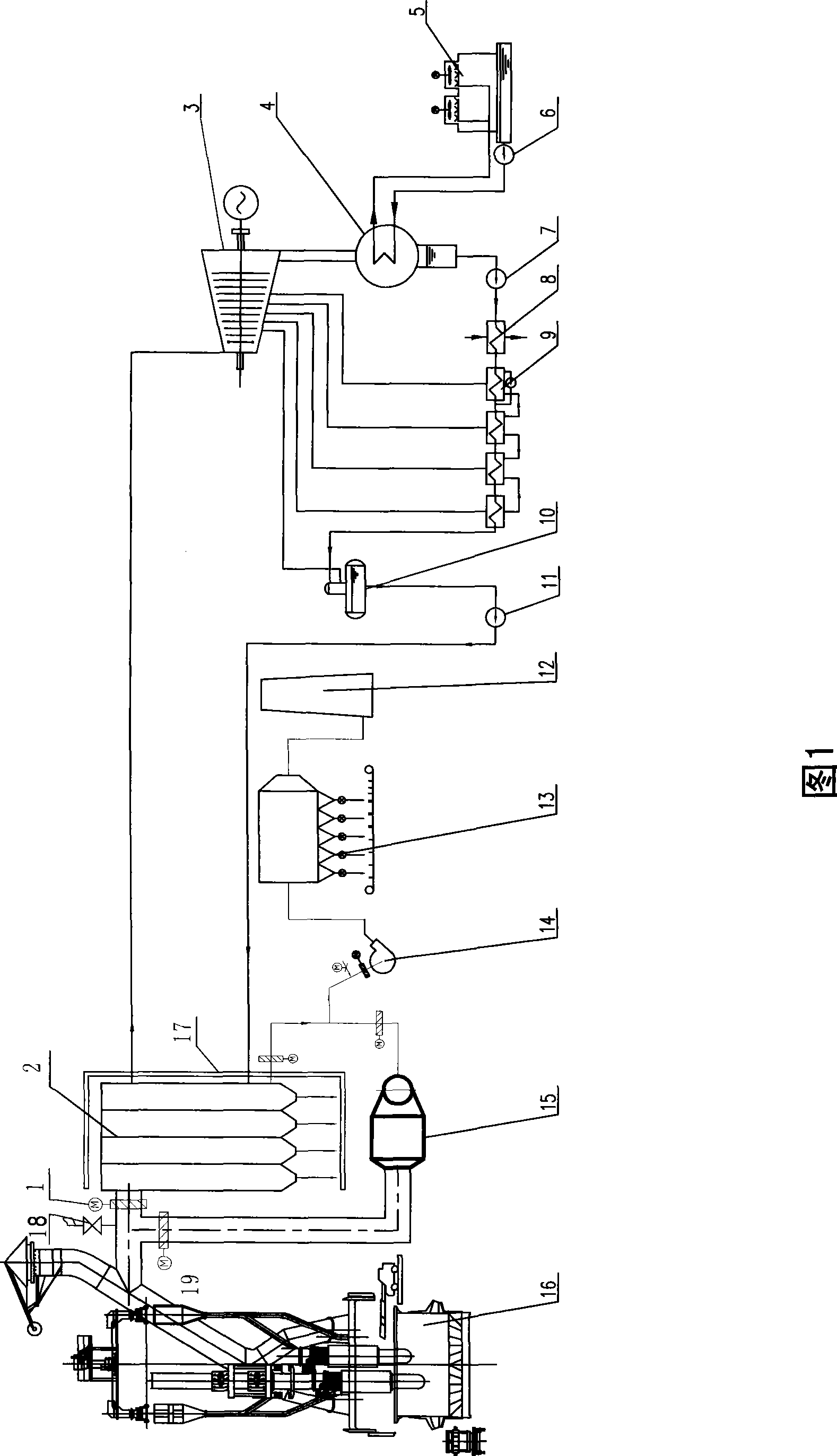

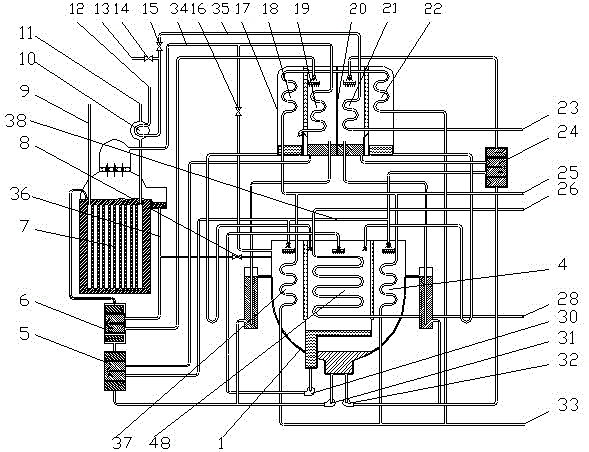

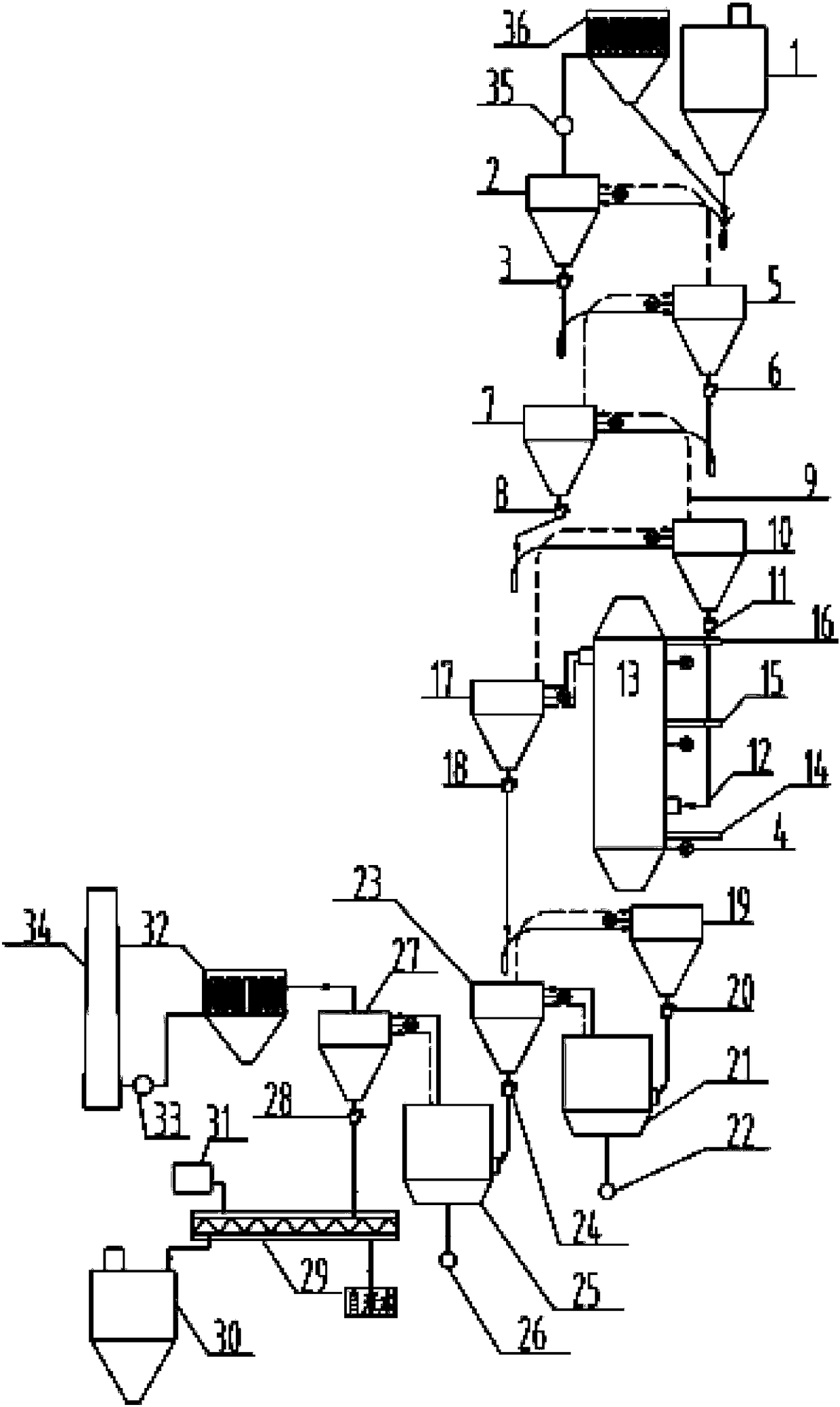

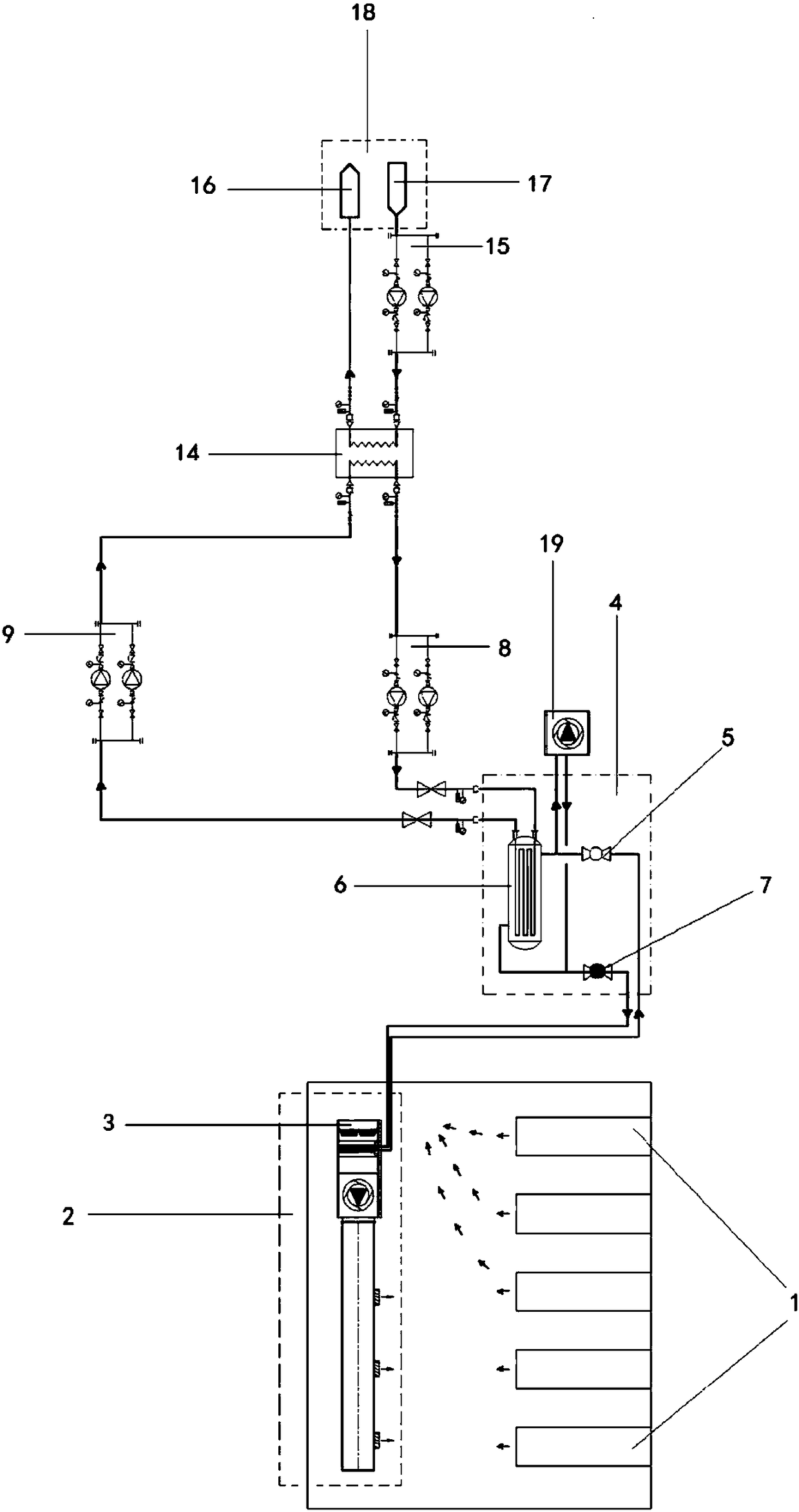

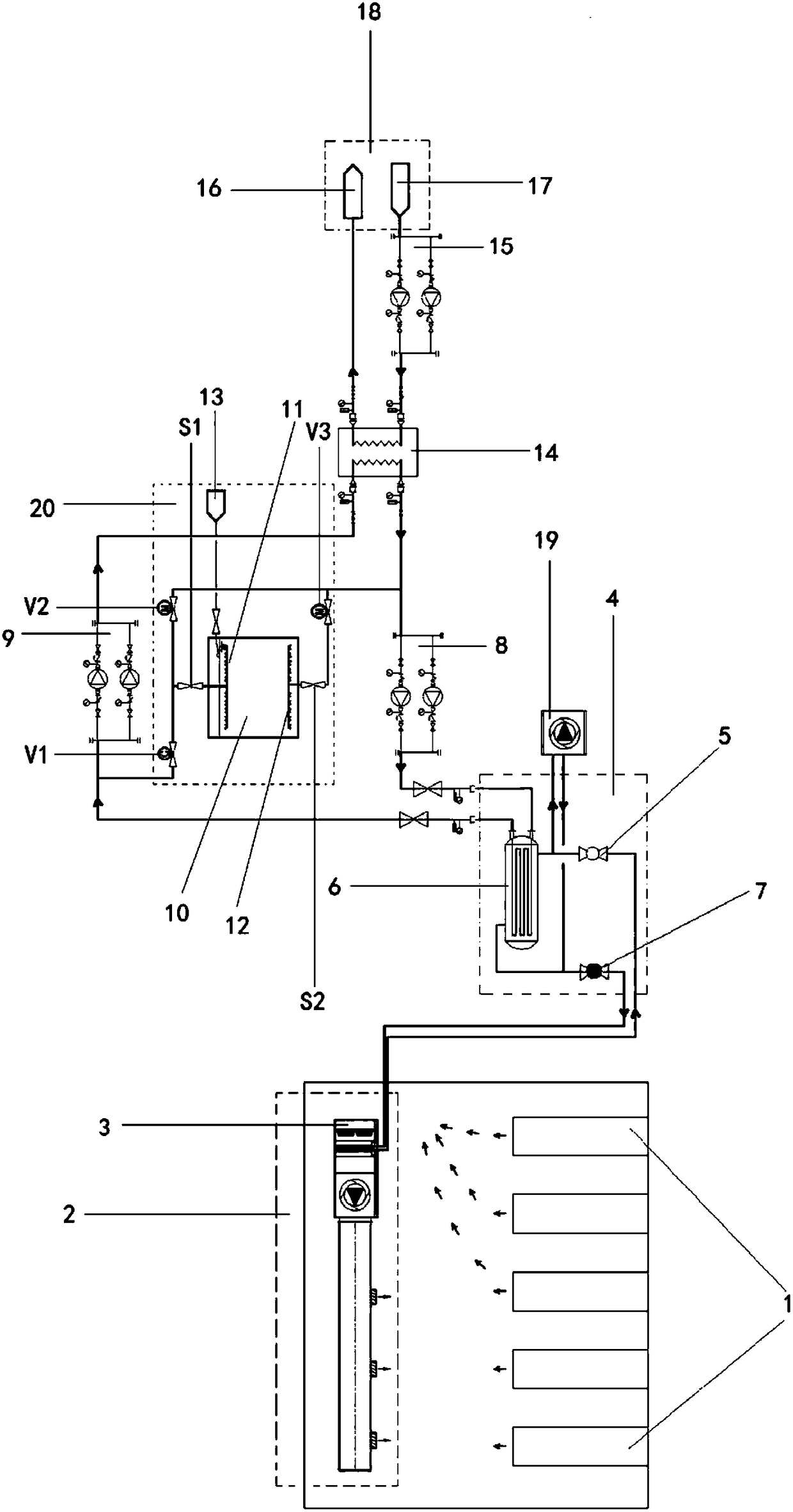

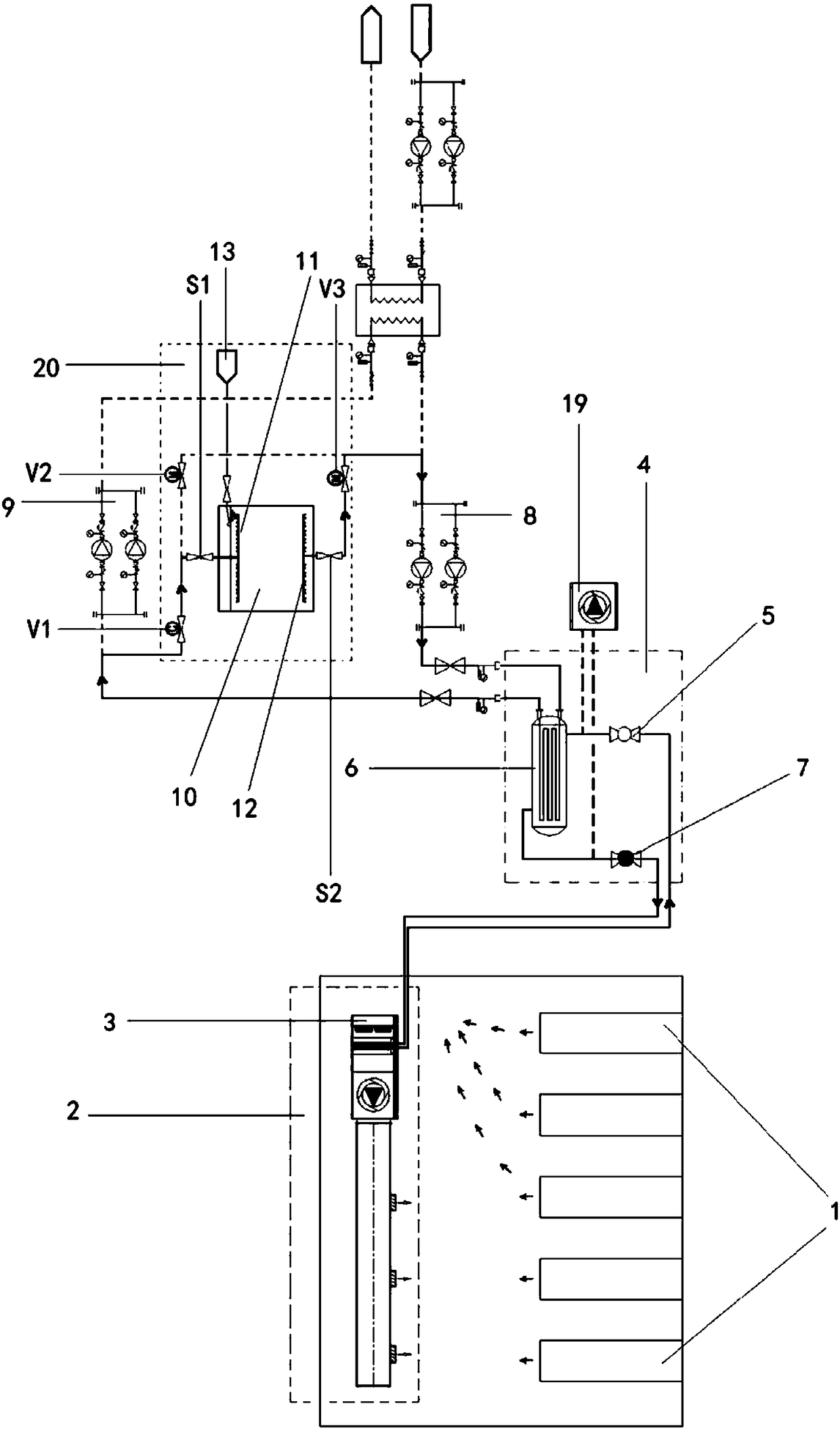

Silicon smelting electric furnace waste heat power generation process flow and configuration

ActiveCN101392992AEfficient extractionIncrease waste heatEnergy industryIncreasing energy efficiencyCooling towerAtmospheric air

The invention provides silicon smelting electric furnace waste heat power generating equipment, which consists of a valve 1, a waste heat boiler 2, a turbo generator 3, a vapor condenser 4, a cooling tower 5, a circulating water pump 6, a condensing water pump 7, a vapor seal heater 8, a low-pressure heater 9, a deaerator 10, a feed water pump 11, a chimney 12, a bag dust collector 13, an induced draft fan 14, a air cooler 15, a steel ball collection conveying distribution lifting device 17, a mixing cold air valve 18 and a by-pass valve 19, wherein waste flue gas discharged by a silicon smelting electric furnace 16 is introduced into the waste heat boiler to release partial heat; and when the temperature of the waste flue gas is reduced to nearly 180 DEG C, the waste flue gas enters the bag dust collector through the induced draft fan, and finally is discharged to atmosphere through the chimney. The desalted water enters the waste heat boiler through the feed water pump, vapor generated by the waste heat boiler enters the turbo generator; and after the vapor does work, the vapor enters the vapor condenser to be condensed into water, and the water enters the deaerator through a condensate removal pump, and the deoxidized water enters the waste heat boiler through the feed water pump. The silicon smelting electric furnace waste heat power generating equipment has the advantages of good energy saving effect, little investment and low cost.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

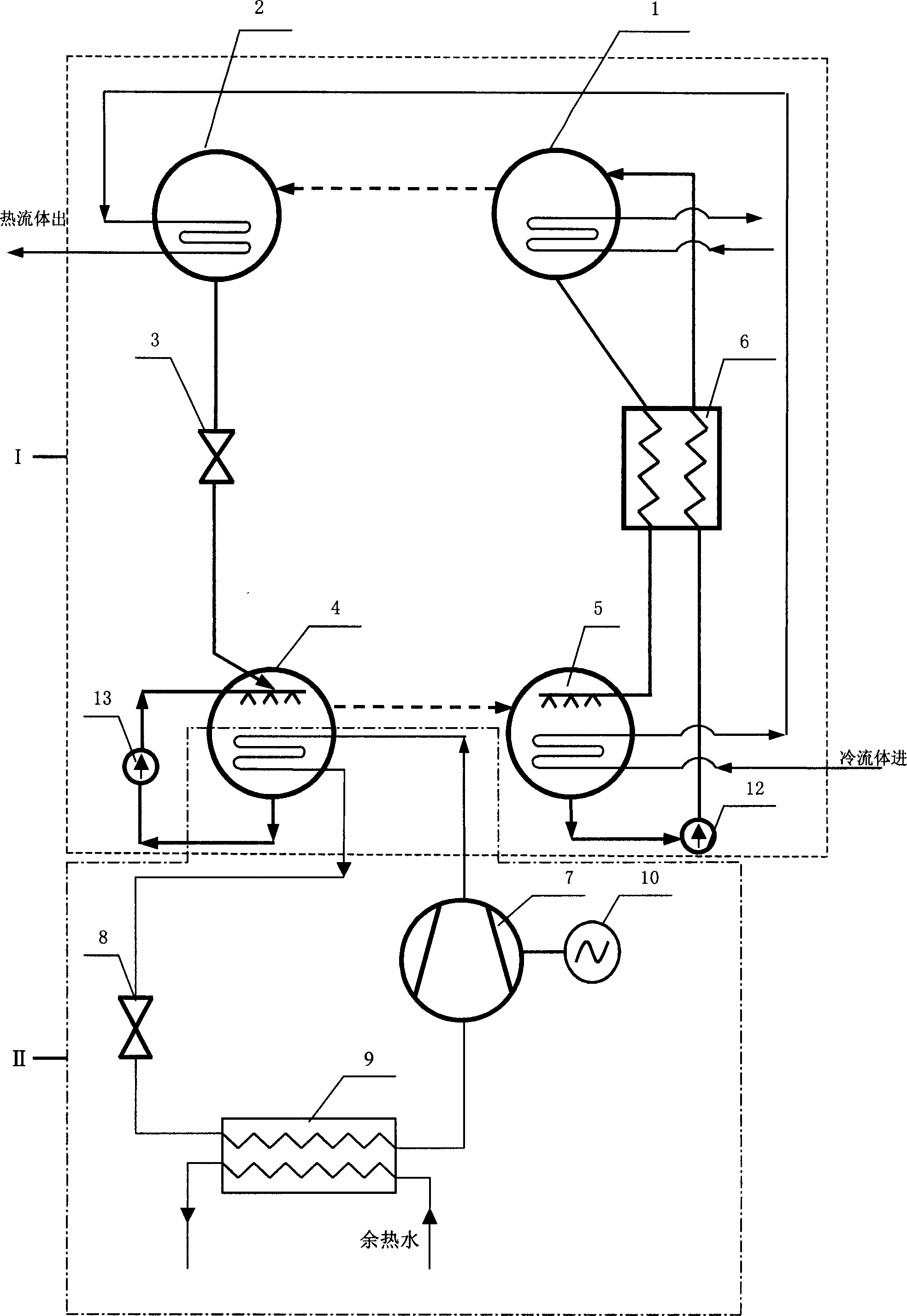

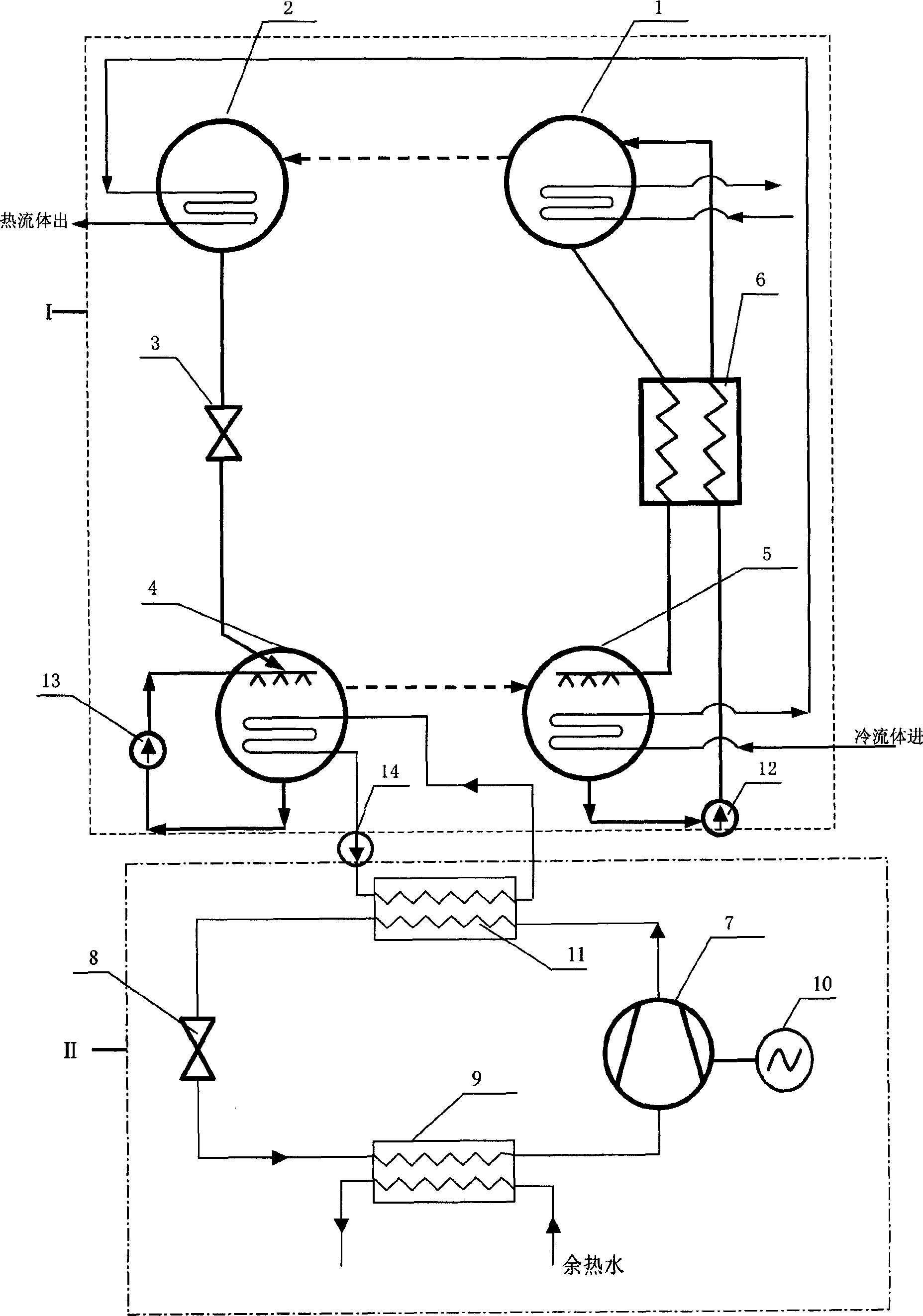

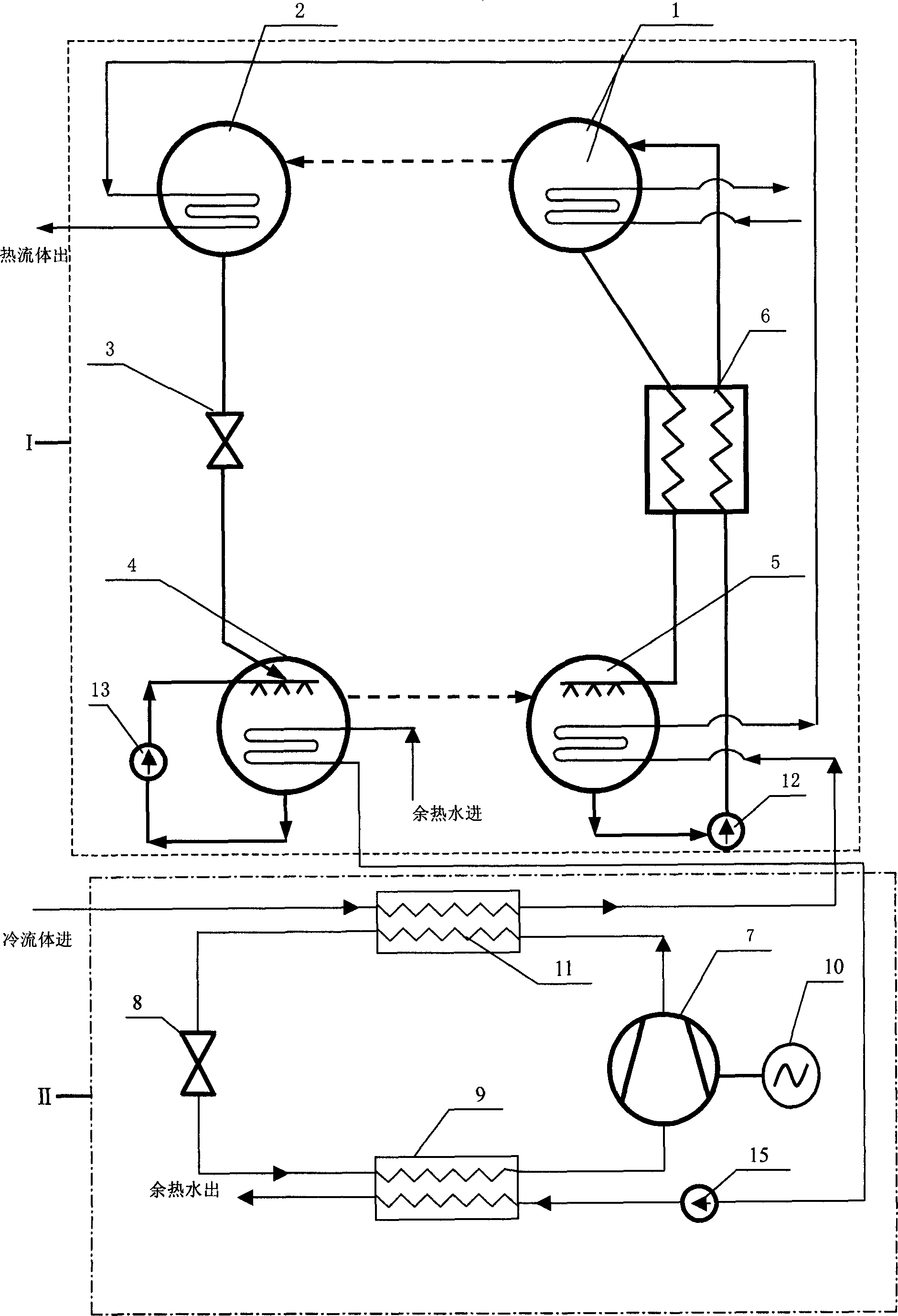

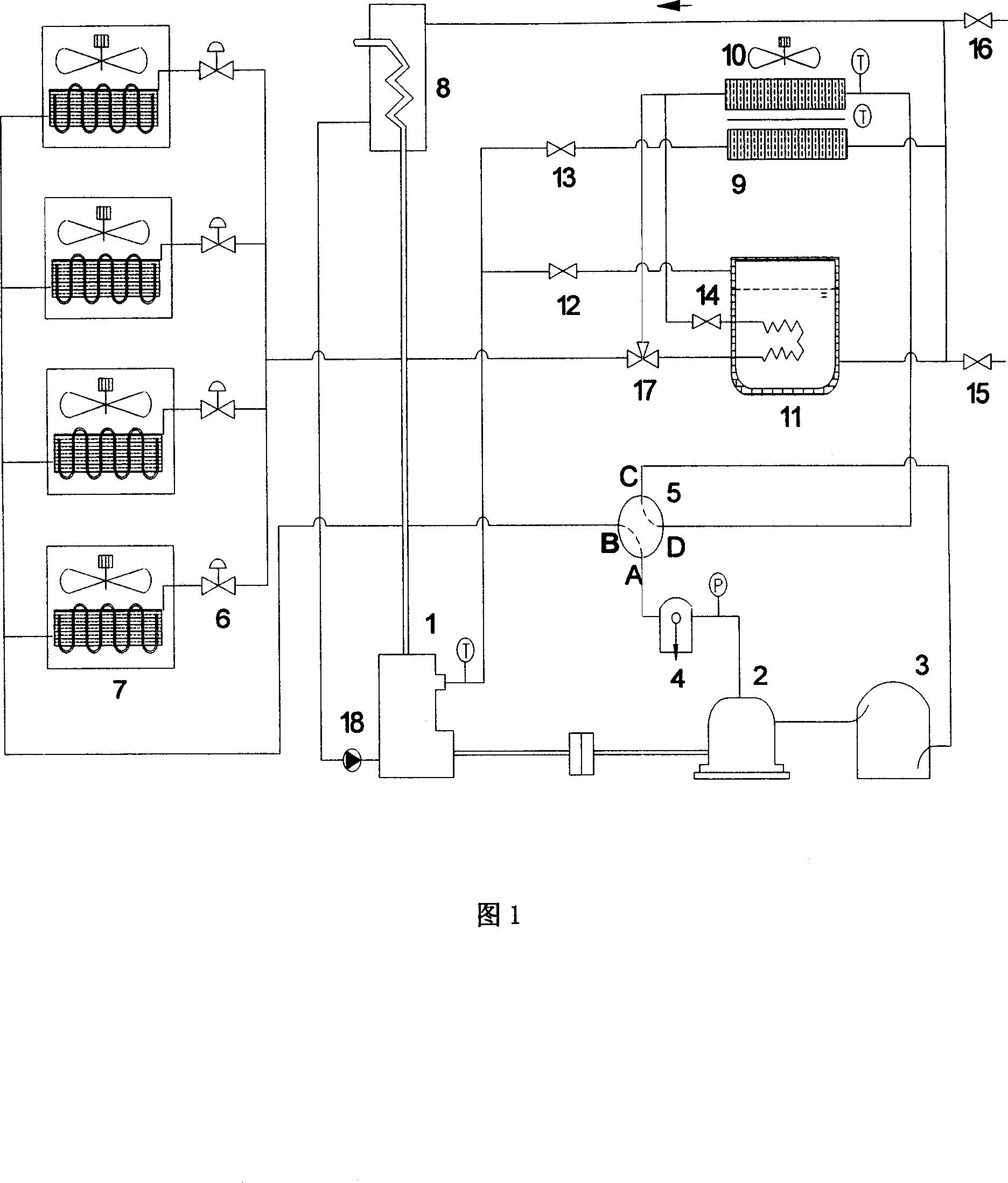

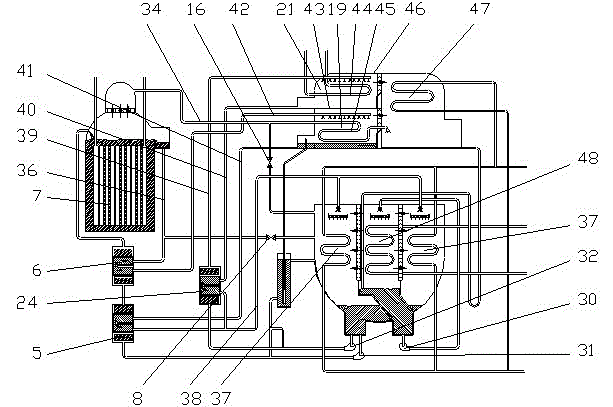

Gas engine driven steam compressing and absorbing combined type heat pump hot water unit running method

ActiveCN105674558AImprove waste heat utilizationIncrease profitFluid heatersHeat pumpsEngineeringHigh pressure

The invention discloses a gas engine driven steam compressing and absorbing combined type heat pump hot water unit running method. The method includes the following steps that a gas engine drives a compressor to act. A refrigerant is compressed into high-temperature and high-pressure gas, becomes liquid after heat exchange and enters the compressor after absorbing heat and being evaporated into gas, and compression type refrigerant cycling is formed. The method further includes solution cycling and refrigerant cycling, hot user return water is divided into two ways to be heated; the first way of return water is subjected to heat exchange with exhaust fume of the gas engine in an exhaust fume heat exchanger and then enters a first condenser and a cylinder sleeve heat exchanger in sequence to be subjected to heat exchange, and therefore the temperature of the return water can be increased; and the second way of return water absorbs absorbing heat generated in an external cooling absorber, then enters a second condenser, is subjected to heat exchange with ammonia steam in the second condenser and is provided for a user to use after being heated. By means of the method, the primary energy ratio can be increased.

Owner:蓝焰高科(天津)燃气技术有限公司

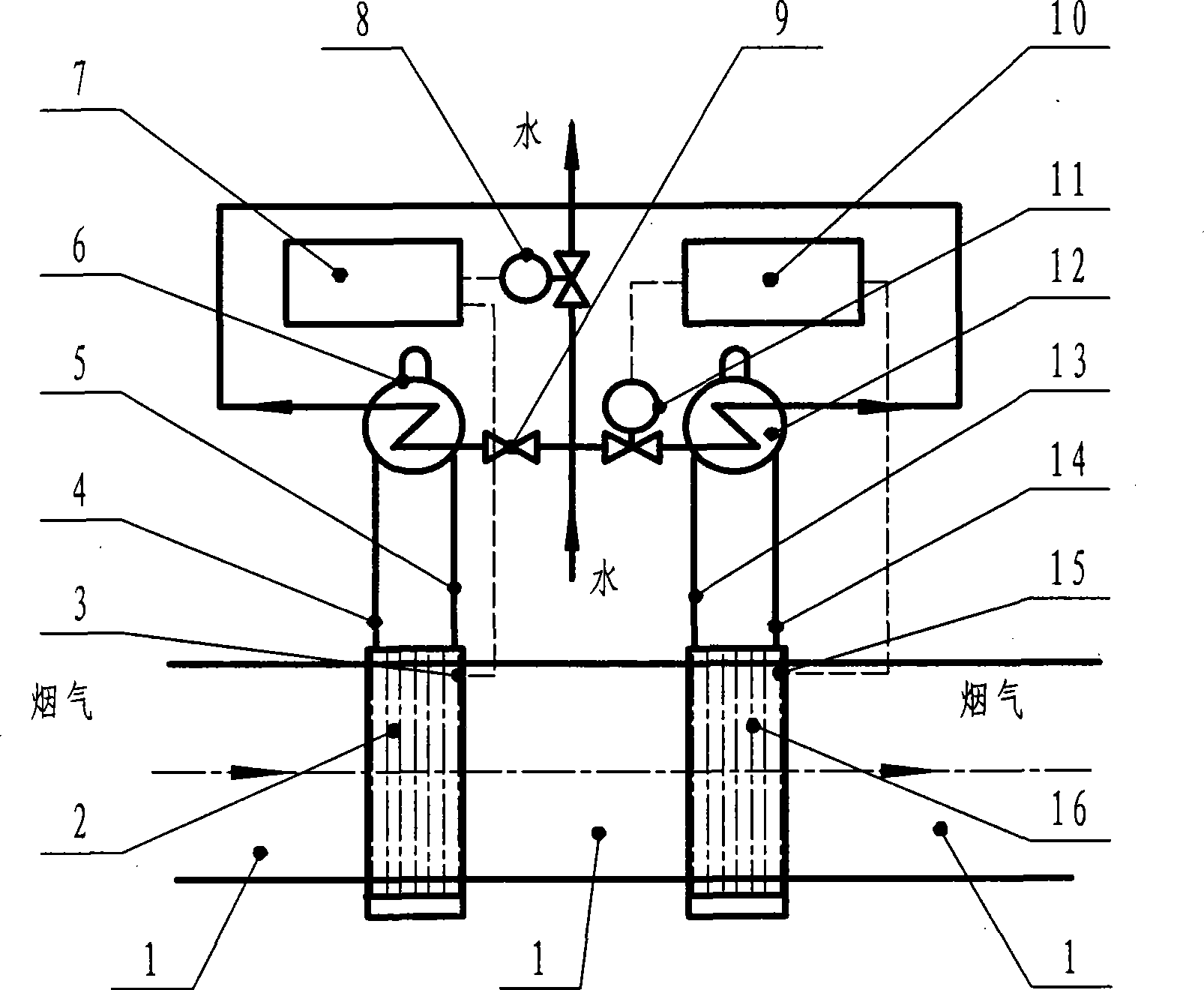

Double wall temperature composite phase change heat exchanger

InactiveCN101398266AReduce temperature differenceImprove waste heat utilizationIndirect heat exchangersHeat exchange apparatusAutomatic controlDouble wall

The invention discloses a composite phase change heat exchanger with double wall temperatures. A phase change section is divided into a high-temperature phase change section and a low-temperature phase change section that are serially connected in a flue gas channel, a descending pipe and an ascending pipe of the high-temperature phase change section are communicated with a steam header of the high-temperature section, a descending pipe and an ascending pipe of the low-temperature phase change section are communicated with a steam header of the low-temperature section, and a desalted water pipeline used for heat exchange is respectively connected in the steam header of the high-temperature section and the steam header of the low-temperature section; an automatic control device adjusts and controls the flow of desalted water in the high-temperature section and wall surface temperature of the high-temperature phase change section, and simultaneously adjusts and controls the flow of the desalted water in steam header of the low-temperature section and wall surface temperature of the low-temperature phase change section. Temperature control of different wall surfaces of the two phase change sections separates flue gas into two temperature decreasing sections, reduces the temperature decreasing difference between each temperature decreasing section, reasonably distributes the heat flow density between heated surface tube banks of each phase change section, and can not only ensure good global heat conductivity with temperature decreasing value of the flue gas larger than 60 DEG C and improve the afterheat utilization rate, but also can satisfy the higher output temperature requirement of the heated desalted water by setting proper wall temperature of the high-temperature section.

Owner:杨本洛 +1

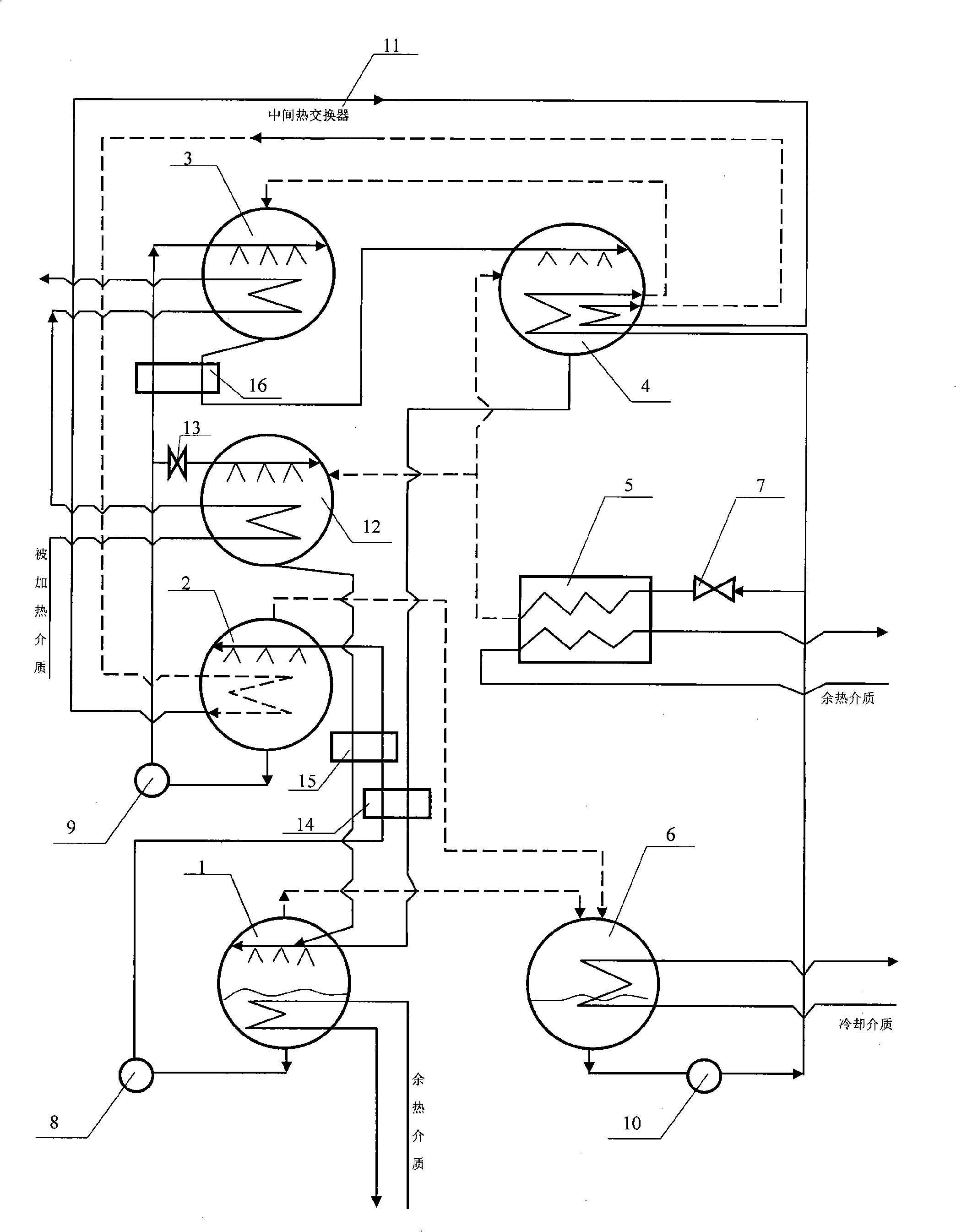

Composite absorption heat pump of second type

ActiveCN101266086AIncreased heat demandSmall structural changesHeat pumpsClimate change adaptationIntermediate heat exchangerAbsorption heat pump

The invention provides a composite second absorption heat pump, belonging to the heat pump technology field, mainly comprising a plurality of generators, a high-temperature absorber, a low-temperature absorber, an absorption-evaporator, an evaporator, a condenser, a reducer, a regulating valve, a solution pump and a cold agent pump. The steam of cold agent generated by the generator goes into the condenser, and then cold agent pump provides the cold agent to the evaporator and the absorption-evaporator, and then the cold agent which is throttled and flows into the evaporator absorbs heat and is gasified and then flows into the low-temperature absorber, the absorption-evaporator, and then the cold agent in the absorption-evaporator absorbs heat and is gasified and flows into the high-temperature absorber; thin solution absorbs heat and releases steam with gradually increased consistency, and the steam of the cold agent which flows into the low-temperature absorber and the high-temperature absorber releases heat thereby supply heat for outside. The solution respectively flows through the high temperature absorber, the absorption-evaporator for gradually absorbing the cold agent steam, and flows through the low-temperature absorber for absorbing the cold agent steam, so that the consistency of the steam is reduced and the solution flows into a first-level generator; an intermediate heat-exchanger conducts heat between the absorption-evaporator for heating the solution.

Owner:李华玉

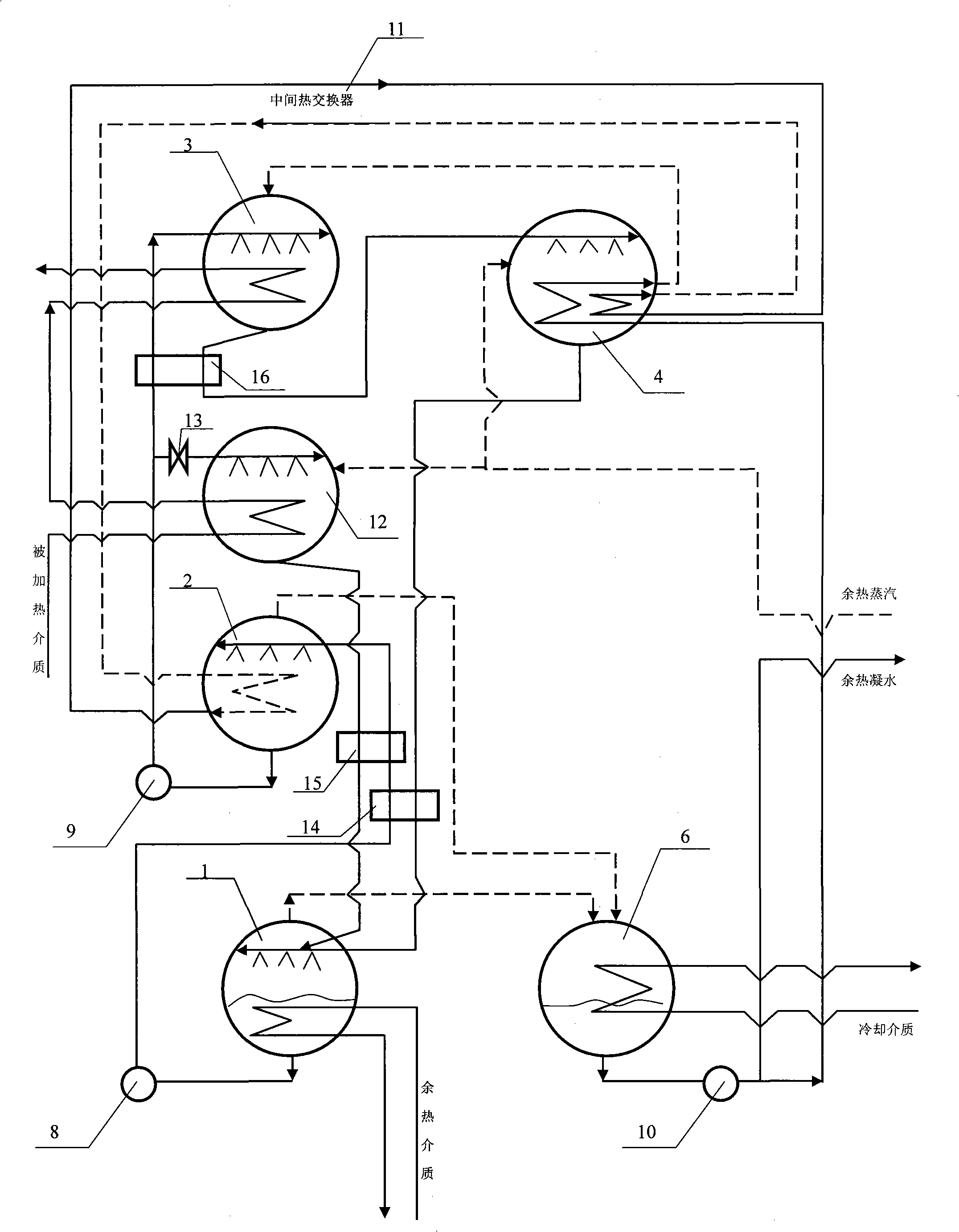

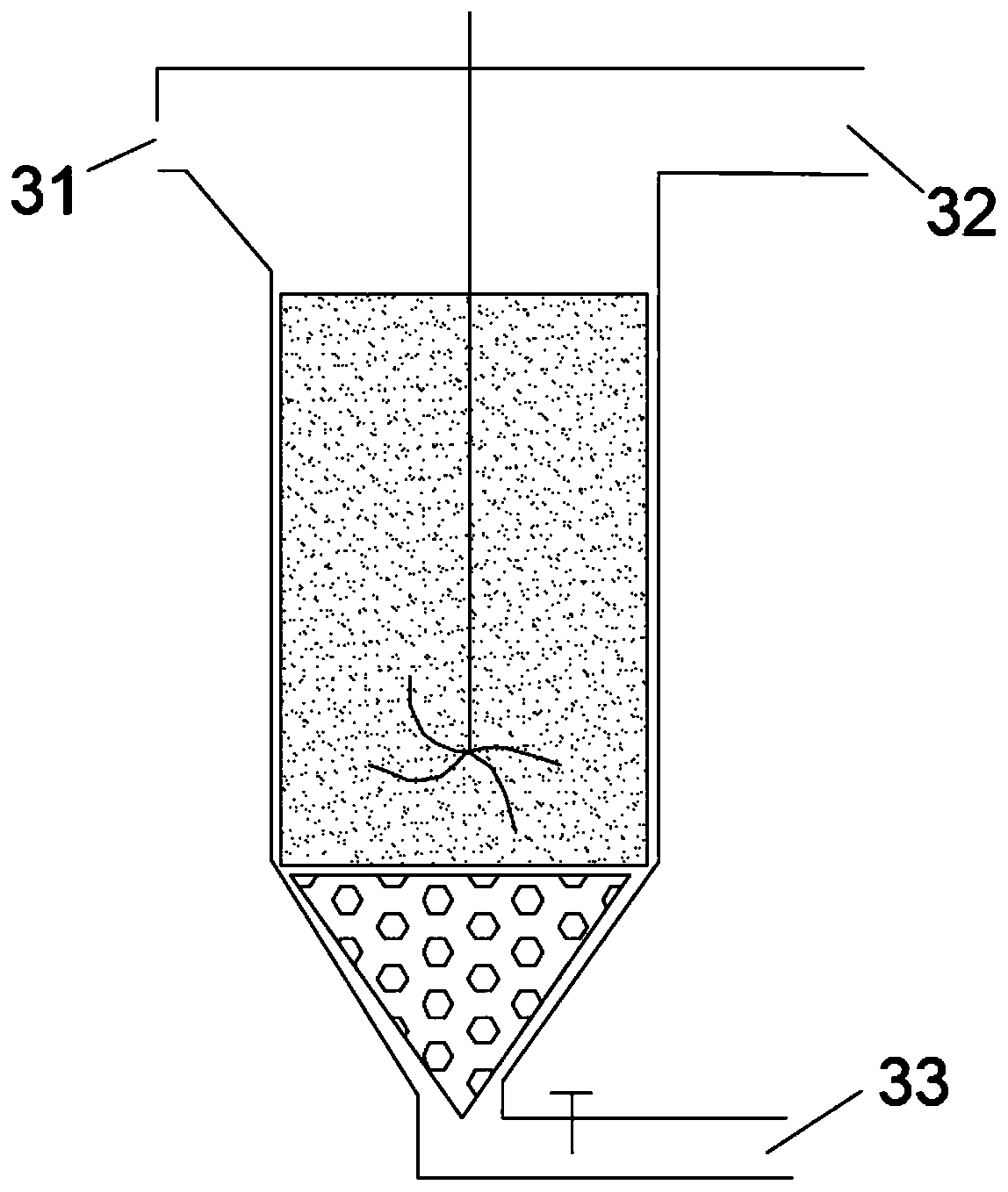

Two-section flue gas hot-water single/double-effect composite lithium bromide absorption type refrigerating unit

InactiveCN102914081AImprove waste heat utilizationRelieve pressureClimate change adaptationEnergy efficient heating/coolingFlue gasLithium bromide

The invention relates to a two-section flue gas hot-water single / double-effect composite lithium bromide absorption type refrigerating unit which comprises a flue gas type high-pressure generator (7), an evaporator, an absorber, a steam generator (19), a hot-water generator (21) and a condenser, and is characterized in that the condenser comprises a single-effect condenser (22) and a double-effect condenser (18); a heat exchange tube bundle of the hot-water generator (21) and a heat exchange tube bundle of the single-effect condenser (22) are arranged in a cavity; a heat exchange tube bundle of the steam generator (19) and a heat exchange tube bundle of the double-effect condenser (18) are arranged in another cavity; the cooling water process of the single-effect condenser (22) and the double-effect condenser (18) is a series process; and cooling water flows into the single-effect condenser (22) and flows out of the double-effect condenser (18). According to the two-section flue gas hot-water single / double-effect composite lithium bromide absorption type refrigerating unit, the generation pressure of the hot-water generator can be reduced, the dilute solution concentration of a hot-water single-effect cycle is reduced, and the waste heat flue gas outlet temperature is reduced.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Method and device for smelting low grade zinc lead material

InactiveCN101215643AHigh recovery rateSimple structureBlast furnace detailsProcess efficiency improvementSulfurSmelting process

The invention relates to a smelting process of low-grade zinc and lead material and a device, which conduct blast furnace reducing smelting through adopting hot air to blow powdered fuel, directly produce high grade zinc oxide and wet lead, wherein the content of pellet zinc in zinc and lead material is 10%-20%, the content of lead is 2%-8%, the content of sulfur is lower than 2%, moisture is 5%-15%, the height of material column in furnace is remained between 2-3m, the temperature of a molten pool is 1100 DEG C-1250 DEG C, the temperature of hot air is 350 DEG C-480 DEG C, the pressures is 15-25 KPa, the coke yield is 18%-25%, the four alkality of R=0.5-1.2. Double air inlets (3) are arranged on the upper portion and the lower portion of a furnace hearth (2), and a hot air sleeve (4) is arranged on the middle lateral portion of the blast furnace. The invention has the advantages of simple structure, stable and reliable working, excellent continuous production, convenient operation, high recovery rate of zinc and lead and low cost, which can effectively treat low grade zinc and lead material.

Owner:KUNMING KUNZHIJIE TRADING

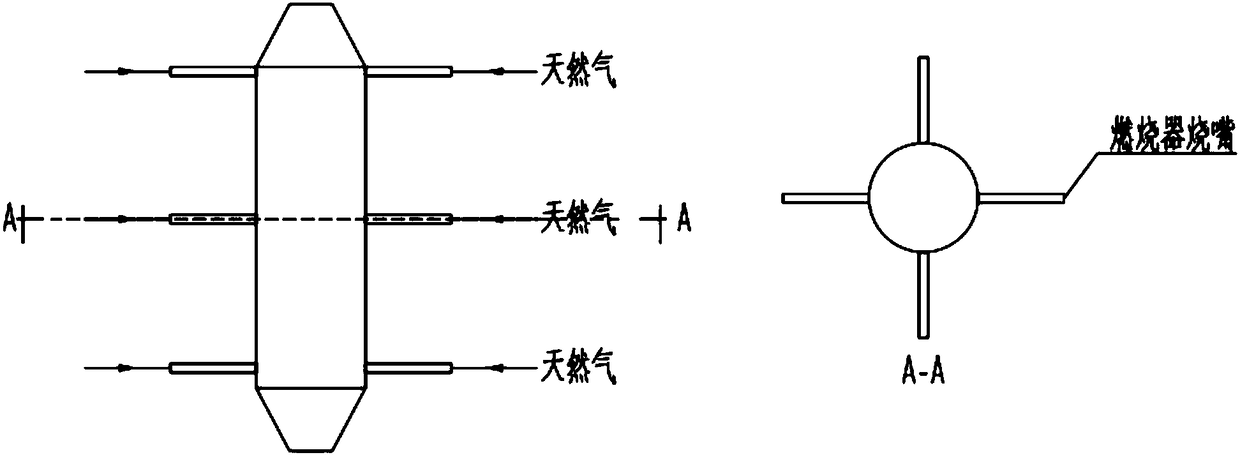

Device and method for producing hydrogen by catalytic cracking of natural gas or coalbed methane

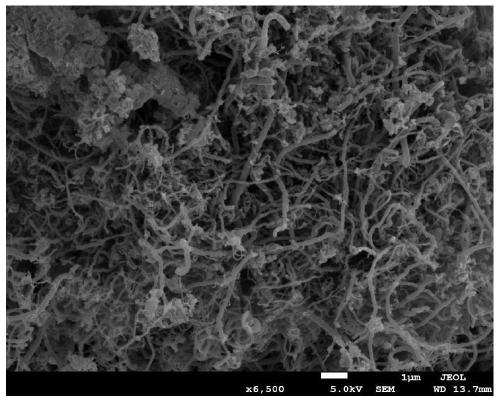

PendingCN111422832APlay a role in carbon sequestrationImprove waste heat utilizationCarbon compoundsHydrogen separation using solid contactAlkaneGas solid

The invention discloses a device and a method for producing hydrogen by catalytic cracking of natural gas or coalbed methane, and belongs to the technical field of hydrogen preparation. The natural gas or coalbed methane catalytic cracking hydrogen production device comprises a main reaction device, a gas-solid separation device, a catalyst recovery device, a nano carbon storage tank, a gas purification device and a high-purity hydrogen storage tank. The invention also discloses the method for producing hydrogen by catalytic cracking of natural gas or coalbed methane by using the device for producing hydrogen by catalytic cracking of natural gas or coalbed methane. The natural gas or coalbed methane catalytic cracking hydrogen production device can realize online real-time separation of gas-solid and gas-gas, is suitable for a continuous hydrogen production process, and has a carbon sequestration effect on raw material gas (alkane gas such as natural gas and coalbed methane), i.e., a process product is solid nanocarbon without carbon dioxide emission. In addition, closed circulation is formed after tail gas purification, comprehensive utilization of waste heat is improved after heat exchange, and overall comprehensive energy consumption is reduced.

Owner:QINGDAO HAITONG NEW MATERIAL TECH DEV CO LTD +1

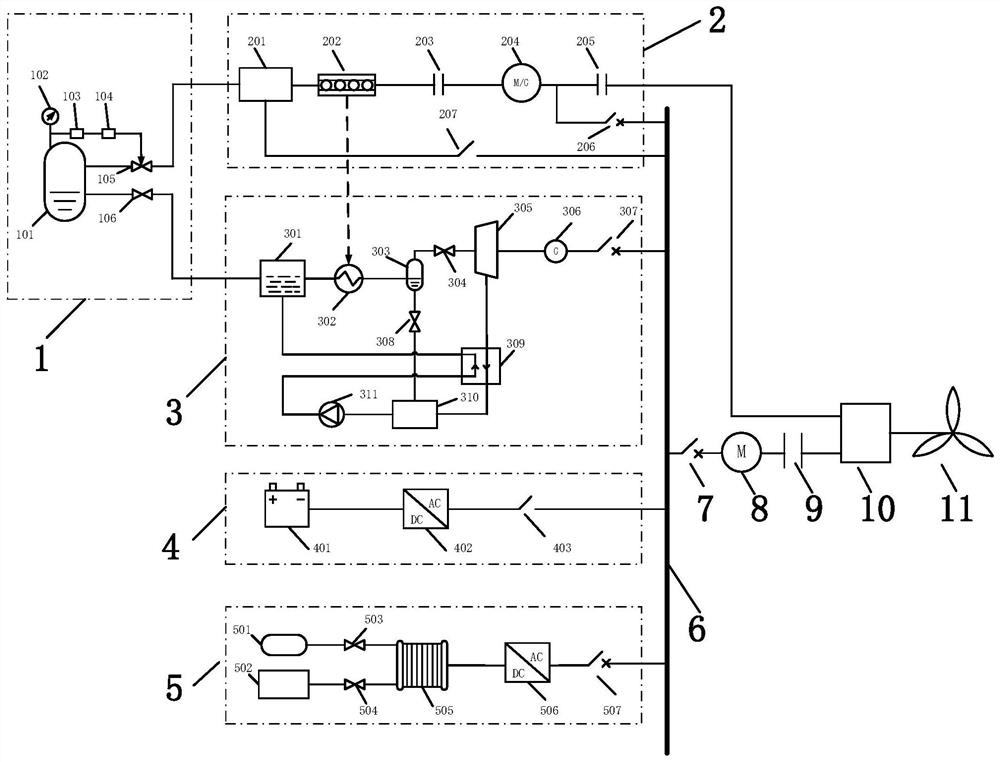

Composite ship hybrid power system based on ammonia-hydrogen driving

ActiveCN113650768AEmission reductionAchieve energy saving and emission reductionPropulsion based emission reductionPower plants using propulsion unit combinationsPower apparatusCircuit breaker

The invention aims to provide a composite ship hybrid power system based on ammonia-hydrogen driving. The systemcomprises a liquid ammonia supply device, an ammonia fuel power device, a hydrogen fuel power device, a ship main bus and a gearbox, a liquid ammonia tank is connected with an electric heater, the electric heater is connected with the ship main bus, the electric heater is connected with an ammonia fuel engine, te ammonia fuel engine is connected with a reversible motor, and the reversible motor is connected with the gearbox and the ship main bus; the hydrogen tank is connected with a proton exchange membrane fuel cell, the compressed air is connected with a proton exchange membrane fuel cell, and the proton exchange membrane fuel cell, a first inverter and a second circuit breaker are sequentially connected and connected with the ship main bus; the ship main bus is connected with a main motor through a main motor switch, the main motor is connected with the gearbox through a main clutch, and the gearbox is connected with ship propellers. The problems of excessive emission of sulfur dioxide and hydrocarbon, low waste heat utilization rate and the like when the current ship sails can be solved.

Owner:HARBIN ENG UNIV

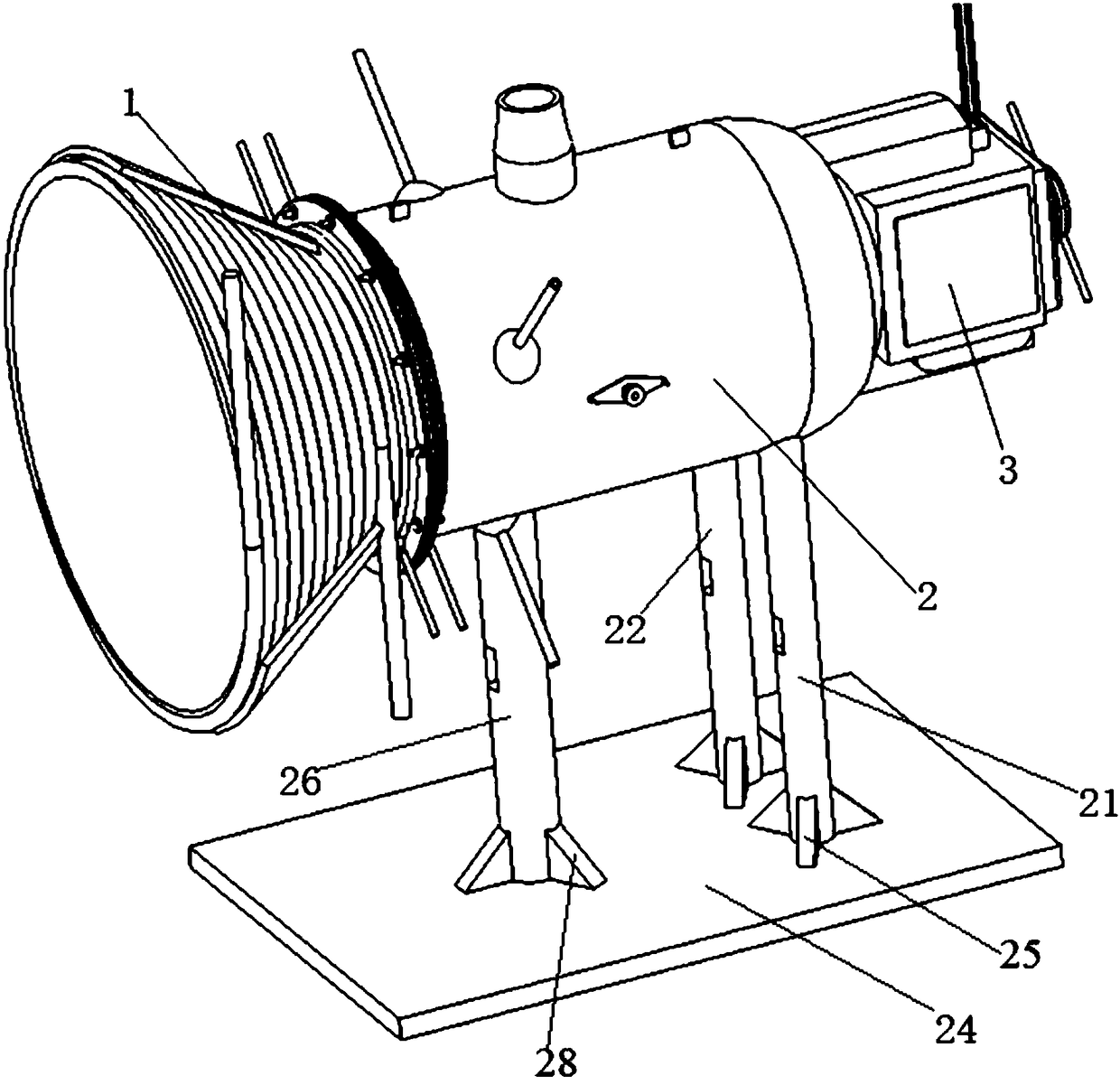

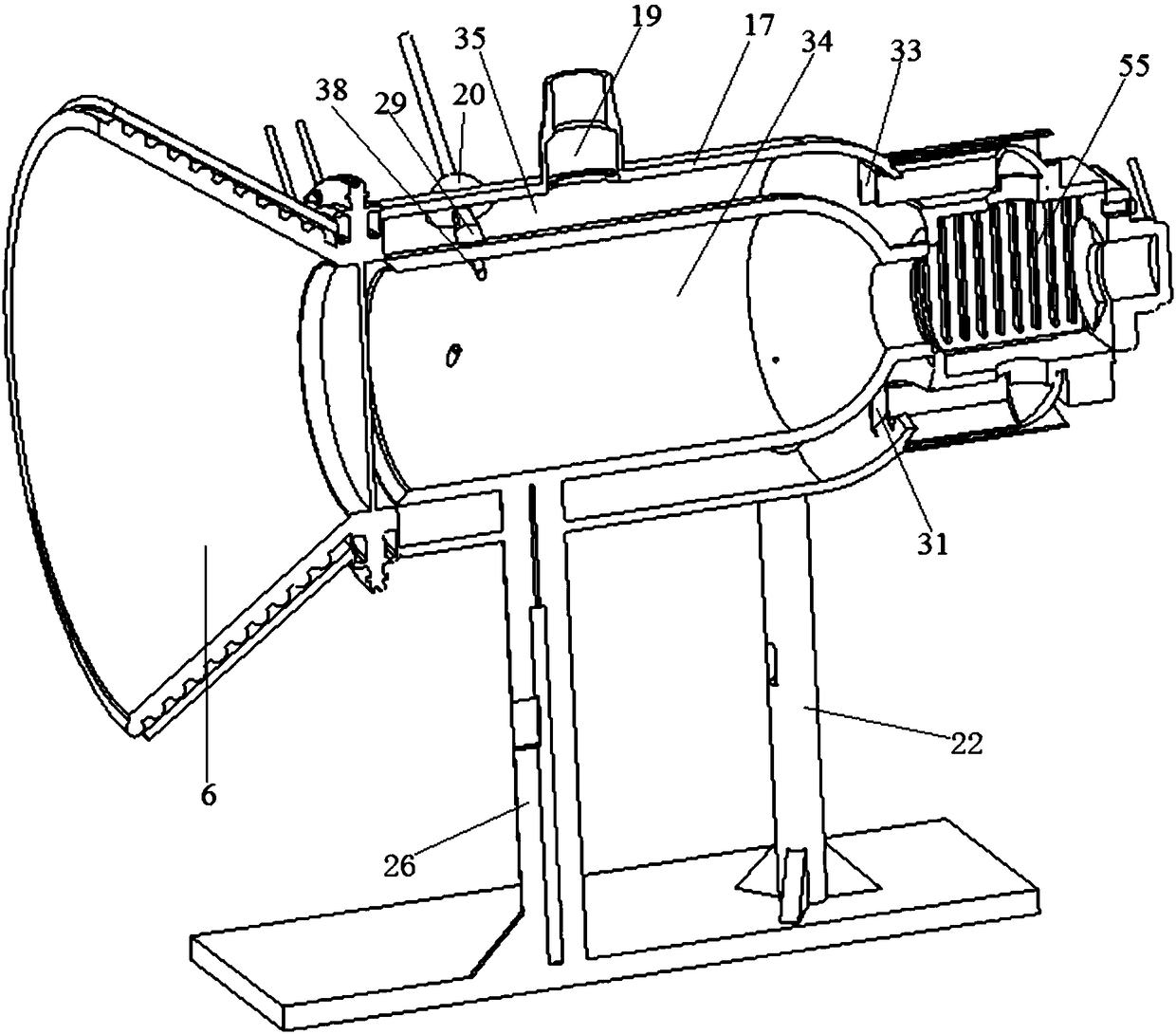

Energy-saving and environment-friendly solar reactor for hydrogen production by methanol reforming

ActiveCN108190834AWide range of usesImprove securityHydrogenEnergy inputEnergy conservationHydrogen production

The invention relates to an energy-saving and environment-friendly solar reactor for hydrogen production by methanol reforming and belongs to the technical field of photovoltaic heating equipment. Thereactor comprises a solar reception system, a methanol reforming reaction system, a tail gas dedusting treatment system and a support base, wherein the solar reception system, the methanol reformingreaction system and the tail gas dedusting treatment system are fixedly arranged on the support base sequentially, located on the same horizontal plane and communicated mutually. The energy-saving andenvironment-friendly solar reactor has the advantages that energy use ratio can be increased greatly, and losses of optical energy and waste heat can be reduced; dust pollution caused by nanoparticles and thermal pollution caused by excessive released waste heat are reduced, environment is protected, and energy is saved; operating data is monitored in real time by the equipment, feedback controlis realized by a computer, and the reactor has the characteristics of being high in automation degree, efficient, clean, environmentally friendly and energy-saving.

Owner:KUNMING UNIV OF SCI & TECH

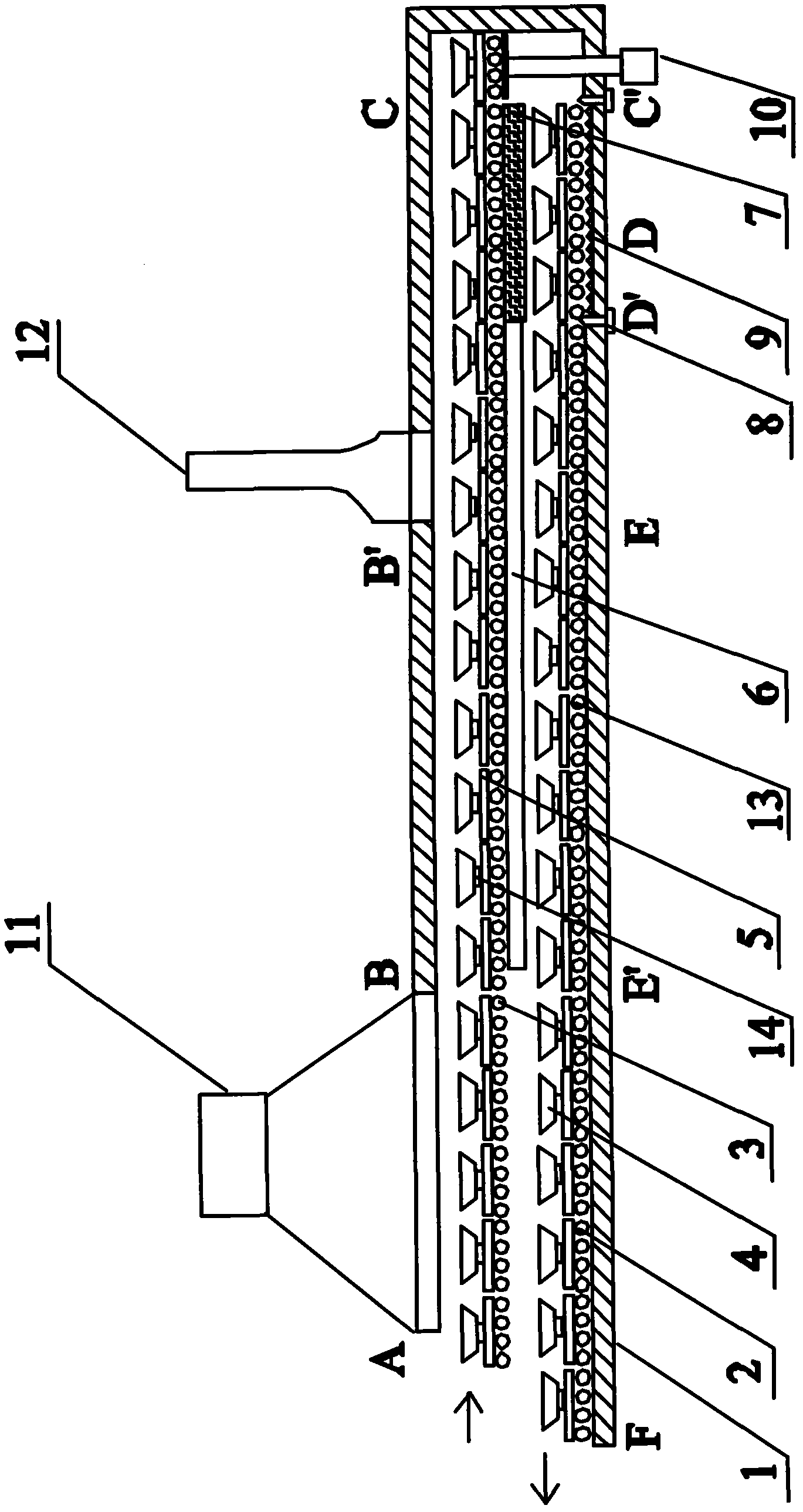

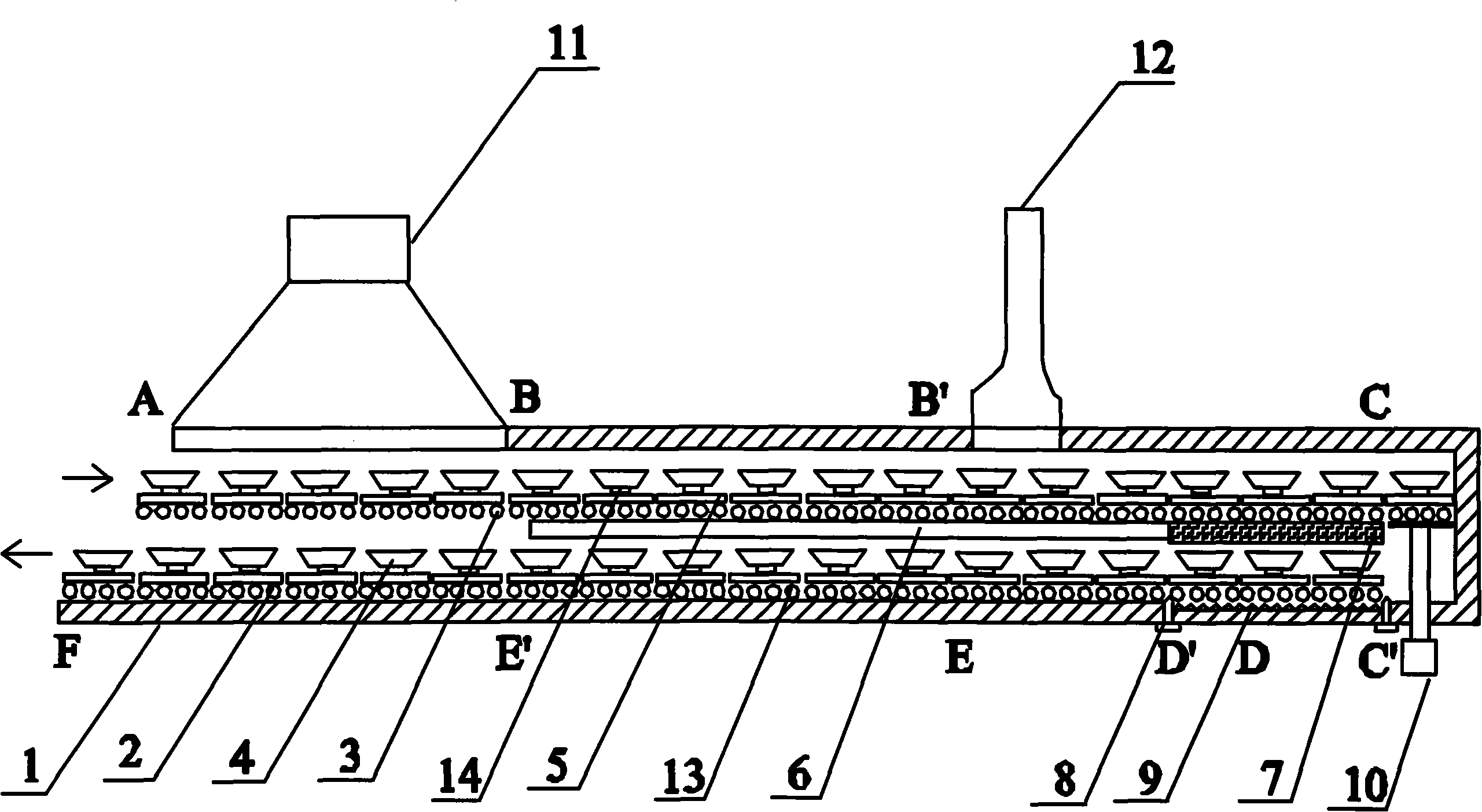

Novel tunnel-type folded-rail continuous sintering furnace and sintering method thereof

InactiveCN102620559ARigorous and simple structureSmall footprintFurnace typesSlagTemperature difference

The invention relates to a novel tunnel-type folded-rail continuous sintering furnace and a sintering method thereof. The novel tunnel-type folded-rail continuous sintering furnace comprises a furnace body, wherein one end of the furnace is open while the other end of the furnace is closed; an upper layer of roll-type or push-plate-type conveying devices (3) and a lower layer of roll-type or push-plate-type conveying devices (2) which are folded and move in opposite directs are arranged in the inner cavity of the furnace; a slag falling-preventing baffle plate (6) and a carrying mechanism (10) capable of doing an up-and-down reciprocating movement are arranged between the two layers; and a heating device (9) and a fuel gas curtain separating nozzle (8) are arranged in the inner cavity of the lower layer of the furnace. By virtue of a super-fast single-sided heating sintering mechanism, and by the adoption of a pair of opposite conveying devices with an extremely high heat exchanging rate and an extremely high afterheat utilizing rate, the temperature difference between the upper layer and the lower layer can remain about 150-300 DEG C at the same section, thus achieving the most economical ceramic continuous sintering state; therefore, the novel tunnel-type folded-rail continuous sintering furnace is a novel continuous sintering furnace with a super-high sintering speed, an extremely high heat exchanging rate and a super-short length.

Owner:JIANGXI KOAON IND

Light roasting MgO suspension calcination production process and device

The invention discloses a light roasting MgO suspension calcination production process and device. The device comprises a raw material cabin, a five-stage cyclone preheating tube, a suspension calcination furnace, three sets of combustion systems, a three-stage suspension cooling cylinder, a two-stage fluidized bed, a waste gas treatment device, a sleeve type water cooling spiral conveyor, a finished product cabin, a fan, a turning plate valve, a temperature detector and the like. The defects that the existing light calcination MgO calcination equipment has the narrow calcination temperature regulation range, the activity of the produced light calcination MgO product is single, collapse materials under the abnormal work conditions cannot be timely treated, the stable operation of the wholesystem is influenced, and the like are overcome. The combustion systems are arranged in the height direction and the radial direction of the suspension calcination furnace; the two-stage fluidized bed is arranged at the discharging opening of the suspension calcination furnace; the problem of the material collapse phenomenon occurring under the abnormal work conditions can be solved; meanwhile, the precise different-region calcination of the MgO with different activities can be realized; the popularization and application of the light calcination MgO in the building industry can be facilitated.

Owner:ZHENJIANG SOBUTE NEW MATERIAL CO LTD +1

Waste heat recovery system based on data center and control method for waste heat recovery system

PendingCN108469111AImprove waste heat recovery efficiencyImprove cooling effectEnergy recovery in ventilation and heatingMechanical apparatusWaste heat recovery unitData center

The invention discloses a waste heat recovery system based on a data center and a control method for the waste heat recovery system. The waste heat recovery system comprises a waste heat collecting unit, a heat pump unit, a heat storage unit, a waste heat conveying unit and a user end. The waste heat recovery system has the advantages that the waste heat collecting unit collects heat generated ina machine room of the data center, and the heat is transmitted to the user end through the waste heat conveying unit after being compressed and condensed by the heat pump unit; the waste heat recoverysystem further stores a part of waste heat in advance through the heat storage unit, when the waste heat is insufficient, the waste heat is released and used, and therefore the waste heat utilizationrate is increased; the purposes that the indoor waste heat is extracted and utilized, circulating water of a heat supply network is heated, and heat supply is realized can be achieved by the waste heat recovery system; and the heat generated by the machine room of the data center can be recycled and reused by the waste heat recovery system, so that energy waste and environmental pollution causedby emission of the waste heat of the machine room can be avoided.

Owner:ZHONGSHOUNENG ENERGY INVESTMENT BEIJING CO LTD

Binary Rankine cycle waste heat generating method, binary Rankine cycle waste heat generating system and generator

PendingCN110593977AImprove power generation efficiencyImprove waste heat utilizationSteam engine plantsEvaporationEngineering

The invention provides a binary Rankine cycle waste heat generating method, a binary Rankine cycle waste heat generating system and a generator. The binary Rankine cycle waste heat generating system comprises a dual evaporation pressure waste heat boiler, a high pressure steam heat recovering system and a low pressure steam heat recovering system, wherein the high pressure steam heat recovering system is used for recycling high pressure steam waste heat; the low pressure steam heat recovering system is used for recycling low pressure steam waste heat; the high pressure steam heat recovering system is a Rankine cycle system of water; and the low pressure steam heat recovering system is a Rankine cycle system containing water and an organic working medium. According to the binary Rankine cycle waste heat generating method, the binary Rankine cycle waste heat generating system and the generator, the dual evaporation pressure waste heat boiler is adopted; the high pressure steam heat recovering system is used for recovering high pressure steam, and the low pressure steam heat recovering system is used for recovering low pressure steam, so that stepped recycling of steam waste heat is realized and is effectively utilized; and compared with a single evaporation pressure waste heat boiler, the dual evaporation pressure waste heat boiler has the advantages that main steam parameters entering a steam turbine can be effectively improved and the generating efficiency of the steam turbine is improved.

Owner:GREE ELECTRIC APPLIANCES INC

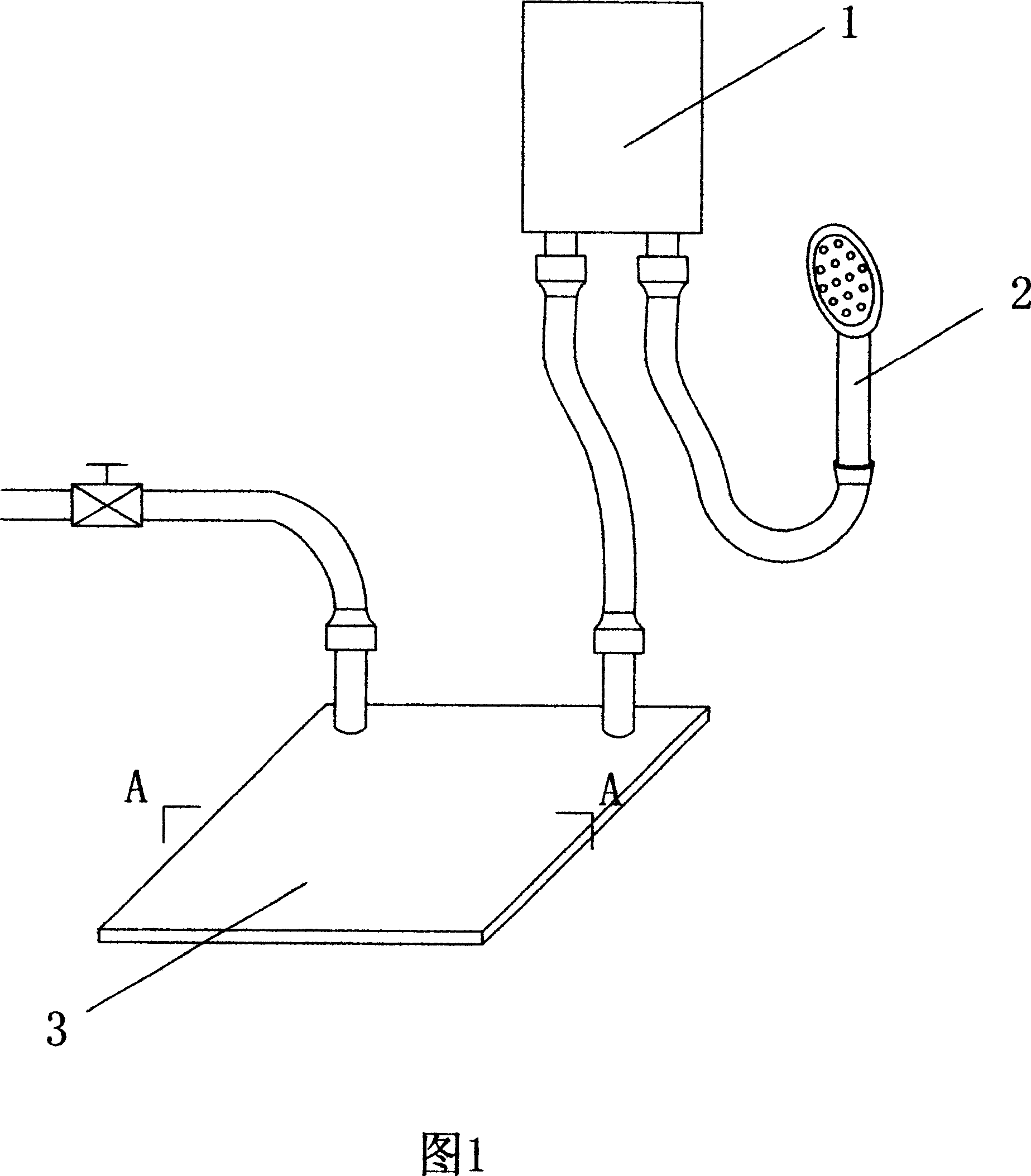

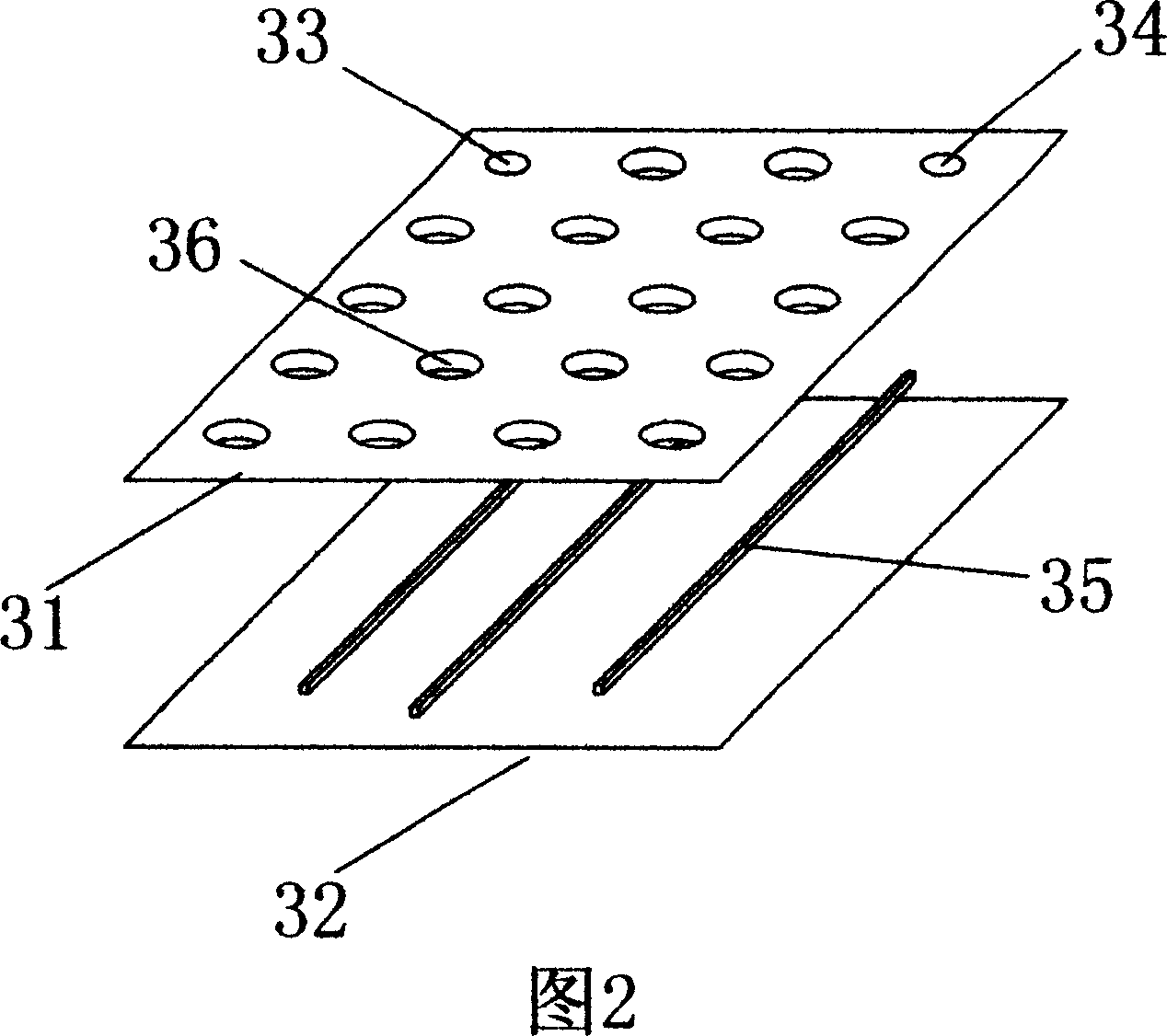

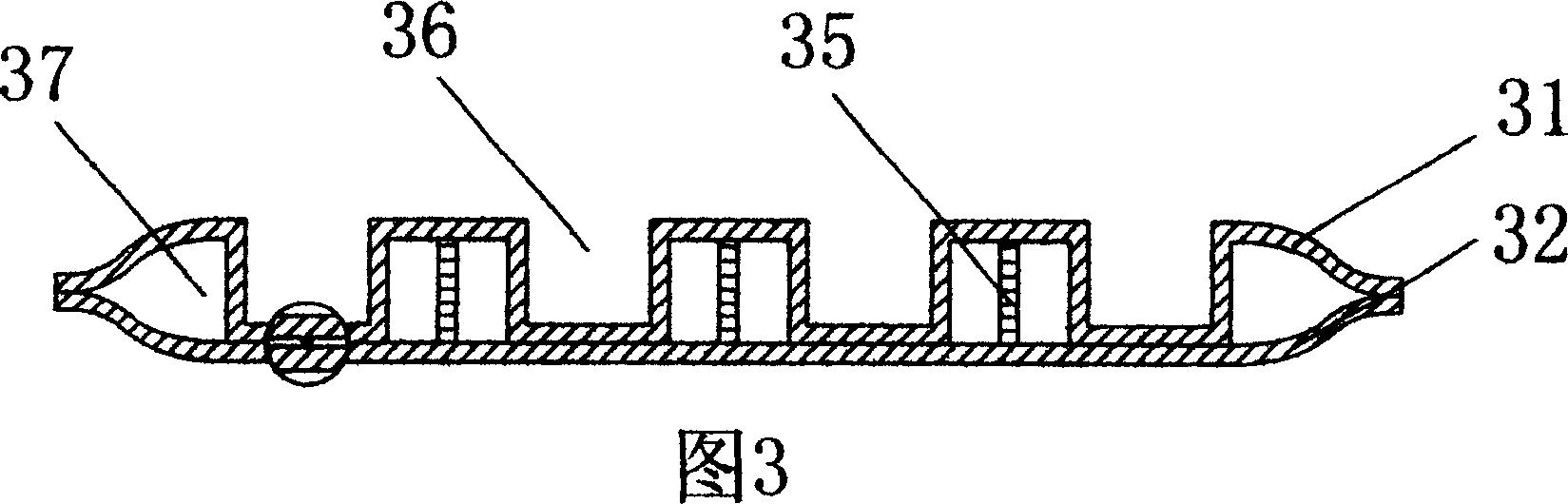

Energy-saving shower

ActiveCN1967127ALight structureReduce energy consumptionStationary conduit assembliesEngineeringGuide wires

An energy saving shower comprises a heater, shower head, heat transmitter, with the heater connecting with shower head and heat transmitter, featuring in the heat transmitter made of seal container, water intake port, and water outlet port, upper panel and bottom plate for the seal container forming a hollow layer around them, with the water intake and outlet ports connecting with the hollow layer which has flow guide wire inside. It is simple, light, reliable, energy saving and low in cost, with residual heat utilization rate reaching 80%.

Owner:蔡应麟 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com