Method and device for smelting low grade zinc lead material

A low-grade, zinc-lead technology, applied in furnaces, blast furnace details, blast furnaces, etc., can solve the problems of high energy consumption, low production efficiency, and difficulty in realization of zinc oxide ore, and achieve good continuous production and high utilization rate of waste heat. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

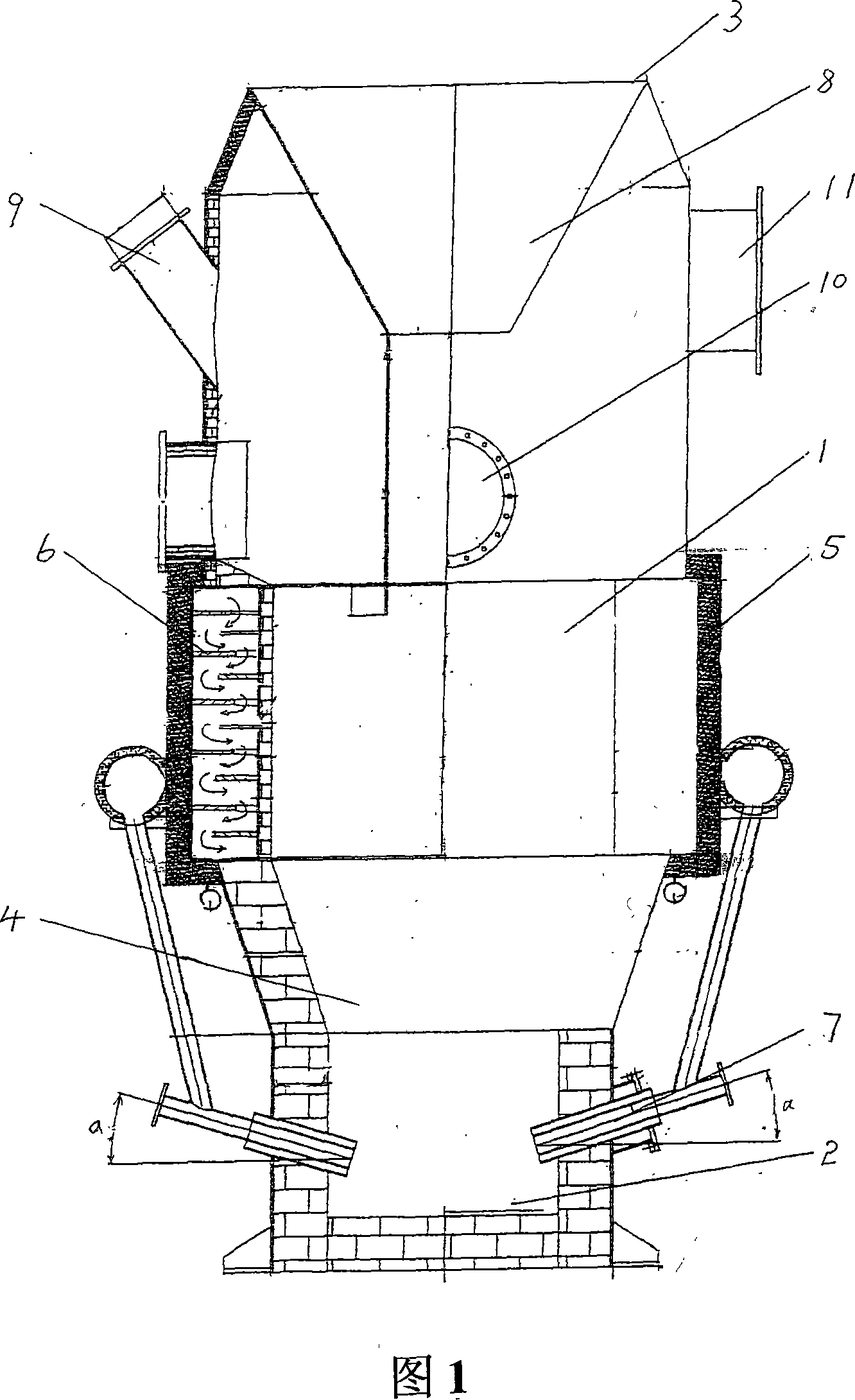

Embodiment 1

[0019] Embodiment 1: Zinc oxide ore is mixed with reducing agent, additive and binder to make pellets with a diameter of 60mm; the humidity is 5%; powdered fuel is blown by hot air to carry out blast furnace reduction smelting; Added into the furnace, the height of the material column in the furnace is controlled at 3m, the angle α between the direction of spraying powdered fuel and the vertical line is 15°, the temperature of the molten pool is 1100°C, the temperature of the hot air is 450°C, and the pressure It is 20kpa; the coke rate is 18%; the quaternary alkalinity of the slag type is R=0.55. Primary hot air and powdered fuel are blown in from the bottom air nozzle 7, the reduction temperature is controlled to volatilize a large amount of lead oxide in the zinc oxide pellets, and the zinc oxide and lead oxide are quickly reduced to zinc and lead, so that the lead oxide can be as much as possible before volatilization. Reduced to metallic lead to reduce its volatilization....

Embodiment 2

[0025] Embodiment 2: Mix the dust mineral material of iron and steel plant with reducing agent additive and binding agent to make pellets with a diameter of 50 mm; the humidity is 7%; use hot air to blow powdered fuel to carry out blast furnace reduction smelting; pellets from The feeding port is added to the furnace, the height of the material column in the furnace is controlled at 3m, the angle α between the direction of the hot air spraying the powdered fuel and the vertical line is 20°, the temperature of the molten pool is 1150°C, and the temperature of the hot air is 360°C ℃, the pressure is 18kpa; the coke rate is 20%; the quaternary alkalinity of the slag type is R=0.8. Primary hot air and powdered fuel are blown in from the bottom air nozzle 7, the reduction temperature is controlled to volatilize a large amount of lead oxide in the zinc oxide pellets, and the zinc oxide and lead oxide are quickly reduced to zinc and lead, so that the lead oxide can be as much as possi...

Embodiment 3

[0030] Example 3: Mix smelting waste slag mineral materials with reducing agent additives and binders to make pellets with a diameter of 50mm; the humidity is 7%; hot air is used to blow powdered fuel to carry out blast furnace reduction smelting; Put it into the furnace, the height of the material column in the furnace is controlled at 3m, the temperature of the molten pool is 1150°C, the angle α between the direction of the hot air spraying the powdered fuel and the vertical line is 20°, and the temperature of the hot air is 460°C. The pressure is 18kpa; the coke rate is 25%; the quaternary alkalinity of the slag type is R=1.2. Primary hot air and powdered fuel are blown in from the bottom air nozzle 7, the reduction temperature is controlled to volatilize a large amount of lead oxide in the zinc oxide pellets, and the zinc oxide and lead oxide are quickly reduced to zinc and lead, so that the lead oxide can be as much as possible before volatilization. Reduced to metallic l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com