Gas engine driven heat pump defrosting device

A gas engine, heat pump technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of power consumption, limited heat, long defrosting time, etc., to improve the utilization rate of primary energy and enhance the utilization of waste heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

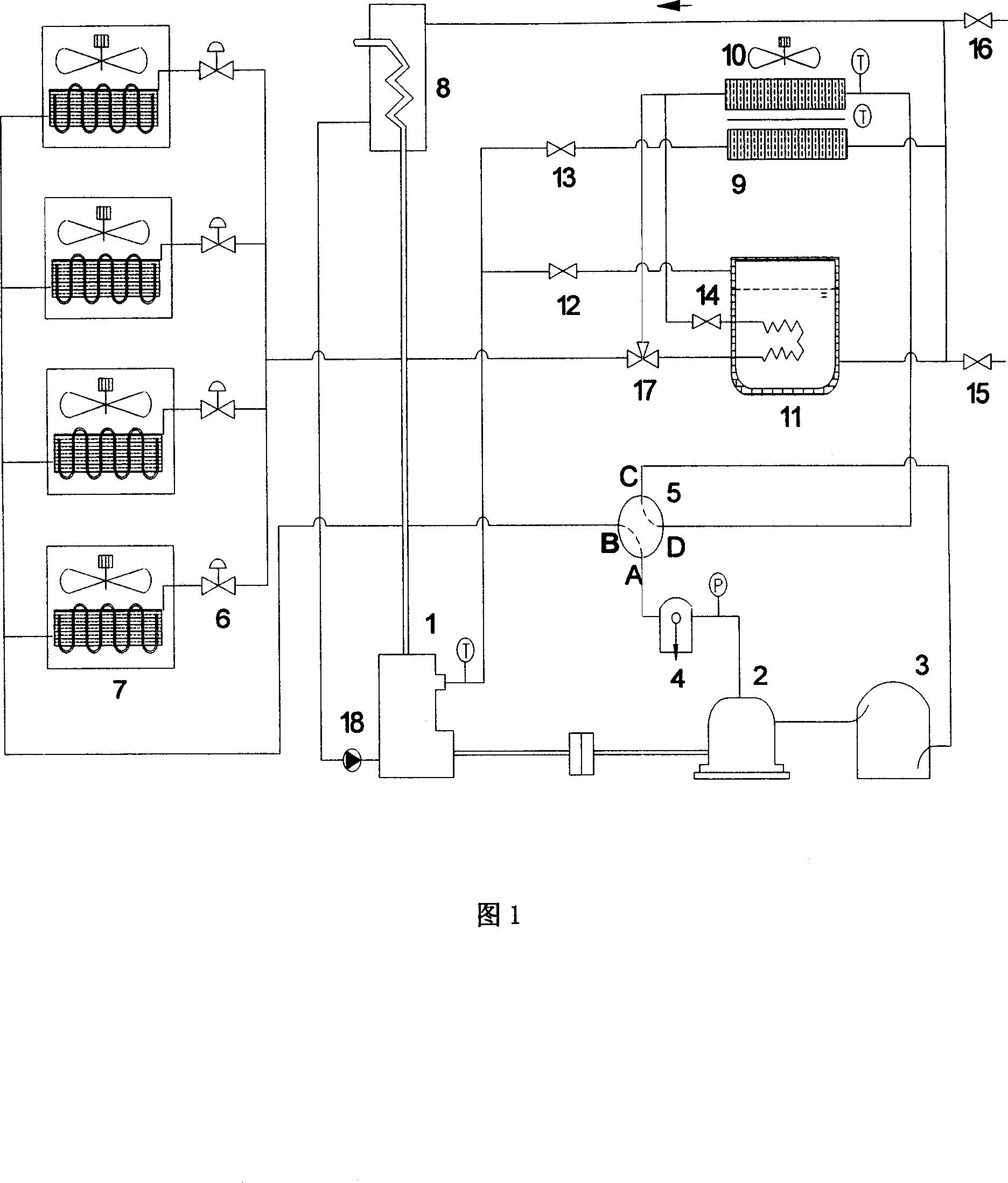

[0020] As shown in Figure 1, the gas engine-driven heat pump novel defrosting device of the present invention includes a heating defrosting circulation system, a cooling water circulation system and a control system; the heating defrosting circulation system is connected with the cooling water tank 11 The water circulation system is connected, and the heating and defrosting circulation system and the cooling water circulation system are connected with the control system through a circuit.

[0021] The heating and defrosting cycle system is composed of a gas engine 1, a compressor 2, a gas-liquid separator 3, an oil separator 4, a four-way valve 5, an electronic expansion valve 6, an indoor heat exchanger 7, and an outdoor heat exchanger. Device 10, heat preservation water tank 11, third shut-off valve 14 and three-way valve 17 etc. are connected by pipeline and form.

[0022] The cooling water circulation system is composed of a first stop valve 12, a second stop valve 13, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com