Automobile engine tail gas waste-heat and electricity converting stand test device and method for controlling same

An automobile engine and thermoelectric conversion technology, which is applied in the direction of engine testing, measuring devices, internal combustion engine testing, etc., can solve the problems of high maintenance cost, long cost recovery period, hindering marketization and industrialization, etc., and achieve precise cold end temperature control and stability, improve thermoelectric conversion efficiency, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

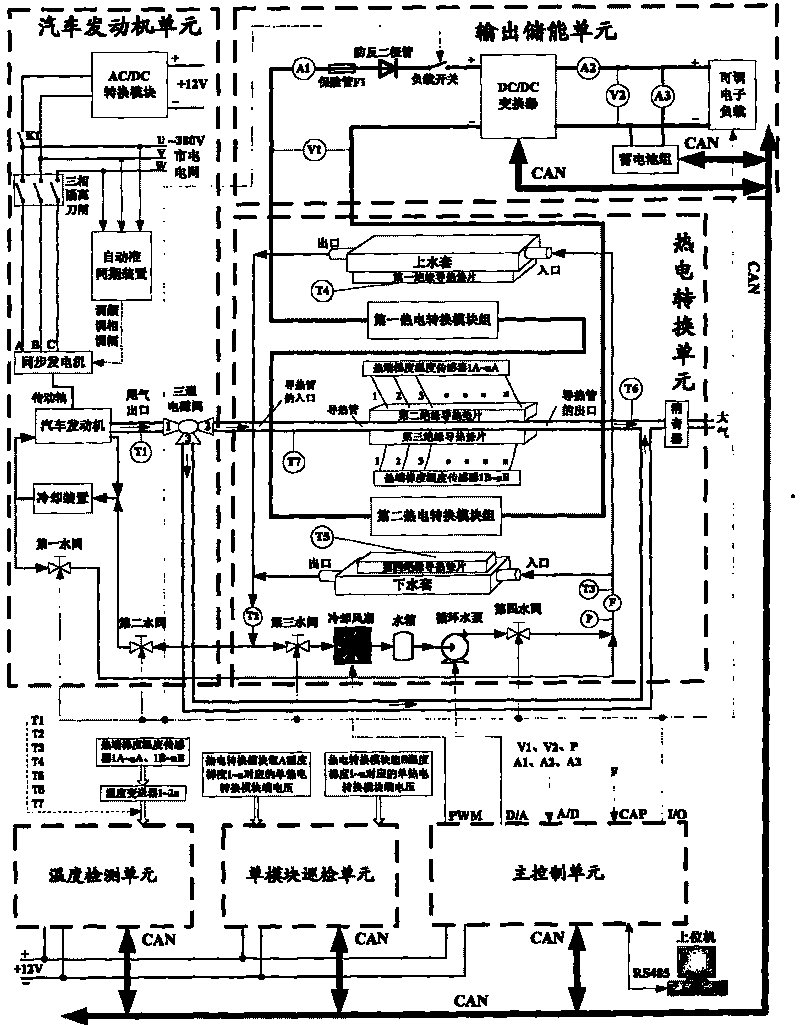

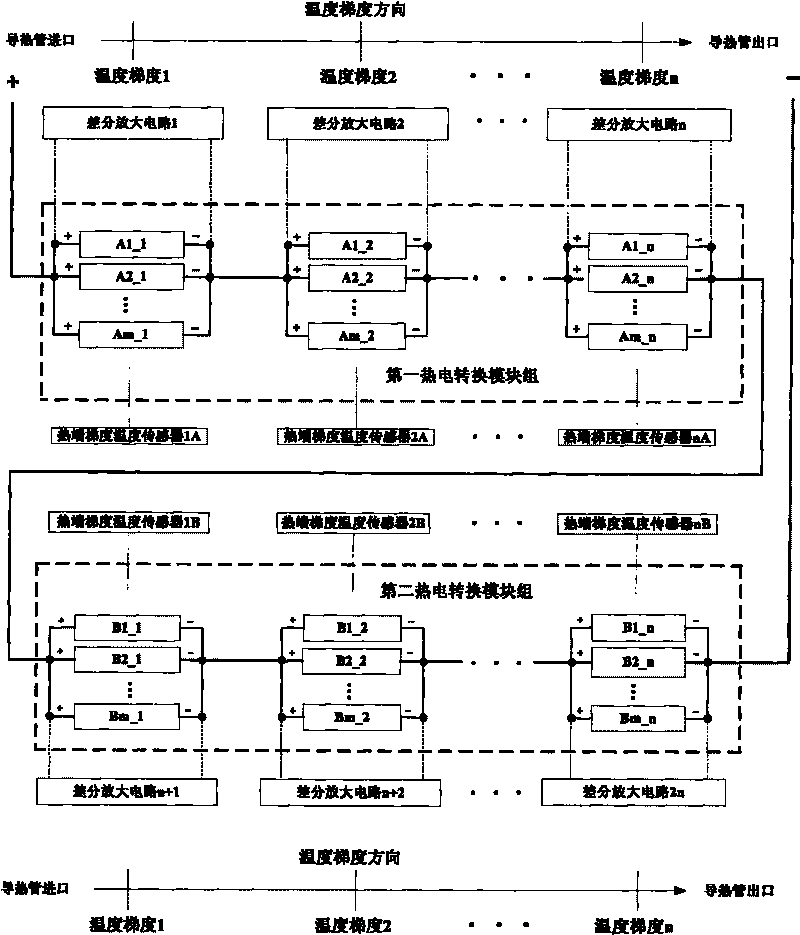

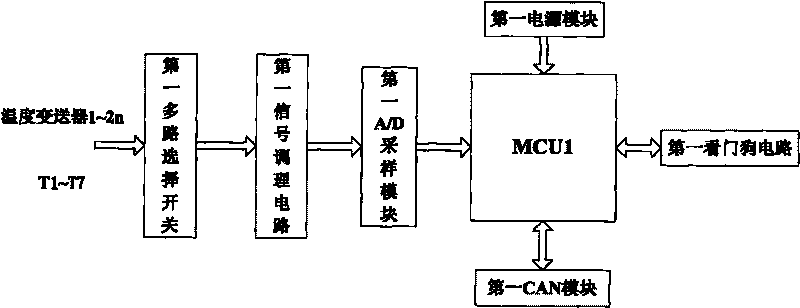

[0027] The main part of the present invention is made of automobile engine unit, thermoelectric conversion unit, output energy storage unit, temperature detection unit, single module inspection unit, main control unit ( figure 1); Among them: the automobile engine unit uses the automobile engine to drive the generator to generate electricity and connect to the three-phase mains grid, and discharges high-temperature exhaust gas; the thermoelectric conversion unit absorbs the waste heat of the exhaust pipe in the exhaust pipe to perform thermoelectric conversion to generate DC power; the output energy storage unit will The generated DC power is converted into voltage and supplied to the load or stored; the temperature detection unit detects all temperature information in each unit; the single-module inspection unit detects the terminal voltage of the thermoelectric conversion modules connected in parallel under each temperature gradient; the main control unit detects the output vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com