Percolate atomization evaporation technology

A technology of leachate and process, applied in the field of landfill leachate atomization and evaporation process, can solve the problems of long residence time, high treatment cost, difficult to meet water quality standards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

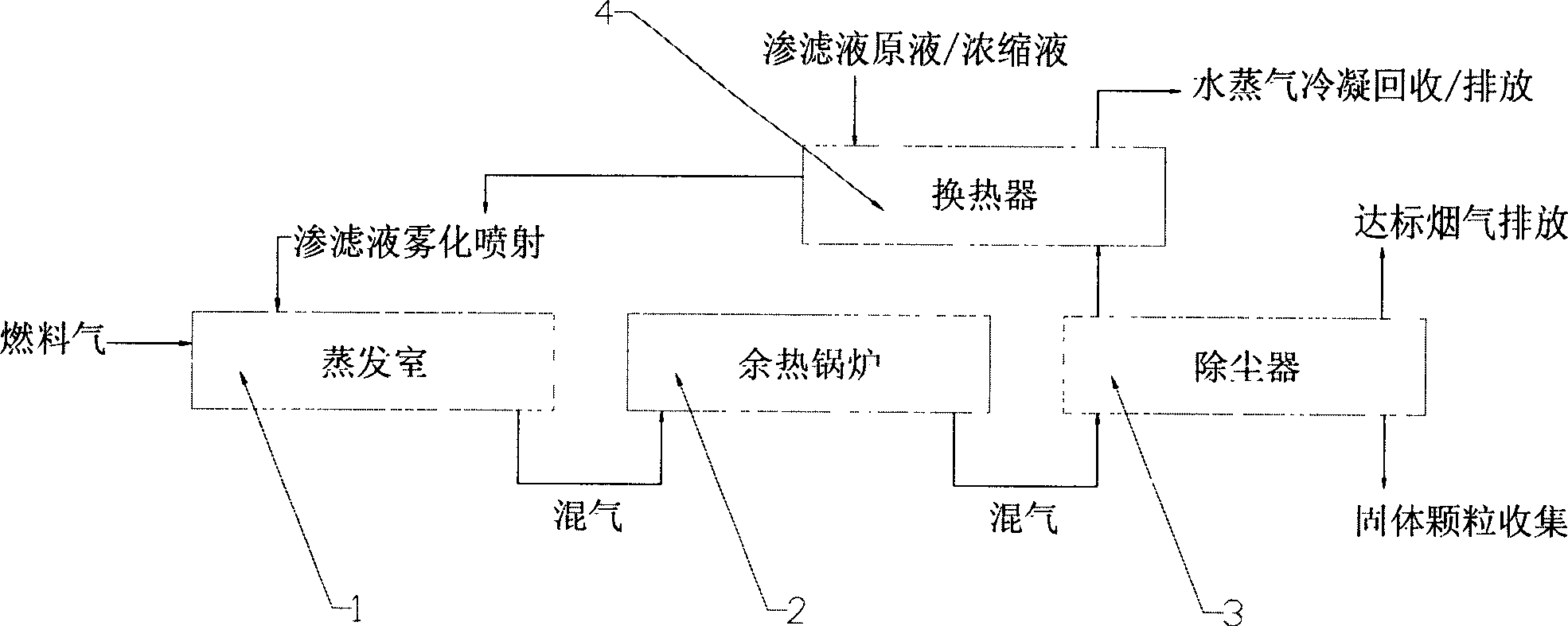

[0013] The specific steps are as follows: firstly, the leachate stock solution or the leachate concentrated solution is preheated and atomized by the waste heat exchanger 4, and then sprayed into the flame area of the evaporation chamber 1, using landfill gas or other fuels as energy sources, and burned by the burner. Incinerate the combustibles in the leachate in the flame zone while the water in the leachate evaporates in the evaporation chamber 1, so that the temperature of the mixed gas reaches 850±50°C; the mixed gas then enters the waste heat boiler 2, and the temperature of the mixed gas after heat exchange The temperature is lowered to 200-300°C; then the mixed gas enters the dust collector 3, the solid particles are removed and collected, and the water vapor is introduced into the leachate waste heat exchanger 4 to be condensed, collected or discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com