Binary Rankine cycle waste heat generating method, binary Rankine cycle waste heat generating system and generator

A Rankine cycle and waste heat power generation technology, which is applied in the direction of machines/engines, mechanical equipment, steam turbines, etc., can solve the problems that threaten the safe operation of steam turbines and easily bring liquid into the steam turbines, so as to improve the utilization rate of heat and power and waste heat utilization , The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

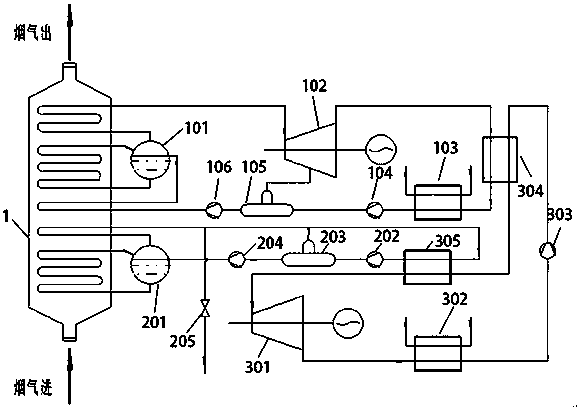

[0023] Embodiment 1: A duplex Rankine cycle waste heat power generation system.

[0024]A duplex Rankine cycle waste heat power generation system, including a double evaporating pressure waste heat boiler 1, a high-pressure steam heat recovery system and a low-pressure steam heat recovery system, the high-pressure steam heat recovery system specifically includes a high-pressure steam drum 101, a steam turbine 102, a second A condenser 103, a first condensate pump 104, a first deaerator 105, a first circulating water pump 106, the outlet end of the high-pressure steam drum 101 is connected to the inlet end of the steam turbine 102, and the outlet end of the steam turbine 102 is connected to the The inlet port of the first condenser 103, the outlet port of the first condenser 103 is connected to the inlet port of the first deaerator 105 through the first condensate pump 104, and the outlet port of the first deaerator 105 is connected through the first circulating water pump 106 ...

Embodiment 2

[0028] Embodiment 2: A waste heat power generation method of a duplex Rankine cycle.

[0029] A duplex Rankine cycle waste heat power generation method. The high-pressure steam in the double-evaporating pressure waste heat boiler 1 is recovered and utilized through the high-pressure steam heat recovery system. The steam separated from the high-pressure steam drum 101 is heated and then rushed to the steam turbine 102 to generate electricity. The steam turbine 102 The exhaust steam passes through the preheater 304 and continues to release part of the latent heat of condensation of the steam. The steam enters the first condenser 103 to continue to release heat and condense. It is pressurized by the first circulating water pump 106 and enters the high-pressure steam drum 101. Realize the effective utilization of high-pressure steam waste heat, ensure the high quality of the steam entering the steam turbine 102, and recover the low-pressure steam in the double-evaporating pressure...

Embodiment 3

[0031] Embodiment 3: a kind of generator.

[0032] A generator, including a power generation system, characterized in that the power generation system is specifically the duplex Rankine cycle waste heat power generation system as described in any one of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com