Light roasting MgO suspension calcination production process and device

A suspension calcination and production device technology, applied in the field of industrial production of light-burned MgO, can solve the problems of narrow calcination temperature adjustment range, affecting the stable operation of the system, and single product activity, so as to achieve good product quality, reduce kiln shutdown maintenance times, and dust The effect of low emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

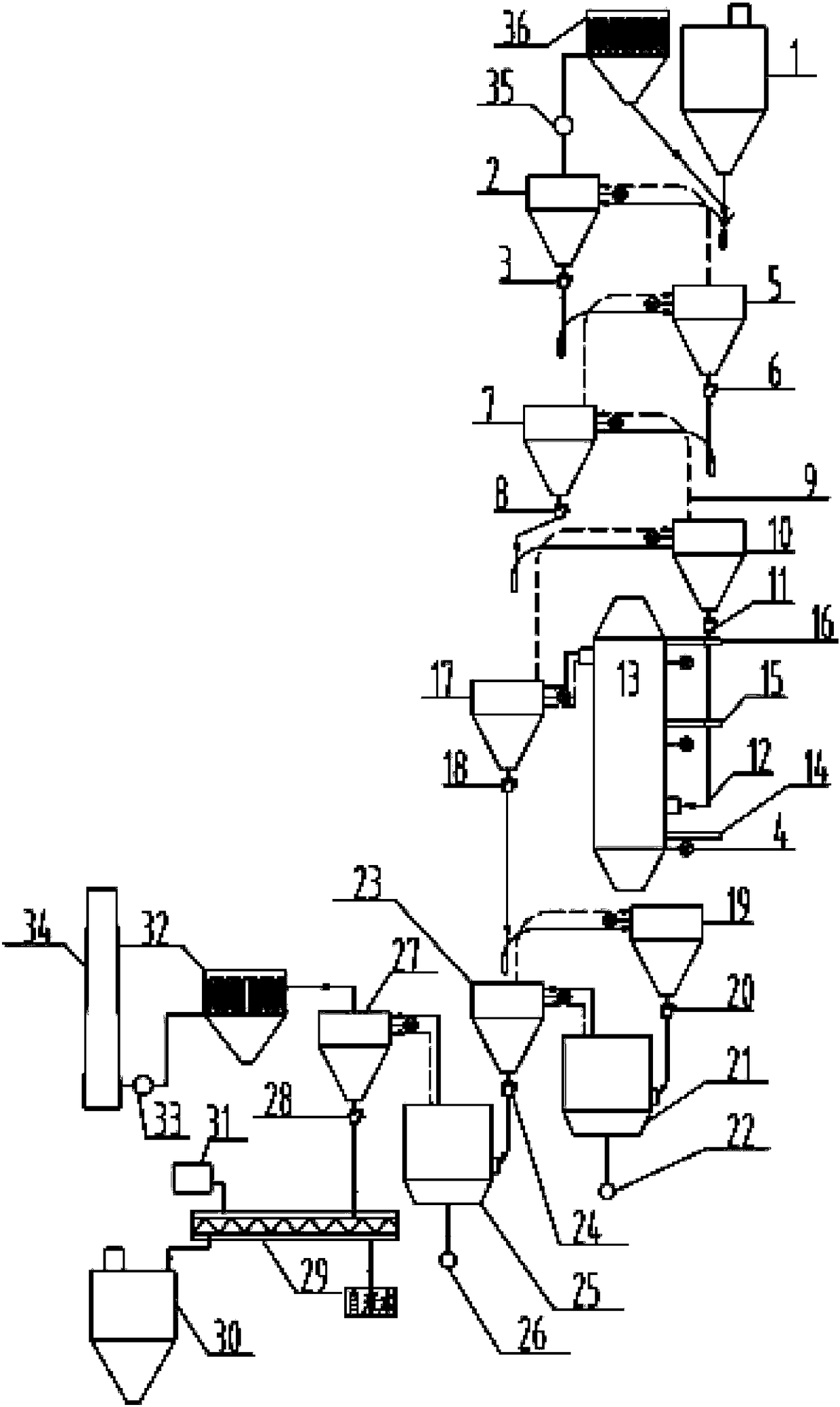

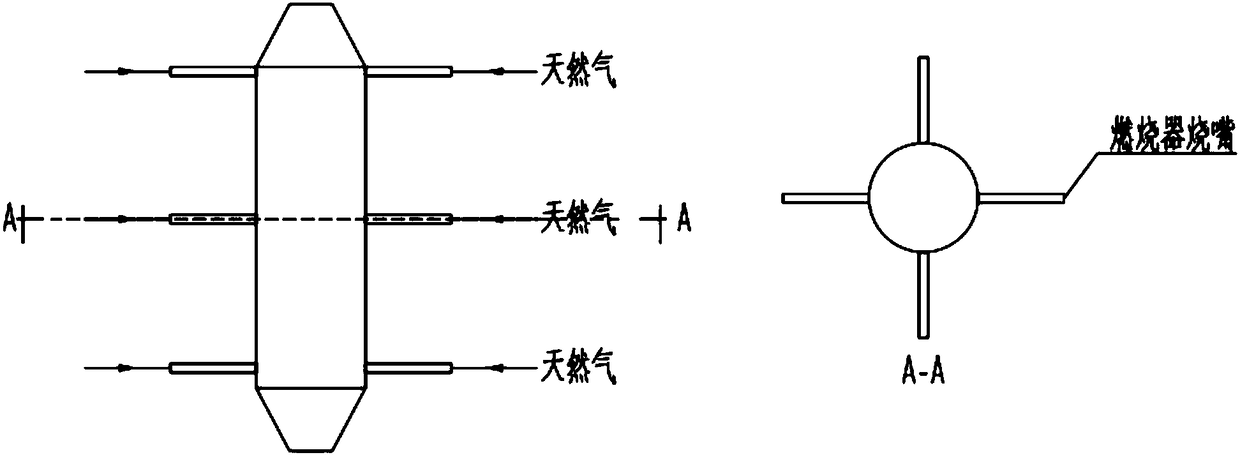

Embodiment 1

[0050] Open the four burner burners of the first combustion system 14 and the two burner burners arranged symmetrically at 180° in the second combustion system 15, and close the remaining two burner burners of the second combustion system 15 and the third combustion burner. System 16, adjust the gas supply to stabilize the temperature field in the suspension calciner at 750°C. The magnesium carbonate powder is fed into the gas outlet pipeline of the secondary cyclone preheating cylinder at a feeding speed of 92t / h, and the magnesium carbonate is produced after being preheated by the primary, secondary, third and fourth cyclone preheating cylinders respectively. The material temperature is preheated to 480°C, and then fed into the suspension calciner, which is calcined and decomposed at a temperature of 750°C in the suspension calciner to form MgO clinker powder, which is separated by a five-stage cyclone and fed into the suspension cooling system for cooling and separated step ...

Embodiment 2

[0052] Turn on the four burner burners of the first combustion system 14, the two burner burners arranged symmetrically at 180° in the second combustion system 15, and the two burner burners arranged symmetrically at 180° in the third combustion system 16, Close the remaining two pairs of burners in the second combustion system 15 and the third combustion system 16, adjust the gas supply, and stabilize the temperature field in the suspension calciner at 850°C. The magnesium carbonate powder is fed into the gas outlet pipe of the secondary cyclone preheating cylinder at a feeding speed of 90t / h, and the magnesium carbonate is produced after being preheated by the primary, secondary, third and fourth cyclone preheating cylinders respectively. The material temperature is preheated to 500°C, and then fed into the suspension calciner, which is calcined and decomposed at a temperature of 850°C in the suspension calciner to form MgO clinker powder, which is separated by a five-stage c...

Embodiment 3

[0054] Turn on the four burner burners of the first combustion system 14, the four burner burners of the second combustion system 15, and the two burner burners arranged symmetrically at 180° in the third combustion system 16, and close the third combustion For the remaining two burners in the system 16, adjust the gas supply to stabilize the temperature field in the suspension calciner at 970°C. The magnesium carbonate powder is fed into the gas outlet pipeline of the secondary cyclone preheating cylinder at a feeding speed of 87t / h, and the magnesium carbonate is produced after being preheated by the primary, secondary, third and fourth cyclone preheating cylinders respectively. The material temperature is preheated to 530°C, and then fed into the suspension calciner, which is calcined and decomposed at a temperature of 970°C in the suspension calciner to form MgO clinker powder. Finally, after being cooled by a sleeve-type water-cooled screw conveyor, it is fed into the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com