Patents

Literature

613results about How to "Reduce emission concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

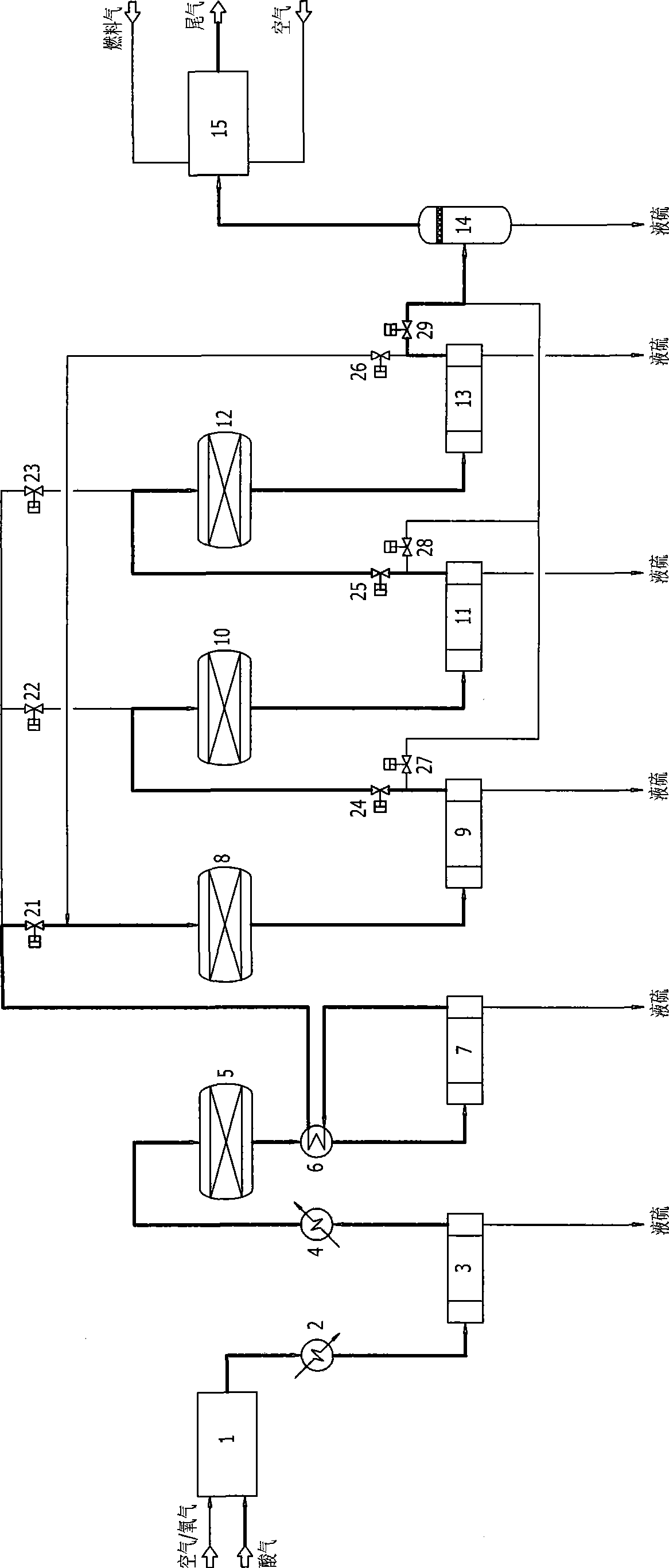

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192AAchieve regenerationImprove conversion rateEnergy inputSulfur preparation/purificationReaction temperatureOxygen

Owner:CHENGDU SEPMEM SCI & TECH

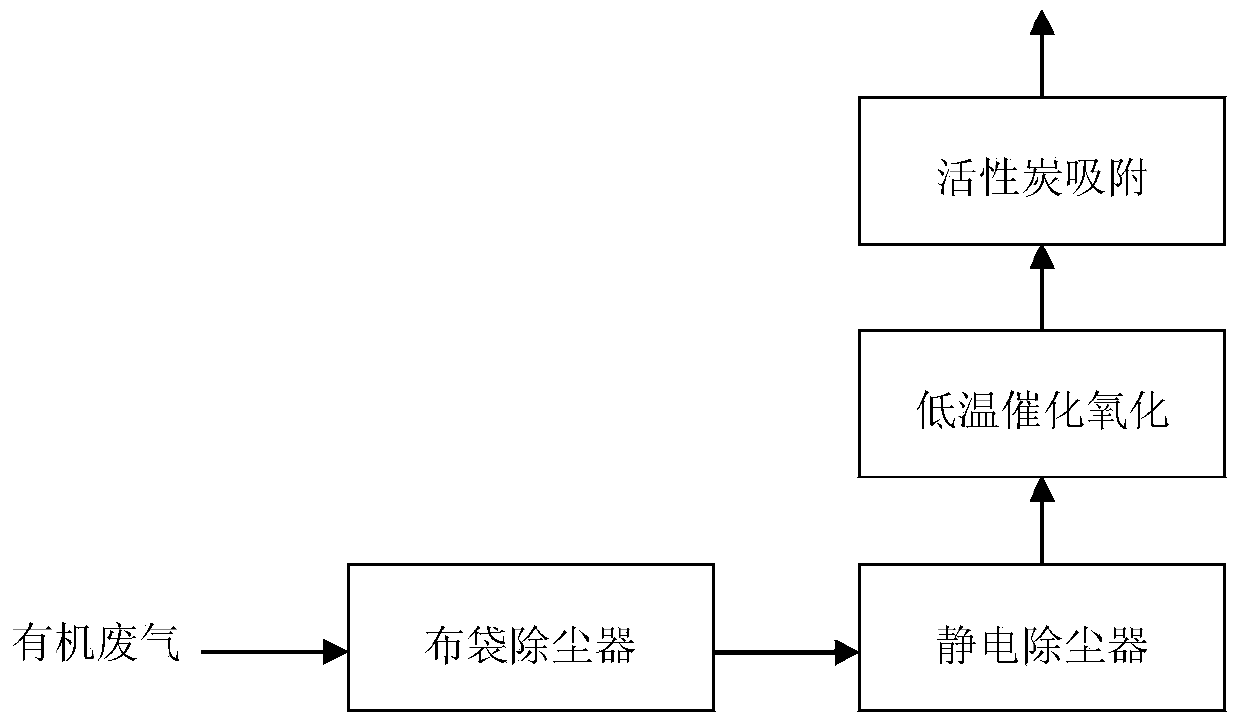

VOCs high-efficiency processing method

InactiveCN103721510AEasy to recycleGood emission concentrationCombination devicesHigh concentrationAdditive ingredient

The invention relates to a VOCs (Volatile Organic Compounds) high-efficiency processing method. In the method, dust removal processing, odor removal processing and tail gas processing are carried out on waste gas. Firstly, a bag-type dust collector is adopted to carry out preprocessing on the waste gas, parts of materials are recovered and then an electrostatic dust collector is introduced to further recovery the materials; then the waste gas is subjected to low-temperature catalytic oxidation processing; the waste gas is subjected to adsorption processing. According to the invention, the petrochemical industrial organic waste gas is processed by utilizing the combination of catalytic oxidation and adsorption processes, so that the materials can be well recovered, odor of the organic waste gas is eliminated and the problem of emission of petrochemical industrial tail gas is solved. The method disclosed by the invention has a good purifying effect and low consumption and is low in engineering cost; the materials can be recovered; flue gas emission concentration is lower than the emission standard by over 30 percent; the VOCs high-efficiency processing method has obvious economic benefits and social benefits and can be used for processing the petrochemical industrial organic waste gas with high concentration, high flow and complex ingredients.

Owner:JIANGSU ZHONGKE RUISAI POLLUTION CONTROL ENG +1

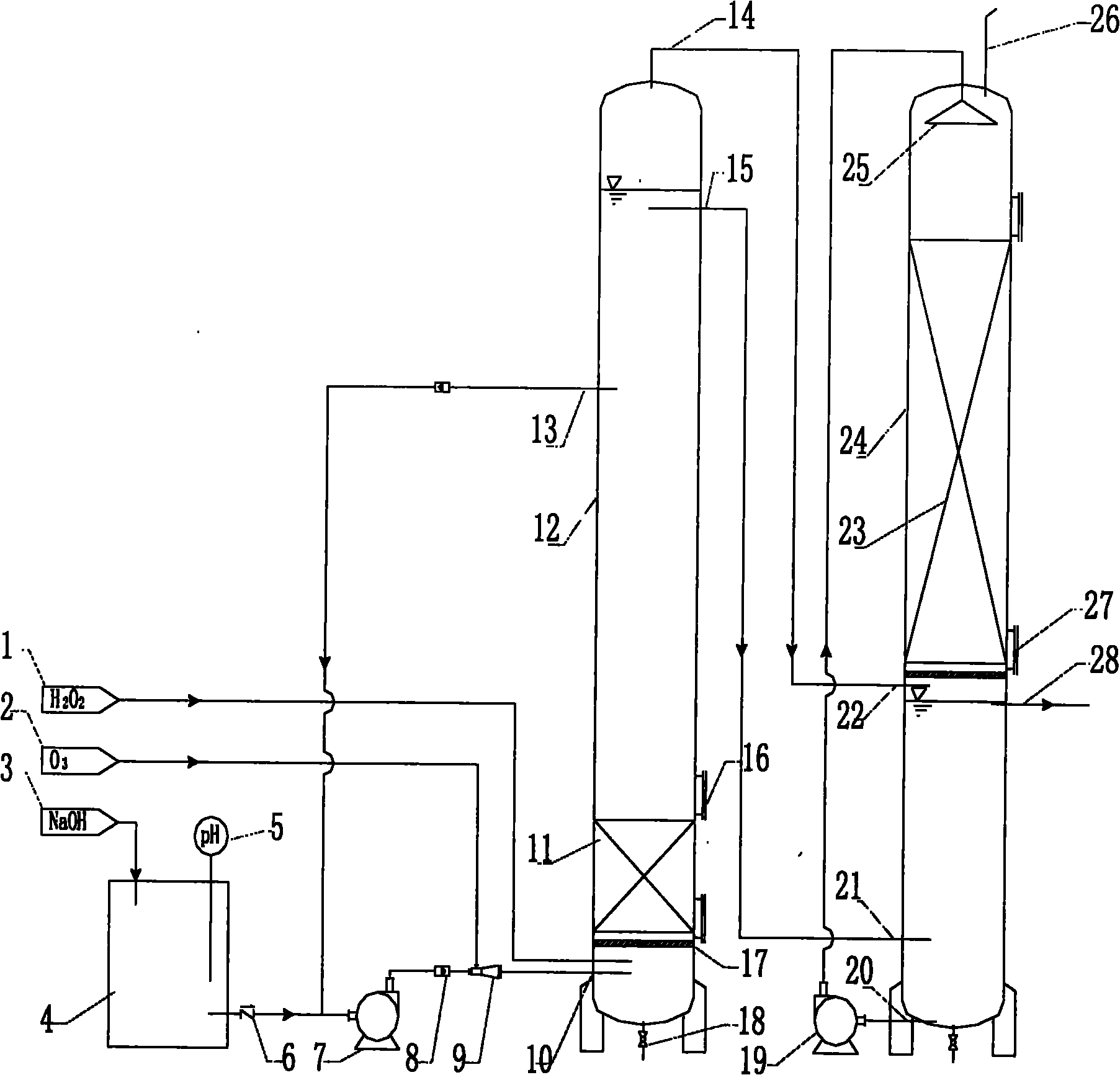

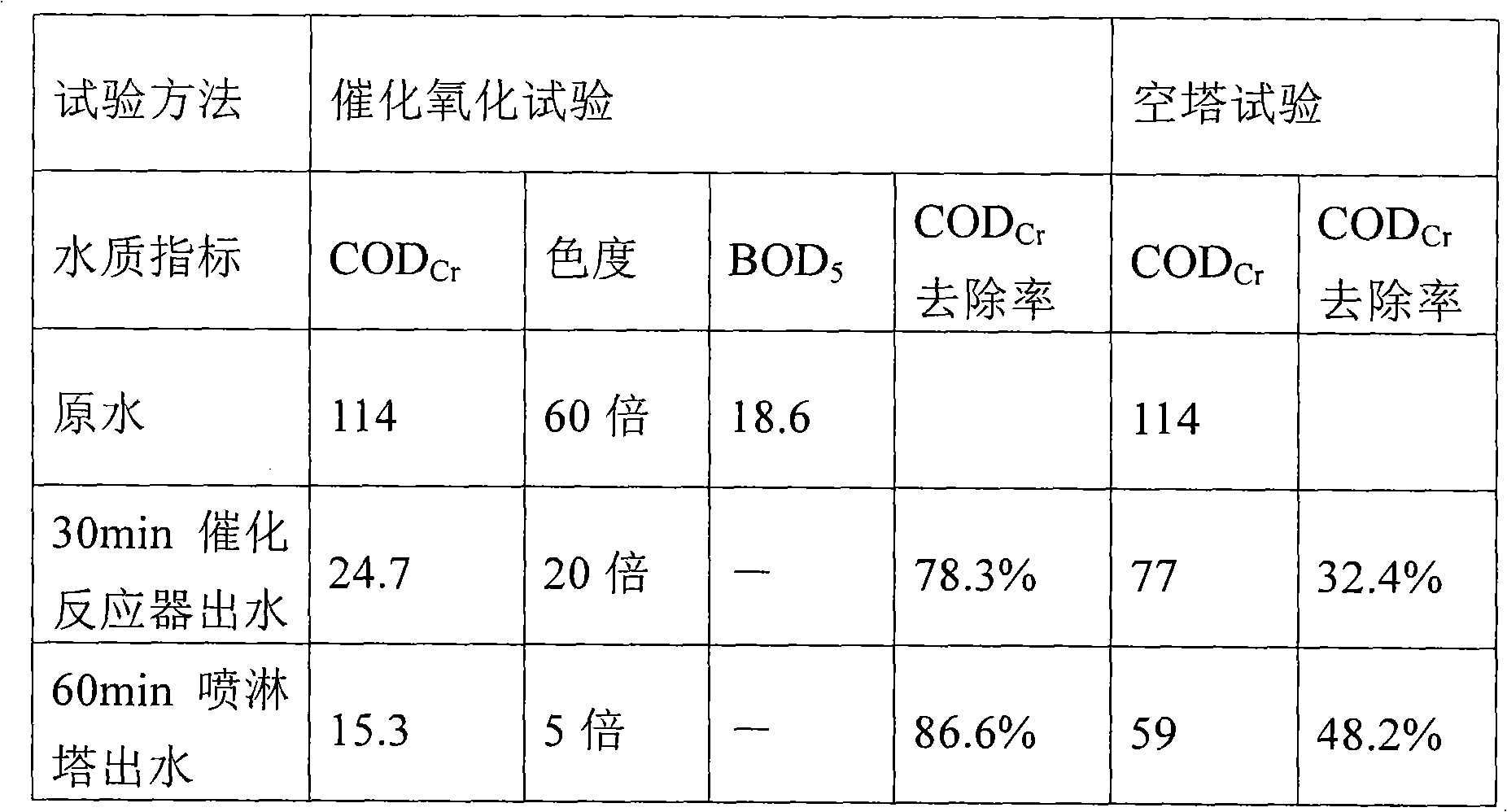

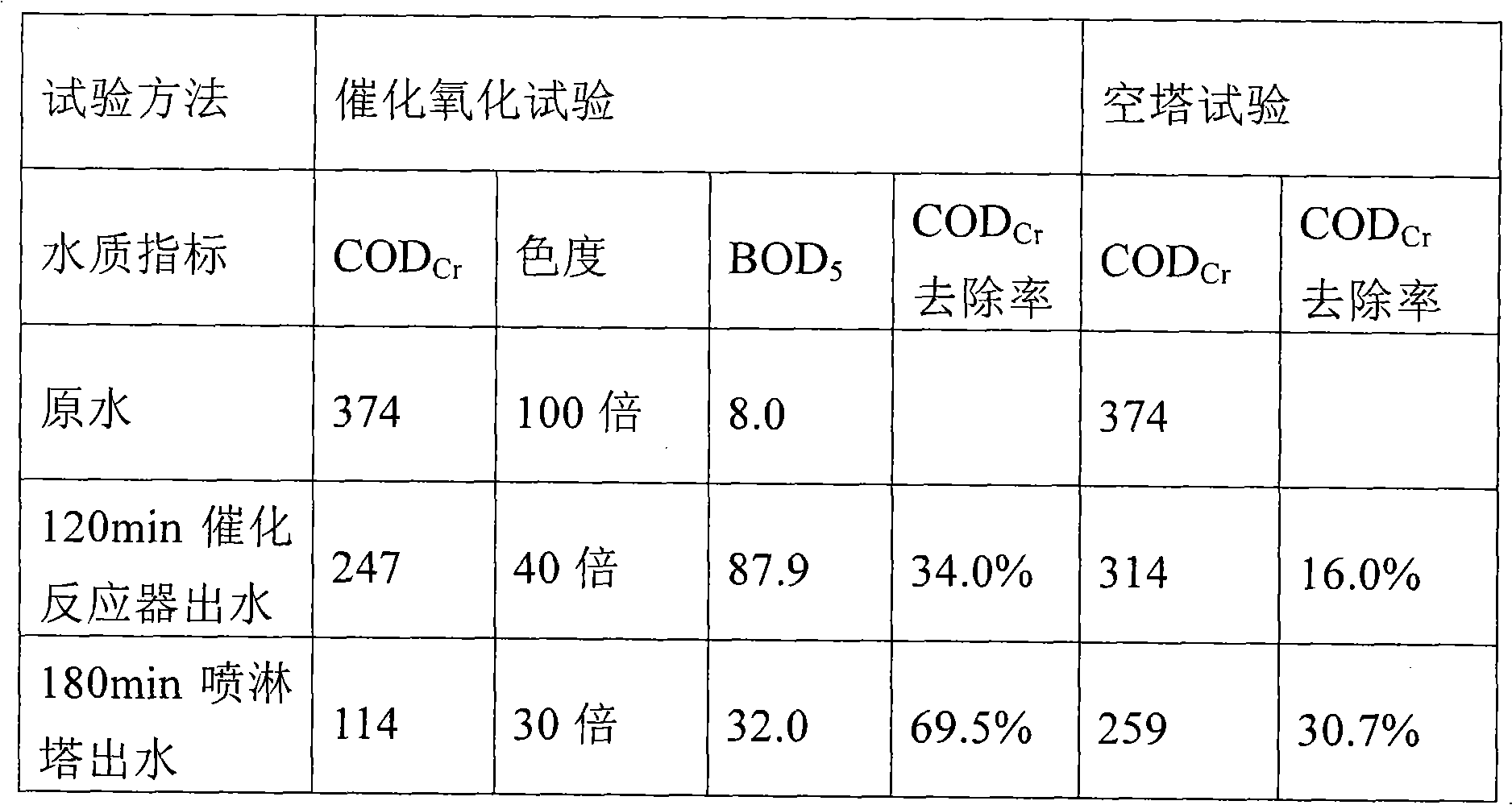

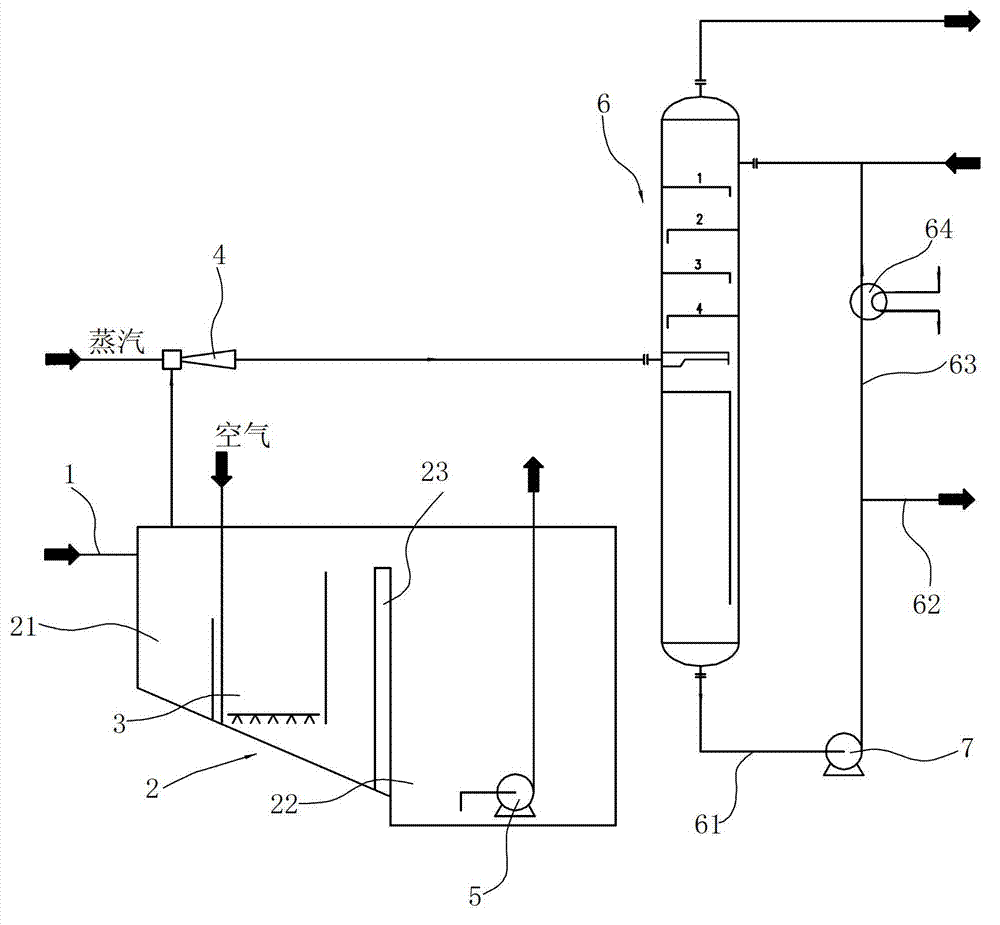

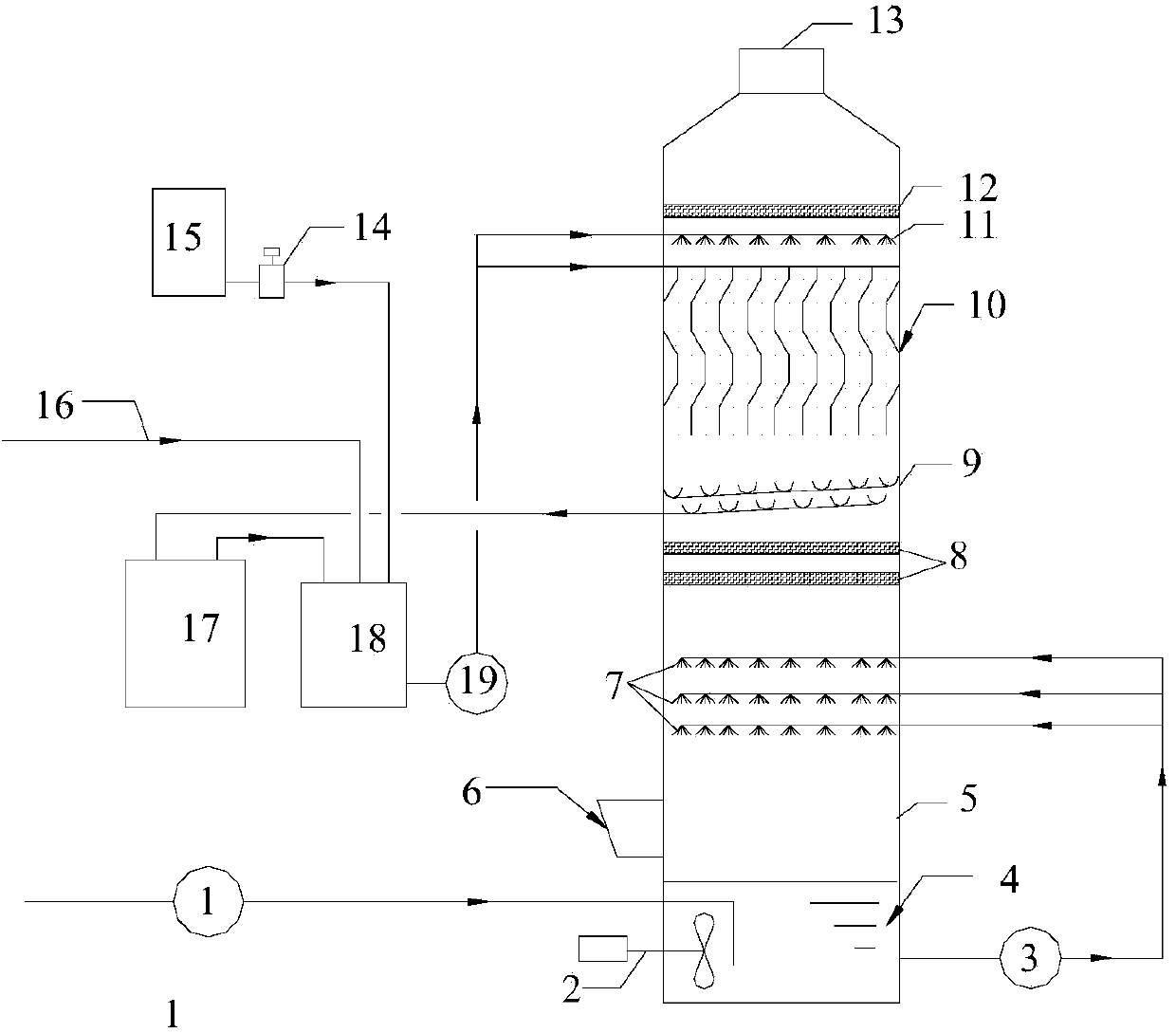

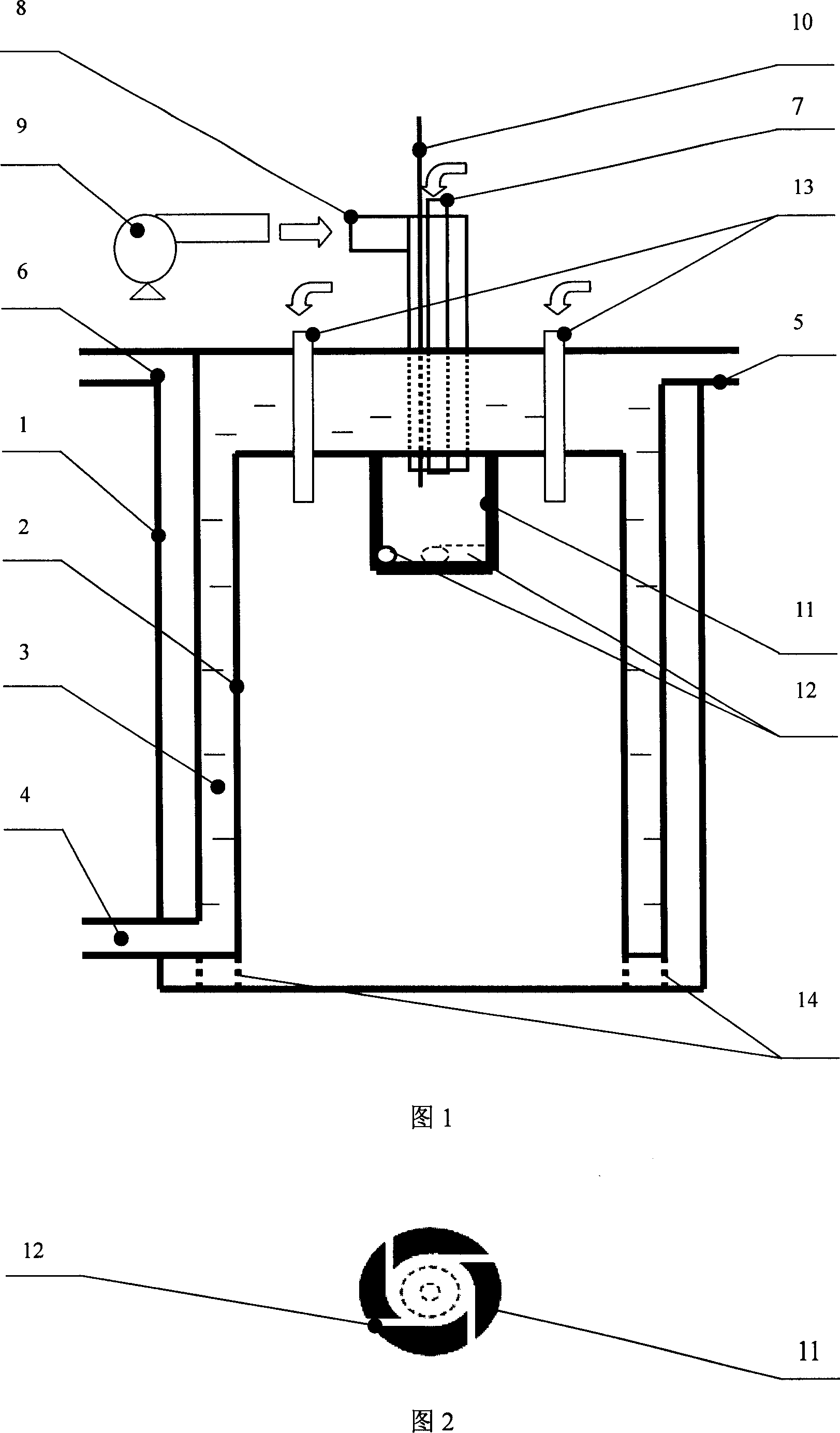

Equipment and method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone

ActiveCN101781036AIncrease contact areaImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentWastewaterPh regulation

The invention provides equipment and a method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone. The equipment comprises a feeding system, an ozone catalytic reaction tower and a spray absorbing tower; the feeding system comprises a wastewater pH regulation device, a wastewater feeding pipeline, a hydrogen peroxide aqueous solution feeding pipeline, an ozone feeding pipeline and a pH regulator feeding pipeline; the wastewater pH regulation device is communicated with the wastewater feeding pipeline and the pH regulator feeding pipeline respectively; the ozone feeding pipeline is communicated with the wastewater feeding pipeline; the ozone catalytic reaction tower is communicated with the wastewater feeding pipeline and the hydrogen peroxide aqueous solution feeding pipeline respectively so that wastewater undergoes once catalytic reaction in the presence of a first catalyst to generate a liquid flow and an ozone tail gas flow which are subjected to initial treatment; and the spray absorbing tower is communicated with a catalytic reaction system, is used for spraying at least one part of the liquid flow which is subjected to the initial treatment, and is contacted with the ozone tail gas flow in the presence of a second catalyst to undergo second catalytic reaction.

Owner:ENN ENVIROTECH CO LTD

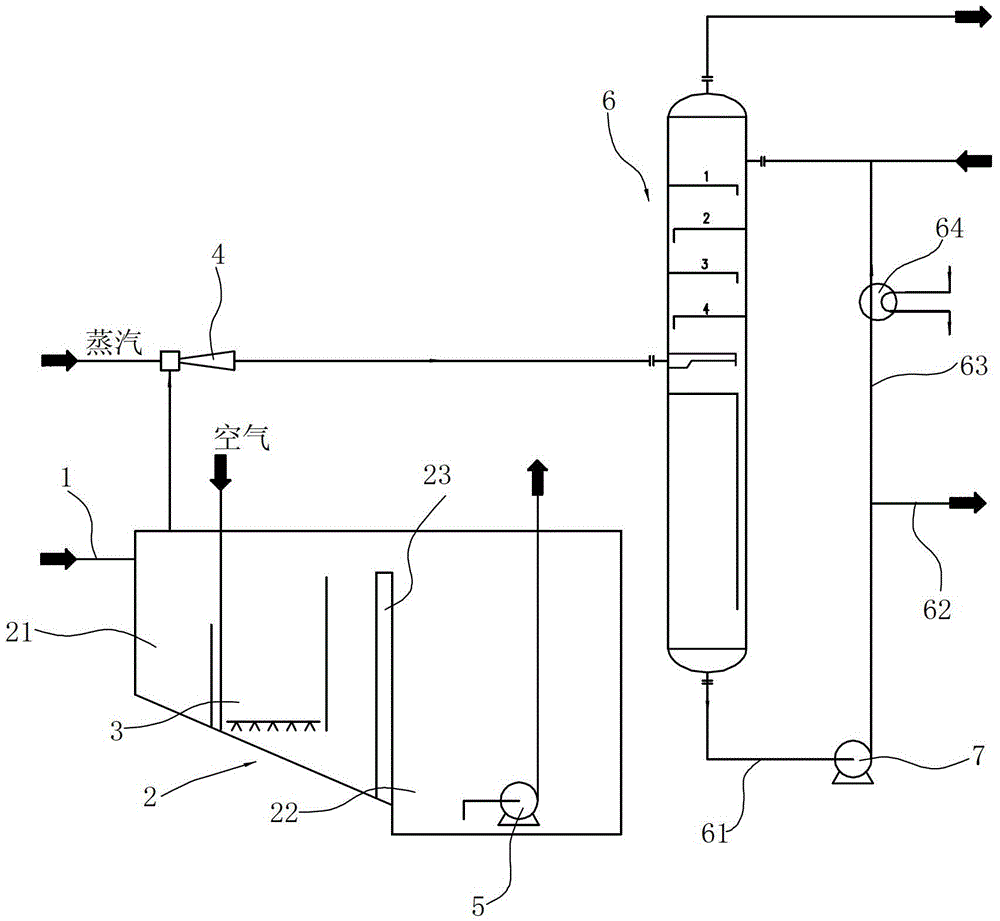

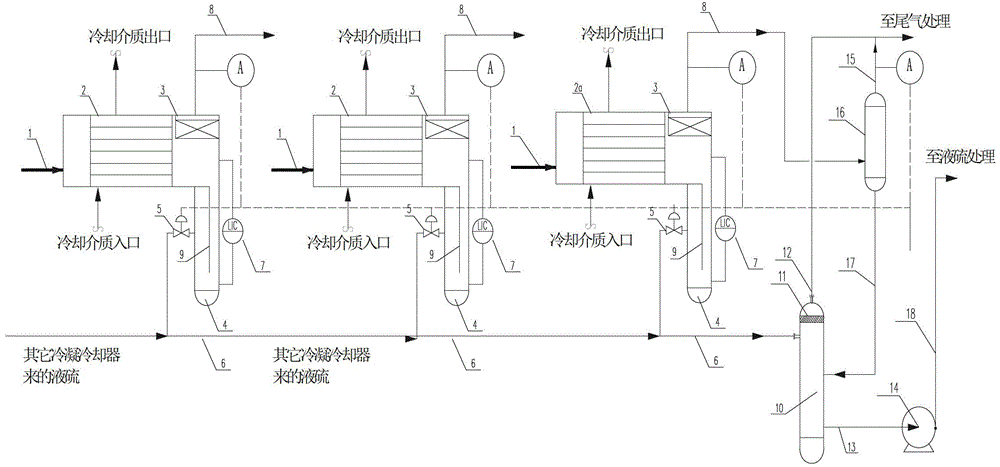

Liquid sulphur degassing device and liquid sulphur degassing method

The invention relates to a liquid sulphur degassing device and a liquid sulphur degassing method. The liquid sulphur degassing device comprises a liquid sulphur tank communicated with a liquid sulphur pipeline, wherein the liquid sulphur tank is internally provided with gas stripping equipment which can strip hydrogen sulphide gas in liquid sulphur, and the upper part of the liquid sulphur tank is provided with gas pumping equipment which can pump the hydrogen sulphide gas with other gases in the liquid sulphur tank out of the liquid sulphur tank; and the liquid sulphur degassing device is characterized in that the liquid sulphur tank comprises a gas stripping tank and a finished product tank, wherein an overflow dam is arranged between the gas stripping tank and the finished product tank; the liquid sulphur pipeline is communicated with the gas stripping tank; the suction inlet of the liquid sulphur pump is connected with the bottom of the finished product tank; the outlet of the gas pumping equipment is connected with the material inlet of an absorption tower; and the top of the absorption tower is provided with a waste gas outlet, the upper part of the absorption tower is provided with an absorption liquid inlet, a liquid outlet arranged at the bottom of the absorption tower is connected with a main pipeline, and the main pipeline is provided with a pressure pump which pumps out, pressurizes and conveys the liquid in the absorption tower. The liquid sulphur degassing device provided by the invention is simple in process, low in equipment investment and good in degassing effect.

Owner:ZHENHAI PETROCHEMICAL ENG CO LTD

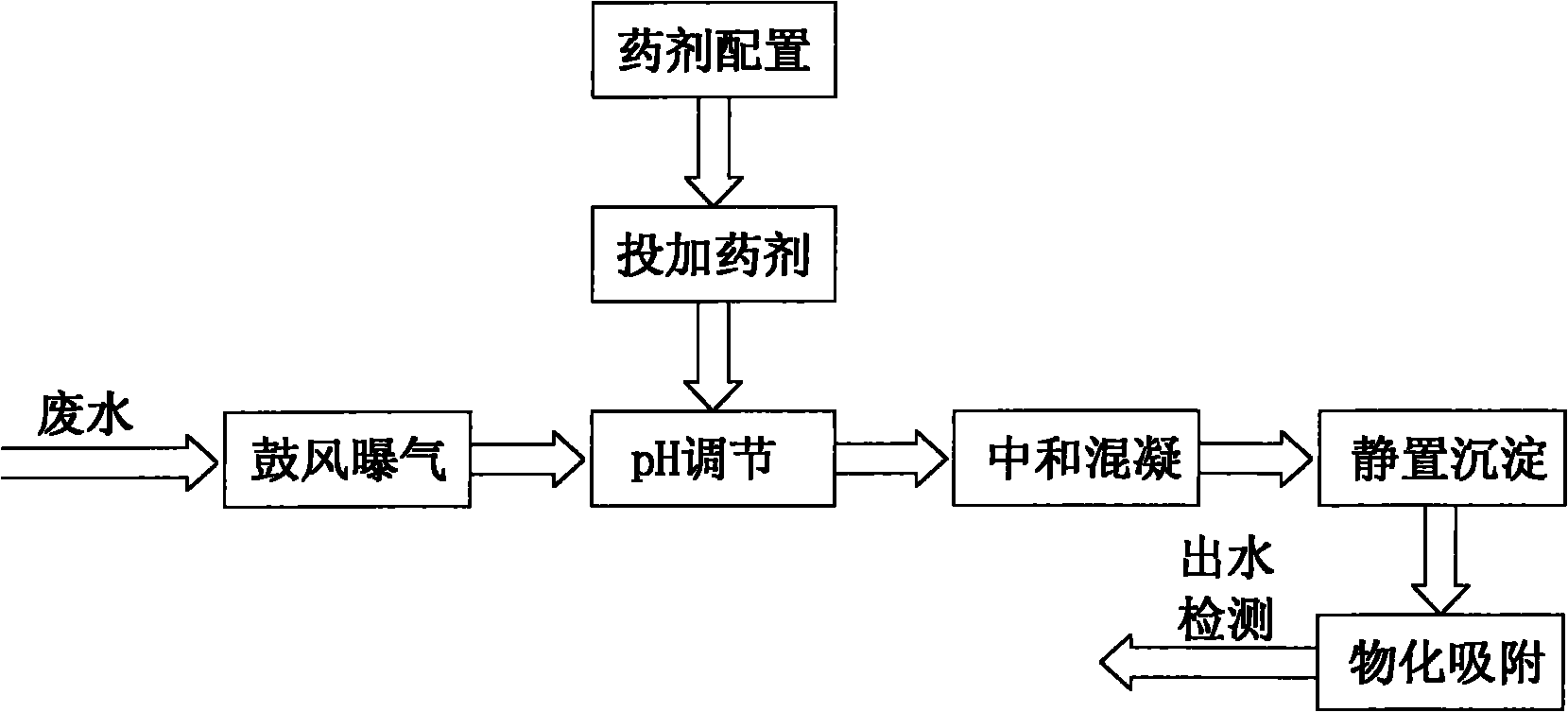

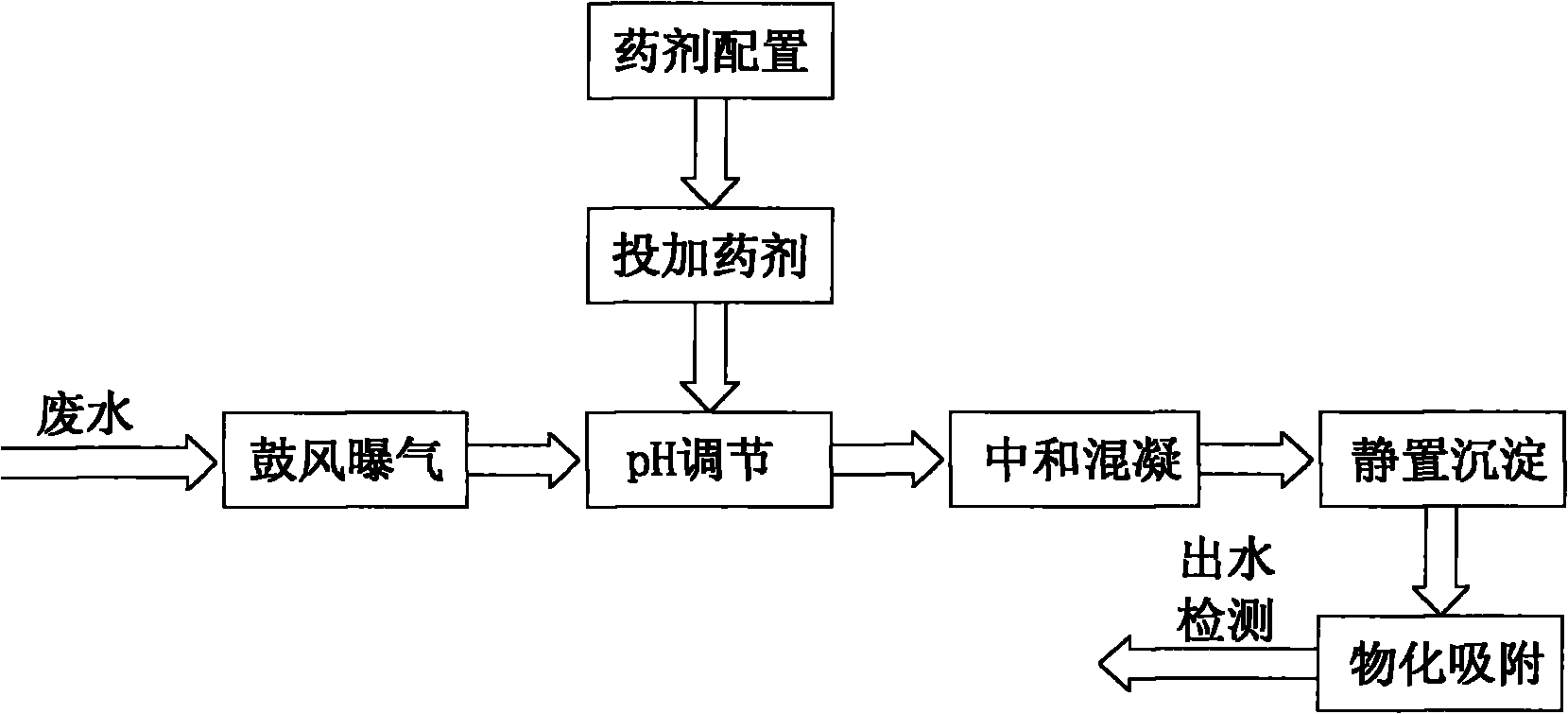

Process for treating mine wastewater containing sulfur minerals, As, Pb and Cd

InactiveCN101805084APrevent precipitationSolve the smellWaste water treatment from quariesEnergy based wastewater treatmentActivated carbon filtrationChemical adsorption

The invention discloses a process for treating mine wastewater containing sulfur minerals, As, Pb and Cd, which comprises the following steps: (1) performing blast aeration and oxidation treatment on the mine wastewater containing the sulfur minerals, As, Pb and Cd in an aeration tank; (2) neutralizing and coagulating the wastewater after the aeration and oxidation in a neutralization tank and controlling the pH to be between 8.6 and 9.5; (3) standing and depositing the wastewater after the neutralization and the coagulation treatment in a sedimentation tank; and (4) after the wastewater is clear after standing for a certain period of time, performing advanced treatment on heavy metal in a supernatant in a physical and chemical adsorption device and an activated carbon filtering system to obtain clean water meeting the environmental-protection or agricultural requirement. Through the process, peculiar smell in the mine wastewater can be eliminated, the wastewater color is changed to be normal, and the requirement of the quality of mine wastewater containing the discharged sulfur minerals, As, Pb and Cd in 'Standards for irrigation water quality' (GB5084-2005) can be met.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

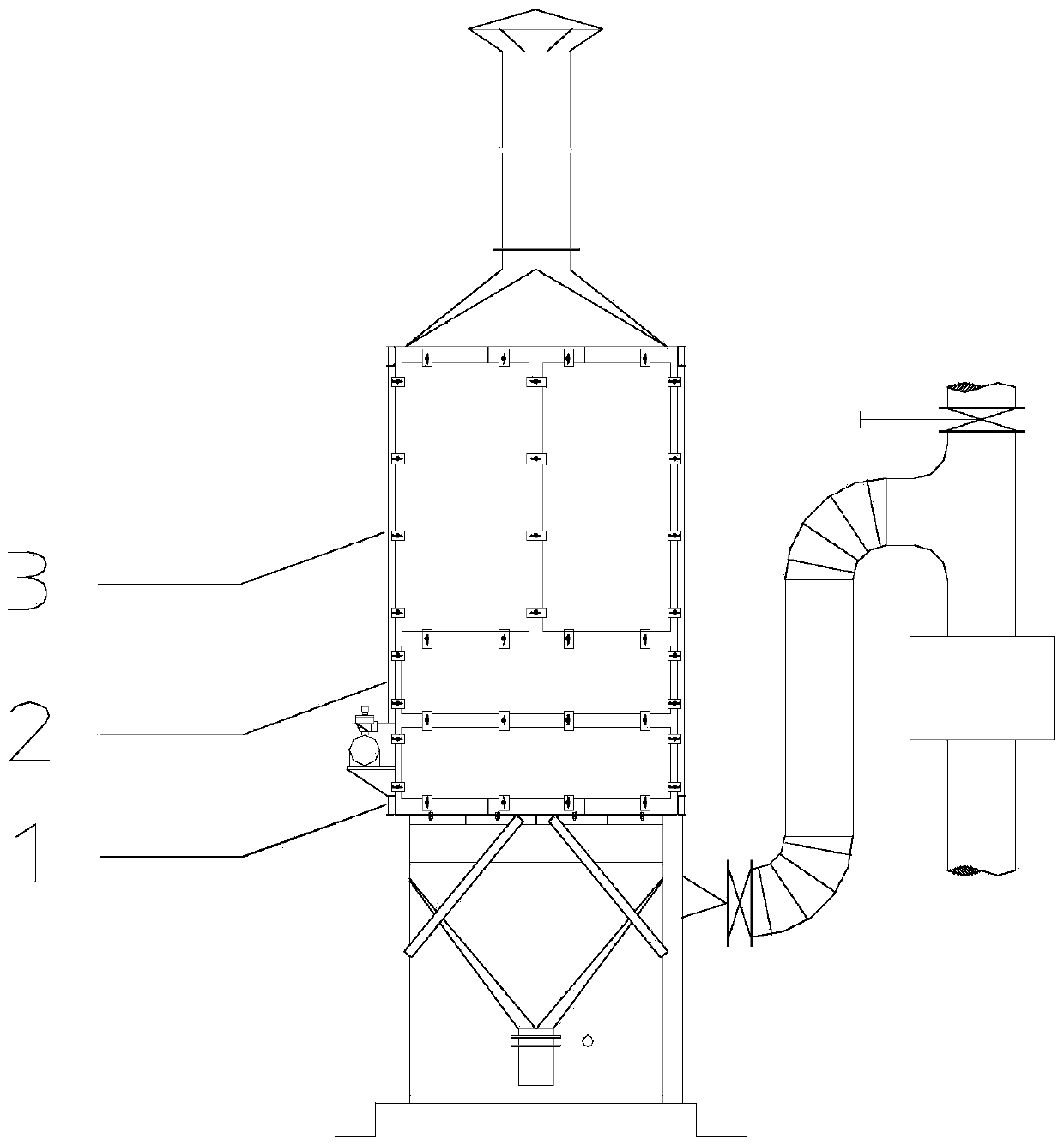

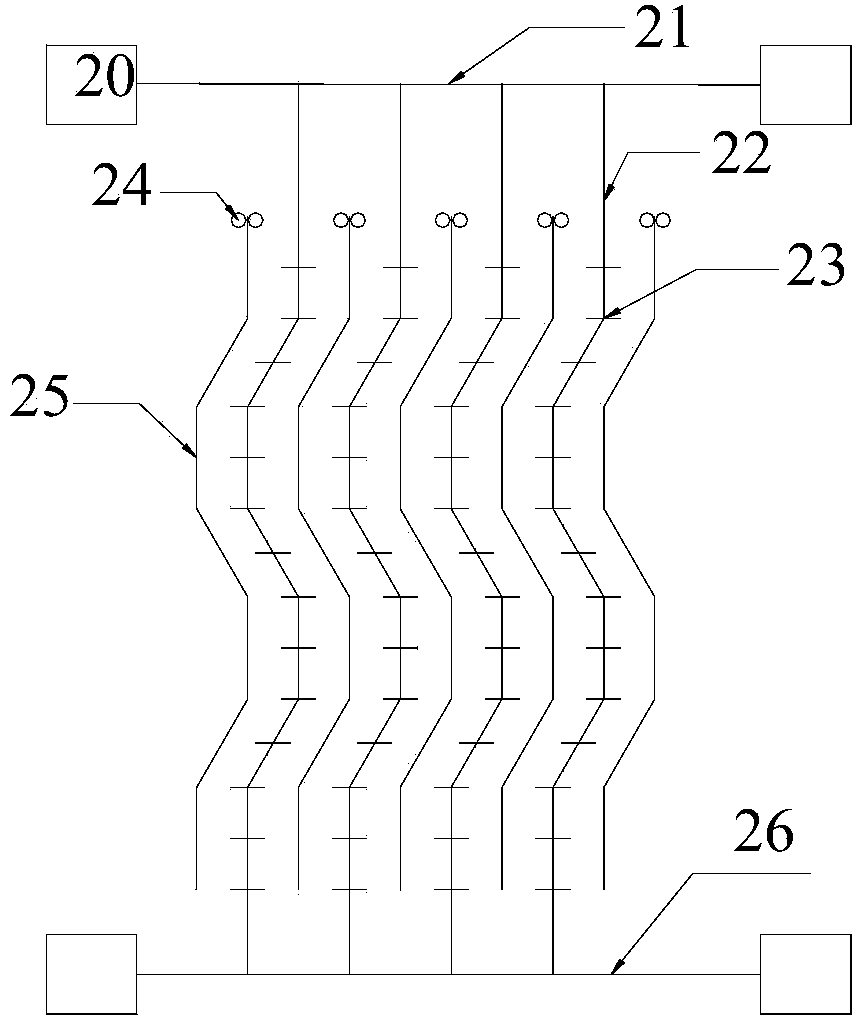

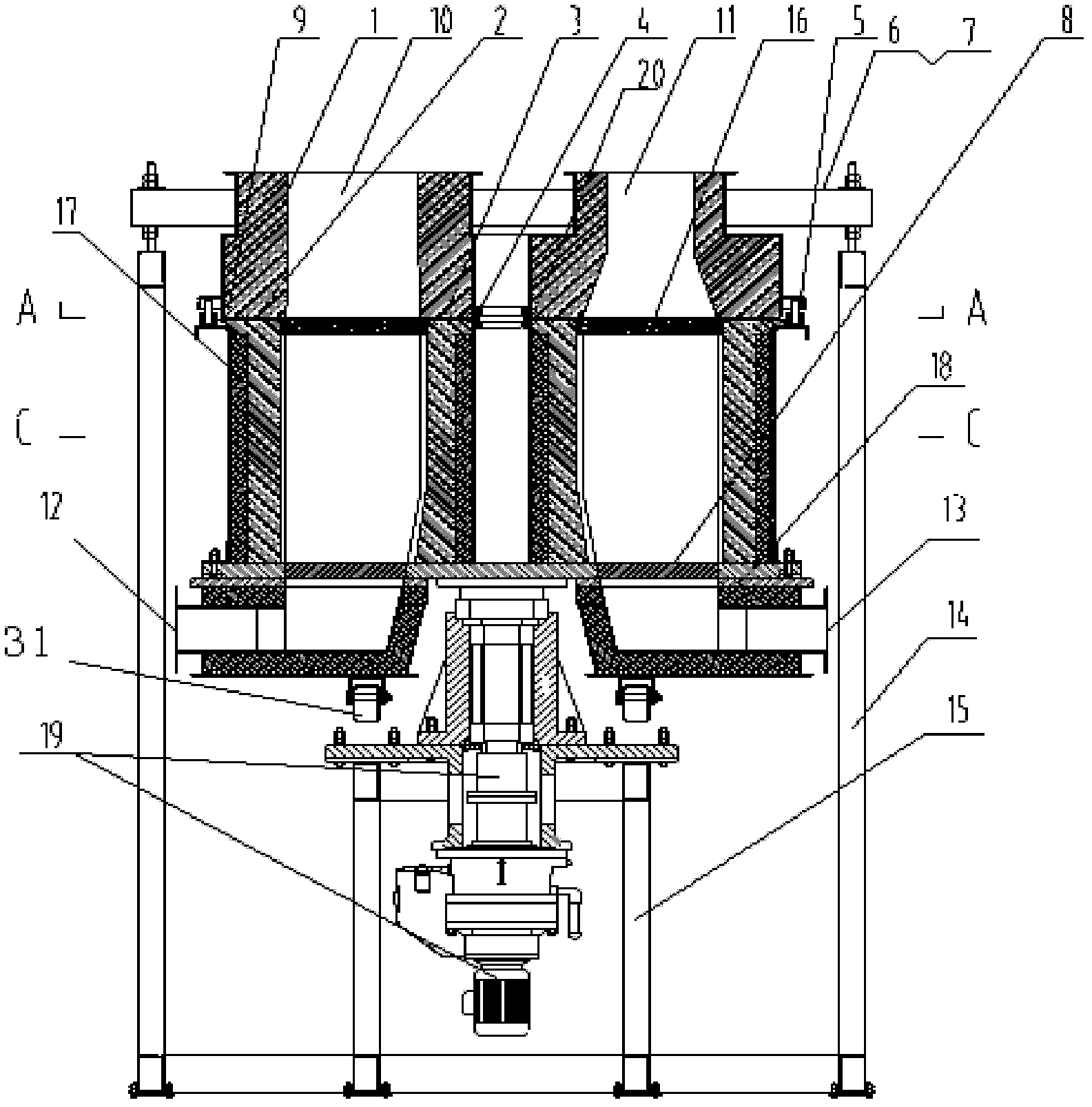

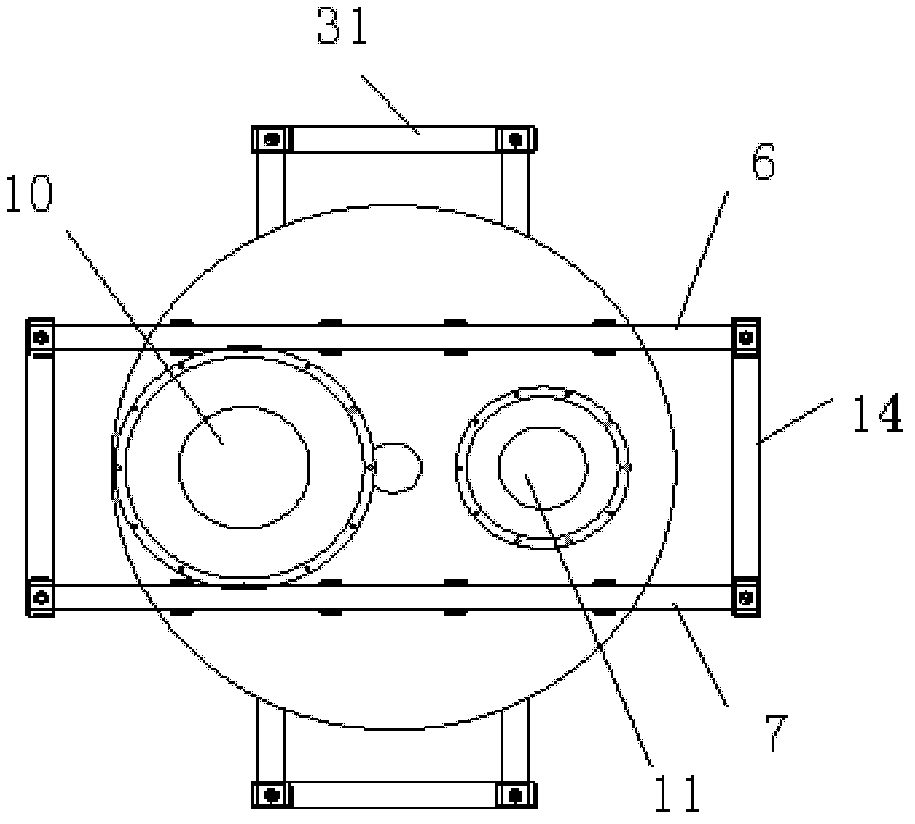

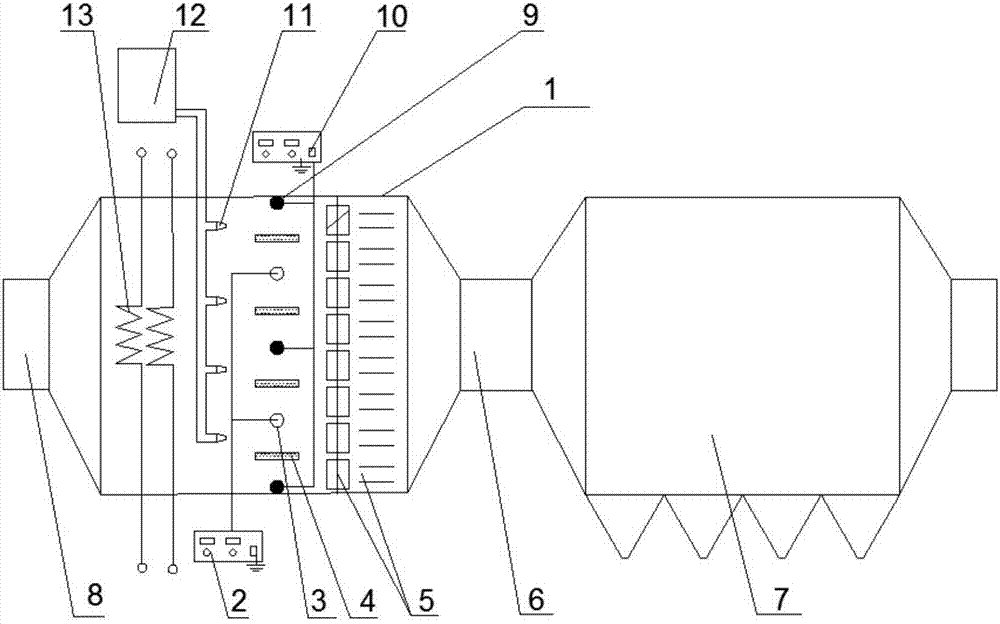

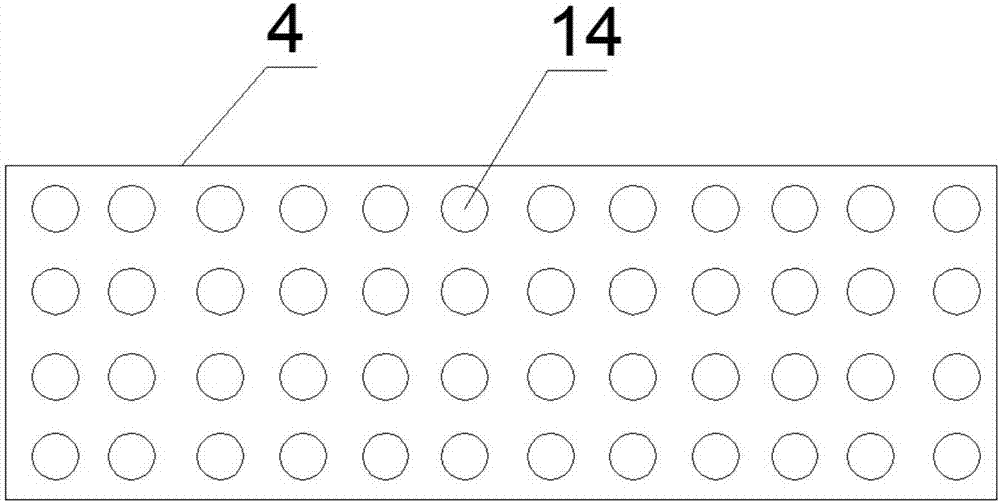

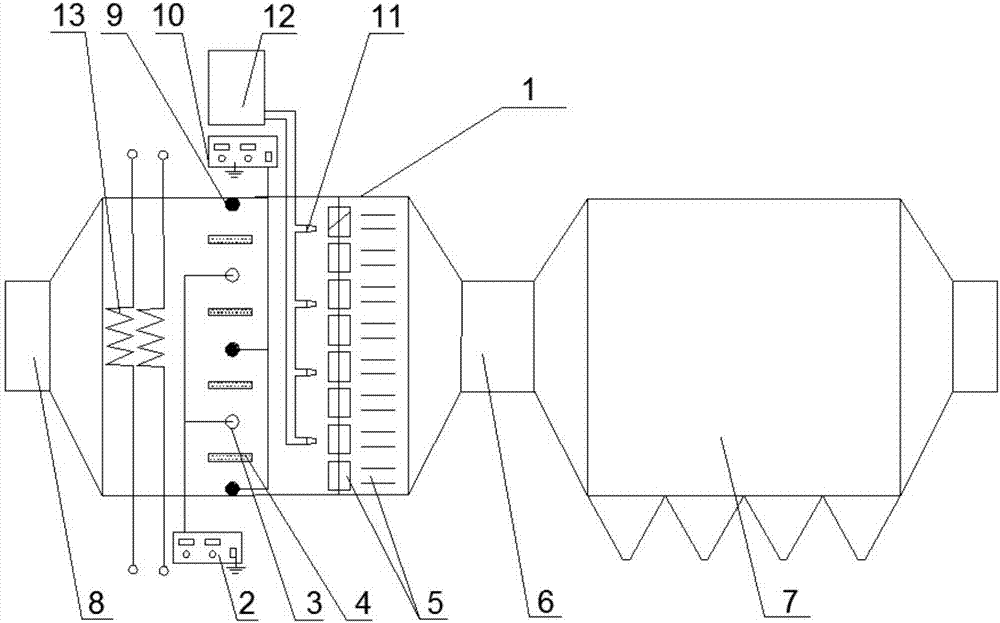

Wet-type electric precipitator and electric precipitation desulfurization device comprising same

ActiveCN104190543AIncreased disorderCombined removalCombination devicesExternal electric electrostatic seperatorFlue gasEngineering

The invention discloses a wet-type electric precipitator and an electric precipitation desulfurization device comprising the same. The wet-type electric precipitator comprises anode plates, cathode rays, two cathode ray suspension frames, an insulator chamber and a cleaning water pipe, wherein multiple bending plates which extend along the vertical direction and are arranged in parallel are used as the anode plates; the multiple cathode rays are suspended between two adjacent bending plates and are bent in tendency the same as that of the bending plates; multiple barbs are fixed on each cathode ray at intervals; the two cathode ray suspension frames are respectively positioned above and below the anode plates and are used for fixing the top ends and bottom ends of the cathode rays; the insulator chamber is used for fixing the ends of the two cathode ray suspension frames; and the cleaning water pipe is arranged above the anode plates. The wet-type electric precipitator disclosed by the invention is used in the desulfurization device, is arranged between two-stage demisting layers in a desulfurization tower and is used for performing fine dust removal on flue gas subjected to primary demisting.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

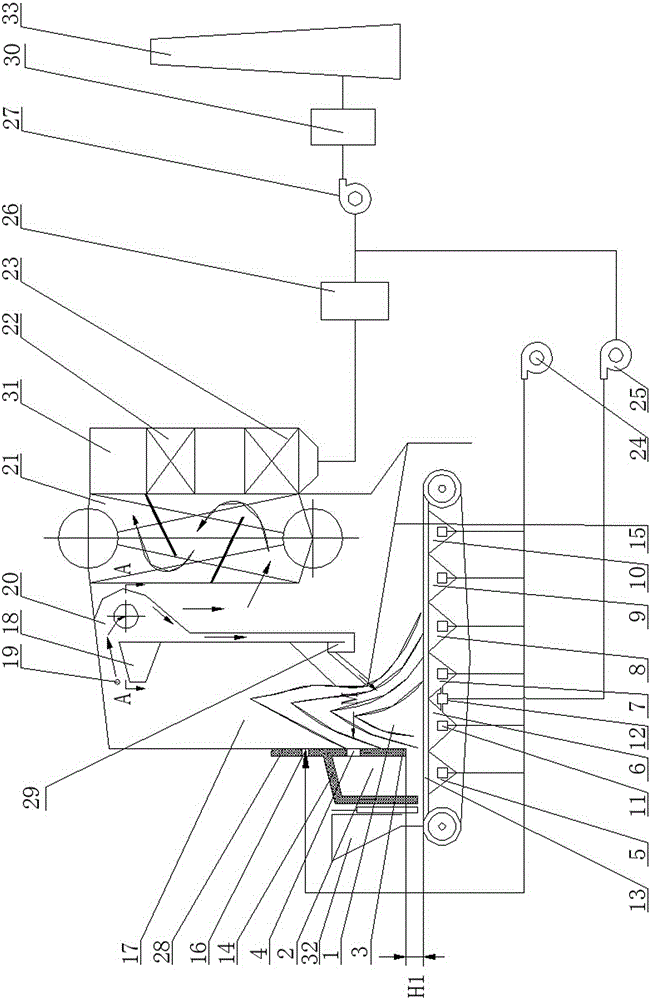

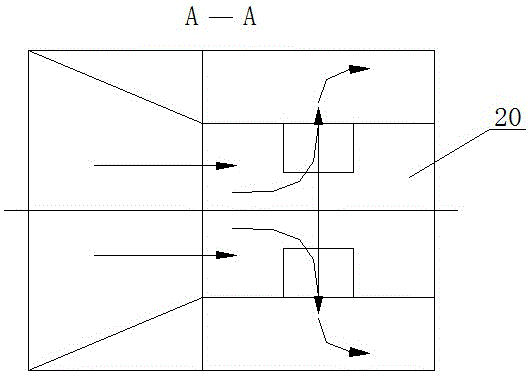

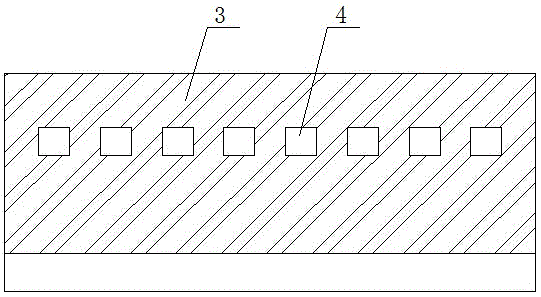

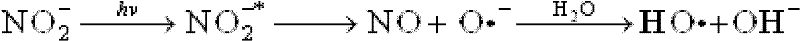

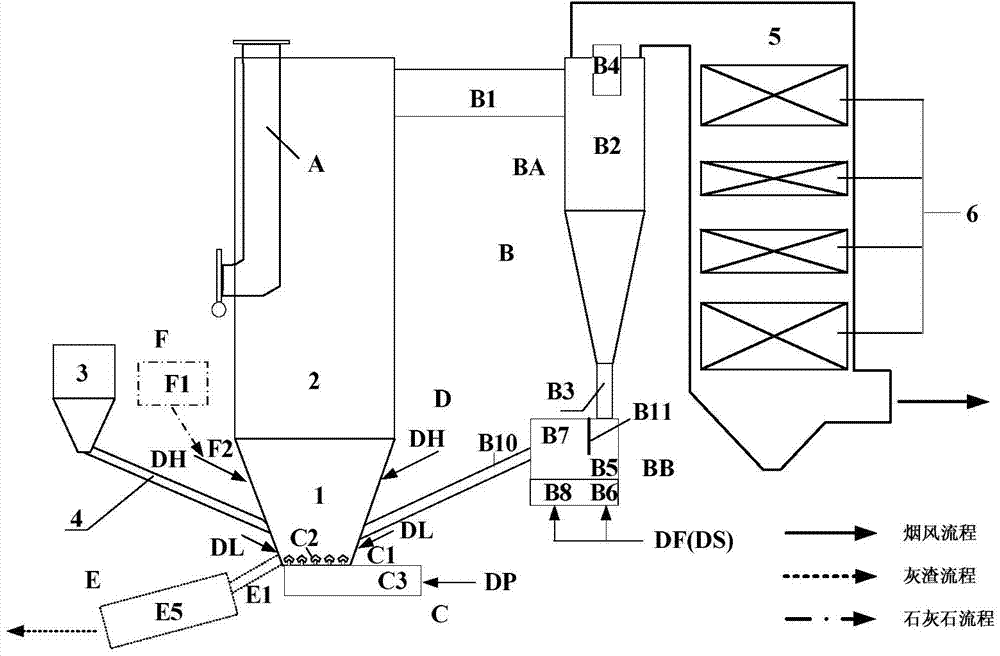

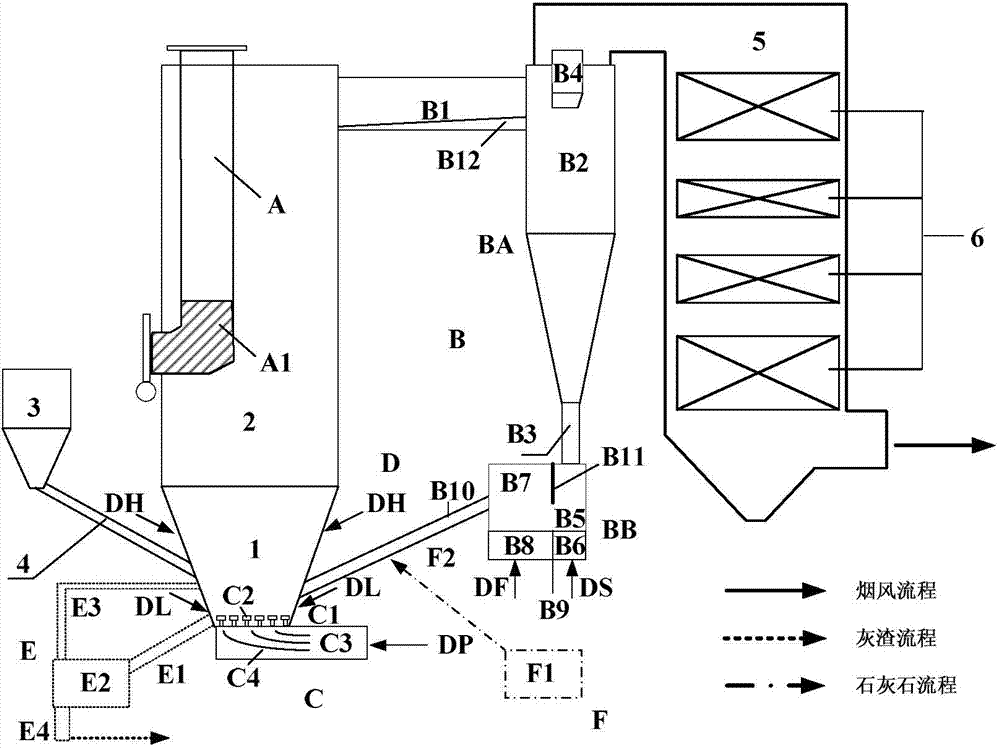

Layer combustion boiler combination denitration device and method

ActiveCN105020700AEmission reductionAchieve staged combustionDispersed particle separationSolid fuel combustionAir preheaterCyclone

The invention belongs to the field of coal layer combustion boiler pollutant discharge control and discloses a layer combustion boiler combination denitration device and method. The invention aims to enable NOx discharged by layer combustion boilers to reach the standard. A vaporizing chamber is arranged below the front arch in a hearth, and the partition of the hearth is provided with a gas outlet. A vaporization air chamber, a first air chamber, a second air chamber, a third air chamber, a fourth air chamber and a fifth air chamber are sequentially formed below a fire grate from front to back. A secondary air port is formed in the part, above the front arch, of the front wall of the hearth. The outlet of the hearth is communicated with the inlet of a horizontal type cyclone separator with an acceleration section, and the bottom of the horizontal type cyclone separator with the acceleration section is communicated with a main combustion zone of the lower part of the hearth through a return valve. The horizontal type cyclone separator with the acceleration section is sequentially communicated with a convection calandria, an economizer and an air pre-heating device, the air pre-heating device is communicated with a dust remover, the dust remover is communicated with a recycling fan and a draught fan, and the recycling fan is communicated with a smoke channel. An air supply fan is communicated with the vaporization air chamber, the first air chamber, the second air chamber, the third air chamber, the fourth air chamber, the fifth air chamber and the secondary air port. The layer combustion boiler combination denitration device and method are used for layer combustion boiler combination denitration.

Owner:HARBIN INST OF TECH

Solid waste innocent treatment device and method

ActiveCN104588402AExcellent emission indicatorsMeet environmental protection requirementsSolid waste disposalIncinerator apparatusCombustion chamberEmission standard

The invention discloses a solid waste innocent treatment device and a solid waste innocent treatment method. The solid waste innocent treatment device comprises a solid waste pyrolysis gasifier, a fuel gas oxygen replenishment premixing and filtering chamber, a fuel gas combustion chamber, a dechloridation and desulfurization drying device and a solid waste pretreatment device which are sequentially communicated; the solid waste innocent treatment device also comprises a biomass pyrolysis gasifier and a tail gas treatment device, wherein the biomass pyrolysis gasifier is communicated with the fuel gas oxygen replenishment premixing and filtering chamber; the tail gas treatment device is communicated with the top of the dechloridation and desulfurization drying device. When the method and the device are used for treating solid waste, the content of Dioxin in a detected emitted tail gas is lower than 0.023ng / m<3>, and the emission allowances of other gases, such as CO, SO2, HC1 and NOx, are also highly superior to the emission standard (GB18485-2014) issued by the nation in July 1st, 2014, and can completely meet the requirement of environment-friendliness.

Owner:深鹏环保工程有限公司

Wet-type purification treatment method and device for flue gas of domestic garbage incineration power plant

ActiveCN105289248ARun smoothlyImprove dust removal efficiencyDispersed particle filtrationBiofuelsActivated carbonDomestic waste

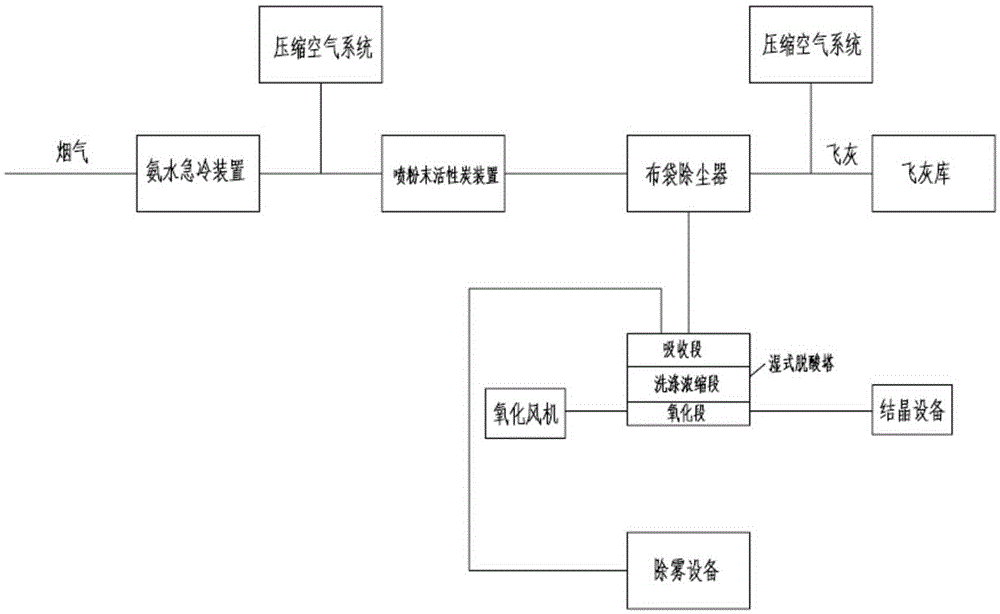

The invention discloses a wet-type purification treatment method and device for flue gas of a domestic garbage incineration power plant. An ammonia water quenching device, a power spray activated carbon device and a bag-type dust collector are sequentially connected through air ducts, the air inlet end of the ammonia water quenching device can be connected with the flue gas outlet end of the domestic garbage incineration power plant, and a compressed air system is further connected to the air duct between the ammonia water quenching device and the power spray activated carbon device; a compressed air system is arranged below a dust hopper of the bag-type dust collector, the dust hopper is connected with a flying dust bin through a pipeline, an outlet flue of the bag-type dust collector is connected with a washing and concentration section of a wet-type deacidifying tower through a pipeline, and the wet-type deacidifying tower comprises an absorption section, the washing and concentration section and an oxidizing section; spray nozzles capable of spraying ammonia water are arranged in the absorption section of the wet-type deacidifying tower, a flue gas exhaust pipeline of the wet-type deacidifying tower is connected with defogging equipment, the oxidizing section of the wet-type deacidifying tower is connected with an oxidation air blower, and an ammonia chloride and ammonia sulfate outlet of the oxidizing section of the wet-type deacidifying tower is connected with crystallizing equipment.

Owner:王全

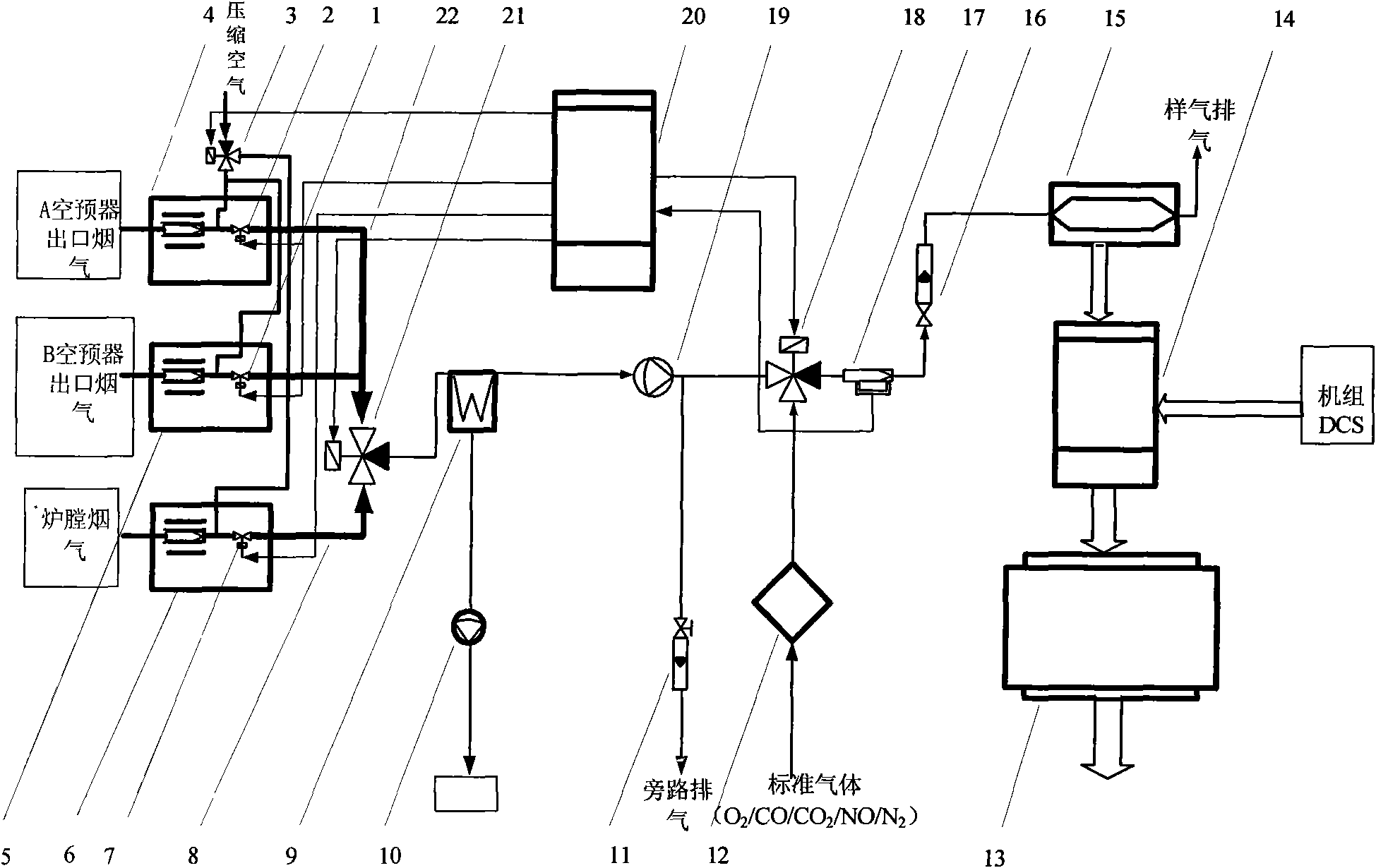

Stratified combustion on-line optimization control system of boiler coal dust and optimization method thereof

ActiveCN101619859AGood running safetyReduce emission concentrationWithdrawing sample devicesIndirect carbon-dioxide mitigationAir preheaterCoal dust

The invention discloses a stratified combustion on-line optimization control system of boiler coal dust, comprising a gas sampling system and a data processing system, wherein the gas sampling system comprises a fume sampling probe and a fume component continuous monitoring system. The invention is characterized in that the fume sampling probe comprises a first fume sampling probe arranged at an opening of an A air preheater, a second fume sampling probe arranged at an opening of a B air preheater and a third fume sampling probe arranged in a boiler chamber; the data processing system comprises an industrial computer connected with the fume component continuous monitoring system and provided with a stratified combustion on-line optimization computation module; and DCS data of the industrial computer and a generator set are connected by a data collector. The invention utilizes a support vector machine theory by the method and the method to establish an on-line optimization model to carry out automatic training and optimization so as to obtain combustion optimization condition parameters to guide operation, thereby keeping high operation safety of the boiler, improving operation economical efficiency and reducing the emission concentration and totals of pollutants.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

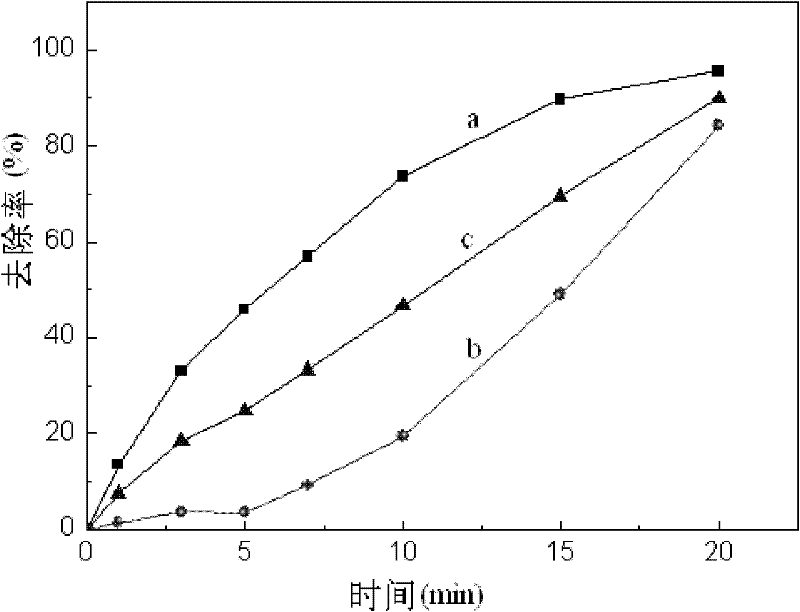

Ozone low-temperature oxidation denitration technology and system

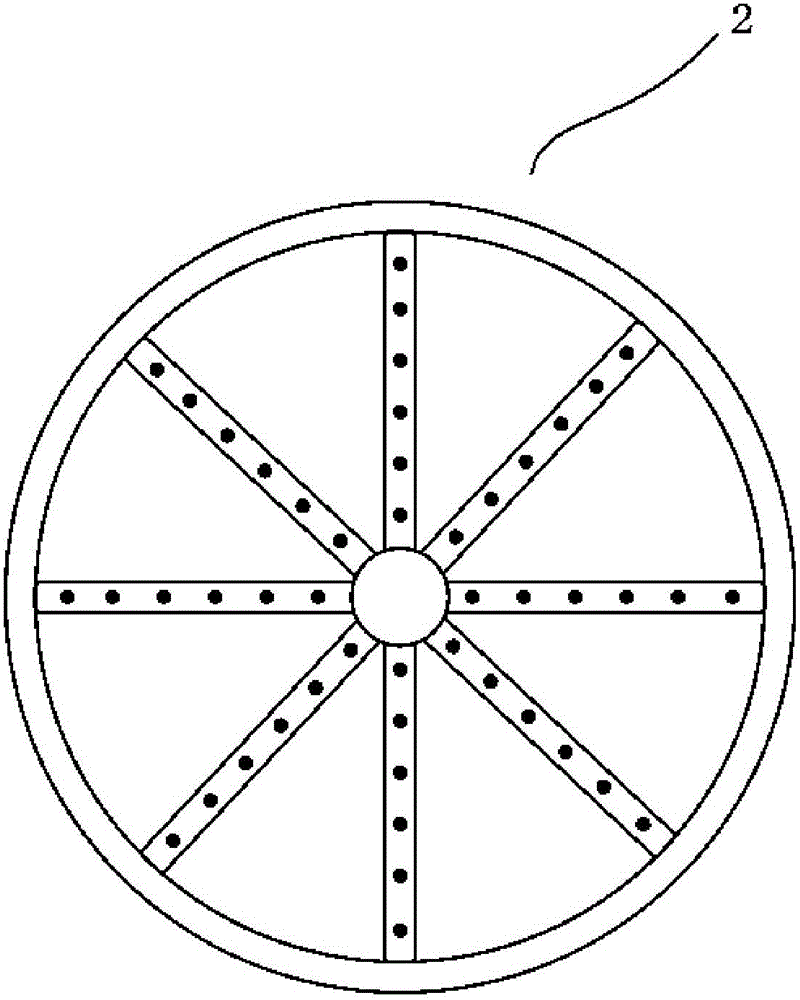

ActiveCN105854554AHigh removal rateCompact layoutGas treatmentDispersed particle separationDistributorPollution

The invention discloses an ozone low-temperature oxidation denitration system which comprises a flue, an ozone generator and a washing tower. The ozone low-temperature oxidation denitration system is characterized in that an ozone distributor is mounted in the flue; the ozone is supplied to an ozone channel of the ozone distributor through a pipeline at an outlet of the ozone generator; the ozone is jetted into the flue by the ozone distributor; the outlet of the flue is connected with the washing tower; the mixture of the ozone and exhaust gas in the flue enters into the washing tower. Compared with the prior art, the ozone low-temperature oxidation denitration system has the beneficial effects that the investment and running cost is lower than that of SCR (Selective Catalytic Reduction) technology; NOx removal rate is high and can reach 95% or more; the technique is simple, the expandability is excellent and the technological operation is simple, stable and reliable; the adaptation of the technical condition is wide; operation at low temperature is carried out and no high-temperature window is required; the system is free from ammonia escape secondary pollution and ammonium sulfate corrosion. The invention also discloses an ozone low-temperature oxidation denitration technology.

Owner:山东普莱斯玛环保设备有限公司

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

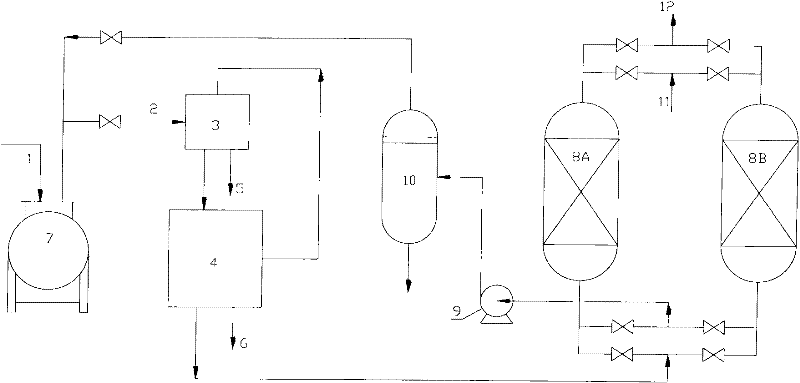

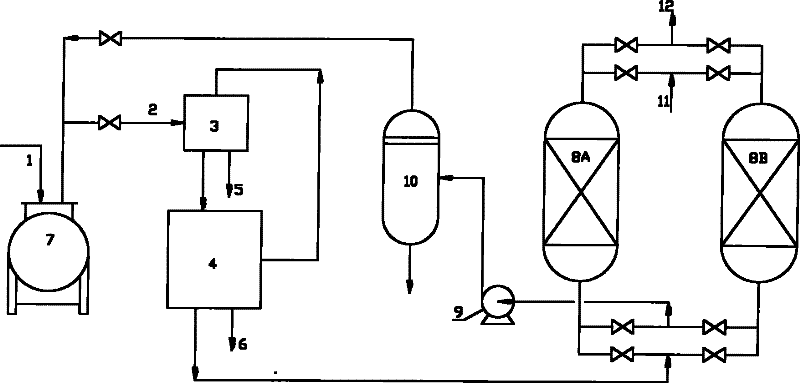

Method for recovering oil gas and device

InactiveCN102441310AExtended service lifeReduce the temperatureDispersed particle separationVapor condensationRecovery methodGas phase

The invention relates to a method for recovering oil gas and a device. Oil gas exhausted from an oil product storage device is firstly condensed; condensate is recovered; uncondensed gas phase enters an adsorption device for adsorption; after being in adsorption saturation, the adsorption device is regenerated by adopting a vacuum regeneration manner; and concentrated oil generated by vacuum regeneration is recycled to the oil product storage device. According to the method and the device, provided by the invention, the oil gas is recovered by combining the mode of returning the oil gas to the oil product storage device and an oil gas recovery technology, desorbed oil gas is returned to the gas-liquid balanced system of the oil product storage device, the partial pressure of the oil gas is increased, and the loss of an oil product, caused by evaporating, is fundamentally reduced. The method and the device, provided by the invention, have the characteristics of large operating flexibility, low energy consumption, small investment, no potential safety hazard, reachability in tail gas emission standards, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal-saving desulfurization synergistic additive for cement clinker calcination

InactiveCN101229963APromote combustionIncrease productionClinker productionSilicon dioxideAmmonium nitrate

The invention discloses an additive of coal saving and increased desulphurization function used for burning cement clinker. Calcium oxide, silicon dioxide, calcium ammonium nitrate, sodium nitrate, potassium permanganate, ammonium nitrate, ferric oxide, alumina, active carbon and borax are mixed by certain weight percentage and grinded into powder with particle size of 100 to 150 meshes in a grinder; then the powder is placed into a stirrer and stirred, after which, the powder is inspected and packed as finished product if qualified. The invention has remarkable desulphurization function and energy conservation and consumption reduction effect; besides, the invention has promotion function for the combustion of coal and increases the output and quality of the cement clinker. The intensity of the cement clinker can be increased by over 5MPa; the desulphurization rate can reach 35 to 55 percent; the soot emission concentration is clearly decreased; the discharge amount of sulfur dioxide and nitrogen oxide is greatly reduced; therefore, the invention is additive of energy conservation and environmental protection specially used for cement, which can save energy, reduce consumption, increase output and profit, remove environmental pollution, increase income and cut expenditures.

Owner:SHAANXI E LEELY POWER DEV

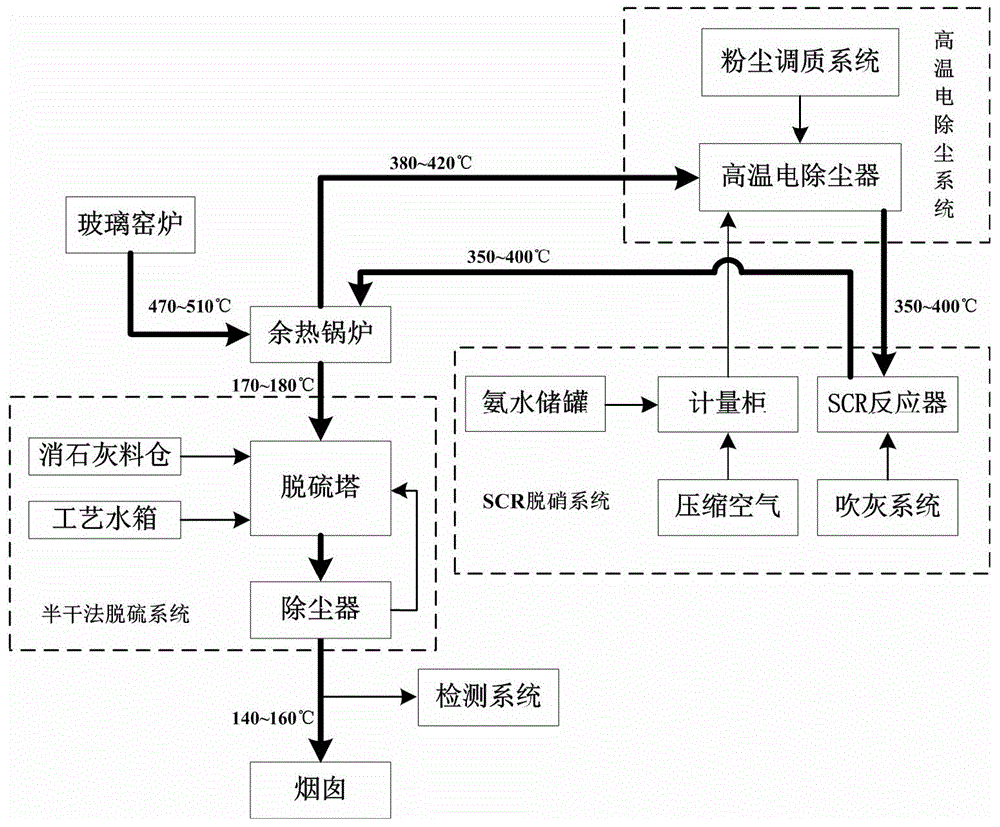

Comprehensive purification process of glass kiln smoke

InactiveCN104984640AImprove dust removal efficiencyHigh temperature resistantDispersed particle separationIncreasing energy efficiencyAtmospheric airEngineering

The invention discloses a comprehensive purification process of glass kiln smoke. The comprehensive purification process comprises the process flows of performing waste heat recovery on high-temperature smoke generated by a glass kiln through a waste heat boiler, leading the smoke into a high-temperature electric precipitator system for high-temperature smoke dust removal treatment in the section of the waste heat boiler at 380 to 420 DEG C, cooling the standard smoke after dust removal to 350 to 400 DEG C, so as to satisfy the requirement of the best active temperature of an SCR denitration catalyst, then leading the smoke after dust removal into an SCR denitration system for removing NOx, leading the smoke after denitration back to the waste heat boiler for waste heat recovery, and leading the smoke into a desulfurization system with a semidry method after the smoke in the waste heat boiler is cooled to 170 to 180 DEG C, so that the standard smoke after desulfurization is cooled to 140 to 160 DEG C and then is discharged into the atmospheric environment through a chimney. The glass kiln smoke after process treatment by adopting the comprehensive purification process reaches the regulations of related national environmental protection discharge standards of a glass industry, the dust discharge concentration is lower than 50 mg / m<3>, the NOx discharge concentration is lower than 700 mg / m<3>, and the SO2 discharge concentration is lower than 400 mg / m<3>.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Gas firing or oil firing boiler using thin flameless burning mode

InactiveCN1987286AShorten warm-up timeReduce emission concentrationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelNitrogen oxideFuel supply

A gas or oil boiler working in thin-flameless combustion mode is disclosed. The outlets of the air delivering tub and the primary fuel tube in said air delivering tube are surrounded by a pre-burning hood. Several cyclone tubes are arranged from said pre-burning hood to combustion box. Several secondary fuel tubes have their inlets connected via fuel flow controller to fuel supplying tube and their outlets extended in combustion box. The thin combustion takes place in said pre-burning hood and the flameless combustion is formed in the combustion box.

Owner:UNIV OF SCI & TECH OF CHINA

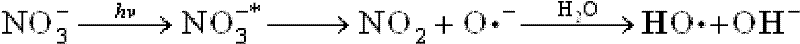

Method for removing ammonia nitrogen, nitrogen nitrate and nitrogen nitrite in water synchronously

InactiveCN102225793AQuick removalSafe by designWater/sewage treatment by irradiationWater dischargeUltraviolet lights

A method for removing ammonia nitrogen, nitrogen nitrate and nitrogen nitrite in water synchronously. The invention relates to a method for removing ammonia nitrogen, nitrogen nitrate and nitrogen nitrite in water synchronously. Through the invention, the technical problems that nitrogen in three forms can not be removed synchronously through the existing method removing ammonia nitrogen, nitrogen nitrate and nitrogen nitrite in water and the existing method is complex in operation and can produce a secondary pollution thus can not be utilized in drinking water treatment are solved. In the invention, water needing to be treated is subjected to a PH adjusting process and a dissolved oxygen control process, and then is radiated by ultraviolet light with a wavelength in the range of 150 to 260 nm. The method can remove ammonia nitrogen, nitrogen nitrate and nitrogen nitrite synchronously without multistage removal, expensive oxidizing agents and catalysts, no secondary pollution and no subsequent process, and show the characteristics of safety, convenience, economy and high efficiency while removing nitrogen in three forms. Therefore, the method can be utilized for treatments of underground water, drinking water, water discharged from sewage treatment plants, industrial water and domestic water, and the remediation of natural water body.

Owner:HARBIN INST OF TECH

Integrated modification method for reducing pollutant emission of circulating fluidized bed boiler

ActiveCN103900077AReduce emission concentrationGood environmental benefitsFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention discloses an integrated modification method for reducing pollutant emission of a circulating fluidized bed boiler. The modification method comprises the following steps: modifications on a screen type heating surface, a material return system, an air distribution system, a secondary air nozzle system, a slag cooling system and a desulfurizer adding system. Through the modifications, the concentration of SO2 and NOx in smoke is finally reduced to 30-70% of that before modifications, the fly ash concentration is reduced to 70-90% of that before modifications and the environmental protection characteristic of boiler operation can be remarkably improved without adding new equipment. The integrated modification method has the advantages of being small in investment cost, short in modification period and stable in boiler operation; at the time the integrated modification is performed, the problems existing in arrangement of the original heat surface, a funnel cap, a separator, a slag cooler and a lime stone transmission system of the boiler can be synchronously solved, and therefore the economy, stability and safety performance of boiler operation are comprehensively improved.

Owner:HUANENG CLEAN ENERGY RES INST

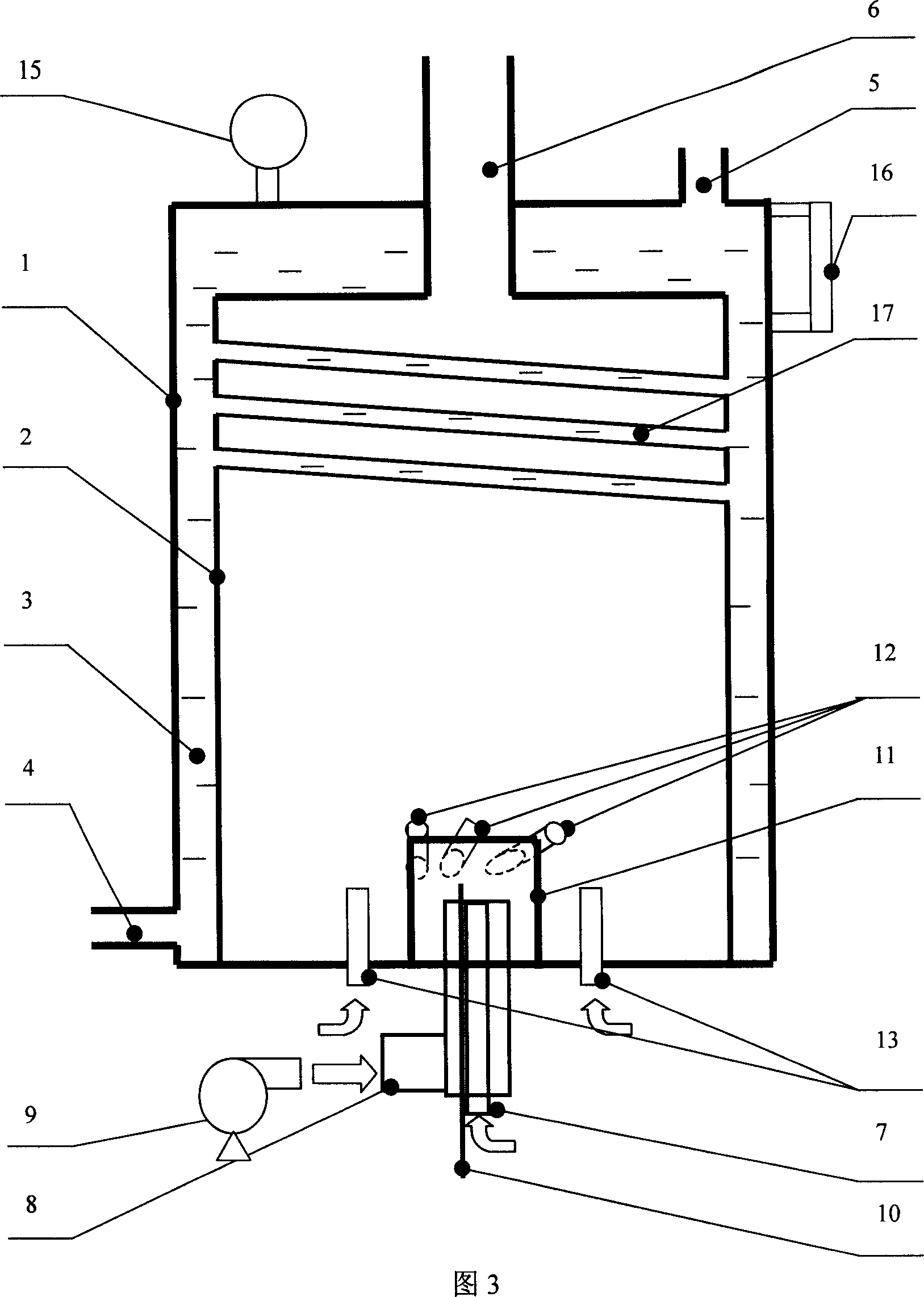

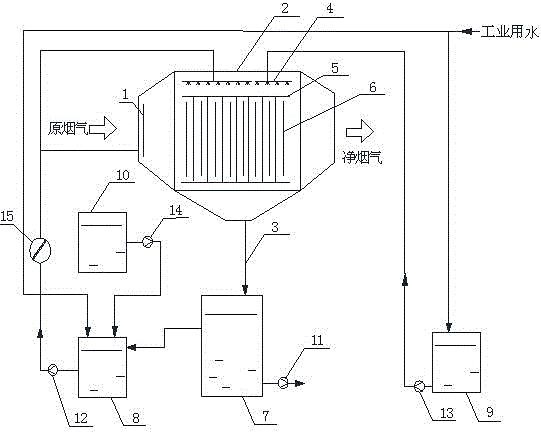

Wet type electrostatic dust collector for semidry method (CFB) waste water zero discharging

InactiveCN104874481AAvoid secondary pollutionReduce processingDispersed particle separationWaste water treatment from gaseous effluentsSocial benefitsWastewater

The invention discloses a wet type electrostatic dust collector for semidry method (CFB) waste water zero discharging. The wet type electrostatic dust collector comprises a smoke humidification device, a wet type electrostatic smoke purifying system and a waste water circulating utilizing system. The wet type smoke purifying system mainly comprises a spraying device, an anode plate and a cathode wire. The waste water circulating utilizing system comprises a waste water tank, a circulation water tank, a waste water pump, a circulation water pump, an alkali liquor tank, an alkaline pump, an automatic filter, a technology water tank and a technology water pump. By means of the wet type electrostatic dust collector, tiny dust, SO3, heavy metal and the like in smoke can be efficiently removed, meanwhile, waste water zero discharging is achieved, environmental friendliness is achieved, and good economic benefits and social benefits are achieved.

Owner:ZHEJIANG ZHONGTAI ENVIRONMENTAL PROTECTION EQUIP CO LTD

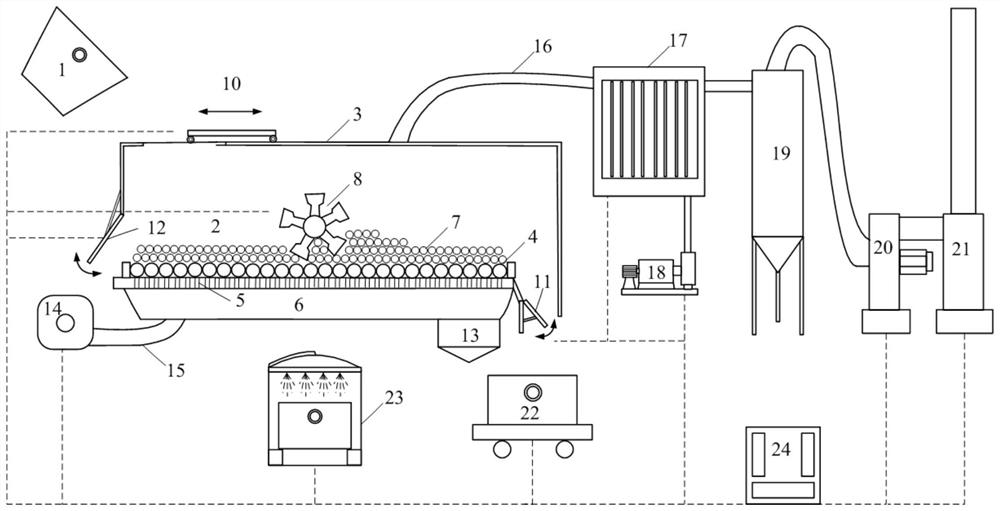

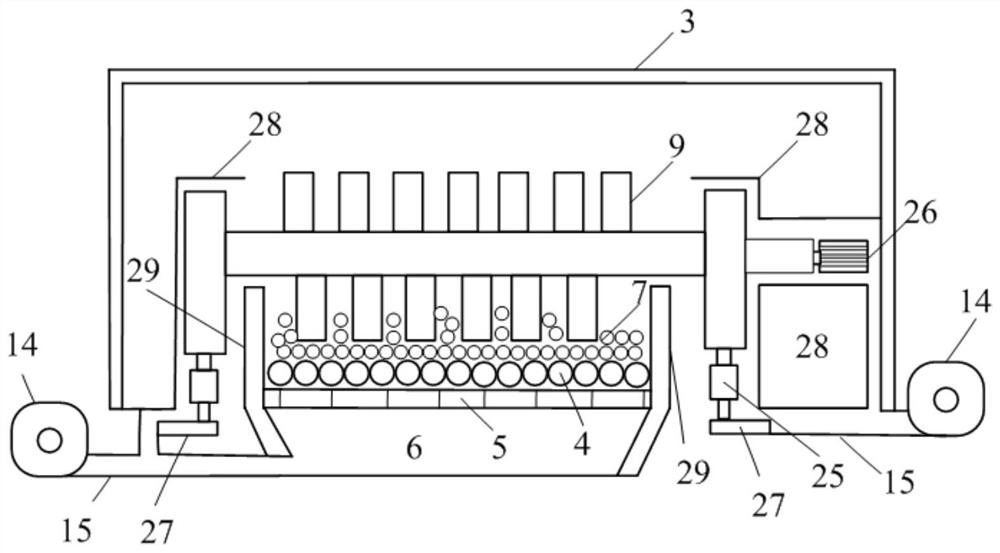

High-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method

PendingCN111850194AImprove pulverization rateImprove processing efficiencyExhaust gas handlingRecycling and recovery technologiesSlagDust control

The invention relates to a high-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method. A crushing bed is adopted as a high-temperature steel slag treatment carrier, a crusher is adopted for efficiently crushing steel slag, meanwhile, cold air is introduced into a bottom blowing air cooling box to solidify and cool the high-temperature steel slag, and meanwhile, the crusher rotates at a certain speed, moves forwards and backwards and rotates to crush the steel slag. A heat exchanger and a generator are adopted for cooling the high-temperature steel slag to generate high-temperature waste heat for recovery and power generation. The crushing capacity is high, the steel slag treatment efficiency is greatly improved, and meanwhile, waste heat recoveryand power generation can be realized by adopting air cooling heat exchange. Efficient crushing and waste heat recovery of the high-temperature steel slag are realized, a steel slag water cooling system device is omitted, a simple dry dust removal mode is adopted to replace a wet flue gas treatment system caused by a previous water cooling process, the advantages of being high in automation degree,small in space occupation, good in leakproofness, low in system investment, capable of achieving ultra-clean emission and the like are achieved, and the comprehensive economic benefits of steel slagtreatment are improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

Liquid sulphur degassing device and liquid sulphur degassing method

Owner:ZHENHAI PETROCHEMICAL ENG CO LTD

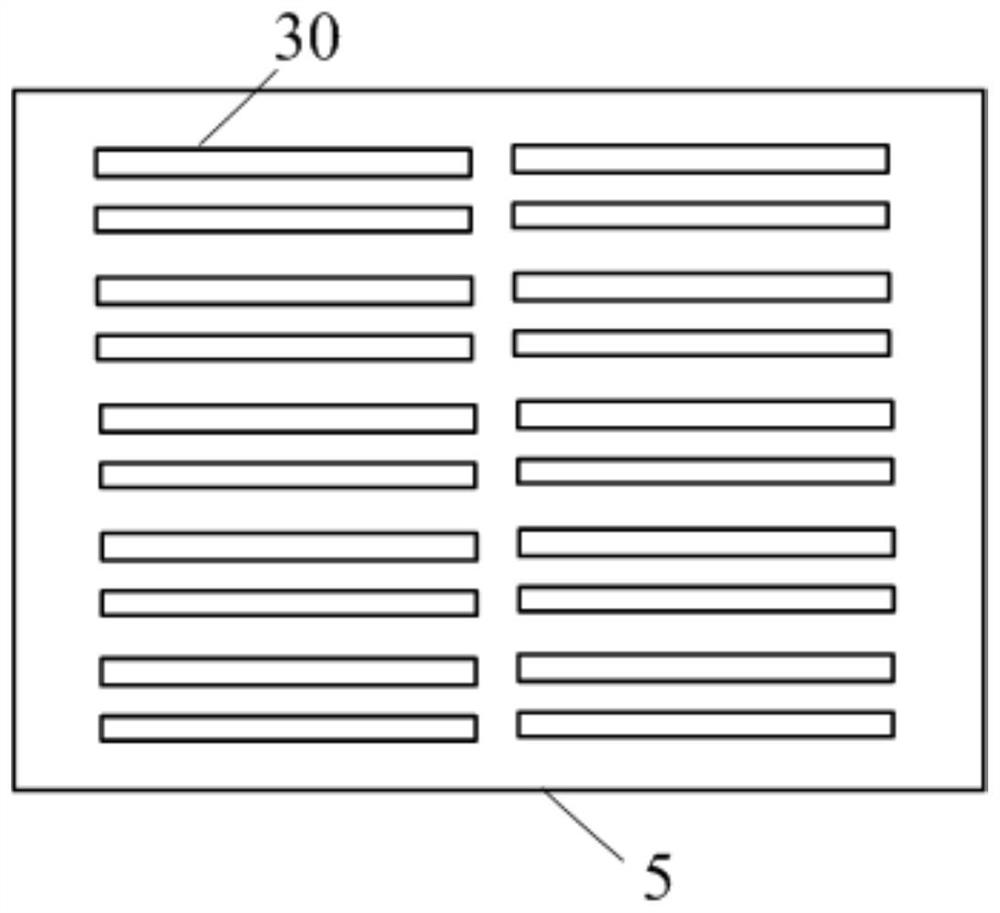

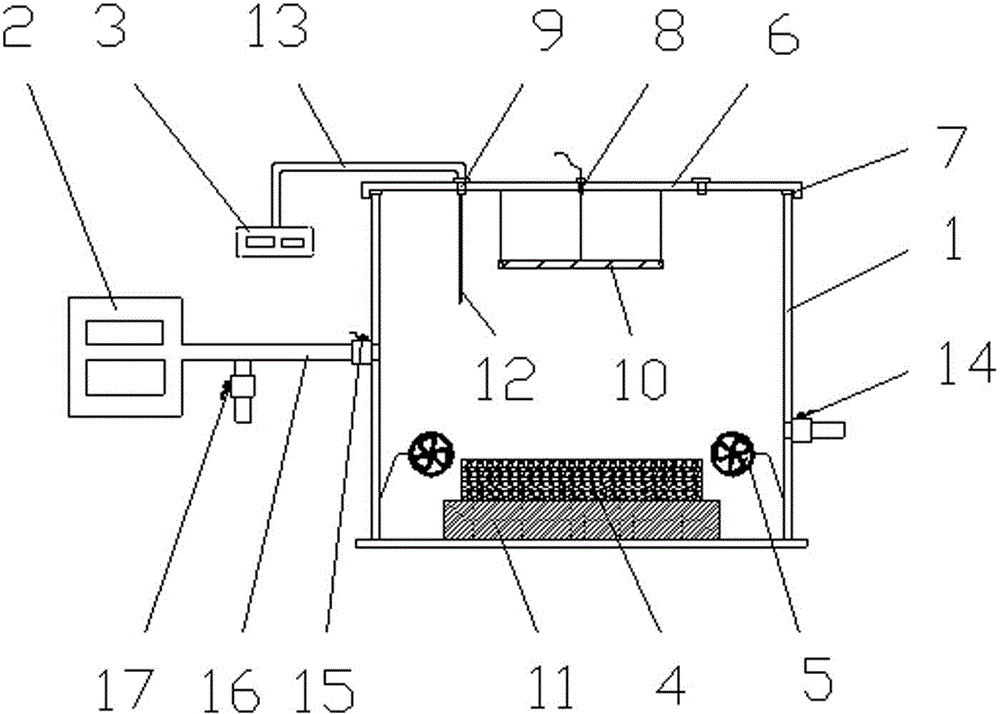

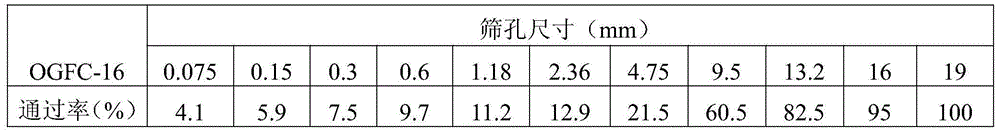

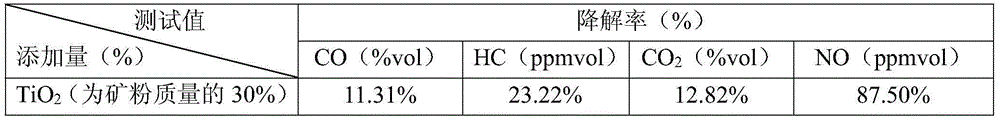

Device and method for evaluating automobile exhaust degradation effect of OGFC mixture

InactiveCN104807950ASimple structureEasy to operateChemical analysis using catalysisRoad surfaceData treatment

The invention discloses a device for evaluating the automobile exhaust degradation effect of an OGFC mixture. The device comprises a closed container, an automobile engine, an automobile exhaust analyzer, a track board test piece, and air supplying devices, wherein the air supplying devices are arranged in the closed container. The invention further discloses an evaluation method which comprises the following steps in sequence: preparing the track board test piece, and generating automobile exhaust; simulating the degradation of automobile exhaust on a pavement and testing the concentration of each gas in the automobile exhaust; processing data. The track board test piece is prepared from the OGFC mixture which is added with a photocatalytic material; the evaluation index, used for evaluating the automobile exhaust degradation effect, of the OGFC mixture is taken as the degradation rate. The evaluation device can simulate the automobile exhaust degradation processes of the OGFC mixture in different illumination conditions by controlling the number of ultraviolet lamp tubes. The evaluation method is accurate and reliable, and coincides with the automobile exhaust degradation situation on a real pavement.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

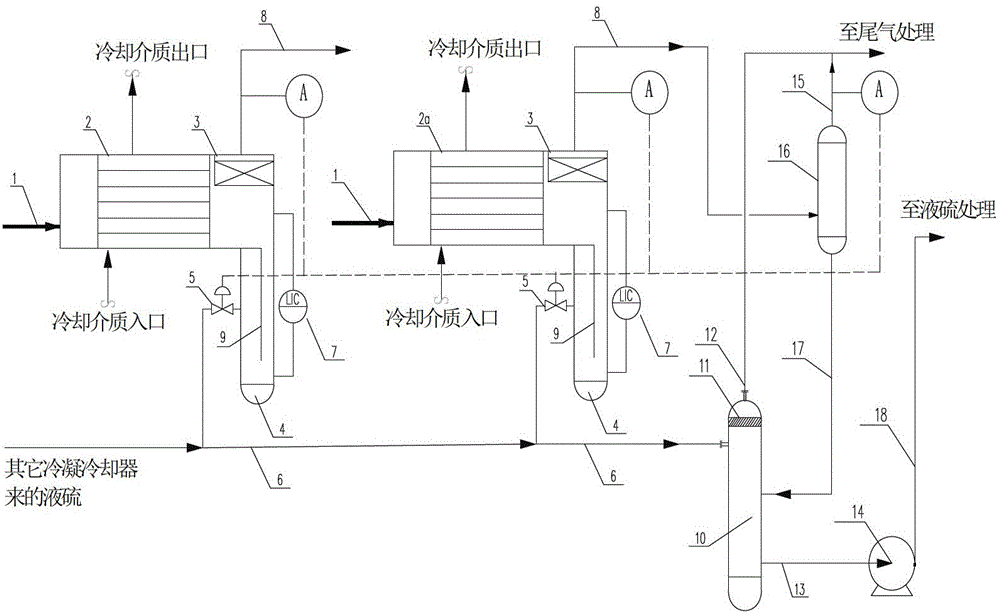

Liquid sulfur collection method for sulfur recovery

The invention discloses a liquid sulphur collecting method suitable for a sulfur recovery device. Process gas of the sulphur recovery device enters a process gas condensate cooler to carry out gas-liquid separation; condensed and separated gas enters the next stage of reaction or condensate cooling system after a liquid sulphur catcher traps the liquid sulphur; the condensed liquid sulphur is collected by a liquid sulphur collector below the process gas condensate cooler; the collecting process is controlled by a process operation module; the collected liquid sulphur is directly delivered to a sealed liquid sulphur middle tank with pressure; the liquid sulphur is fed to a liquid sulphur treatment system after passing through a liquid sulphur degassing pump after gas-liquid secondary separation; and the separate gas is separated from the final stage of process gas condensate cooler and enters a tail gas treatment unit together with the tail gas which is further separated by a tail gas delivery tank. By adopting the technology, arrangement of a sulphur sealing tank, a sulphur sealing tank pond and a liquid sulphur pond is concealed; the technologic process is shortened; the investment on the equipment is reduced; and pollution of the liquid sulphur, the hydrogen sulfide and related treatment technologies on the soil, environment and ground water quality is partially removed.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

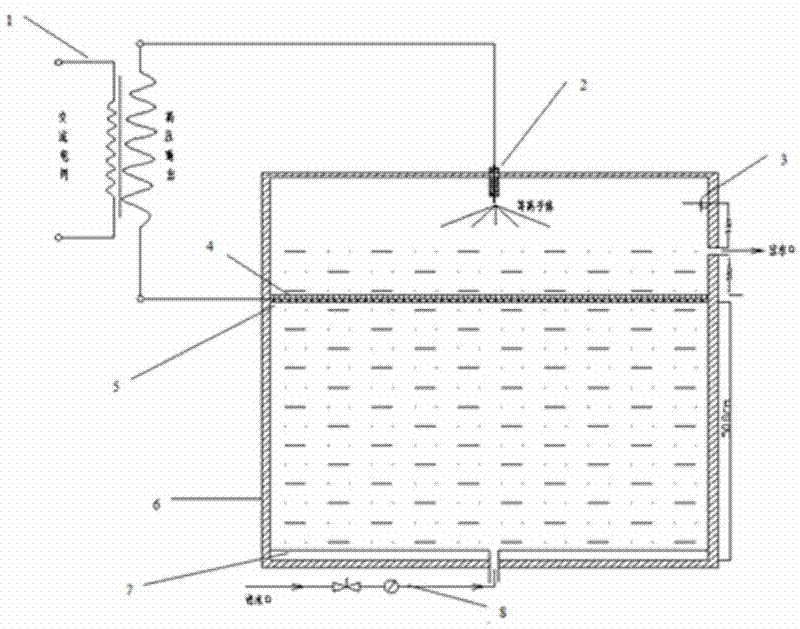

A low-temperature plasma wastewater treatment device and its treatment method

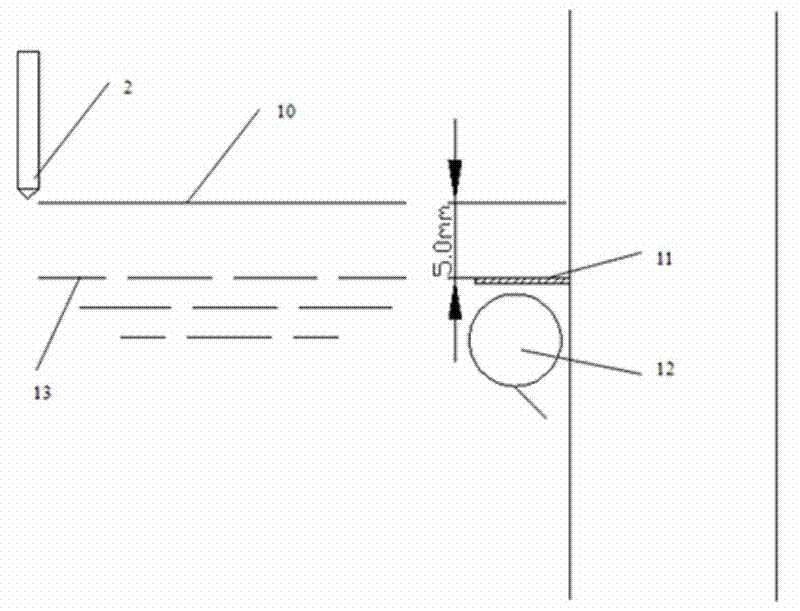

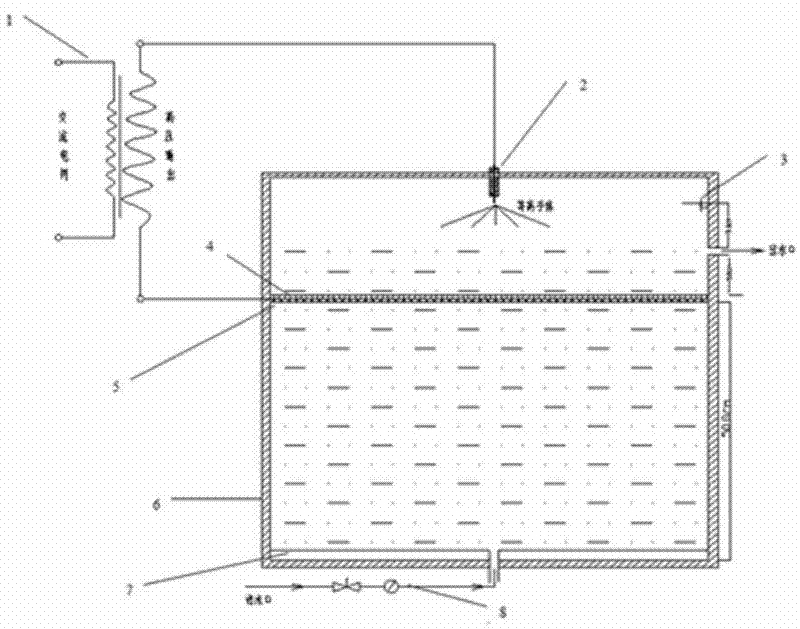

ActiveCN102267739AReduce emission concentrationMeet emission standardsWater/sewage treatment by irradiationPollutant emissionsWater level

The invention discloses a low-temperature plasma waste water treatment device and method. The method comprises the following steps of: draining waste water into a reaction groove and putting into a low-temperature plasma environment, wherein the low-temperature plasma environment is provided by using a dielectric barrier discharge low-temperature plasma device; and arranging the discharging anodeof the dielectric barrier discharge low-temperature plasma device at a position 1.0-10.0 centimeters away from a waste water level plane, charging waste water at the power / cm<2> 1.0-5.0 watts, and treating the waste water for at least more than 5 minutes. Waste water is treated at the depth of 5.0-10.0 centimeters, so that the discharging concentration of pollutants containing waste water is further lowered, and the discharging standard is increased; and the waste water treatment device has low replacement cost, and is suitable for large-scale investment.

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

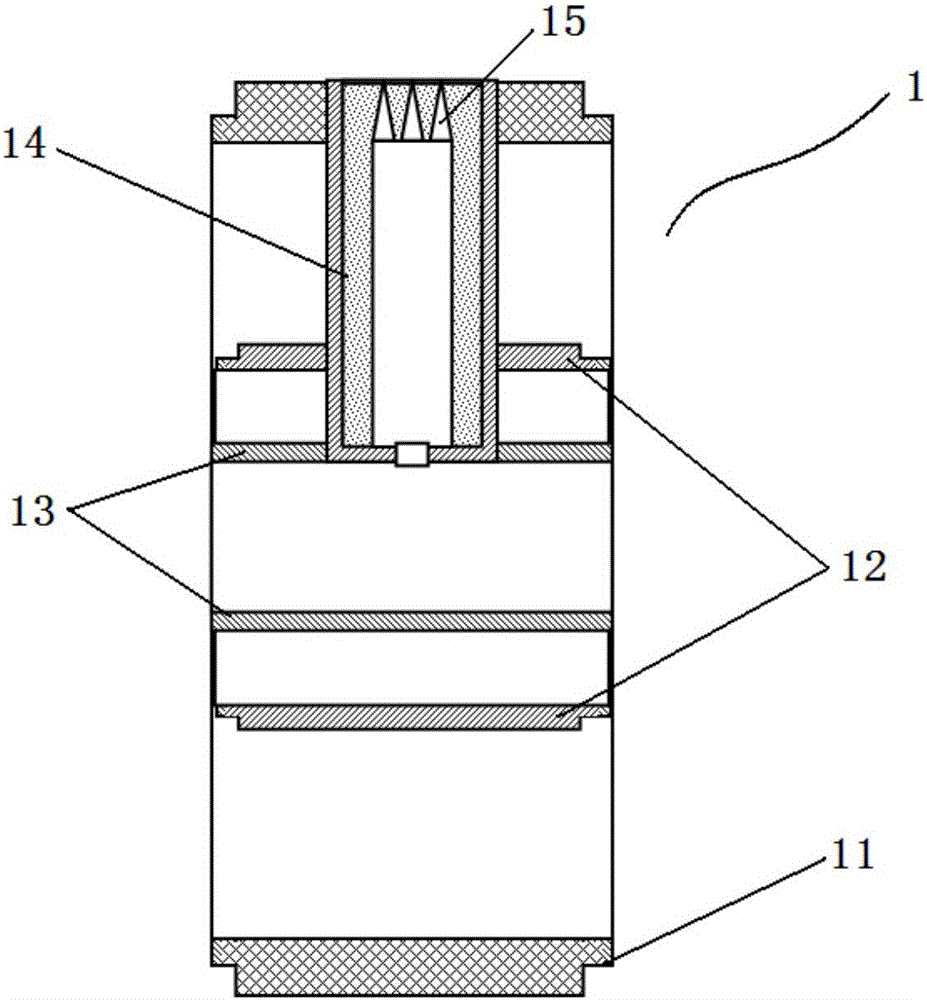

Continuous heat accumulating type heat exchanger

ActiveCN102645116AAchieve alternate flowRealize continuous hot air supplyCombustion processIndirect carbon-dioxide mitigationFurnace temperatureInsulation layer

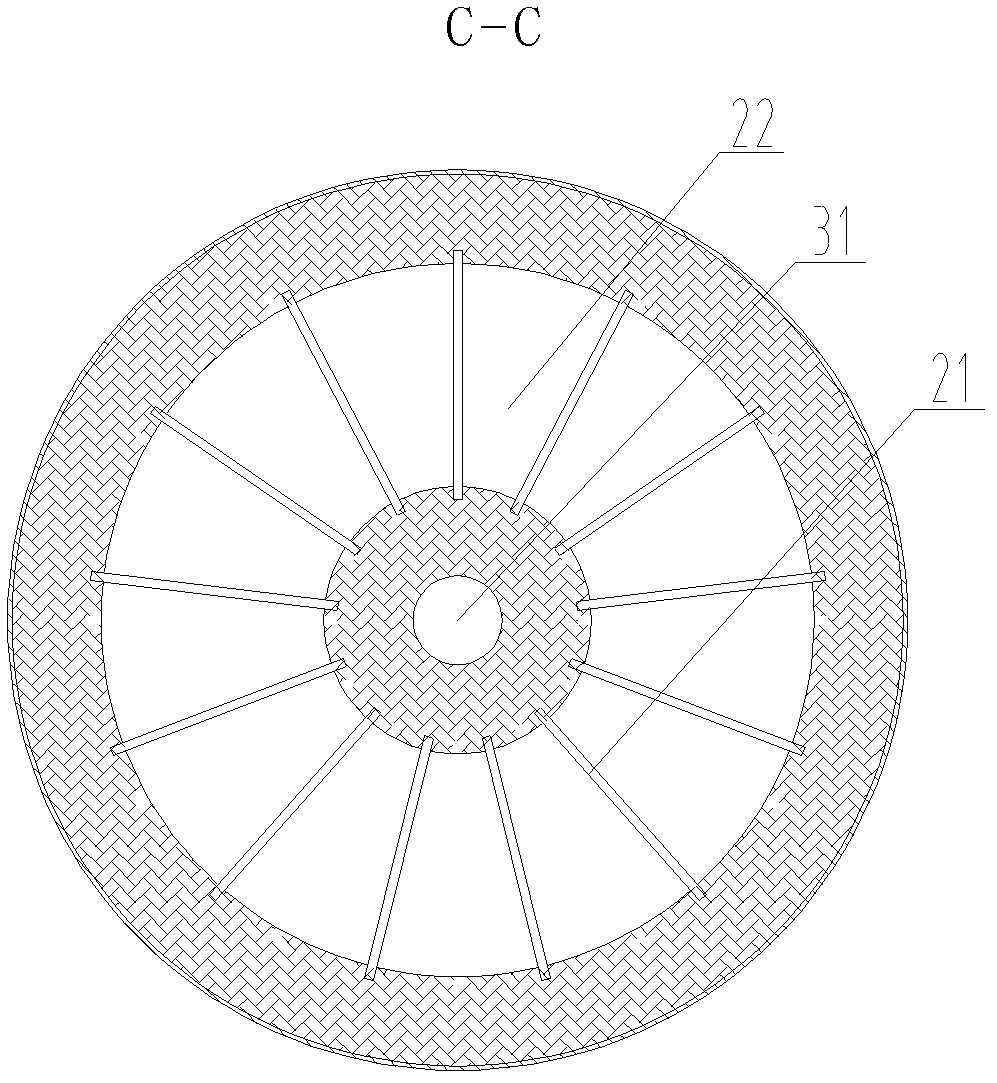

The invention discloses a continuous heat accumulating type heat exchanger. A groove (28) and an air hole (27) are arranged on a supporting plate (8), a plurality of channels are arranged in an annular hollow device (22), and heat accumulators are filled in the plurality of channels. A ceramic covering plate (16) with holes is arranged at the upper portion of a cylinder body (17) which is installed on a power transmission device (19). A high-temperature air cap (1) is in butt-joint with the ceramic covering plate (16) with holes, a sealing device is arranged between the high-temperature air cap (1) and the ceramic covering plate (16) with holes, a low-temperature air cap (18) is in butt-joint with the supporting plate (8), and a sealing structure is arranged between the low-temperature air cap (18) and the supporting plate (8). Smoke flows in from an inlet (10), flows through the heat accumulators, and then is exhausted out from an outlet (12), and air flows in from an inlet (13), flows through the heat accumulators, and then is exhausted out from an outlet (11). The high-temperature air cap (1) and the low-temperature air cap (18) are static. A motor and a transmission device drive the cylinder body (17) to rotate at the constant speed, and insulation layers (20) are arranged both inside and outside the motor, the transmission device and the cylinder body (17). The continuous heat accumulating type heat exchanger is small in fluctuation of furnace temperature, furnace pressure and preheated air temperature.

Owner:CENT SOUTH UNIV

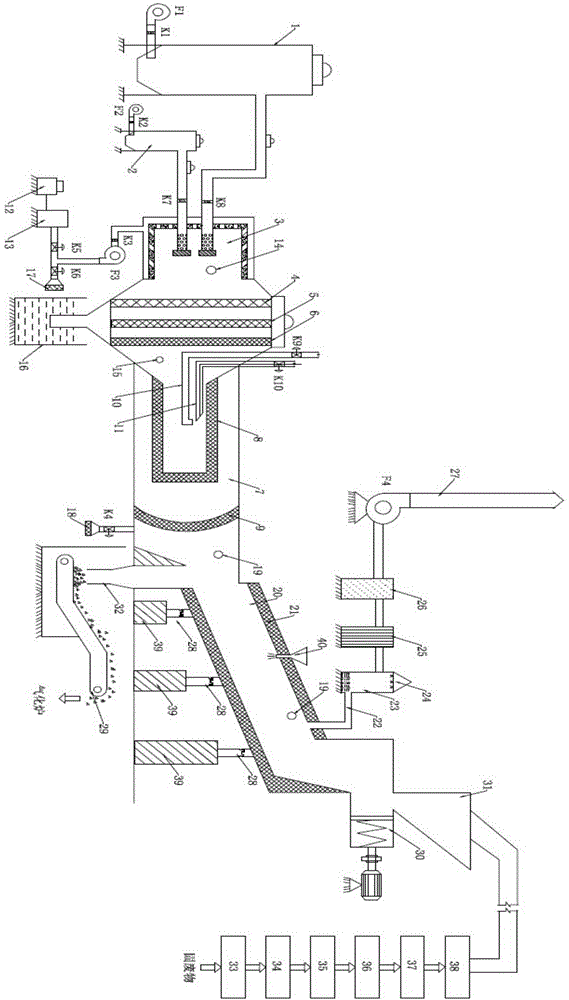

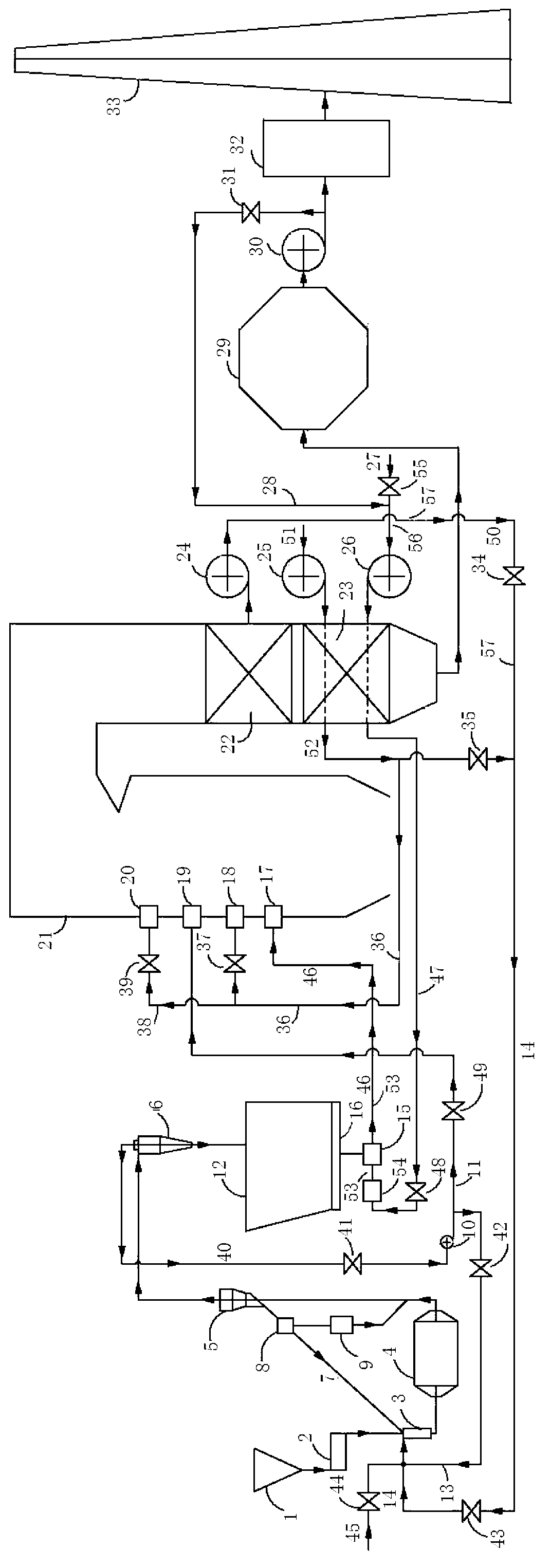

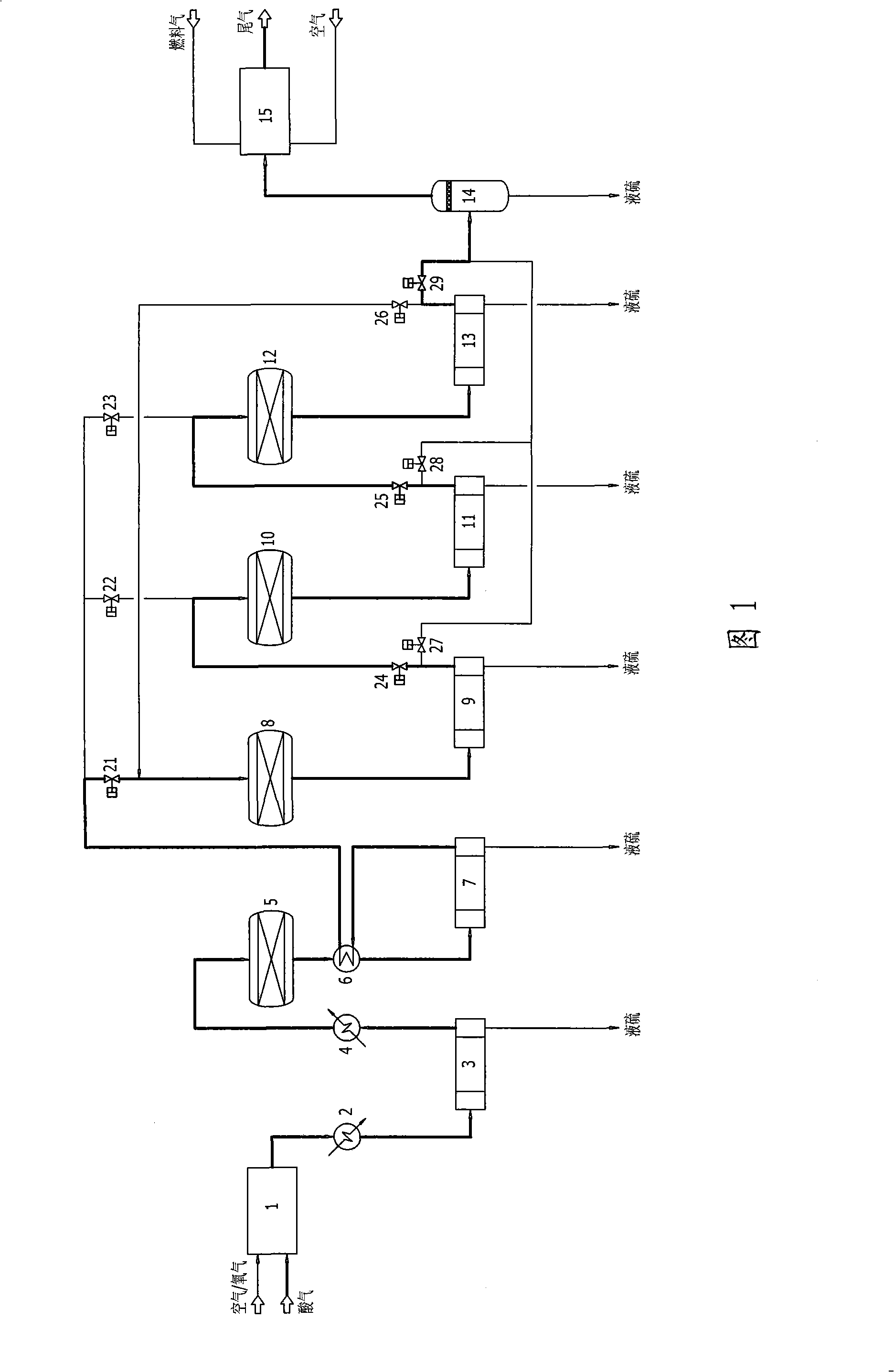

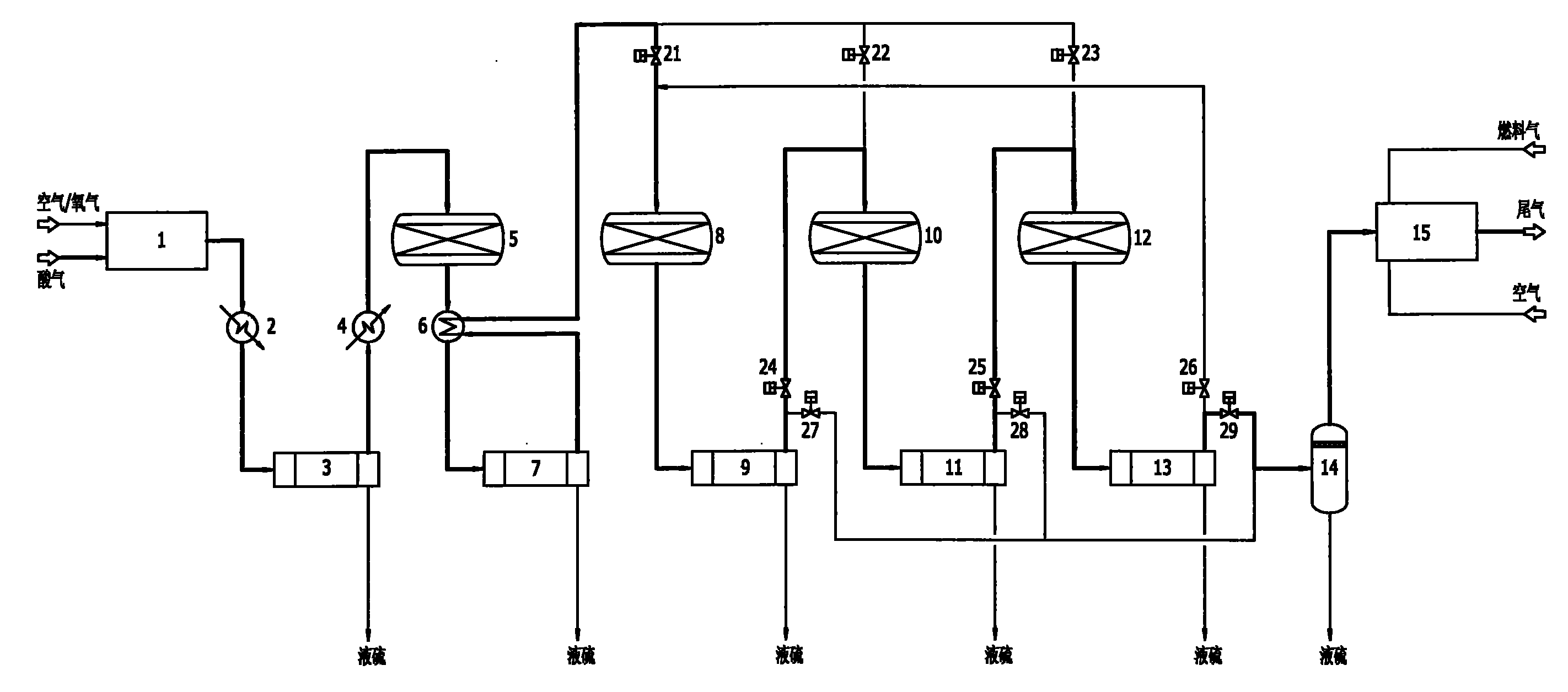

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192BImprove conversion rateReduce emission concentrationEnergy inputSulfur preparation/purificationReaction temperatureOxygen

The invention discloses a low temperature Claus sulfur recovery process. The process mainly comprises a thermal reaction section, a catalytic reaction section and a tail gas incineration section, wherThe invention discloses a low temperature Claus sulfur recovery process. The process mainly comprises a thermal reaction section, a catalytic reaction section and a tail gas incineration section, whertion temperature, contributes to performance of chemical equilibrium towards the direction of sulfur generation, so that conversion rate and recovery rate of sulfur are improved. Moreover, the processtion temperature, contributes to performance of chemical equilibrium towards the direction of sulfur generation, so that conversion rate and recovery rate of sulfur are improved. Moreover, the process has the advantages of simple process flow, relative small equipment and investment, low operation cost and more contribution to environmental protection. The invention also discloses a device for thehas the advantages of simple process flow, relative small equipment and investment, low operation cost and more contribution to environmental protection. The invention also discloses a device for the low temperature Claus sulfur recovery process.low temperature Claus sulfur recovery process.ein in a combustion furnace of the thermal reaction section, partial hydrogen sulfide reacts with oxygen to be converted into sulfur dioxide, the hydrogen sulfide and the sulfur dioxide undergo a Clauein in a combustion furnace of the thermal reaction section, partial hydrogen sulfide reacts with oxygen to be converted into sulfur dioxide, the hydrogen sulfide and the sulfur dioxide undergo a Claus reaction to generate sulfur, and process gas after sulfur separation enters the catalytic reaction section; in the reactor of each stage of the catalytic reaction section, the hydrogen sulfide and ts reaction to generate sulfur, and process gas after sulfur separation enters the catalytic reaction section; in the reactor of each stage of the catalytic reaction section, the hydrogen sulfide and the sulfur dioxide under conventional Claus reaction, catalyst reactivation, sub-dewpoint and sub-solid point low temperature Claus reaction in sequence; after the catalyst reaction section, the tail ghe sulfur dioxide under conventional Claus reaction, catalyst reactivation, sub-dewpoint and sub-solid point low temperature Claus reaction in sequence; after the catalyst reaction section, the tail gas which is subjected to sulfur separation enters the tail gas incineration section, and the tail gas is incinerated and exhausted in the tail gas incineration furnace. The process adopts a lower reacas which is subjected to sulfur separation enters the tail gas incineration section, and the tail gas is incinerated and exhausted in the tail gas incineration furnace. The process adopts a lower reac

Owner:CHENGDU SEPMEM SCI & TECH

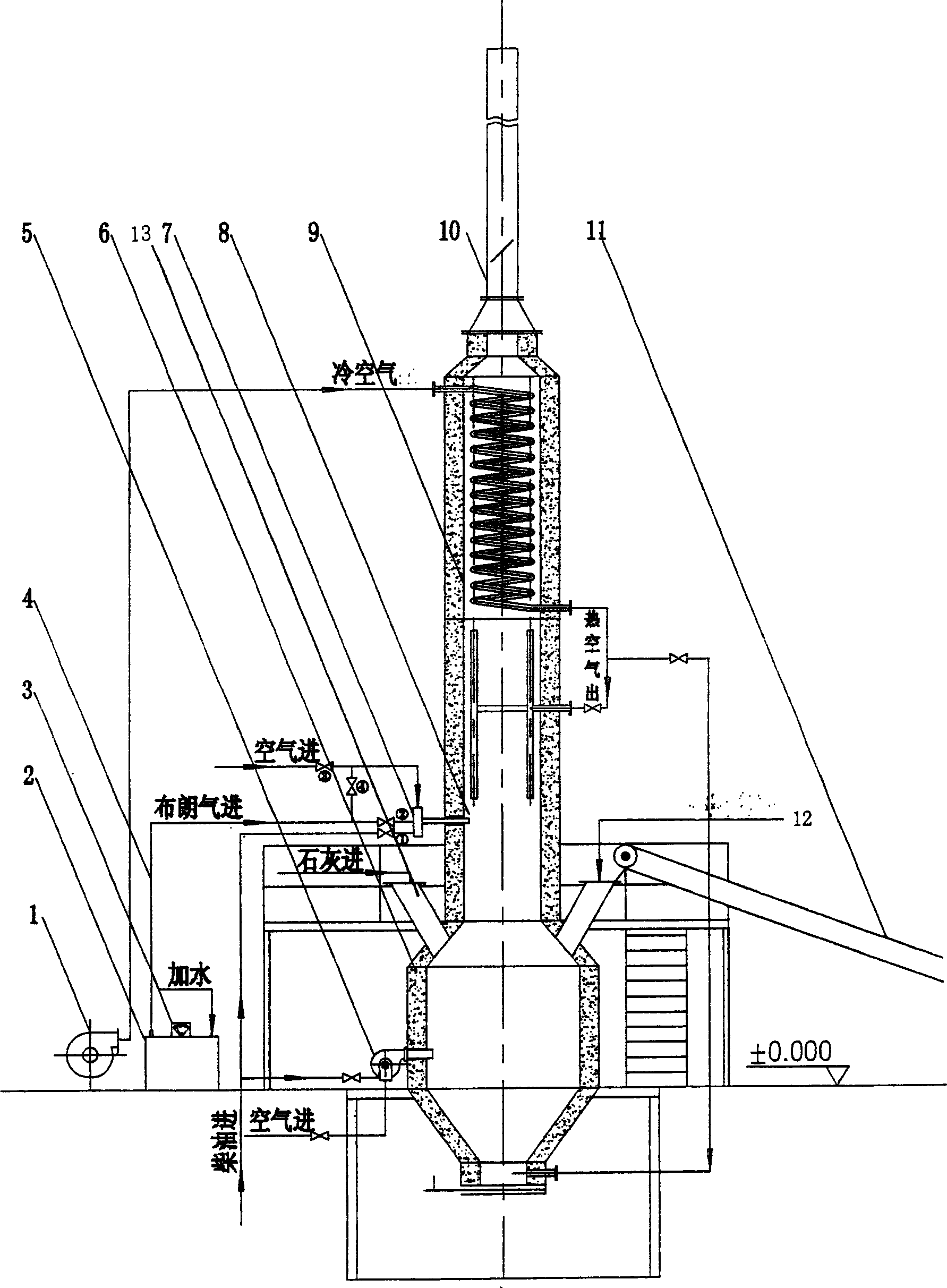

Brown gas type integrated solid waste incinerator

InactiveCN1800712ADe novo synthesisSimple processIncinerator apparatusCombustion chamberSmall footprint

The invention relates to a brown air integrated solid waste incinerator, which lifts the solid waste via the feeding belt machine (11) to the waste feeding inlet (12) into the burning room (6); then fires the burning machine (5) while the generated smoke is fed into the secondary burning room (8); then fires the oil ejector (7) which can burn the air, brown air or the mixture between air and brown air; the burnt smoke will be fed into gas-gas heat exchanger (9); and discharges the tail gas. The invention has the characterized in that fully burning, less CO discharge as 5mg / NM3 which is less than national discharge standard, simplified process, reduced device, saved cost and the application for integrating incinerate system.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH +1

Neural network-based SCR intelligent ammonia-spraying optimization method and apparatus

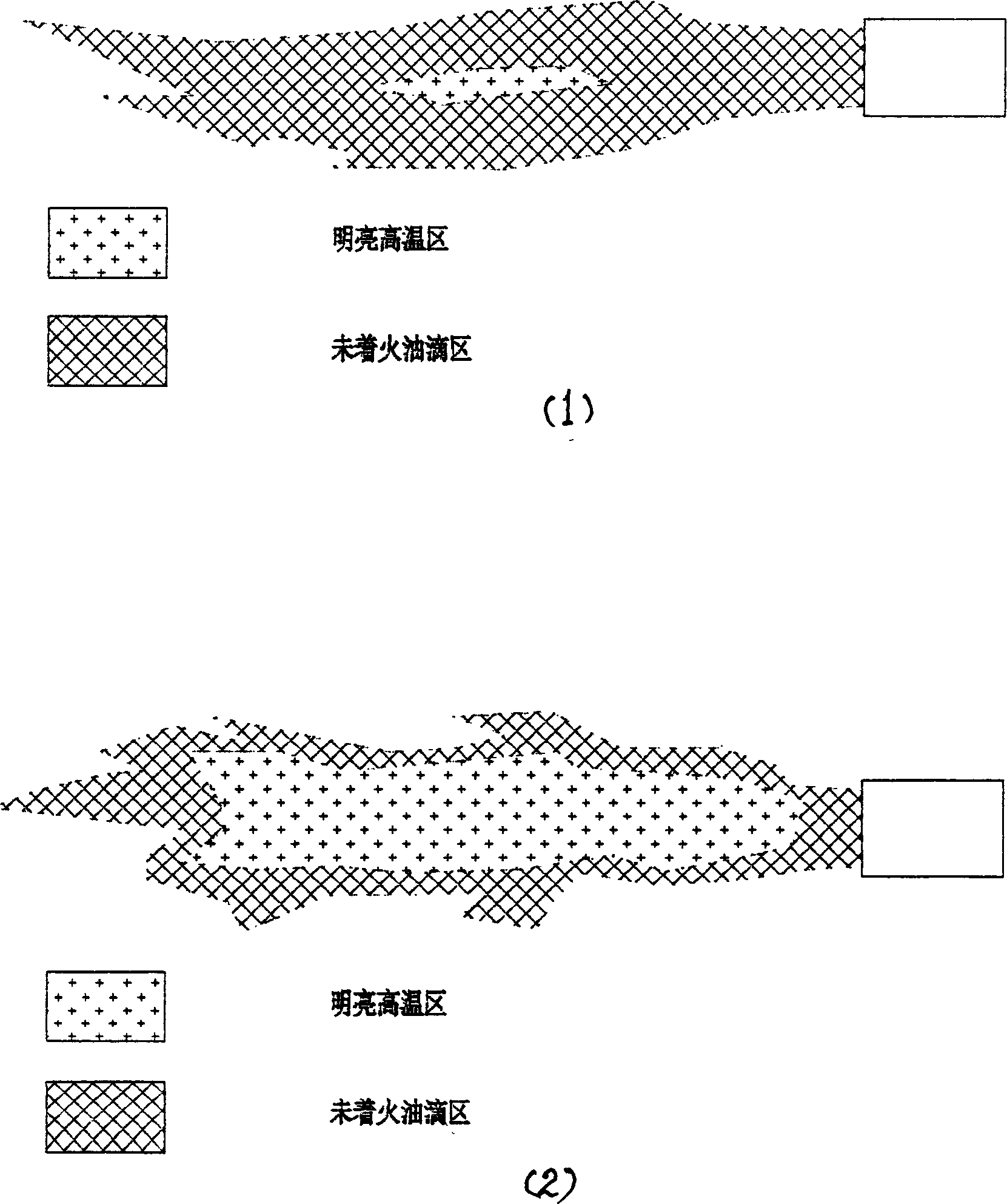

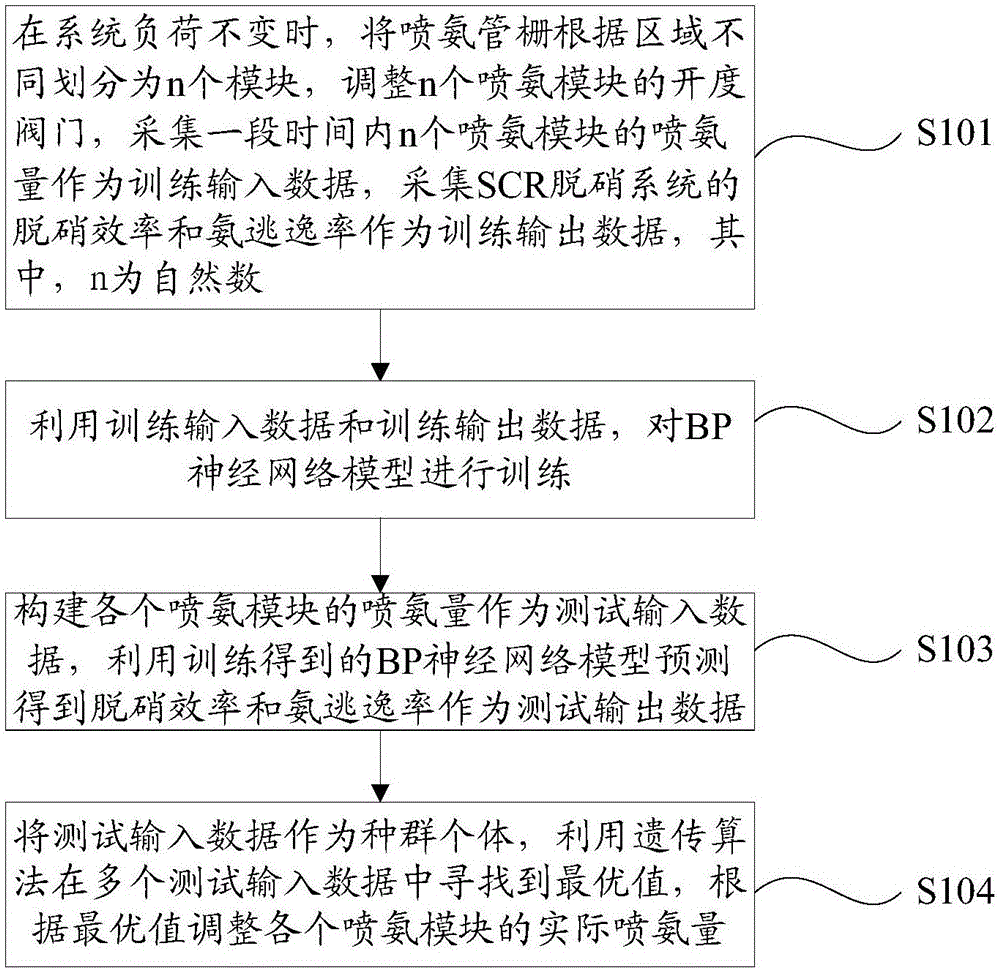

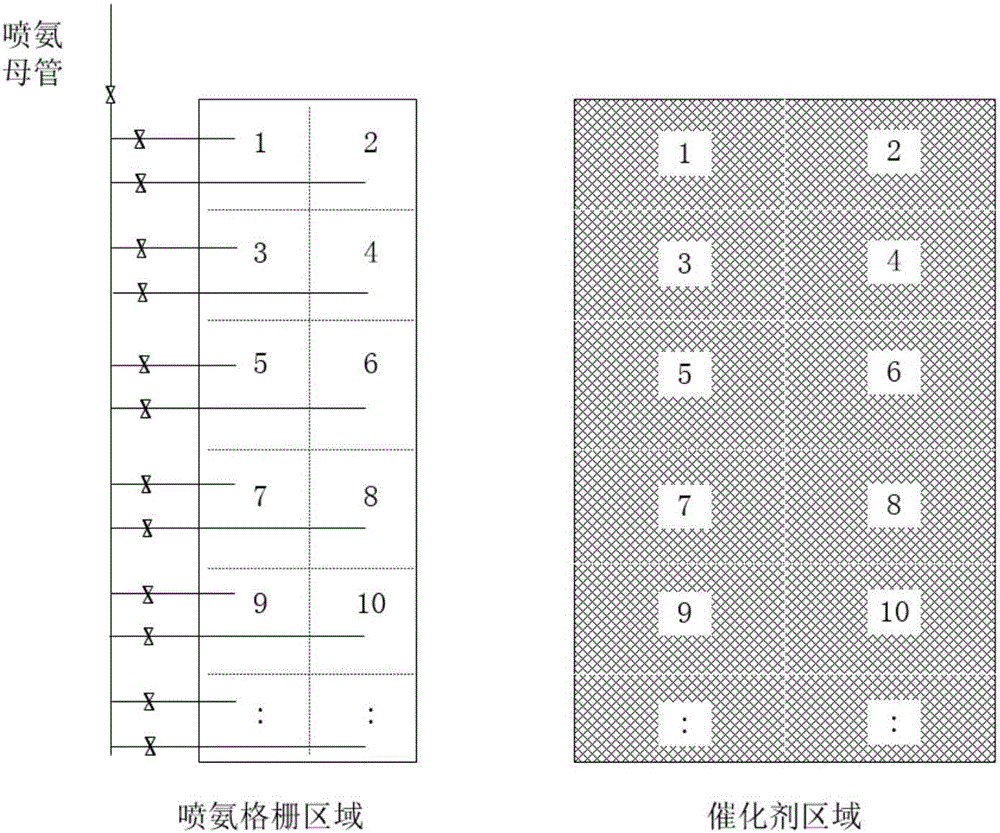

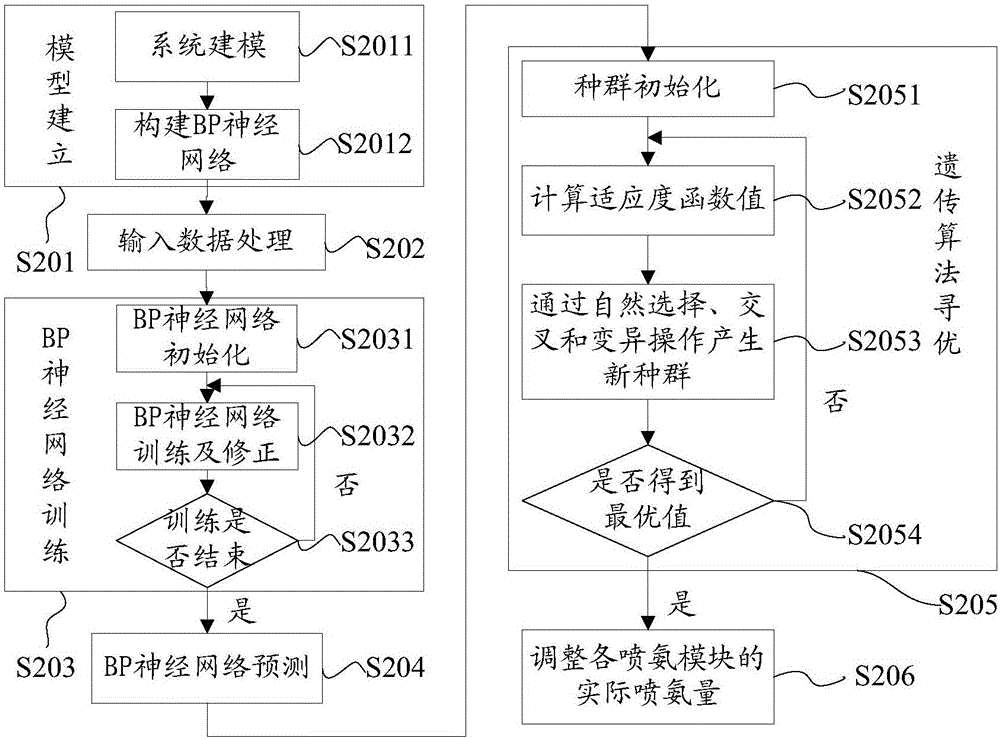

ActiveCN106599586AImprove uniformityIncrease profitChemical processes analysis/designSpecial data processing applicationsTest inputEscape rate

The invention discloses a neural network-based SCR intelligent ammonia-spraying optimization method and apparatus, and relates to the field of a fire coal denitration technology. The method comprises the steps of dividing an ammonia-spraying pipe gate into n modules when system load is unchanged, adjusting valves of n ammonia-spraying modules, collecting ammonia-spraying quantity of the n ammonia-spraying modules within certain time to be used as training input data, and taking denitration efficiency and ammonia escape rate as training output data; performing BP neural network training based on the training input data and the training output data; taking ammonia-spraying quantity of each ammonia-spraying module as test input data, and predicting the denitration efficiency and the ammonia escape rate through a BP neural network model obtained by training; and searching an optimal value from multiple test input data through a genetic algorithm, and adjusting actual ammonia-spraying quantity of each ammonia-spraying module according to the optimal value. By adoption of the scheme, the differentiation control on the ammonia-spraying quantity can be realized, the denitration efficiency is improved, the ammonia escape rate is lowered, and the ammonia-spraying quantity of each ammonia-spraying module can be adjusted according to different targets of power plants flexibly.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

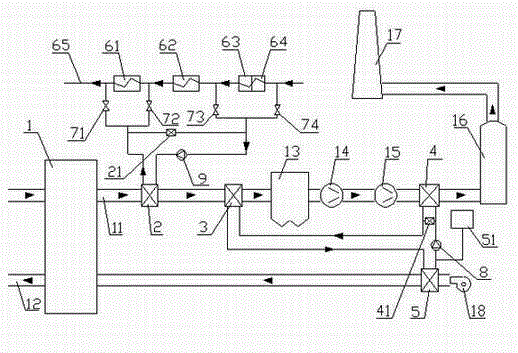

Power station boiler smoke waste heat deep recycling and emission reducing system

ActiveCN104006401AReduce the temperatureImprove temperature distributionCombustion processIndirect carbon-dioxide mitigationAir preheaterPower station

The invention discloses a power station boiler smoke waste heat deep recycling and emission reducing system. A first low-temperature heat exchanger is arranged between an air pre-heater and a dust remover, a second low-temperature heat exchanger is arranged between a pressurizing fan and a desulfurizing tower, an air heat exchanger is arranged between a secondary fan and the air pre-heater, a heat exchanging medium output end of the air heat exchanger is connected with a heat exchanging medium input end of the second low-temperature heat exchanger through a first water pump, a heat exchanging medium output end of the second low-temperature heat exchanger is connected with a heat exchanging medium input end of the first low-temperature heat exchanger, and a heat exchanging medium output end of the first low-temperature heat exchanger is connected with a heat exchanging medium input end of the air heat exchanger. According to the power station boiler smoke waste heat deep recycling and emission reducing system, the defect existing in waste heat recycle of traditional low-temperature economizers is overcome, smoke temperatures can be deeply reduced, smoke temperature distribution is optimized, and the purposes of deeply recycling smoke waste heat and reducing dust discharge concentration are achieved.

Owner:CHENGXIN GREEN INTEGRATION

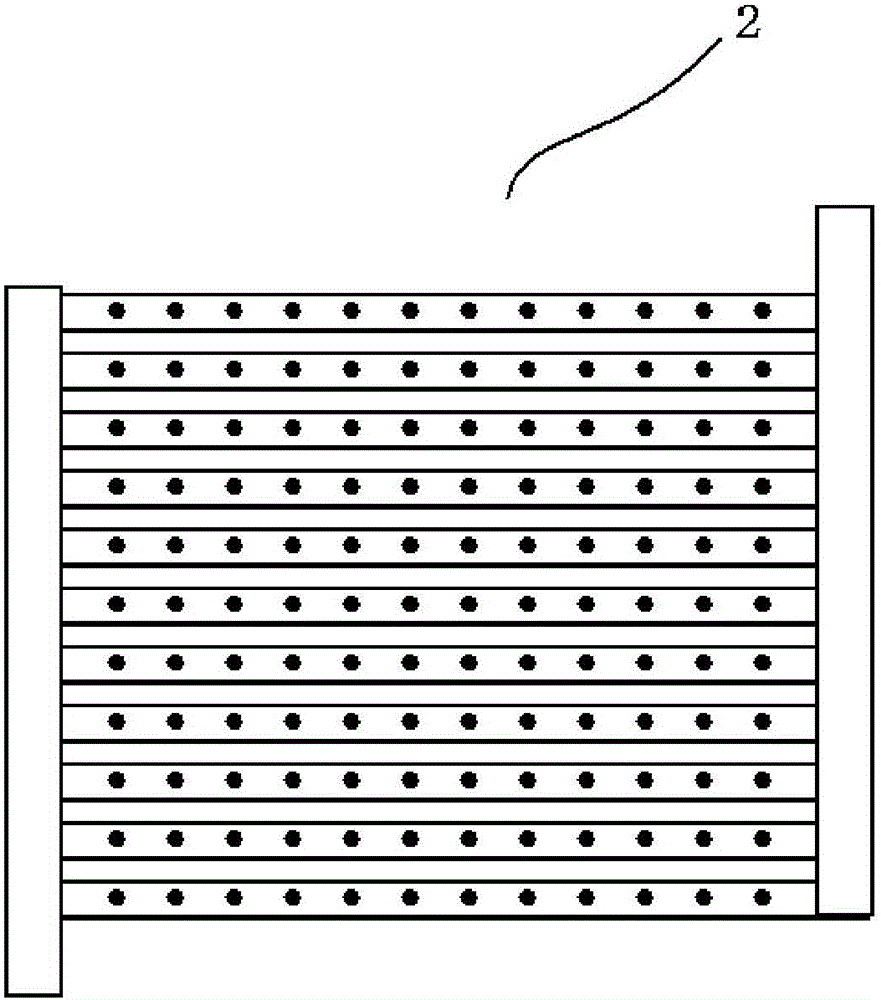

Multifield promotion-based coagulation and aggregation strengthening device and method for particulate matters

InactiveCN107138016AIncrease the probability of collisional condensationImprove removal effectAuxillary pretreatmentParticulatesEngineering

The invention relates to a multifield promotion-based coagulation and aggregation strengthening device and method for particulate matters. According to the coagulation and aggregation strengthening device, a heat-exchange cooling condenser, an ion wind-assisted orifice plate type electric coagulation system and a coagulation mixer are arranged in sequence in a coagulator, the ion wind-assisted orifice plate type electric coagulation system comprises an anode, orifice plate type polar plates and an cathode, the anode and the cathode are respectively arranged between two adjacent orifice plate type polar plates, a spray humidifier is also arranged in front of or behind the orifice plate type electric coagulation system, and the spray humidifier comprises a plurality of nozzles communicated with a liquid drop generating device. The coagulation and aggregation strengthening device combines phase change condensation with spray humidification and growth, simultaneously improves the particle collision and coagulation probability by using the ion wind convection field effect in an electric dust collector, and integrates multifield effects of electric field force, liquid bridge force, van der waals force, viscous force and the like in the same equipment for strengthening the coagulation and aggregation effects of the particles, so the average particle diameters of the particles are increased obviously, and the method is an efficient way for further increasing the removal effect of dedusting equipment and reducing the discharge concentration of particulate matters in flue gas.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com