Stratified combustion on-line optimization control system of boiler coal dust and optimization method thereof

A technology of stratified combustion and optimized control, which is applied to control combustion, analysis of materials, indirect carbon dioxide emission reduction, etc., to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

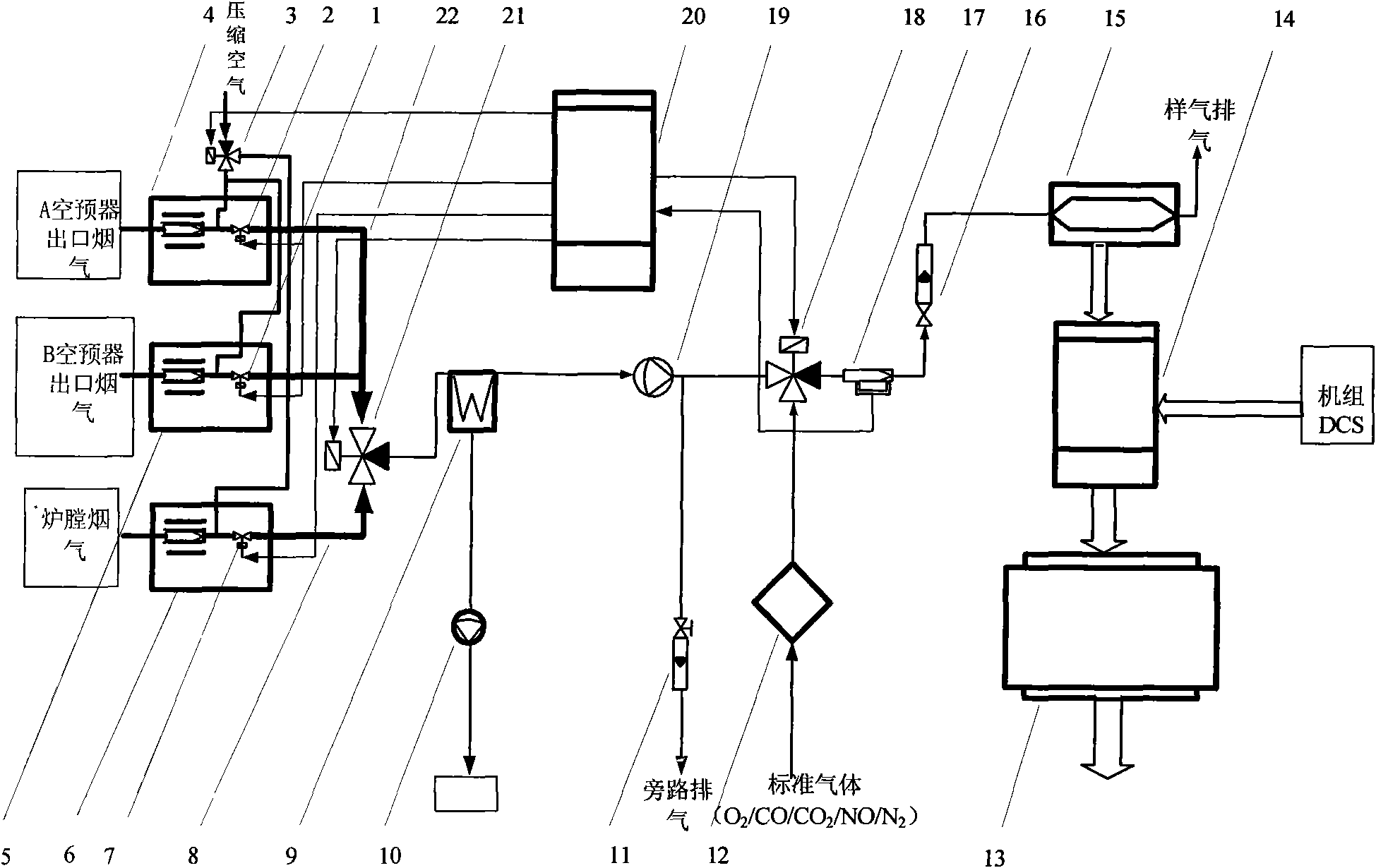

[0040] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the online optimization system for pulverized coal layered combustion of the present invention.

[0041] In order to solve the above technical problems, the present invention provides an online optimization control system for boiler pulverized coal layered combustion, including a gas sampling system and a data processing system. The gas sampling system includes a flue gas sampling probe and a continuous monitoring system for flue gas components. It is characterized in that the flue gas sampling probe includes a first flue gas sampling probe 4 located at the outlet of the air preheater A, a second flue gas sampling probe 5 located at the outlet of the air preheater B and a third flue gas sampling probe 6 located at the furnace , the data processing system includes an industrial computer 13 connected to a continuous monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com