Separated concrete barrier with longitudinal connection capable of moving rapidly and manufacturing method thereof

A technology of vertical connection and fast movement, applied in roads, road safety devices, roads, etc., can solve the problems of insufficient anti-collision safety of movable guardrails and insufficient mobility of concrete guardrails, so as to ensure collision avoidance and safety, Good application effect and the effect of ensuring flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

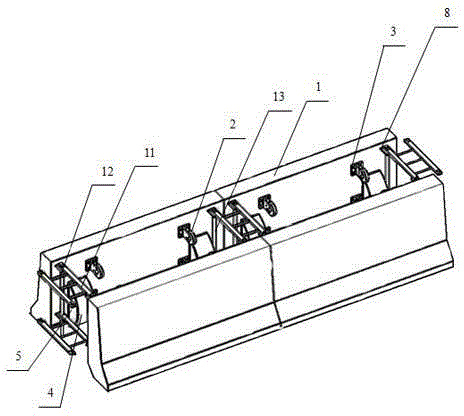

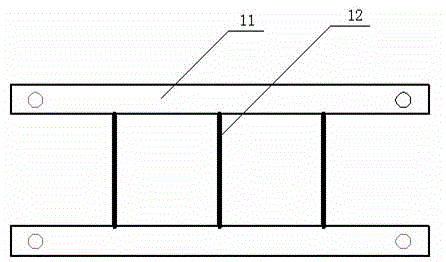

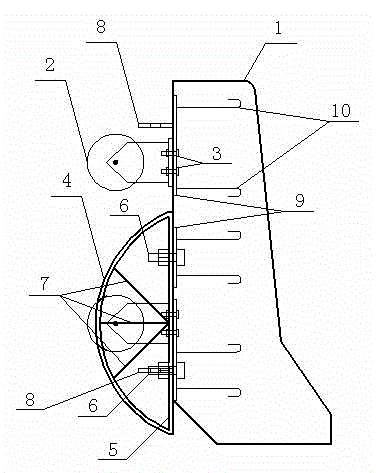

[0026] Such as figure 1 As shown, the guardrail of the present invention is composed of two half guardrails 1, and the two half guardrails 1 are connected by connectors. A rolling device is arranged inside each half guardrail 1, wherein the rolling device is a caster or a roller. In this embodiment, the rolling device adopts casters 2 to achieve the purpose of rapid movement. When the guardrail needs to be moved, the guardrail is tilted, and the rolling effect of the casters is used to quickly move to the roadside or other places; A chamfer is cut at the bottom of the back side, so that it can maintain a stable state when it is placed freely, but the horizontal force applied to it will lose the stable state and cause a tilting effect, so that it is convenient for demolition personnel to quickly tilt it by their own strength Guardrail: two arc-shaped buffer devices are installed at both ends of the upright back of the guardrail, and the guardrail will move along the arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com