Automobile door ring manufacturing technology

A manufacturing process and door knocker technology, which is applied in the field of automobile door knocker manufacturing process, can solve the problems of poor anti-corrosion ability of the weld seam and reduce product strength, etc., and achieve the effect of improving welding strength and corrosion resistance, reducing processing costs and reducing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

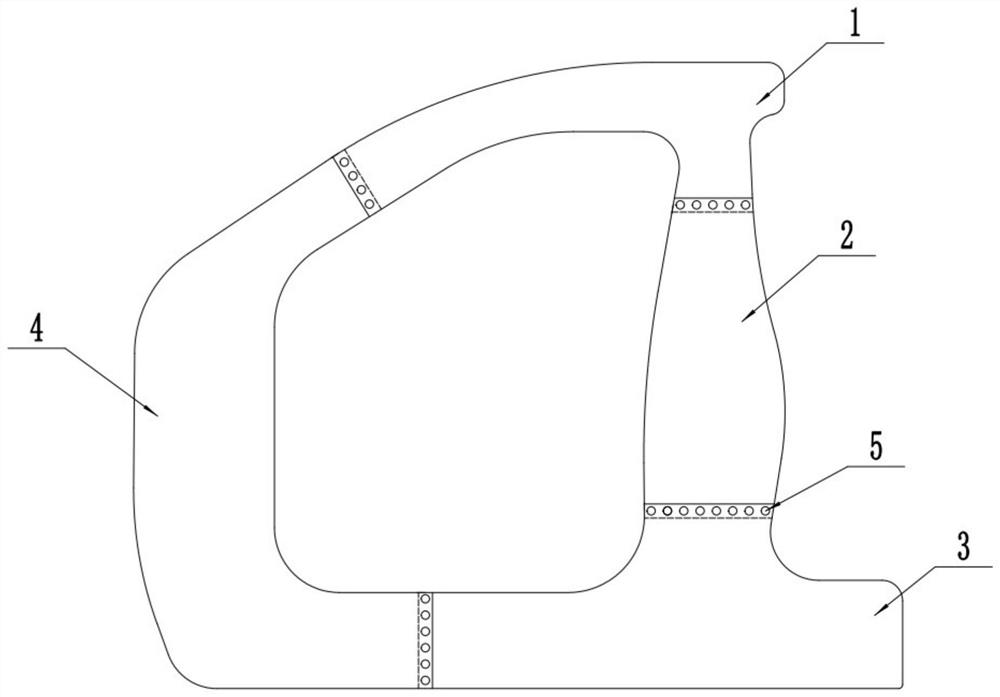

[0034] Please refer to figure 1 and figure 2 , a kind of automobile door knocker manufacturing process, comprises the following steps:

[0035] Welding: According to the composition of the door knocker, obtain the required size of the panels, wherein the door knocker includes A-pillar panel 1, B-pillar panel 2, threshold panel 3 and H-pillar panel 4. The joint width is 16mm-60mm, and resistance spot welding or laser spot welding is performed on the overlapping position to form solder joints 5 at the overlapping position;

[0036] According to the thickness of the sheet metal and the number of solder joints, select an appropriate lap width. When the lap width is less than 16 mm, the weldable area of the solder joint 5 is limited, and insufficient welding strength is prone to occur, resulting in hidden safety and quality risks for the door knocker; When the lap width is greater than 60mm, the lap width is too large, resulting in the weight of the door ring sheet, which cann...

Embodiment 2

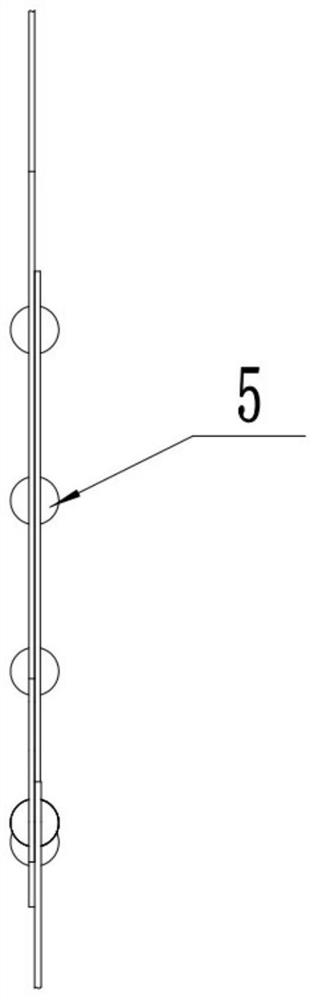

[0057] Please refer to image 3 , The difference from Example 1 is the arrangement of solder joints, and the rest are the same as Example 1.

[0058] A manufacturing process of an automobile door ring, in which a plurality of welding spots 5 are arranged crosswise during welding, thereby increasing the welding strength.

Embodiment 3

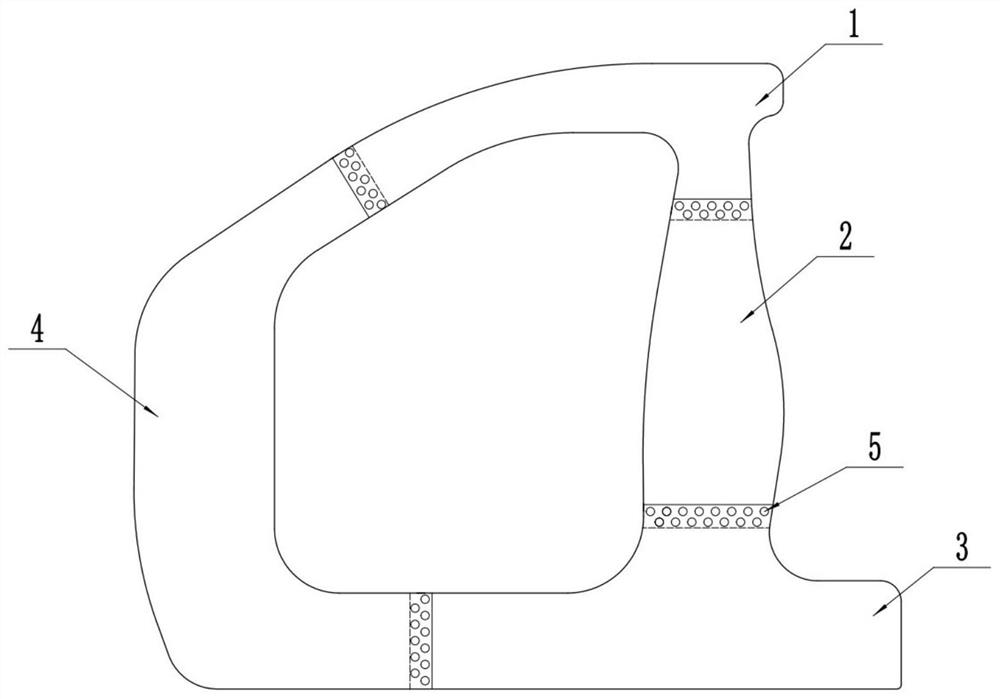

[0060] Please refer to Figure 4 , different from Embodiment 1 is the structure of the knocker, and the rest are the same as Embodiment 1.

[0061] A manufacturing process for an automobile door knocker is not only suitable for the closed door knocker shown in Embodiment 1, but also for the semi-closed door knocker in this embodiment. In this implementation, the door knocker includes A-pillar sheet material 1, B-pillar sheet material 2 and H-pillar sheet material 4. Adjacent sheets are overlapped together up and down, and laser spot welding or resistance spot welding is performed on the overlapping positions. A plurality of welding spots 5 are formed at the overlapping positions.

[0062] Optionally, semi-closed door knockers including different panels can also be manufactured according to actual usage conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com