Aluminum alloy laser welding method

A laser welding and aluminum alloy technology, which is applied in the butt welding of aluminum alloy plates or profiles, and in the field of aluminum alloy laser welding, can solve the problems of threatening the health of operators, high sensitivity to thermal cracks, and burning of alloy elements, etc., to improve welding Effect of quality and welding efficiency, reduction of weld width and heat-affected zone width, improvement of welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

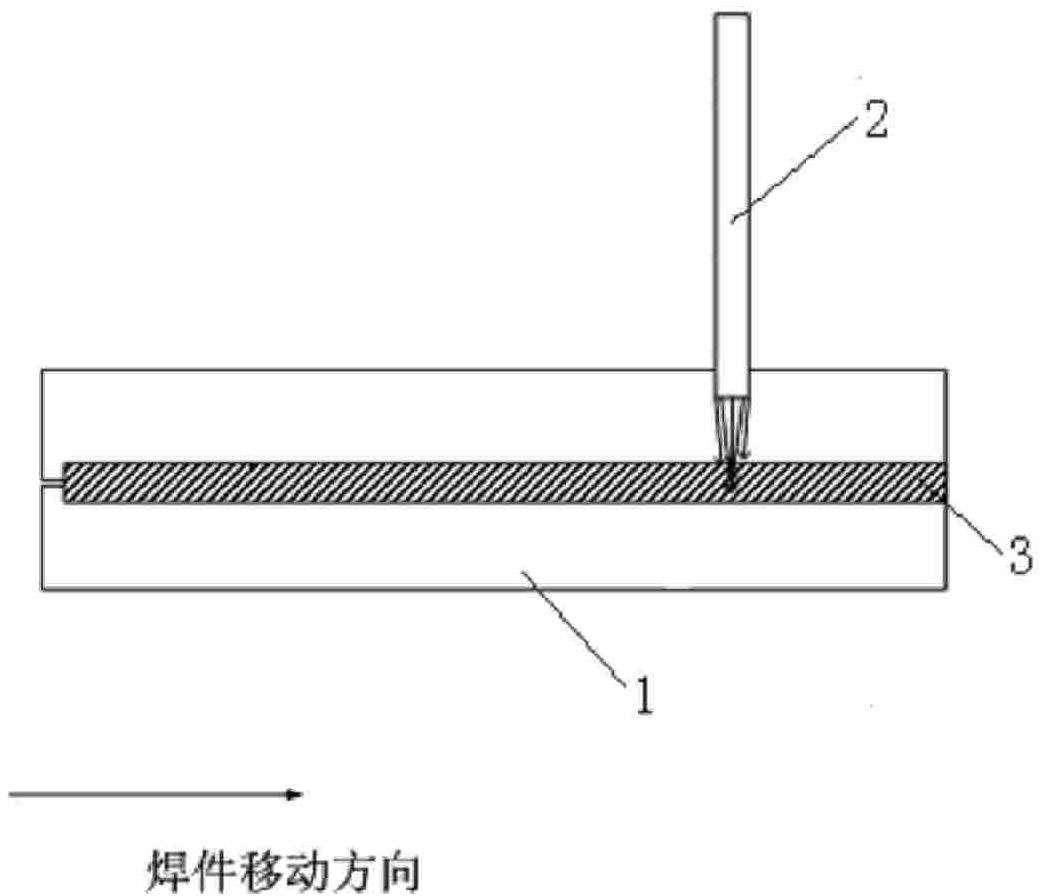

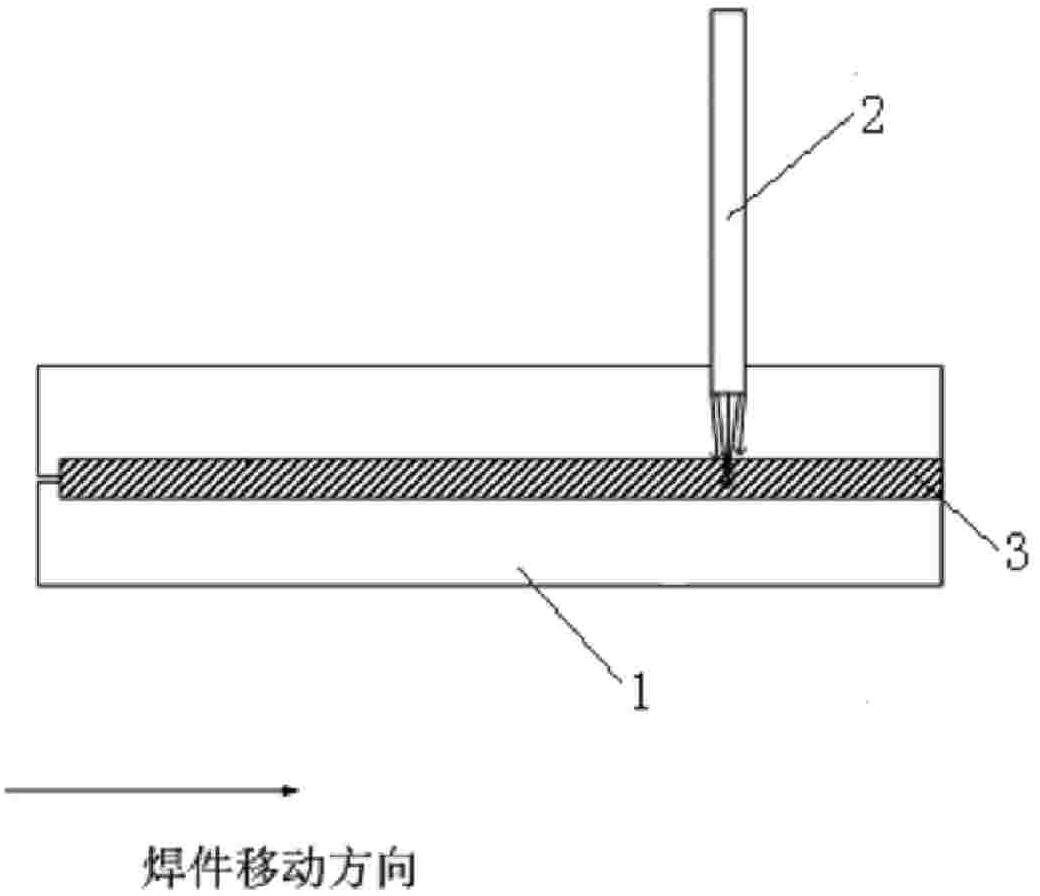

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] As shown in Figure 1, the aluminum alloy laser welding method of the present invention adds a process of carrying out nano-metal oxide pretreatment on the part to be welded before laser welding, and the welding thickness is 5mm below, the width is 200mm, and the length is 1500mm aluminum alloy plate is taken as an example to describe in detail.

[0021] The laser welding machine adopts HL2006D type Nd:YAG continuous laser, the wavelength is 1.06 microns, the laser output is 0-2000W (average power), the single pulse energy is 0-200J, the pulse waveform can be set arbitrarily, 0.6mm optical fiber transmission, focusing lens The focal length is 200mm and the focal diameter is 0.6mm.

[0022] According to the characteristics that metal oxides have good absorption of laser light, and according to the quantum size effect, small size effect, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com