Patents

Literature

166 results about "Stratified combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

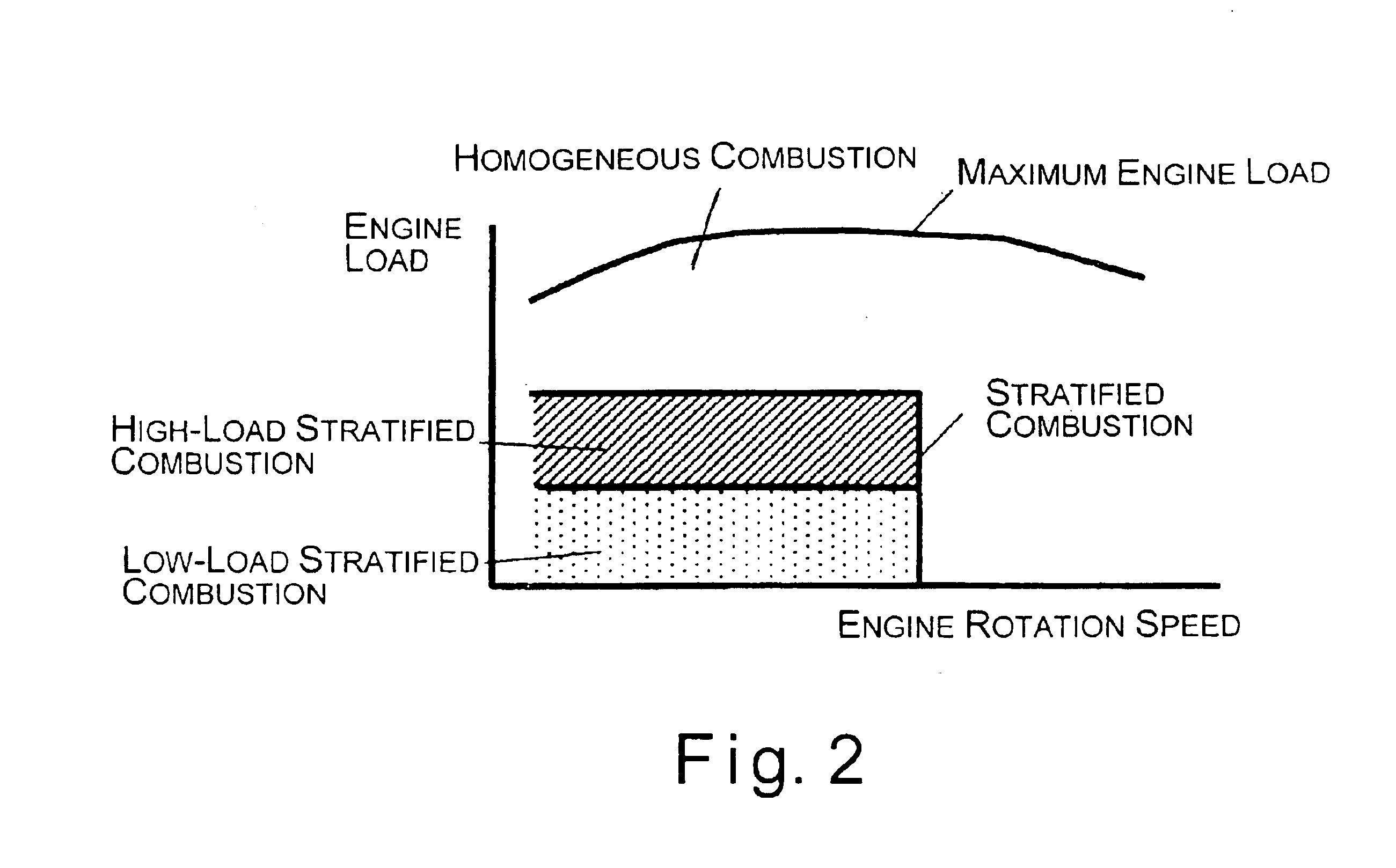

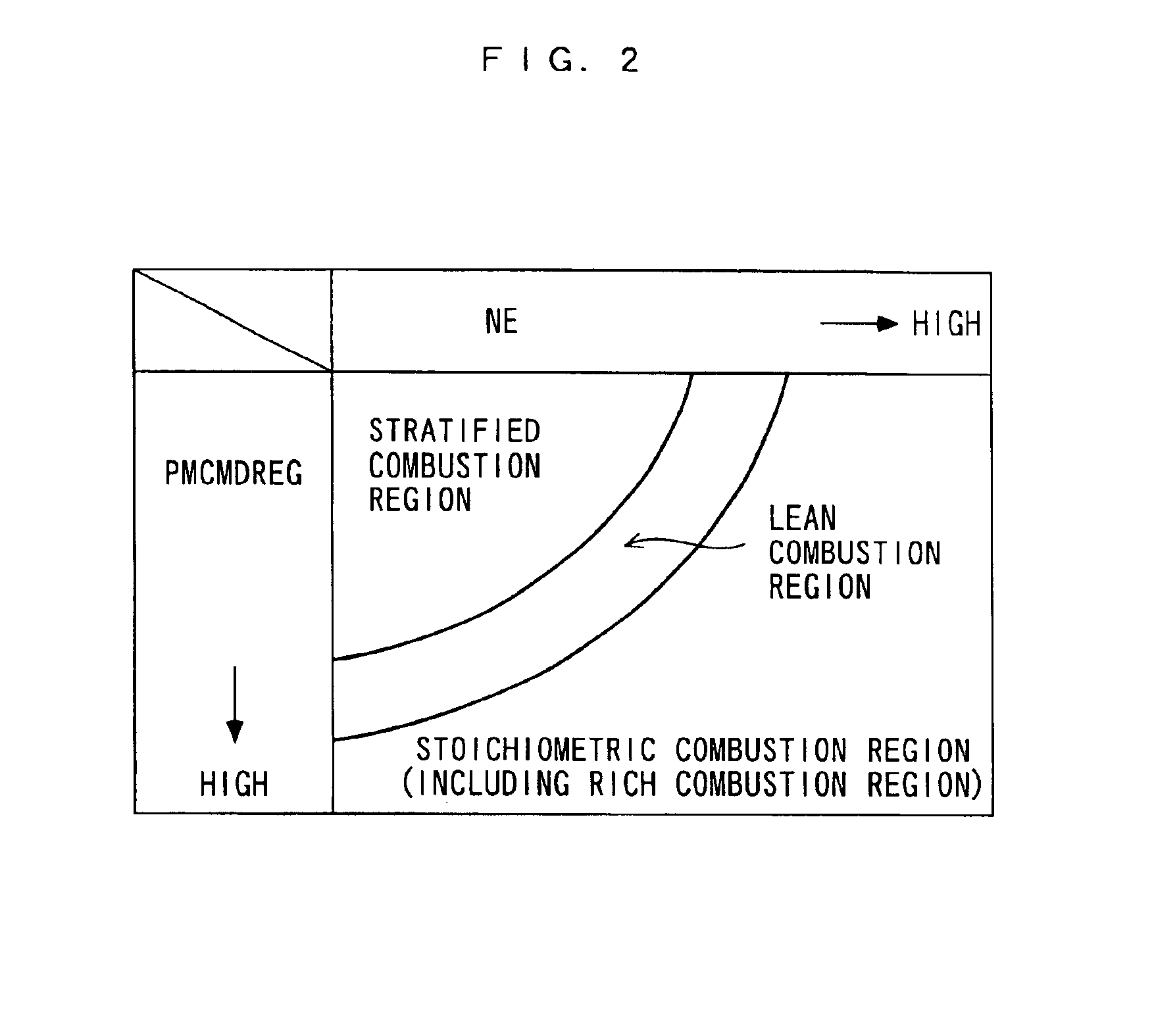

Stratified combustion is typically used during idle and light to moderate loads at low engine speeds while homogeneous combustion is used at moderate to high loads and medium to high engine speeds.

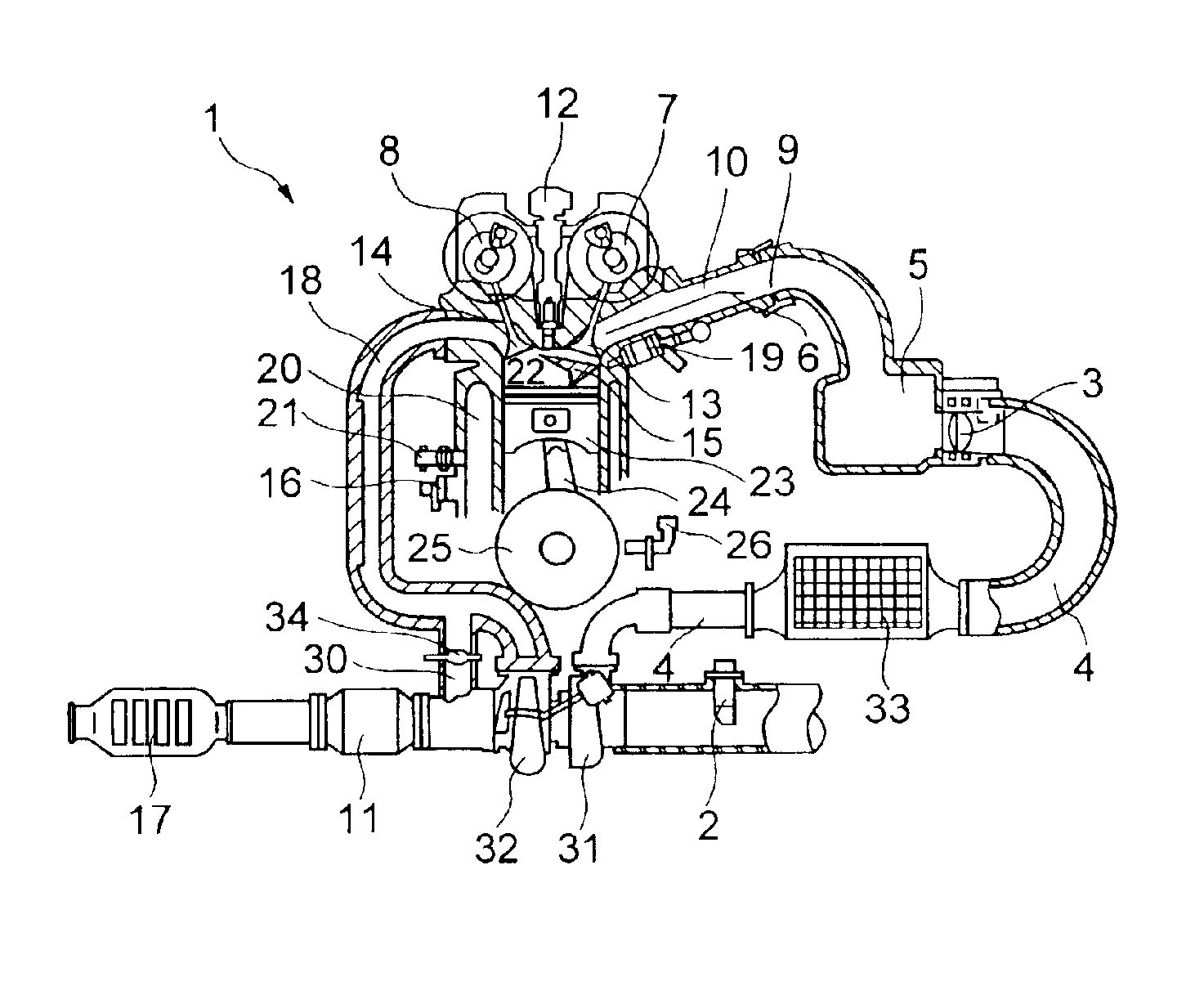

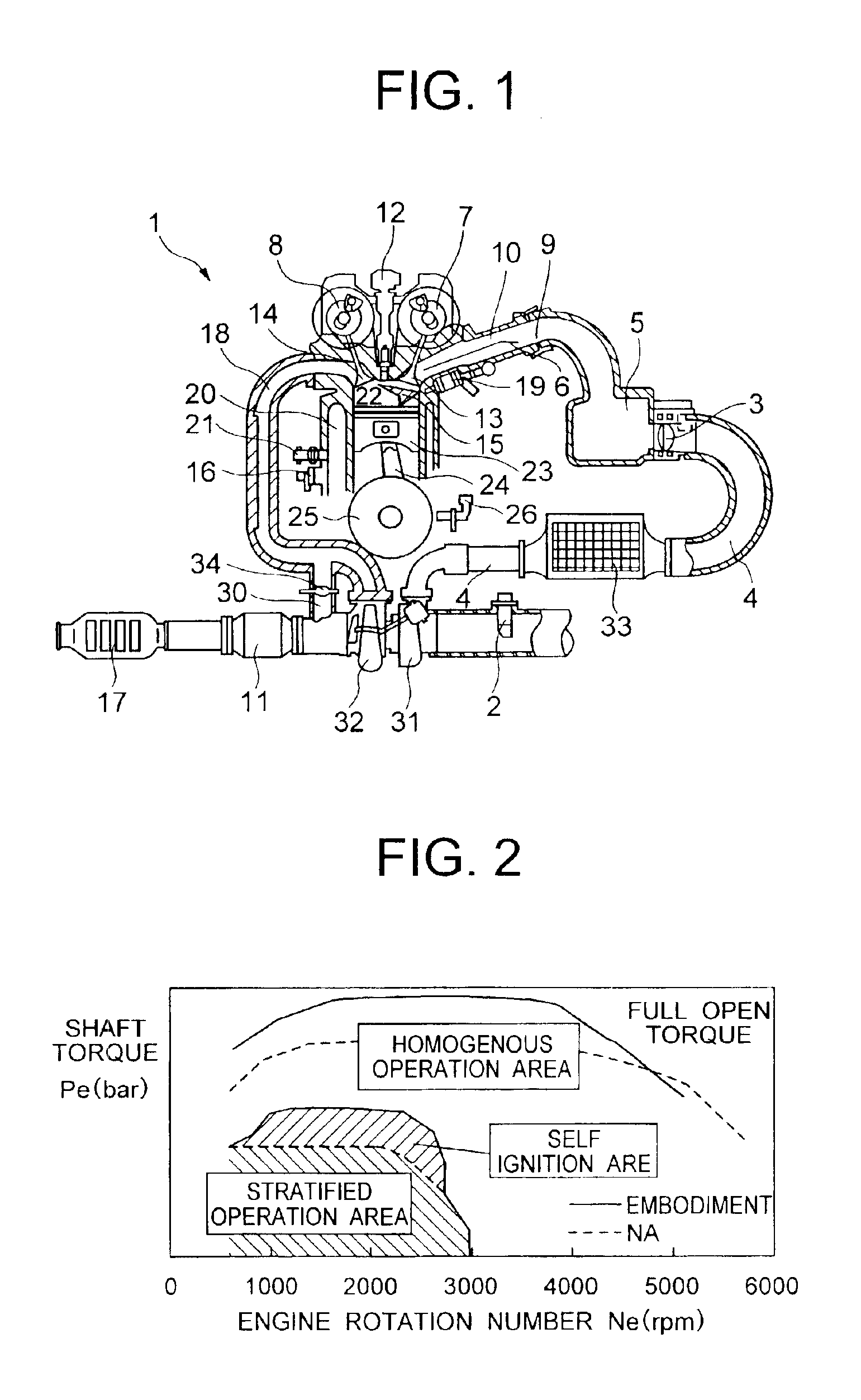

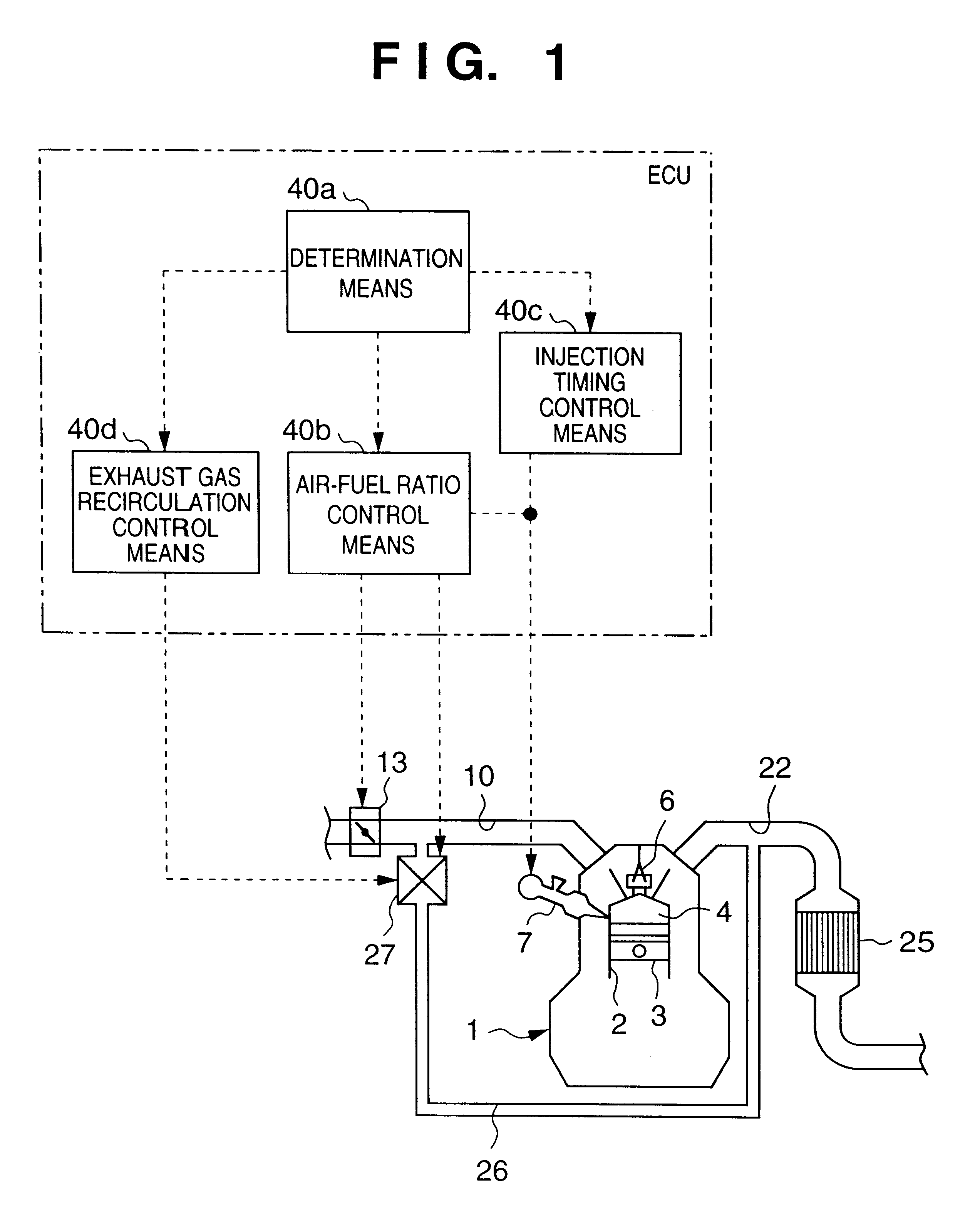

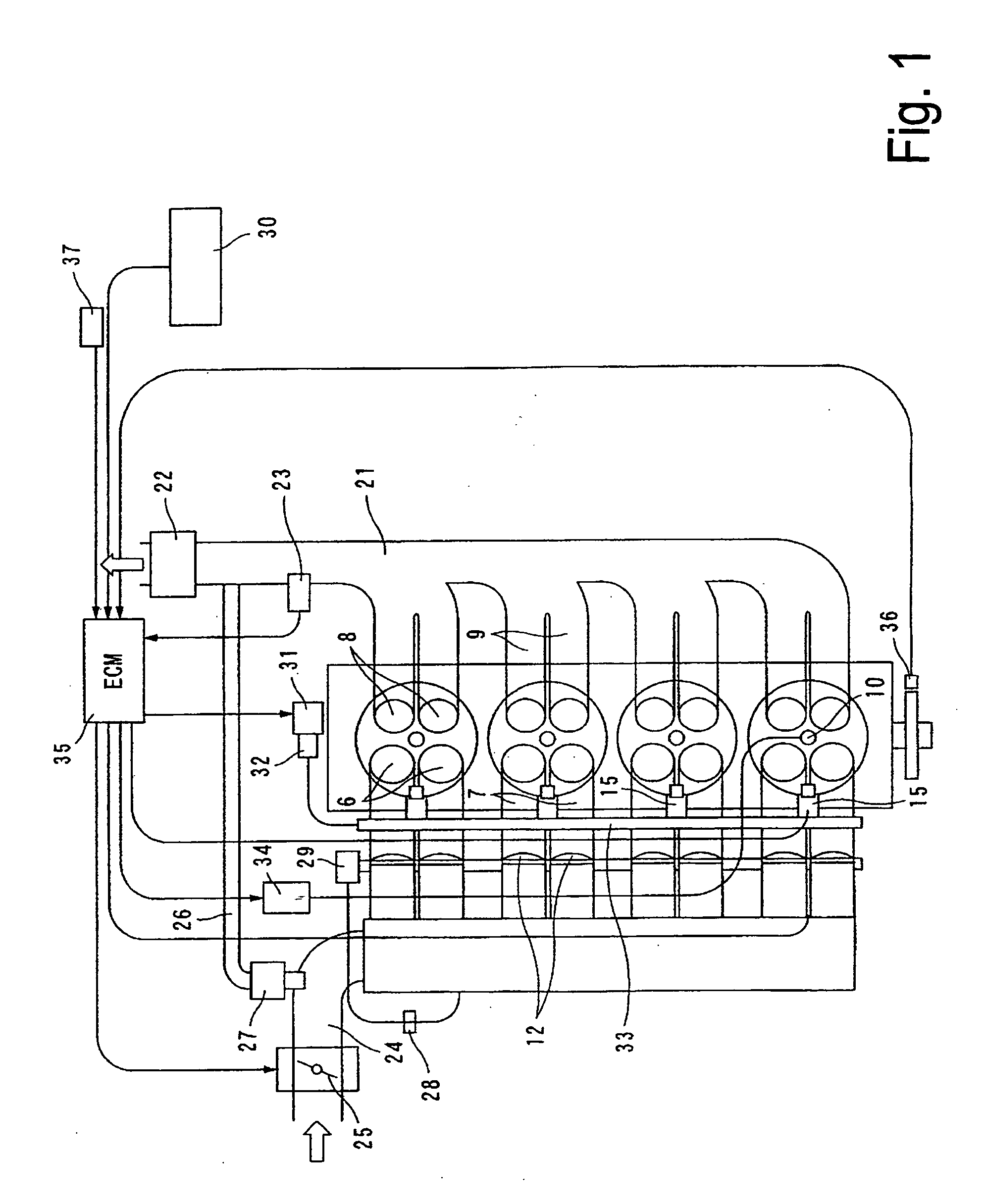

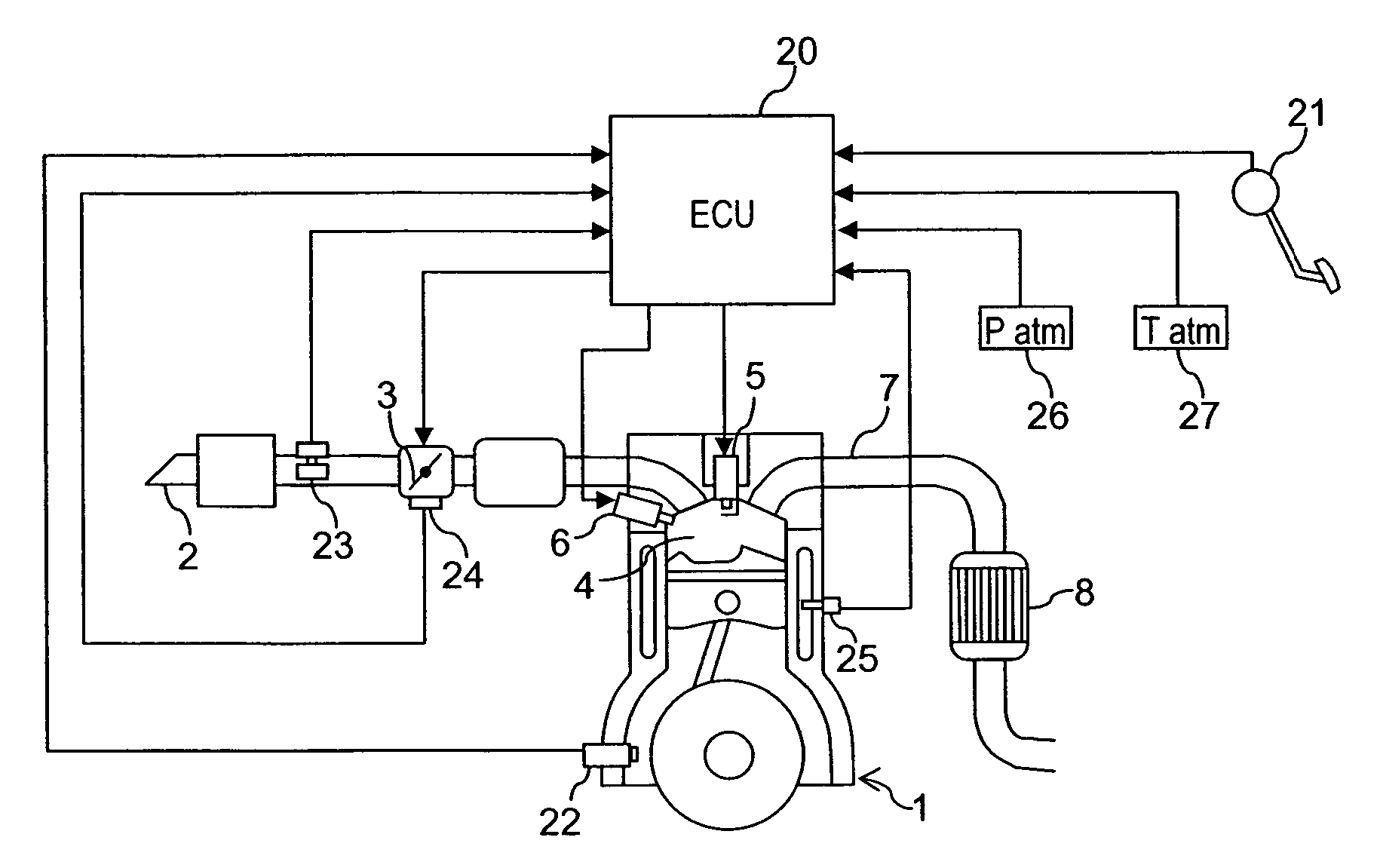

Method of controlling direct gasoline injection type internal combustion engine with turbocharger and direct gasoline injection type internal combustion engine with turbocharger

InactiveUS6880518B2Reduce decreaseReduce exhaustValve arrangementsElectrical controlTop dead centerTurbocharger

A first object of the invention is to reduce an exhaust gas in a lean burn area which is expanded by a supercharging, in a direct gasoline injection type internal combustion engine provided with a turbocharger. A second object of the invention is to prevent a knocking and a misfire at a time of self ignition combustion. The invention is used for the direct gasoline injection type internal combustion engine provided with the turbocharger. In order to achieve the first object, a combustion mode is switched from a stratified combustion mode to a self ignition combustion mode at a time when a suction pressure of the engine is equal to or more than an atmospheric pressure. Further, in order to achieve the second object, an ignition timing is set to a range between a top dead center and 10 degrees after the top dead center (0 to 10 (ATDC)) at a time of operating an engine in accordance with a self ignition combustion mode.

Owner:HITACHI LTD

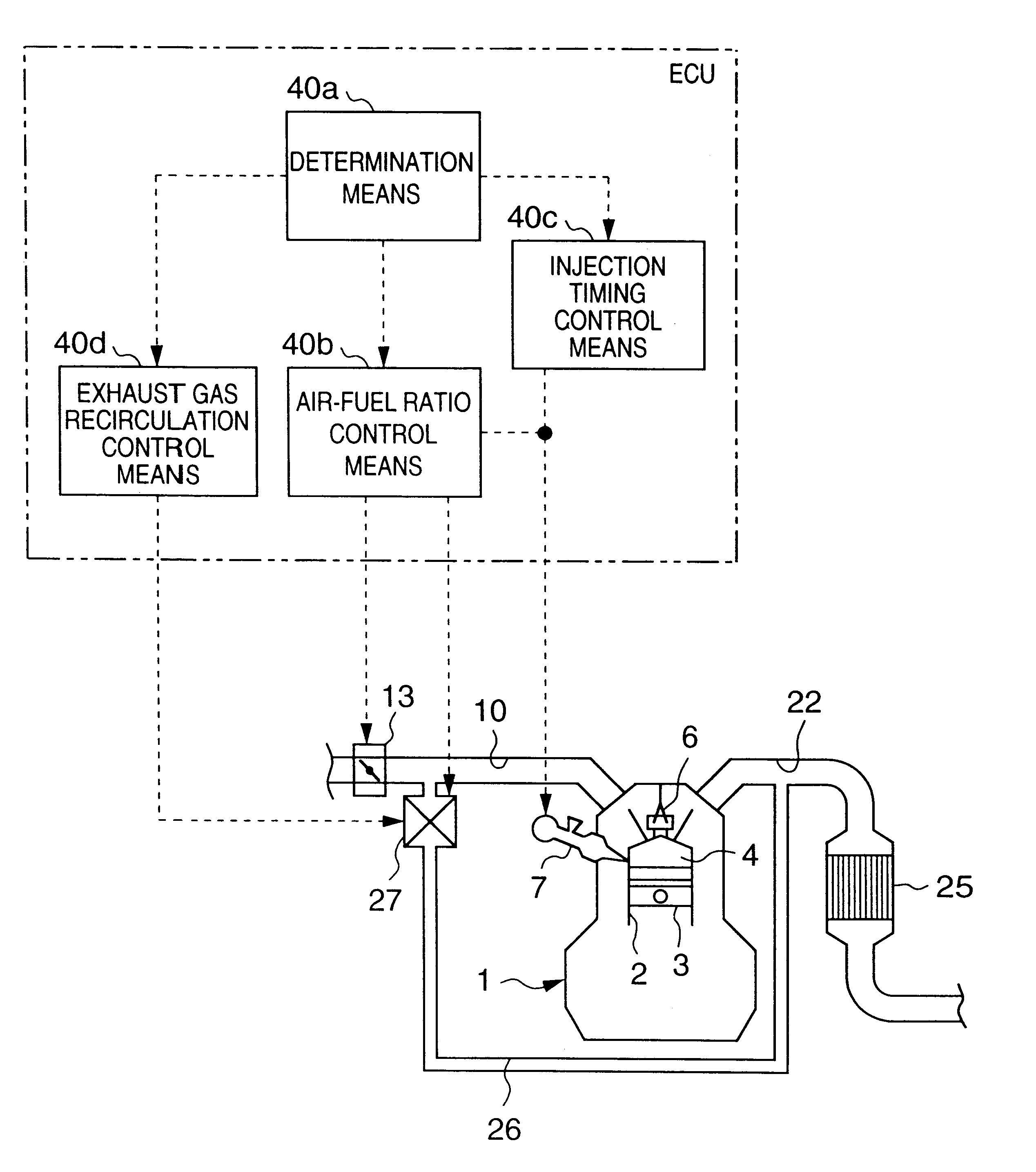

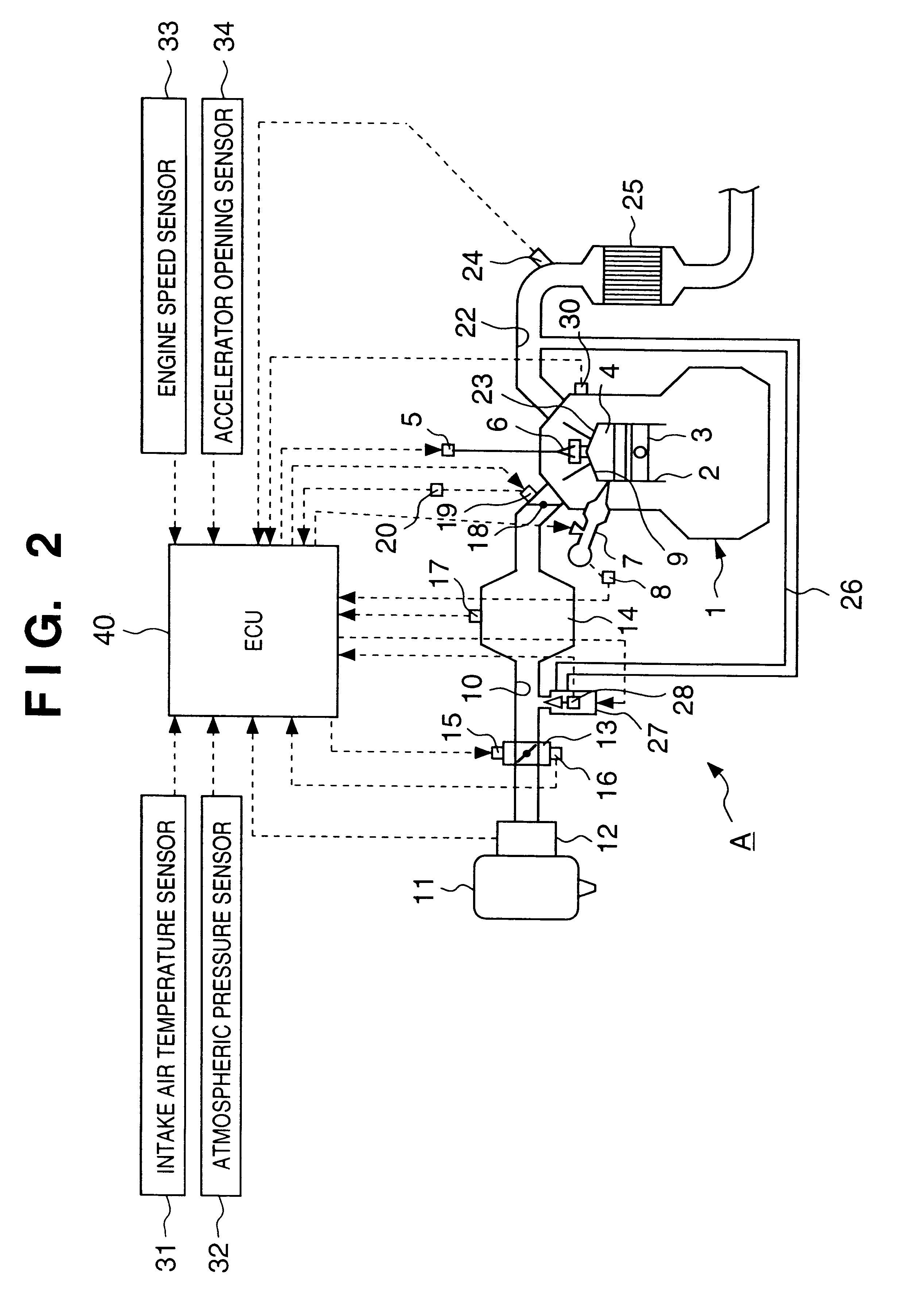

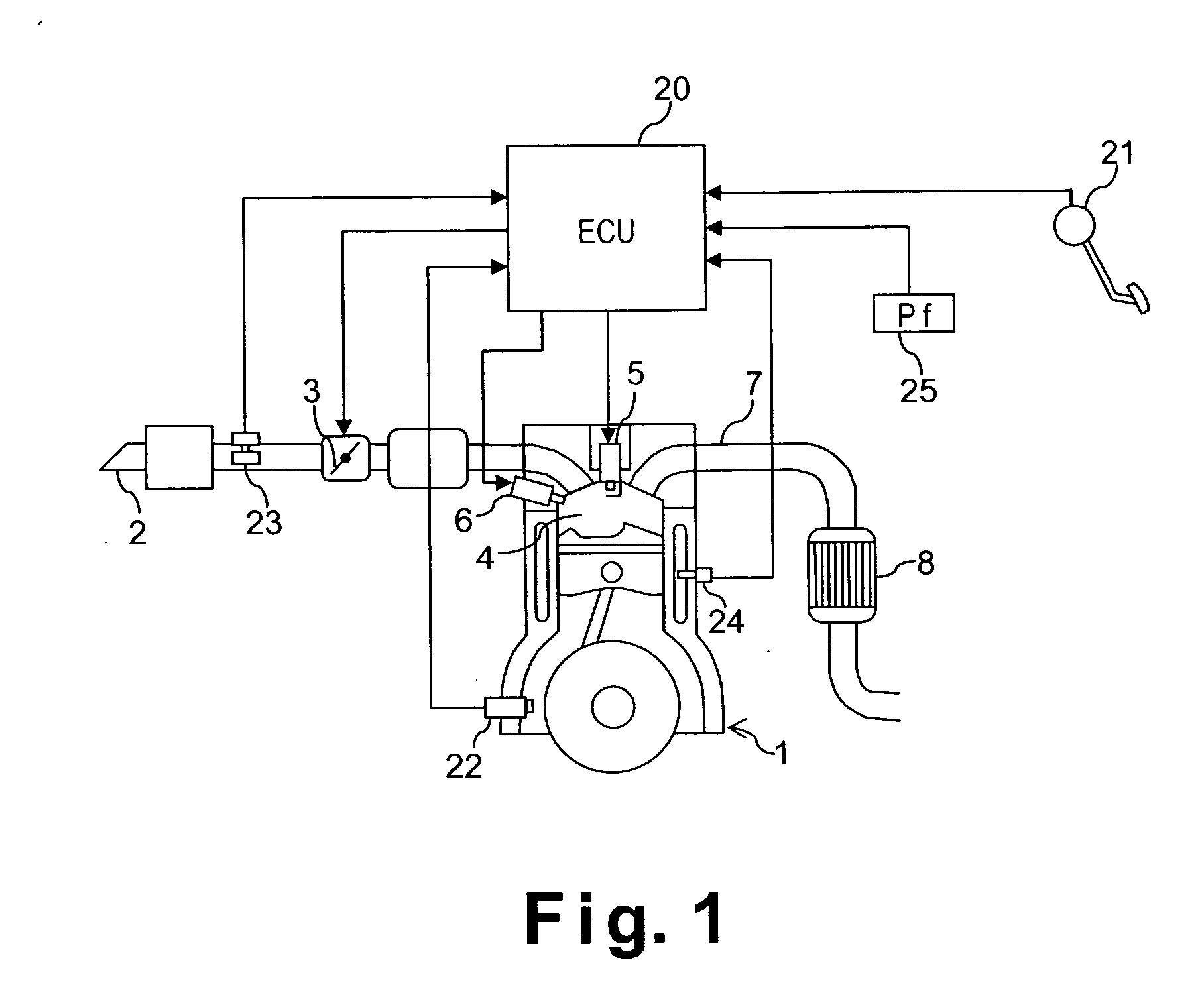

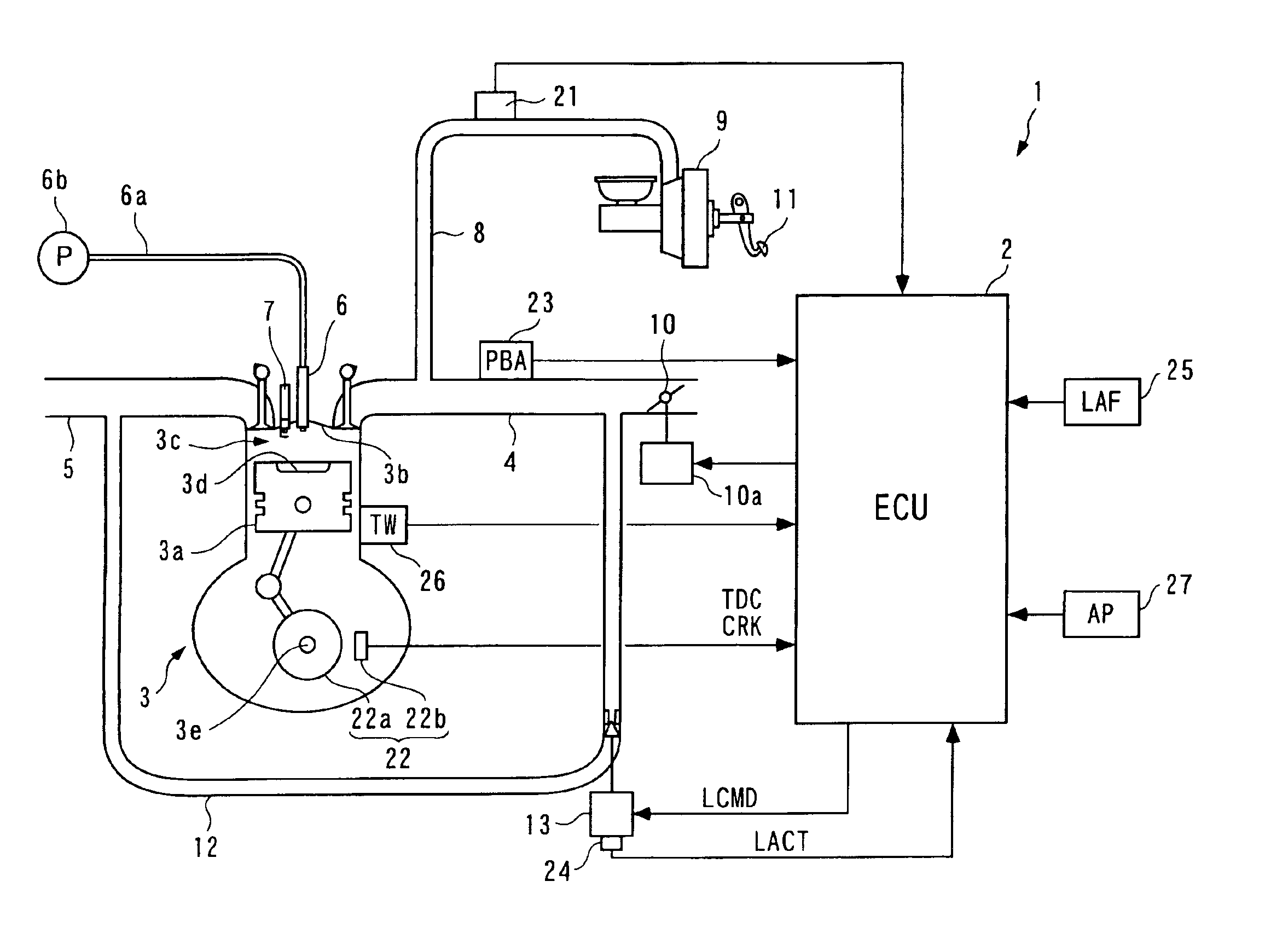

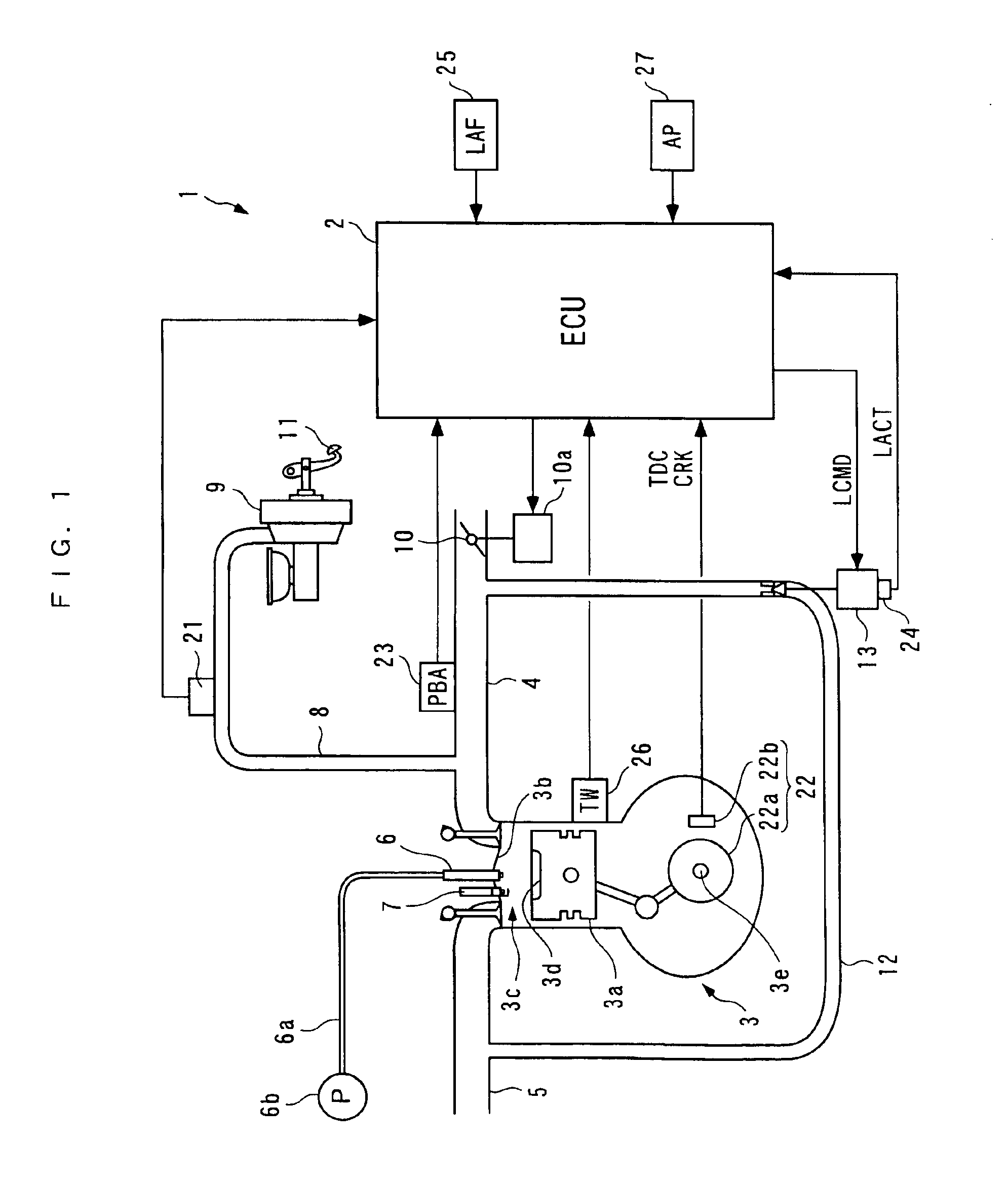

Control apparatus for spark ignition type direct injection engine

Upon refreshing a catalyst (25) in steps SA2 to SA6, the air-fuel ratio of each combustion chamber (4) of an engine (1) is dither-controlled to periodically vary to the rich and lean sides of a target value (A / F=15 to 16) in steps SA16 and SA17. In step SA15, an injector (7) divisionally injects fuel in two injections within the period from the intake stroke to the compression stroke of each cylinder, thus accomplishing weakly stratified combustion. In step SA18, the opening of an EGR valve (27) is controlled to recirculate a large amount of exhaust gas to an intake path (10) so as to achieve around 40% EGR ratio.

Owner:MAZDA MOTOR CORP

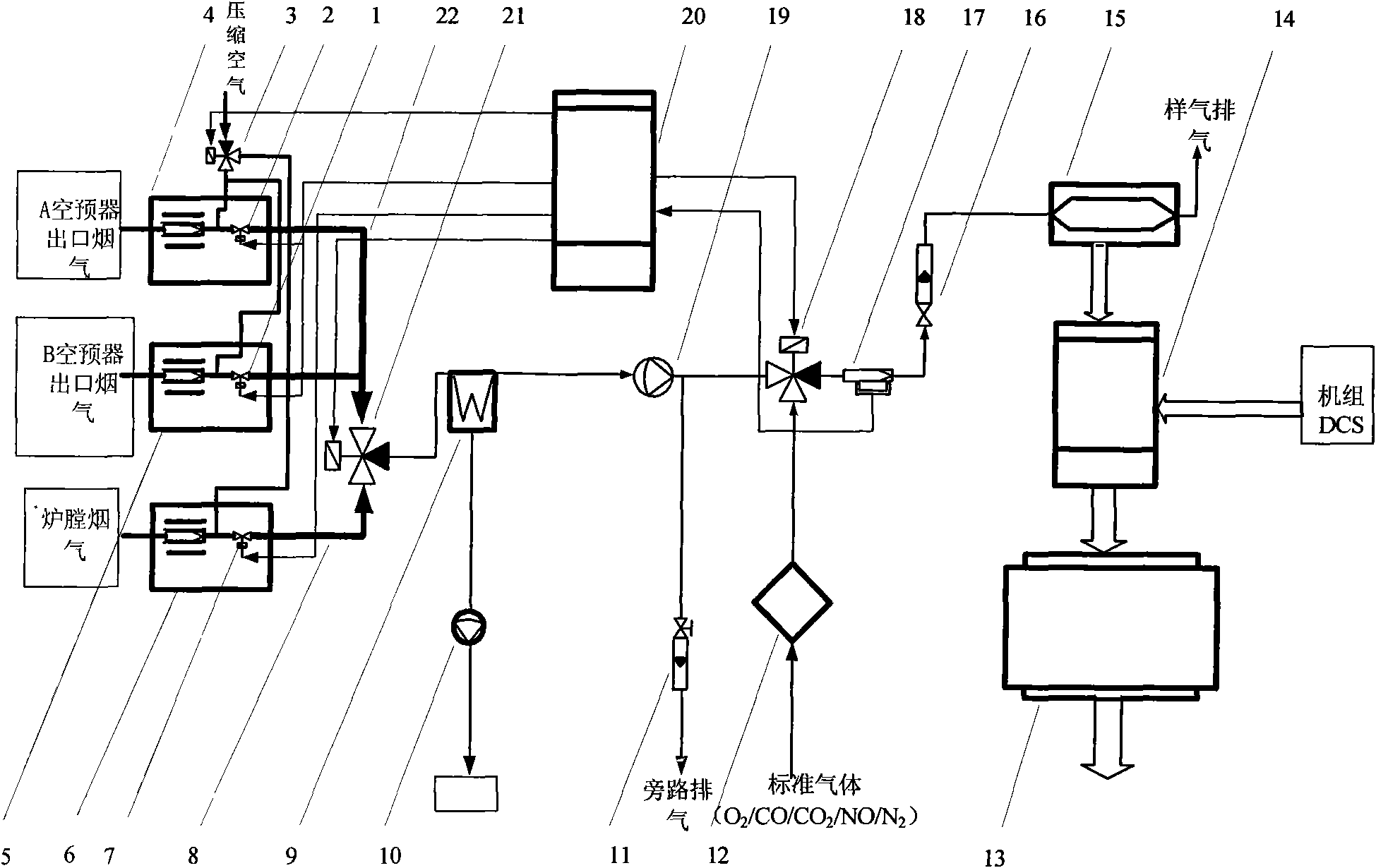

Stratified combustion on-line optimization control system of boiler coal dust and optimization method thereof

ActiveCN101619859AGood running safetyReduce emission concentrationWithdrawing sample devicesIndirect carbon-dioxide mitigationAir preheaterCoal dust

The invention discloses a stratified combustion on-line optimization control system of boiler coal dust, comprising a gas sampling system and a data processing system, wherein the gas sampling system comprises a fume sampling probe and a fume component continuous monitoring system. The invention is characterized in that the fume sampling probe comprises a first fume sampling probe arranged at an opening of an A air preheater, a second fume sampling probe arranged at an opening of a B air preheater and a third fume sampling probe arranged in a boiler chamber; the data processing system comprises an industrial computer connected with the fume component continuous monitoring system and provided with a stratified combustion on-line optimization computation module; and DCS data of the industrial computer and a generator set are connected by a data collector. The invention utilizes a support vector machine theory by the method and the method to establish an on-line optimization model to carry out automatic training and optimization so as to obtain combustion optimization condition parameters to guide operation, thereby keeping high operation safety of the boiler, improving operation economical efficiency and reducing the emission concentration and totals of pollutants.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

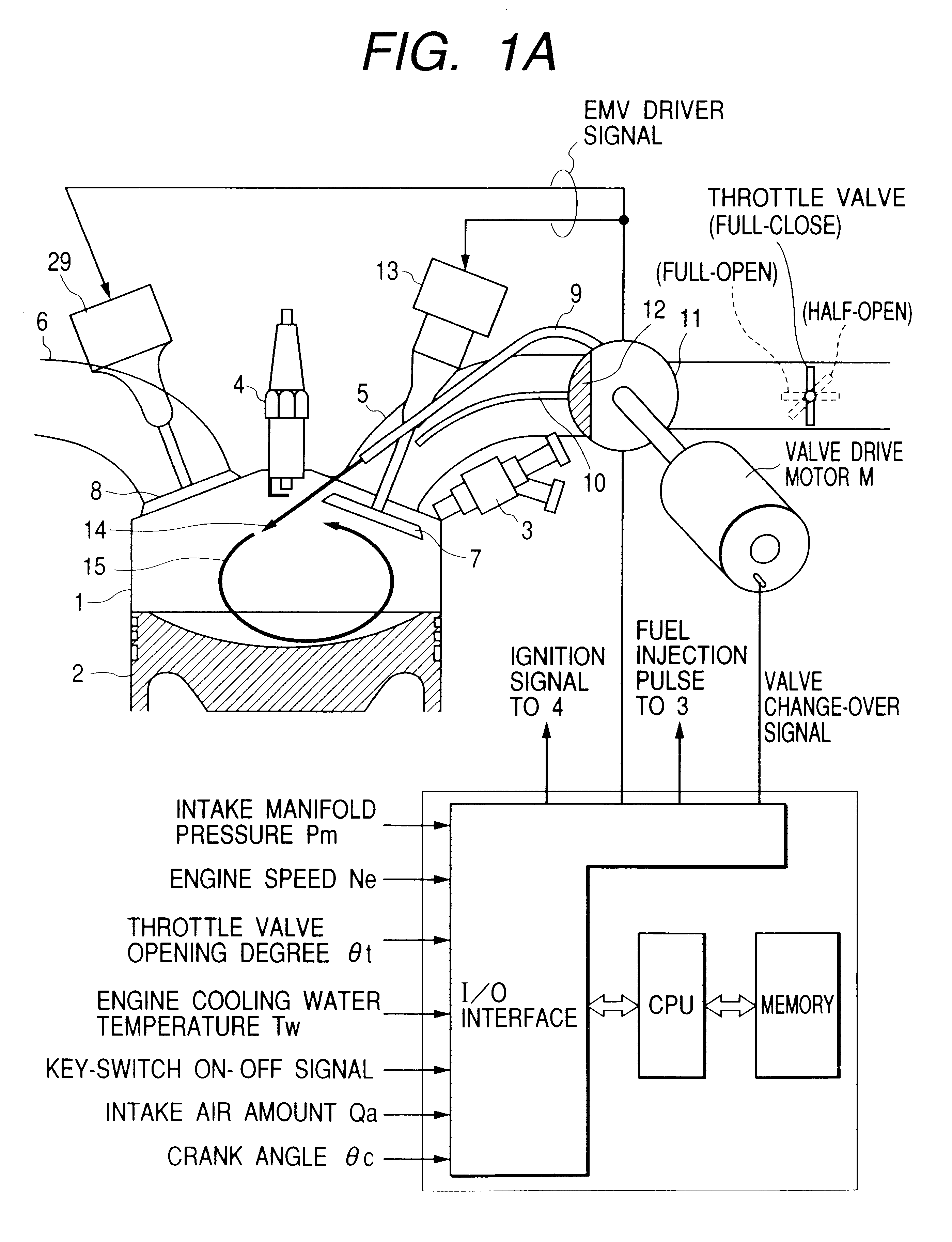

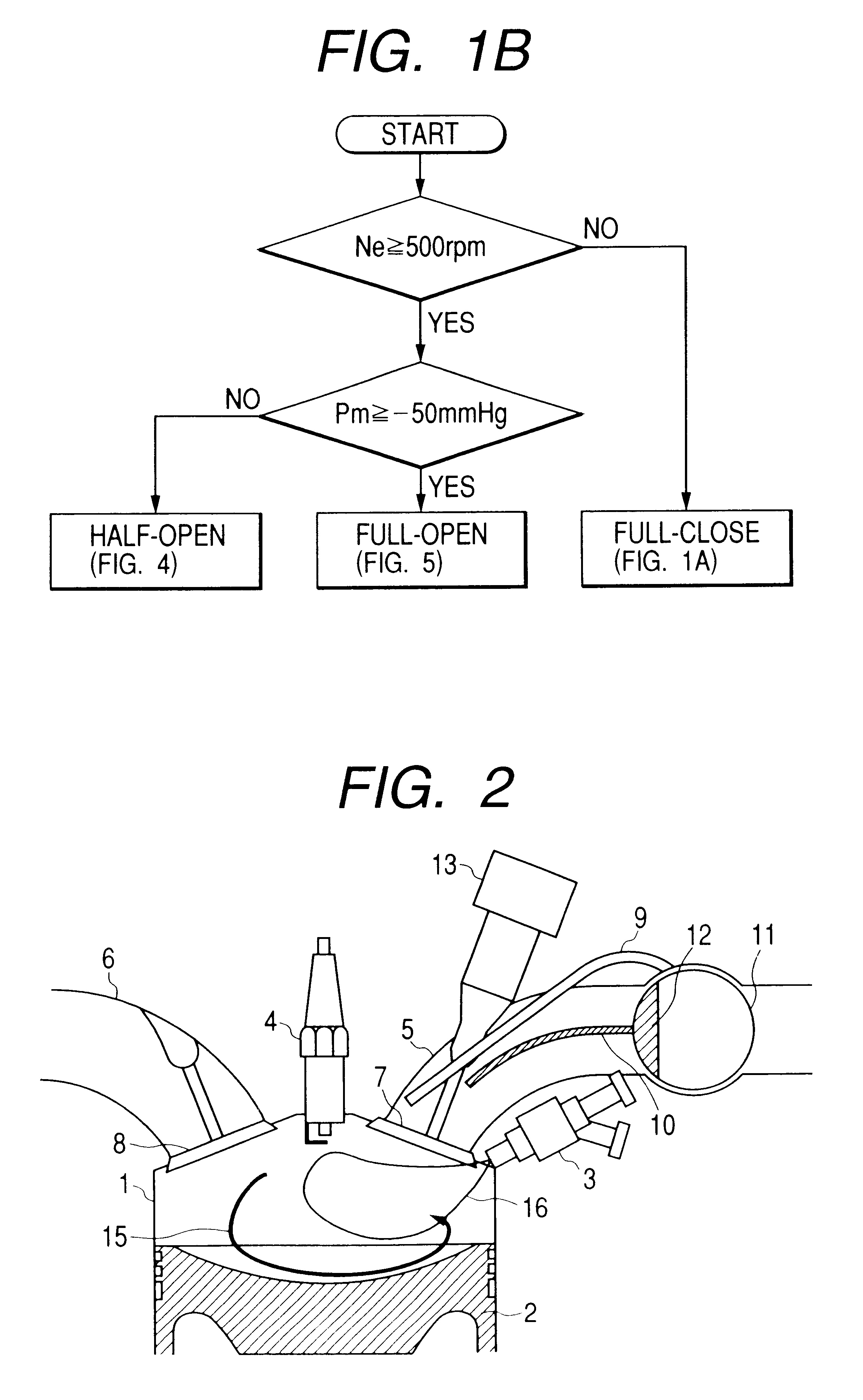

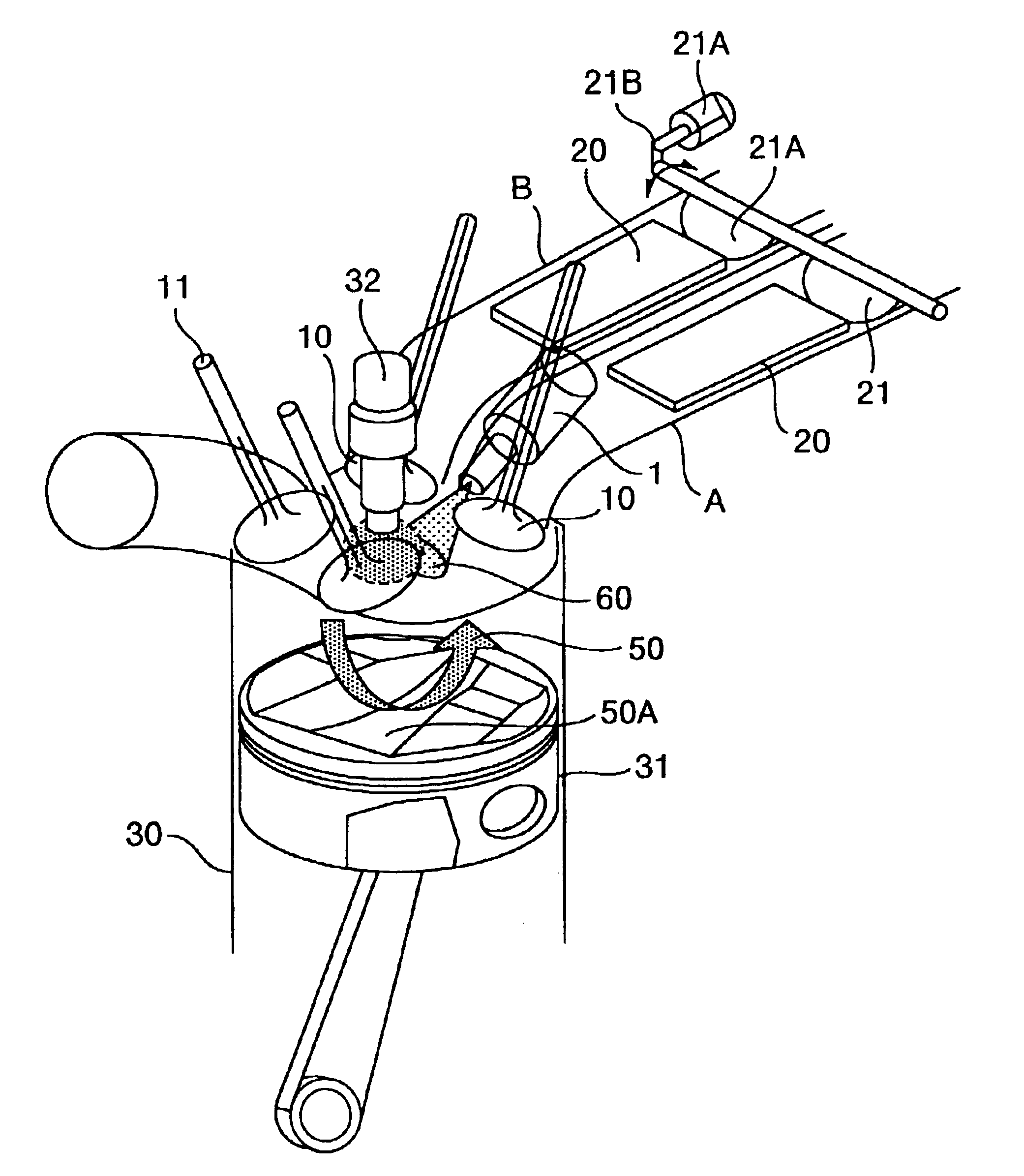

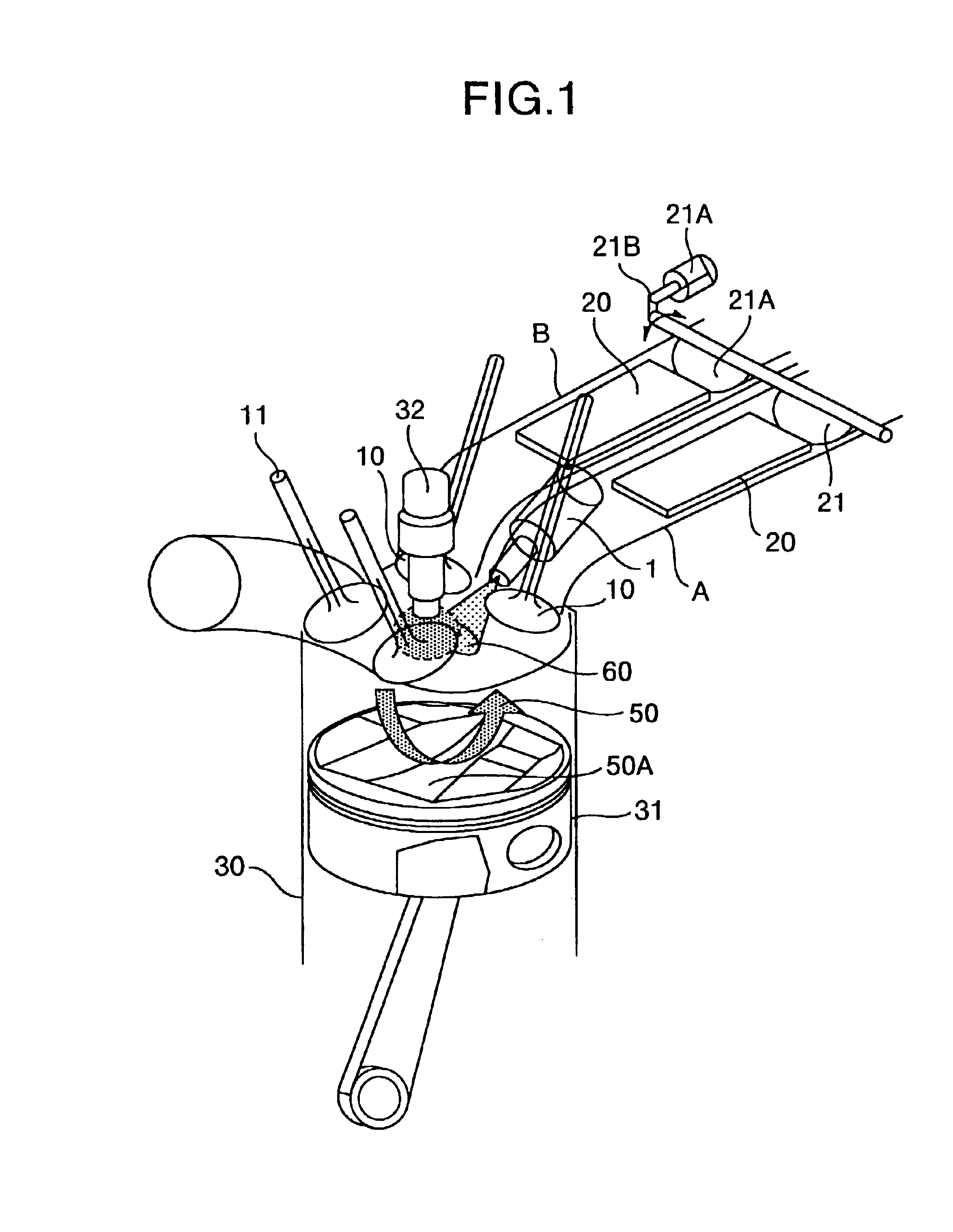

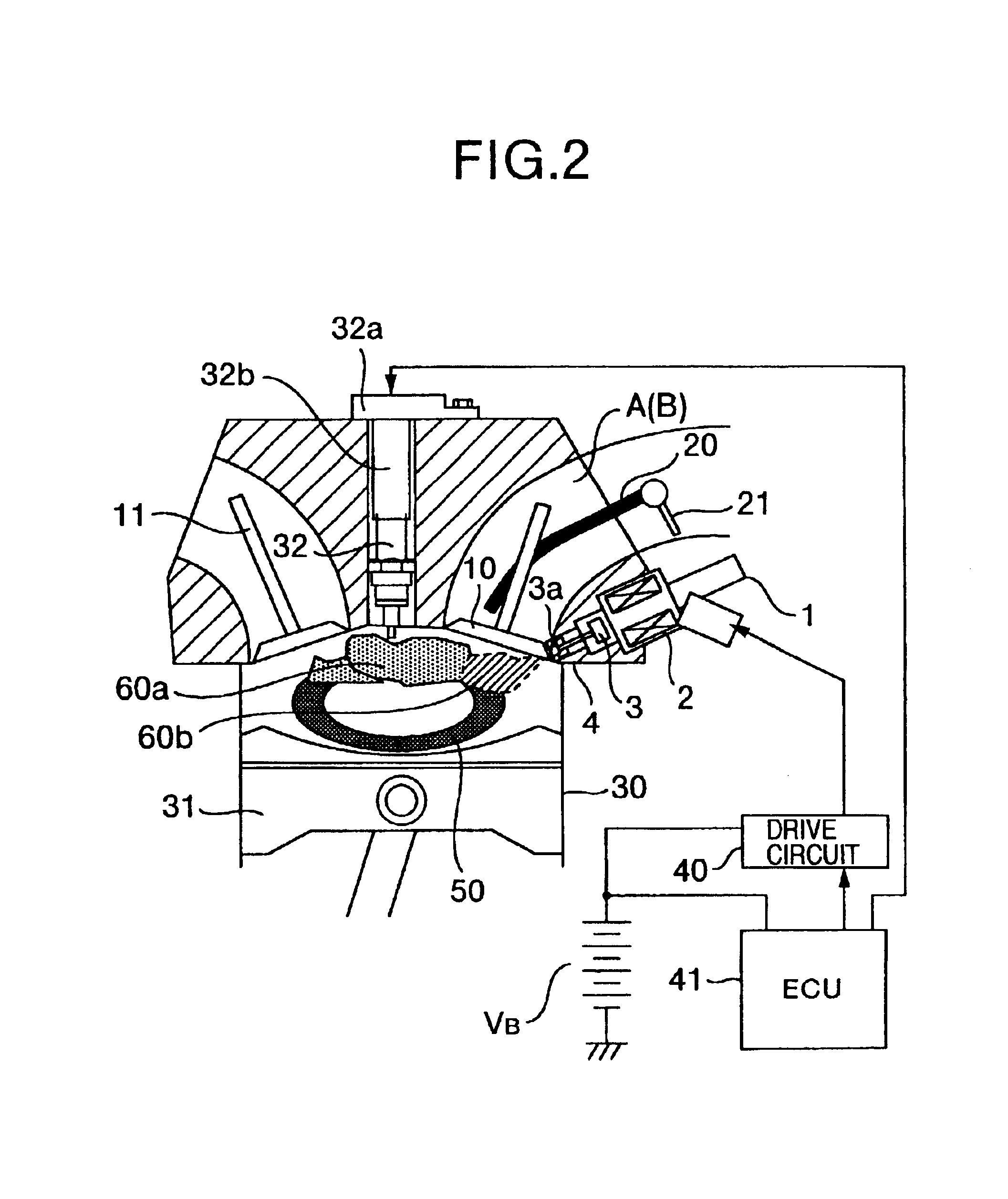

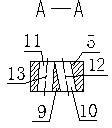

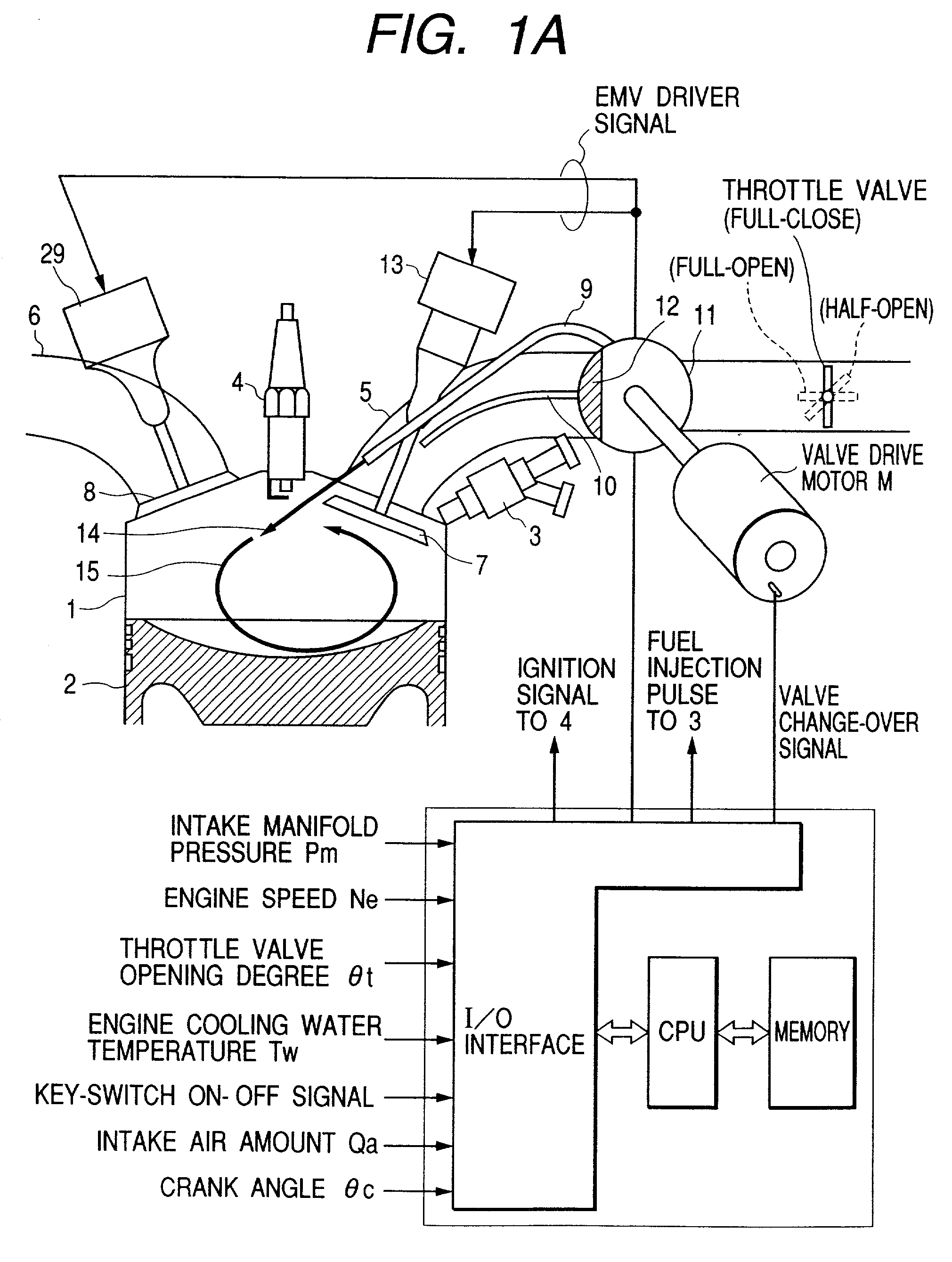

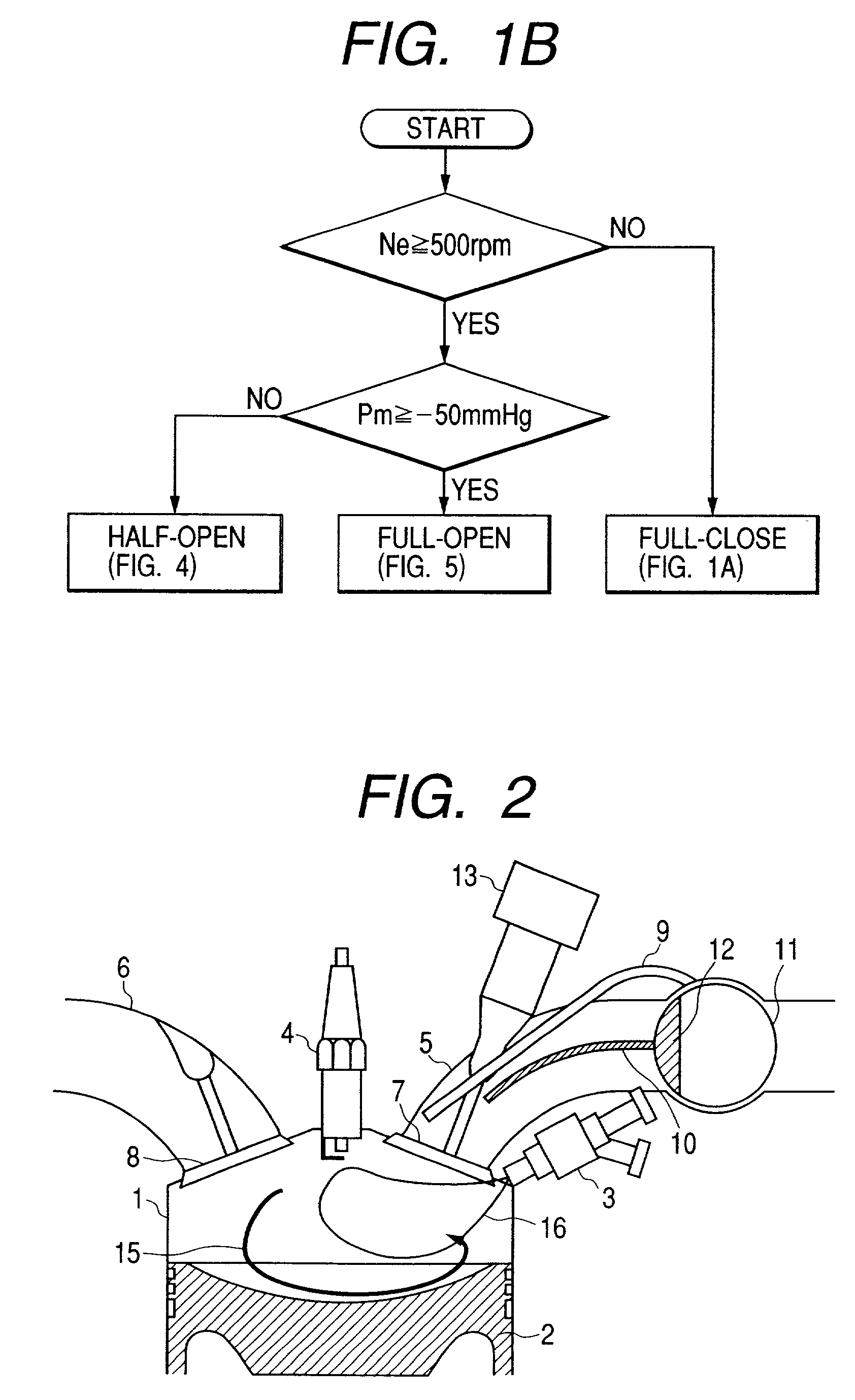

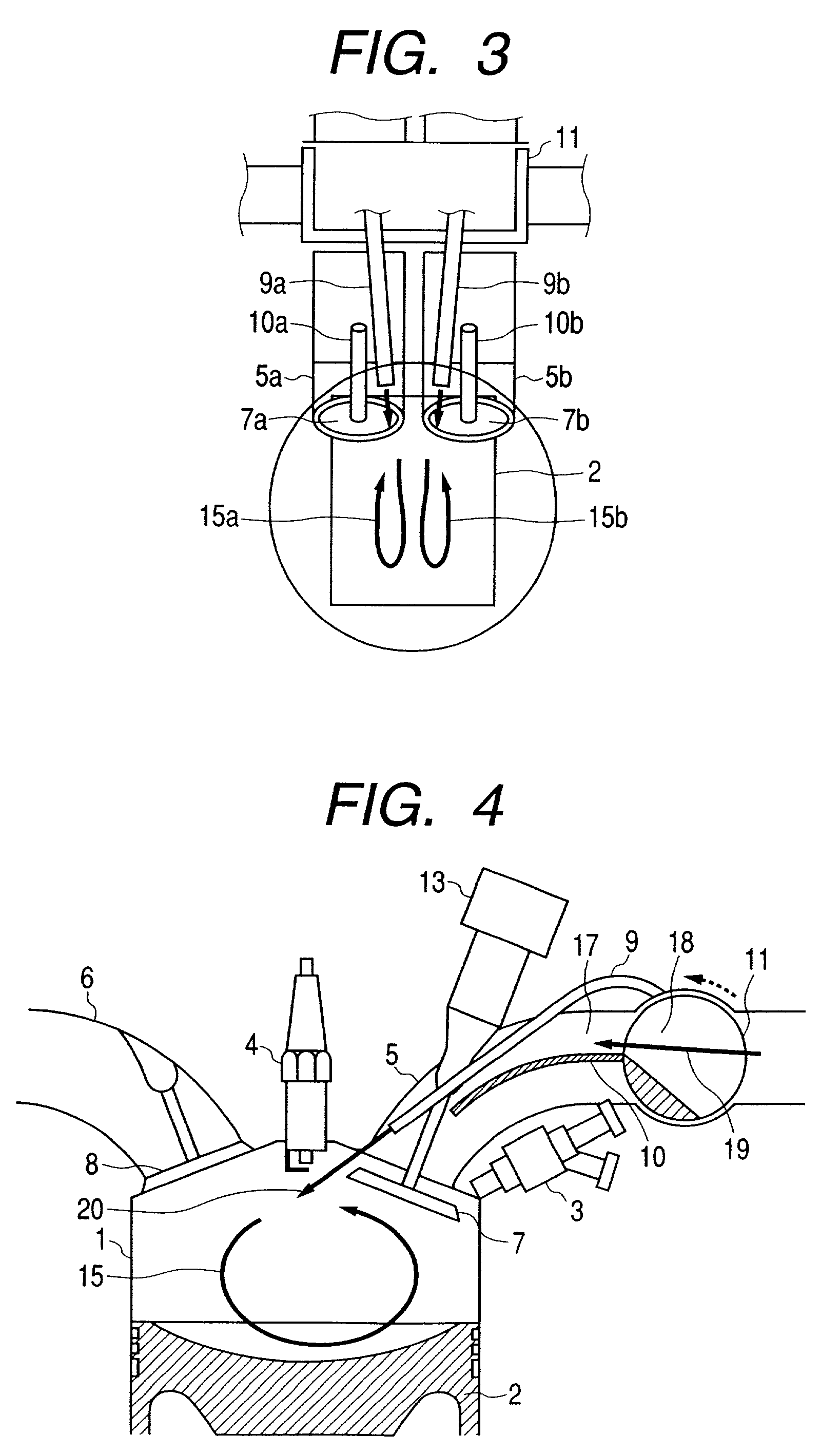

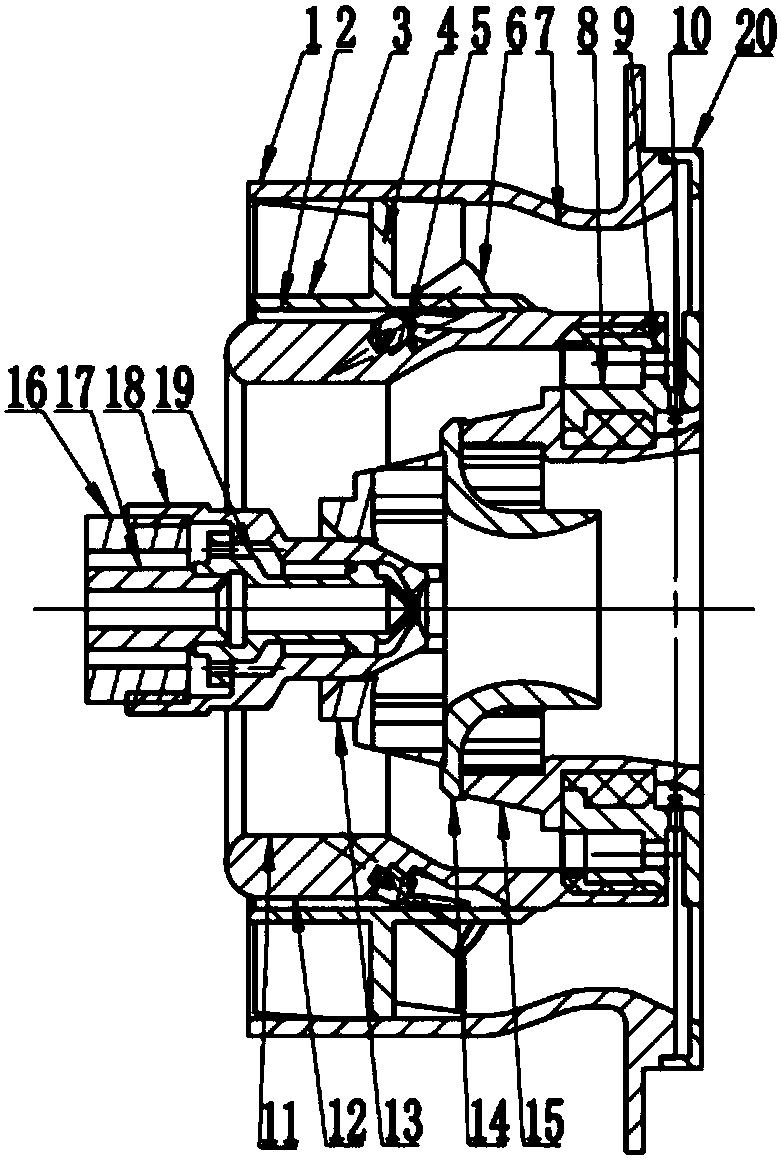

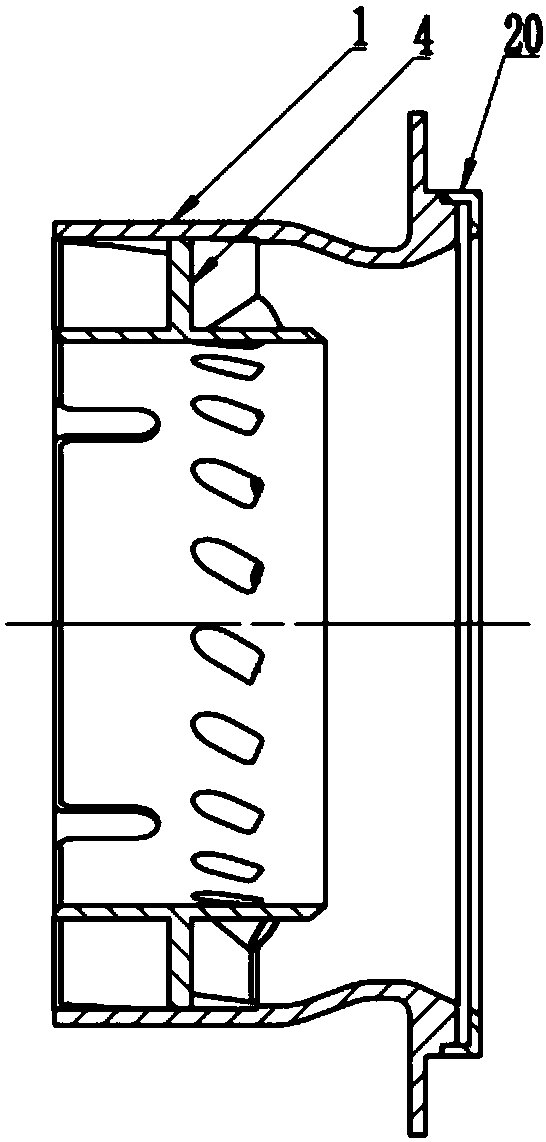

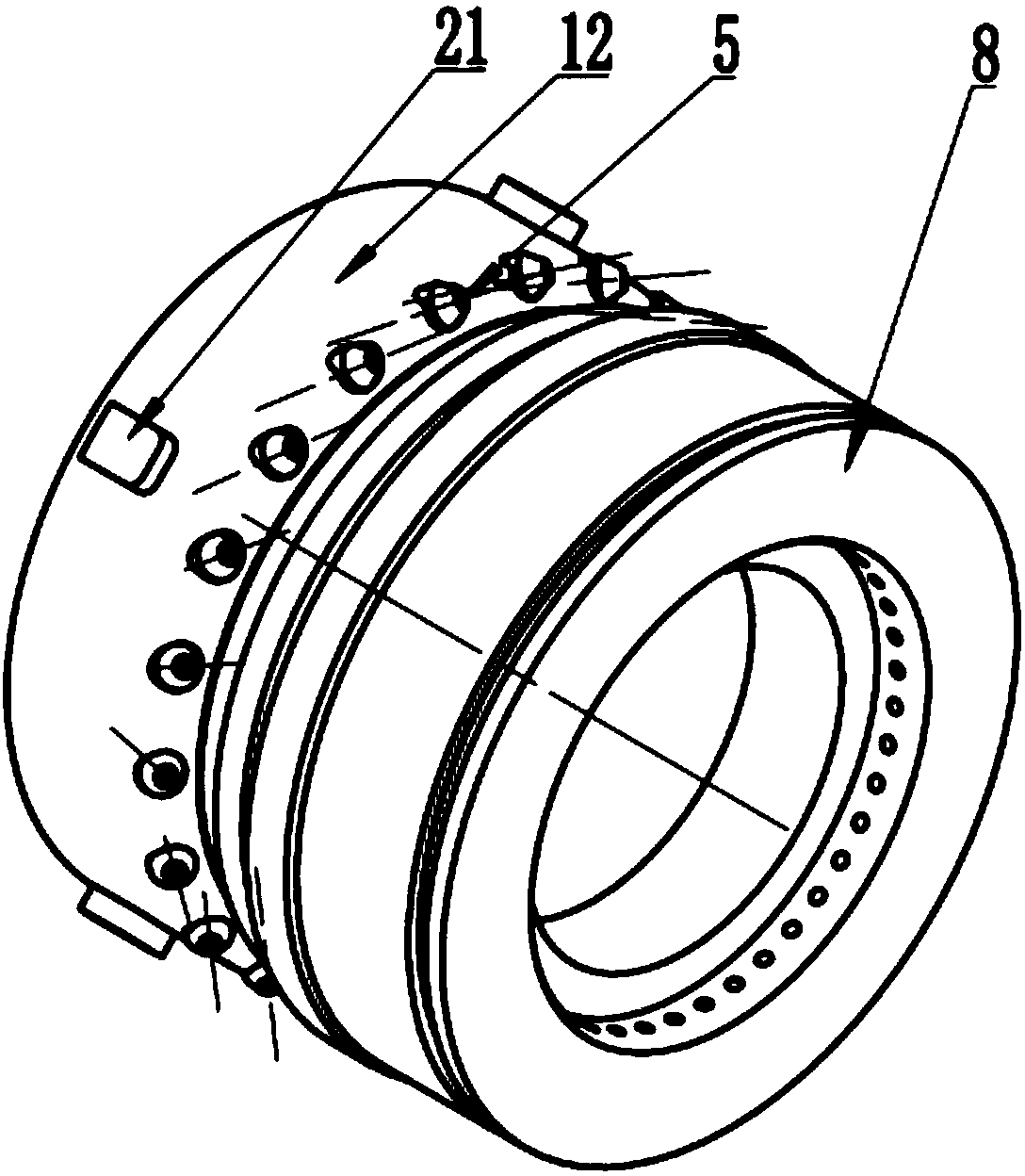

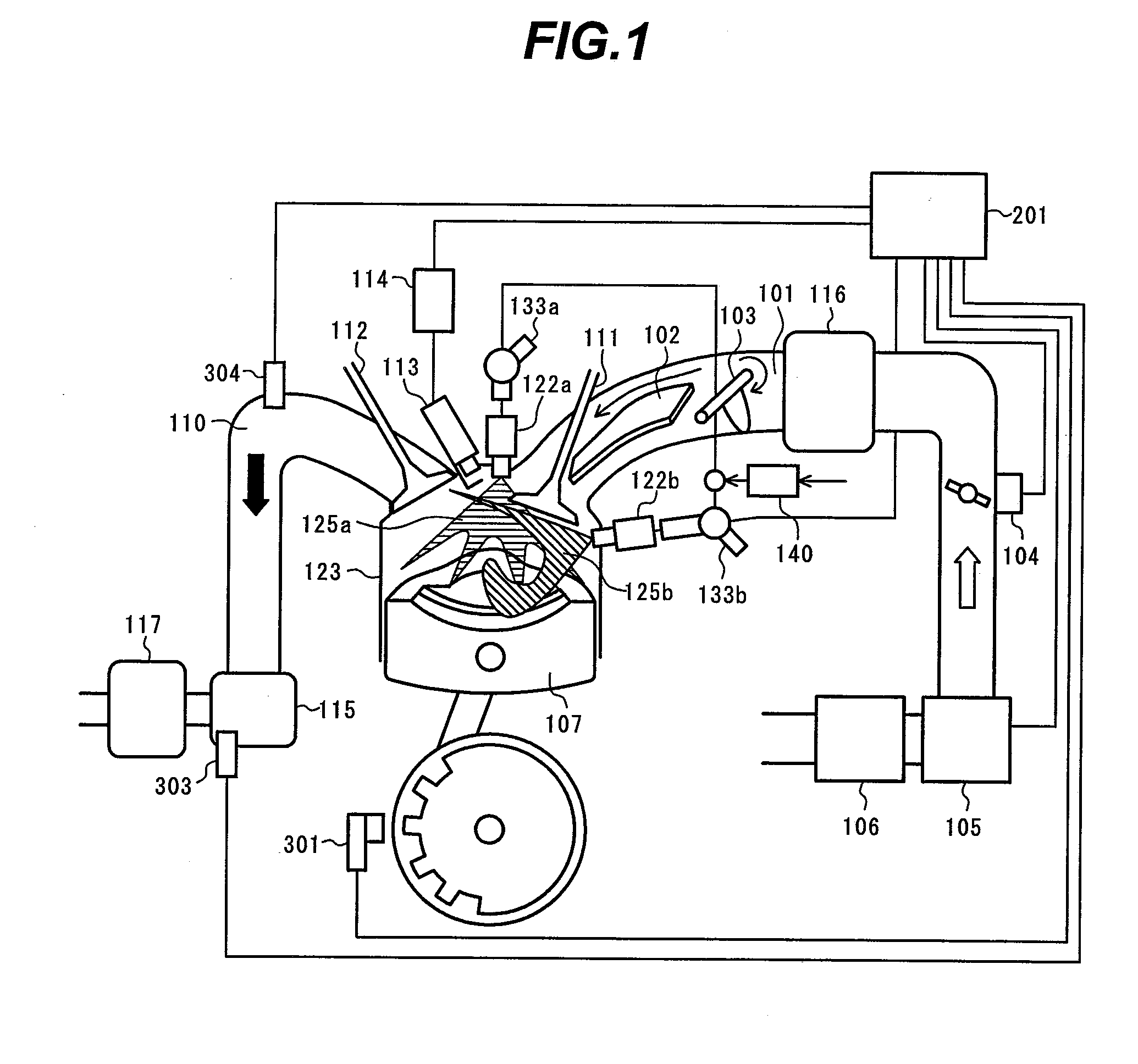

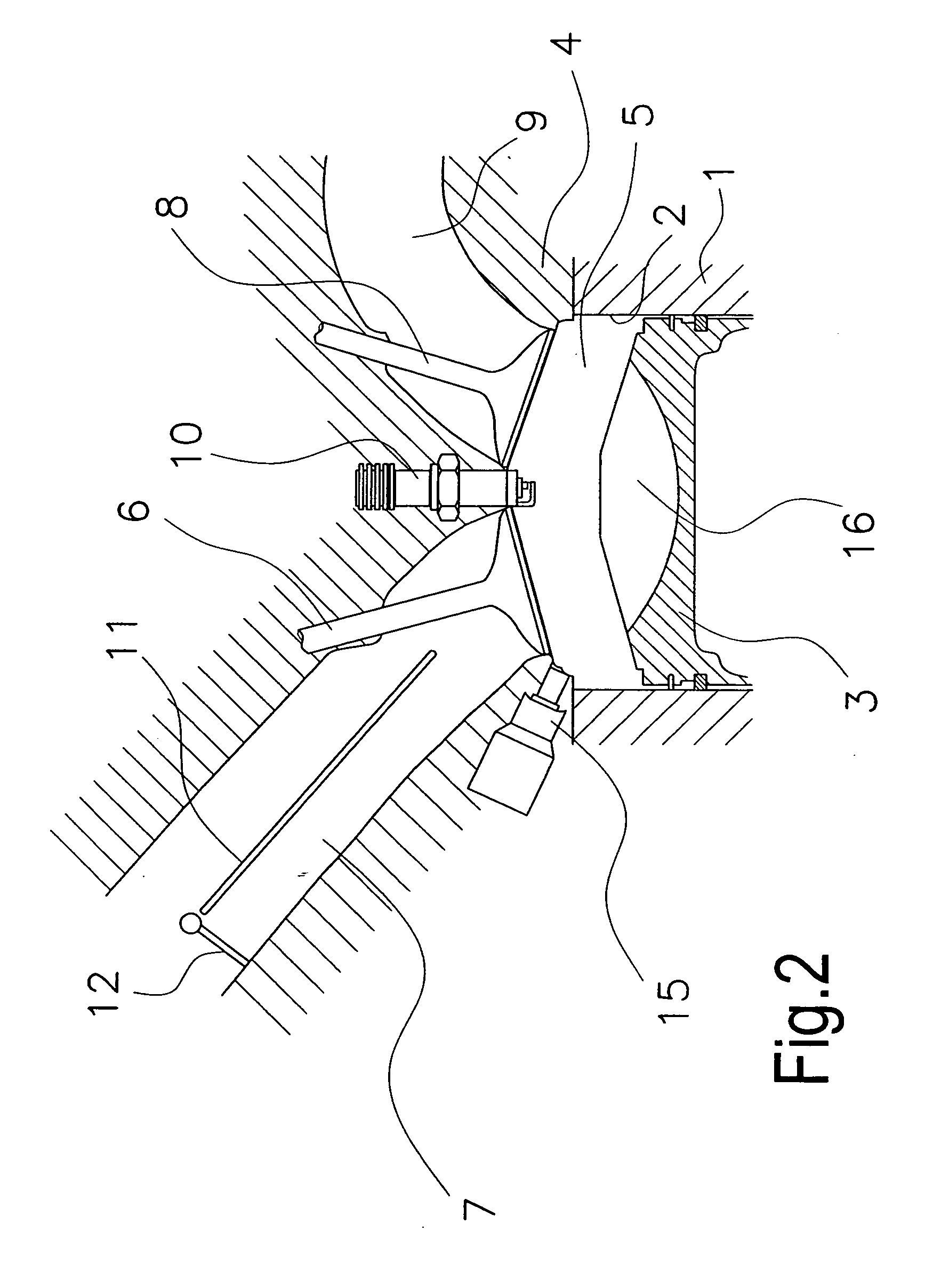

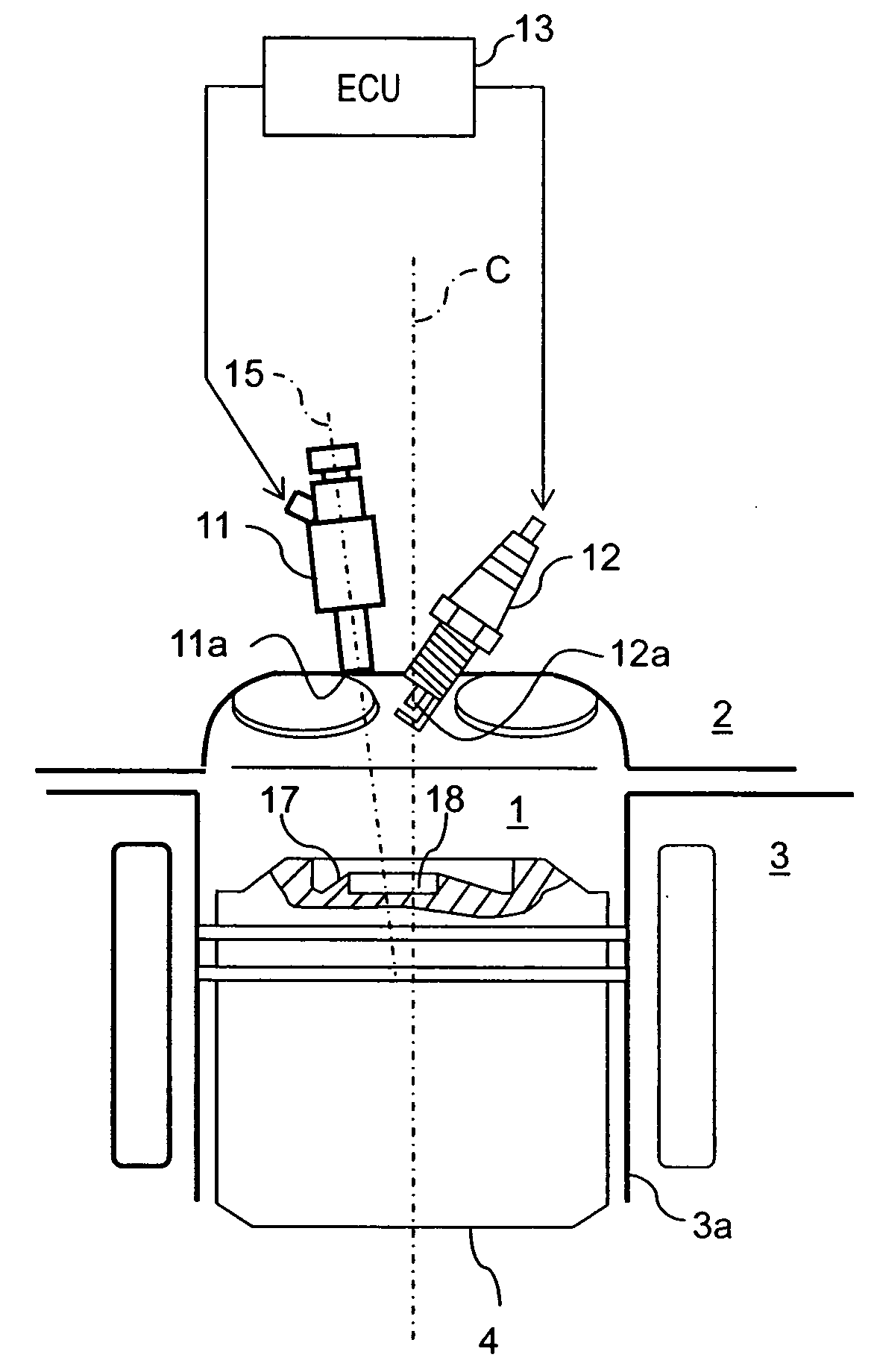

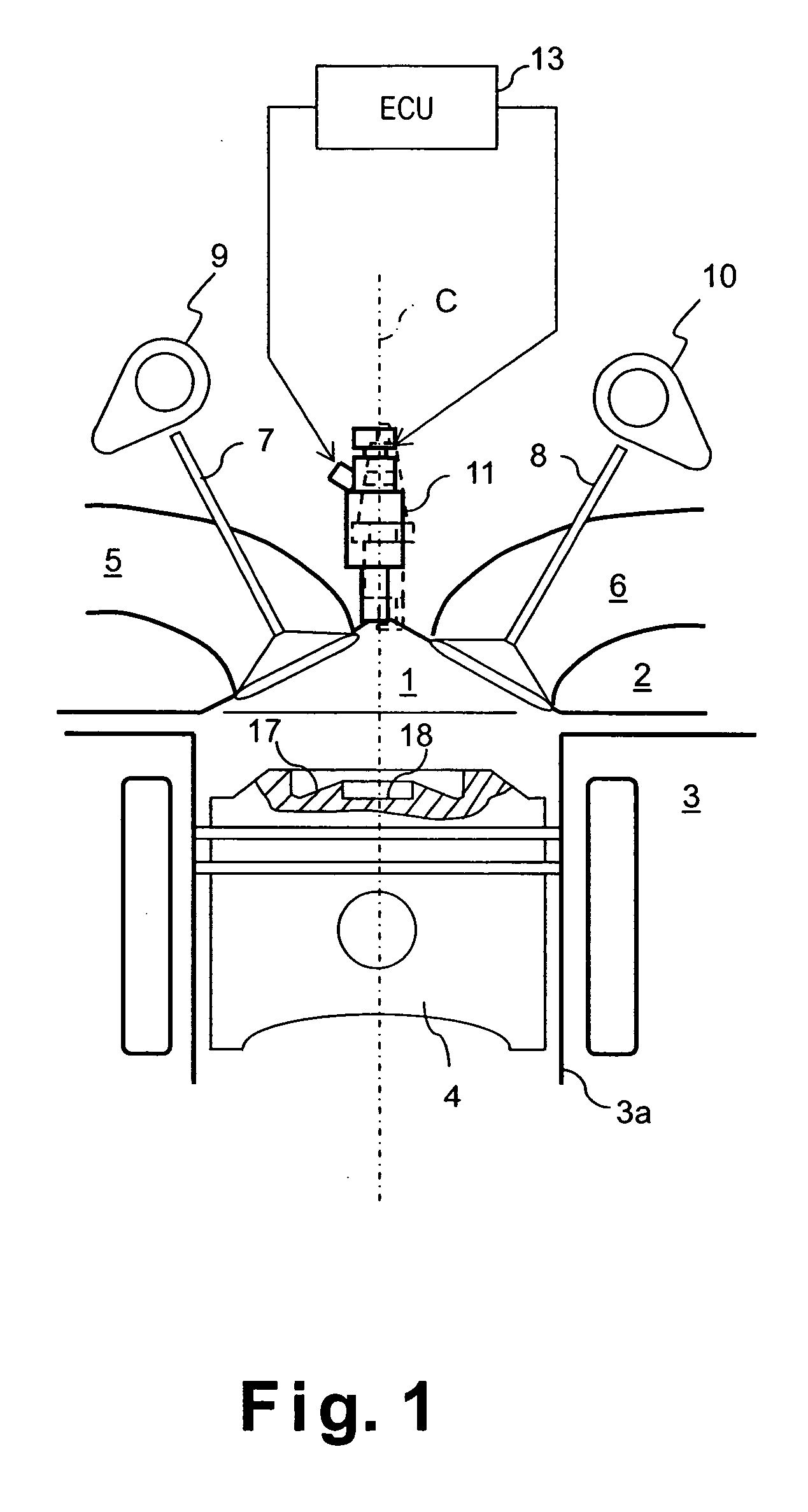

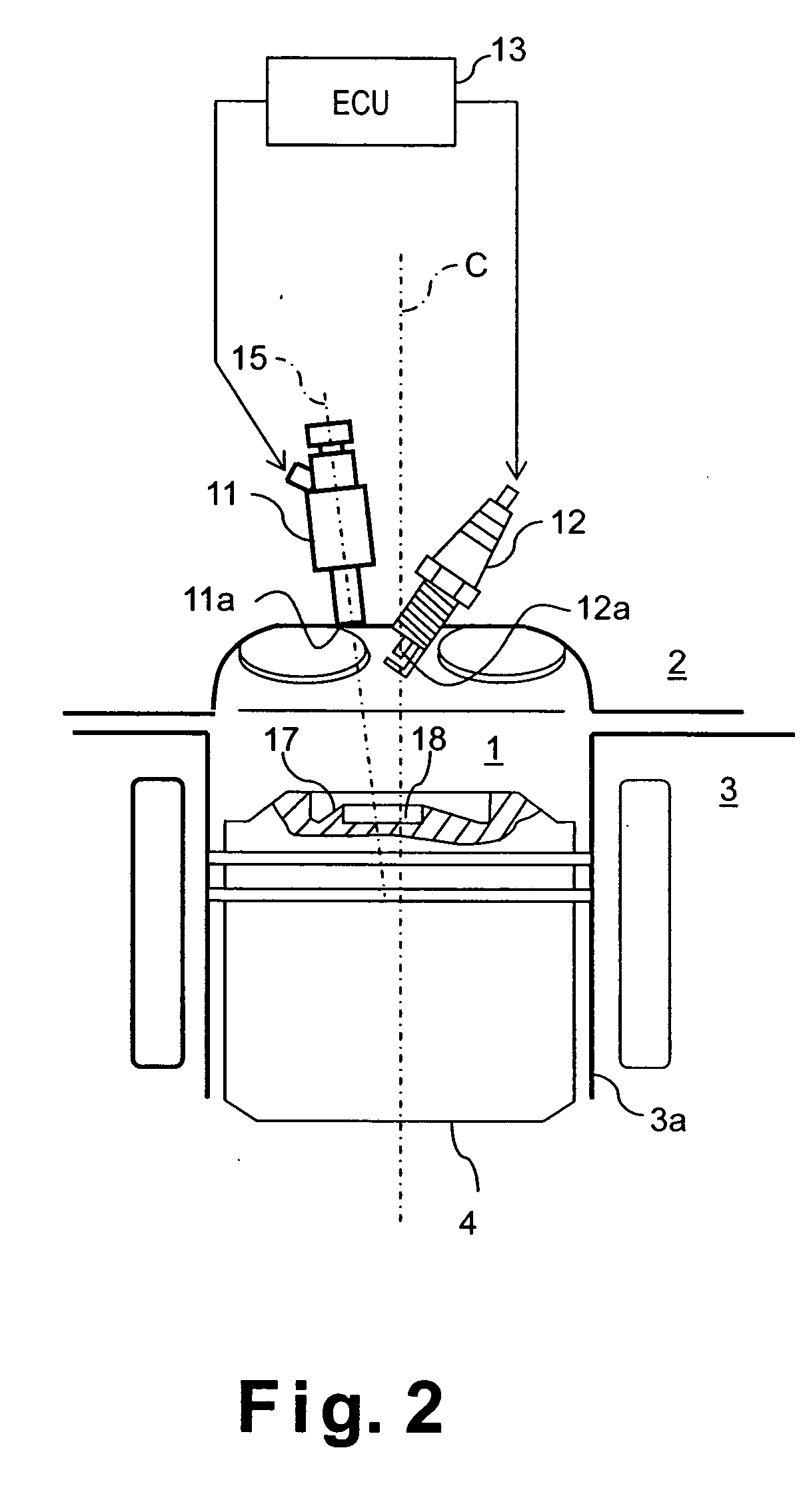

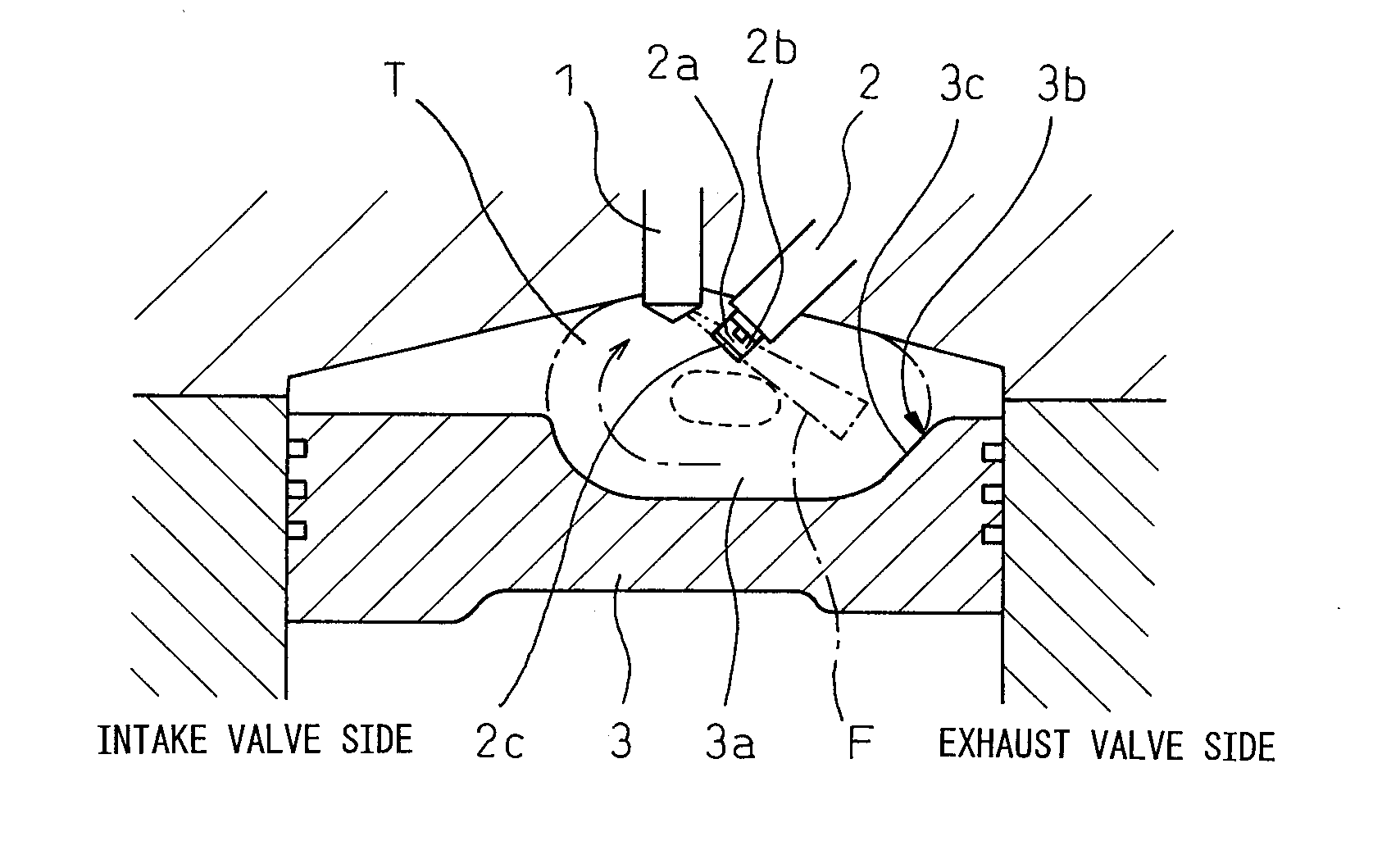

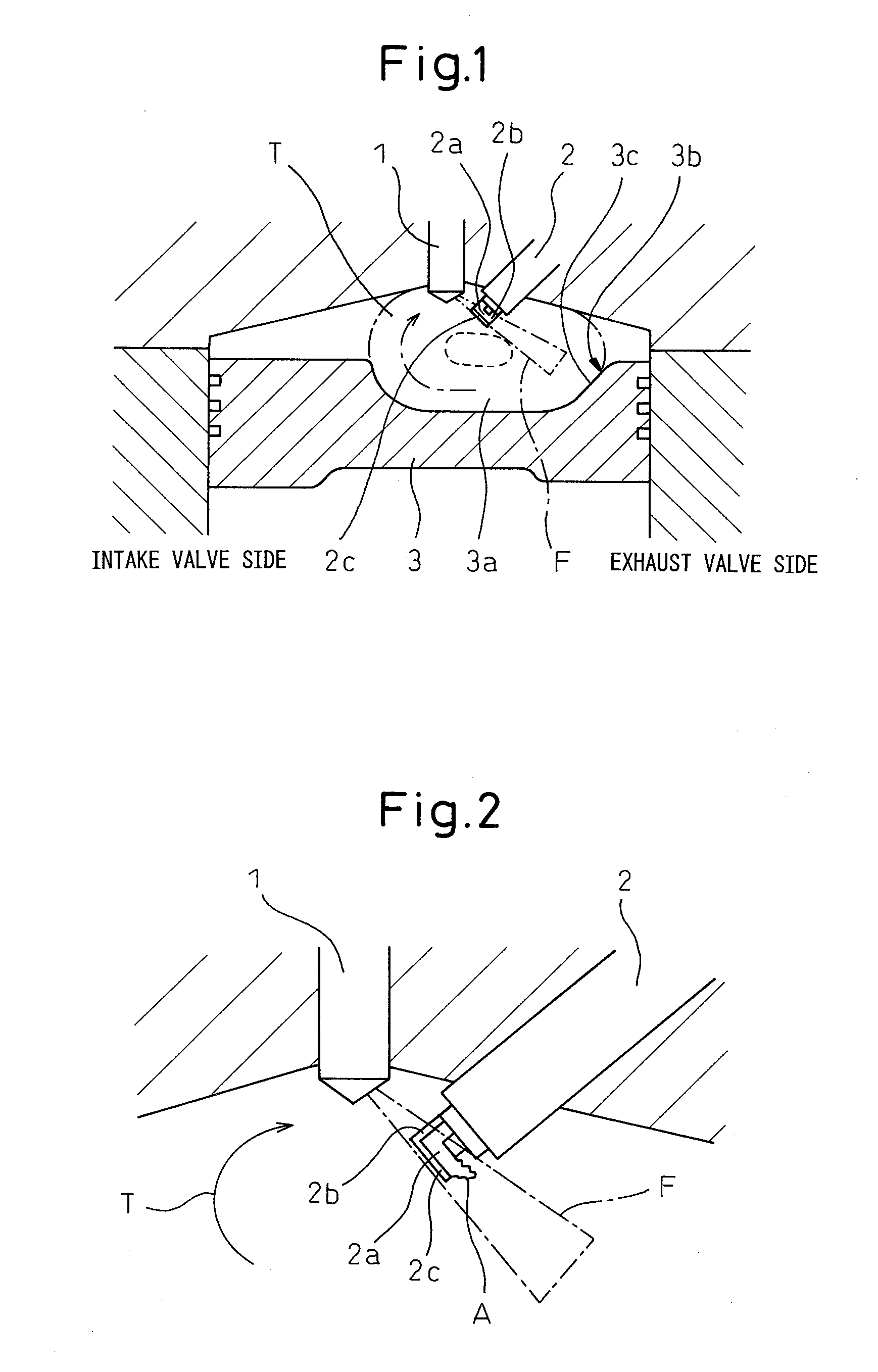

Direct injection type internal combustion engine

InactiveUS6634333B2Easy dischargeElectrical controlInternal combustion piston enginesStart timeCombustion

In a starting time in which an air motion is little, a means for heightening the motion is added, from the starting time a stratification combustion operation is enable to carry out, and a discharge of an unburned fuel is minimized. From the starting time of an engine (from the firstly combustion cylinder) it is possible to carry out a stable stratification combustion. In accordance with the stratification combustion in the exhaust air a large quantity of the surplus oxygen remains. In the engine in the exhaust stroke twice (two time) fuel injection is carried out and the after burn phenomenon is caused in the exhaust port and then the exhaust gas temperature can be raised.

Owner:HITACHI LTD

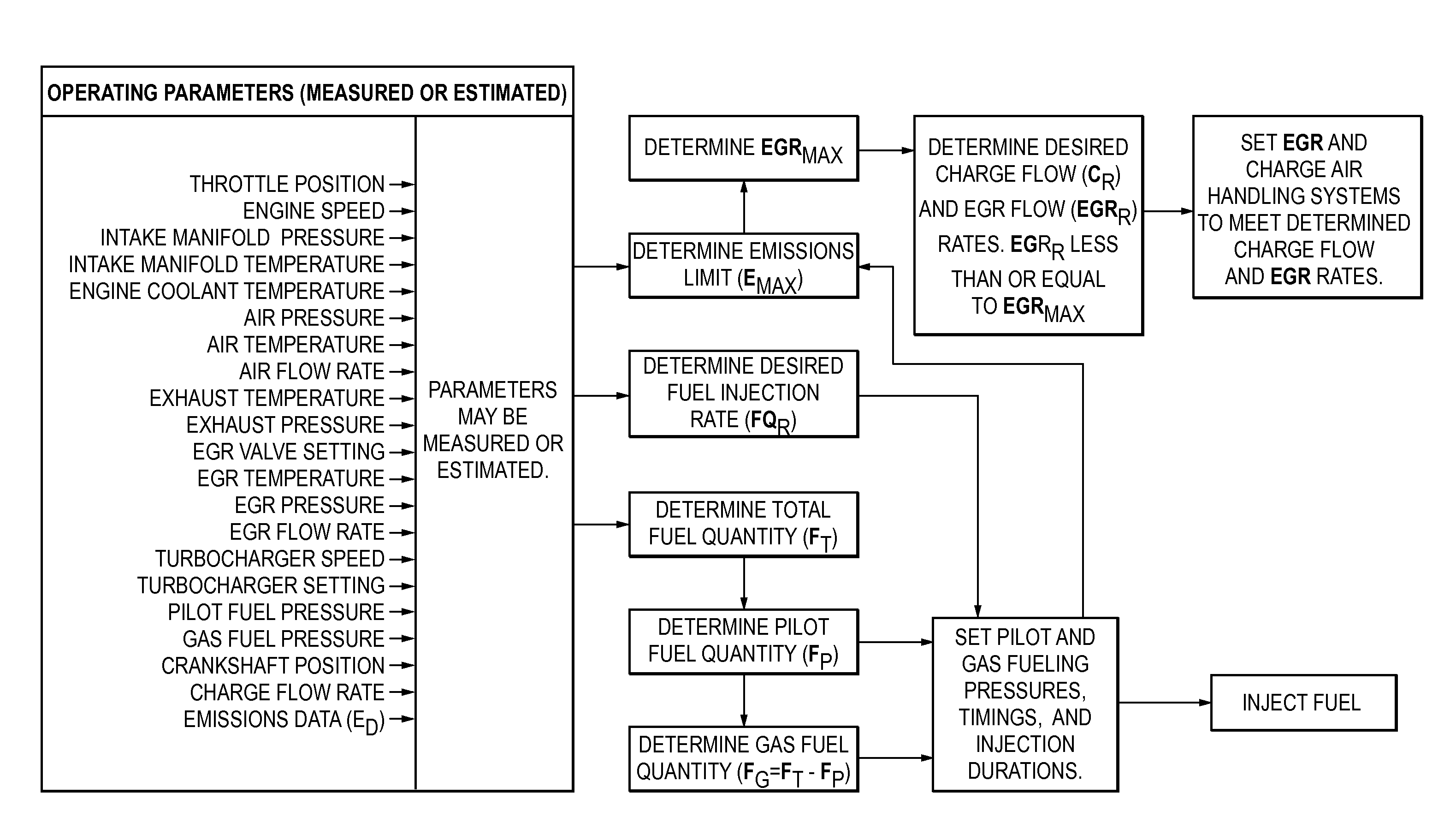

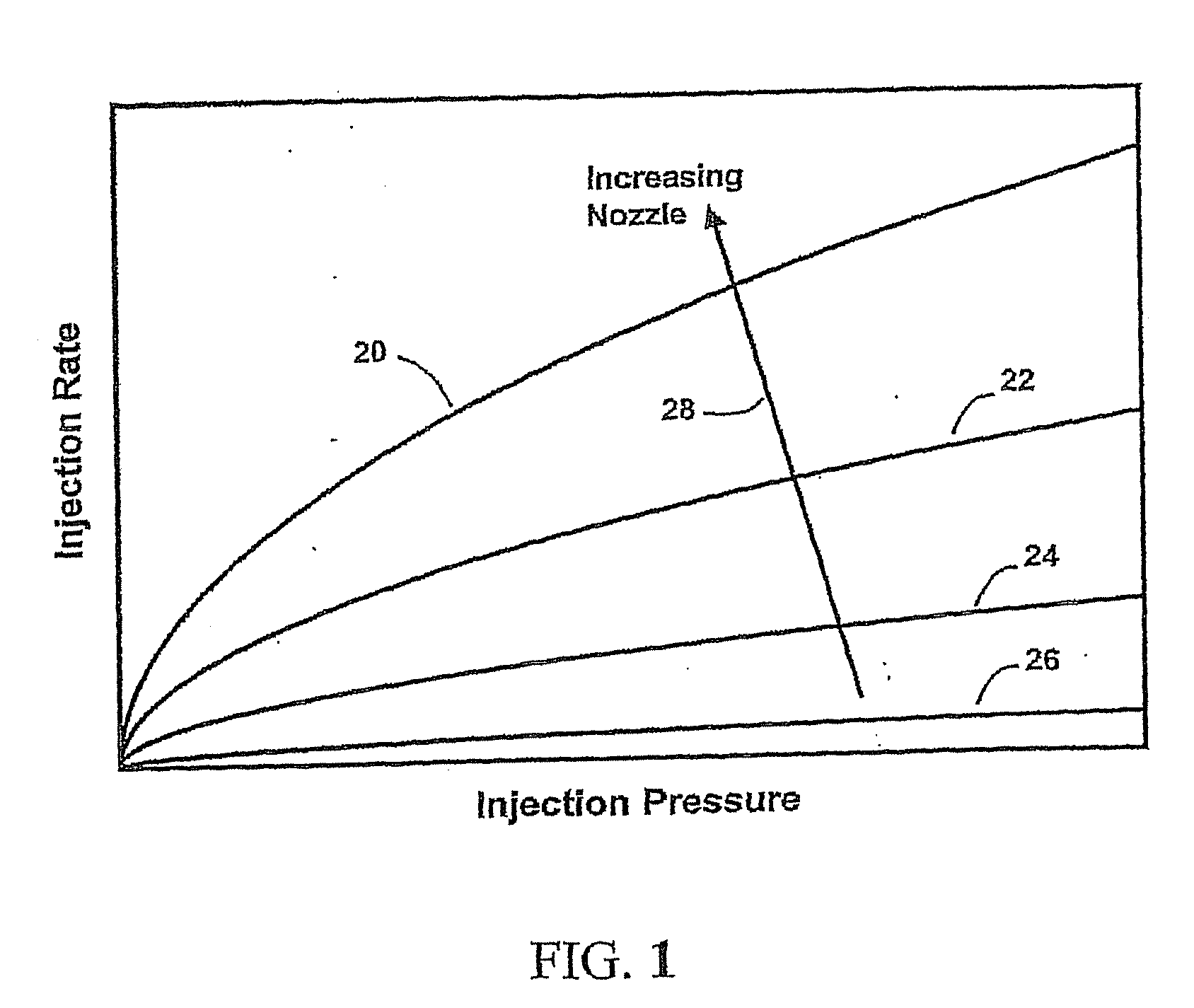

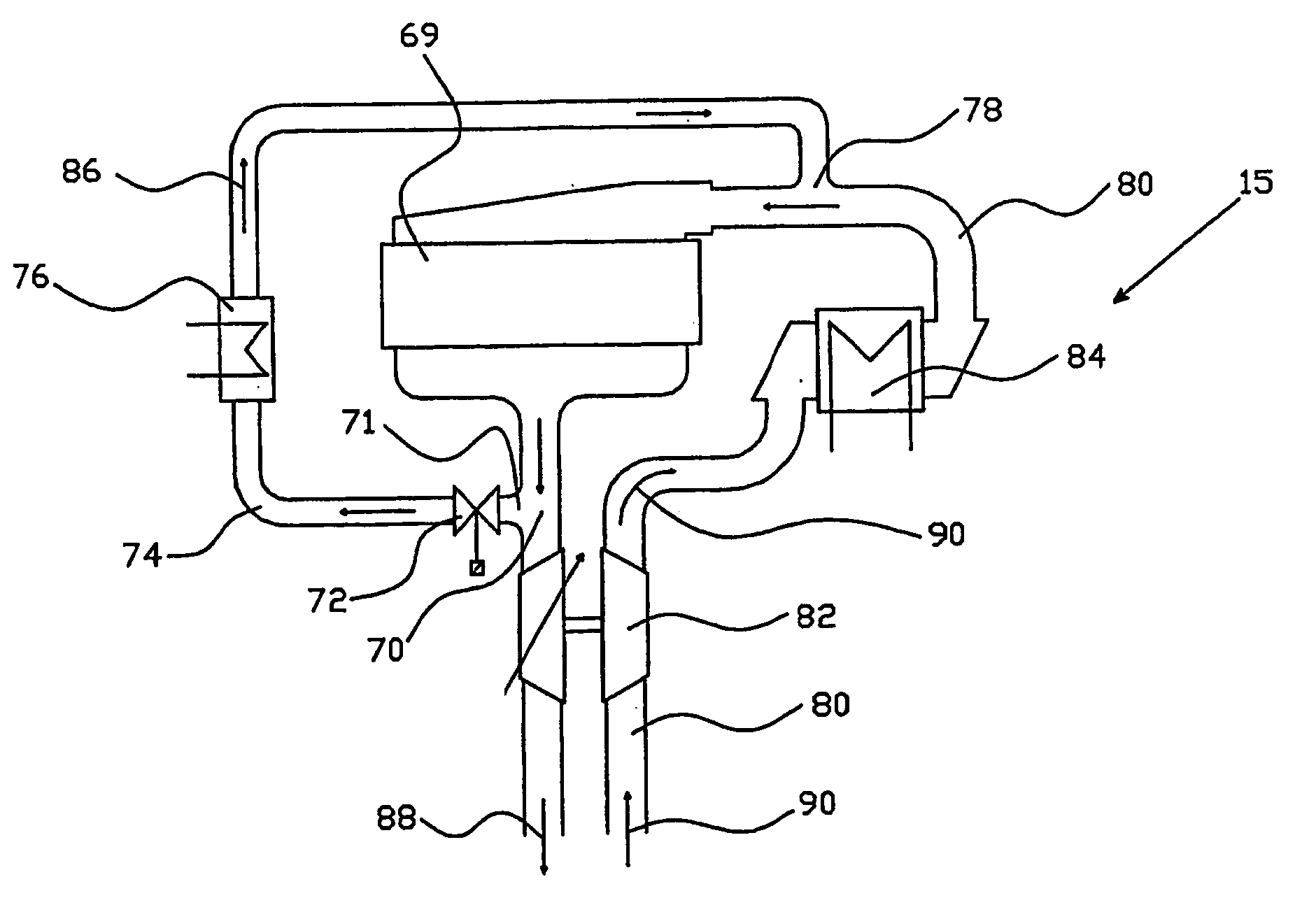

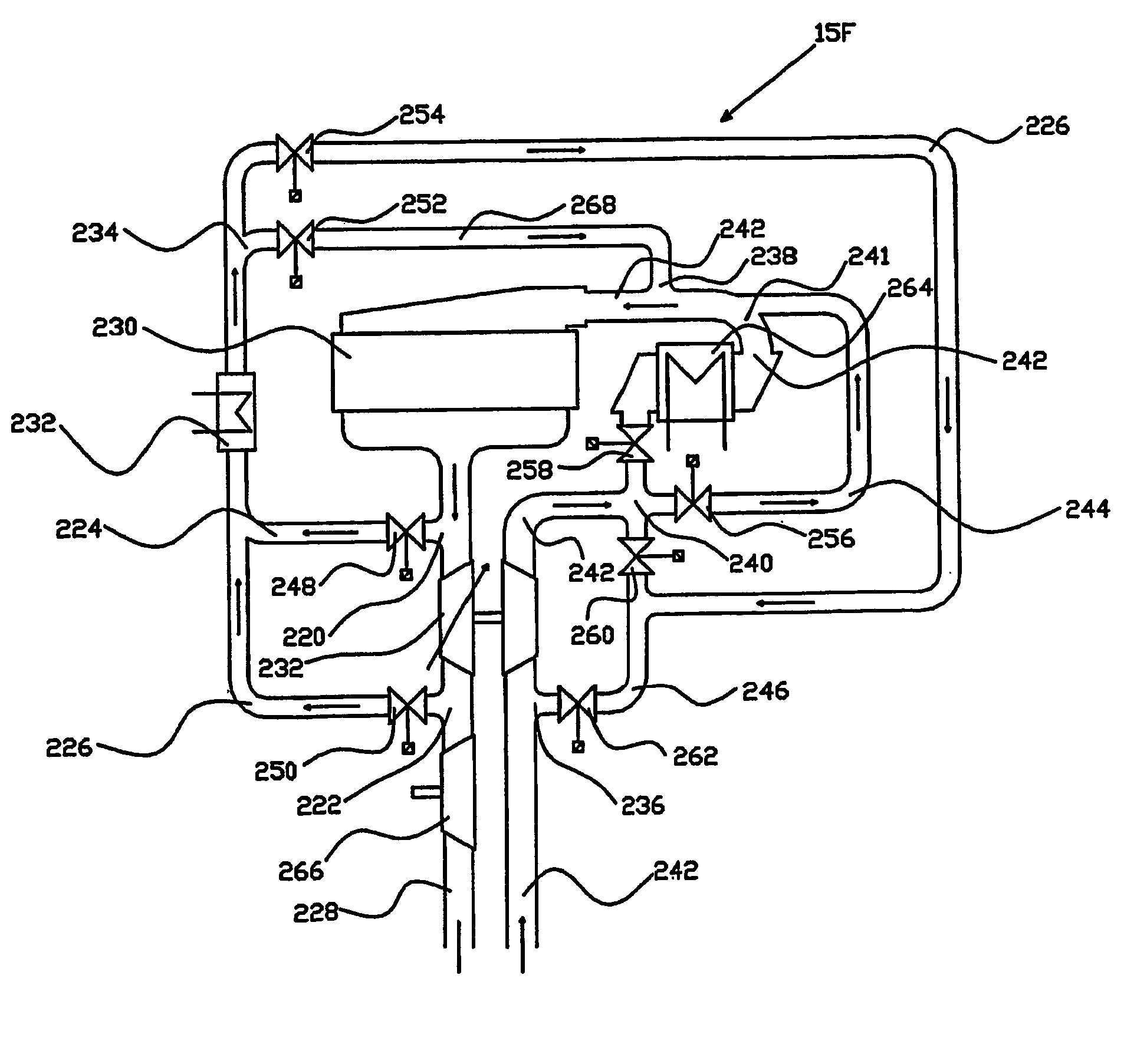

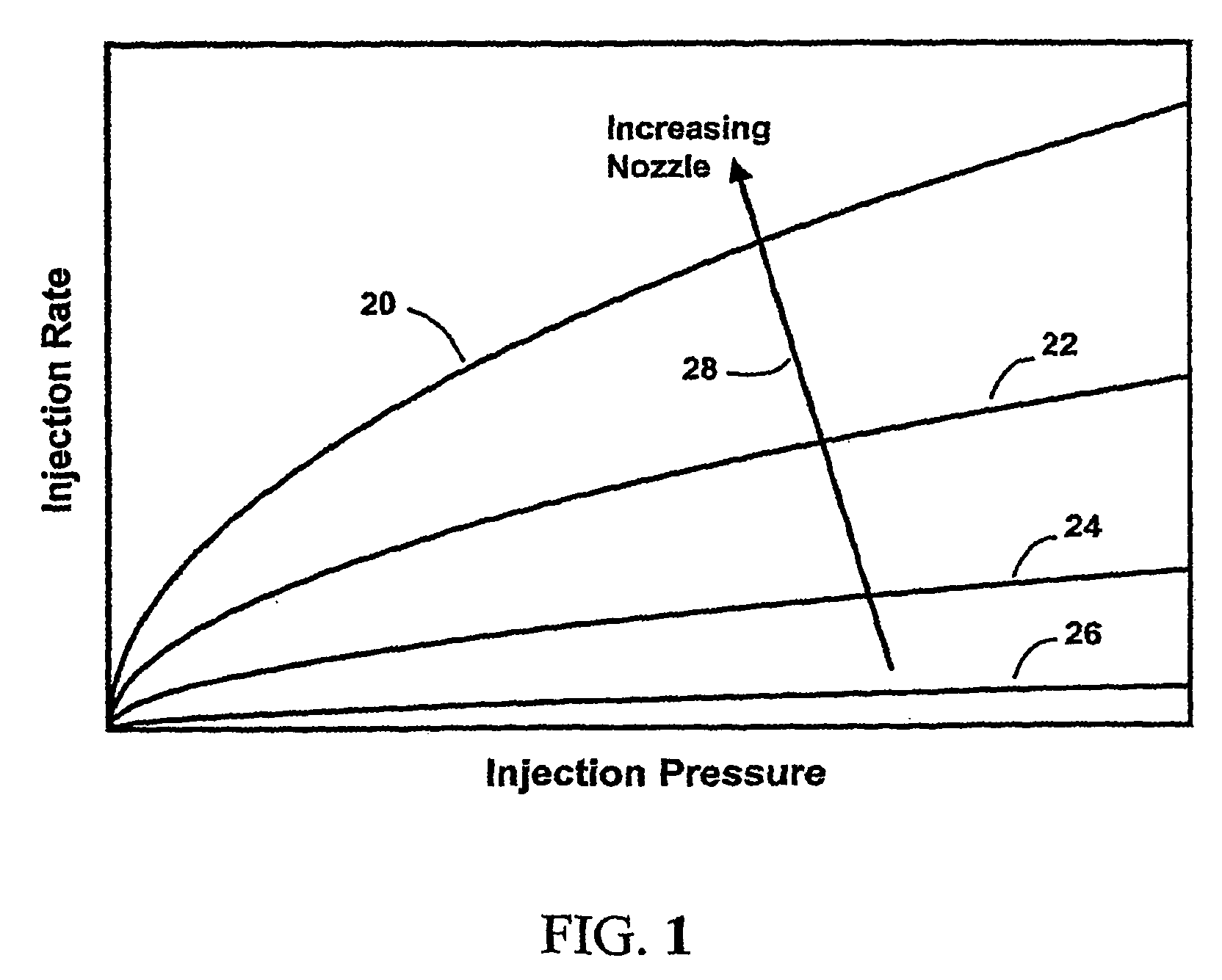

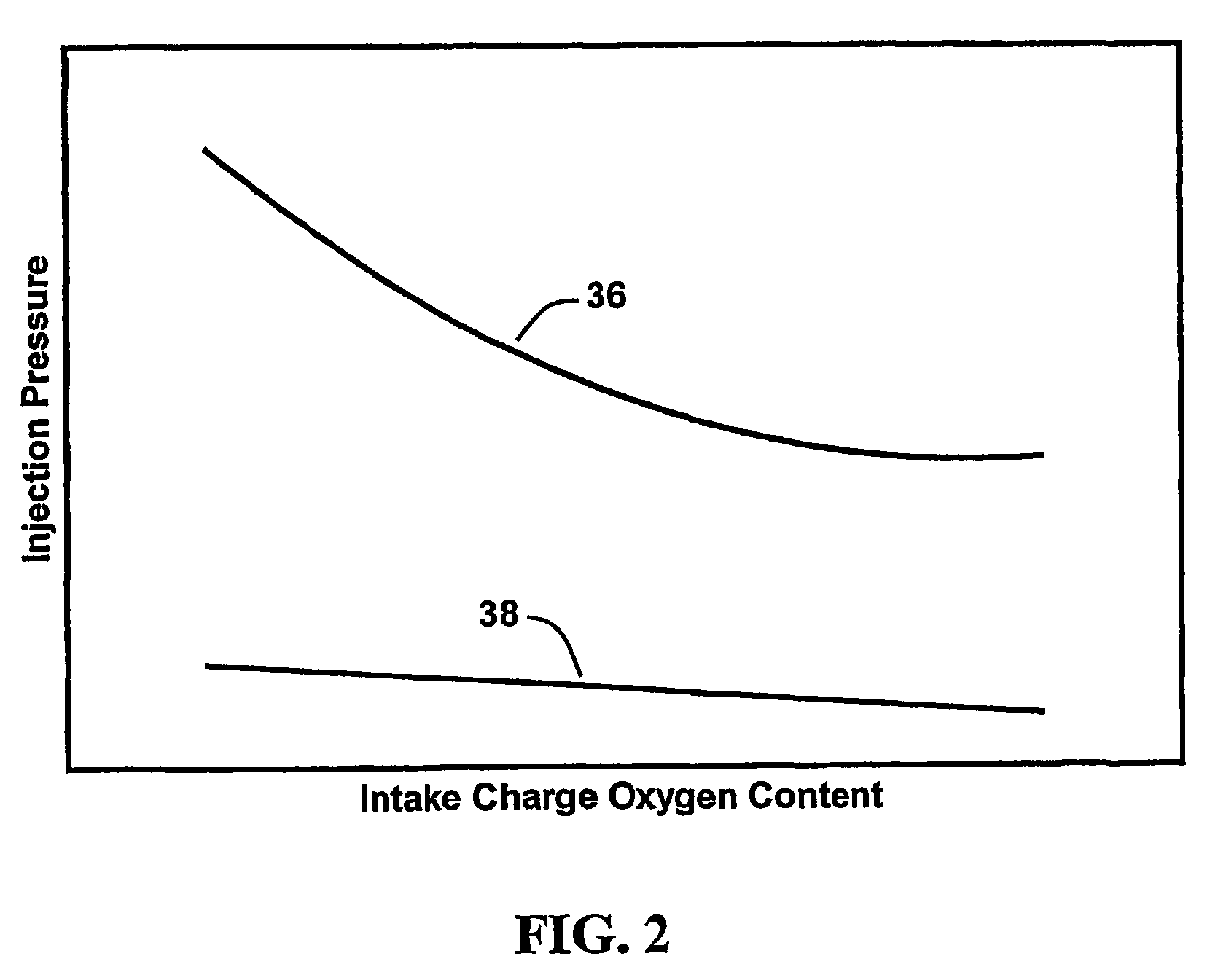

EXHAUST GAS RECIRCULATION METHODS AND APPARATUS FOR REDUCING NOx EMISSIONS FROM INTERNAL COMBUSTION ENGINES

InactiveUS20080149078A1Reduce sensitivityFavorable ignition environmentNon-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesExhaust gas recirculation

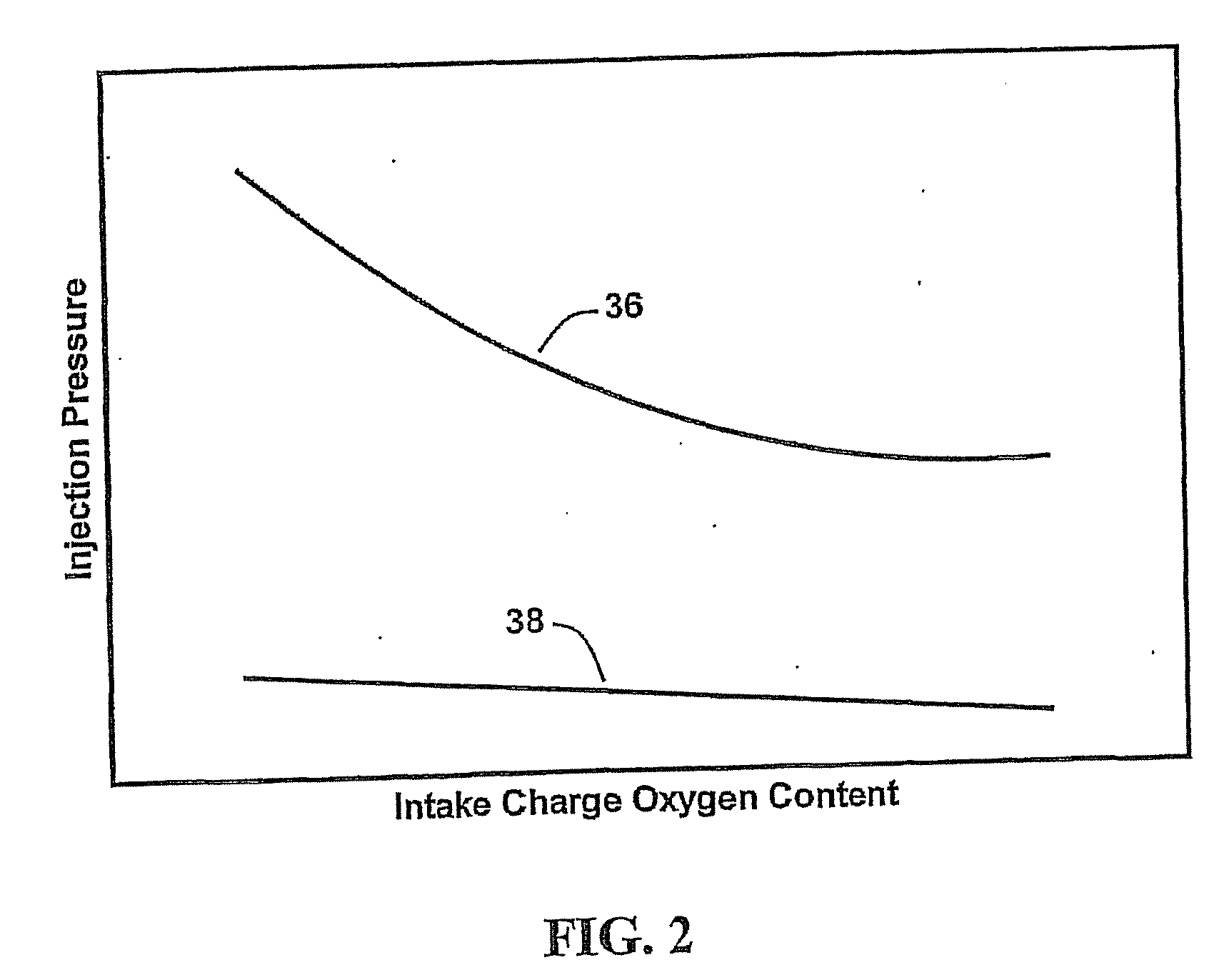

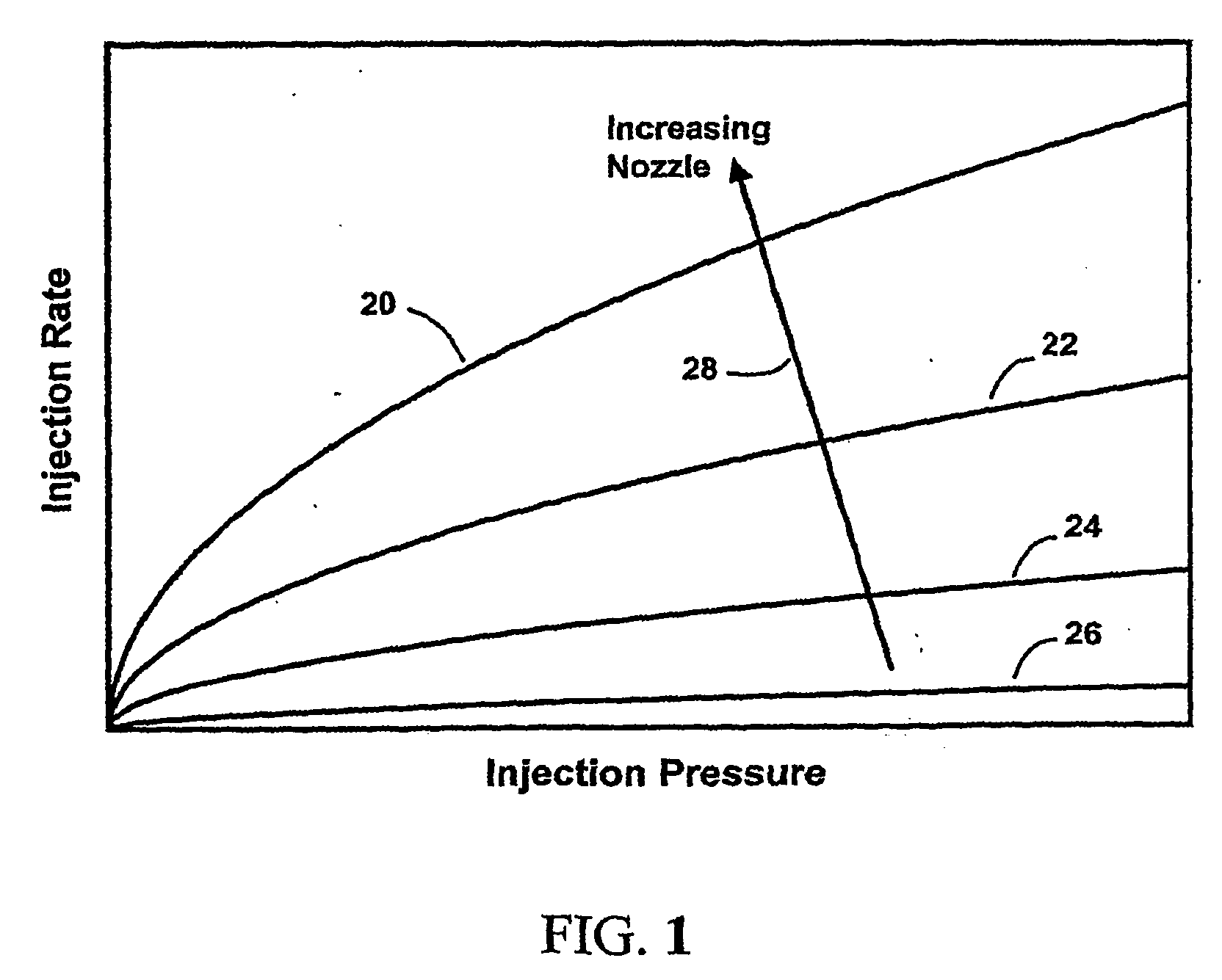

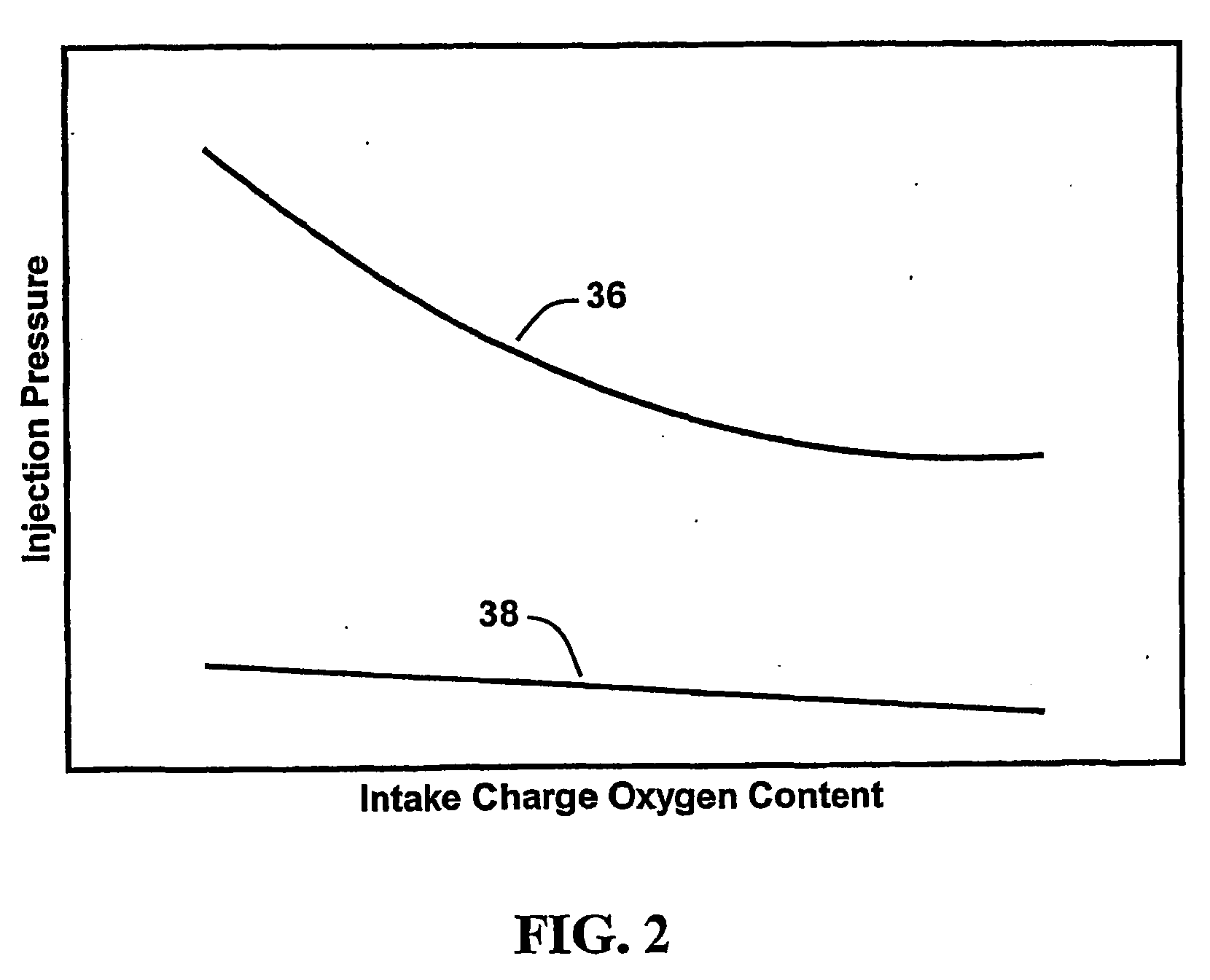

A method of operating an internal combustion engine employs exhaust gas recirculation (EGR) in combination with directly injected gaseous fuels that are burned within the engine in a stratified combustion mode. An engine that employs EGR includes an injector adapted to provide a high pressure quantity of fuel into a combustion chamber within a given pressure range, at a given angle and through a nozzle hole size to help provide for EGR tolerance and, consequently, reduce emissions.

Owner:WESTPORT POWER

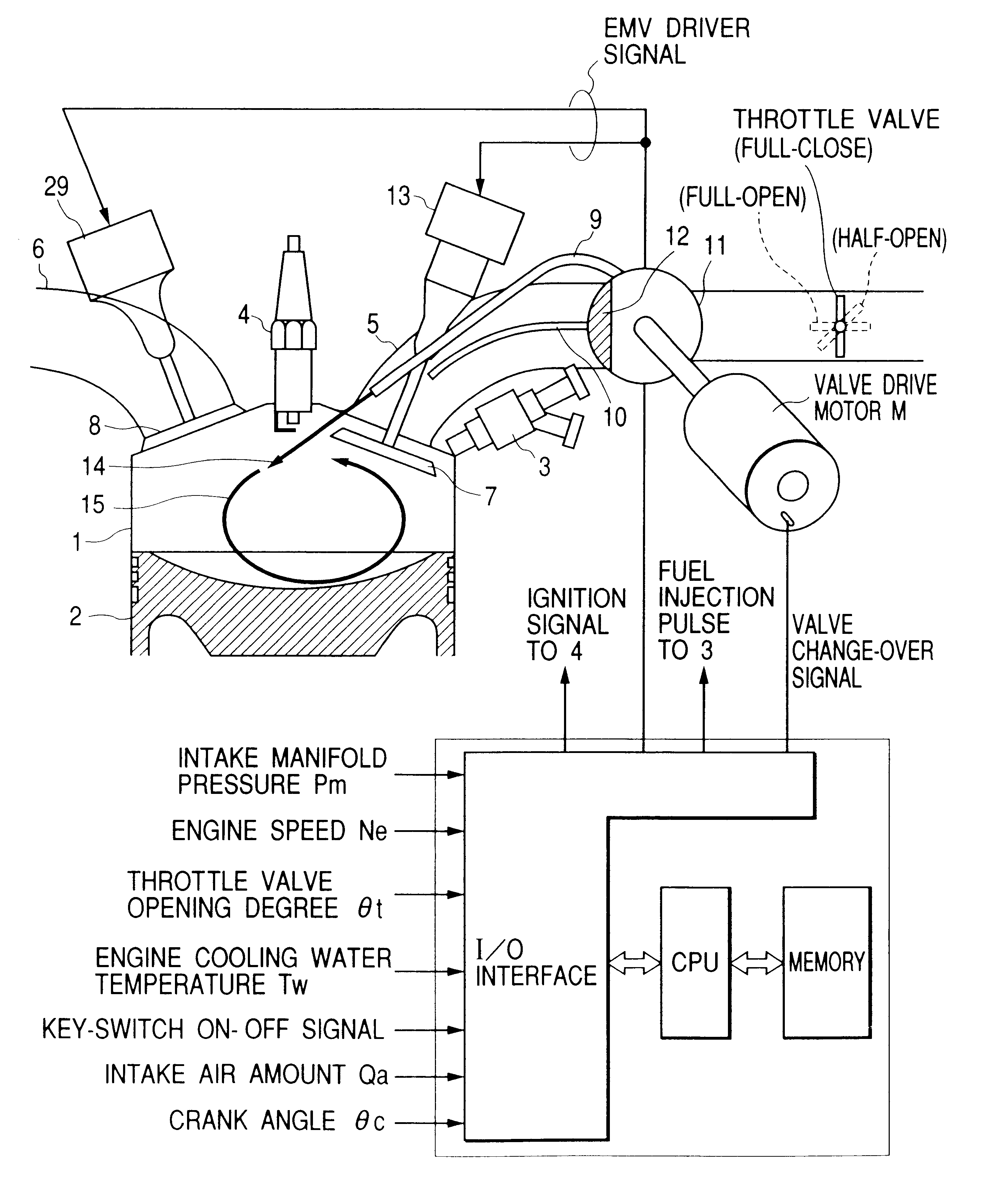

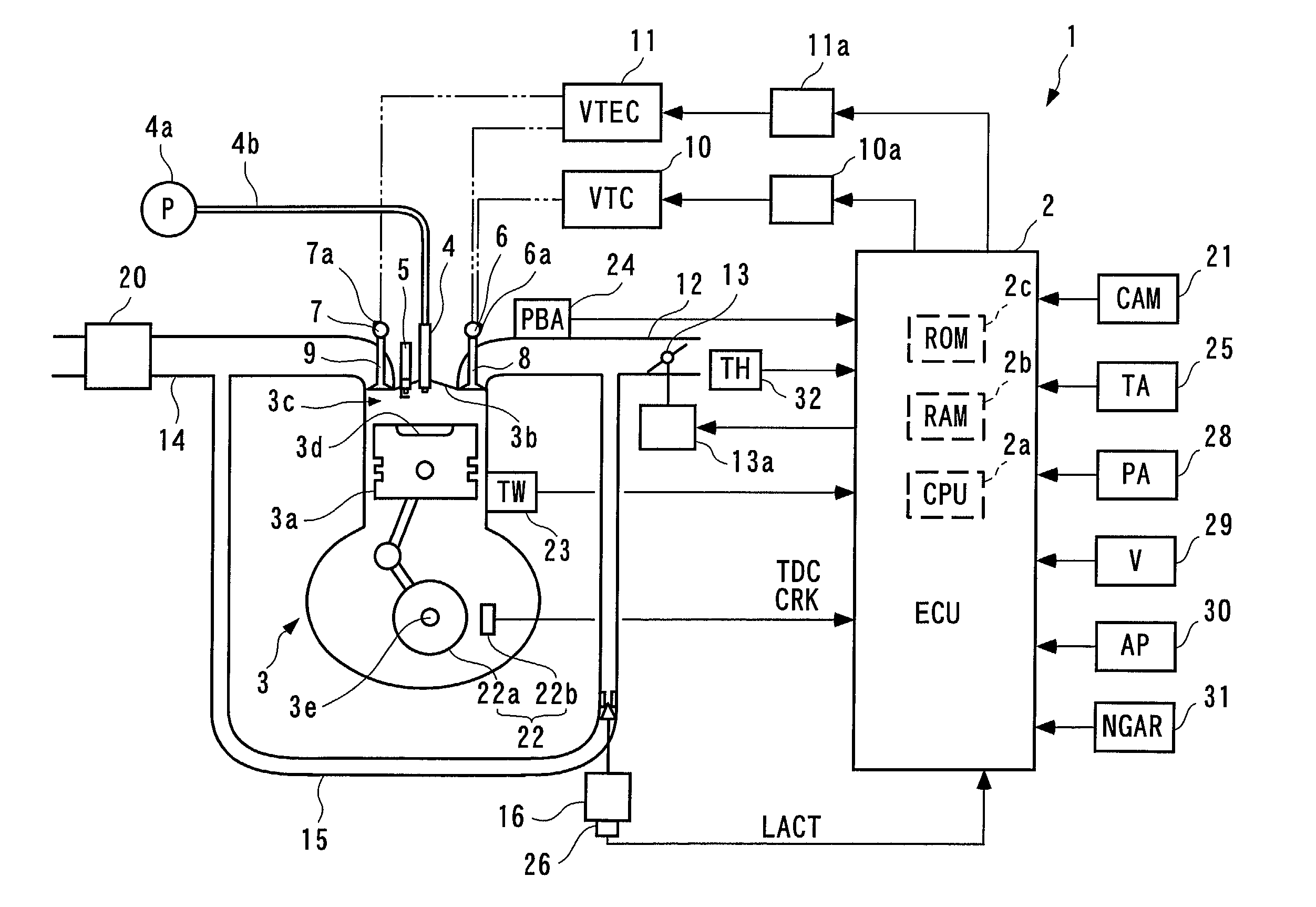

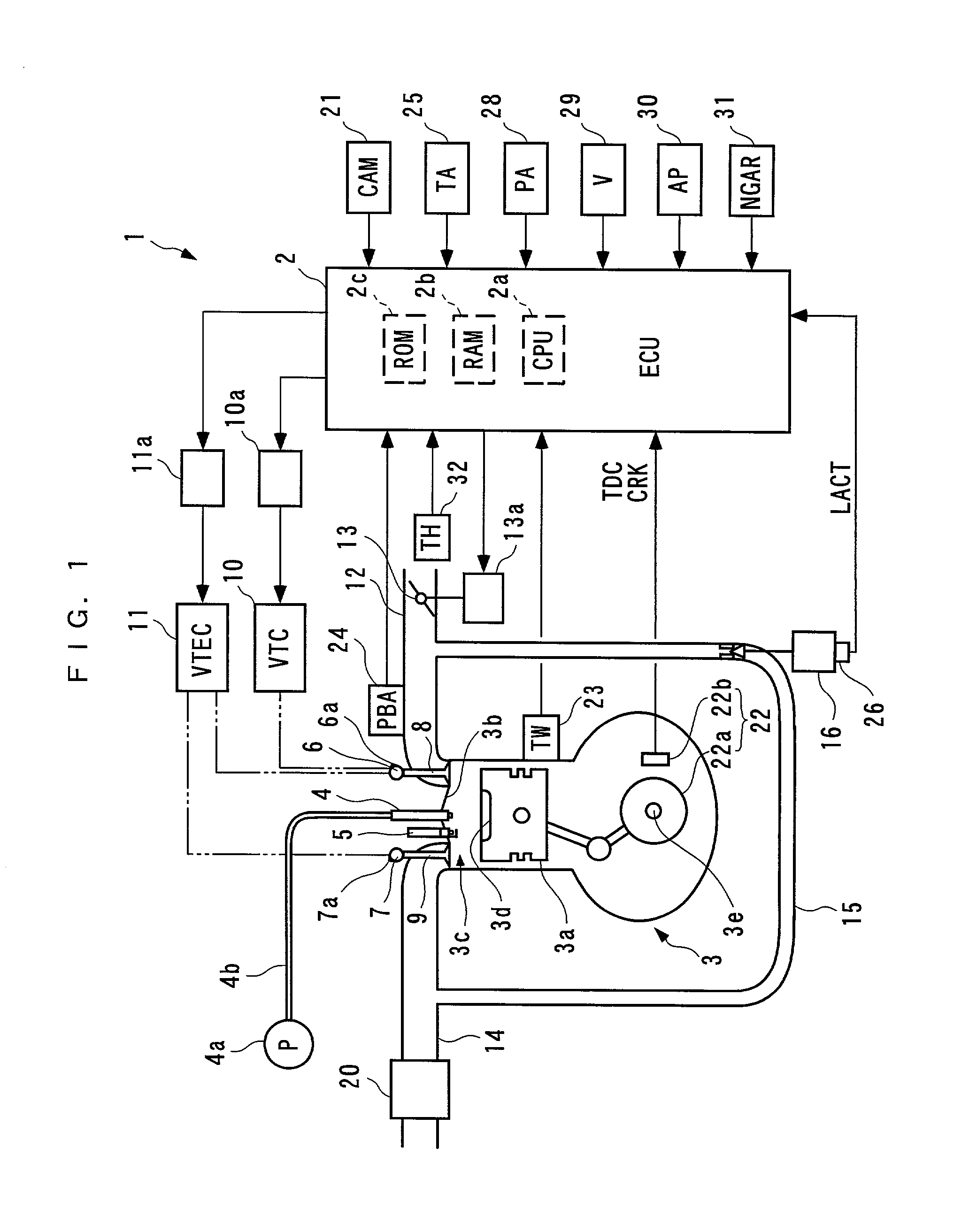

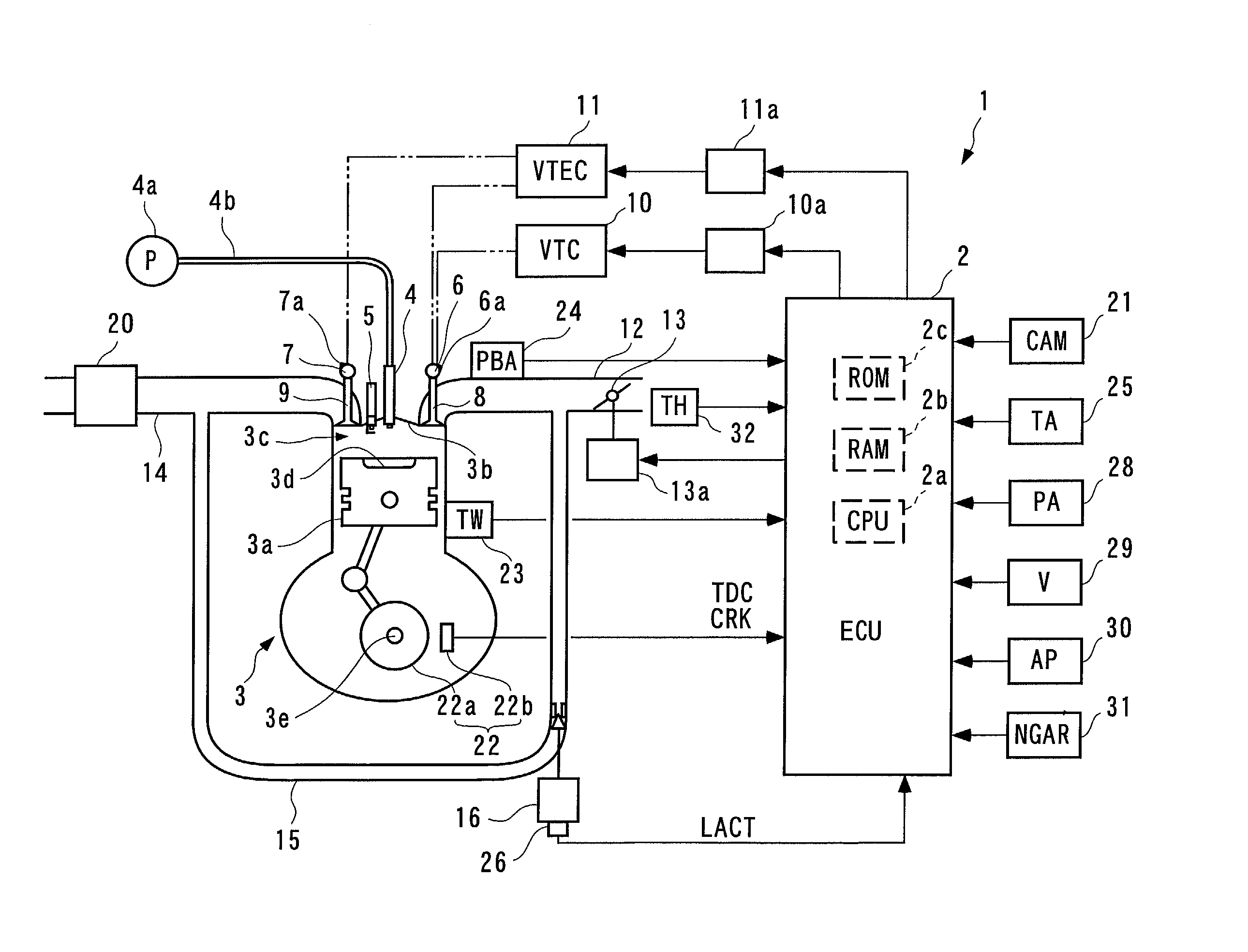

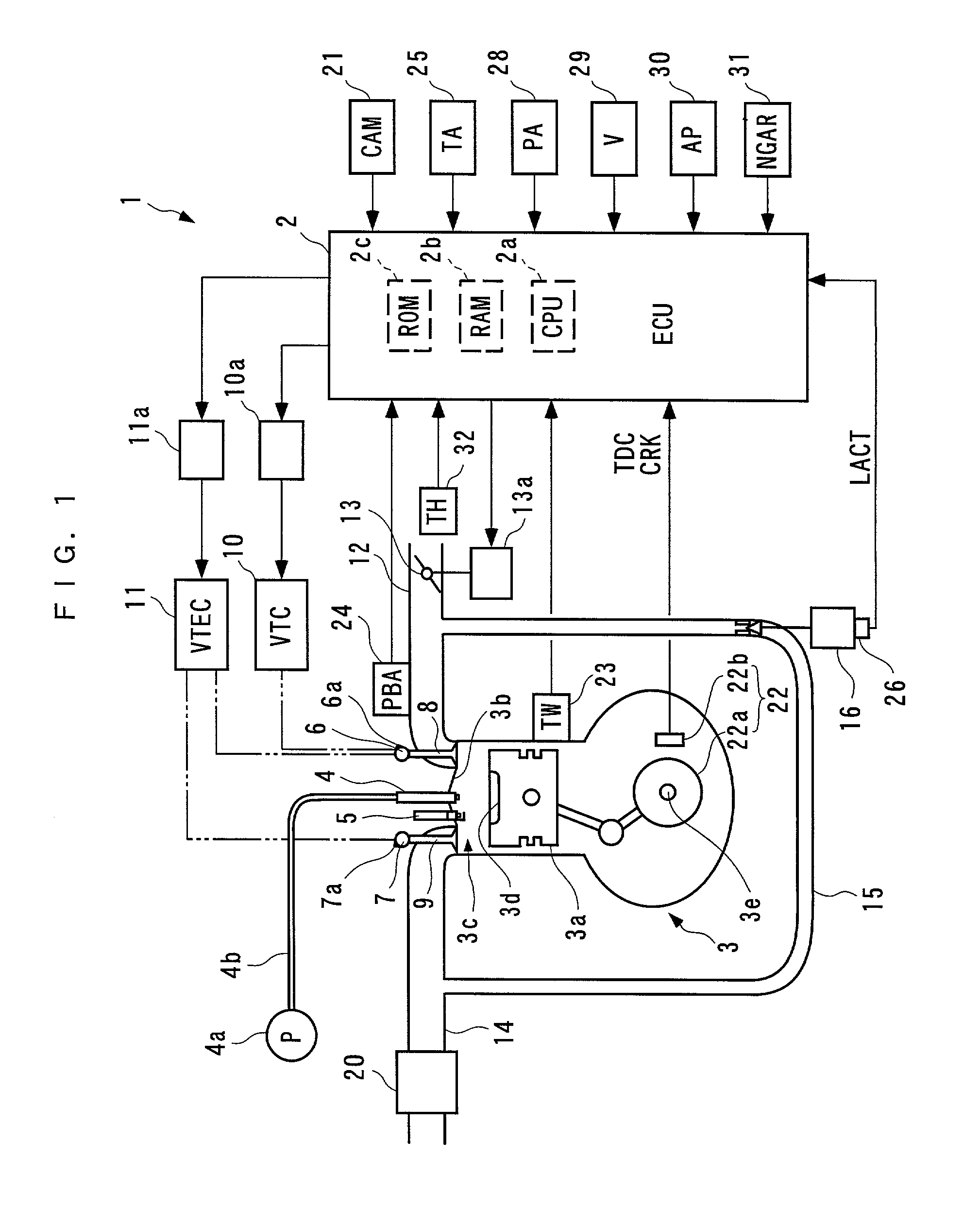

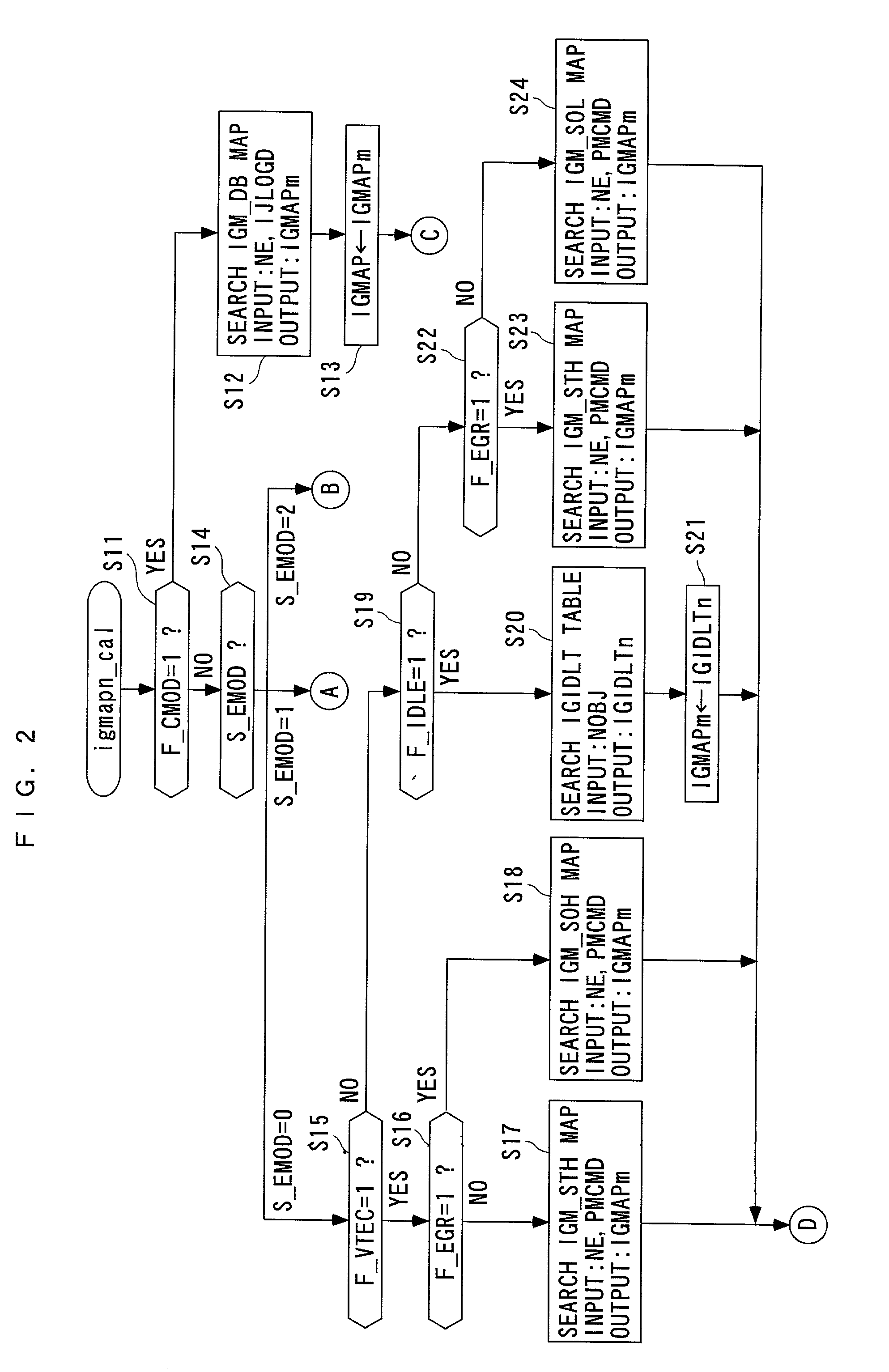

Ignition time controller, ignition time control method and engine control unit for internal combustion engine

InactiveUS6581564B2Electrical controlInternal combustion piston enginesExternal combustion engineCam

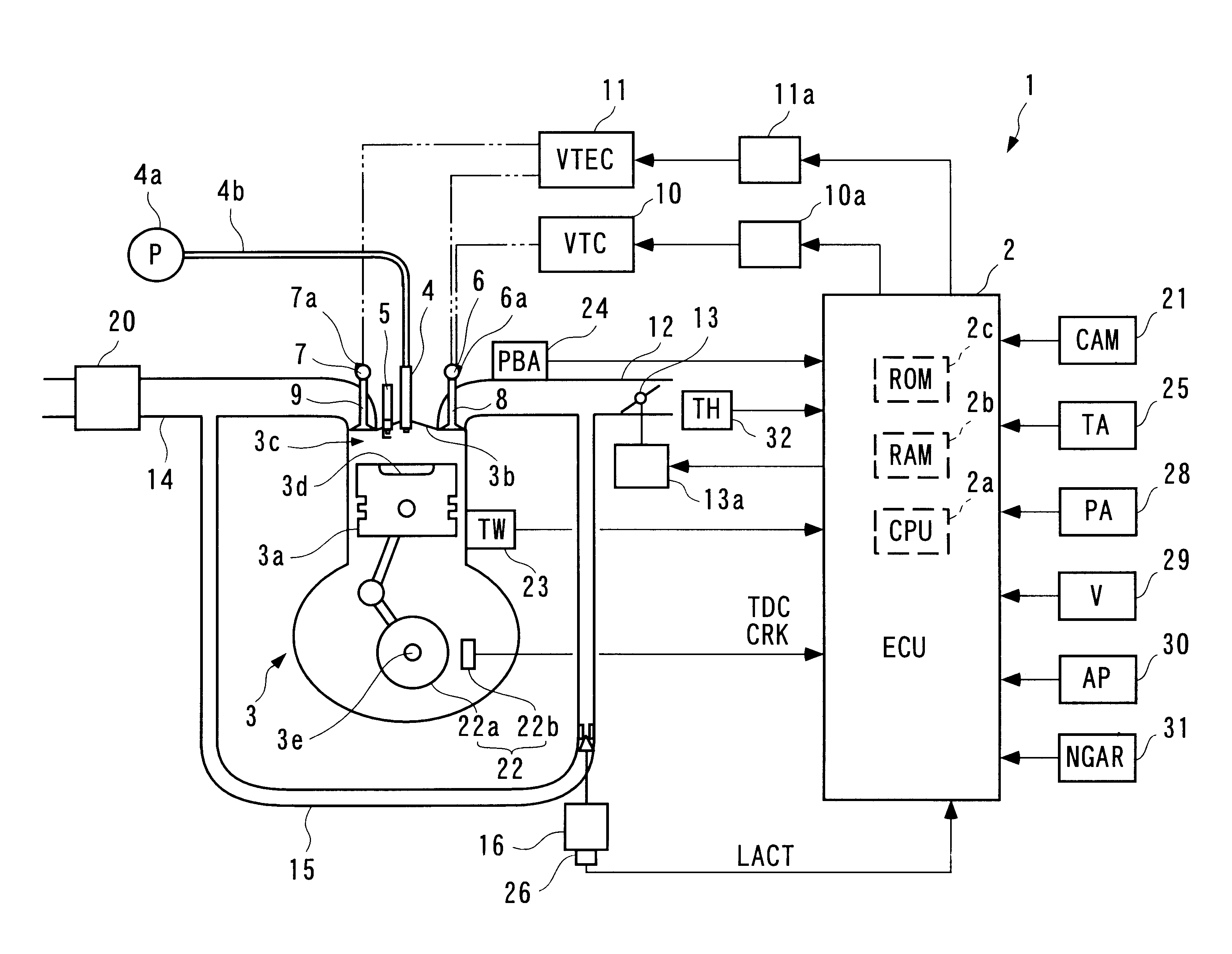

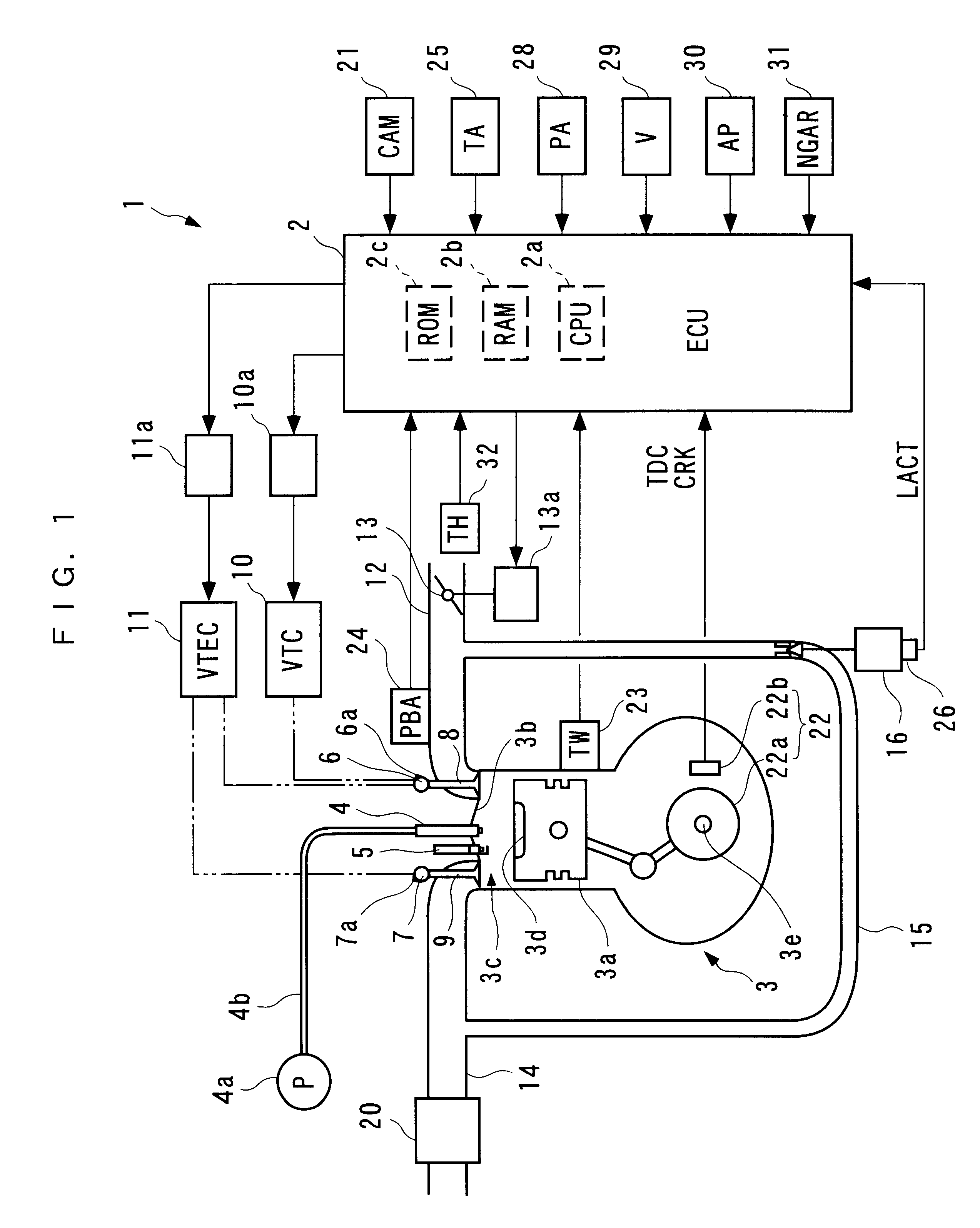

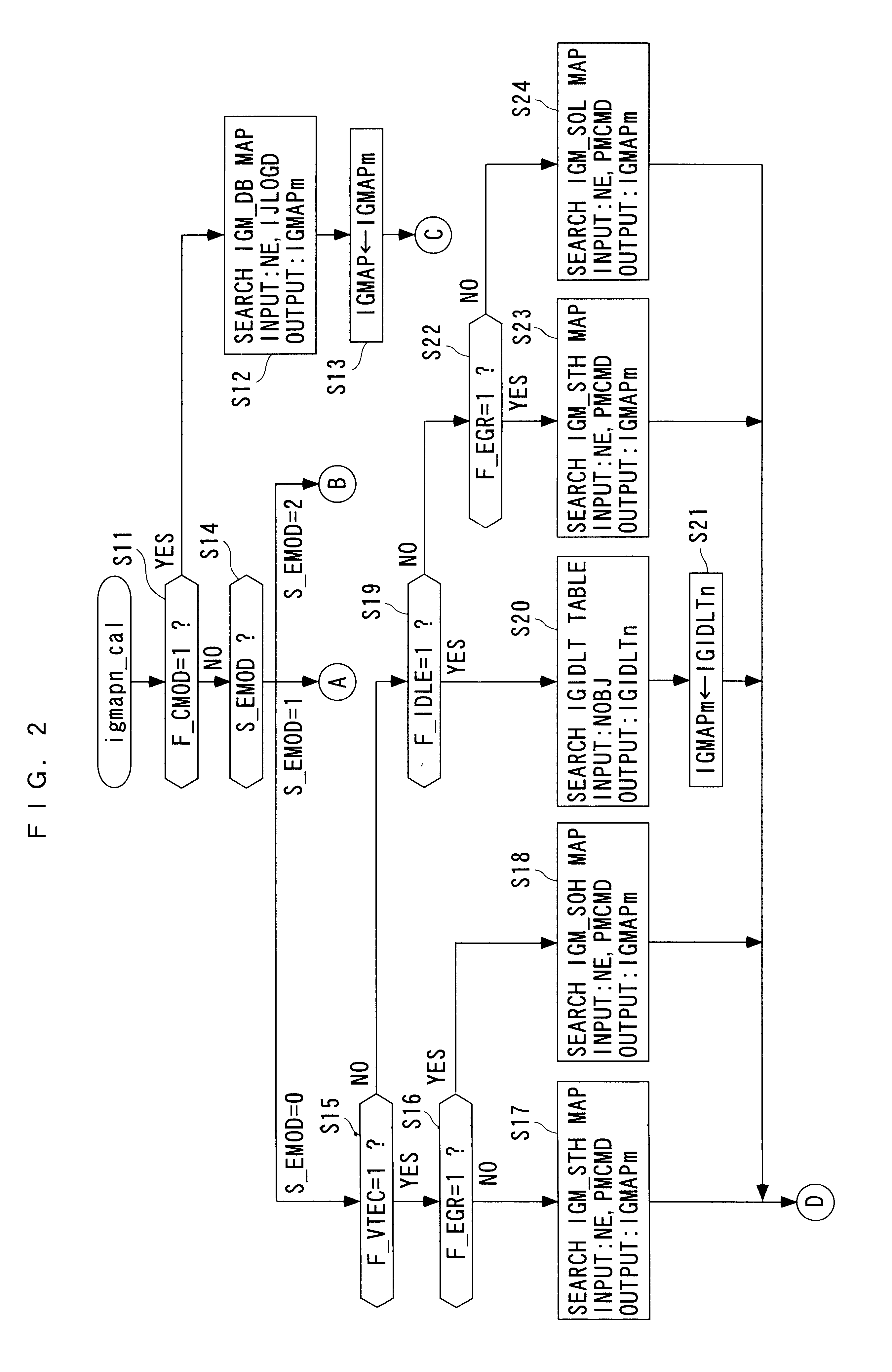

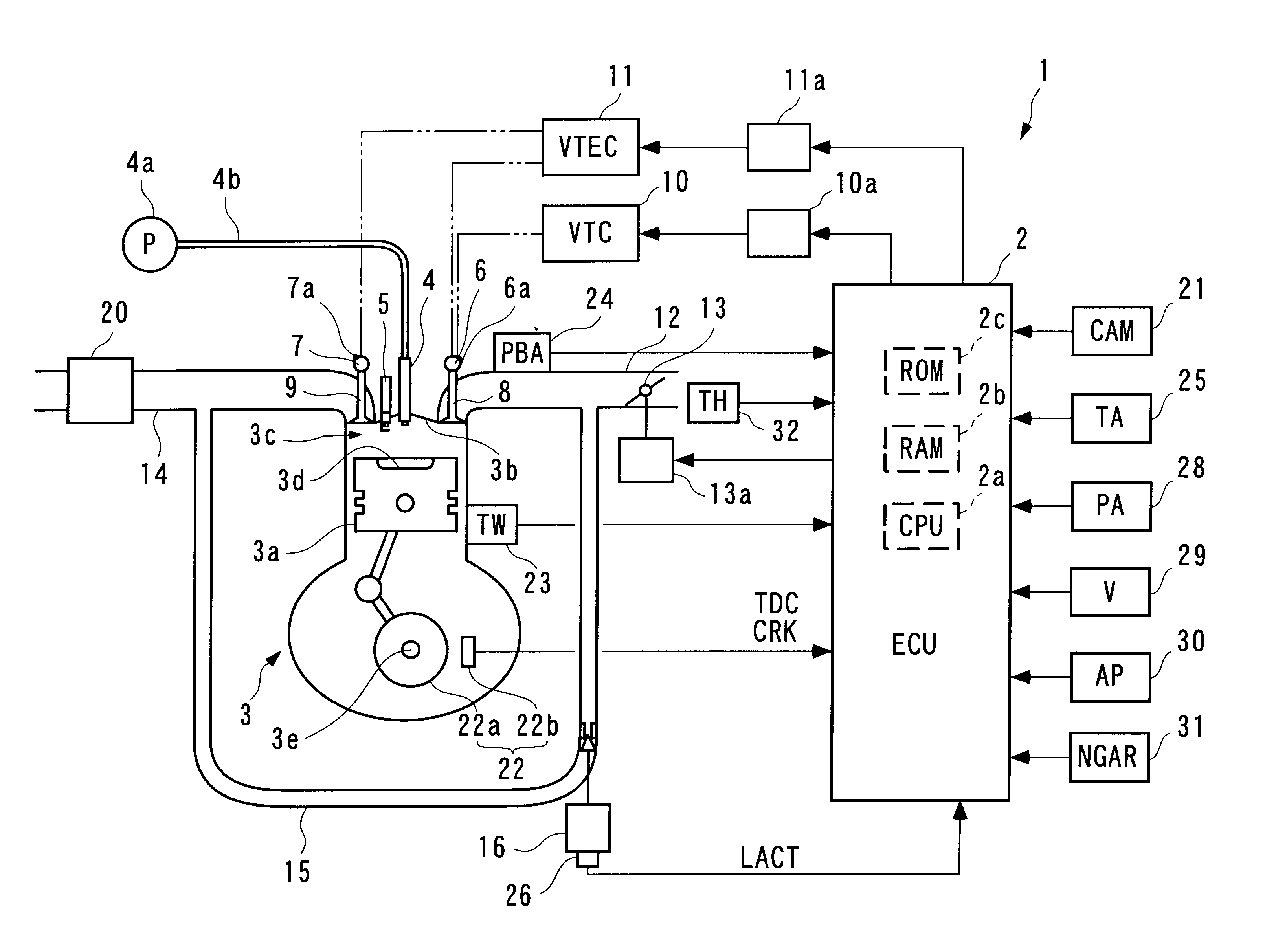

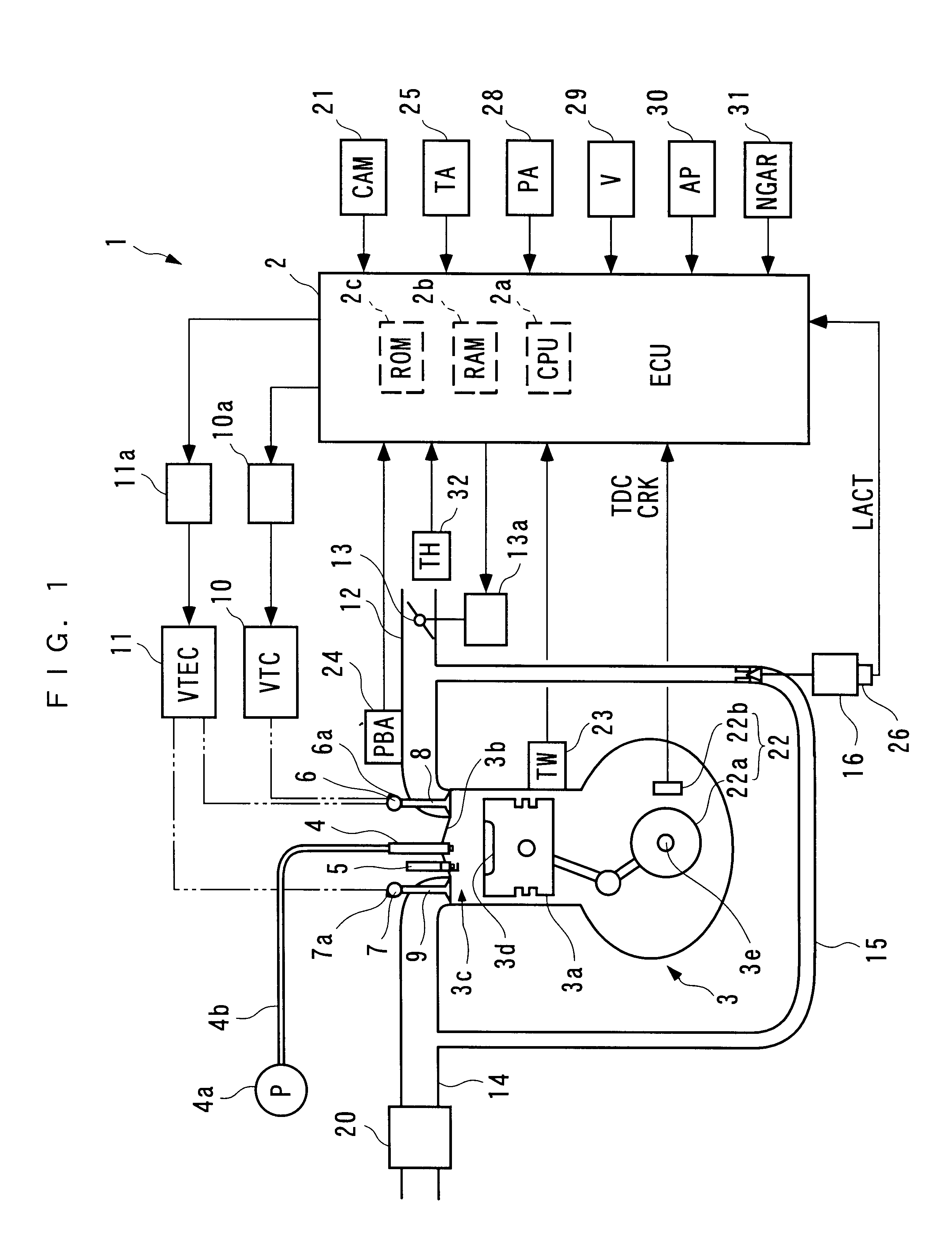

An ignition time controller for an internal combustion engine is provided for setting an ignition time such that it can rapidly converge to an appropriate value in accordance with a change in intake characteristics associated with a change in cam phase in either of a uniform combustion mode and a stratified combustion mode in a direct injection type internal combustion engine having a cam phase changing mechanism. The ignition time controller comprises a required torque determining unit for determining a required torque outputted by the internal combustion engine based on an engine rotational speed and an accelerator opening, a fuel injection time determining unit for determining a time at which a fuel is injected into a cylinder, a basic ignition time determining unit for determining a basic ignition time based on the engine rotational speed and the required torque in the uniform combustion mode and based on the engine rotational speed and the fuel injection time in the stratified combustion mode, and a basic ignition time correcting unit for correcting the basic ignition time in accordance with a cam phase deviation between an actual cam phase and a target cam phase.

Owner:HONDA MOTOR CO LTD

Fuel injection apparatus and method for cylinder injection type internal combustion engine

InactiveUS6880519B2Improve fuel economyImprove emission characteristicsElectrical controlInternal combustion piston enginesLow loadEngineering

With a cylinder direct injection engine in which fuel is injected directly into combustion chambers and air-fuel mixture is guided by an air flow, it is difficult to secure combustion stability under low engine speed and low load conditions such as during idling. Furthermore, there are needs for improvement of emission characteristics and fuel economy in other operation modes as well. An engine according to the invention injects fuel while dividing the same in plural parts during a compression stroke. The first injection forms a lean air-fuel mixture around an ignition plug, and the second injection makes a flammable air-fuel mixture reach an area around the ignition plug. This ensures efficient stratified combustion and allows improvement in emission and fuel economy performance.

Owner:HITACHI LTD

Exhaust gas recirculation methods and apparatus for reducing NOX emissions from internal combustion engines

InactiveUS20050224060A1High EGR levelReduce sensitivityInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesHigh pressure

A method of operating an internal combustion engine employs exhaust gas recirculation (EGR) in combination with directly injected gaseous fuels that are burned within the engine in a stratified combustion mode. An engine that employs EGR includes an injector adapted to provide a high pressure quantity of fuel into a combustion chamber within a given pressure range, at a given angle and through a nozzle hole size to help provide for EGR tolerance and, consequently, reduce emissions.

Owner:WESTPORT POWER

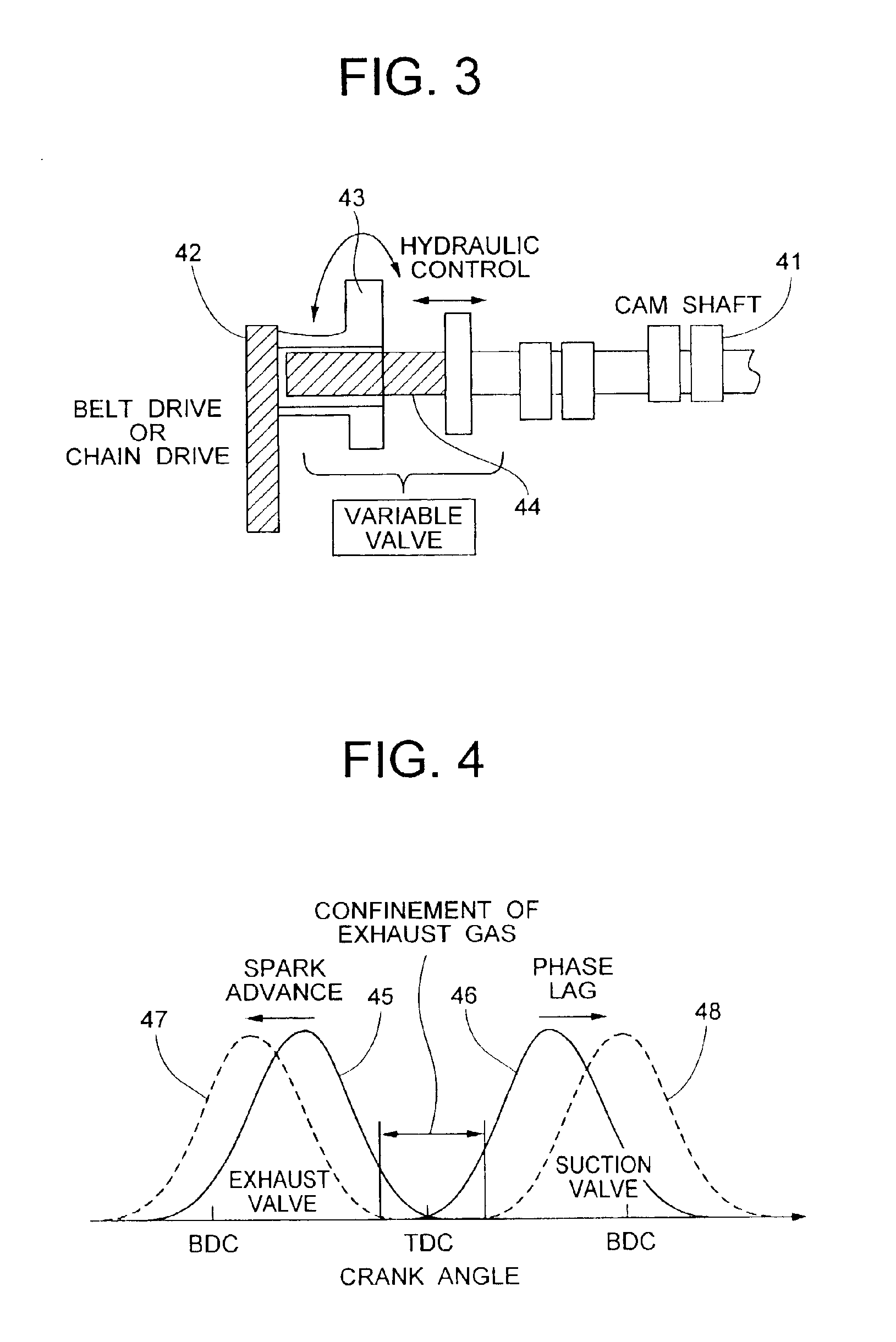

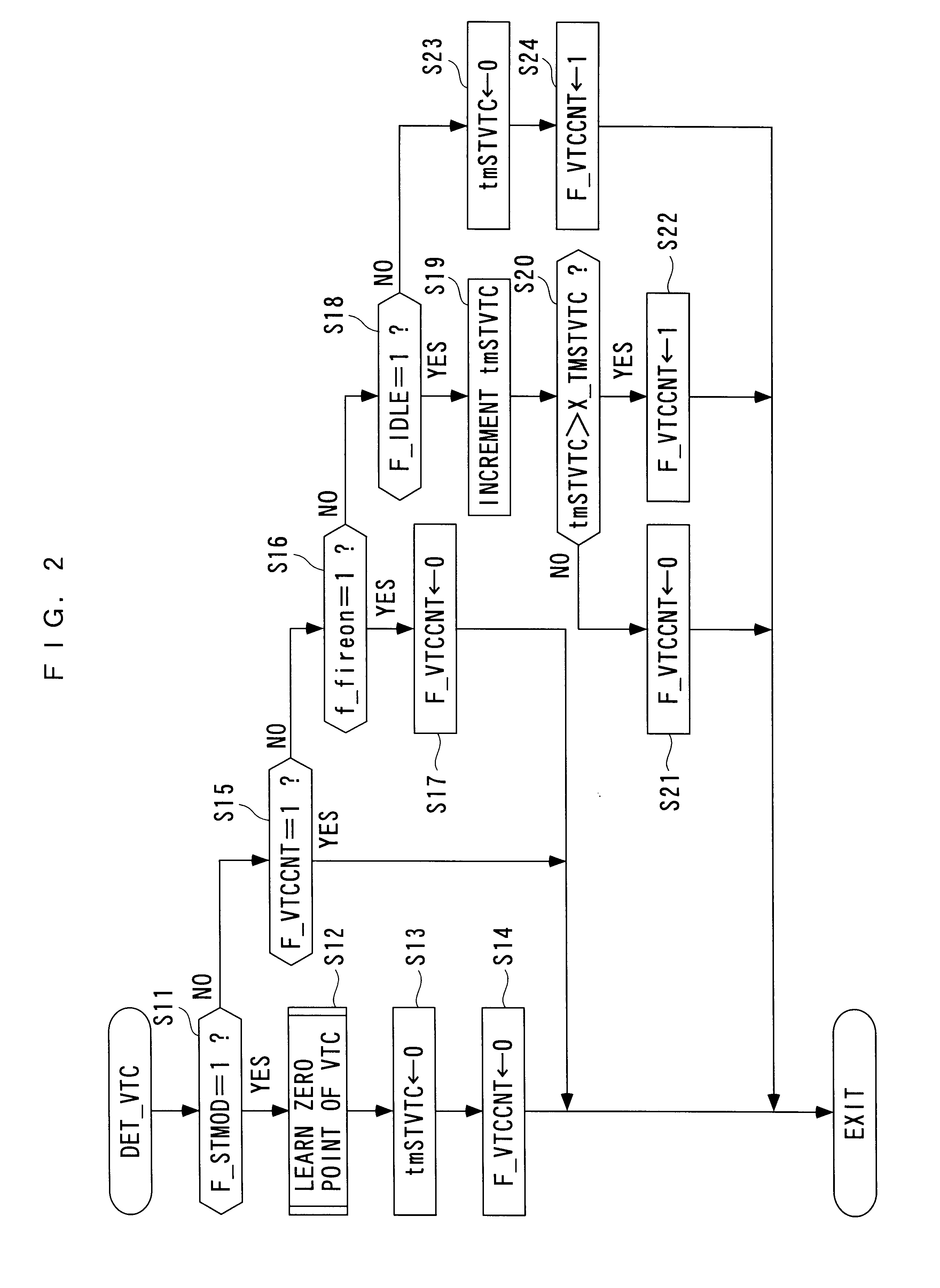

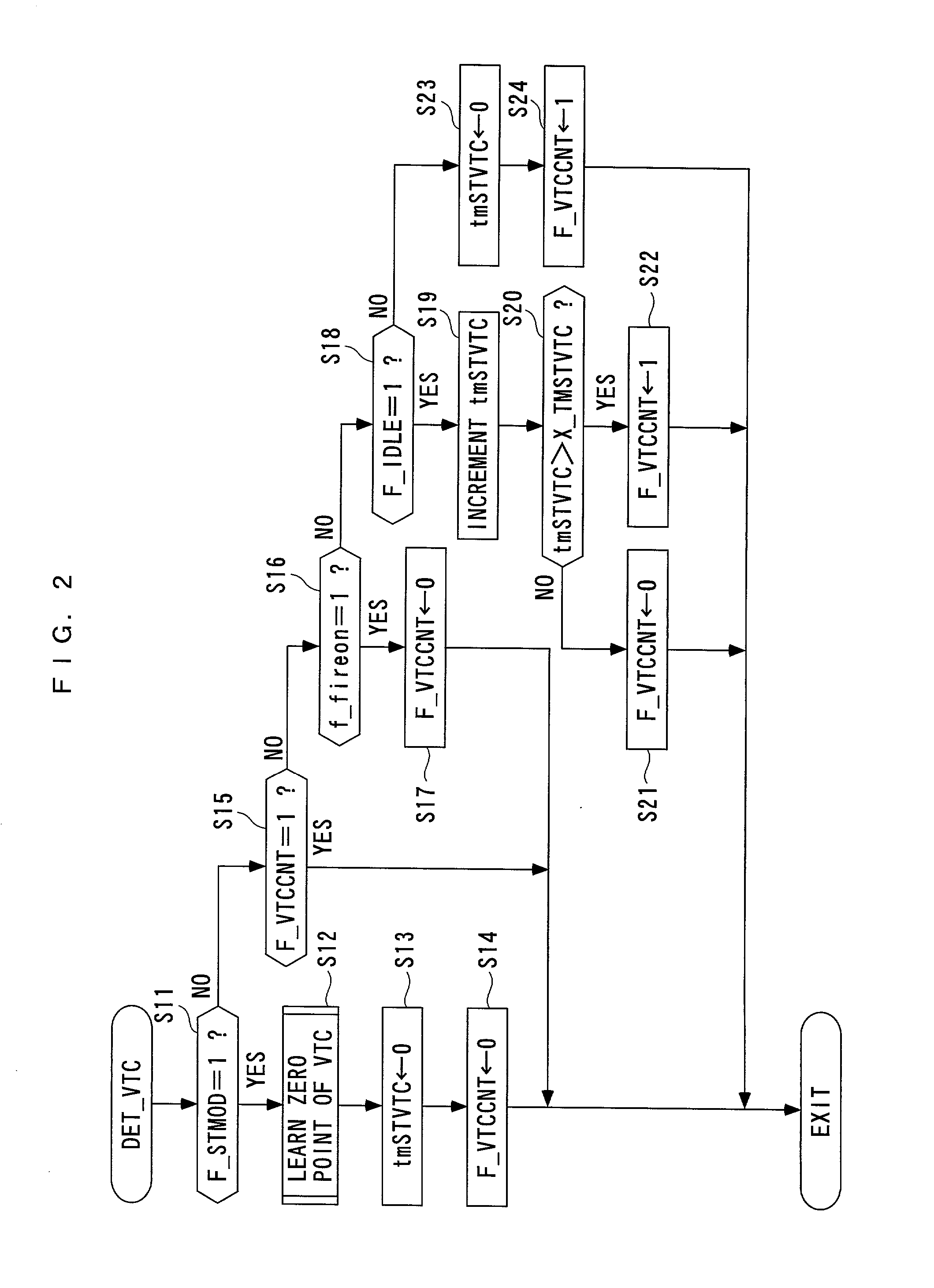

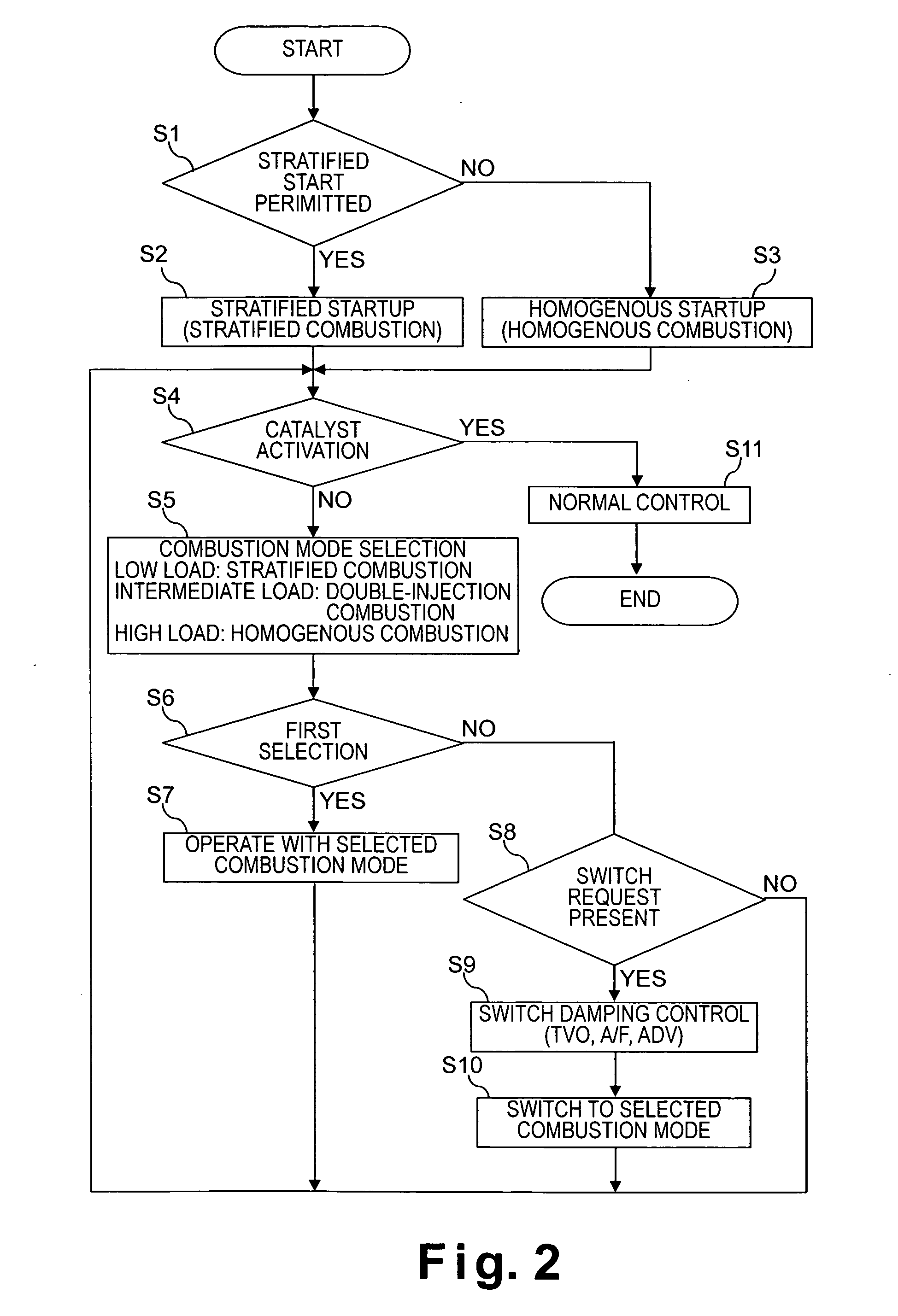

Valve timing controller, valve timing control method and engine control unit for internal combustion engine

A valve timing controller for use in a direct injection type internal combustion engine is provided for enabling a valve timing to be appropriately set in accordance with a load on the engine even in a stratified combustion mode. The internal combustion engine has a valve timing changing mechanism for changing a valve timing of at least one of an intake valve and an exhaust valve so that it is operated in a combustion mode switched between a uniform combustion mode in which a fuel is injected into a cylinder during an intake stroke and a stratified combustion mode in which a fuel is injected into a cylinder in a compression stroke. The valve timing controller comprises a required torque determining unit for determining a required torque outputted by the internal combustion engine based on the engine rotational speed and accelerator pedal opening, and a valve timing determining unit for determining the valve timing in accordance with the required torque and the engine rotational speed.

Owner:HONDA MOTOR CO LTD

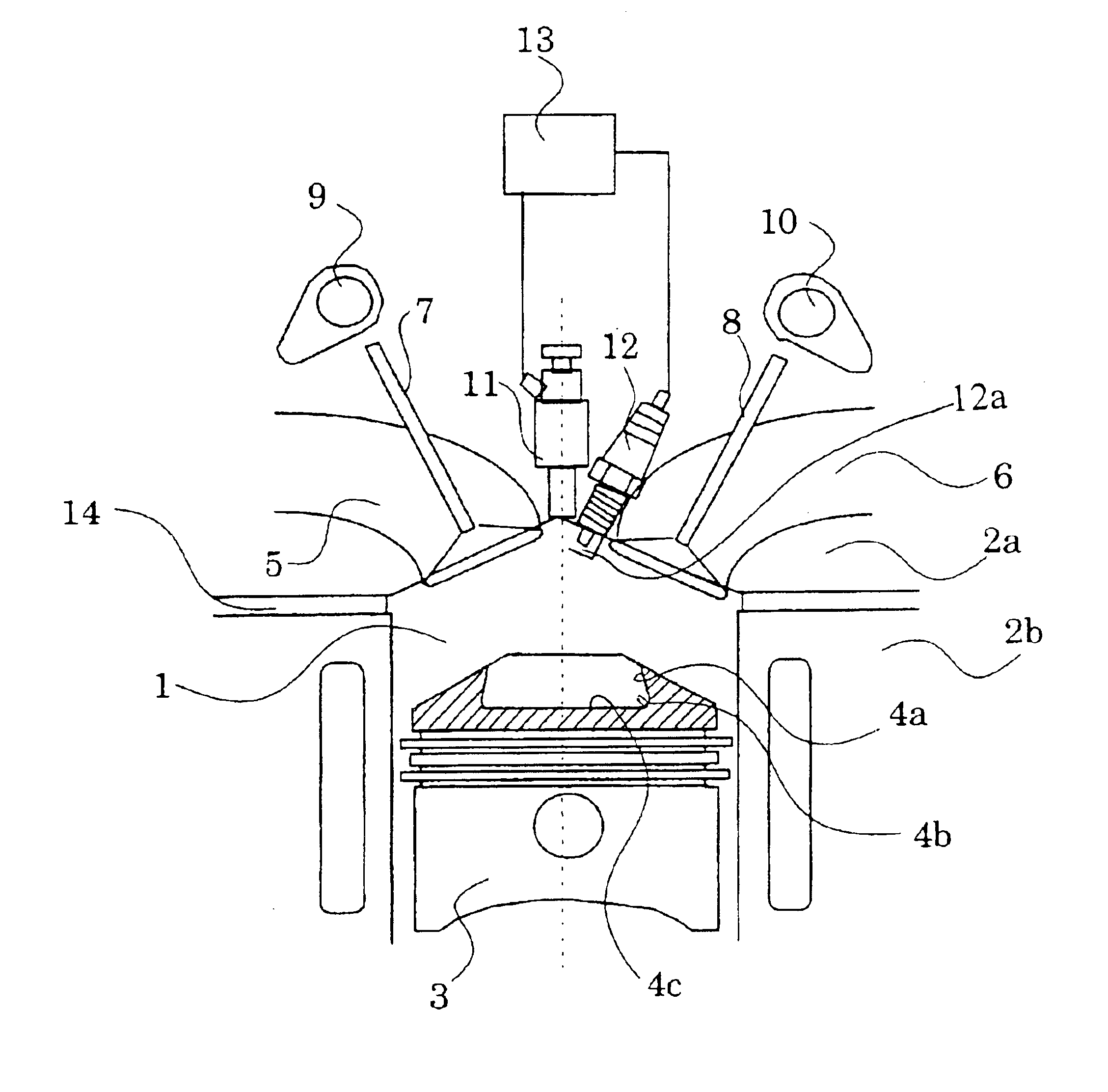

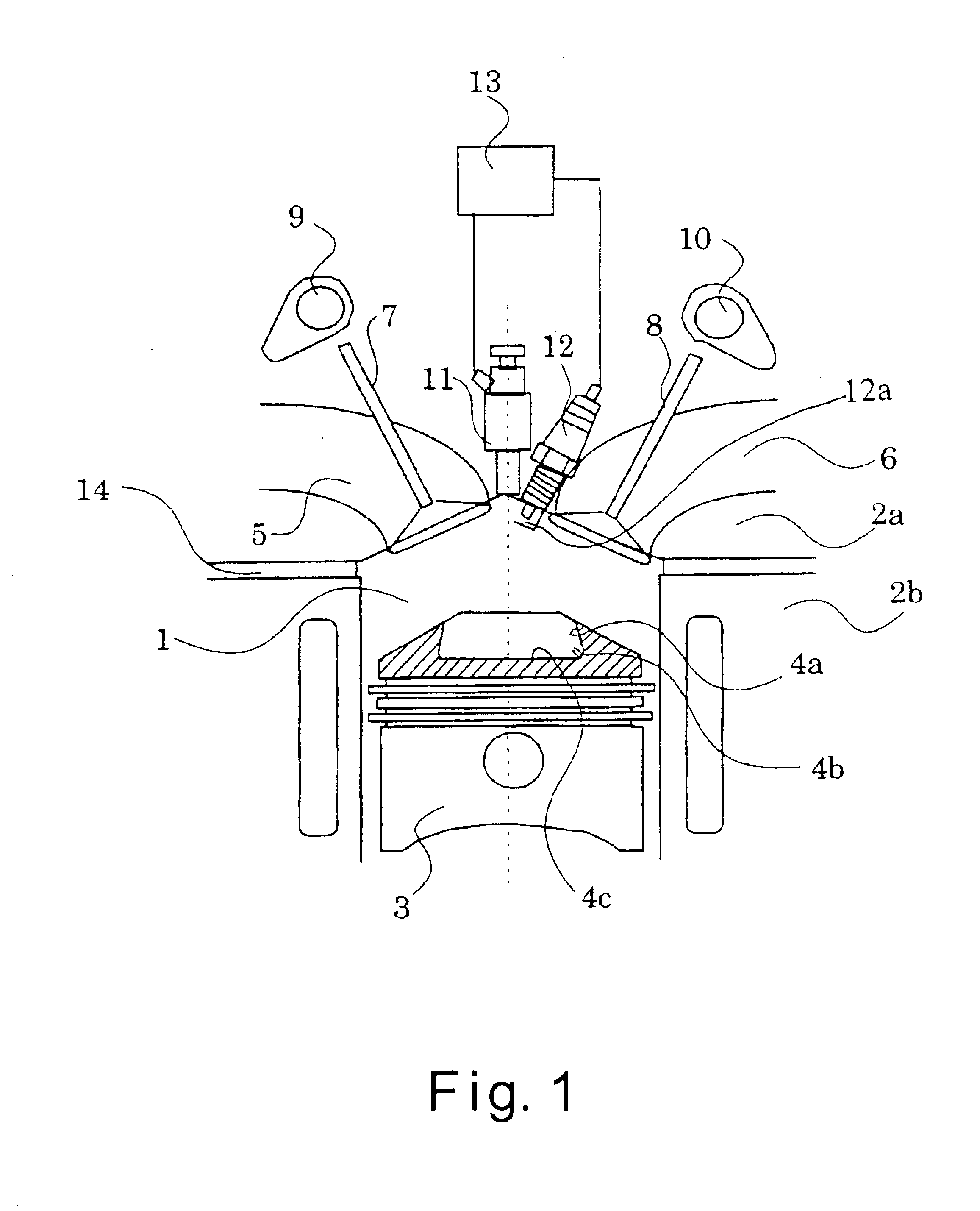

Direct fuel injection engine

A direct fuel injection engine basically comprises a combustion chamber, a piston with a cavity, a fuel injection valve, a spark plug and a control unit. The fuel injection valve is configured and arranged to directly inject a fuel stream into the combustion chamber in a substantially constant hollow circular cone shape in a stratified combustion region. The control unit is configured to ignite a first air-fuel mixture formed directly after the fuel stream is injected and prior to a majority of the fuel stream striking the cavity when the direct fuel injection engine is operating in a low-load stratified combustion region, and to ignite a second air-fuel mixture formed after a majority of the fuel stream is guided by the cavity toward an upper portion of the combustion chamber above the cavity when the direct fuel injection engine is operating in a high-load stratified combustion region.

Owner:NISSAN MOTOR CO LTD

Exhaust gas recirculation methods and apparatus for reducing NOx emissions from internal combustion engines

InactiveUS7302939B2Reduce sensitivityFavorable ignition environmentNon-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesExhaust gas recirculation

A method of operating an internal combustion engine employs exhaust gas recirculation (EGR) in combination with directly injected gaseous fuels that are burned within the engine in a stratified combustion mode. An engine that employs EGR includes an injector adapted to provide a high pressure quantity of fuel into a combustion chamber within a given pressure range, at a given angle and through a nozzle hole size to help provide for EGR tolerance and, consequently, reduce emissions.

Owner:WESTPORT POWER

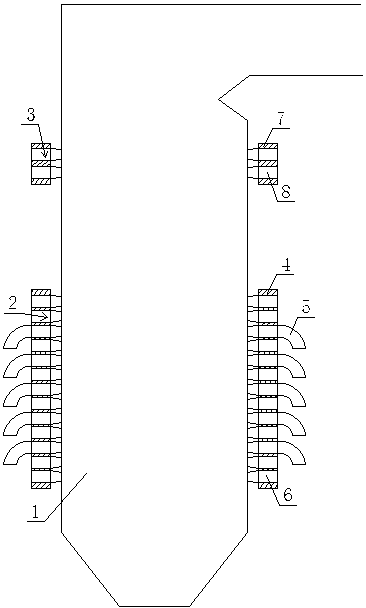

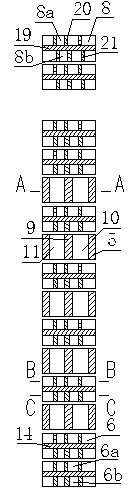

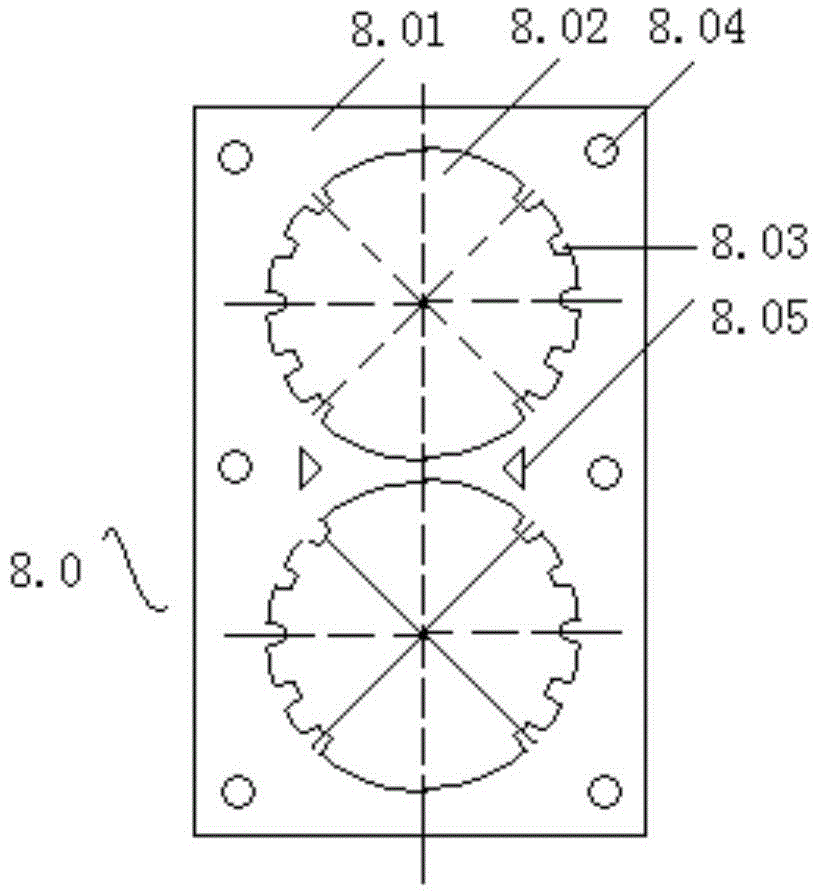

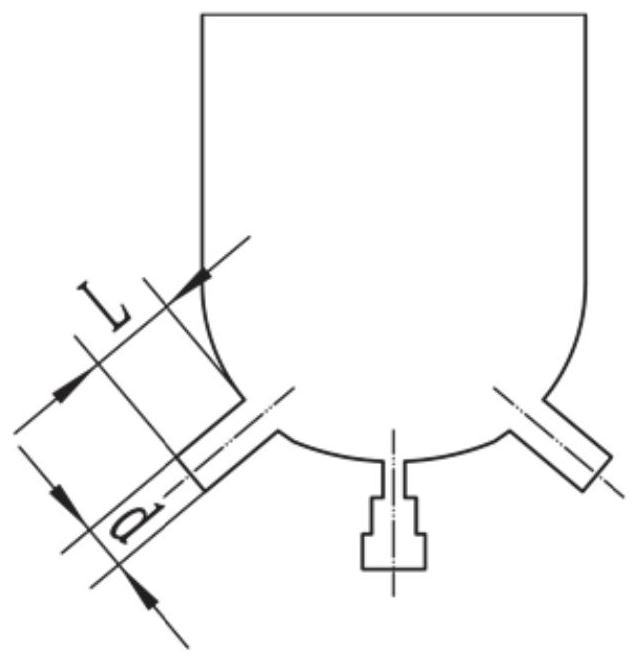

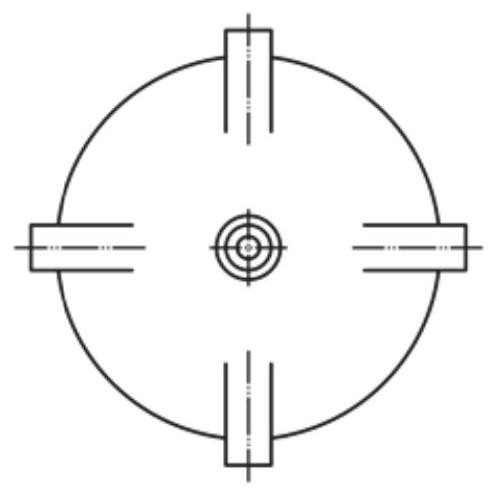

Multi-stage stratified combustion system and method for primary air and secondary air of boiler

ActiveCN103216821ARigid enoughWell mixedCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemSpray nozzle

The invention discloses a multi-stage stratified combustion system and a multi-stage stratified combustion method for primary air and secondary air of a boiler. The multi-stage stratified combustion system comprises combustors and air after-combustion devices, which are arranged on the four corners of a furnace chamber; each combustor comprises a secondary air box, at least one primary air tube and at least one primary secondary air spray nozzle; each air after-combustion device comprises an after-combustion air box and at least one after-combustion air spray nozzle; the secondary air boxes and the after-combustion air boxes are connected with a main air duct by the respective air tubes; the primary air tube spray nozzle is divided into a thick primary air spray nozzle and a thin primary air spray nozzle; the primary secondary air spray nozzle is divided into a secondary direct-blowing air spray nozzle and a secondary deviation-blowing air spray nozzle; the after-combustion air spray nozzle is divided into an after-combustion direct-blowing air spray nozzle and an after-combustion deviation-blowing air spray nozzle; and an effect of covering powder by air is formed during the combustion process by virtue of the multi-stage stratification of the primary air and the secondary air. The multi-stage stratified combustion method and the multi-stage stratified combustion method for the primary air and the secondary air of the boiler not only can be used for ensuring the ultralow emission of NOx and improving the combustion efficiency of the pulverized coal, but also can be used for preventing the agglomeration and the high-temperature corrosion of the water-cooling wall and reducing the thermal deviation of the heating area at the outlet of the furnace chamber.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

Direct injection type internal combustion engine

InactiveUS20010023677A1Easy dischargeElectrical controlInternal combustion piston enginesStart timeCombustion

In a starting time in which an air motion is little, a means for heightening the motion is added, from the starting time a stratification combustion operation is enable to carry out, and a discharge of an unburned fuel is minimized. From the starting time of an engine (from the firstly combustion cylinder) it is possible to carry out a stable stratification combustion. In accordance with the stratification combustion in the exhaust air a large quantity of the surplus oxygen remains. In the engine in the exhaust stroke twice (two time) fuel injection is carried out and the after burn phenomenon is caused in the exhaust port and then the exhaust gas temperature can be raised.

Owner:HITACHI LTD

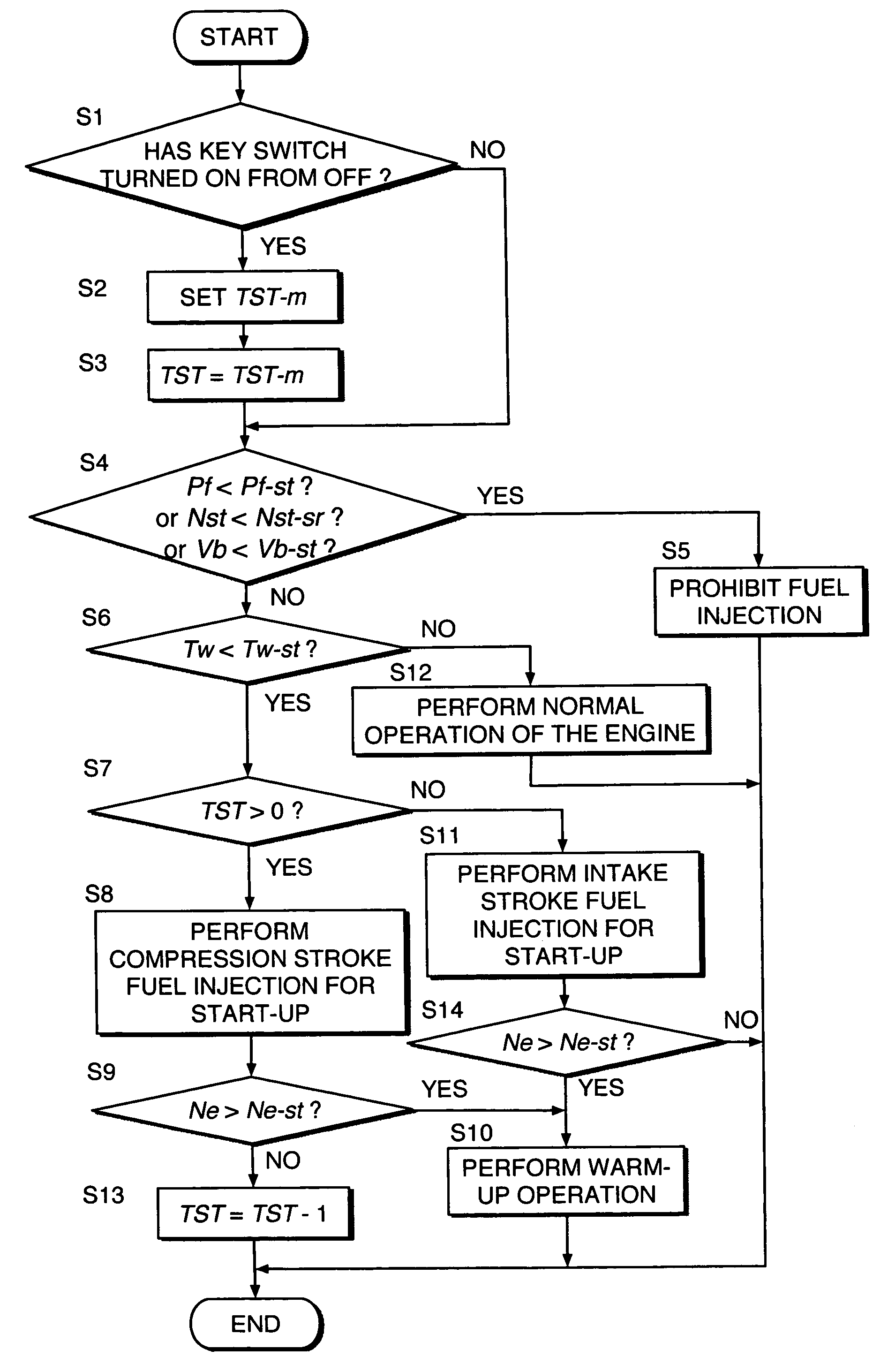

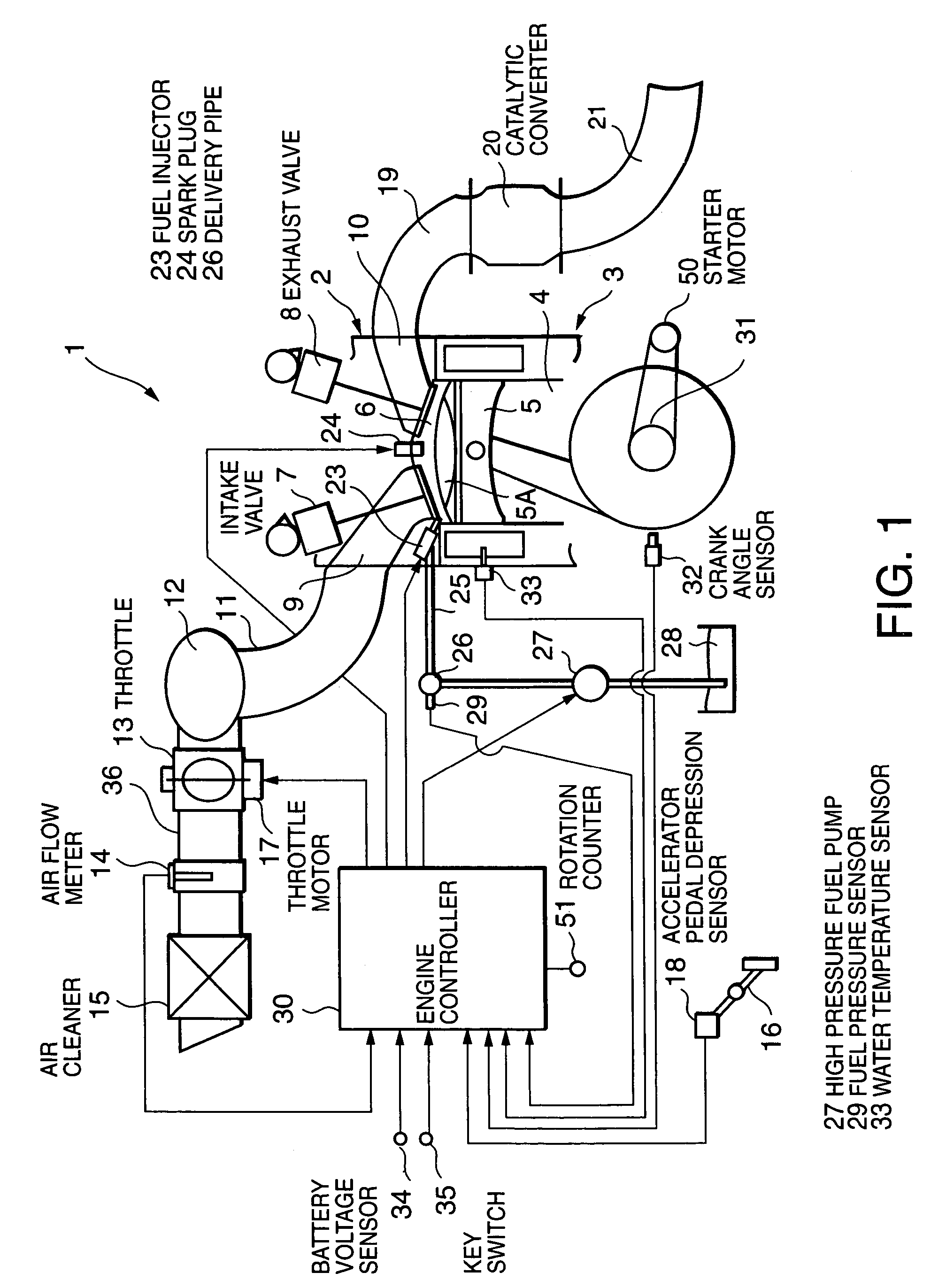

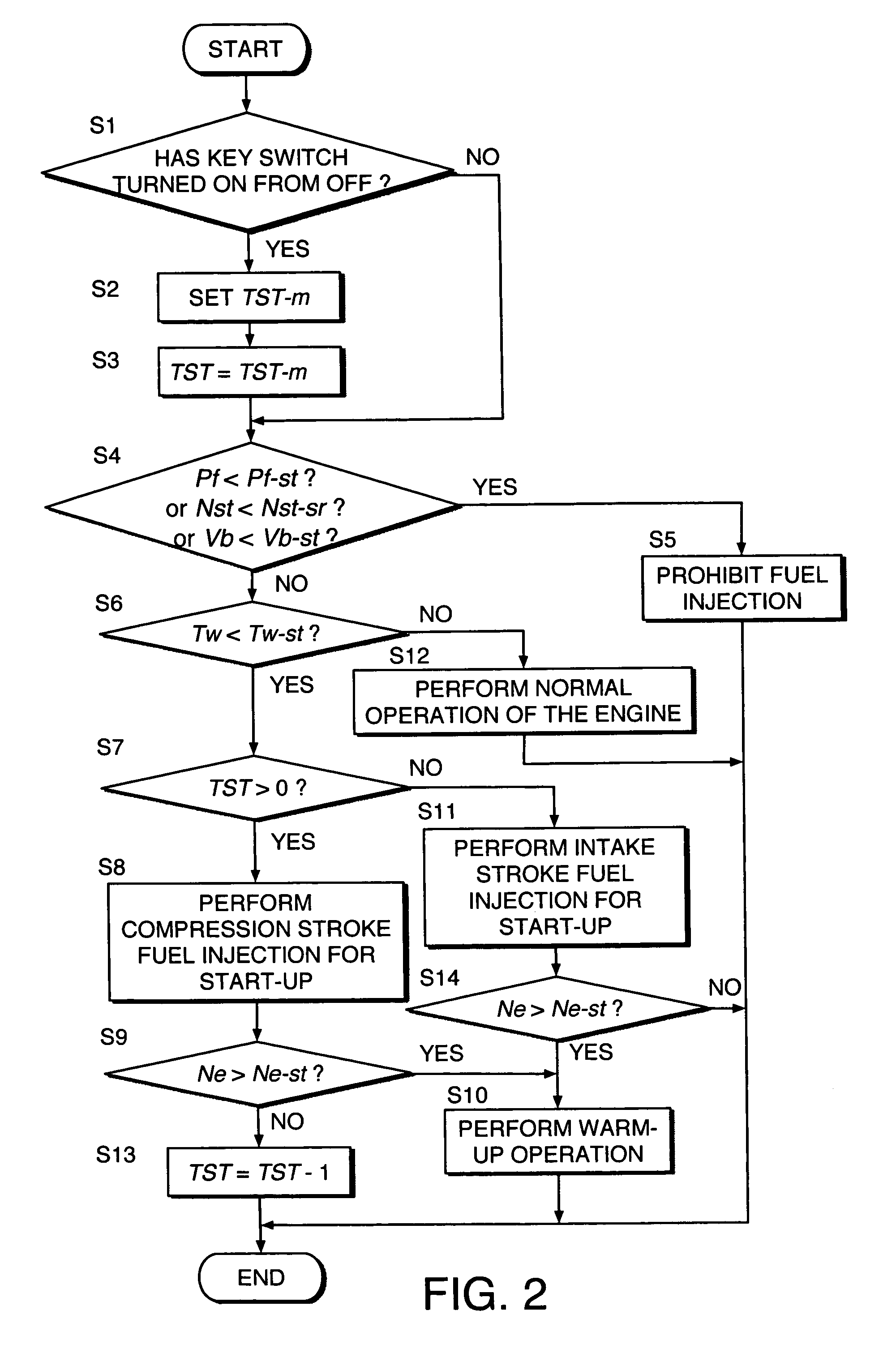

Start-up control of in-cylinder fuel injection spark ignition internal combustion engine

ActiveUS6978759B2Favorable and stable startabilityElectrical controlCombustion enginesStart upFuel injection

An in-cylinder fuel injection internal combustion engine (1) is started up by means of compression stroke fuel injection from the beginning of cranking of the engine (1) to the end of a stratified combustion start-up period TST. If the engine (1) reaches complete combustion during the period, a warm-up operation is begun immediately. If the engine (1) does not reach complete combustion during the period, start-up of the engine (1) is continued using intake stroke fuel injection. By means of this control, stable start-up is assured while suppressing the discharge of unburned fuel during start-up of the engine (1).

Owner:NISSAN MOTOR CO LTD

Low-pollution combustor head structure with main combustion stage oblique jetting nozzle

ActiveCN107559881AIncrease mixing intensityPremixed gas premixed evenlyContinuous combustion chamberCombustorPollutant emissions

The invention discloses a low-pollution combustor head structure with a main combustion stage oblique jetting nozzle. The low-pollution combustor head structure is composed of a main combustion stageblade, a pre-combustion stage blade, a main combustion stage premixing channel, a Venturi tube, an interstage section, the main combustion stage oblique jetting nozzle and a pre-combustion stage nozzle. A combustor adopts a center grading combustion structure mode, specifically, in the main combustion stage, air passes through an axial swirler to be blended with obliquely jetted fuel, and the mixture passes through a pre-mixing section, so that uniformly mixed gas is formed; and in the pre-combustion stage, air flows into the combustor through a two-stage radial swirler, fuel is jetted out bya dual-oil-path nozzle to be blended with air for diffusive combustion, and a stable ignition source is provided for the combustor. By means of the oblique jetting structure, fuel and air can be sufficiently mixed in the main combustion stage, the fuel and air premixing uniformity is improved, and thus pollutant emission is reduced; and as a pneumatic flow guide structure is adopted for the head,flames of the main combustion stage and the pre-combustion stage are burnt layer by layer, and the ignition performance and combustion efficiency under small conditions and the flame stability and discharging performance under large conditions are improved advantageously.

Owner:BEIHANG UNIV

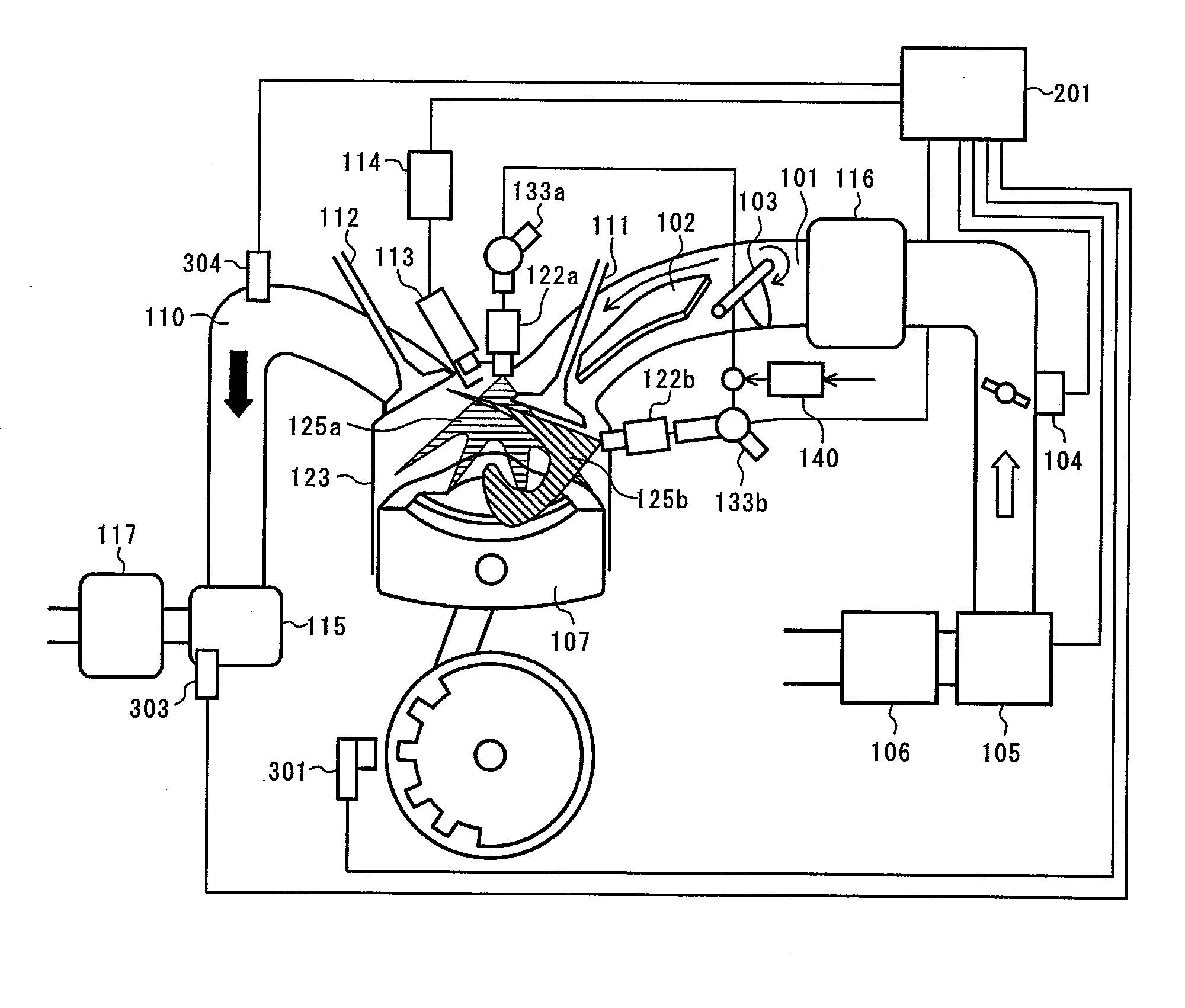

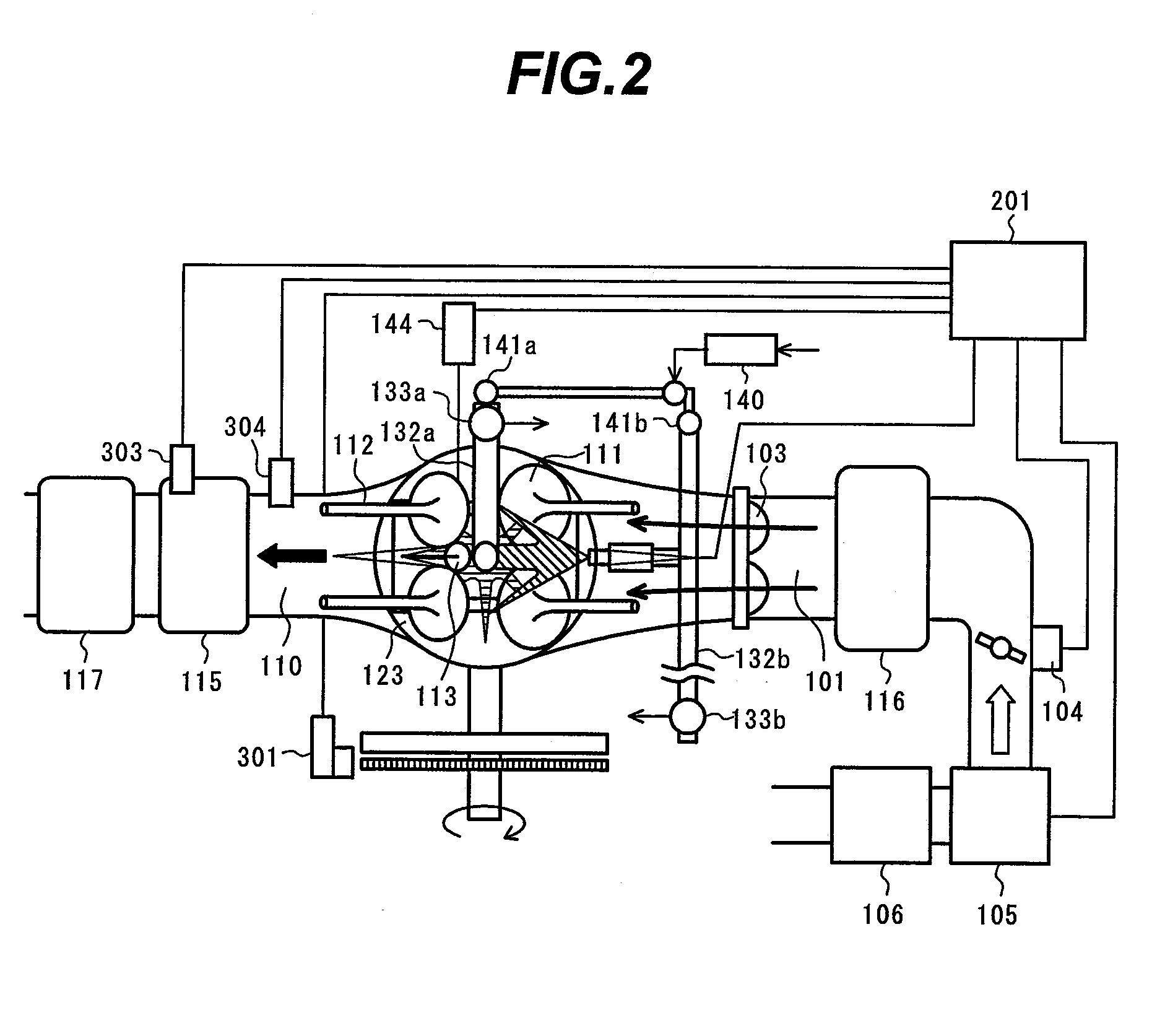

Gasoline engine

InactiveUS20100147261A1Increase exhaust temperatureReduce HCElectrical controlInternal combustion piston enginesCombustionGasoline

A gasoline engine is provided that effectively uses two injectors to enhance homogeneity of mixture at the time of high-load for improving output power and to enable stable operation also when stratified or weak stratified combustion is performed.One cylinder is provided with a first injector 122a and a second injector 122b, which directly inject fuel into the cylinder. An ECU 201 uses one or both the injectors to perform fuel injection during one combustion cycle depending on operating conditions.

Owner:HITACHI LTD

Valve timing controller, valve timing control method and engine control unit for internal combustion engine

InactiveUS20020029757A1Effective controlAppropriate settingValve arrangementsElectrical controlExhaust valveCombustion

A valve timing controller for use in a direct injection type internal combustion engine is provided for enabling a valve timing to be appropriately set in accordance with a load on the engine even in a stratified combustion mode. The internal combustion engine has a valve timing changing mechanism for changing a valve timing of at least one of an intake valve and an exhaust valve so that it is operated in a combustion mode switched between a uniform combustion mode in which a fuel is injected into a cylinder during an intake stroke and a stratified combustion mode in which a fuel is injected into a cylinder in a compression stroke. The valve timing controller comprises a required torque determining unit for determining a required torque outputted by the internal combustion engine based on the engine rotational speed and accelerator pedal opening, and a valve timing determining unit for determining the valve timing in accordance with the required torque and the engine rotational speed.

Owner:HONDA MOTOR CO LTD

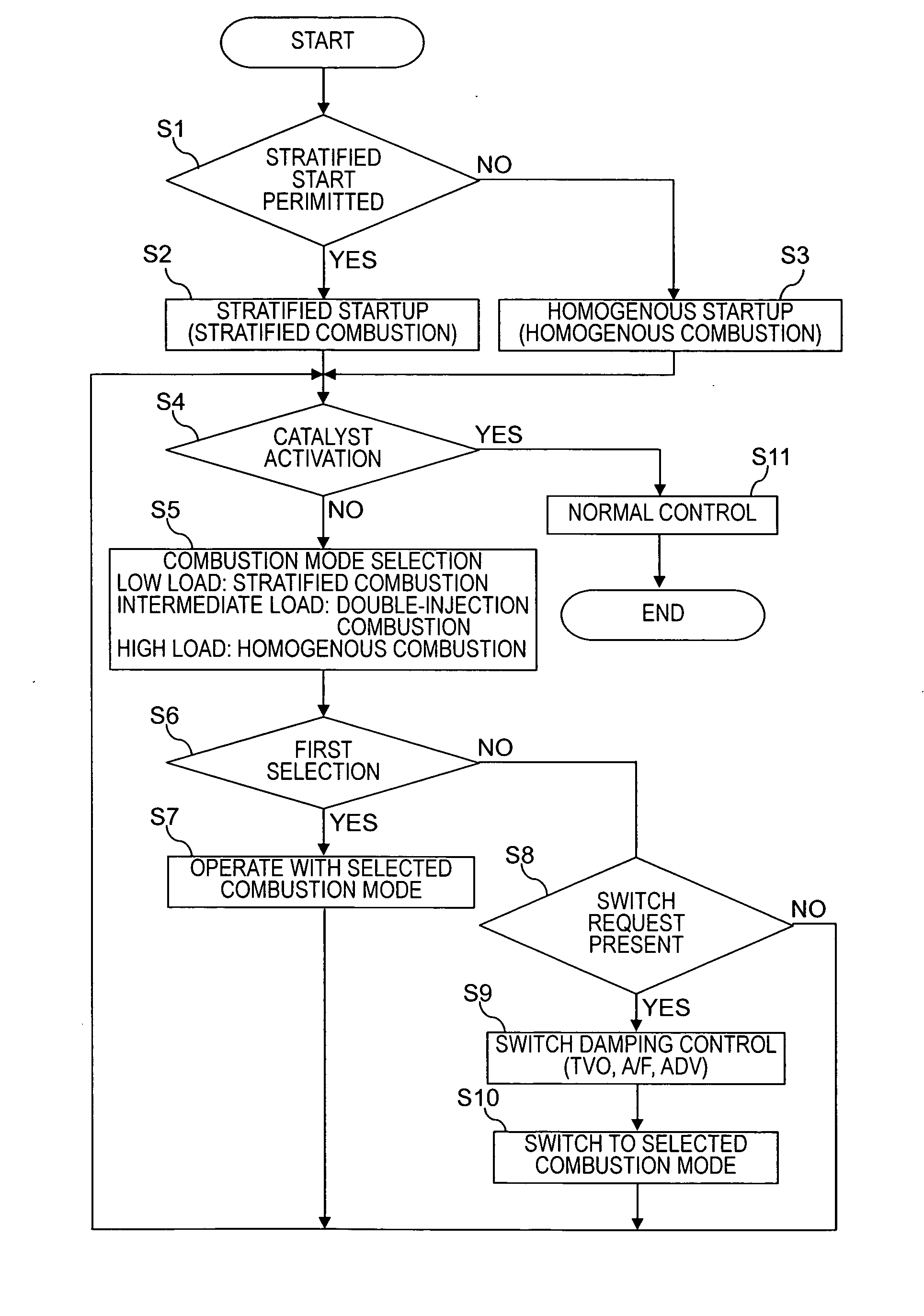

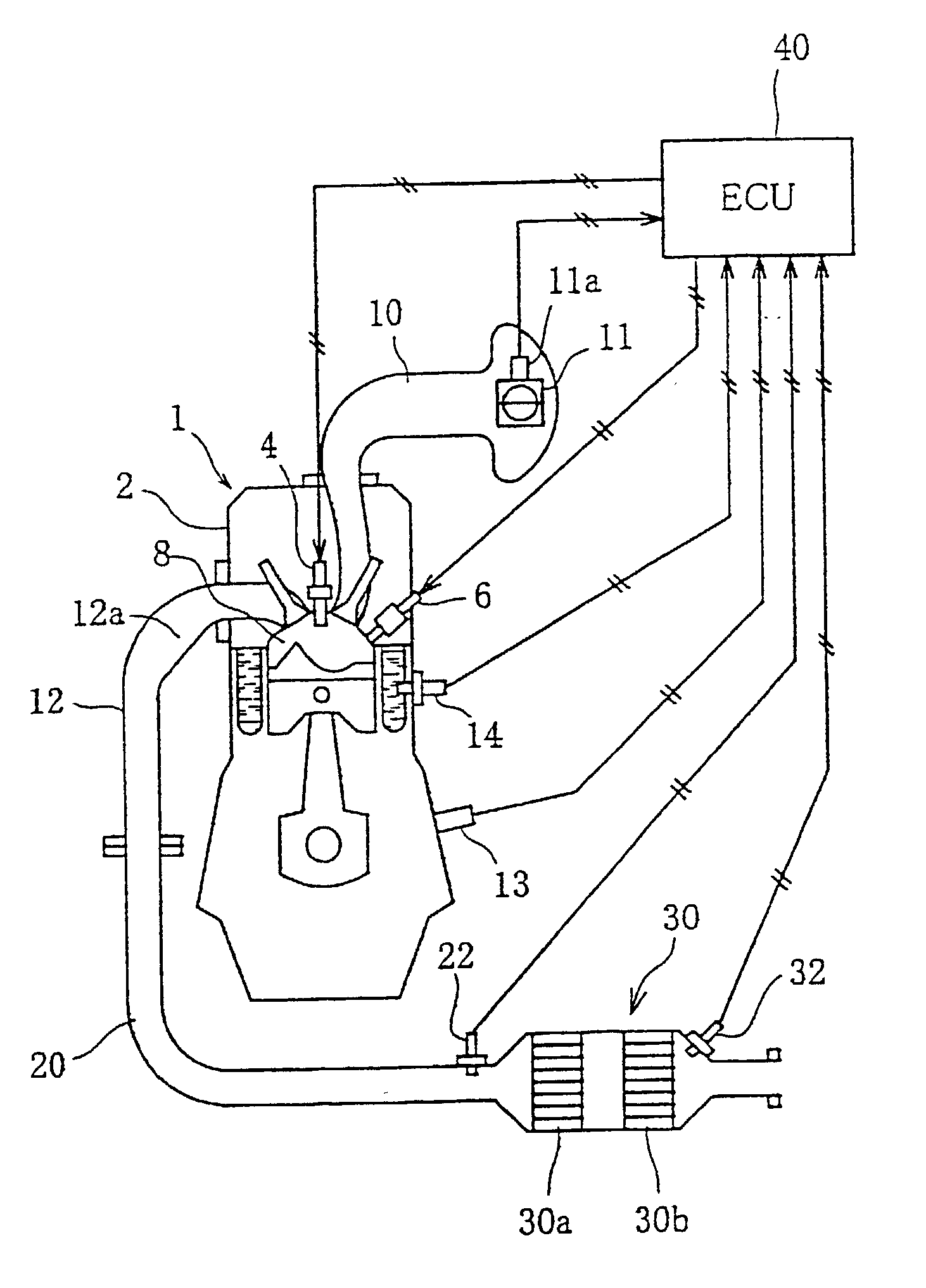

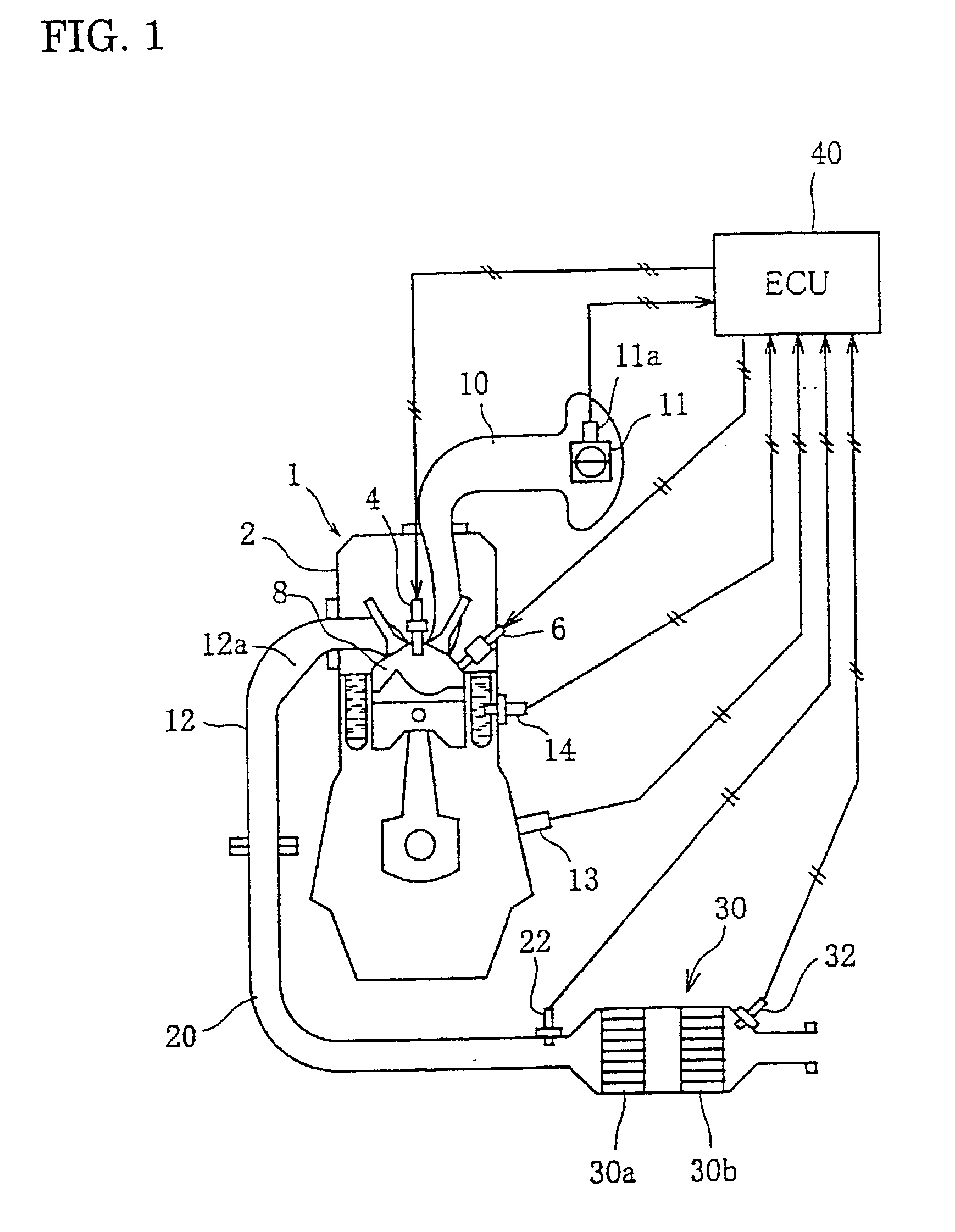

Direct fuel injection/spark ignition engine control device

An engine control device is configured to cause an engine to operate at the optimum combustion mode according to the load when warming up of an emissions purification catalyst is required, and to obtain reduced HC discharged from the engine and accelerated warm-up of the catalyst. The engine control device performs stratified combustion with a compression stroke injection in a low-load region according to the engine load, and performs double-injection combustion with an intake stroke injection and a compression stroke injection in an intermediate load region, when warming up of the catalyst is required. In a high-load region, the engine control device performs homogenous combustion with an intake stroke injection.

Owner:NISSAN MOTOR CO LTD

Cylinder injection type internal combustion engine

InactiveUS20020129600A1Improve efficiencyImprove featuresElectrical controlInternal combustion piston enginesExternal combustion engineExhaust fumes

When an increase in a temperature of an exhaust-gas purifying catalyst device in an in-cylinder injection type internal combustion engine is demanded, a temperature-increase control section in an electronic control unit accomplishes stratified combustion by causing each fuel injection valve to inject fuel directly into the associated combustion chamber in a compression stroke in such a way that the air-fuel ratio of the internal combustion engine is in a vicinity of a stoichiometric air-fuel ratio. This allows the temperature of the exhaust-gas purifying catalyst device to be maintained or increased without increasing fuel consumption.

Owner:MITSUBISHI MOTORS CORP

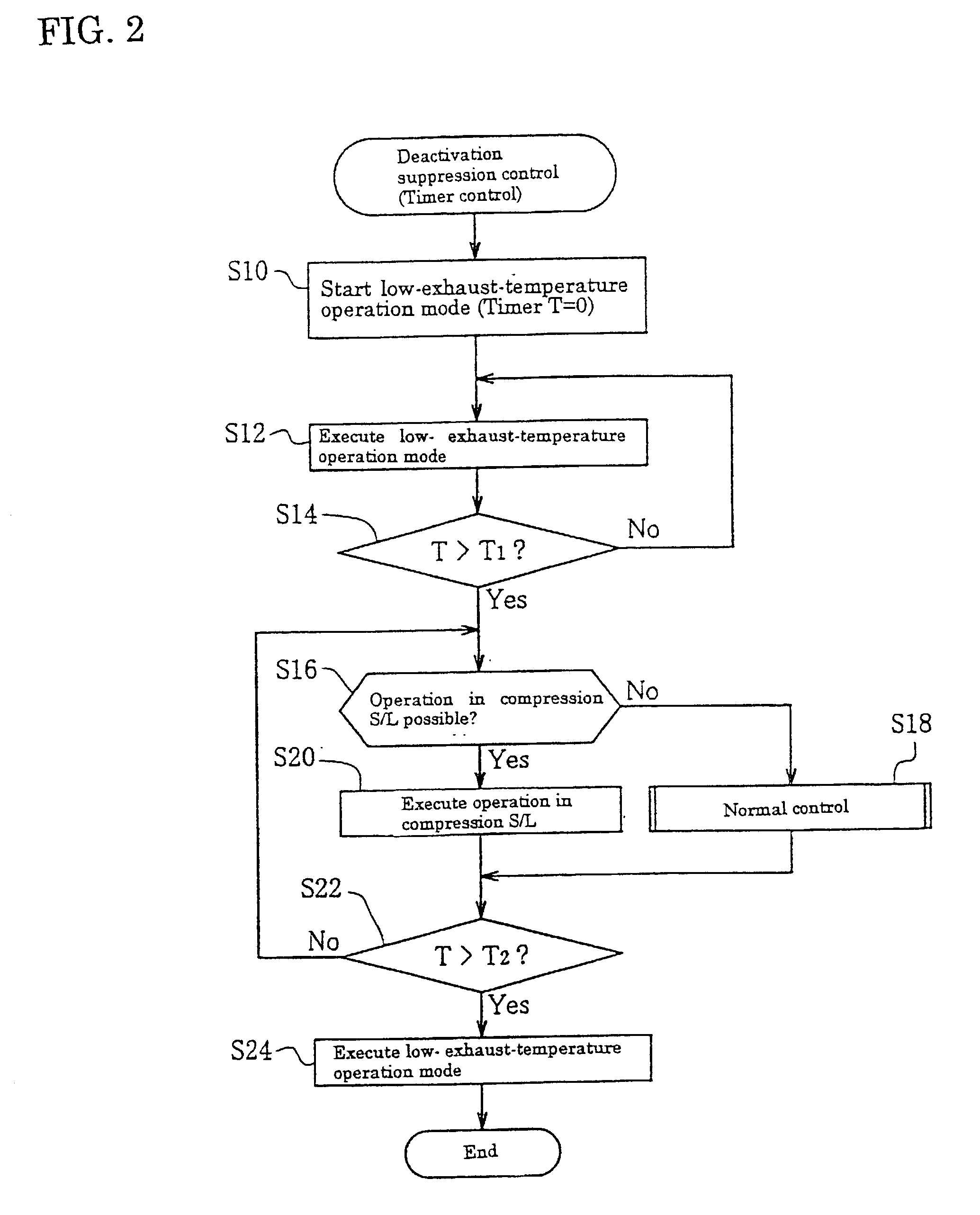

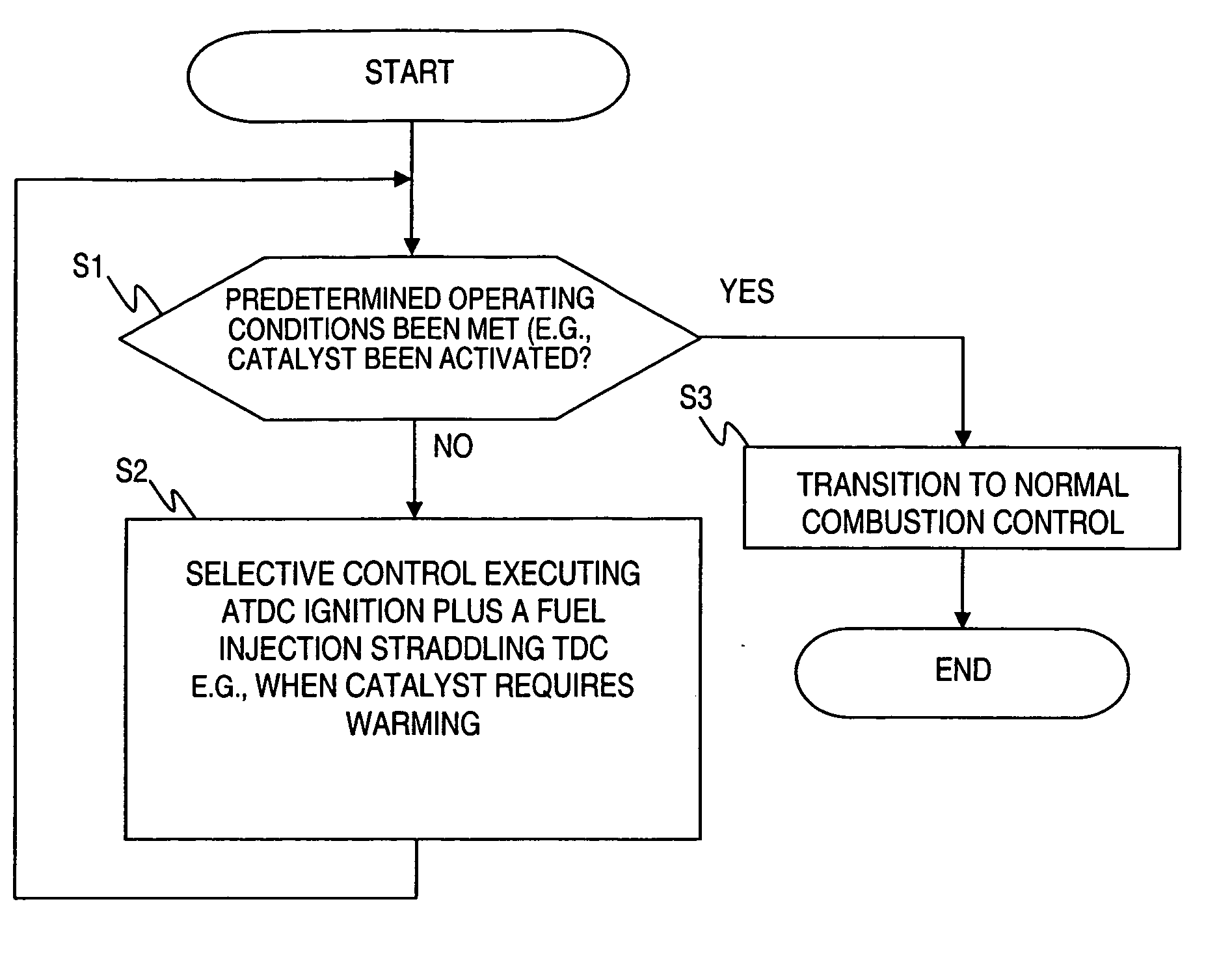

Direct fuel injection/spark ignition engine control device

ActiveUS20050161021A1Improve combustion stabilityReduce HCElectrical controlInternal combustion piston enginesStart timeTop dead center

A control apparatus is configured to achieve considerably delayed ignition timing and combustion stability, and to bring about an increase in exhaust gas temperature and a reduction in HC discharge when the engine is cold. Normal stratified combustion operation and homogeneous combustion operation are carried out when warming has been completed and the coolant temperature of the internal combustion engine has exceeded 80° C. In an injection operation at the top dead center, the injection start timing ITS occurs prior to compression top dead center (TDC) and the injection end timing ITE occurs after compression top dead center (TDC), whereby fuel injection is carried out so as to straddle the compression top dead center. The ignition timing ADV occurs after compression top dead center (TDC) and ignition occurs with a timing that is delayed from the injection start timing ITS.

Owner:NISSAN MOTOR CO LTD

Ignition time controller, ignition time control method and engine control unit for internal combustion engine

InactiveUS20020033164A1Electrical controlInternal combustion piston enginesExternal combustion engineEngineering

An ignition time controller for an internal combustion engine is provided for setting an ignition time such that it can rapidly converge to an appropriate value in accordance with a change in intake characteristics associated with a change in cam phase in either of a uniform combustion mode and a stratified combustion mode in a direct injection type internal combustion engine having a cam phase changing mechanism. The ignition time controller comprises a required torque determining unit for determining a required torque outputted by the internal combustion engine based on an engine rotational speed and an accelerator opening, a fuel injection time determining unit for determining a time at which a fuel is injected into a cylinder, a basic ignition time determining unit for determining a basic ignition time based on the engine rotational speed and the required torque in the uniform combustion mode and based on the engine rotational speed and the fuel injection time in the stratified combustion mode, and a basic ignition time correcting unit for correcting the basic ignition time in accordance with a cam phase deviation between an actual cam phase and a target cam phase.

Owner:HONDA MOTOR CO LTD

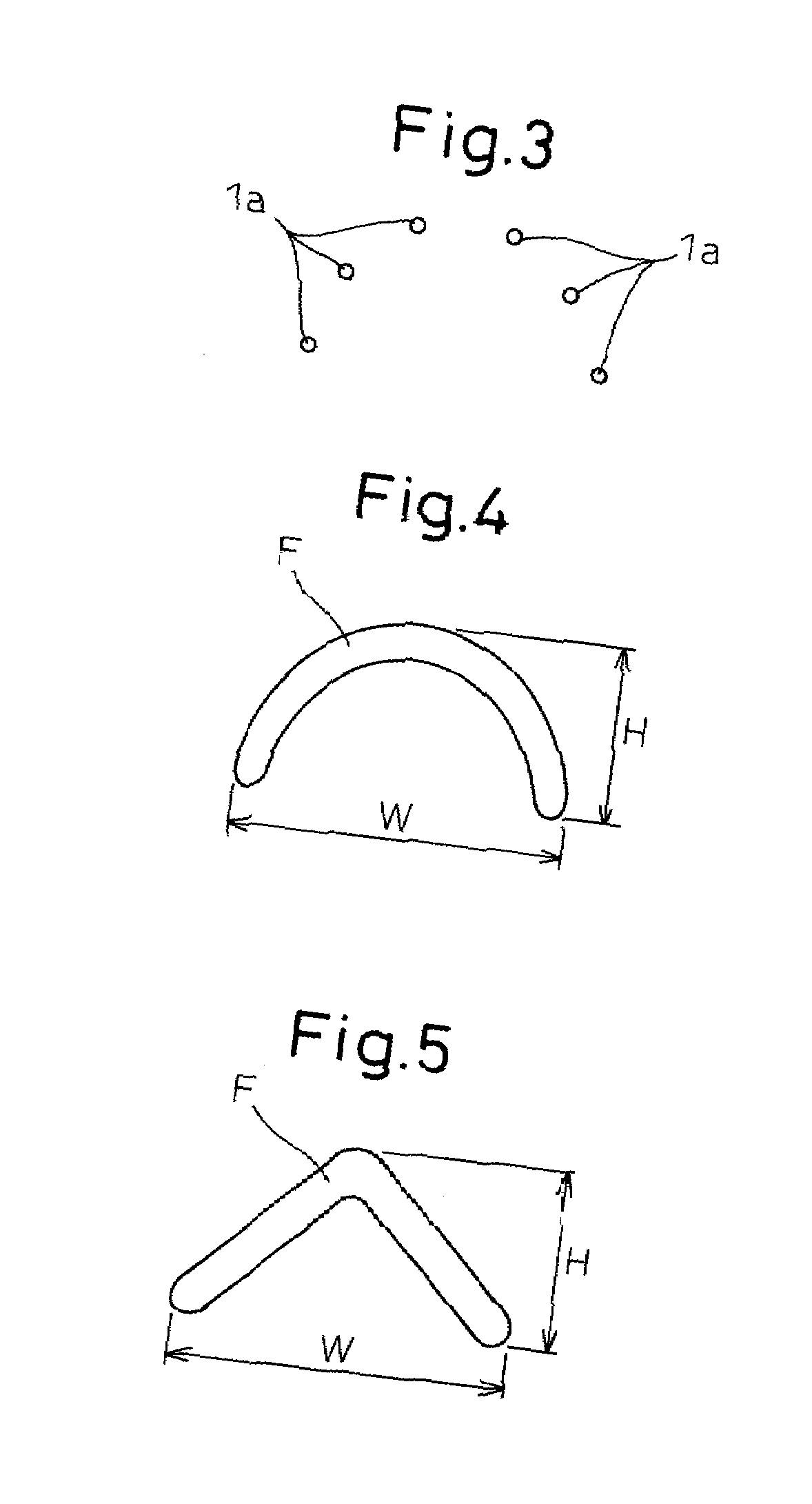

Direct fuel injection engine

InactiveUS20050098145A1Stable stratified combustionInternal combustion piston enginesPistonsPistonFuel injection

A direct fuel injection engine is provided that an appropriate stratified fuel-air mixture is formed to conduct good stratified combustion over a wide range of loads. The engine has a fuel injection valve that is arranged at an upper surface of the combustion chamber on or near the center reciprocation axis of the piston and oriented such that the injection center axis of the fuel stream injected therefrom is slanted with respect to the center reciprocation axis of the piston. The piston is disposed in the combustion chamber to move along a cylinder center axis. The piston has a top surface having a first outer cavity having a first cavity center axis, and a second inner cavity located in the outer cavity. The second inner cavity has a second cavity center axis offset from the cylinder center axis of the piston in a direction perpendicular to the cylinder center axis.

Owner:NISSAN MOTOR CO LTD

Cylinder injection type spark ignition internal combustion engine

InactiveUS20090194066A1Avoid it happening againReliably burnedElectrical controlInternal combustion piston enginesEngineeringPiston

An engine provided with a fuel injector for directly injecting fuel into a cylinder, a spark plug positioning a spark gap in a flight path of fuel injected from the fuel injector, and a cavity formed in a piston top face, wherein at the time of stratified combustion, the fuel injector injects substantially all of the fuel in a direction merging with a tumble flow, swirling in a longitudinal direction along the cavity at the compression stroke, along the swirl direction of the tumble flow and uses the spark plug to ignite the fuel while the fuel at the end period of injection is passing through the spark gap.

Owner:TOYOTA JIDOSHA KK +1

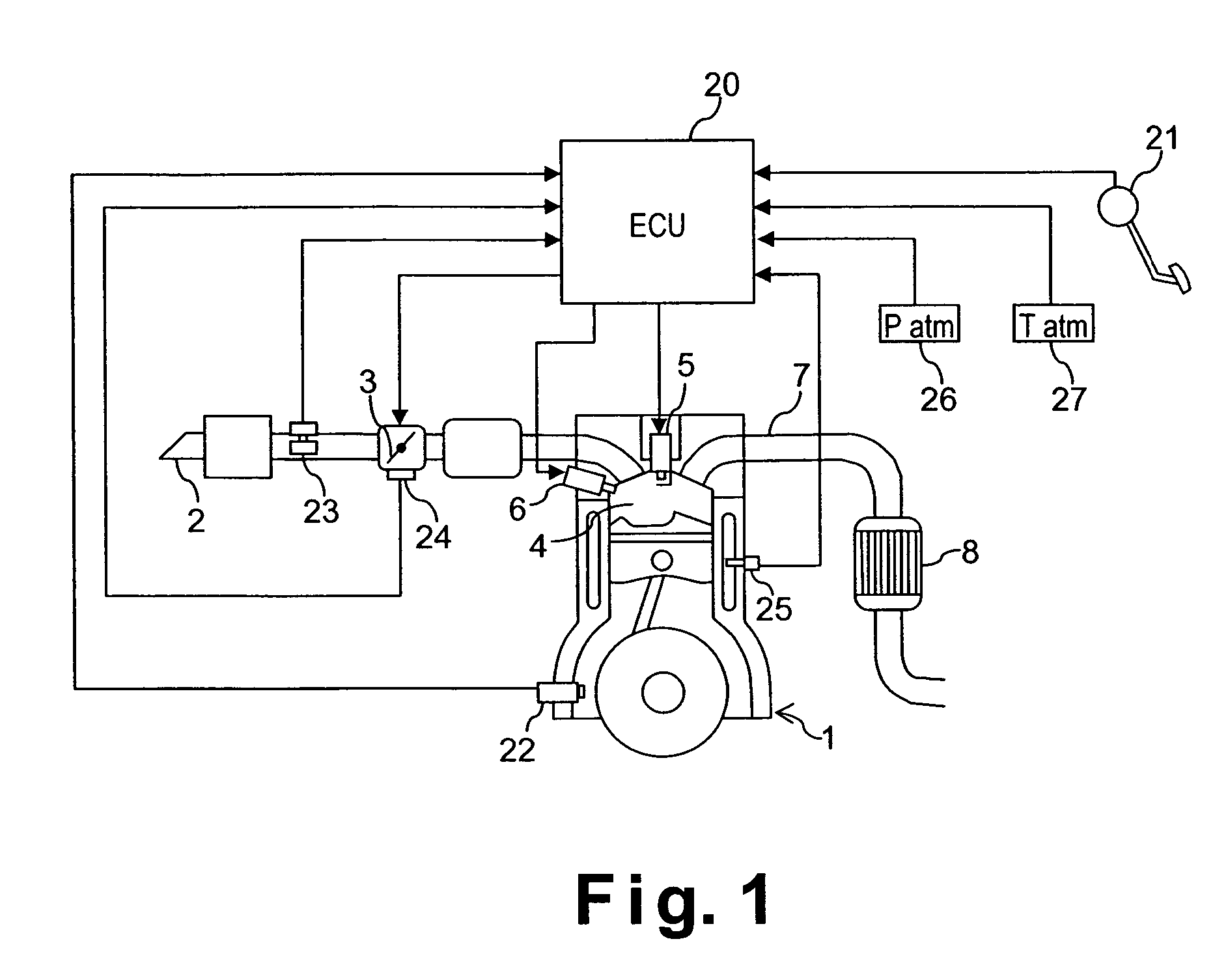

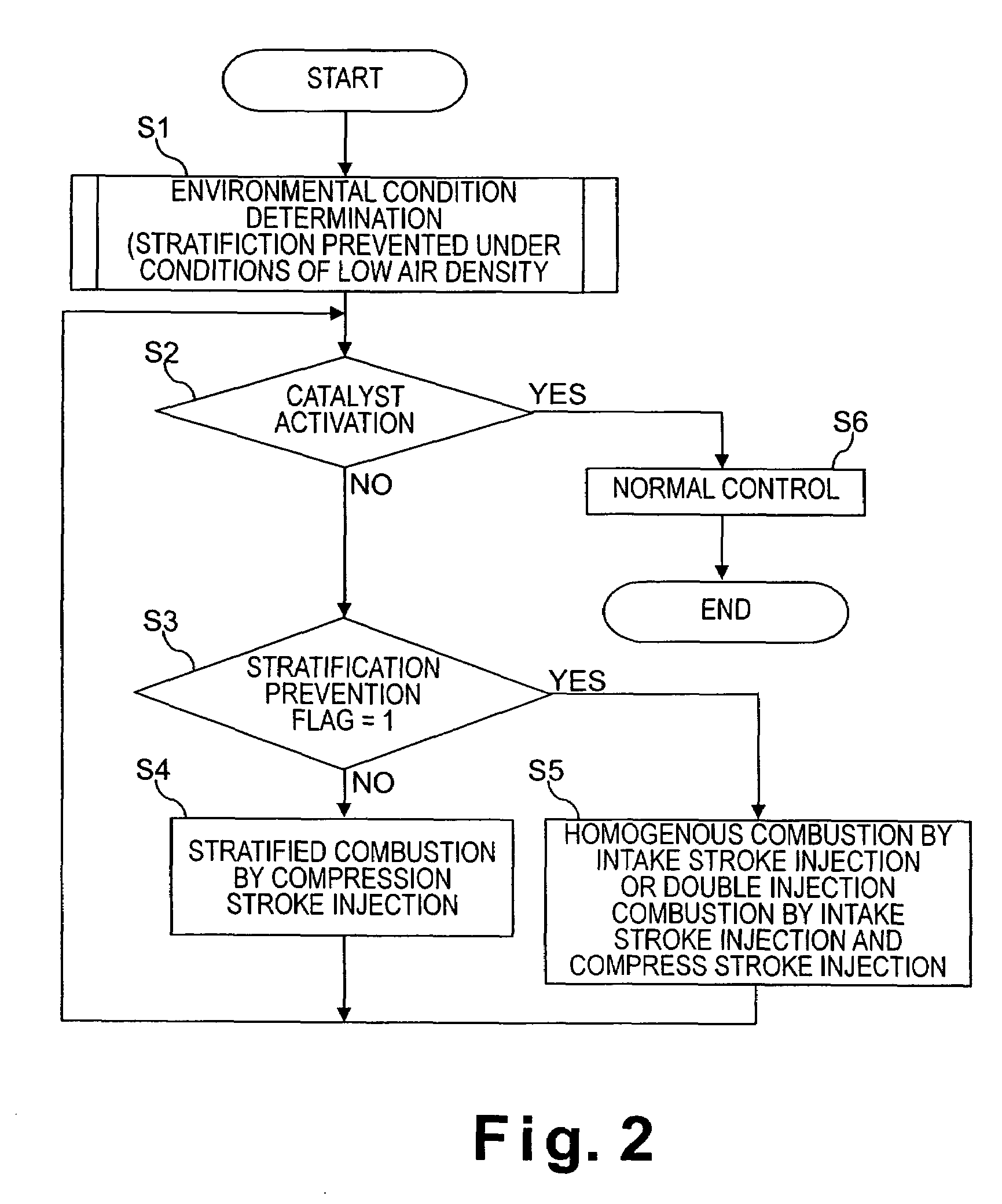

Direct fuel injection/spark ignition engine control device

An engine control device is configured to perform optimum combustion control according to environmental conditions when warming up of a catalyst for emission purification is required. The engine control device performs stratified combustion by the compression stroke injection at the time of startup, when warming up of the catalyst is required. However, under conditions of low air density, stratified combustion by compression stroke injection is prevented, and either homogenous combustion by intake stroke injection is performed, or double injection combustion by intake stroke injection and compression stroke injection is performed. Thus, the engine control device maintains starting properties and prevents adverse effects on engine operability.

Owner:NISSAN MOTOR CO LTD

Control system and method for internal combustion engine

InactiveUS6857414B2Good effectAnalogue computers for vehiclesElectrical controlCombustionControl system

There is provided a control system for an internal combustion engine, which is capable of matching an output torque of the engine with a demanded torque excellently when the combustion mode is switched, thereby enhancing drivability. A demanded fuel amount and a demanded torque of the engine are calculated according to detected operating conditions of the engine. A combustion mode is determined to be either the stratified combustion mode or the homogeneous combustion mode according to the demanded torque. A pre-switching demanded fuel injection time period and a pre-switching demanded torque are stored. When the combustion mode is switched, a switching-time demanded fuel amount (limit value) is calculated according to the stored pre-switching demanded fuel injection time period and pre-switching demanded torque, the current demanded torque, and an estimated combustion efficiency parameter.

Owner:HONDA MOTOR CO LTD

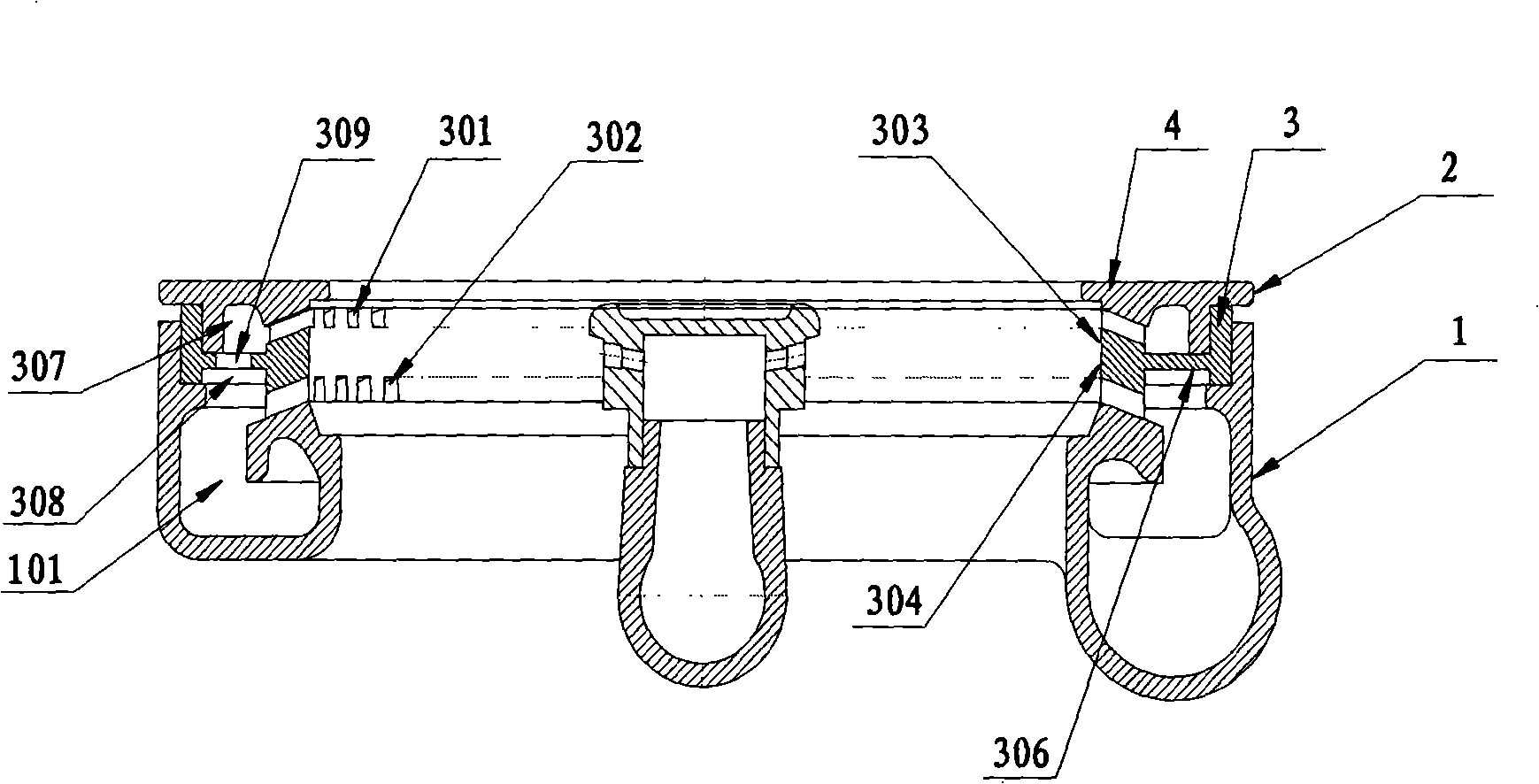

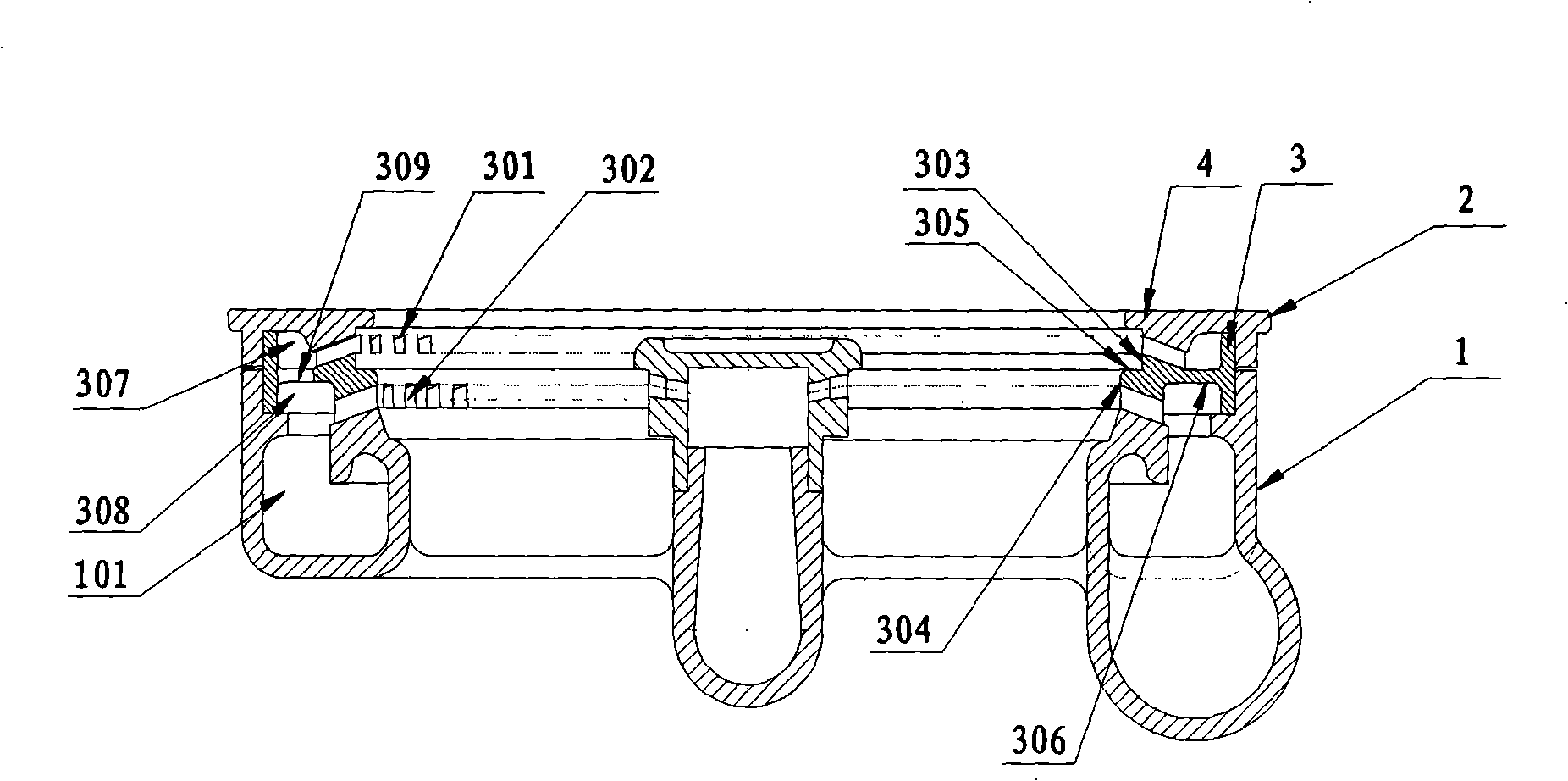

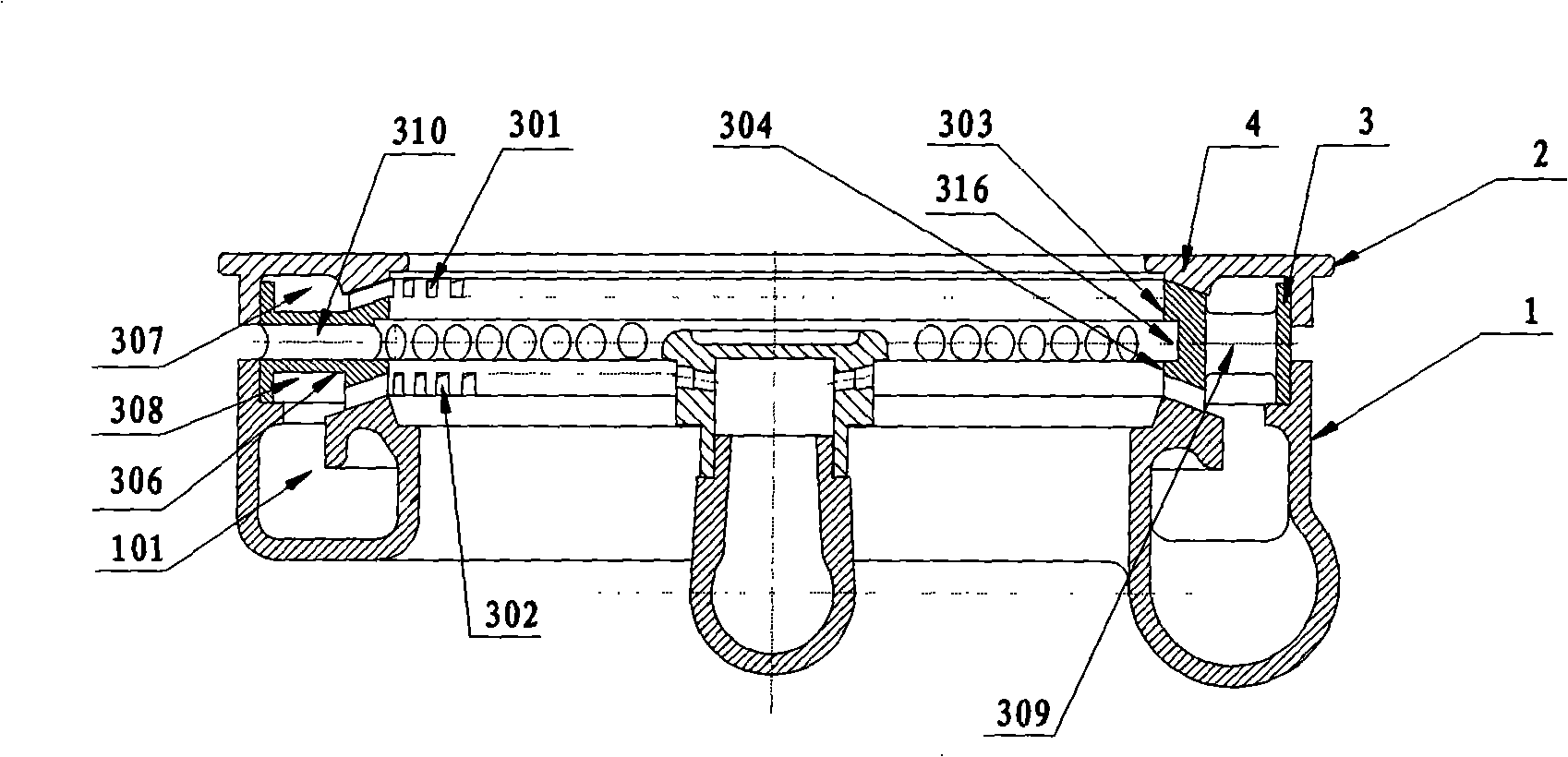

Combustor of inner flame gas range

The invention discloses a burner of an inner flame gas stove, which consists of a burner body and a fire distributer device; an upper layer fire hole and a lower layer fire hole are arranged on the fire distributer device and the direction of the outlets of the fire holes is inward, and an air channel is arranged or not arranged between the upper layer fire hole and the lower layer fire hole; a single inner cavity or two independent inner cavities is or are arranged; the two independent inner cavities are arranged so that the flame at the upper layer and the lower layer can be regulated independently; while the air channel is arranged so that the air supplementation can be more abundant. The burner utilizes multiple-layer fire holes, stratified combustion and multiple-layer cyclonic flame, and has the advantages of large heat flow, fierce fire power, high heat efficiency, low-CO and low-NOx in smoke gas, no fire hole blocking and the like.

Owner:吴成年 +1

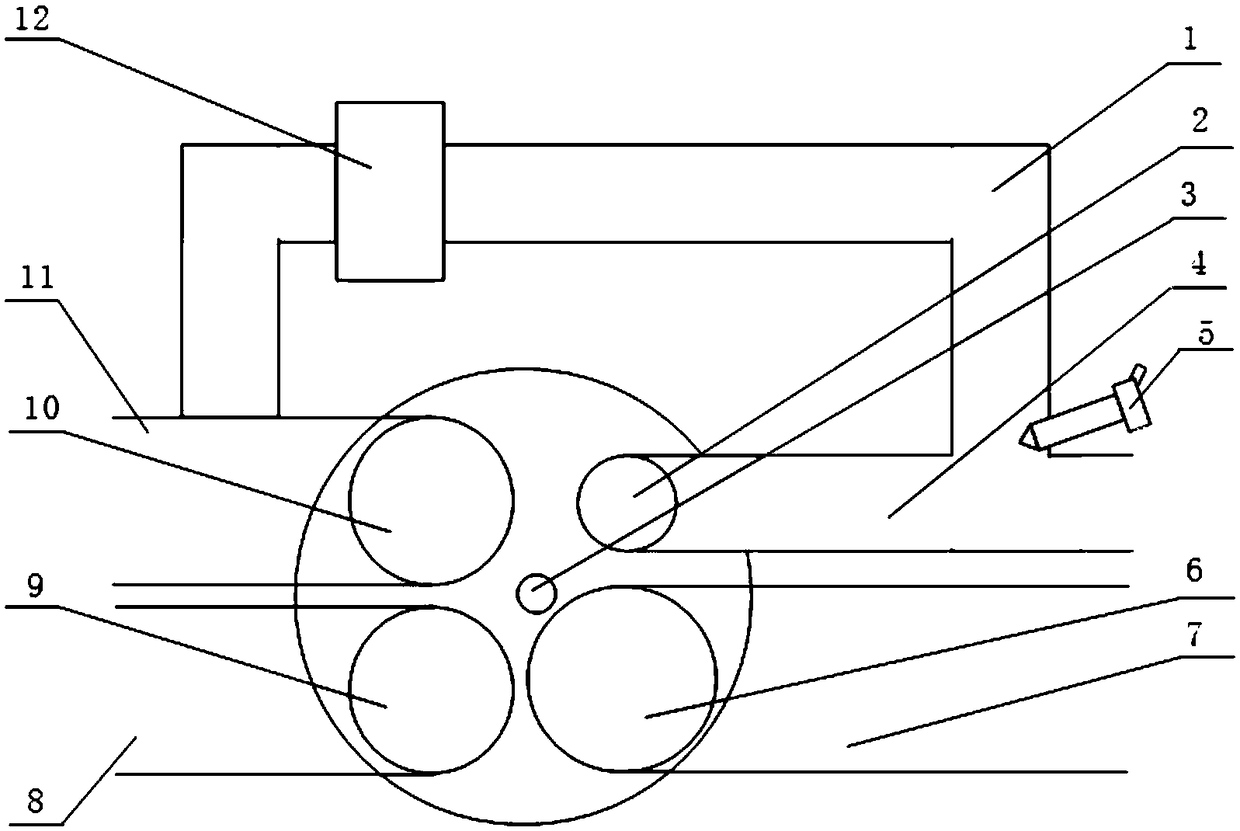

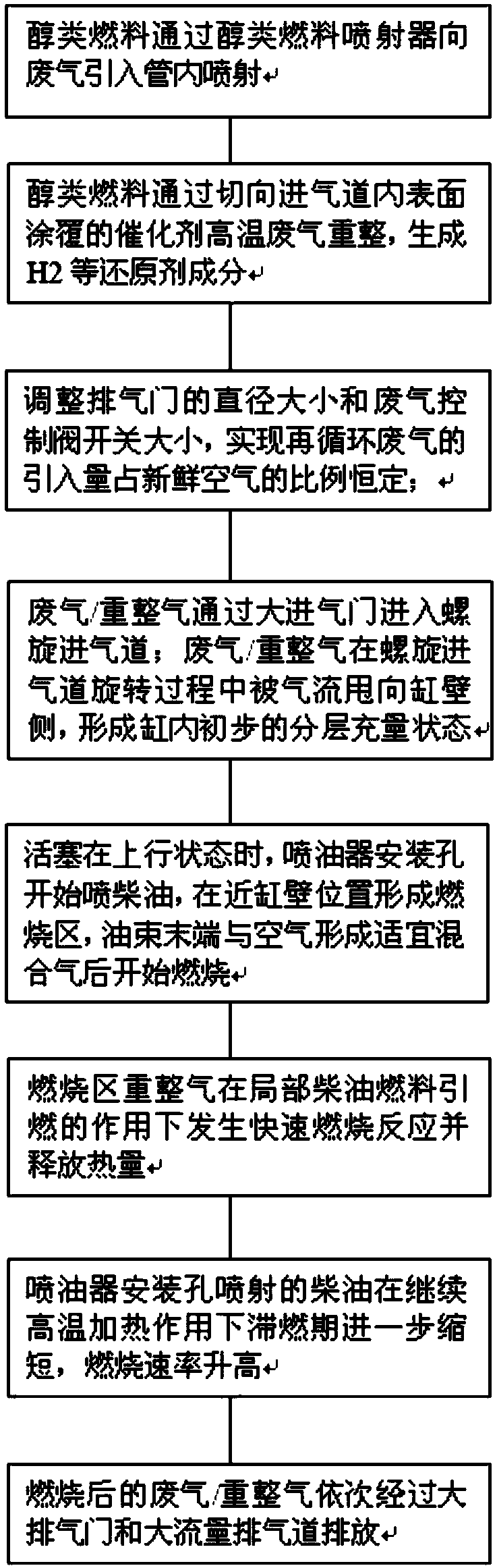

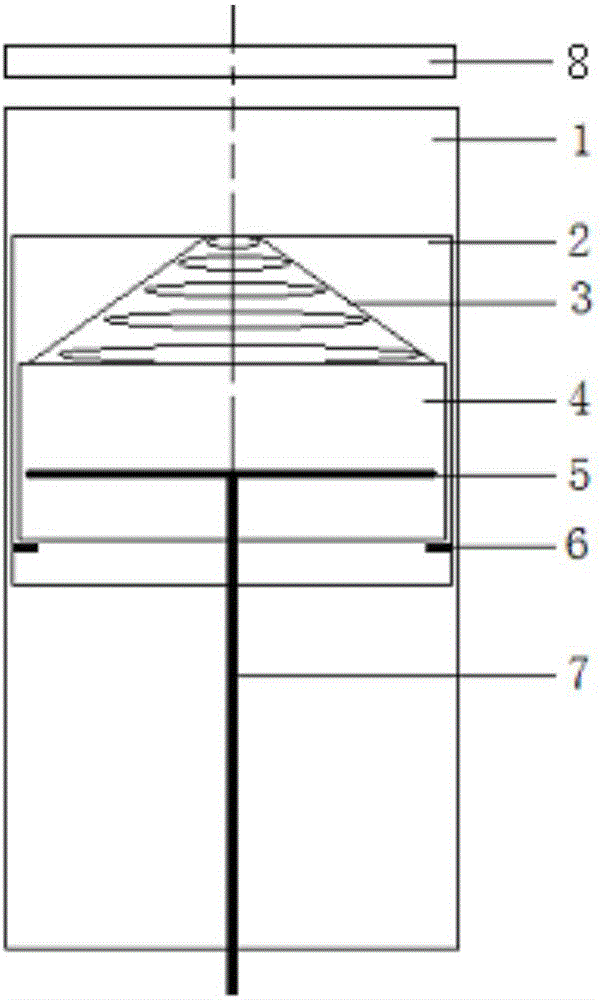

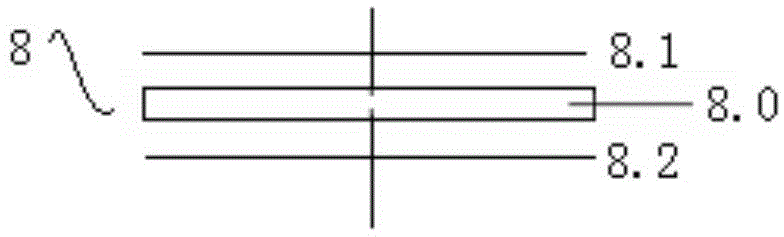

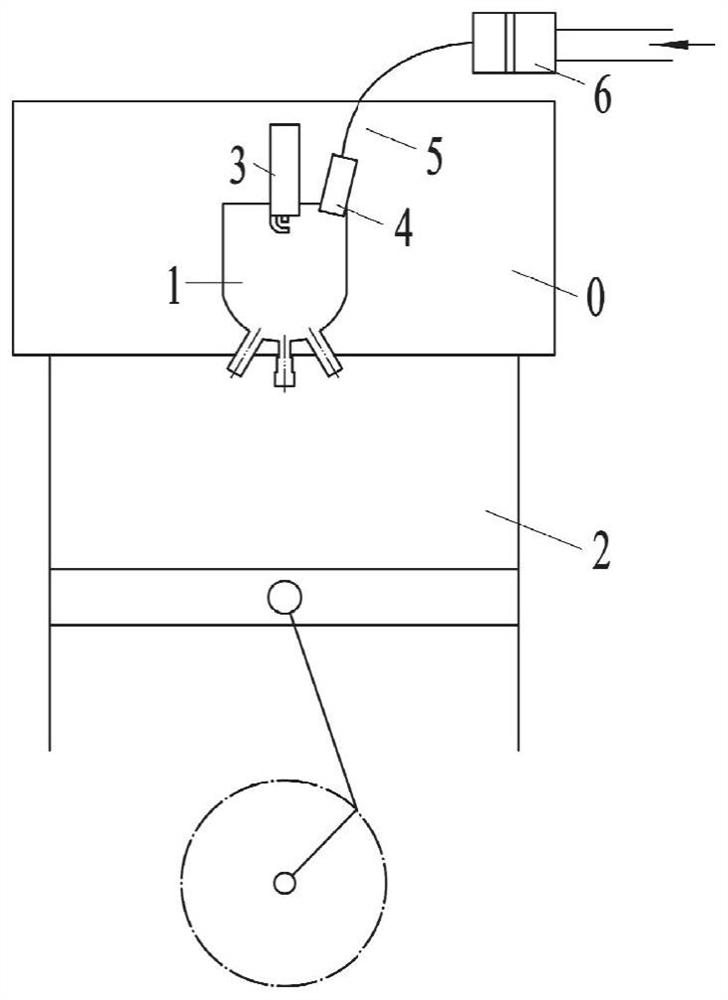

Diesel engine exhaust reforming stratified combustion system and control method

PendingCN108625977AThe amount introduced is constantReduce lossesValve arrangementsInternal combustion piston enginesParticulatesInsulation layer

The invention discloses a diesel engine exhaust reforming stratified combustion system and a control method, and belongs to the technical field of internal combustion engine combustion control. The system comprises a cylinder sleeve, a piston, a cylinder cover, an exhaust guide-in pipe and the like. Reformed gas produced by high temperature exhaust reforming is guided in through a spiral gas flue,the vortex motion condition formed in a cylinder can be effectively utilized, exhaust / reformed gas is thrown to the positions near the cylinder wall, a fuel gas mixture near the cylinder wall is promoted to catch fire at first, gas produced after exhaust / reformed gas mixed gas participates in combustion can be used as a heat insulation layer, and heat transfer losses to the cylinder wall in the whole combustion process are reduced. A catalyst is coated in a gas inlet flue, and reducing agents such as H2 and CO are generated. The heat release rate is increased, hydrocarbon increase is suppressed, H2O and CO2 which are generated after combustion can be used as an inhibitor in the combustion process, the overall specific heat capacity of a working medium of a high temperature zone is increased, increase of combustion temperature is suppressed, and nitric oxide generation amount is reduced. An air deflector is applied to a tangential gas flue with the main purpose of preventing air supplied to the tangential gas flue from entering an exhaust / reformed gas mixed gas zone of the outer side of a combustion chamber, thus, a center zone of the combustion chamber still has a high air content, and the generation amount of particulate matter is prevented from increasing in the later combustion period.

Owner:CHANGCHUN INST OF TECH

Combined pressure regulating piston based on elastic silencing and impact-resistant cylinder gasket

InactiveCN104564403AHigh thermal efficiencyDoes not affect performanceCylinder headsSealing arrangements for enginesDieselingGasoline

The invention discloses a combined pressure regulating piston based on an elastic silencing and impact-resistant cylinder gasket and relates to the combined pressure regulating piston. The elastic silencing and impact-resistant cylinder gasket is arranged between a cylinder cover and a cylinder body and consists of an upper sealing gasket, a cylinder gasket main body and a lower sealing gasket which are connected in sequence; the cylinder gasket main body comprises an elastic steel plate, circular holes, elastic steel claws, mounting holes and water channel holes; the circular holes are formed in the middle of the elastic steel plate; the elastic steel claws are uniformly and symmetrically arranged at the periphery of each circular hole; the mounting holes and the water channel holes are formed outside the circular holes. The combined pressure regulating piston highly affects the heat efficiency of the torque of an engine, the heat efficiency of a gasoline engine can be improved by about 7 percent, and the heat efficiency of a diesel engine can be improved by about 5 percent; under the condition that the elastic force of a pressure regulating spring can be regulated, all the advantages of the combined pressure regulating piston can be played at the same time, and playing of the roles of external additional mechanisms of the engine such as a turbo charging mechanism and a stratified combustion mechanism is not affected.

Owner:陈光明

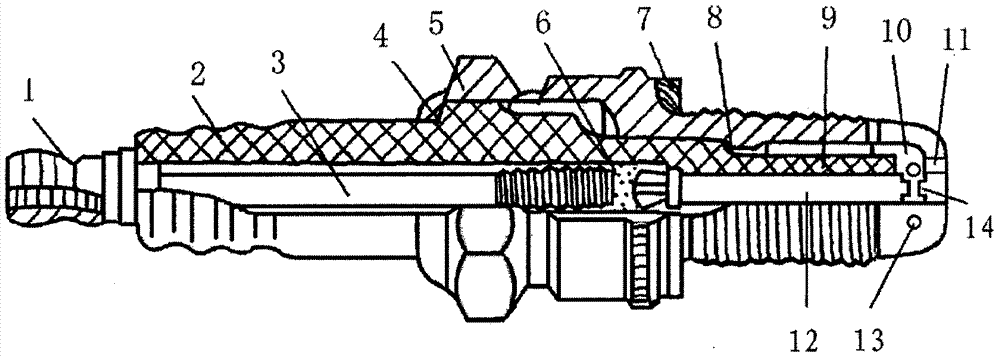

Flame-ejecting sparking plug and internal combustion engine and automobile therewith

The invention discloses a flame-ejecting sparking plug and an internal combustion engine and automobile therewith. On the basis of a conventional sparking plug, a space nearby an electrode is closed to form a cavity. An end face is provided with a plurality of small holes, and a side surface is provided with two or more small holes. The mixture of air and fuel enters the cavity through the small holes, and the discharge happens between the electrodes to generate sparks to ignite the combustible gas in the cavity. The flame in the cavity extends, and the temperature and pressure are increased. The flame is ejected from the small holes to form a plurality of flame cylinders, and passes through a combustor and the combustible gas in a cylinder, thereby achieving the multi-point ignition, large-area ignition and high-energy ignition of the combustible gas. The internal combustion engine employing the sparking plug is high in combustion speed, can employ the layering combustion technology and the lean-burn technology, and is not liable to generate knock while increasing the compression ratio of the cylinder. The conversion efficiency of heat into power of an engine can be expected to increase by 20%-30%, and the requirements for the octane number of gasoline are reduced. Compared with a conventional internal combustion engine automobile, the automobile employing the internal combustion engine can save gasoline by 20%-30%.

Owner:周向进

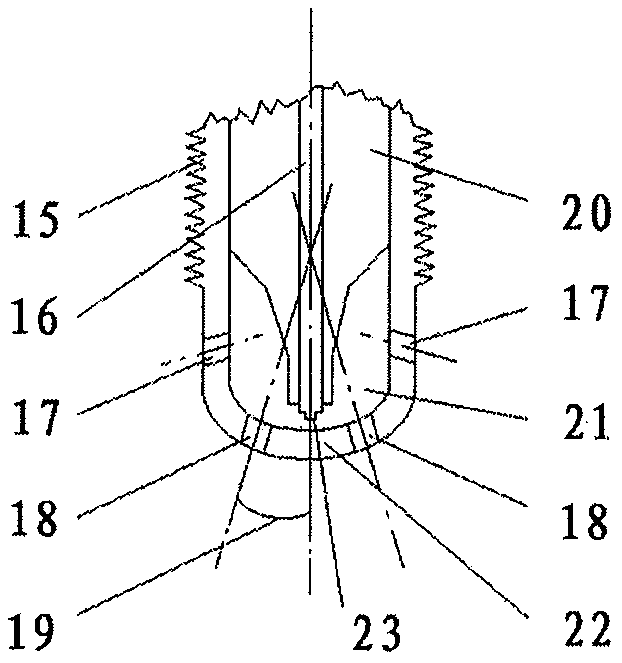

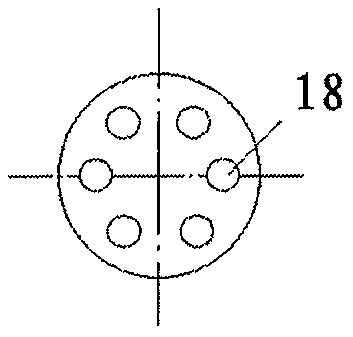

Large-cylinder-diameter gas engine turbulent jet ignition system, gas supply system and method

ActiveCN113982739AShorten the propagation distanceAids in lean burnInternal combustion piston enginesGaseous engine fuelsFlame propagationGas supply

The invention discloses a large-cylinder-diameter gas engine turbulent jet ignition system, a gas supply system and method, and the turbulent jet ignition system comprises a pre-combustion chamber which forms a spatial umbrella-shaped distributed ignition source in a main combustion chamber through a plurality of fluid passages; a sparking plug which is arranged on the pre-combustion chamber and used for igniting mixed gas in the pre-combustion chamber; a pre-combustion chamber gas injection valve which is connected with the pre-combustion chamber through a gas conveying pipeline and a one-way valve and used for injecting auxiliary gas into the pre-combustion chamber in a timed and quantitative mode. The gas supply system comprises a controller and the turbulent jet ignition system, and the controller is used for controlling gas supply of the pre-combustion chamber and fuel supply of the gas inlet channel of the main combustion chamber. Accurate stratified combustion can be formed between the pre-combustion chamber and the main combustion chamber; turbulent jet flow generated by mixed combustion in the pre-combustion chamber can form umbrella-shaped ignition source distribution in the main combustion chamber, the flame propagation distance is effectively shortened, and the combustion speed of mixed gas in the main combustion chamber is increased.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com