Patents

Literature

141results about How to "Increase mixing intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

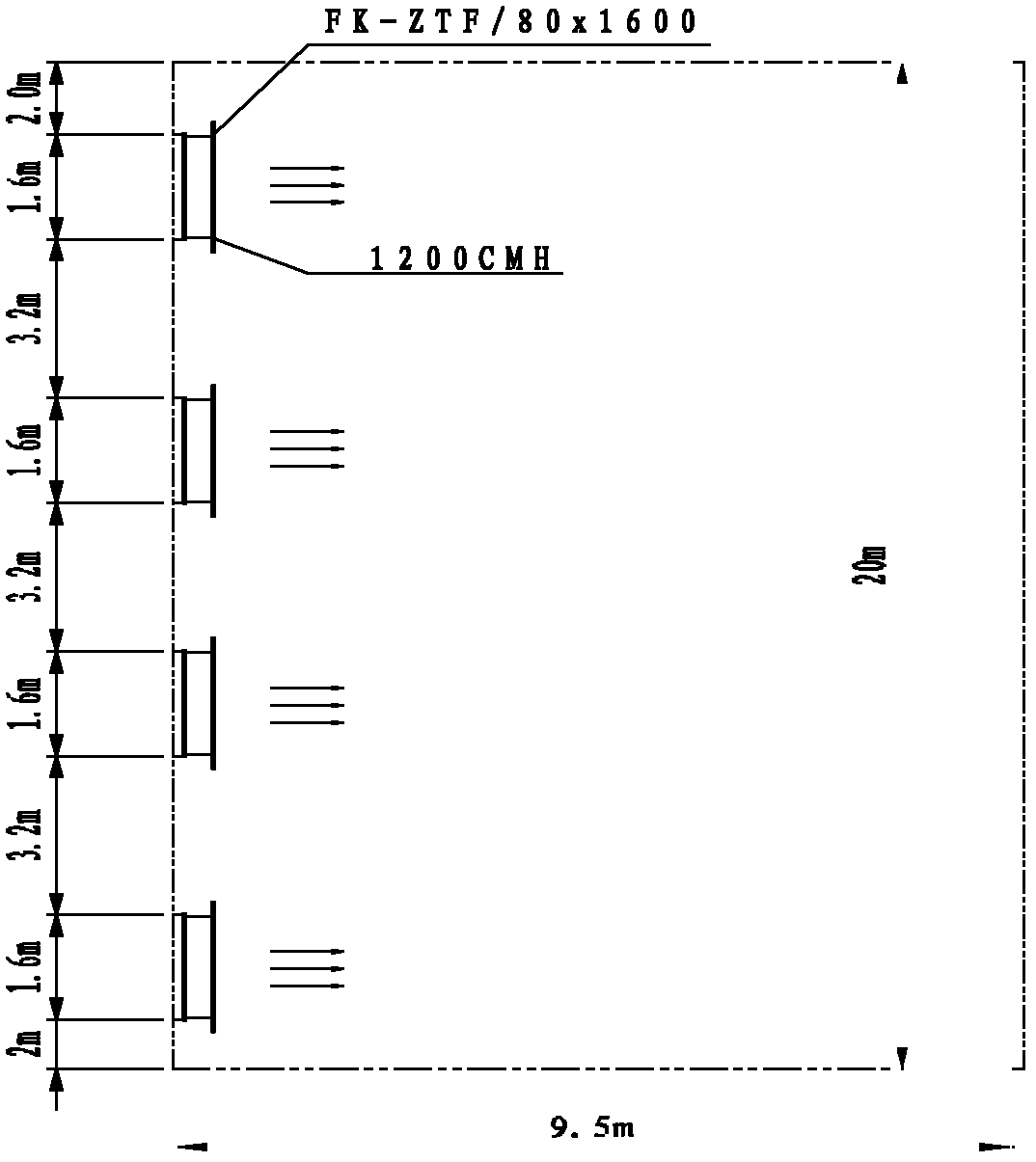

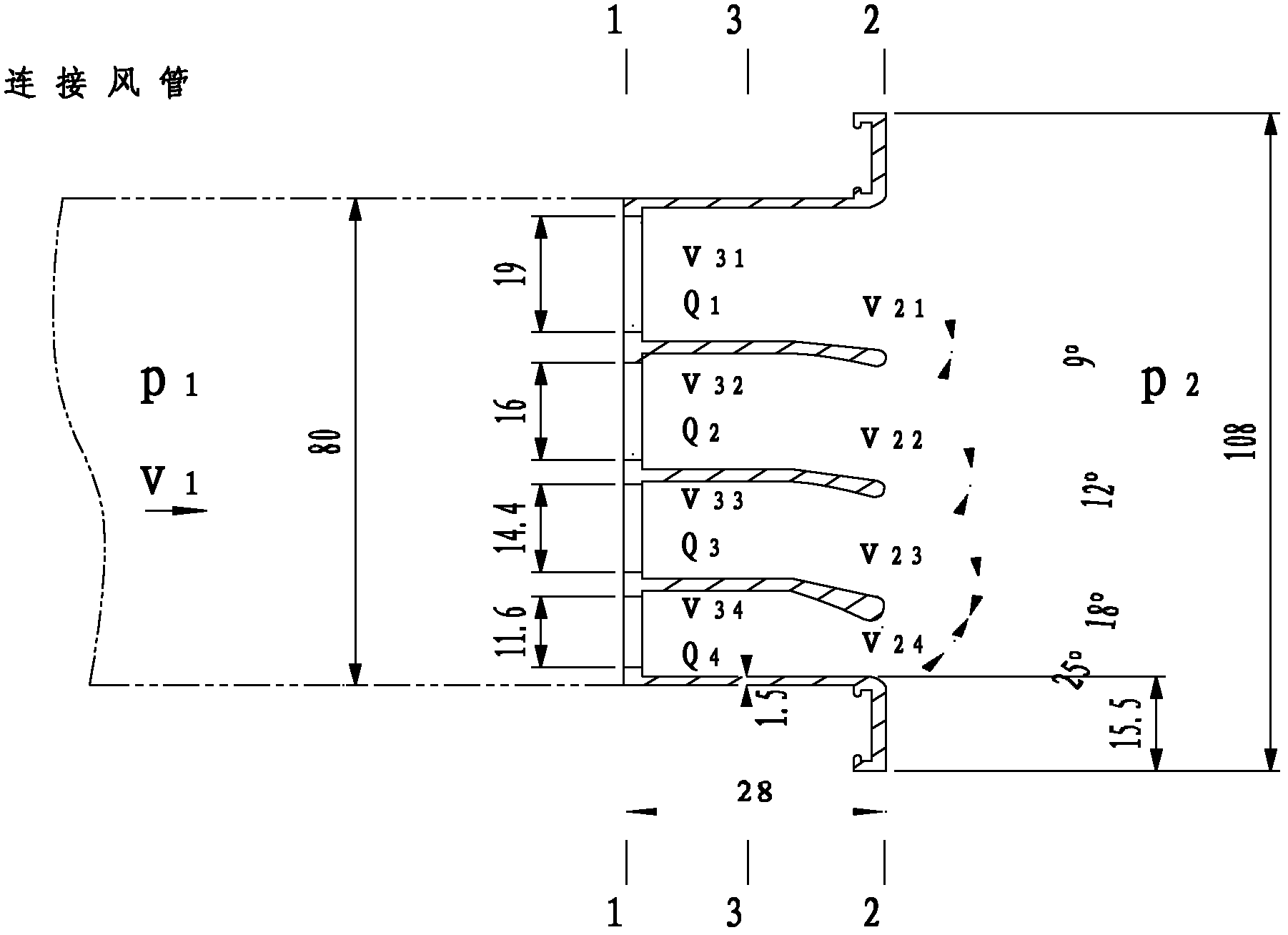

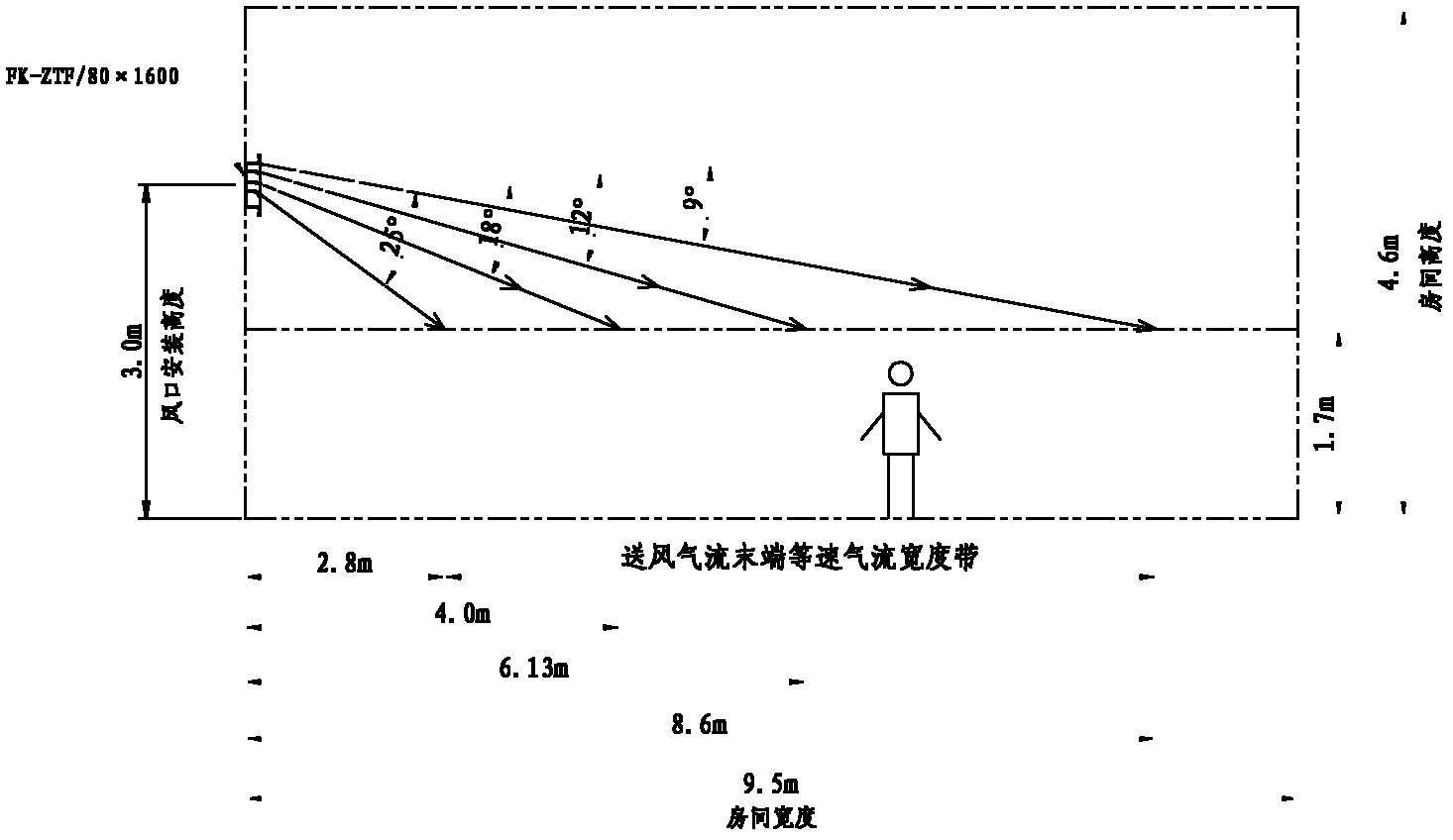

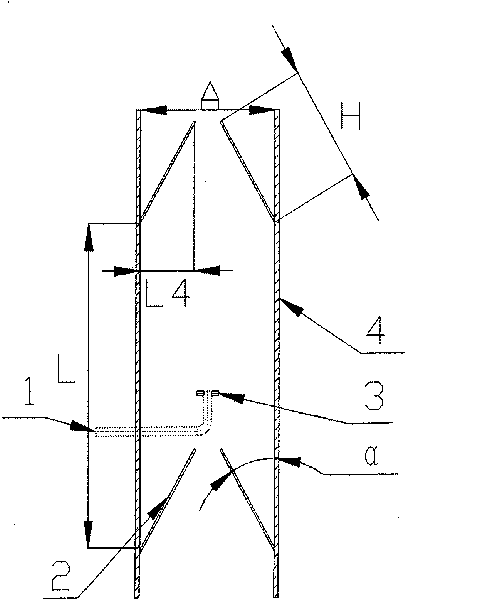

Air conditioner air supply method utilizing air port special structure to realize equal air speed and tepefaction difference

InactiveCN102538146AIncrease mixing intensityAir flow bandwidthSpace heating and ventilation safety systemsLighting and heating apparatusThermodynamicsAir velocity

The invention discloses an air conditioner air supply method utilizing an air port special structure to realize equal air speed and tepefaction difference. In the method, air outlet grooves with different angles, different vane quantities and different effective flow areas and guide vanes of corresponding diversion angles are designed and deployed for air ports according to different installation air port areas or different installation manners and air supply manners indoors, so that the sent airflow bundles are nearly equal in speed; and the air supply airflow frequency width is increased, the covering region of the tail end of air supply airflow is ensured to be large and the mixing intensity of the air supply airflow and indoor air is high. The method can ensure that the tail ends of the air supply airflow bundles reaching a person active region are nearly equal in air speed, thereby reducing the temperature difference caused by the speed distribution difference of the tail ends of the airflow bundles, and promoting the distribution uniformity of a speed field and a thermal field of the air supply airflow; and meanwhile, the overlay area of an air supply airflow uniform speed airflow region is increased, the air supply airflow of a designed room is filled and distributed at every nook and corner of the room to the greatest extent, and the comfortability of an air conditioner field person active region is improved.

Owner:苏州市创建空调设备有限公司

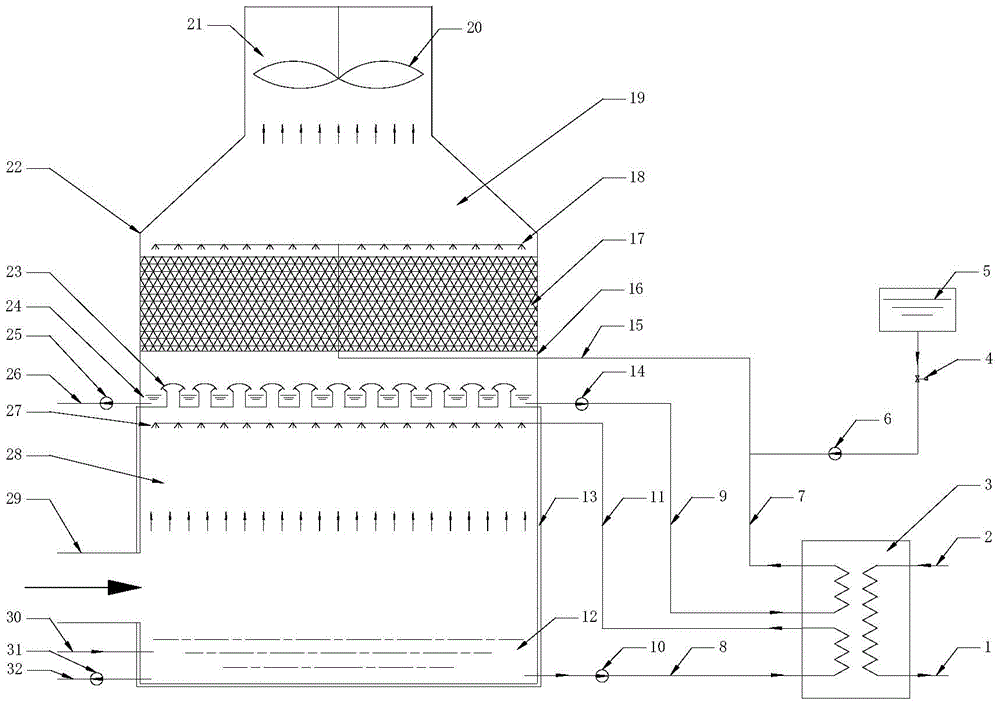

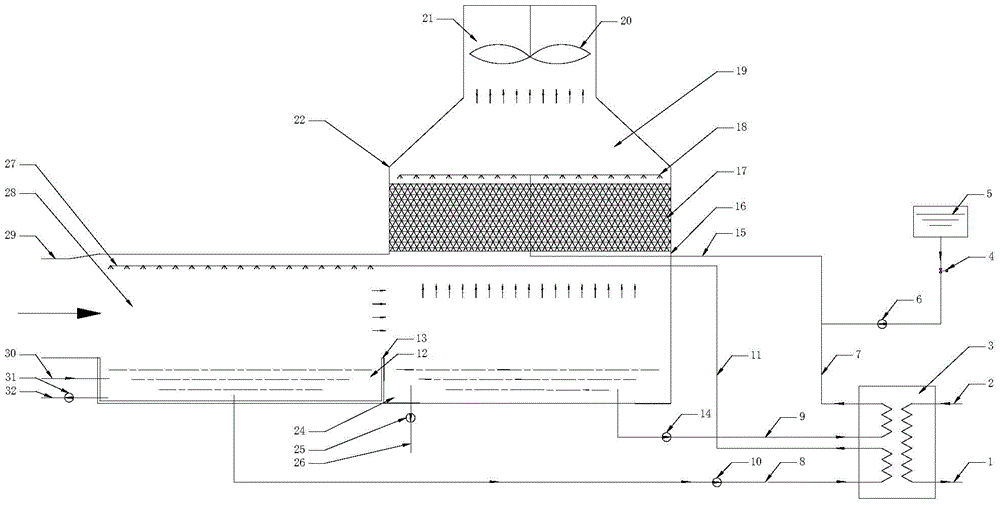

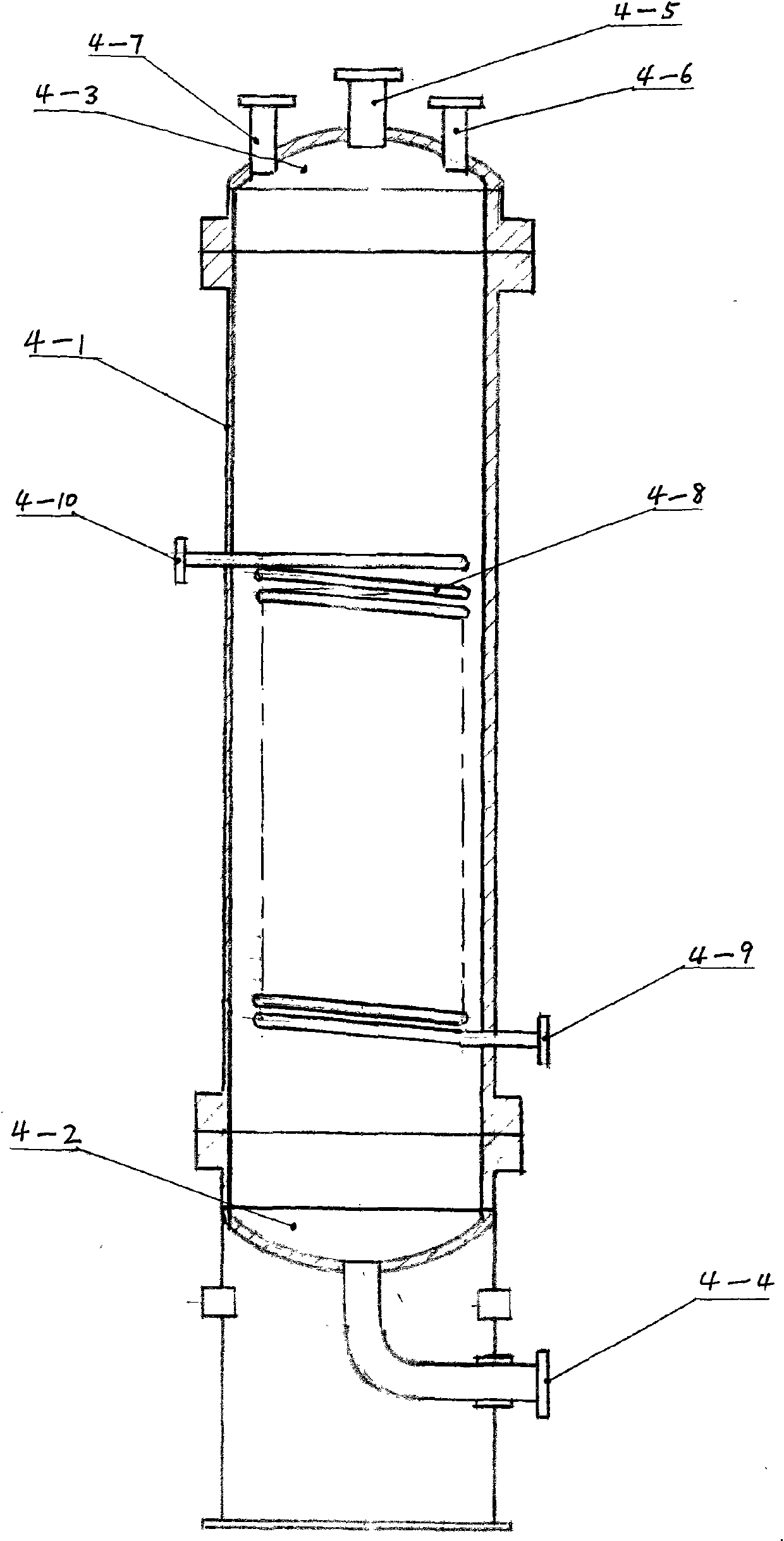

Smoke purifying and residual heat deep recycling integrated device

InactiveCN104014236ASimple structureImprove heat transfer effectUsing liquid separation agentTrickle coolersWater qualityRecuperator

The invention discloses a smoke purifying and residual heat deep recycling integrated device, which comprises a purification and heat exchange tower, a smoke system and a heat exchanger, wherein the inside of the purification and heat exchange tower is partitioned into a spraying chamber at the lower part and a filling chamber at the upper part by a wind cap layer; the spraying chamber comprises a spraying layer and a water pool; the water pool is connected with a water supply system, a water treatment pump, a water quality treatment system and a water circulation pump respectively; the outlet of the water circulation pump is connected with the heating hot water inlet of the heat exchanger; the outlet of the water pool is connected with the spraying layer; a smoke inlet is formed in the tower wall above the water pool; the filling chamber comprises a slurry distribution layer, a filling layer, a slurry pool and a slurry supply device; the slurry pool is connected with a slurry treatment pump, a slurry treatment system and a slurry circulation pump; the outlet of the slurry circulation pump is connected with the heating slurry inlet of the heat exchanger and the outlet of the slurry pool is connected with the slurry supply device. The smoke purifying and residual heat deep recycling integrated device is applicable to comprehensive treatment of tail smoke in gas heating, power and cooling triple combination distribution type systems, natural gas boilers, gas-steam combined circulation and fuel power stations.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

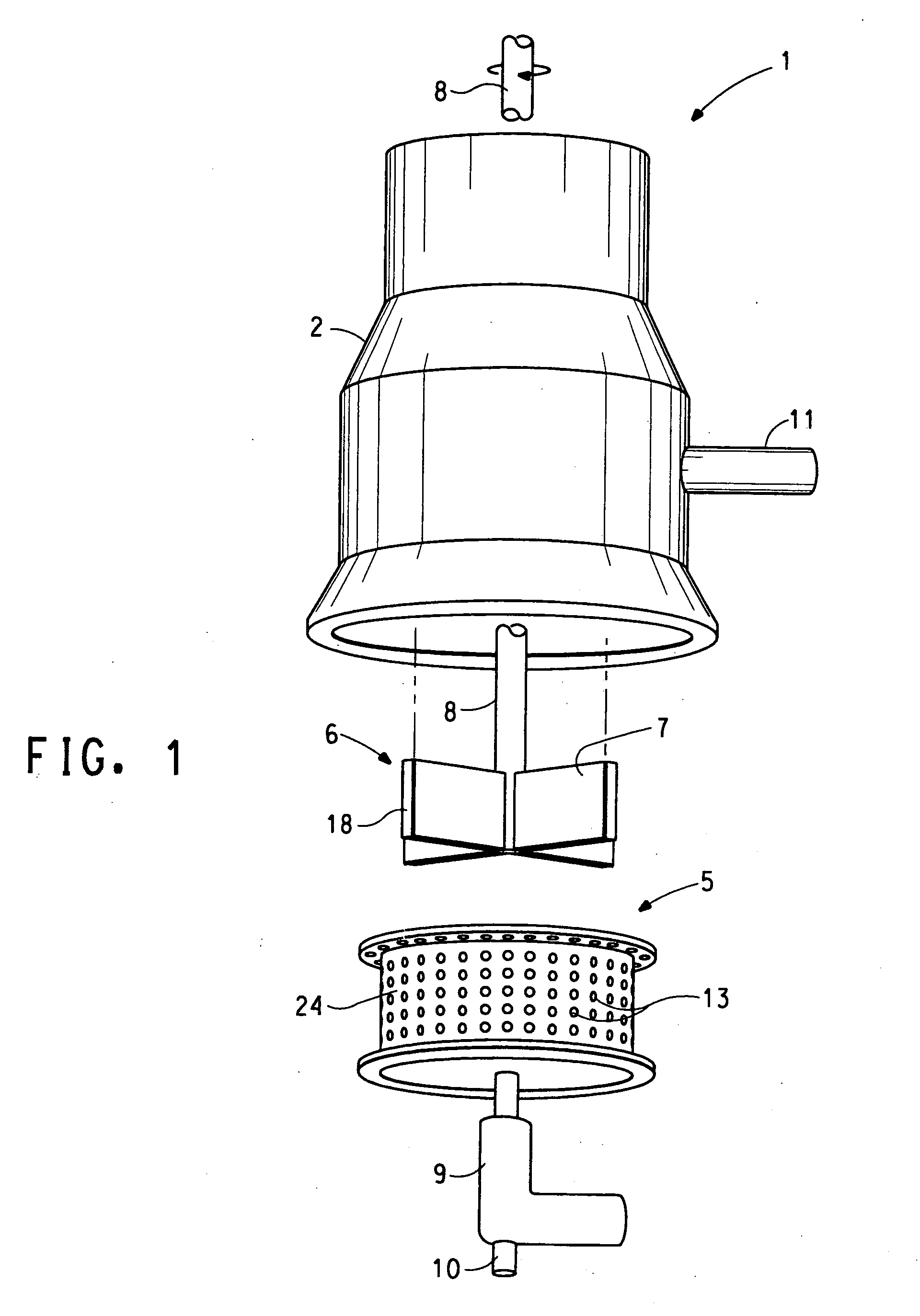

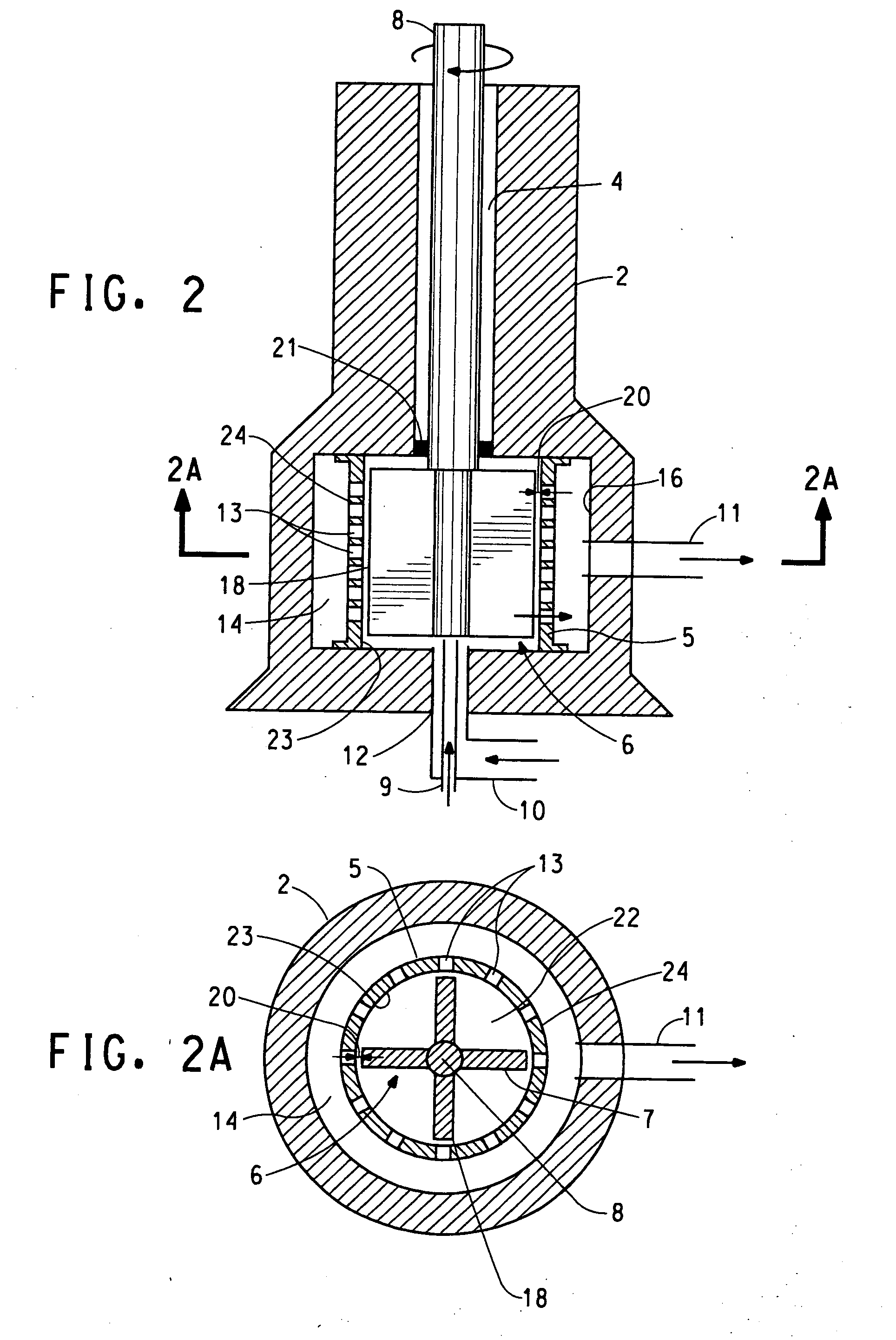

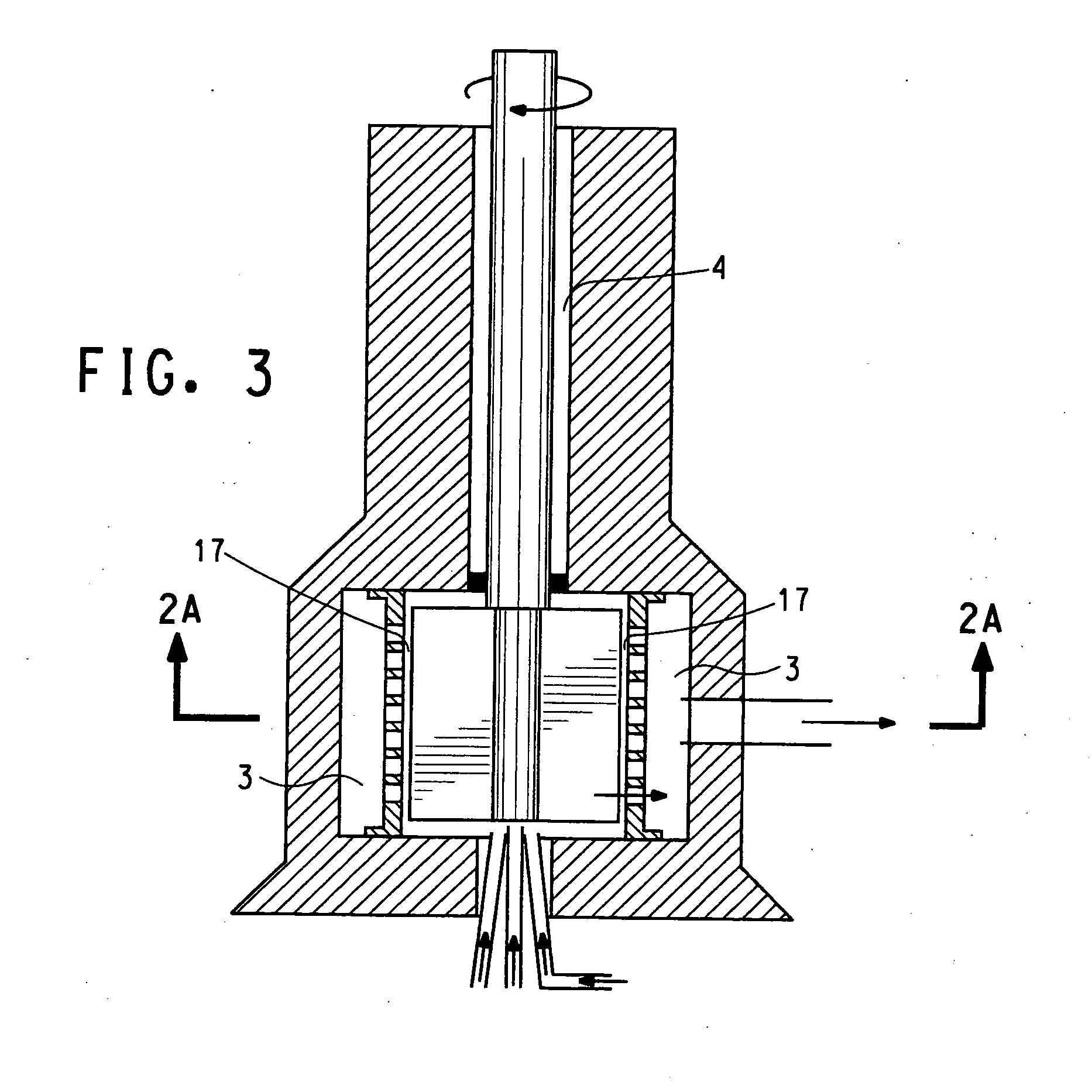

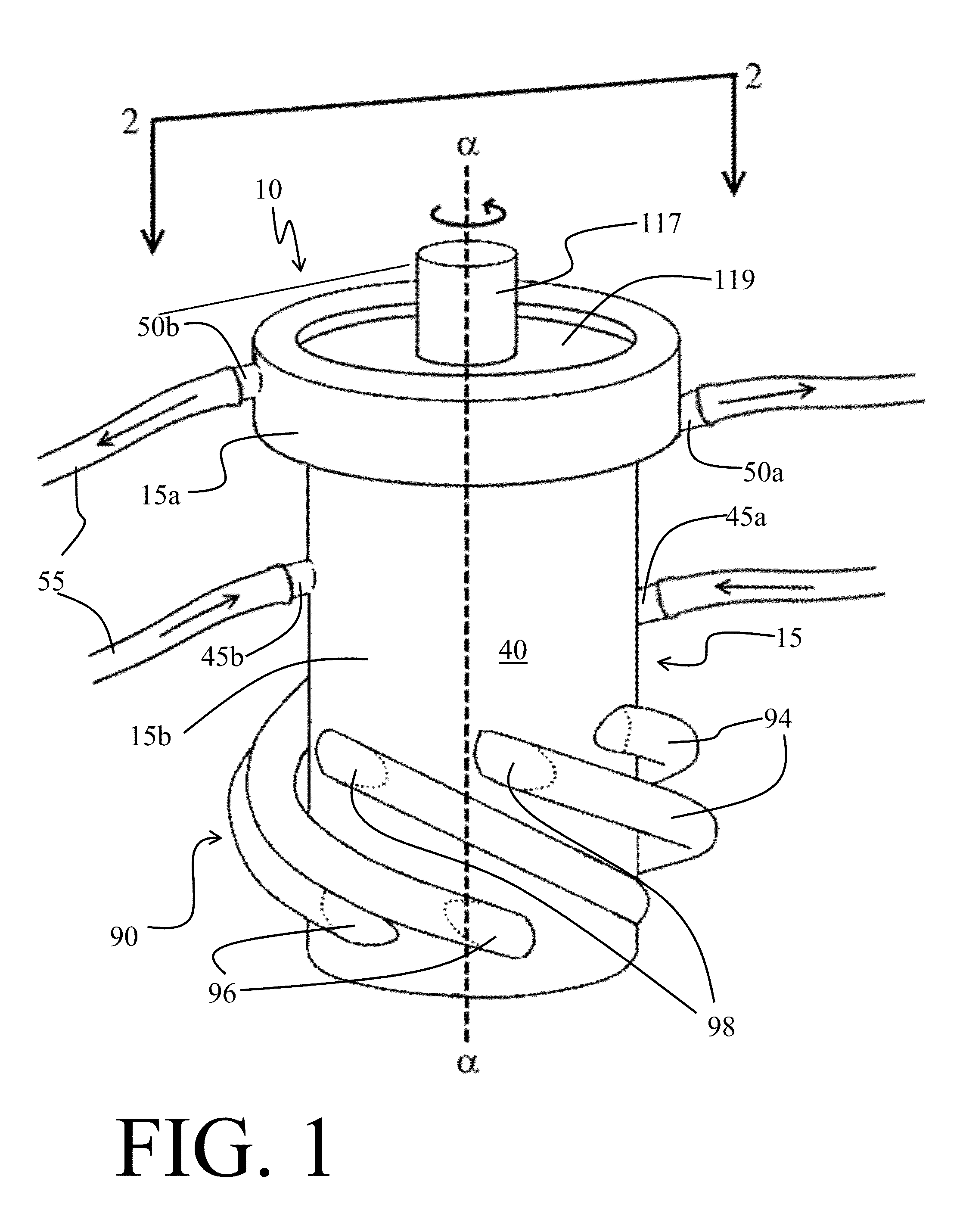

Rotor-stator apparatus and process for the formation of particles

InactiveUS20050202095A1Efficient and simple and easily scaled-upIncrease mixing intensityPowder deliveryFlow mixersSalting outHigh intensity

The present invention relates to the use of a high intensity, in-line rotor-stator apparatus to produce fine particles via antisolvent, reactive, salting out or rapid cooling precipitation and crystallization.

Owner:DAIZIEL SEAN MARK +3

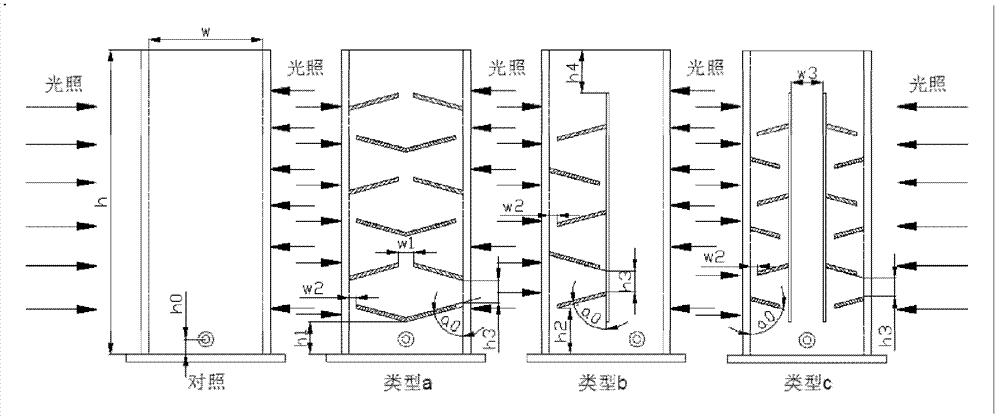

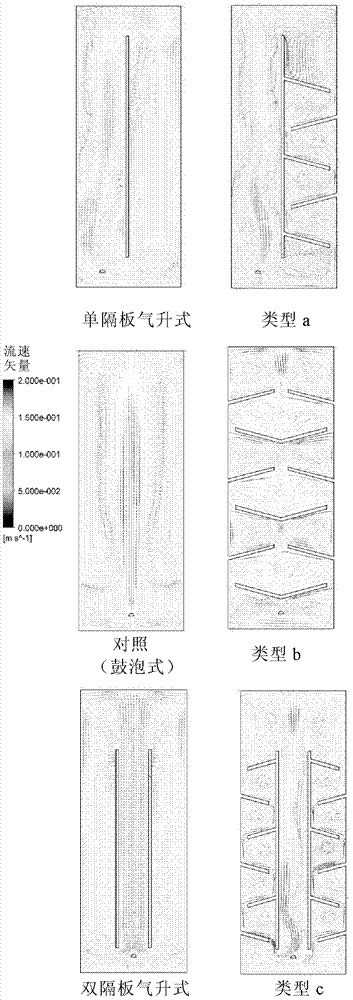

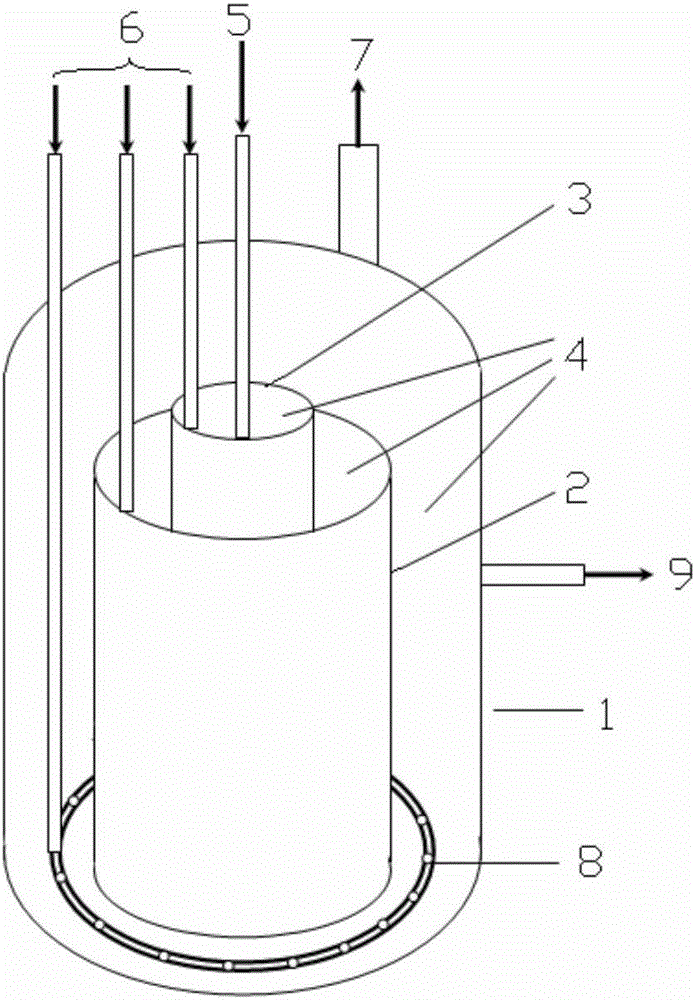

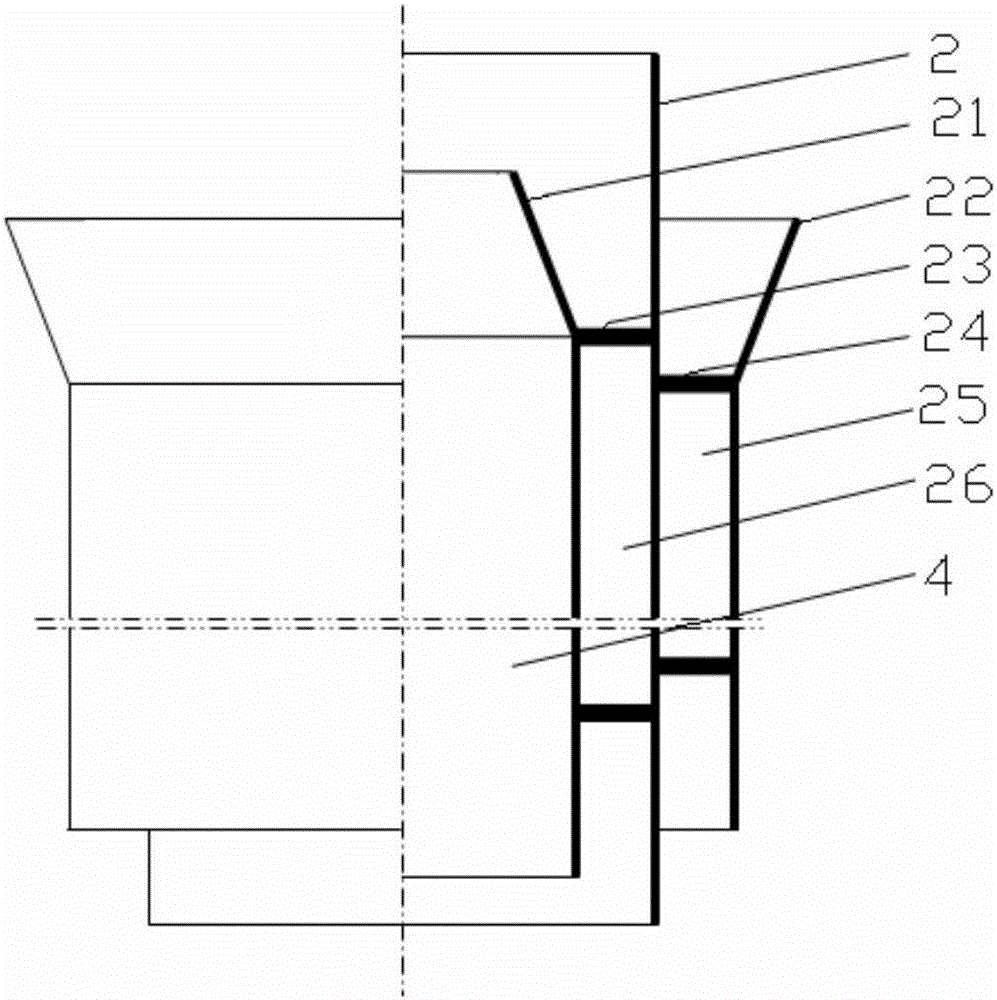

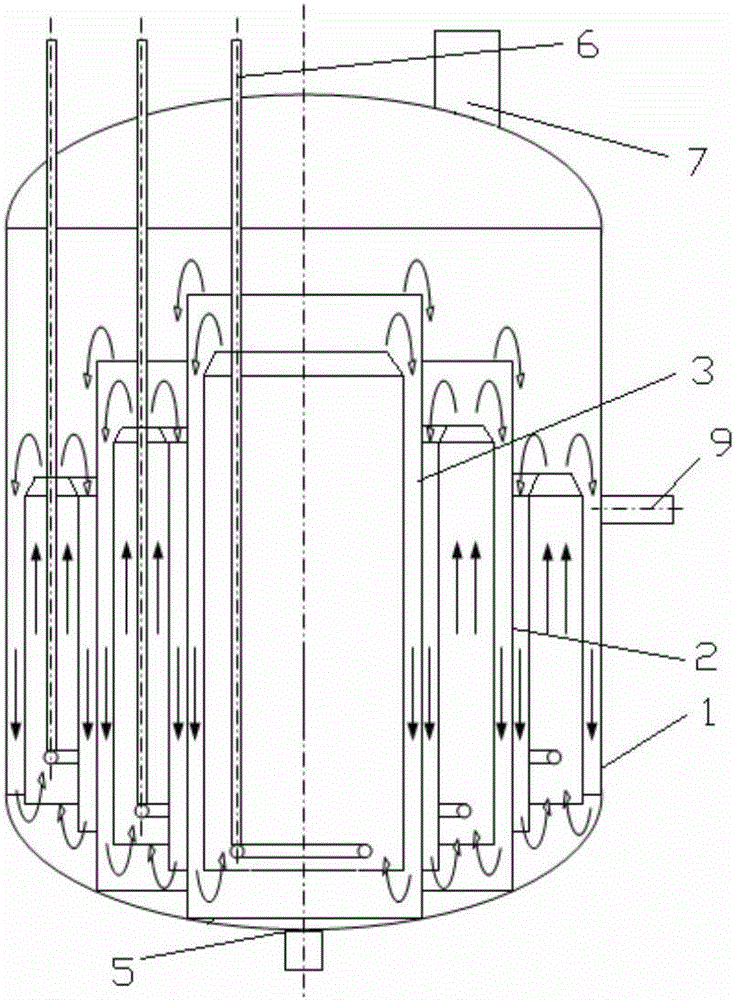

Light direction hybrid reinforcement-based novel internal component and photobioreactor

InactiveCN103361257AIncrease mixing intensityIncrease light intensityBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorEngineering

The present invention provides a novel photobioreactor and an internal component thereof. The photobioreactor comprises a transparent housing and multiple regularly arranged transparent baffle plates. The baffle plates are axially placed in the housing and tilt horizontally. A trapezoidal partial space is formed between the baffle plates. The photobioreactor enables fluid in a central area (dark area) of the reactor and fluid in a surface area (light area) of the reactor to rapidly and periodically circulate, thereby enhancing mixing of fluid along a radial direction (light direction) of the reactor.

Owner:EAST CHINA UNIV OF SCI & TECH +2

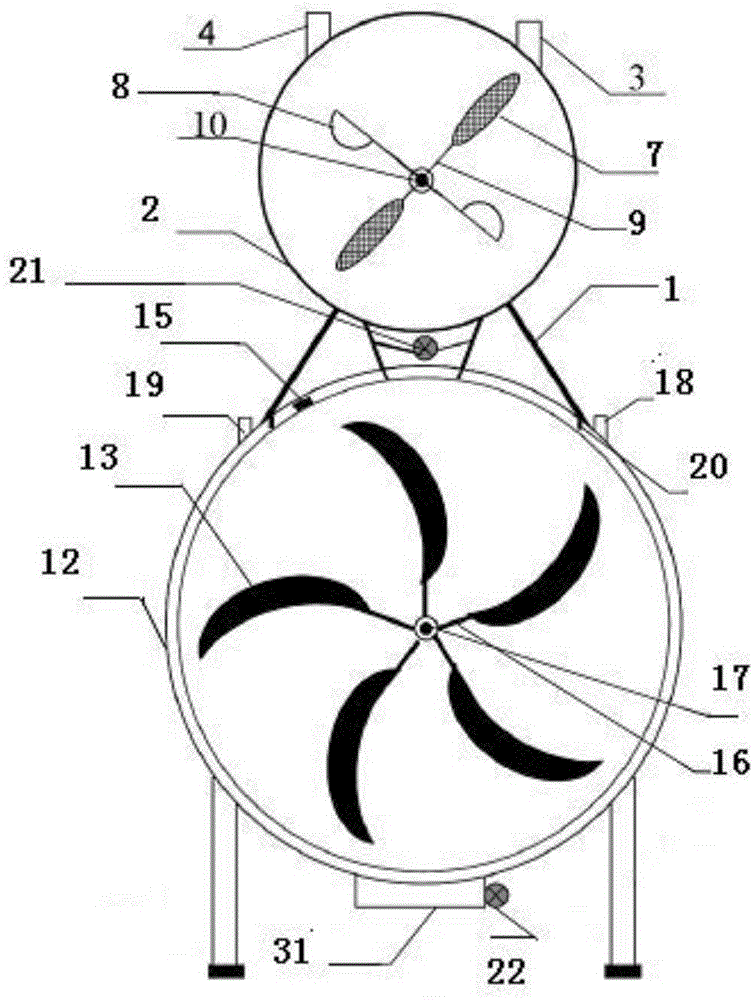

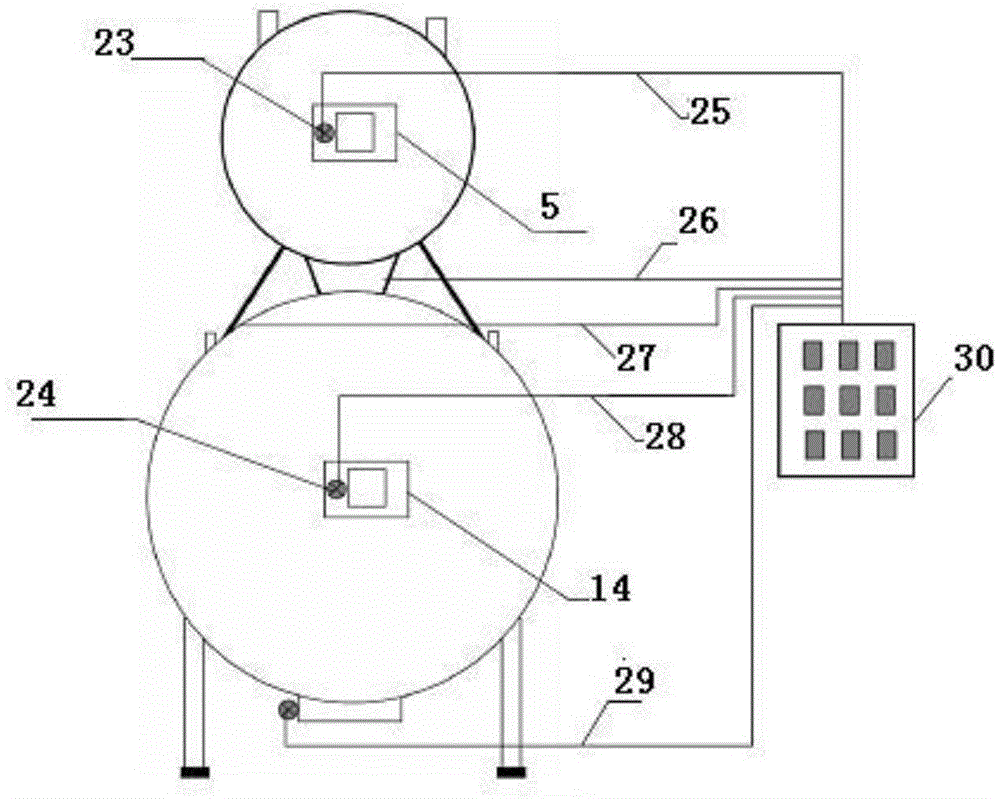

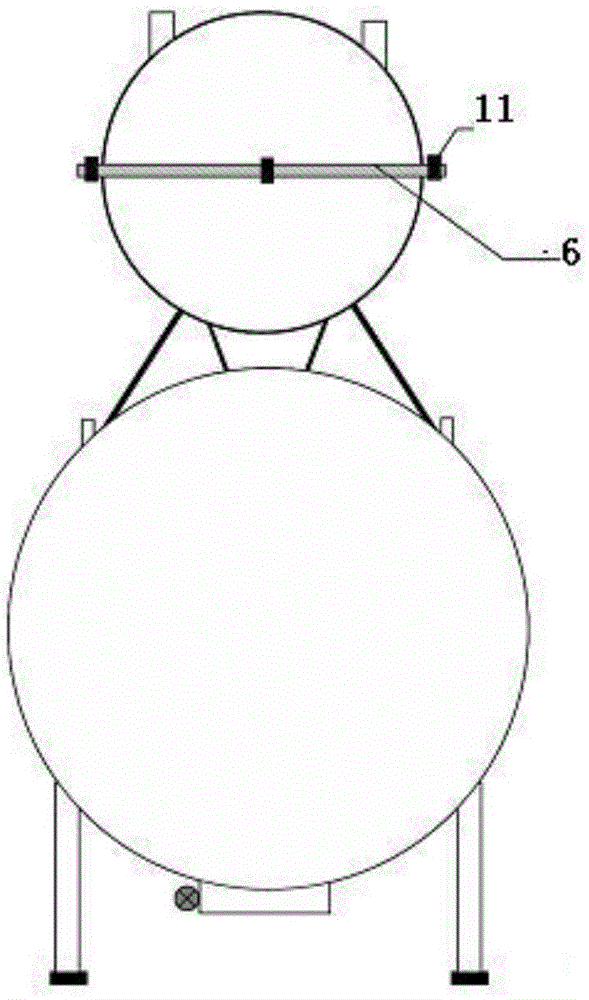

Automatic mixing device for mixed feed additive

ActiveCN105536586AImprove the tightnessQuality improvementFeeding-stuffTransportation and packagingHybrid typeAutomatic control

The invention discloses an automatic mixing device for a mixed feed additive. The automatic mixing device comprises four parts, namely a premixing system, a mixing system, a temperature control system and an automatic control system, wherein the premixing system comprises a premixing bin body, a main and auxiliary material feeding hole, a mixing blade, an adjustable motor and a fixed sealing flange; the mixing system comprises a mixing bin body, a mixing blade, an adjustable motor and a vibrator; the temperature control system comprises an internally inlet / outlet, a seal sheet and an interlayer; and the automatic control system comprises a relay switch gear, a connecting circuit and an automatic control board. The automatic mixing device has the characteristics of high automation, convenience in use, high main / auxiliary material mixing strength and obviously improved mixing degree, is high in device sealing degree, is capable of lowering the pollution rate and the material loss rate, reducing damage to human bodies, decreasing heat produced by machine operation and improving the activity and heat-labile component quality of the mixed feed additive, and is beneficial to quality stability of products in different batches.

Owner:FUJIAN BRADY PHARMA CO LTD

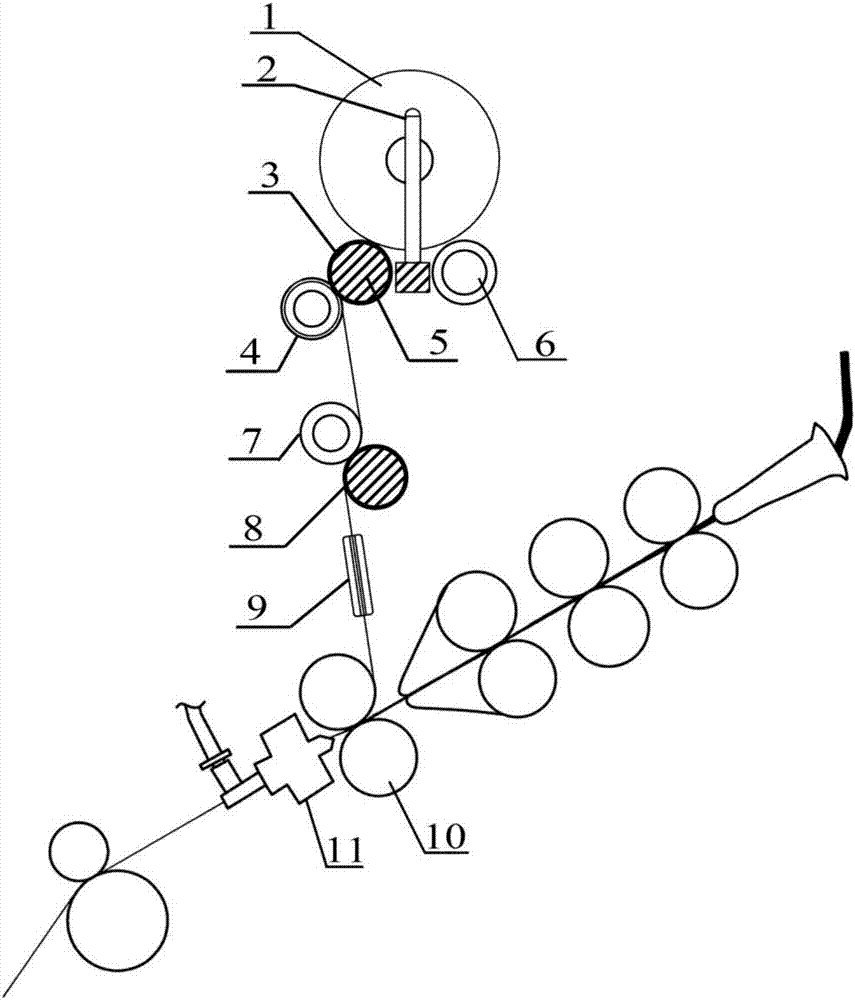

Compound vertex spinning method for film silkening

ActiveCN107059186AUniform outputHigh strengthContinuous wound-up machinesOpen-end spinning machinesMicro nanoFiber

The invention relates to a compound vertex spinning method for film silkening, pertaining to the technical field of weaving. A film cutting drafting device is arranged above a front roller pulling jaw of each drawing mechanism of a vortex flow spinner. A cutting region is formed between a cutting-endurable ring and a cutting roller of a film placing and cutting device. Uniformly-expanded stripped-shaped multifilaments are cut and silken to form a film. The conventional linear discharge and filamentation method for spinneret holes is changed. The multifilaments are drafted and thinned through a first drafting region and a second drafting region to form improved and thinned micro-nano strands. The micro-nano strands of multifilaments and short fibers outputted out of a drafting region of the vortex flow spinner are fully mixed. Short fiber heads of fiber strands clamped by strands enter a hollow yarn-guiding channel of a static spindle of a vortex spinner. The tail ends of short fibers are wounded around strands and short fiber head ends so that vortex compound yarns are formed with micro-nano strands uniformly mixed with the short fibers. The difficulty that filaments, nanofibers and conventional staple fibers are difficult to be mixed uniformly and twisted during vortex compound spinning is solved. Therefore, a film industry and a weaving industry are effectively merged.

Owner:WUHAN TEXTILE UNIV

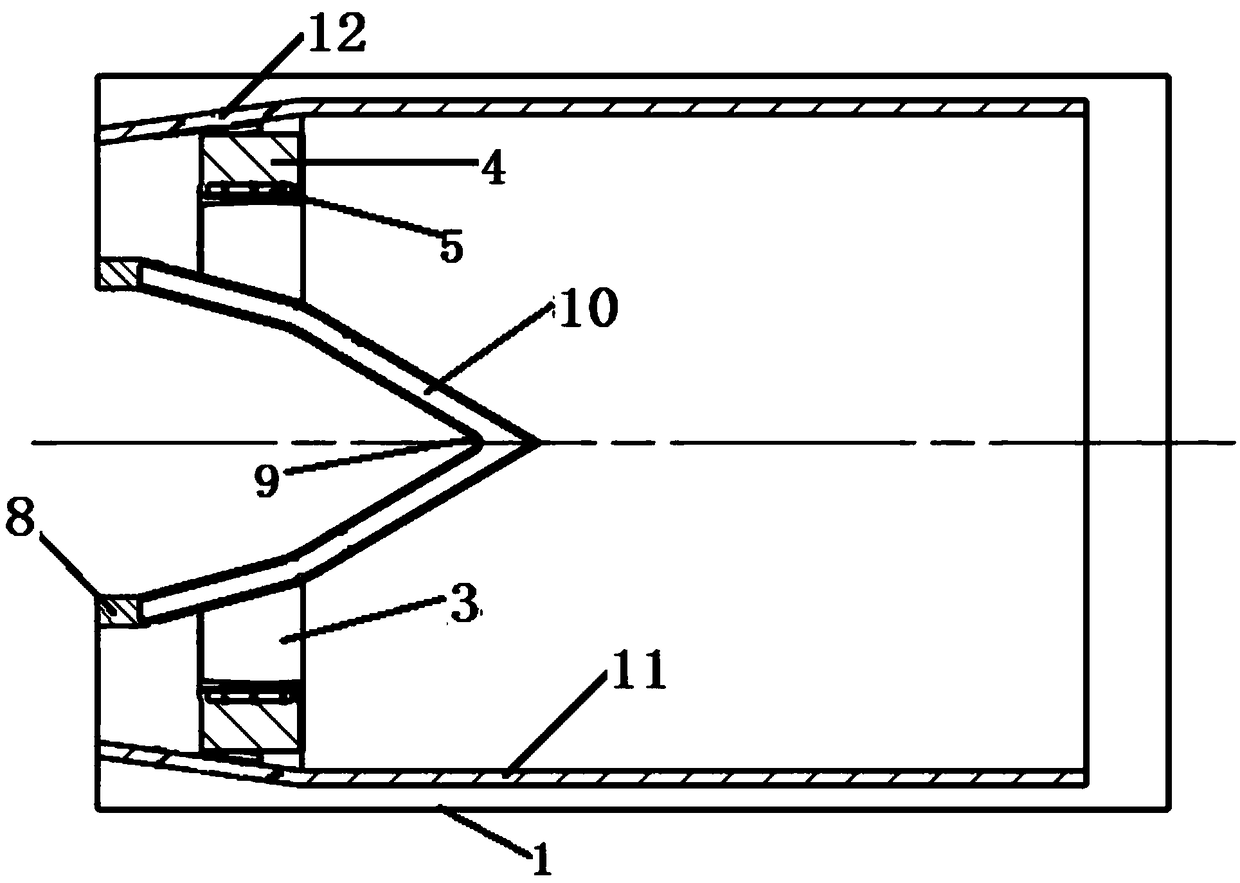

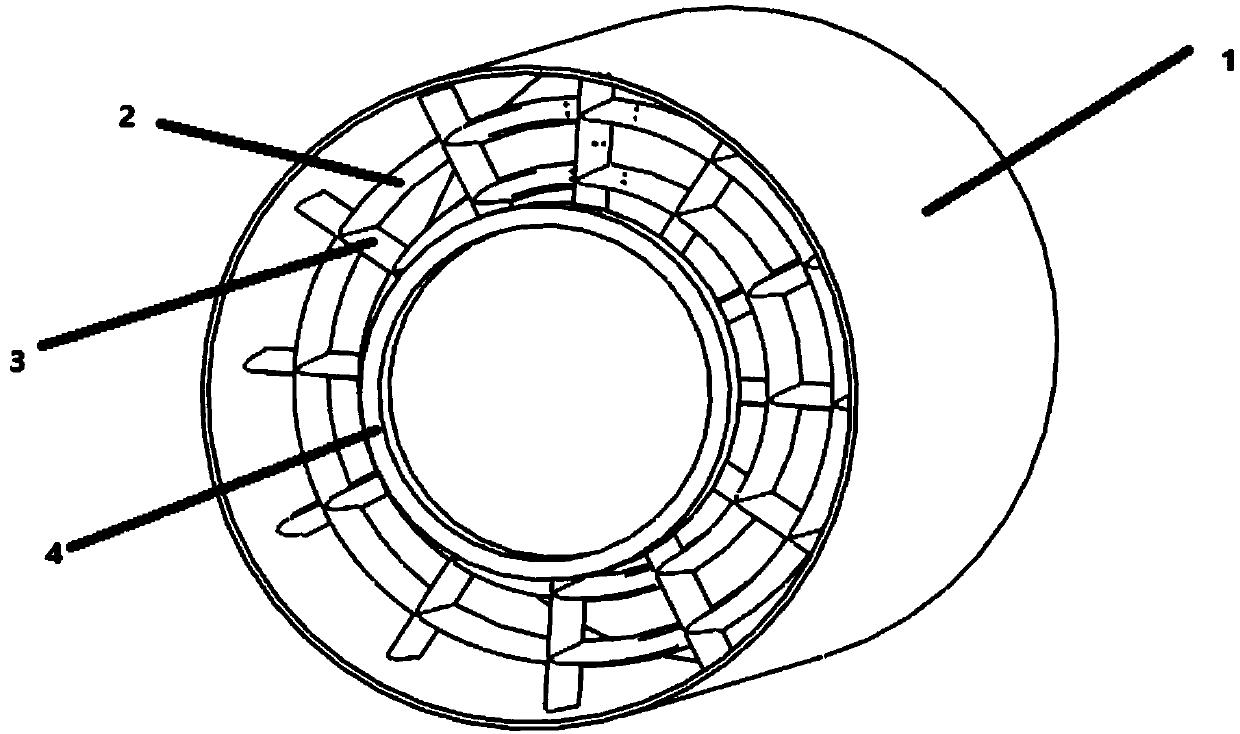

Annular oil supply type integrated afterburner

ActiveCN108131684AStable jobIncrease mixing intensityContinuous combustion chamberCombustion chamberEngineering

The invention provides an annular oil supply type integrated afterburner. A worm gear rear rectification supporting plate and a flame stabilizer are integrated, two stages of rectification supportingplates and the flame stabilizer are subjected to radially misplaced structure design, and in this way, a stable low speed backflow area large in size range and high in swirl flowing is more easily formed at the downstream of the annular oil supply type integrated afterburner. A whole-ring groove stabilizer is arranged between the two stages of rectification supporting plates. An oil cavity is formed inside a force-adding inner cone and is connected with a fuel channel inside the first-stage rectification supporting plate, and after absorbing heat of the force-adding inner cone, fuel finally reaches the inside of the whole-ring groove stabilizer. Main fuel is sprayed out longitudinally from the two sides of the whole-ring groove stabilizer, on-duty fuel is sprayed out from a groove of the whole-ring groove stabilizer to form on-duty flame, and soft ignition is achieved. By reasonably forming nozzle small holes, the atomization effect of the fuel can be effectively improved, and thus thestability and combustion efficiency are improved. The annular oil supply type integrated afterburner has the advantages that the two stages of rectification supporting plates which are radially misplaced are adopted, and a better backflow area is formed; meanwhile, through longitudinal oil spray of the whole-ring groove stabilizer, the fuel-gas mixing effect is improved, the on-duty flame is formed, the soft ignition is achieved, and thus the combustion stability is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

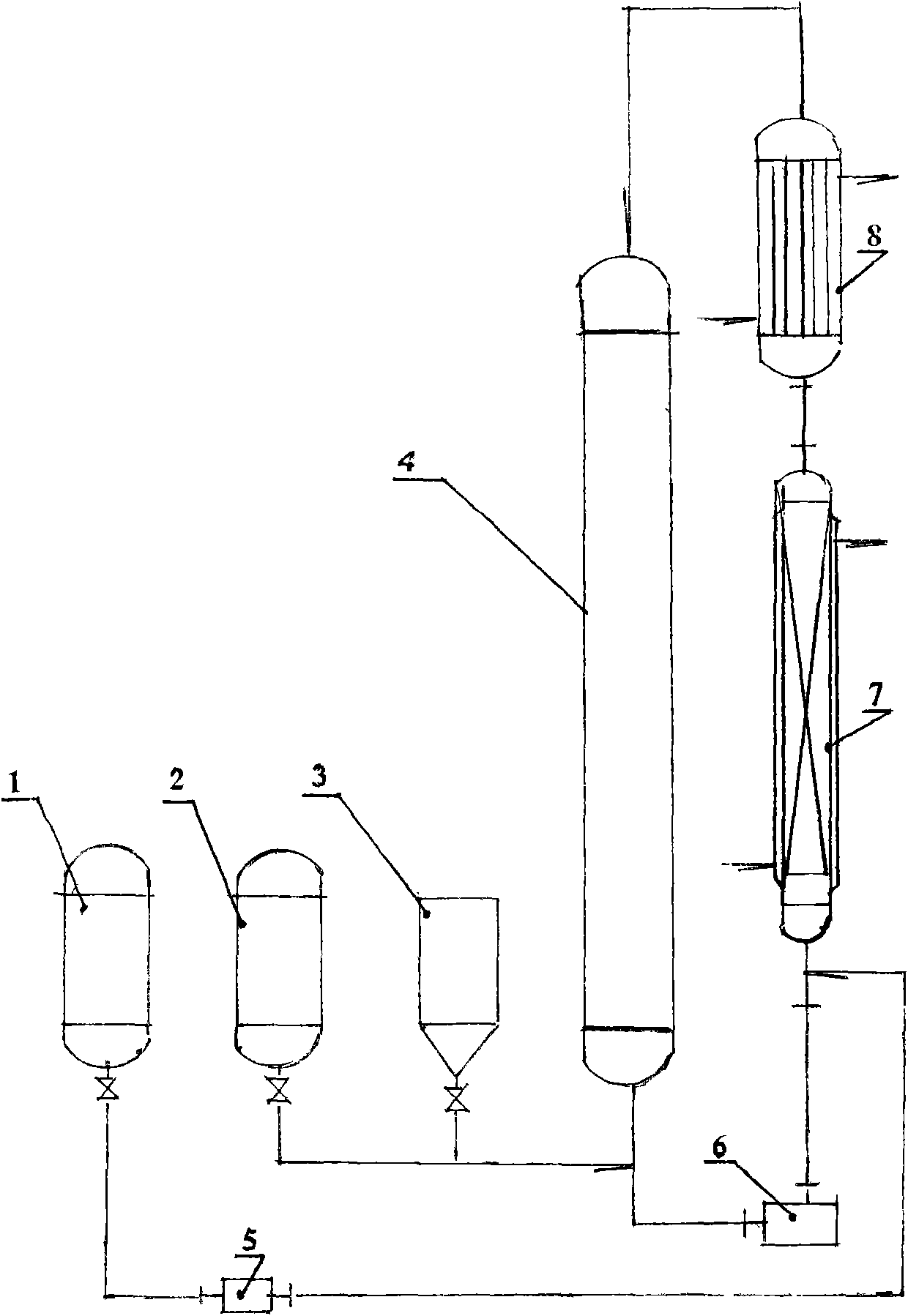

Method and device for producing sulfolane

ActiveCN102020632AIncrease mixing intensityAdequate responseOrganic chemistryFlow mixersChemistrySulfur dioxide

The invention discloses a method and device for producing sulfolane, and relates to a sulfolane production method and a device thereof. The invention mainly aims to solve the problems of poor effect, complex device and the like since kettle type reaction is adopted in the existing method for producing sulfolane. The method comprises the following steps: putting sulfur dioxide and polymerization inhibitor into a synthetic mixed reactor, injecting butadiene, and enabling the materials to circularly react in a synthetic static mixer, a synthetic heating and cooling unit and the synthetic mixed reactor by using a circulating pump; and diluting the sulfolene produced after reaction with benzene, adding catalyst and hydrogen, and enabling the materials to circularly react in a hydrogenation mixed reactor, a hydrogenation static mixer and a hydrogenation heating and cooling unit. The device comprises the synthetic mixed reactor, the circulating pump, the synthetic static mixer, the syntheticheating and cooling unit, the hydrogenation mixed reactor, the hydrogenation static mixer and the hydrogenation heating and cooling unit. The invention has the advantages of favorable reaction effectof materials, simple device and high safety, and the materials can be fed continuously and uniformly.

Owner:LIAODONG FINE CHEM

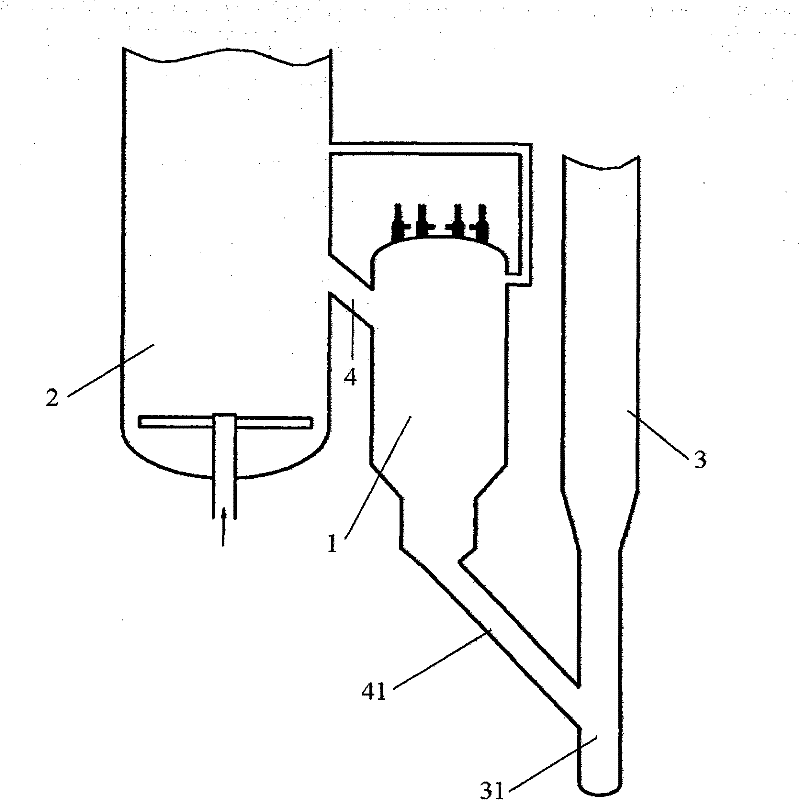

Tower-type powdered coal pressure gasification device with chilling process

ActiveCN101885991ALower the altitudeIncrease catch rateGranular/pulverulent flues gasificationSlagEngineering

The invention discloses a tower-type powdered coal pressure gasification device with a chilling process. The device comprises a pressure shell, and a gasification unit and a steam / water or dust-free gas chilling unit which are hung in the pressure shell. The device is characterized in that the gasification unit is arranged below the steam / water or dust-free gas chilling unit coaxially; the gasification unit comprises a reaction chamber and four nozzles arranged near the bottom of the reaction chamber at interval; the device of the invention also comprises a cooling channel and a returning chamber which are in coaxial arrangement with the gasification unit or the steam / water or dust-free gas chilling unit, and a chilling chamber and a slag pool; the cooling channel is arranged above the steam / water or dust-free gas chilling unit; the returning chamber is arranged on the top of the cooling channel; the chilling chamber is arranged around the cooling channel; the slag pool is arranged below the gasification unit; and the pressure shell is provided with a synthesis gas outlet, a grey water exhaust port and a slag-discharging hole. By using the device of the invention, dust and slag generated by gasification can be effectively separated and processed and the problem of performing thermal compensation to the entire equipment is effectively solved.

Owner:中国船舶集团有限公司第七一一研究所

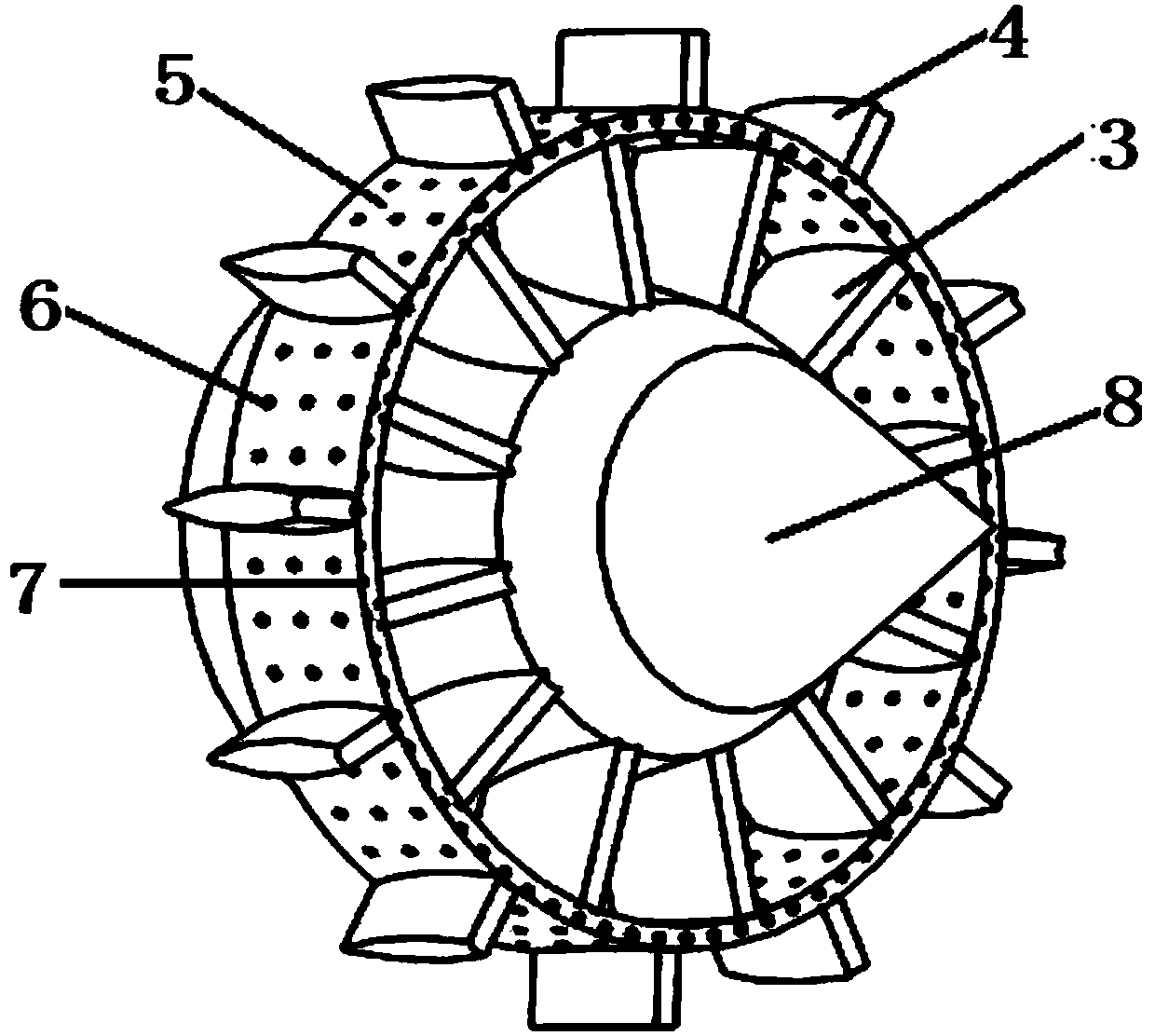

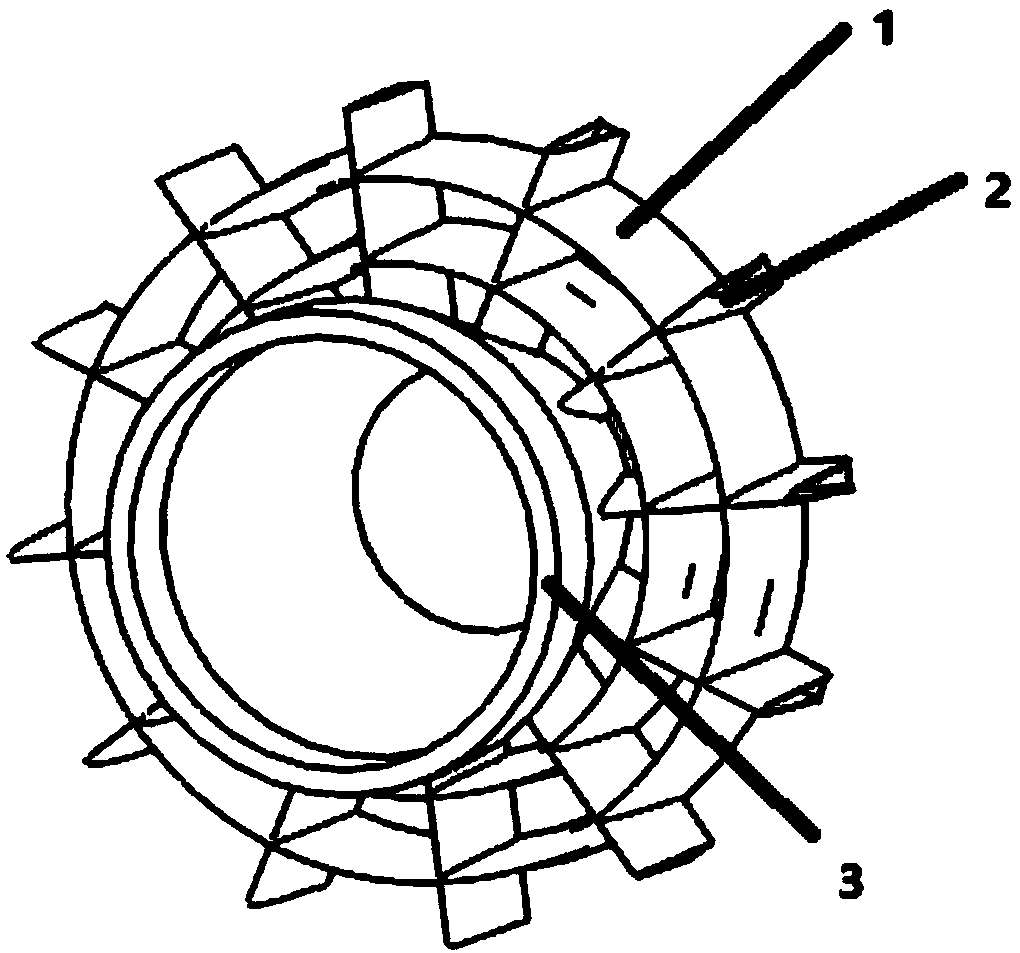

Integrated afterburner with grid-structure rectification supporting plate flame stabilizers

ActiveCN109595590AIncrease mixing intensityImprove combustion stability and combustion efficiencyContinuous combustion chamberSpray nozzleMesh grid

The invention provides an integrated afterburner with grid-structure rectification supporting plate flame stabilizers. The rectification supporting plate flame stabilizers in the radial direction areuniformly distributed on a thrust augmentation inner cone in the circumferential direction; the rectification supporting plate flame stabilizers in the circumferential direction perpendicularly intersect with the rectification supporting plate flame stabilizers in the radial direction and surround the thrust augmentation inner cone for one circle; the cross-sectional shape of the rectification supporting plate flame stabilizers in the radial direction is same as that of the rectification supporting plate flame stabilizers in the circumferential direction; and through the net-shaped structuraldesign of the rectification supporting plate flame stabilizers, a back flow area which is uniform and stable and has the certain fuel gas back flow amount and the appropriate size can be effectively formed on the downstream. Fuel oil enters the rectification supporting plate flame stabilizers through a fuel oil channel, is heated through high-temperature incoming gas and then is sprayed out through main fuel oil spray nozzles and standby fuel oil spray nozzles which are located on the two sides of the V shapes of the rear of the rectification supporting plate flame stabilizers, the fuel oil atomization degree and mixing of fuel oil and air can be effectively enhanced, and the burning stability and burning efficiency are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

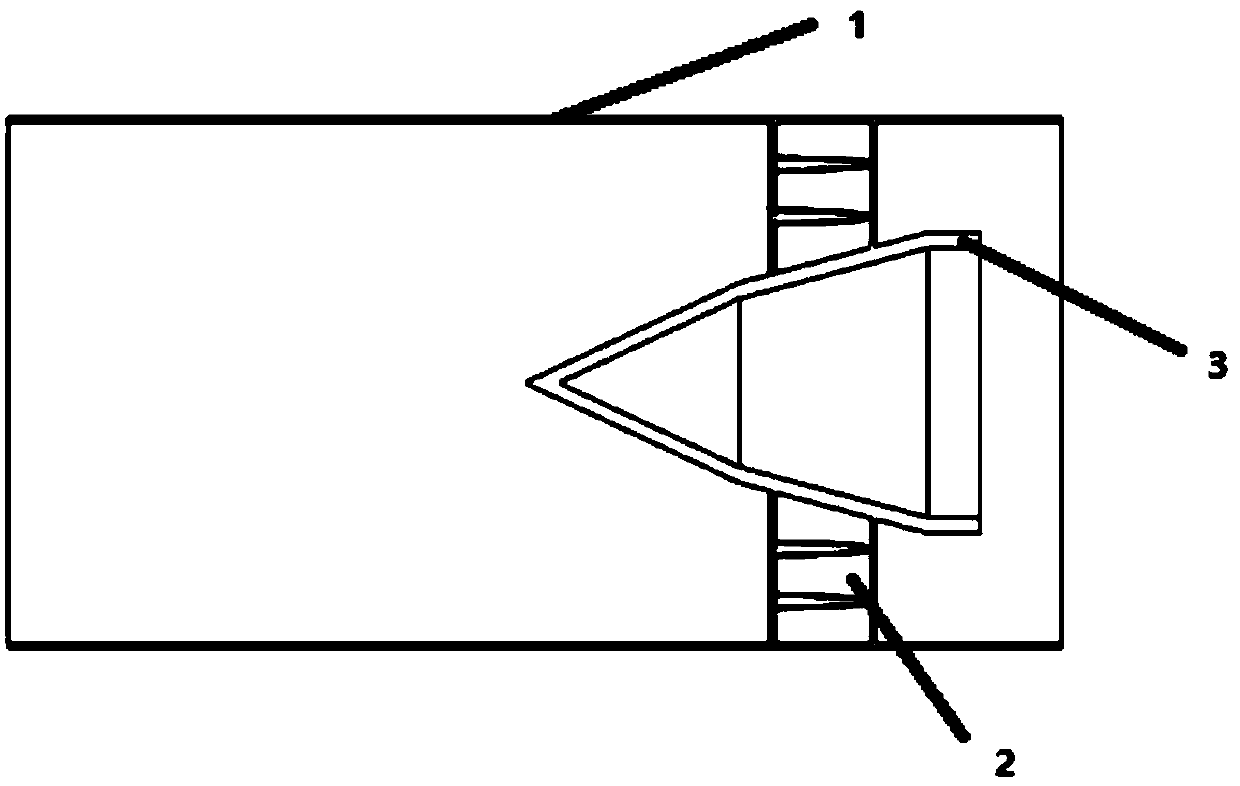

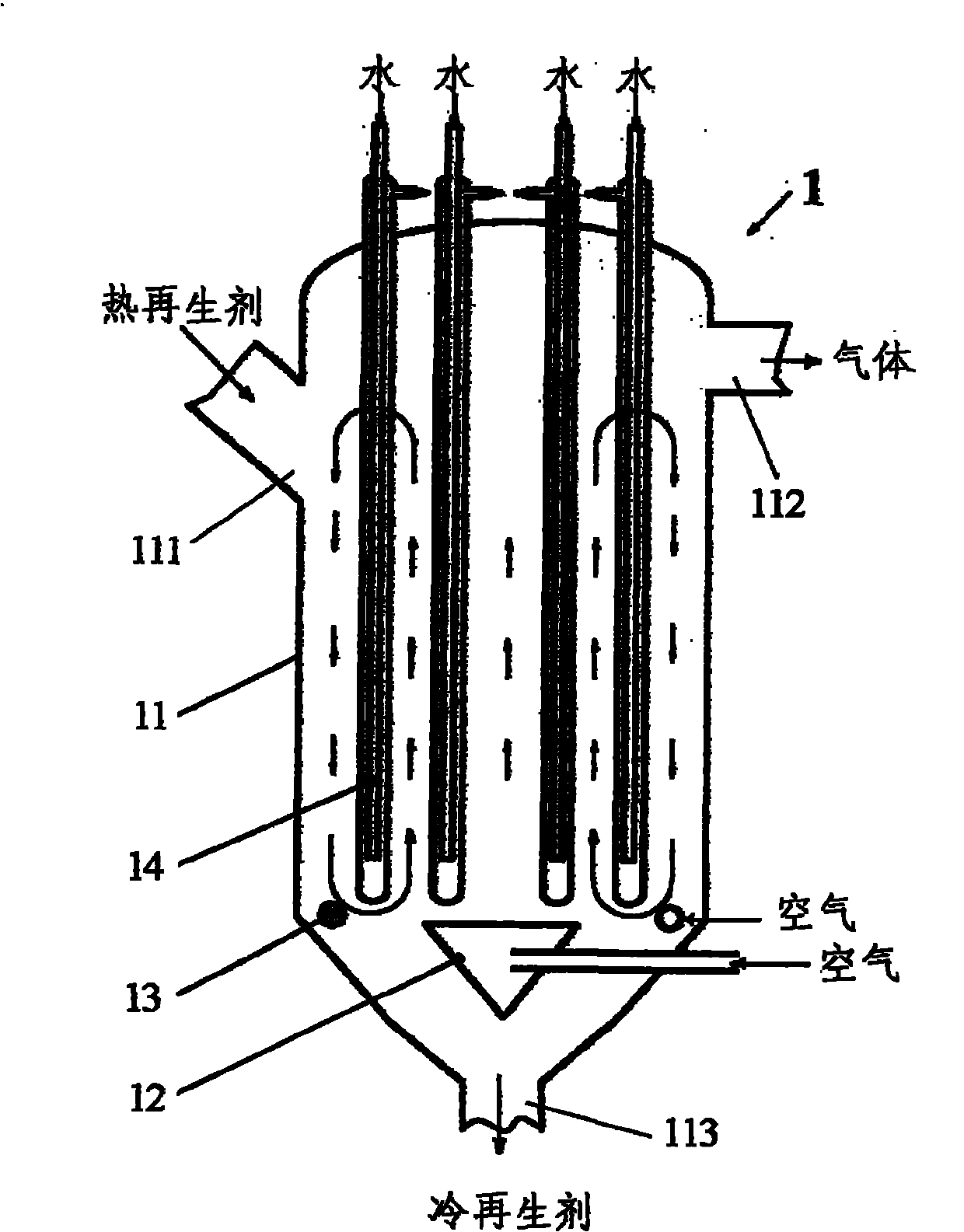

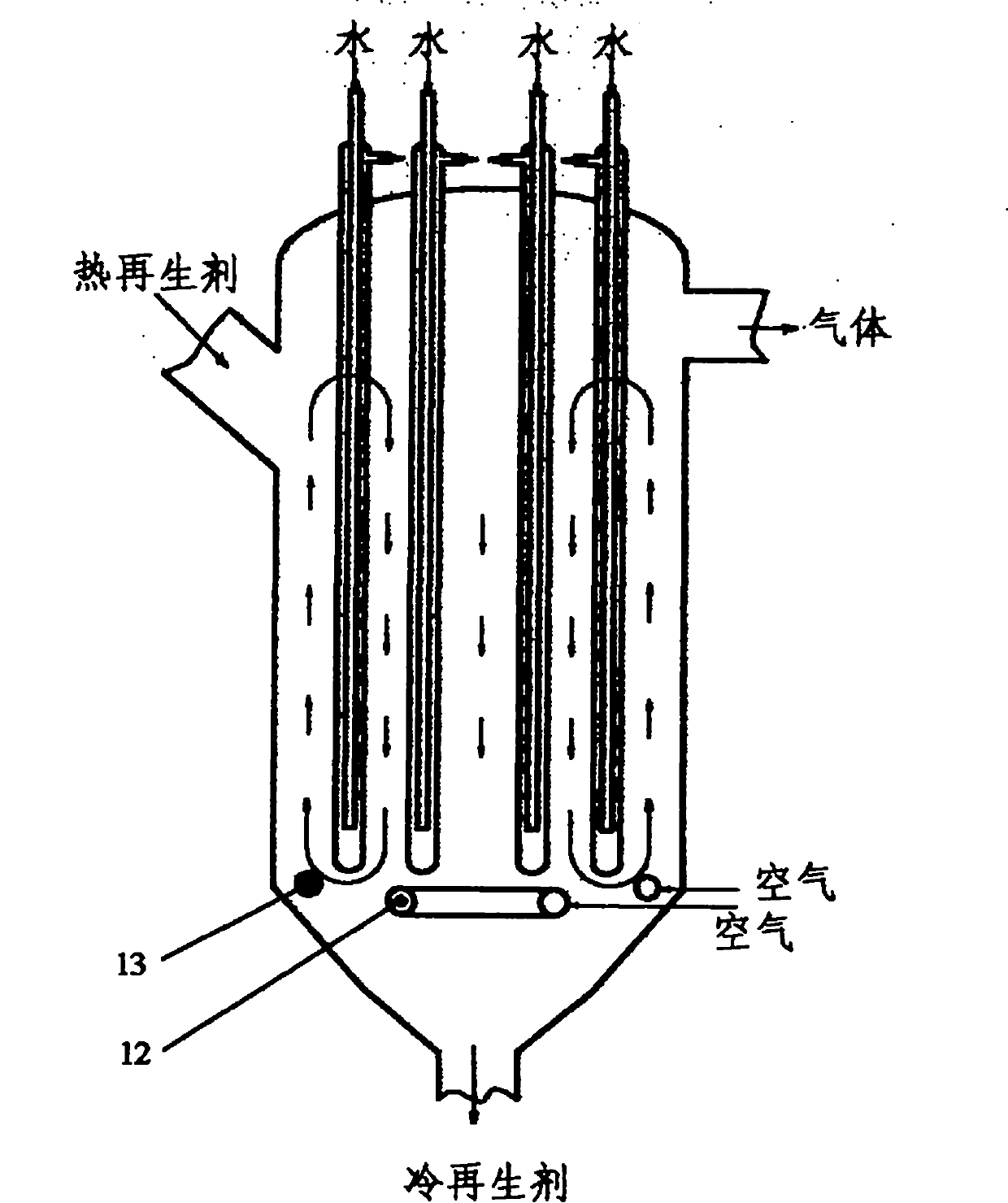

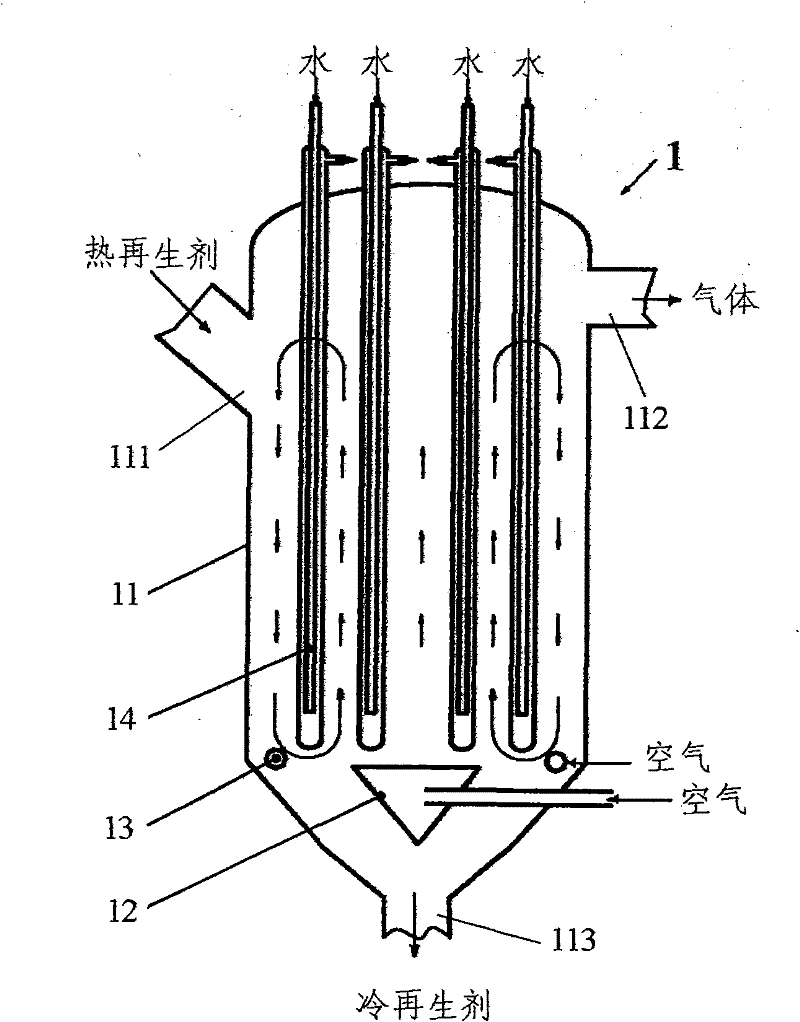

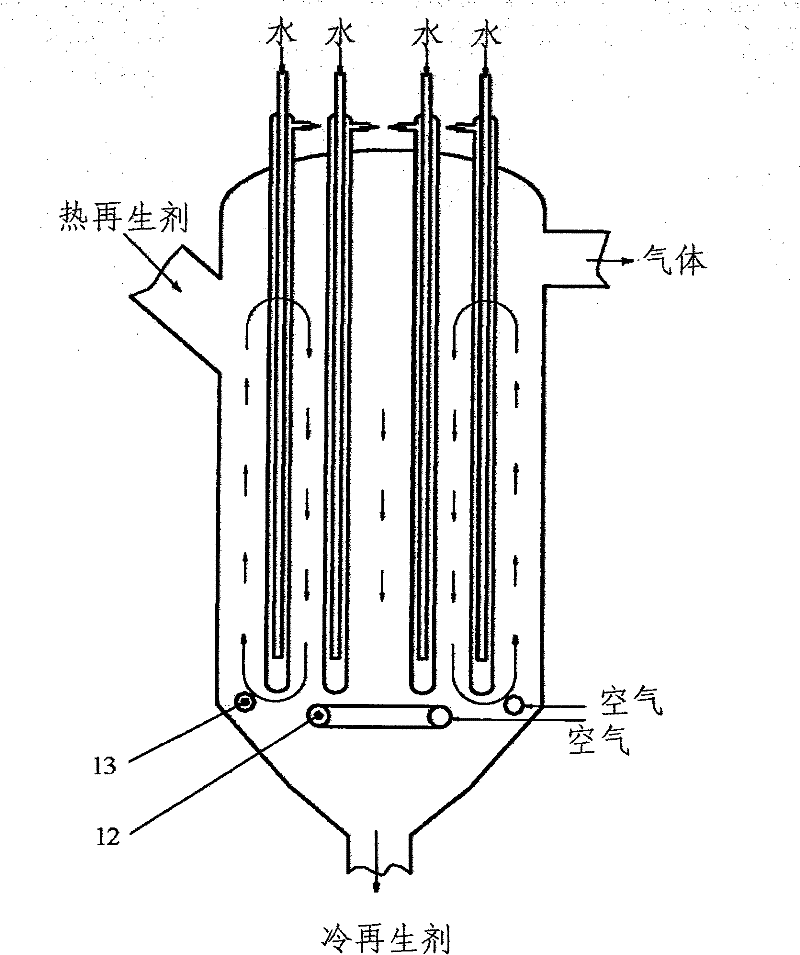

Forced internal recirculation type external cooler for catalytic cracking catalyst

ActiveCN101769694AHigh heat extraction efficiencyMixing Intensity ChangesStationary conduit assembliesFluidised bed heat exchangersPtru catalystEngineering

The invention provides a forced internal recirculation type external cooler for a catalytic cracking catalyst. At least two gas distributors are arranged at the internal bottom of the cooler, and each gas distributor is accessible to fluidized gas independently and can control the gas flow. A plurality of cooling tubes in vertical arrangement are arranged above the gas distributors. Apart from the gas distributors, the cooling tubes and matched fixed parts thereof, no additional components are arranged in the cooler. By controlling the different gas flows of at least two gas distributors, the superficial gas velocity and the bed density in different cross section areas in the cooler are caused to be different and the internal circulation of particles in a bed is strengthened, so the update velocity of the particles on a heat transfer wall is improved and the heat transfer efficiency of the particles and the wall is effectively improved. The cooler has the advantages of simple structure, high heat transfer efficiency and flexible regulation, and can also be used as a themosistor for a catalytic cracking regenerant. In addition, the invention also provides a catalytic cracking device containing the cooler and a catalytic cracking method.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

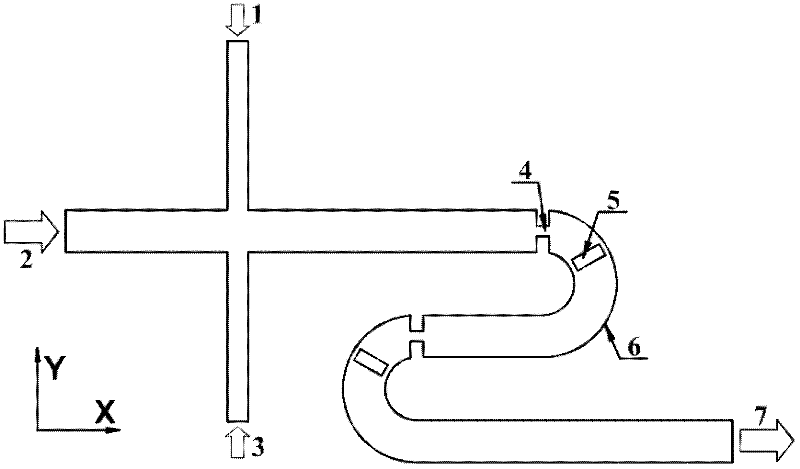

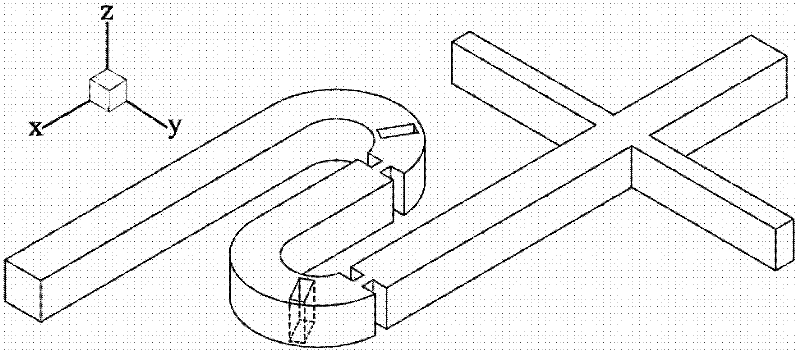

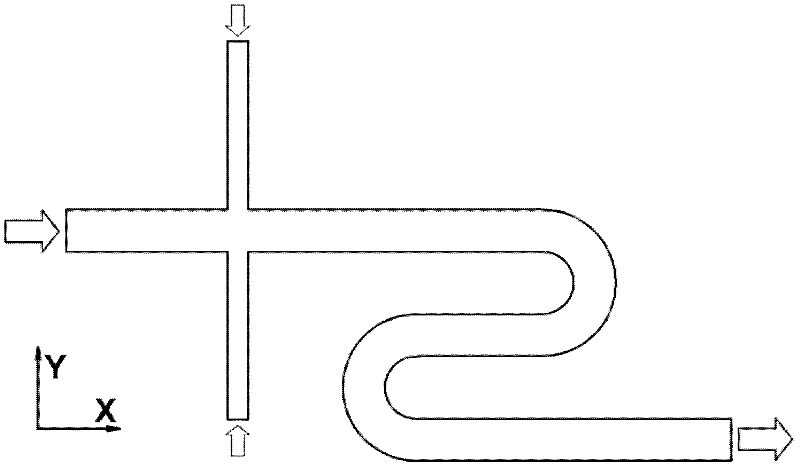

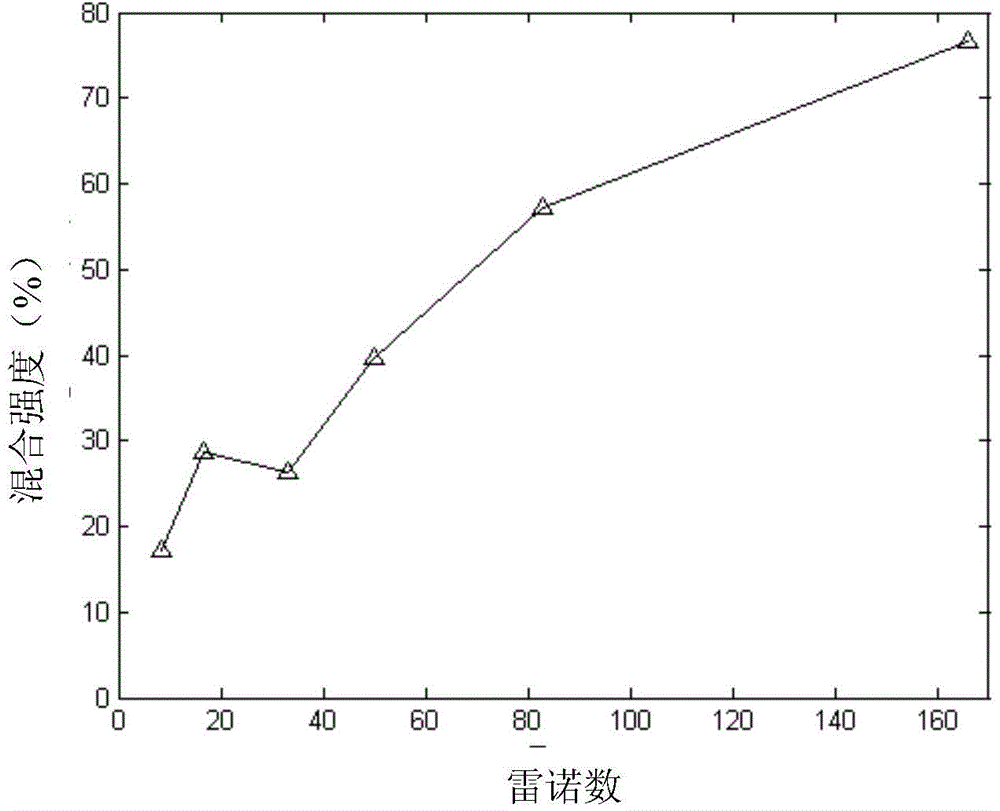

Planar passive micro mixer based on vortex forming structure enhanced mixing

InactiveCN102233241AIncrease contact areaIncrease disturbanceFlow mixersMixing methodsMicrofluidic chipMICRO MIXER

The invention discloses a planar passive micro mixer based on vortex forming structure enhanced mixing, relating to the field of micro fluid mixing in micro total analysis systems and micro fluid control chips as well as the related fields. The micro mixer is formed by connecting a straight passage, a cross passage, a first C-shaped passage and a second C-shaped passage; a passage outlet is formed at a straight passage outlet connected with the second C-shaped passage, and vortex forming structures are arranged in the C-shaped passages; and the end arm of the cross passage, which is opposite to the connected C-shaped passage, is provided with a second passage inlet (2), and the end arm vertical to the end arm is provided with a first passage inlet (2) and a third passage inlet (3) respectively. Compared with a planar passive micro mixer without the vortex forming structures, the planar passive micro mixer based on vortex forming structure enhanced mixing has the advantage of obviously enhancing the mixing strength of the micro fluid in the passages because several kinds of vortex generated by the vortex forming structures are generated in different dimensional planes respectively.

Owner:BEIJING UNIV OF TECH

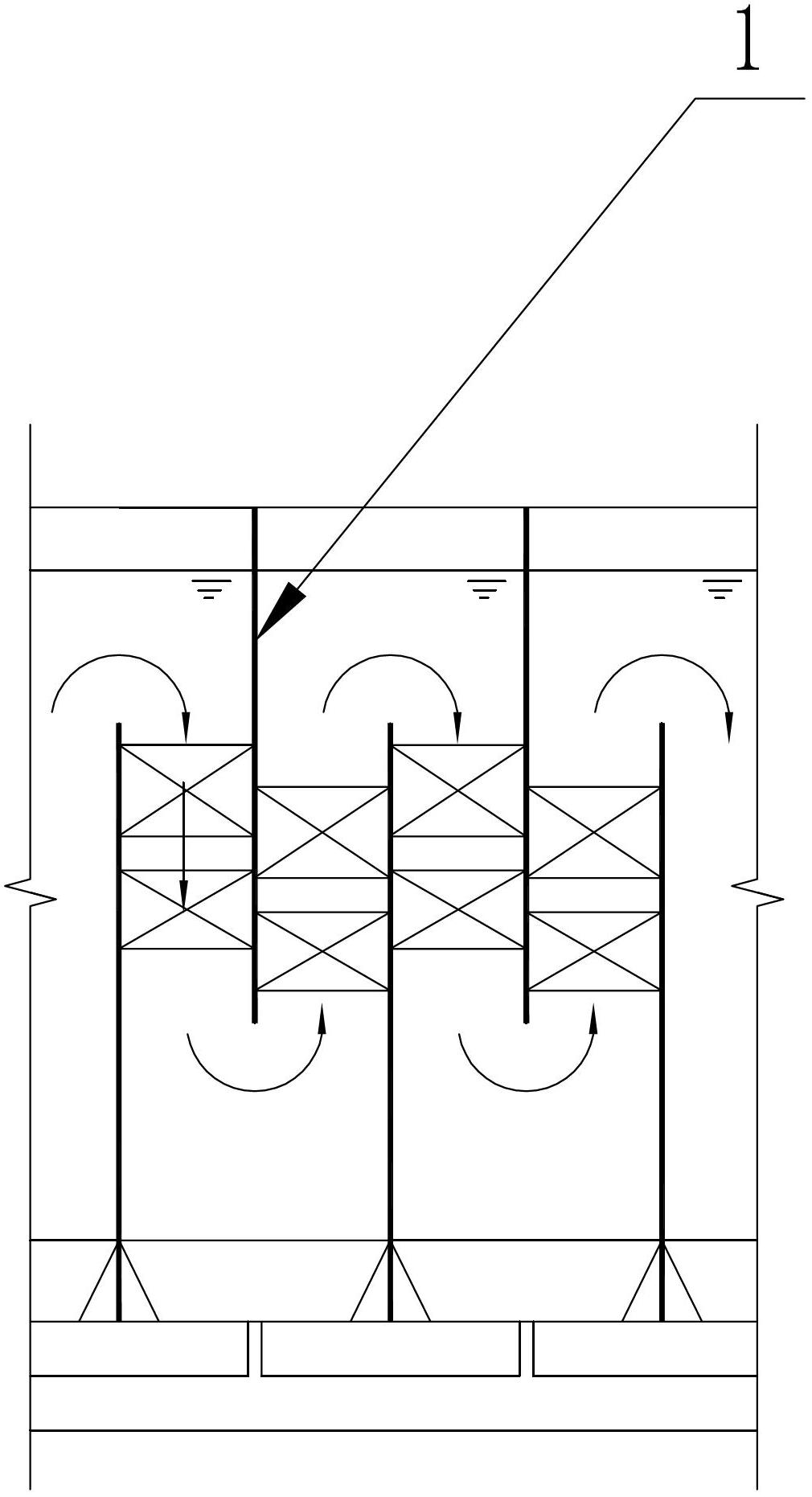

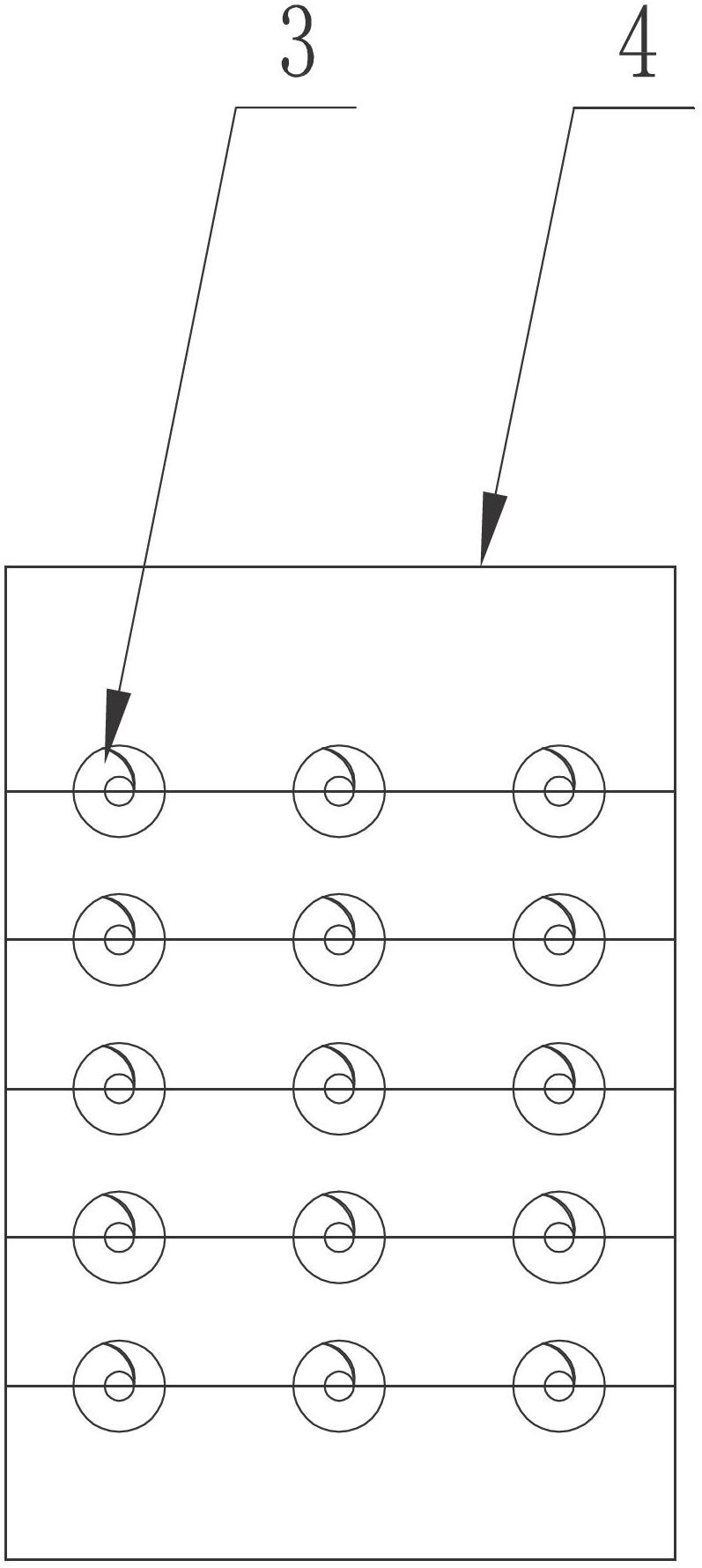

Bubble reactor with multiple layers of draft tubes and using method for bubble reactor

ActiveCN106552577AHigh selectivityAvoid backmixingPreparation by oxidation reactionsOrganic compound preparationReaction rateEngineering

The invention discloses a bubble reactor with multiple layers of draft tubes and a using method for the bubble reactor. The multiple layers of draft tubes are sleeved by a reactor shell; the diameter of each draft tube is different; the draft tubes are used for internally dividing the reactor shell into a plurality of stages of ring-shaped areas, height of the draft tubes is gradually reduced towords the outer side along the center; the draft tube located at the center communicates with a liquid inlet; the ring-shaped area at each stage and the draft tube located at the center communicate with a gas inlet; the ring-shaped area on the outermost layer communicates with a liquid outlet; and a gas outlet is formed in the top of the reactor shell. According to the reactor disclosed by the invention, liquid-phase cyclohexane overflows layer by layer, and oxygen molecule content of introduced air is improved stage by stage to carry out oxidation reaction, so that a mass transfer rate of oxygen can be sufficiently ensured to be matched with a reaction rate, and therefore, oxidation reaction can be stably and efficiently performed. The bubble reactor improves a flowing condition in the reactor, improves selectivity of a process, and can improve cyclohexane selectivity by 1.0%-2.5% in comparison with the prior art.

Owner:CHINA PETROLEUM & CHEM CORP

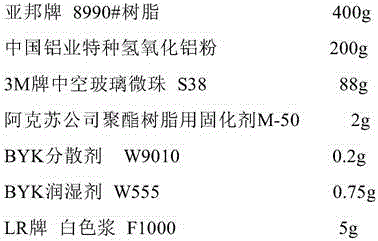

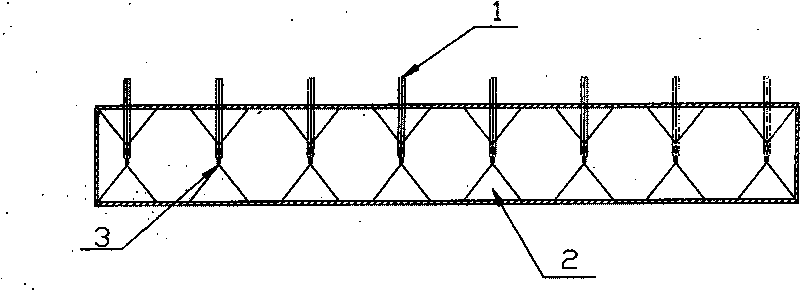

Artificial stone material and preparation method and use thereof

The present invention relates to the field of materials, and discloses an artificial stone material and a preparation method and use thereof, and the artificial stone material comprises the following components by weight: 20 to 60 parts of resin, 10 to 30 parts of a filling material and 6 to 10 parts of hollow glass beads. The hollow glass beads as a lightweight filler are added into the artificial stone formula, on the one hand, the density of the artificial stone formula is reduced, so that the artificial stone material is lighter in weight, on the other hand, due to good interface compatibility of the hollow glass beads and the resin and other filler relative to other lightweight materials, the artificial stone material is higher in strength retention rate, the artificial stone material is easier to polish, a product prepared from the artificial stone material has contamination-resistant surface appearance with good chemical resistance, a surface coating or gel coat is not needed, and artificial stone products are easy to design.

Owner:KOHLER CHINA INVESTMENT

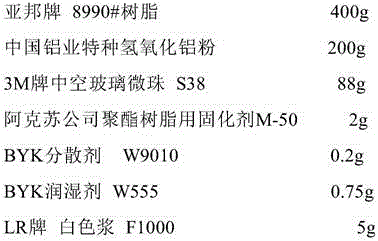

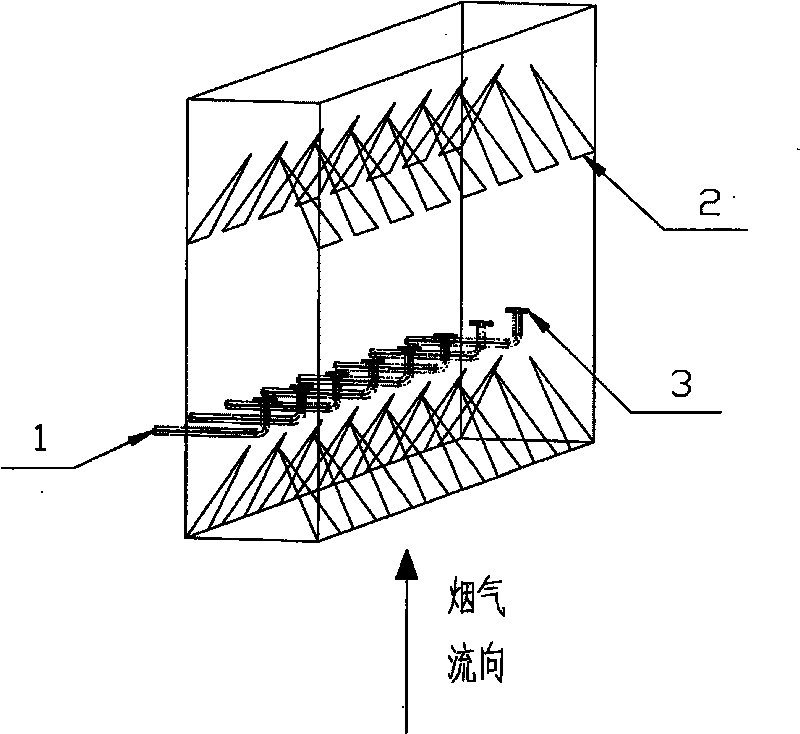

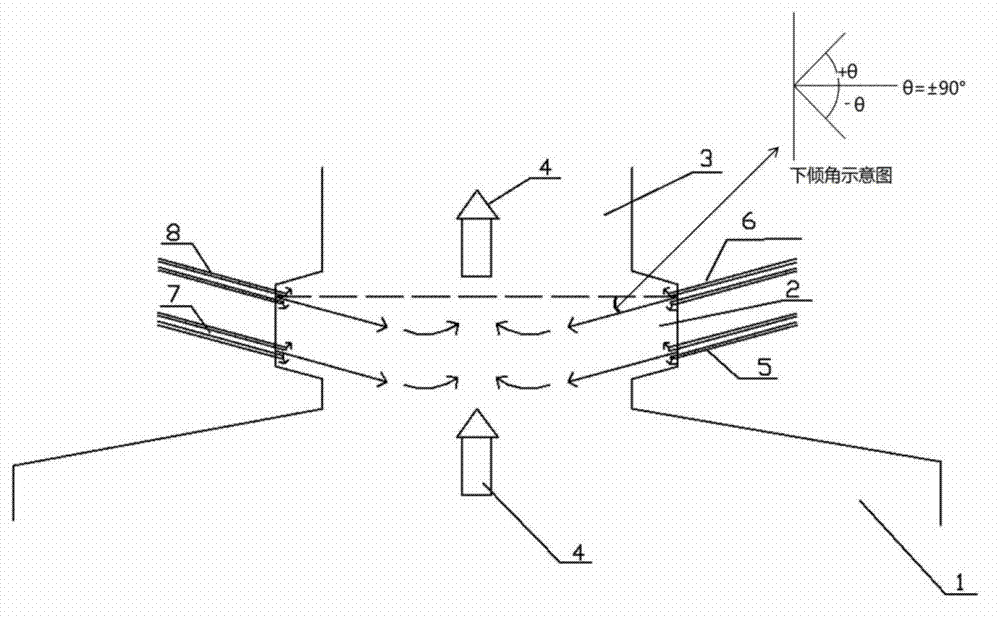

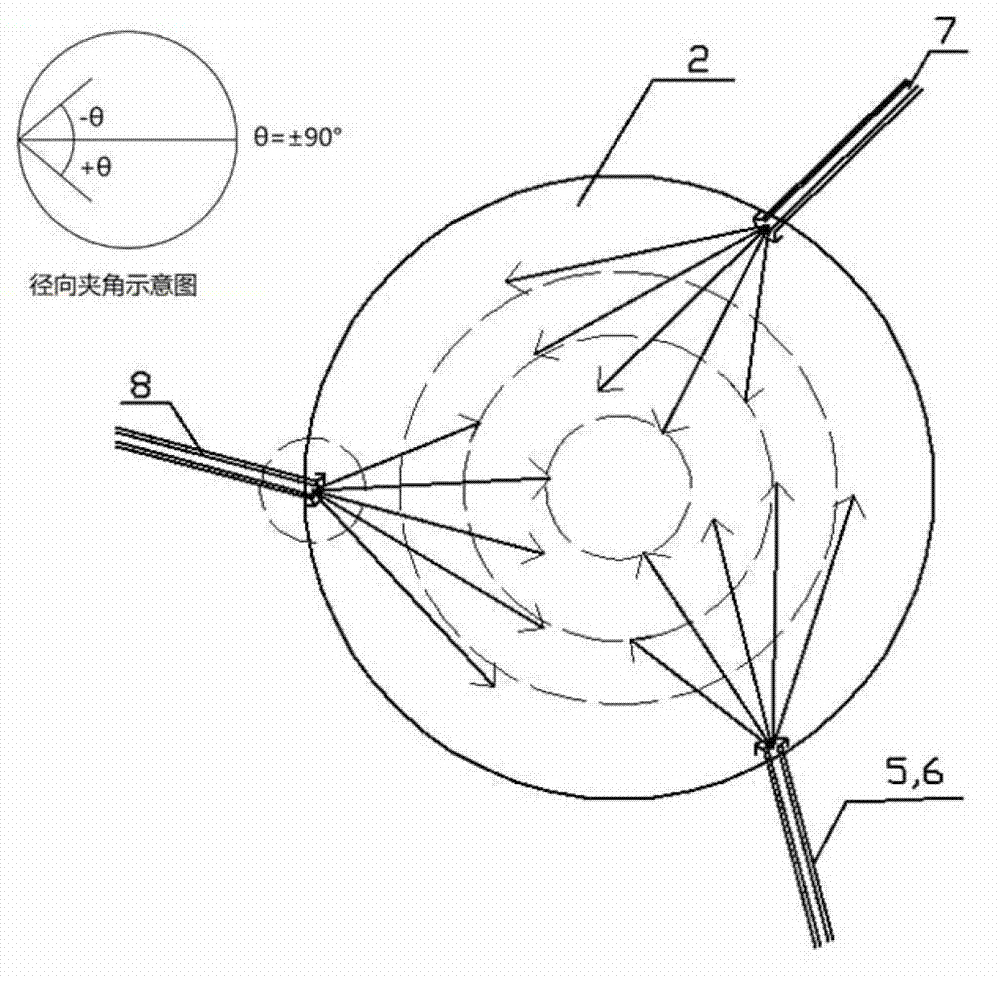

Ammonia spraying and mixing system for coal-fired flue gas SCR denitration technology

InactiveCN101708430AIncrease mixing intensityImprove the mixing effectLighting and heating apparatusDispersed particle separationStreamflowReducing agent

The invention discloses an ammonia spraying and mixing system for the coal-fired flue gas SCR denitration technology and relates to a system used for spraying reducing agent ammonia and strengthening the mixture of ammonia and flue gas. The ammonia spraying and mixing system comprises 5-20 reducing agent ammonia jet tubes with independent flow control systems and longitudinal vortex generation elements, wherein the tail end of each reducing agent ammonia jet tube is provided with a two-way nozzle which is vertical and symmetric to the flue gas stream, each longitudinal vortex generation element is a triangle, a trapezoid, a half round or a half ellipse, each longitudinal vortex generation element is connected with the flue wall and forms 30-60 degrees angle with the flue gas stream so as to form longitudinal vortex of which downstream is stable, increase the intensity of turbulent flow and enhance the mixture of reducing agent ammonia and glue gas. The device has the following advantages: 1) the stable longitudinal vortex is formed, the mixing intensity of vortex is increased, and the mixing effect of ammonia and nitrogen is optimized; 2) the number of the ammonia jet tubes is reduced, the ammonia-spraying regulation difficulty is lowered; and 3) pressure breakdown caused by the system is relatively small and the energy loss is reduced.

Owner:ZHEJIANG UNIV

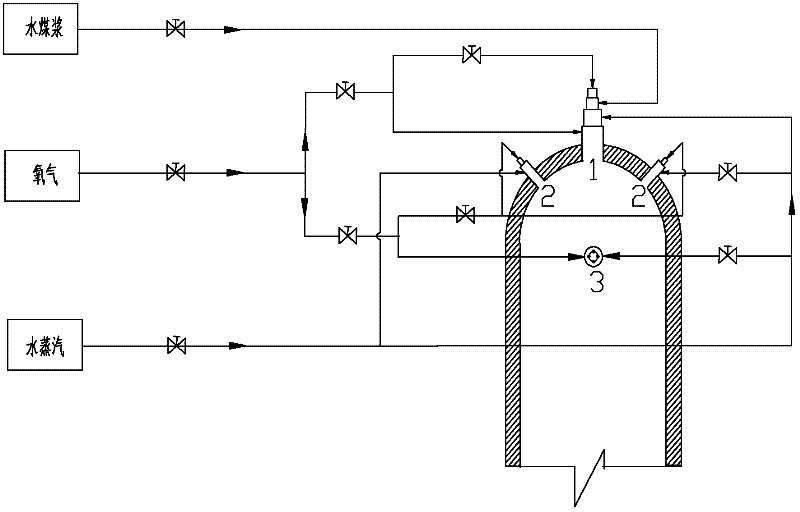

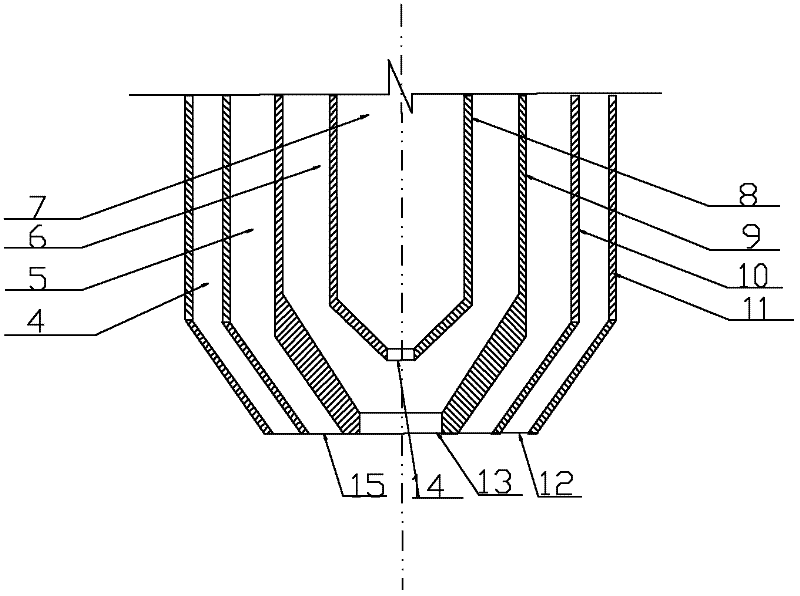

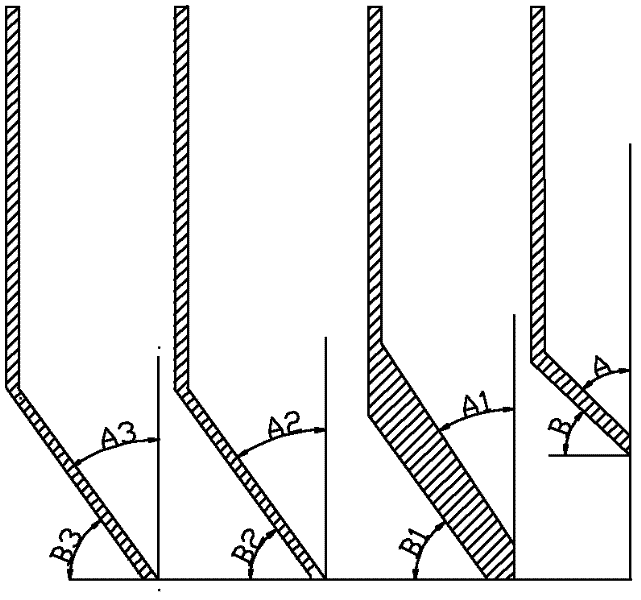

Hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle

InactiveCN102492477AReduce burning intensityLower flame temperatureLiquid spraying apparatusCombined combustion mitigationSlagReaction rate

The invention relates to a hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle which is arranged on a gasification furnace. The hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle comprises a main fuel nozzle which is arranged at the top of a furnace, two steam nozzles which are arranged at the two sides of a furnace arch and two oxygen supply nozzles which are horizontally arranged in a hedging manner, wherein the nozzles are respectively connected with a coal water slurry source, an oxygen source and a steam source, and the openings of the nozzles lead into a hearth of the gasification furnace. According to the invention, an advanced temperature control technology combining a grading oxygen supply temperature control technology and a steam temperature control technology is adopted, combustion intensity and flame temperature in the furnace are effectively reduced, and the aim that ash at the outlet of the gasification chamber is non-fused solid slag; meanwhile, gasification reaction rate and carbon conversion rate are improved, thus gasification solid deslagging on a 'double high' coal type large-scale pressurization entrained bed in China is realized, and the hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle provided by the invention is especially applicable to industrial application of a high-ash (25-27%) and high-ash-fusing-point (FT is more than 1400 DEG C) coal type large-scale gasification device in China.

Owner:SHANGHAI JIAO TONG UNIV

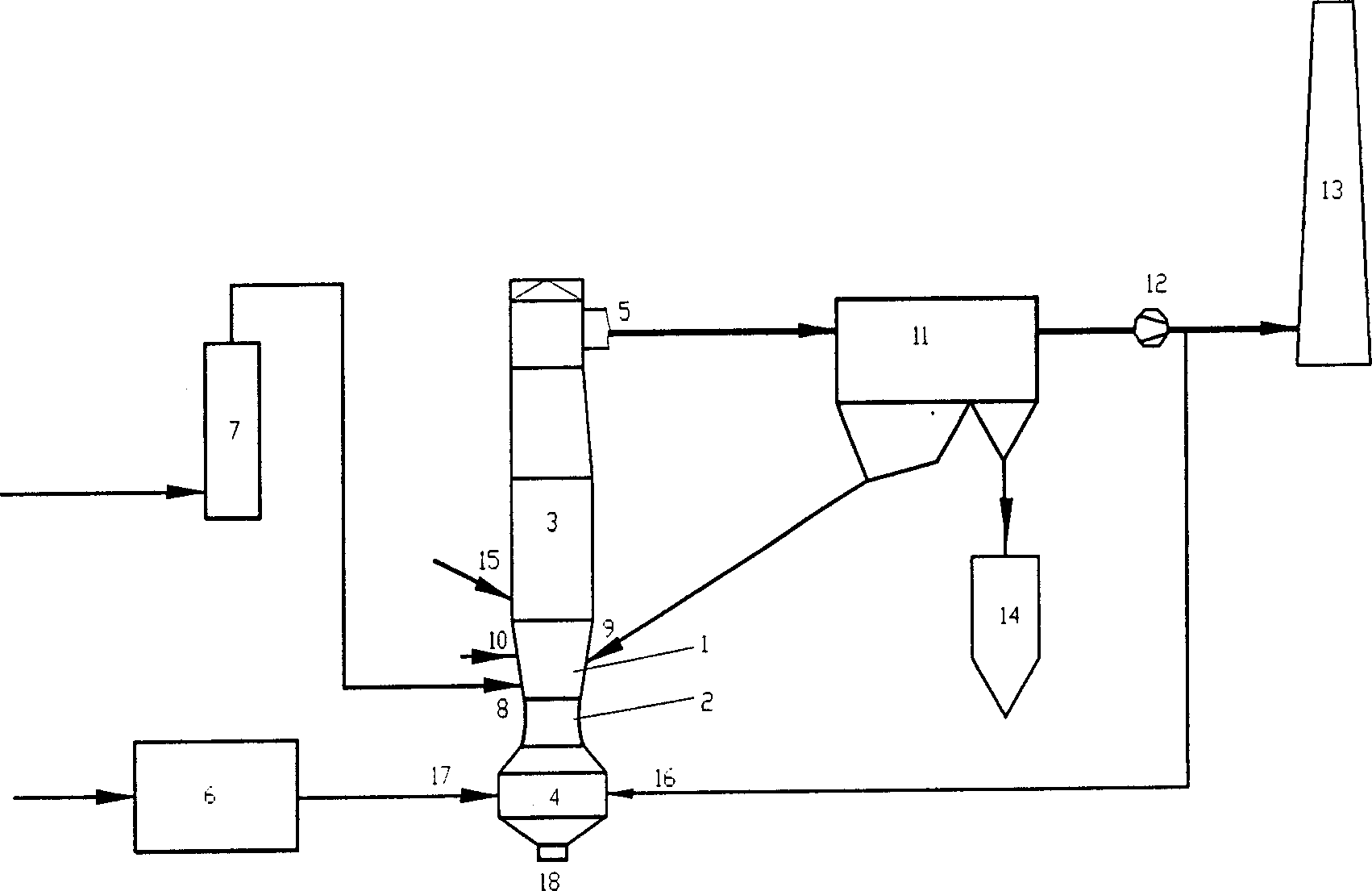

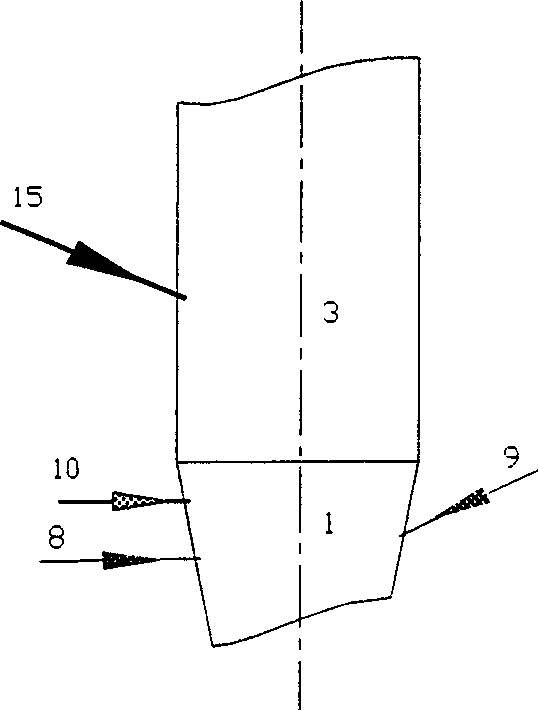

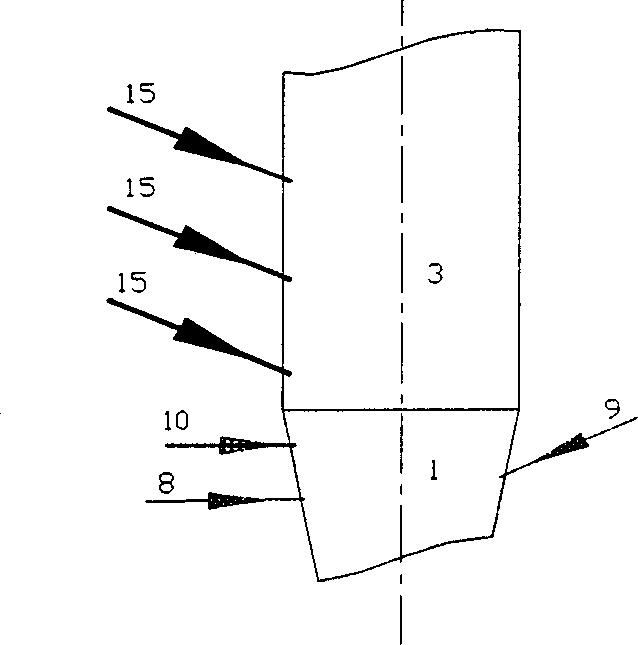

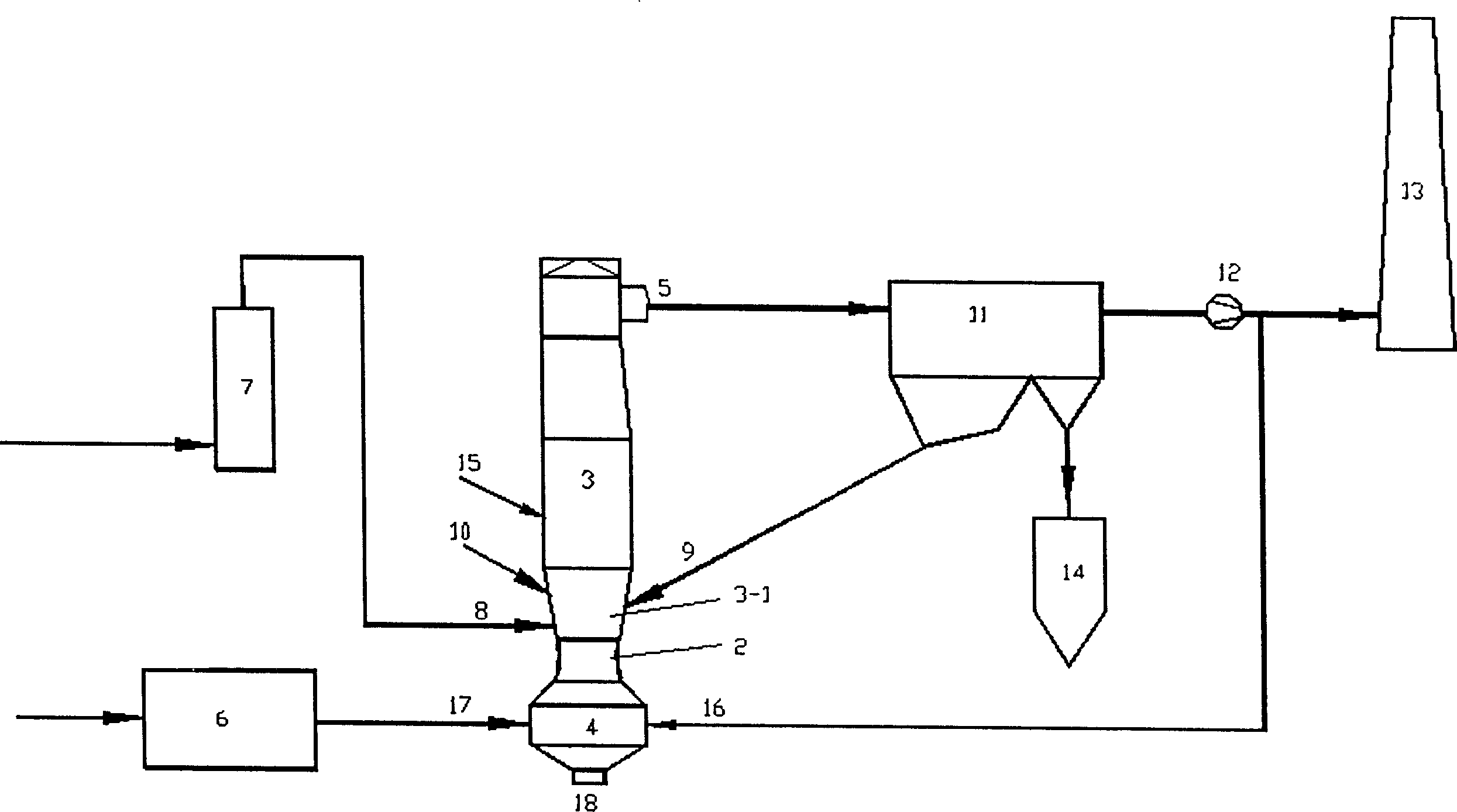

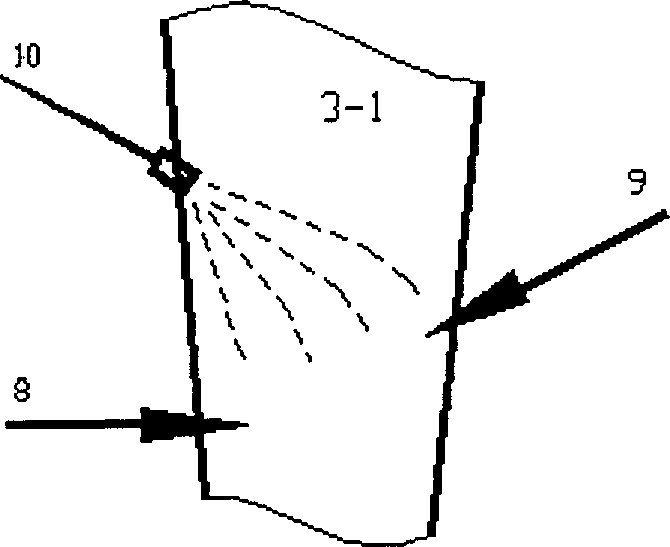

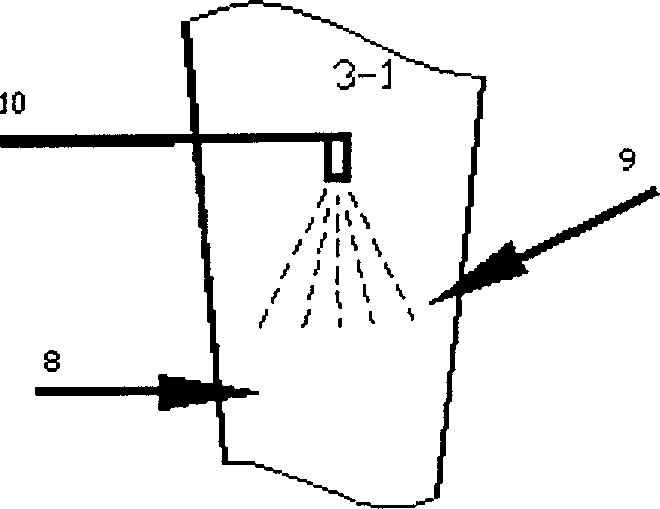

Dry-process flue gas desulfurizing method using combined gas jet

InactiveCN1488426ASmall circulation resistanceIncrease mixing intensityDispersed particle separationFlue gasEngineering

The invention discloses a drying smoke desulfurizing method by using combined smoke jet. The character is that it adds a smoke jet nozzle above the water nozzle and desulfurizing agent muzzle. It realizes the fully combination of gas, solid and liquid in the desulfurizing reaction tower, increases the desulfurizing efficiency.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

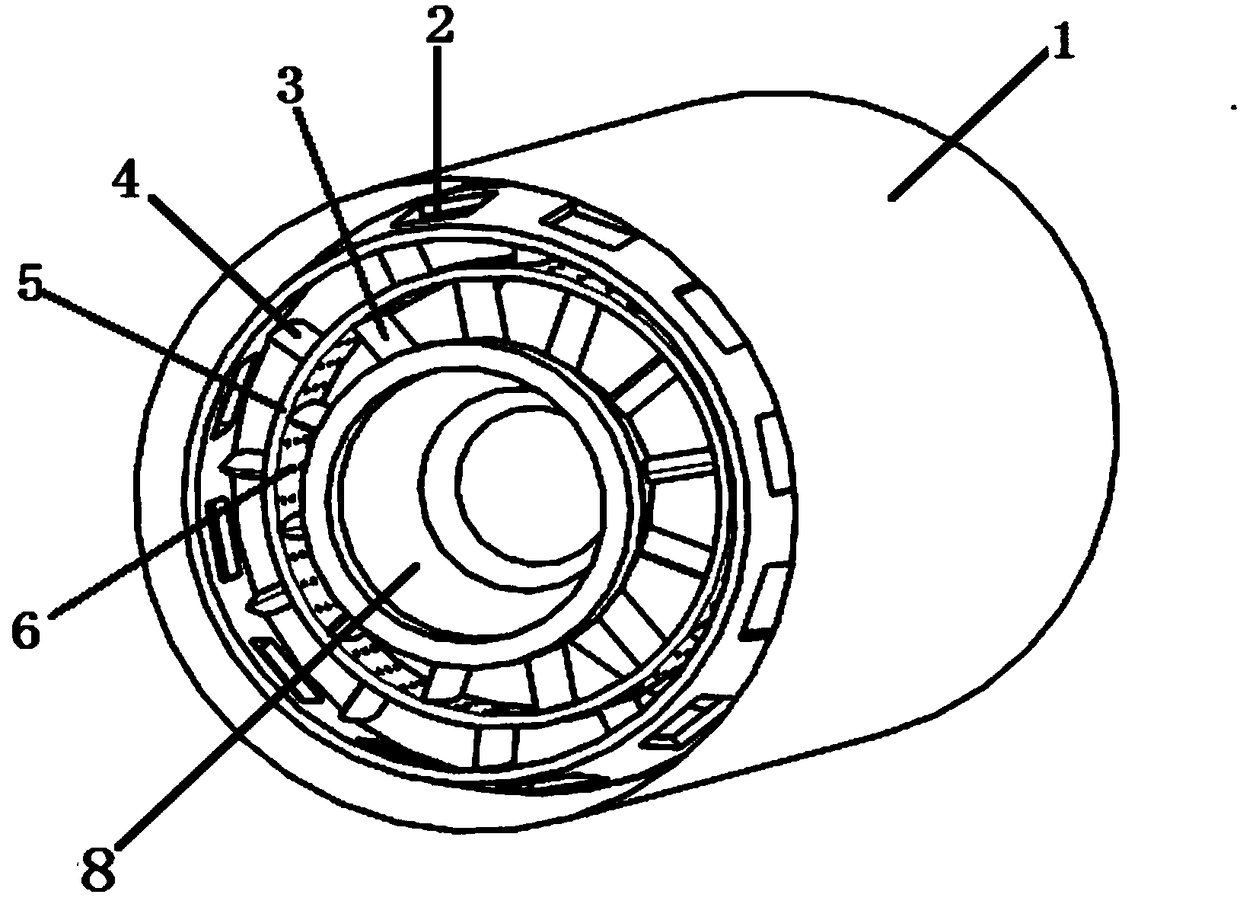

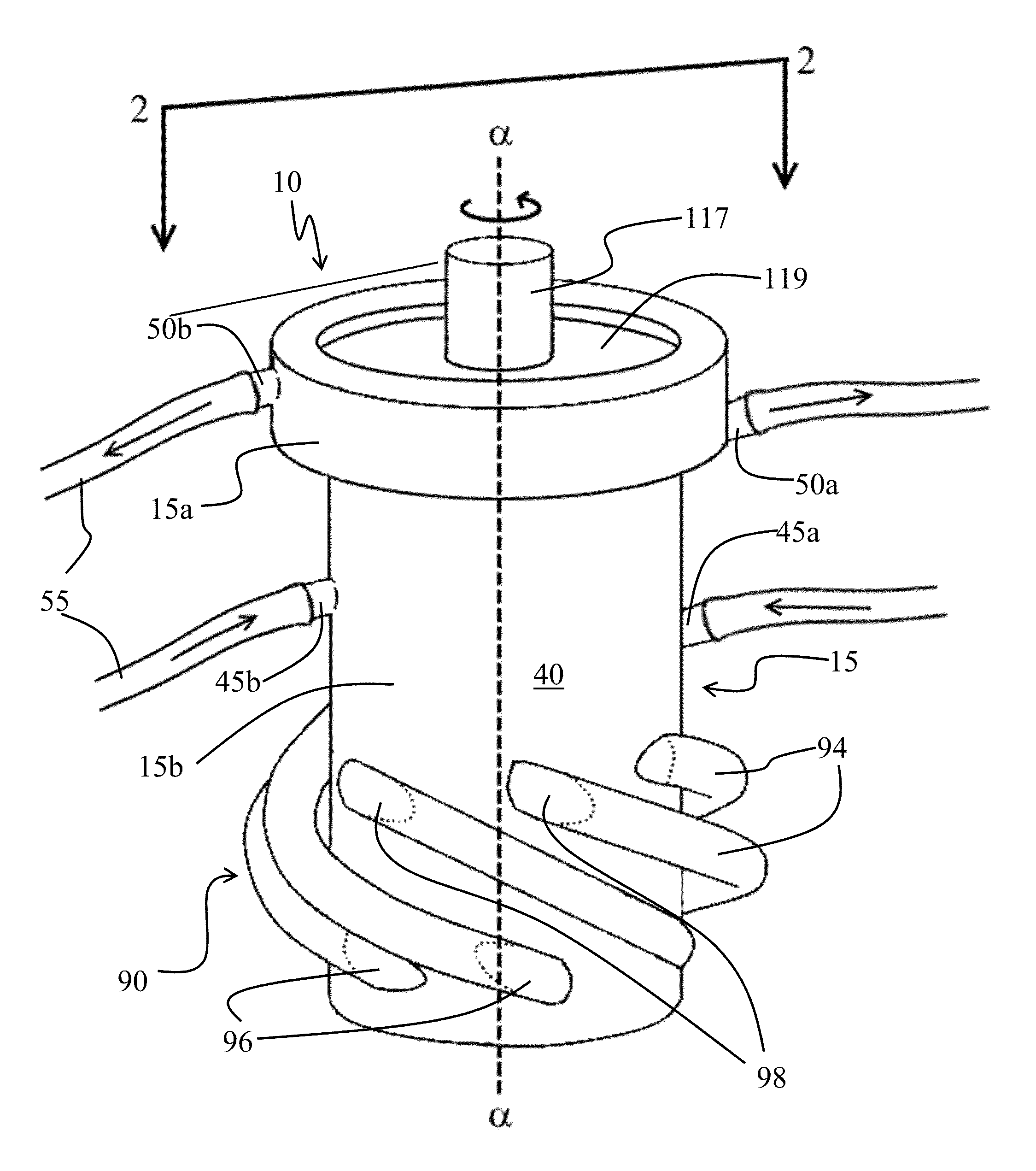

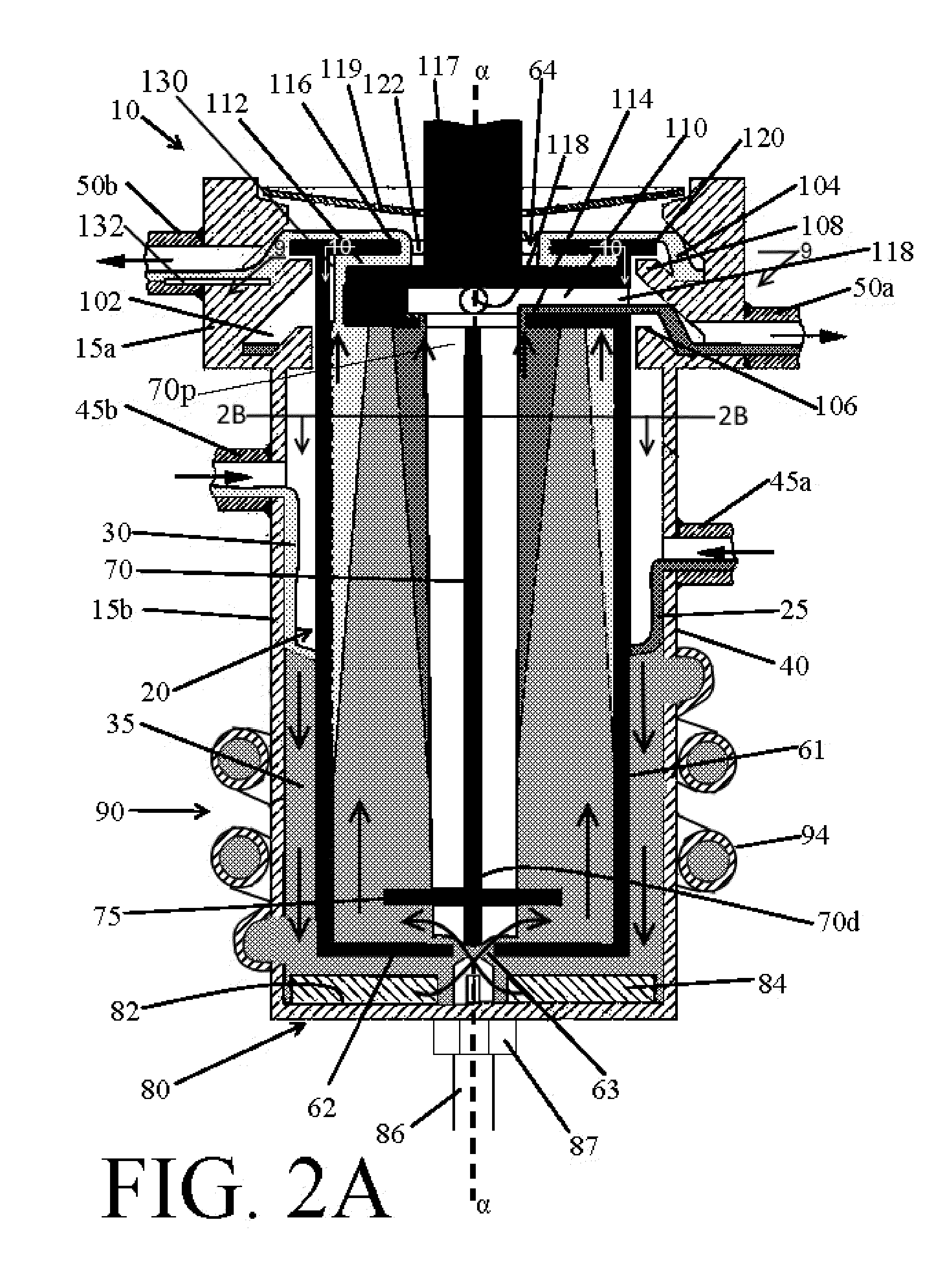

3D printed modular centrifugal contactors and method for separating moieties using 3D printed optimized surfaces

ActiveUS20160184735A1Increase fluid residence timeResidence time can be doubledMixing methodsSolid sorbent liquid separation3d printEngineering

The present invention provides an annular centrifugal contactor, having a housing to receive a plurality of liquids; a rotor inside the housing; an annular mixing zone, with a plurality of fluid retention reservoirs; and an adjustable stem that can be raised to restrict the flow of a liquid into the rotor or lowered to increase the flow of liquid into the rotor. The invention also provides a method for transferring moieties from a first liquid to a second liquid, the method having the steps of combining the fluids in a housing whose interior has helically shaped first channels; subjecting the fluids to a spinning rotor to produce a mixture, whereby the channels simultaneously conduct the mixture downwardly and upwardly; and passing the mixture through the rotor to contact second channels, whereby the channels pump the second liquid through a first aperture while the first fluid exits a second aperture.

Owner:UCHICAGO ARGONNE LLC

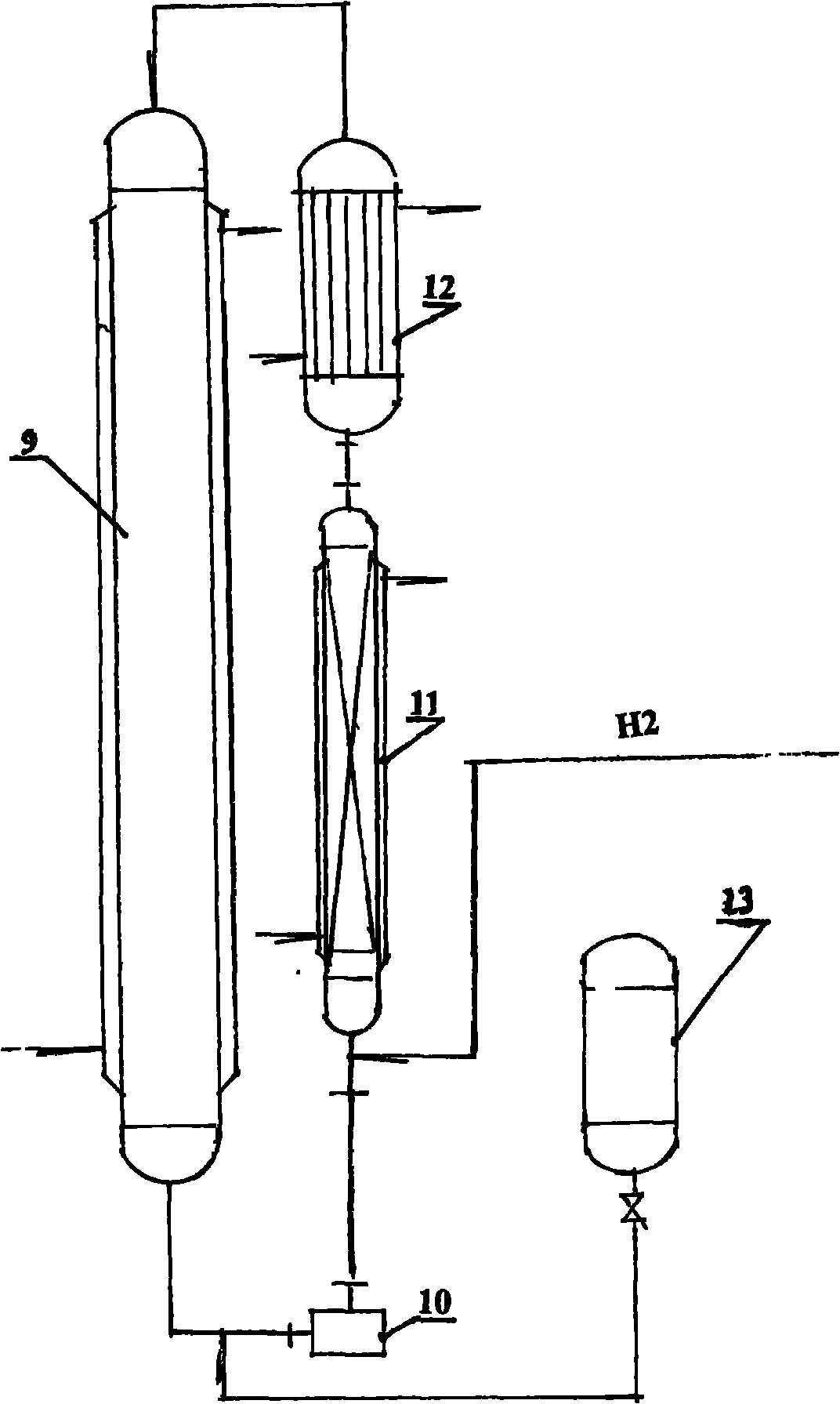

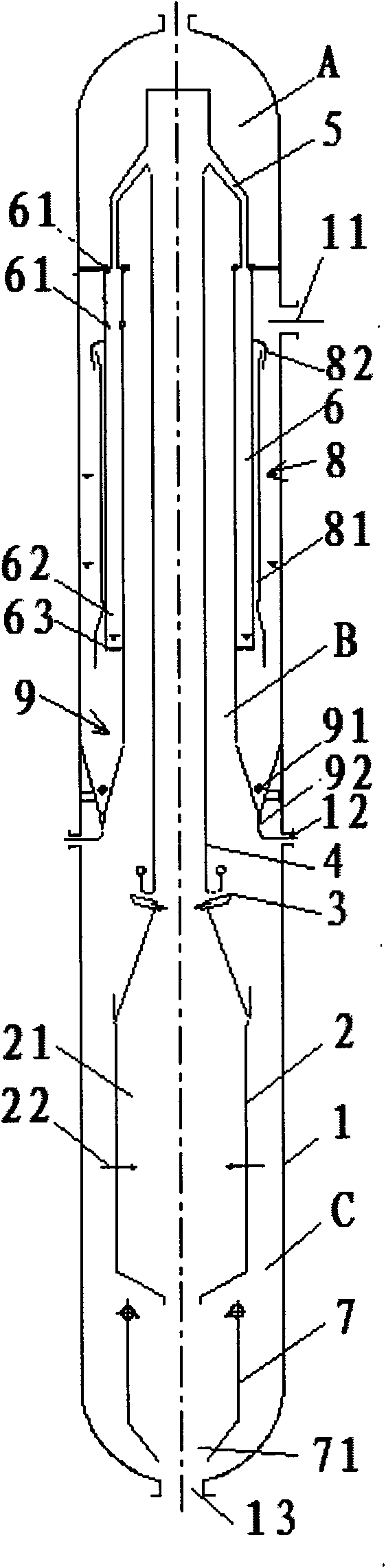

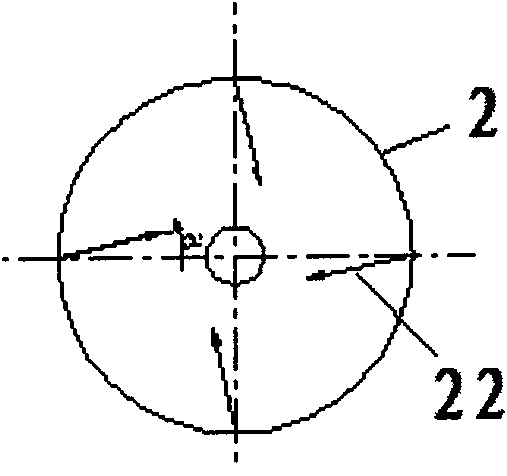

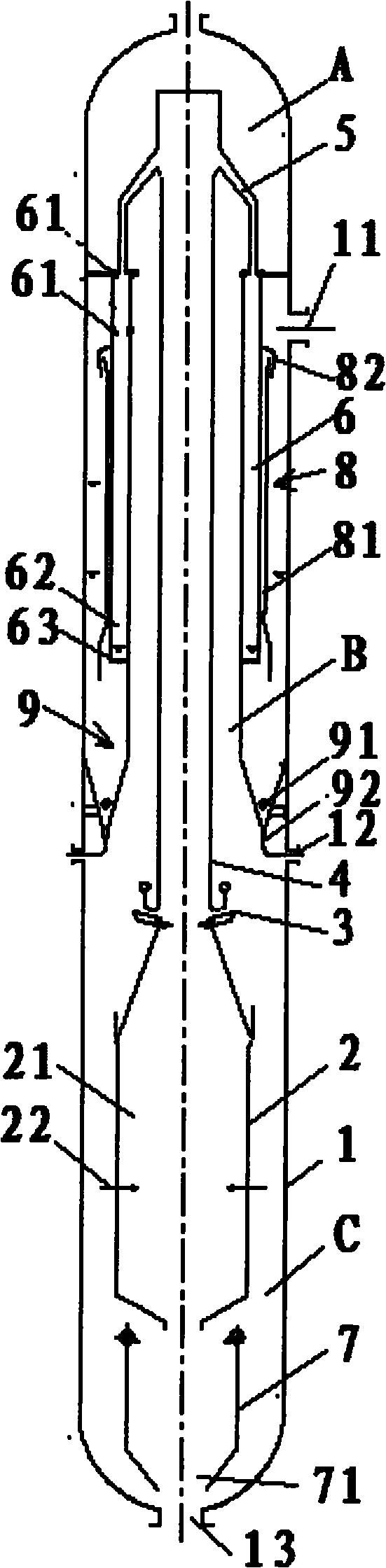

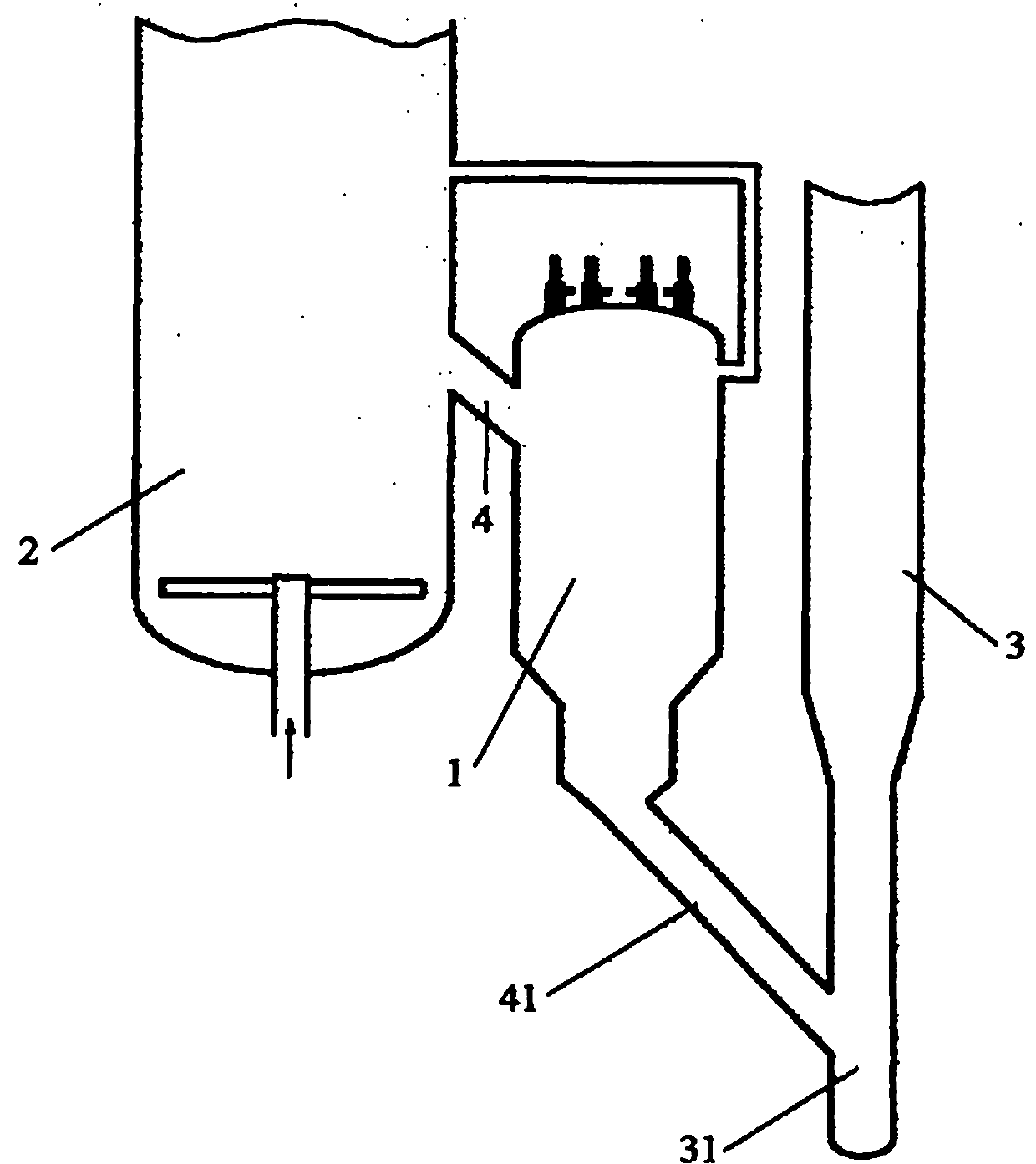

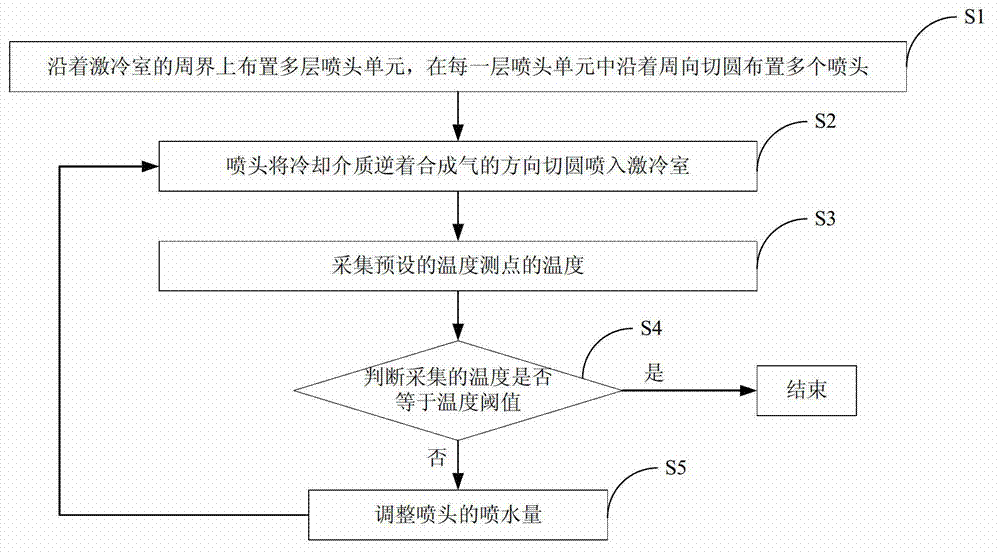

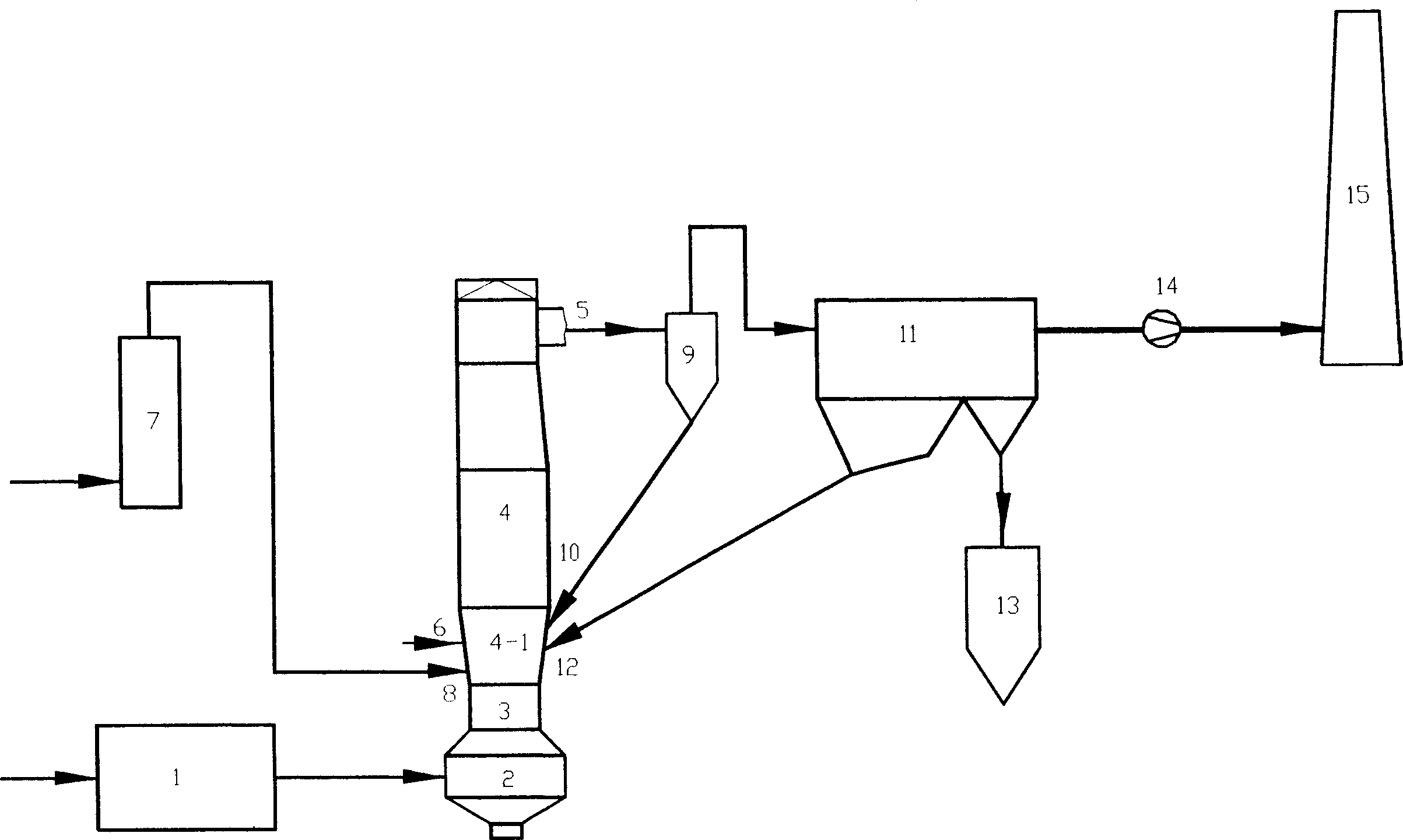

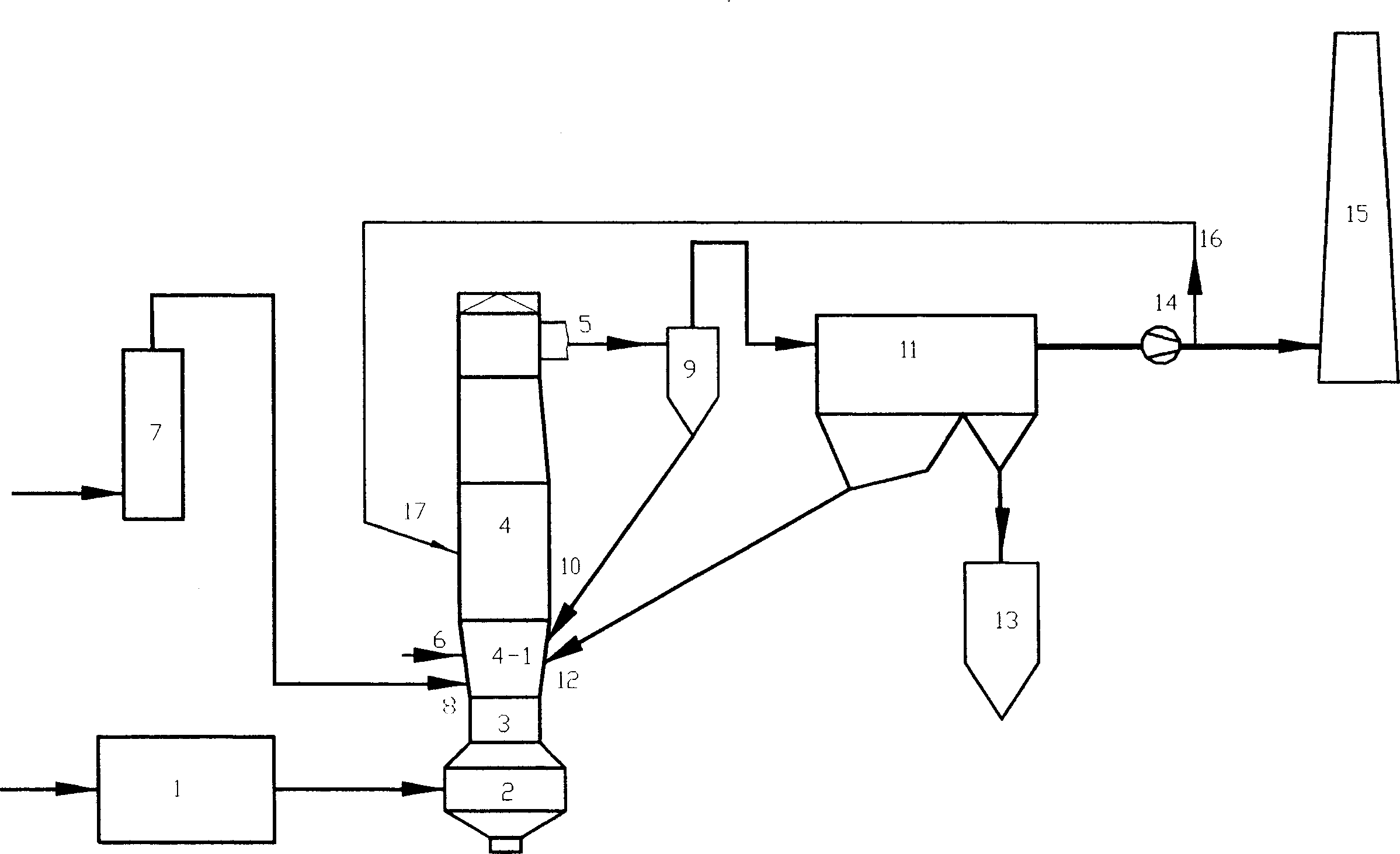

High-temperature synthetic gas chilling device and high-temperature synthetic gas chilling method for gasification furnace

ActiveCN102952588AIncrease mixing intensityReduce residual rotational momentumCombustible gas productionSyngasProcess engineering

The invention discloses a high-temperature synthetic gas chilling device and a high-temperature synthetic gas chilling method for a gasification furnace. The chilling device comprises the coal gasification furnace, a chilling chamber and a synthetic gas guide pipe, wherein the chilling chamber is a space formed in a mode that a round, rectangular or polygonal section moves along the normal direction of the section; multiple layers of sprayer units are distributed on the periphery of the chilling chamber; and each sprayer unit comprises multiple sprayers distributed in a tangential circle shape along the circumferential direction; when the synthetic gas generated by the coal gasification furnace enters into the chilling chamber through the synthetic gas guide pipe so as to be chilled, the sprayers spray a cooling medium along a direction opposite to the synthetic gas movement direction, so that the cooling medium and the synthetic gas are uniformly mixed. According to the device and the method, multiple layers of multiple sprayers distributed in a tangential circle shape along the circumferential direction are adopted for spraying the cooling medium along the direction opposite to the synthetic gas movement direction, so that the influence of the chilling boundary on the temperature of the gasification furnace is reduced; and the cooling medium is sprayed along the direction opposite to the synthetic gas movement direction, so that the mixing intensity is improved, the residual rotation momenta of the synthetic gas are reduced, the length of the outlet guide pipe of the chilling chamber of the gasification furnace is greatly shortened, and the cost is lowered.

Owner:HUAZHONG UNIV OF SCI & TECH +1

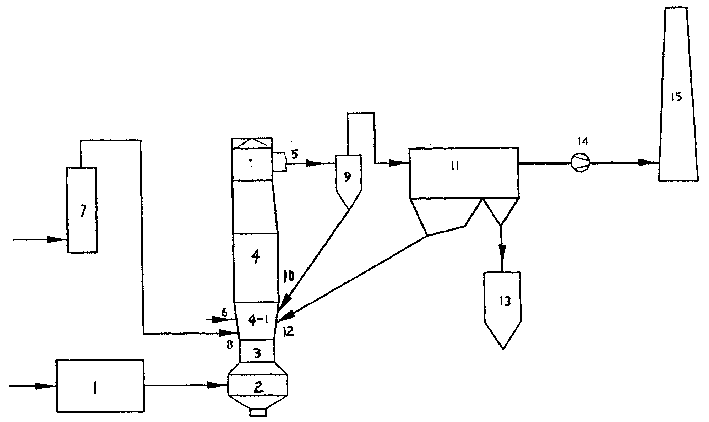

Smoke desulfurizing process by circulation fluid state dry method of layered feed back

The present invention relates to external grain re-circulating technology in large circular fluidizing dry fume desulfurizing system. The desulfurizing process includes preparing desulfurizing agent, desulfurizing reaction inside the desulfurizing reaction tower and external desulfurizing agent grain separation and re-circulation. In the external grain re-circulation, the returned material is two-stage separated and re-circulated, the grains separated by the first stage and the second stage desulfurizing agent grain separator are fed to the fluidizing region in the lower part of the desulfurizing reaction tower separately through different re-circulation inlets, resulting in raised desulfurizing agent grain utilization and desulfurizing reaction efficiency. Compared with available technology, the present invention has much higher fume dedusting efficiency, high desulfurizing efficiency up to 92 % at Ca / S of 1.1-1.3, less adhesion and blocking in the lower desulfurizing tower part and lowered load of the desulfurizing agent grain separator.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

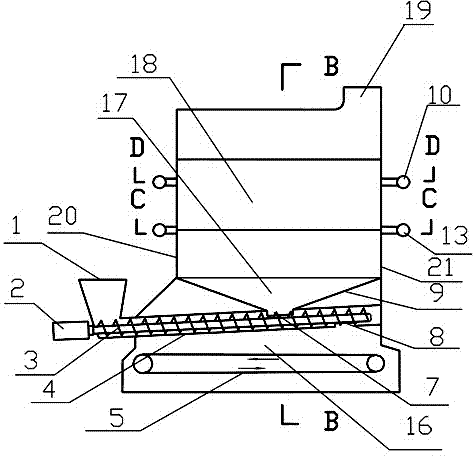

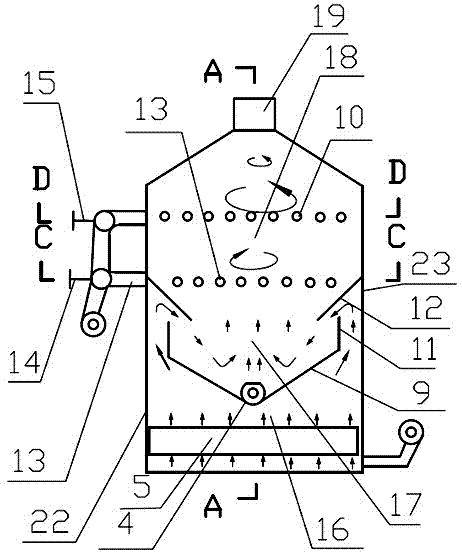

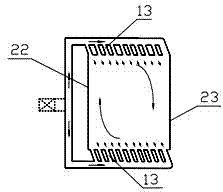

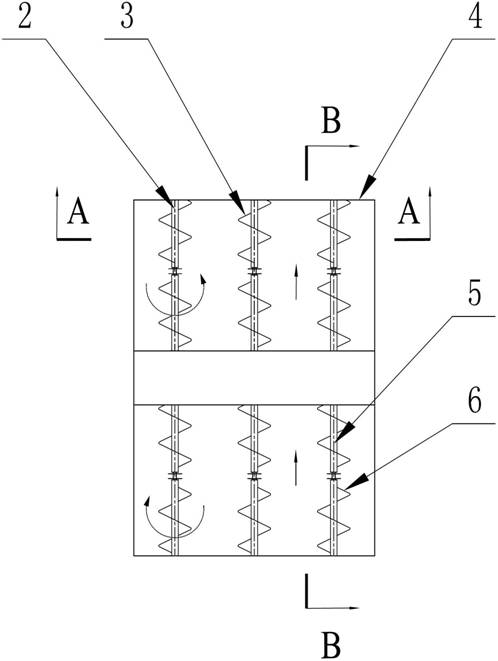

Gas-solid separation and re-coupling type biomass clean combustion device and combustion method

ActiveCN104713078AAchieve separationAchieve combustionSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidCombustion chamber

A gas-solid separation and re-coupling type biomass clean combustion device comprises a spiral feeding system, a chain furnace grate, a solid combustion chamber, a reduction reaction chamber, a gas combustion chamber, a solid combustion air supply system, a primary gas combustion air supply system, a secondary gas combustion air supply system and a cuboid hearth. The spiral feeding system comprises an open hopper, a drive motor, a feeding shaft with a spiral fin and a spiral pipe. The device is provided with the independent reduction reaction chamber, the independent solid combustion chamber and the independent gas combustion chamber. A combustion method of the gas-solid separation and re-coupling type biomass clean combustion device includes the steps that biomass is firstly dissolved into gas and solid through self heat supply, dust of smoke generated after solid combustion is removed, a reduction reaction is conducted on the smoke and gas generated after thermolysis, and NOx is reduced; primary combustion and secondary combustion are conducted, generation of NOx is controlled, and combustion is thorough.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI +1

Spiral flocculator and application to folded plate type flocculation reaction tank

ActiveCN102674518AFully disturbedIncrease mixing intensityWater/sewage treatment by flocculation/precipitationSedimentation settling tanksFlocculationWater flow

The invention belongs to water treatment equipment, and particularly relates to a spiral flocculator which comprises a support. At least two spiral plates with opposite turning directions are longitudinally arranged on the support at intervals, the upper end and the lower end of each spiral plate are rotationally assembled on the support, and strip-shaped blades are radially fixed onto outer edges of the spiral plates. The spiral flocculator is mounted between two adjacent partition boards in a folded plate type flocculation reaction tank when applied to the folded plate type flocculation reaction tank. The spiral flocculator solves problems of large application limitation, poor flocculation effect and large occupied area of an existing reaction tank in the prior art, and has the advantages that a disturbance effect to water flow is good, the occupied area of the reaction tank is small, installation is simple, energy is saved, and the like.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

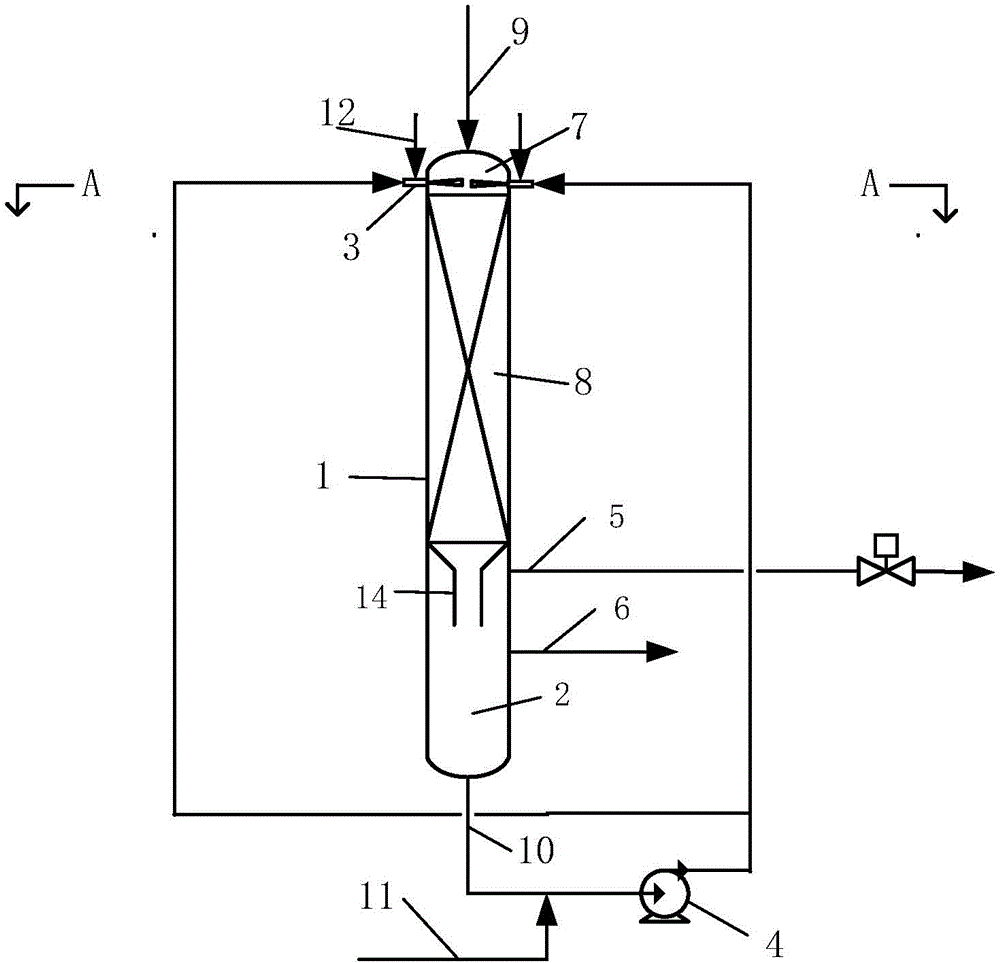

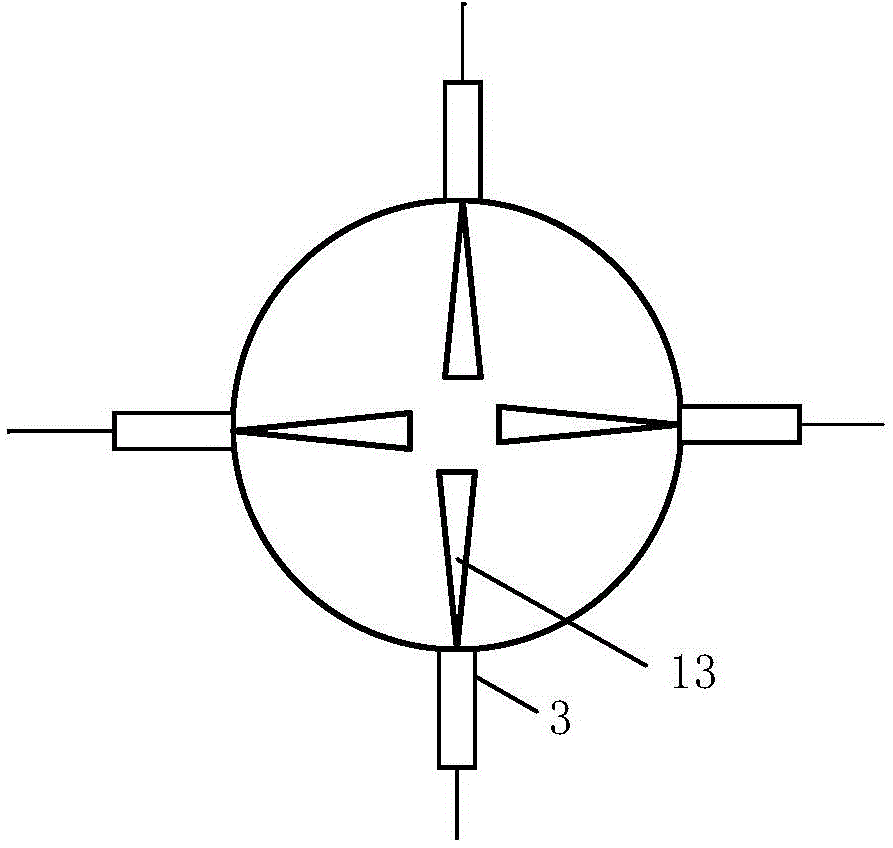

Liquid acid alkylation reactor and application method thereof

ActiveCN105268394AImprove conversion rateSimple mechanical structureLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsAlkyl transferJet flow

A liquid acid alkylation reactor and an application method thereof are provided. The reactor comprises a mixing zone, a reaction zone and a liquid collection zone from top to bottom; the mixing zone is internally provided with at least one group of jetting flow mixers, and each group of jetting flow mixers comprises at least two ejectors which are in centrosymmetry at a same horizontal plane; the reaction zone is internally loaded with a packing; the liquid collection zone is connected with inlets of the jetting flow mixers through a circulating pump, the upper part of the liquid collection zone is provided with a gas outlet, and a liquid-phase product outlet is arranged below the gas outlet. The liquid acid alkylation reactor provided by the invention is suitable for an alkylation reaction with sulfuric acid, an ionic liquid or a mixed acid with sulfuric acid as a main component as a catalyst. The reactor is an alkylation reactor which is simple and compact in structure, small in investment, and convenient to operate and maintain, and saves the power.

Owner:CHINA PETROLEUM & CHEM CORP +1

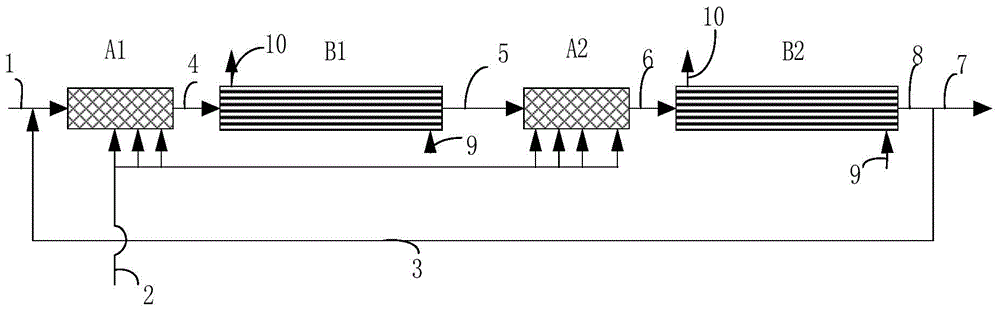

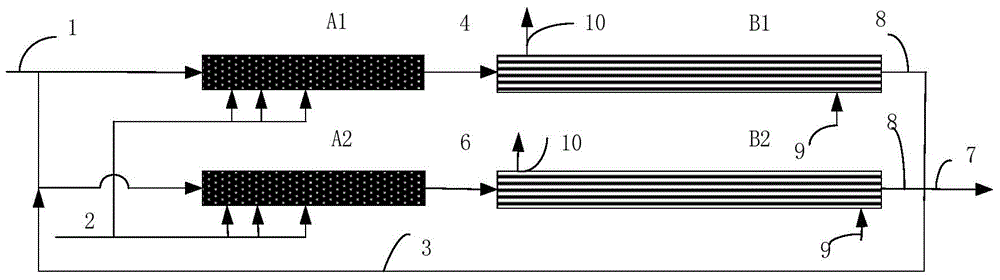

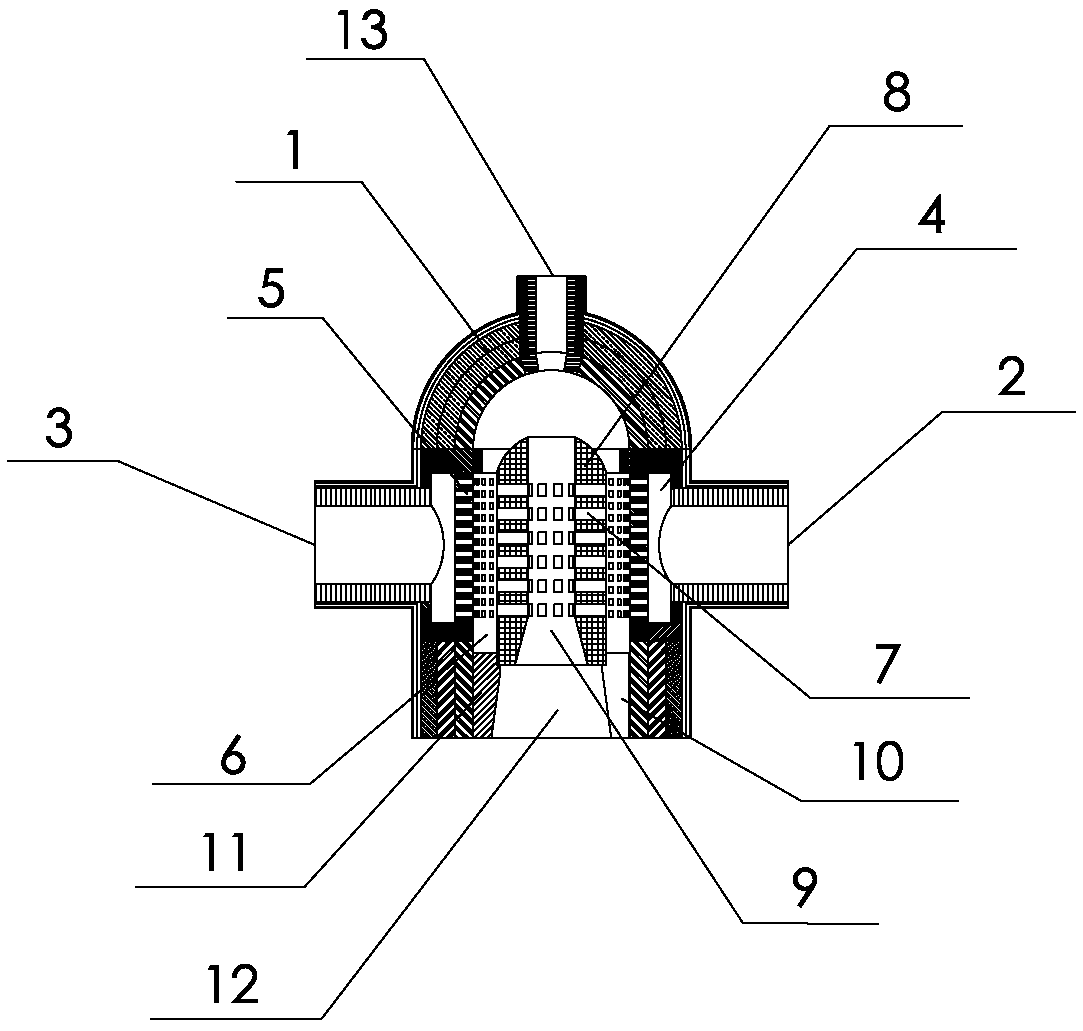

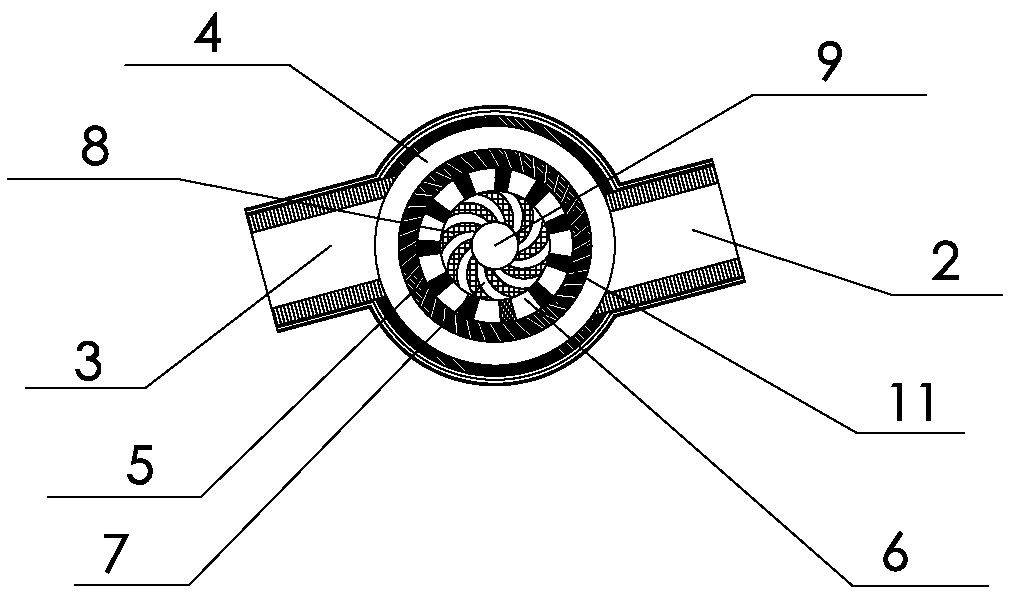

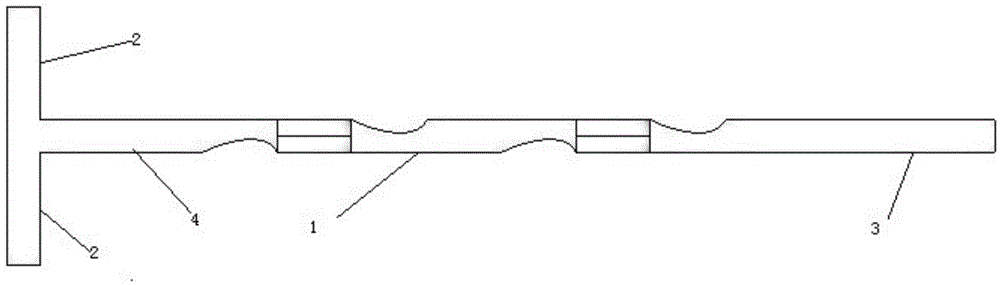

Static tube type alkylation reaction device and alkylation reaction method for liquid acid catalysis

ActiveCN105018134AAvoids disadvantages that impair sealing performanceImprove sealingLiquid hydrocarbon mixtures productionAlkyl transferEmulsion

The invention provides a static tube type alkylation reaction device and an alkylation reaction method for liquid acid catalysis by adopting the same. The reaction device comprises n+1 groups of reactors, wherein n is more than or equal to 1, each group of the reactor comprises a mixed reaction section A and a mixed reaction section B connected in series with the mixed reaction section A, and the mixed reaction section B has a heat exchange function; the mixed reaction section A of the first group of the reactors is marked as A1 which is provided with a fresh liquid acid feed pipeline; the mixed reaction section B of the (n+1)th group of the reactors is marked as Bn+1 which is provided with an alkylation reaction product outlet pipeline for discharging acidolysis hydrocarbon emulsion; part of the acidolysis hydrocarbon emulsion is circulated by a circulating pump; the mixed reaction section A of each group of the reactors is connected with a feed pipeline of an alkylation reaction raw material containing olefin, and the mixed reaction section A is provided with m (m is more than or equal to 1) feed openings for adding the alkylation reaction raw material containing olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combustion device of circuit cyclone pre-mixing multi-row array jet cyclone penetrating heat accumulating sleeve

ActiveCN107893991AImprove performanceImproved swirl premixing characteristicsHeat storage plantsSolid fuel combustionCycloneToxic gas

The invention relates to a combustion device of a circuit cyclone pre-mixing multi-row array jet cyclone penetrating heat accumulating sleeve and solves the problems that combustion air and coal gas are not uniformly mixed, the mixing strength is not high, the coal gas grading combustion effect is poor and uncontrollable, the air flow field distribution is hardly uniform, and the combustion temperature is uncontrollable effectively. Multiple pairs of coal gas inlet pipes and air inlet pipes are arranged on the outer side wall of a cyclone premixing circuit in a cylindrical wall body; multiplerows of cyclone array premixing gas nozzles are arranged in the inner side wall; a high speed cyclone channel is arranged in the barrel-shaped combustion heat accumulating body in an inner cavity; a premixed gas cyclone combustion circuit is arranged between the barrel-shaped combustion heat accumulating body and the cylindrical wall body; multiple rows of cyclone array combustion nozzles are arranged in the cylindrical wall; the spaces in the plurality of combustion heat accumulating body supporting columns in the bottom are combustion fuel gas outlets; and an adjusting air flow spraying inlet pipe is arranged on a semispherical arch crown. The combustion device changes the flow field structure of the combustion air flow, intervenes the combustion process deeply, is fuel- and investment-saving and reduces the emission of toxic gas.

Owner:郑州釜鼎热能技术有限公司

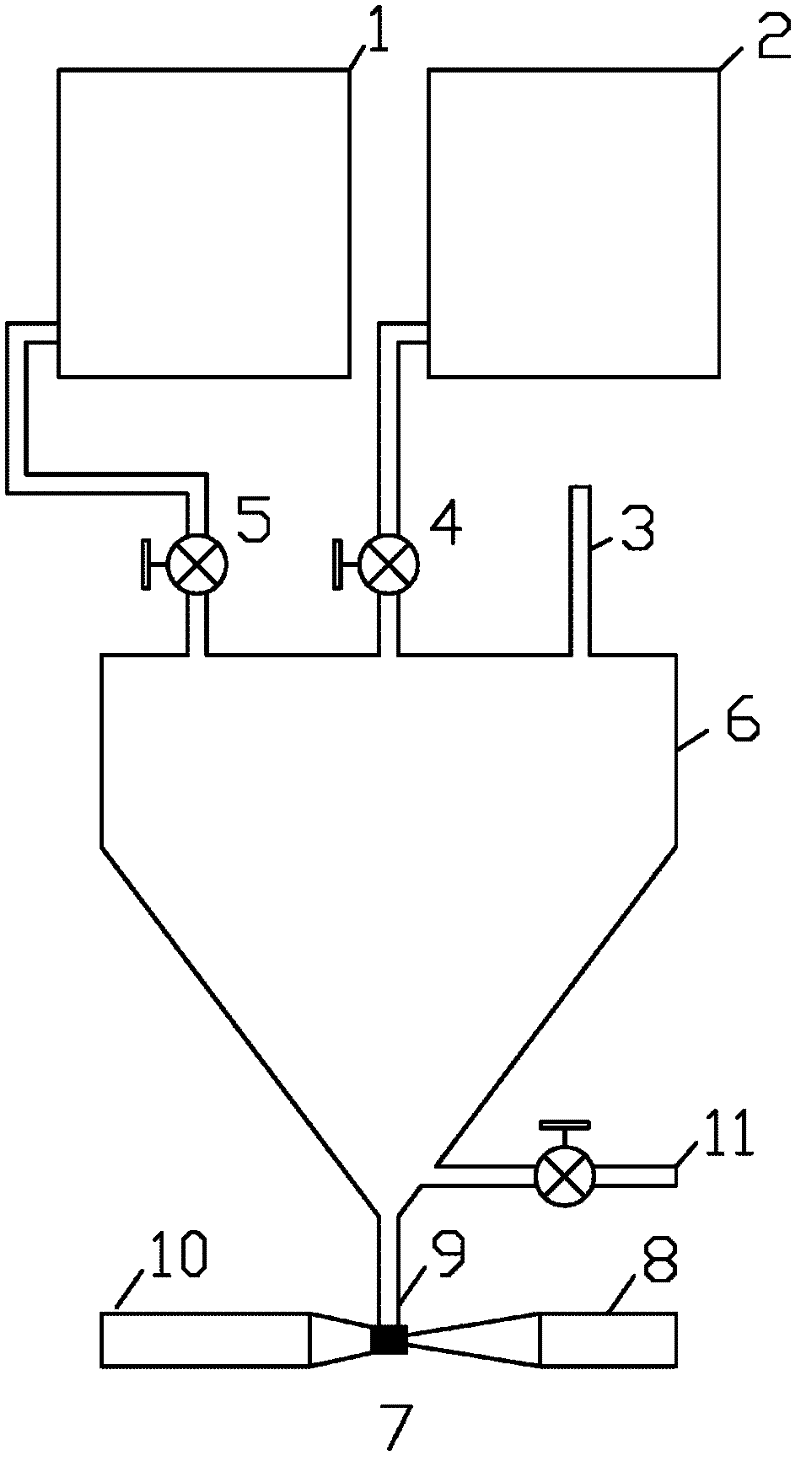

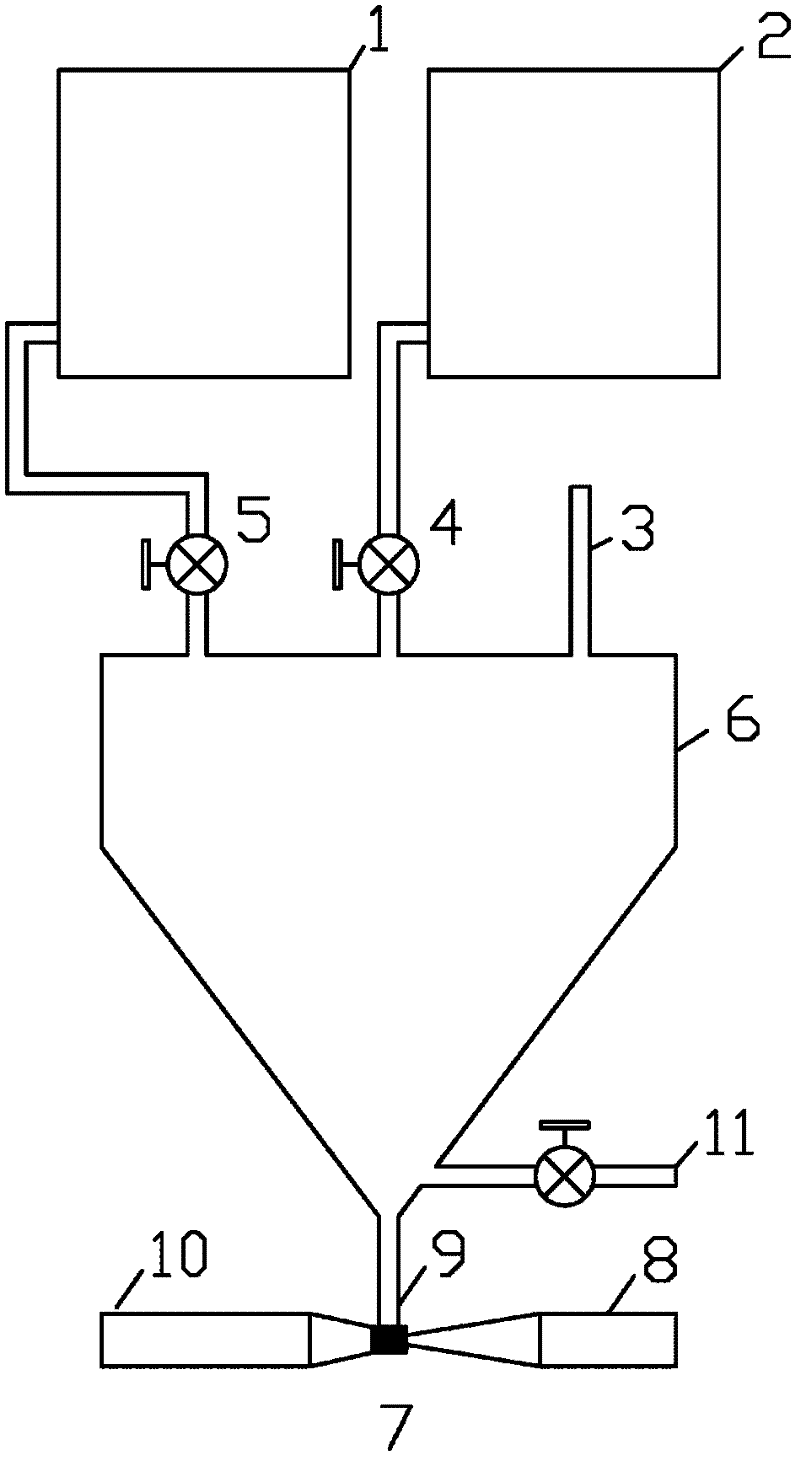

Method and device for treating acid mine wastewater

InactiveCN102515324ASimple structureEasy to operateWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationChemical industryWastewater

The invention discloses a method and a device for treating acid mine wastewater. The device consists of a sodium sulfide solution box, a hydrochloric acid solution box, a drug reactor, a venture tube, a plurality of chemical industry valves and a plurality of corresponding pipelines, wherein a sodium sulfide solution adding port, a hydrochloric acid solution adding port and an air vent are arranged at the top of the drug reactor, a diluted hydrochloric acid solution adding port is arranged right above an automatically-flowing outlet at the bottom of the reactor, and the sodium sulfide solution adding port and the air vent are distributed at two sides of the top of the reactor. The device is simple in structure, the operation method is easy and convenient, and the operation is safe..

Owner:ZIJIN MINING GROUP

Forced internal recirculation type external cooler for catalytic cracking catalyst

ActiveCN101769694BHigh heat extraction efficiencyMixing Intensity ChangesStationary conduit assembliesFluidised bed heat exchangersEngineeringHeat transfer efficiency

The invention provides a forced internal recirculation type external cooler for a catalytic cracking catalyst. At least two gas distributors are arranged at the internal bottom of the cooler, and each gas distributor is accessible to fluidized gas independently and can control the gas flow. A plurality of cooling tubes in vertical arrangement are arranged above the gas distributors. Apart from the gas distributors, the cooling tubes and matched fixed parts thereof, no additional components are arranged in the cooler. By controlling the different gas flows of at least two gas distributors, thesuperficial gas velocity and the bed density in different cross section areas in the cooler are caused to be different and the internal circulation of particles in a bed is strengthened, so the update velocity of the particles on a heat transfer wall is improved and the heat transfer efficiency of the particles and the wall is effectively improved. The cooler has the advantages of simple structure, high heat transfer efficiency and flexible regulation, and can also be used as a themosistor for a catalytic cracking regenerant. In addition, the invention also provides a catalytic cracking device containing the cooler and a catalytic cracking method.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

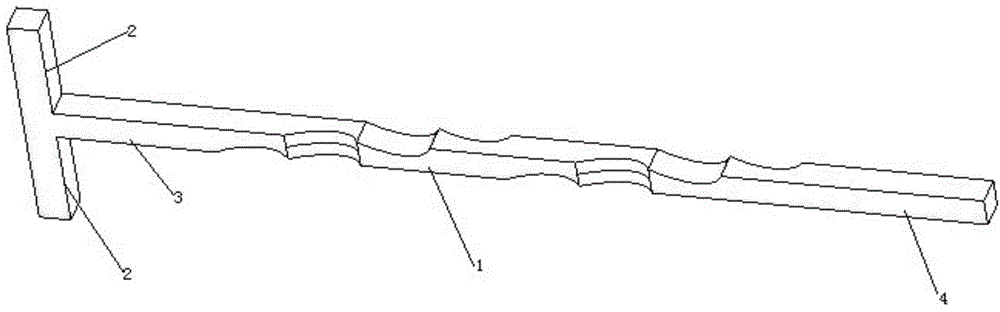

New T type micro mixer

ActiveCN104307413AIncrease contact areaWell mixedMixersLaboratory glasswaresInlet channelMICRO MIXER

A new T type micro mixer includes inlet channels, a preliminary mixing channel and an outlet channel, the number of the inlet channels is at least two, the at least two inlet channels are respectively communicated with inlets of the preliminary mixing channel, the preliminary mixing channel and the outlet channel are linear structures, the mixer also comprises a bending pipe, the bending channel includes a periodic asymmetric curve bending channel, bending channel units in the periodic asymmetric curve bending channel are front and back connected in sequence, the spatial arrangement order is successively as follows: successively repeating as the order of a downward bending face, a rightward bending face, an upward bending face, a leftward bending face, a downward bending face, a rightward bending face, an upward bending face, a leftward bending face, and the like, the headmost bending channel unit in the bending channel is communicated with an outlet of the preliminary mixing channel, and the last bending channel unit in the bending channel is communicated with the outlet channel. The invention provides the new T type micro mixer to improve the mixing efficiency.

Owner:ZHEJIANG UNIV OF TECH

Dry flue gas desulfurizing process with independent feeding, back-returning and water-spraying devices

InactiveCN1515349AImprove desulfurization reaction efficiencyReduce back flowDispersed particle separationProcess engineeringDigestion

The present invention provides a dry flue gas desulfurizing process with independent feeding, feeding back and water-spraying device. It includes desulfurizing agent preparation digestion system, desulfurizing reaction tower and desulfurizing reaction system and exterior desulfurizing granules separation and recirculating system. The water-spraying atomization device of desulfurizing reaction tower, desulfurizing agent feeding device and granules recirculating feed back device are independently placed, and the different heights of the desulfurizing reaction tower are equipped with respective nozzles, so that the structure can raise the utilization rate of the desulfurizing agent and can raise the desulfurizing effect.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

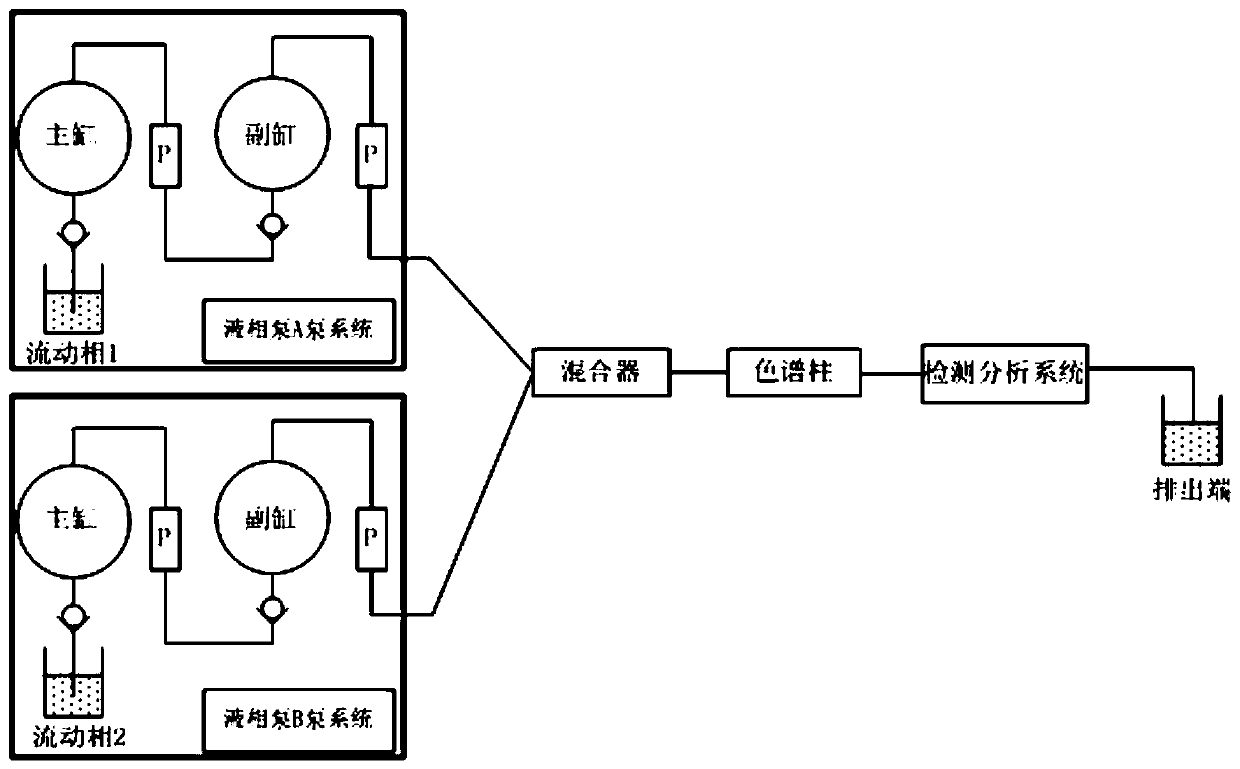

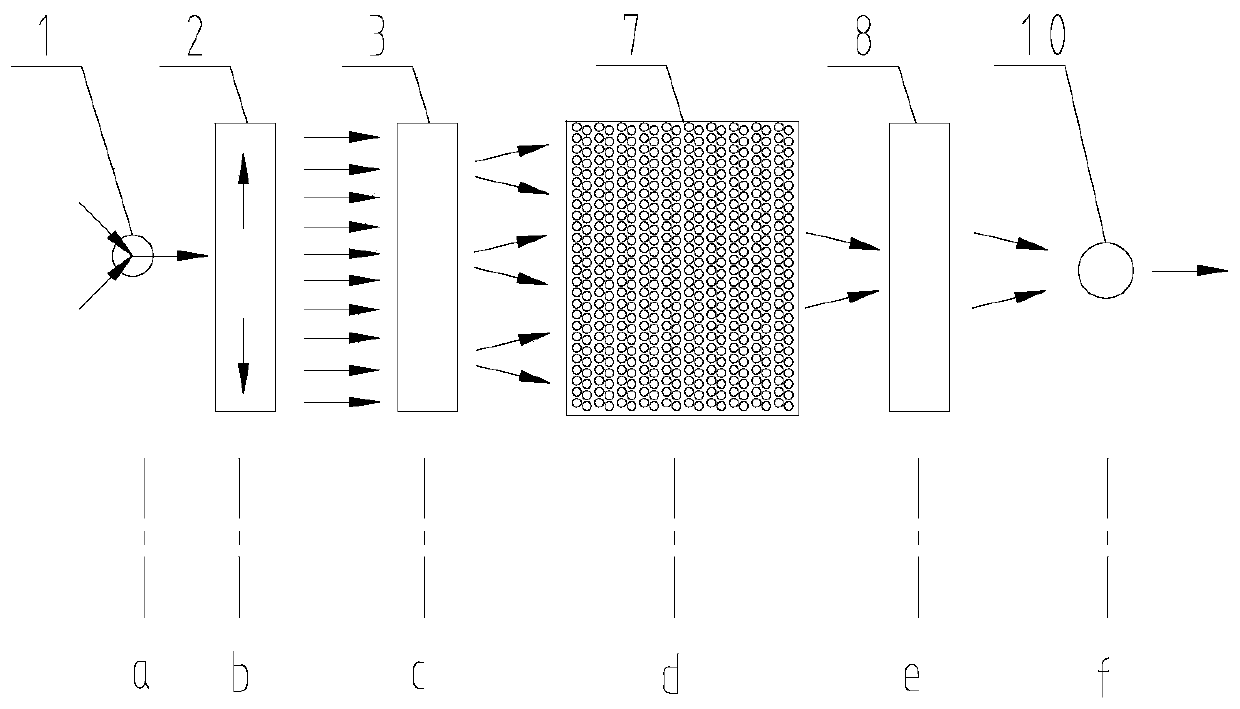

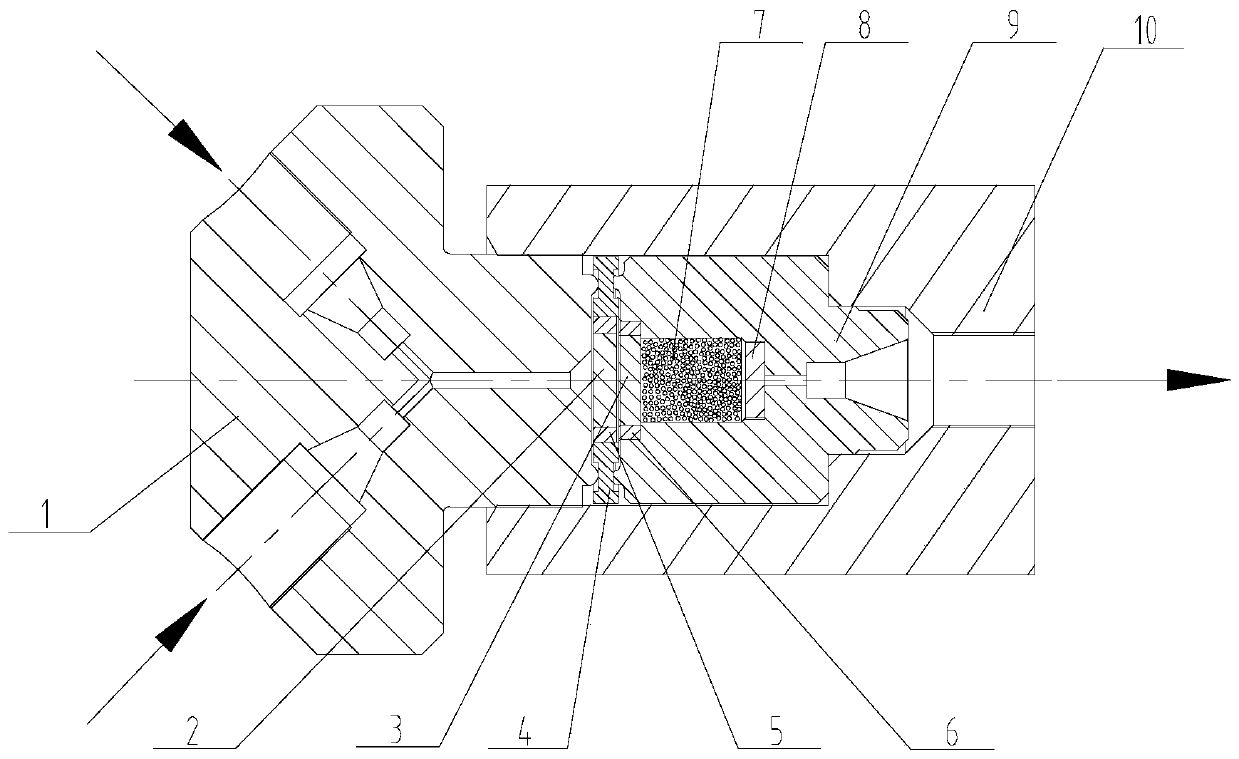

Micro-upgrading passive mixing type mixer

ActiveCN110559929AShorten the diffusion pathPenetrate fastTransportation and packagingMixer accessoriesHybrid typeDead volume

The invention relates to a micro-upgrading passive mixing type mixer, which comprises an inlet end cover (1), a mixing cavity assembly, an ultrahigh-pressure sealing structure assembly and an outlet end cover (10), wherein solvent inlet holes are symmetrically arranged on one end of the inlet end cover (1), the ends of the solvent inlet holes converge into an outlet hole communicated to the end surface of the other end of the inlet end cover (1), the mixing cavity assembly and the ultrahigh-pressure sealing structure assembly are sequentially installed in the inner cavity of the outlet end cover (10), one end of the inlet end cover (1) is installed in the outlet end cover (10), and the ultrahigh-pressure sealing structure assembly and a mixing cavity (9) are pressed. According to the present invention, the micro-upgrading passive mixing type mixer can overcome the problems of large system delay dead volume, low mixing efficiency, low mixing uniformity, insufficient sealing performanceunder high pressure and the like caused by large volume of the existing mixer, and is suitable for ultrahigh performance liquid chromatography analysis by adopting an ultrahigh pressure binary pump gradient elution method in food safety, medicine preparation, environmental protection detection, chemistry and chemical engineering, scientific research and the like.

Owner:BEIJING SATELLITE MFG FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com